Introduction: Navigating the Global Market for how to know you have a bad starter

In the fast-paced world of automotive procurement, understanding how to identify a bad starter is crucial for ensuring operational efficiency and minimizing downtime. A failing starter can lead to unexpected vehicle failures, impacting logistics and transportation in various industries. This guide offers an in-depth exploration of the symptoms and implications of a bad starter, equipping international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe, including Nigeria and Brazil—with the knowledge necessary to make informed purchasing decisions.

Within this comprehensive resource, we delve into the various types of starters, their applications across different vehicle models, and critical factors to consider when sourcing replacements. Additionally, we provide insights on how to effectively vet suppliers to ensure reliability and quality. Understanding the cost implications of starter replacement, including both parts and labor, is also covered, enabling buyers to budget accurately and avoid unexpected expenses.

By empowering B2B buyers with actionable insights and expert guidance, this guide aims to enhance your procurement strategy, ensuring you can swiftly identify and address starter issues before they escalate into costly problems. Navigate the complexities of the global automotive market with confidence, knowing you have the tools to make informed decisions that support your business’s operational needs.

Índice

- A Look at How To Know You Have A Bad Starter Manufacturers & Suppliers

- Introduction: Navigating the Global Market for how to know you have a bad starter

- Understanding how to know you have a bad starter Types and Variations

- Key Industrial Applications of how to know you have a bad starter

- 3 Common User Pain Points for ‘how to know you have a bad starter’ & Their Solutions

- Strategic Material Selection Guide for how to know you have a bad starter

- In-depth Look: Manufacturing Processes and Quality Assurance for how to know you have a bad starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know you have a bad starter’

- Comprehensive Cost and Pricing Analysis for how to know you have a bad starter Sourcing

- Alternatives Analysis: Comparing how to know you have a bad starter With Other Solutions

- Essential Technical Properties and Trade Terminology for how to know you have a bad starter

- Navigating Market Dynamics and Sourcing Trends in the how to know you have a bad starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to know you have a bad starter

- Strategic Sourcing Conclusion and Outlook for how to know you have a bad starter

- Aviso legal importante e termos de utilização

Understanding how to know you have a bad starter Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Ruído de clique | A distinct clicking sound when the ignition is turned | Oficinas de reparação automóvel | Prós: Easy to diagnose; often indicates a specific issue. Contras: May be misdiagnosed if other components are faulty. |

| Luzes do painel de instrumentos | Dashboard lights illuminate without engine cranking | Fleet management, logistics companies | Prós: Quick visual cue; can prevent further damage. Contras: Requires further testing to confirm starter failure. |

| Arranque lento | Engine cranks slowly or hesitates | Serviços de manutenção de veículos | Prós: Indicates potential starter issues early. Contras: Can also signal battery problems, complicating diagnosis. |

| Emissão de fumo | Smoke from the starter area during ignition attempts | Emergency vehicle services | Prós: Clear warning of electrical issues; prompts immediate action. Contras: Indicates severe damage; costly repairs may follow. |

| Arrancador embebido em óleo | Visible oil leakage on or around the starter | Automotive parts suppliers | Prós: Identifies dual issues (oil leak and starter). Contras: Repairs can be extensive and expensive. |

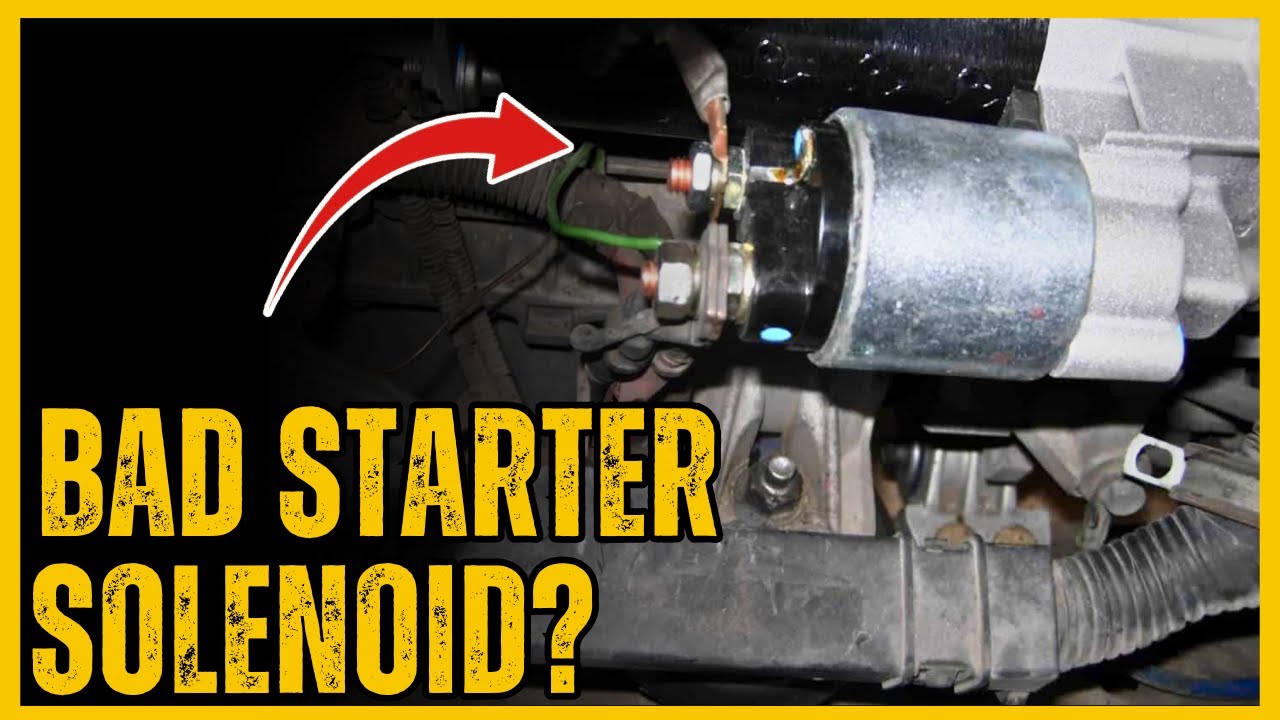

What Are the Key Characteristics of the Clicking Noise Indicator?

The clicking noise is a prominent symptom of starter failure, often resulting from a malfunctioning solenoid or insufficient electrical power. In a B2B context, automotive repair shops frequently encounter this issue, as it is a common complaint among clients. Understanding this symptom allows repair technicians to quickly pinpoint the starter as the problem, streamlining the repair process. However, it is essential to ensure that the battery and other electrical components are functioning correctly to avoid misdiagnosis.

How Do Dashboard Lights Indicate Starter Problems?

When dashboard lights illuminate without the engine cranking, it typically signifies a potential starter issue. This symptom is particularly valuable for fleet management and logistics companies, where vehicle downtime can lead to significant operational losses. The ability to recognize this early warning can help businesses schedule timely maintenance, reducing the risk of unexpected breakdowns. However, it is important to conduct further diagnostics to confirm that the starter is indeed the culprit rather than other electrical issues.

Why Is Slow Cranking a Critical Sign?

Slow cranking is another symptom that can indicate starter failure, as it suggests that the starter is struggling to engage the engine. Vehicle maintenance services often monitor this symptom closely, as it can lead to more severe issues if not addressed promptly. For B2B buyers, recognizing slow cranking can be a proactive measure to prevent costly repairs down the line. However, it’s crucial to differentiate this sign from battery-related problems, which may require a different approach.

What Does Smoke Emission Mean for Starters?

The emission of smoke from the starter area is a serious indicator of electrical issues and potential overheating. This symptom is particularly relevant for emergency vehicle services, where reliability is paramount. The presence of smoke usually necessitates immediate attention to prevent further damage to the vehicle’s electrical system. While this clear warning can prompt swift action, it often indicates extensive damage that may lead to costly repairs, making it a significant consideration for B2B buyers.

Como é que um motor de arranque embebido em óleo afecta o desempenho?

An oil-soaked starter indicates that oil leakage has compromised the starter’s functionality. This dual issue is particularly relevant for automotive parts suppliers, as they may need to provide both starter replacements and oil leak repairs. For businesses, identifying this problem early can prevent extensive damage and costly repairs. However, addressing both issues can complicate maintenance schedules and increase costs, making it essential for B2B buyers to consider the implications of oil leaks on starter performance.

Key Industrial Applications of how to know you have a bad starter

| Indústria/Setor | Specific Application of how to know you have a bad starter | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Diagnostic tools for identifying bad starters in vehicles | Reduces downtime and repair costs by ensuring timely identification of starter issues | Look for reliable diagnostic tools with local support and warranties. |

| Transporte e Logística | Regular maintenance checks on fleet vehicles’ starters | Enhances fleet reliability and minimizes disruptions in service | Consider sourcing parts that are compatible with a diverse range of vehicle makes and models. |

| Equipamento mineiro e pesado | Starter condition monitoring in heavy machinery | Prevents unexpected failures and costly downtime in operations | Ensure availability of durable starters suited for harsh environments. |

| Agricultura | Assessing starter performance in agricultural machinery | Maximizes operational efficiency and productivity during critical harvest periods | Look for suppliers with expertise in agricultural machinery components. |

| Construção | Evaluating starters in construction vehicles | Ensures project timelines are met by avoiding machinery failures | Seek suppliers with a strong track record in providing quality parts for construction equipment. |

How Can Automotive Repair Shops Benefit from Understanding Bad Starter Symptoms?

Automotive repair shops can leverage knowledge about bad starter symptoms to enhance their service offerings. By utilizing diagnostic tools, technicians can quickly identify starter issues, reducing vehicle downtime and repair costs. This not only improves customer satisfaction but also builds trust in the shop’s expertise. For international buyers, particularly in regions with varying vehicle models, sourcing reliable diagnostic equipment with local support is crucial to maintain service efficiency.

Why is Starter Maintenance Critical for Transportation and Logistics Companies?

Transportation and logistics companies rely heavily on their fleet’s operational reliability. Regular maintenance checks that include assessing starters can prevent unexpected vehicle failures, which could disrupt service and lead to financial losses. Businesses should consider sourcing starter parts that are compatible with a variety of vehicle makes and models to ensure they can service their entire fleet without delays.

How Does Starter Monitoring Impact Mining and Heavy Equipment Operations?

In the mining sector, the functionality of heavy machinery is paramount. Monitoring starter conditions can prevent unexpected failures, which are particularly costly in terms of both time and resources. By sourcing durable starters designed for harsh environments, mining companies can enhance their operational uptime. This is especially important for international buyers who may face varying environmental challenges based on location.

What is the Importance of Starter Performance in Agriculture?

In agriculture, the performance of machinery is critical, especially during harvest seasons when time is of the essence. Understanding how to identify bad starters allows farmers to address potential issues before they lead to machinery failures, maximizing productivity. Suppliers with expertise in agricultural machinery components are ideal for sourcing starter parts, ensuring compatibility with specialized equipment used in farming.

How Can Construction Companies Ensure Equipment Reliability Through Starter Evaluation?

Construction companies depend on their machinery to meet project deadlines. Evaluating the condition of starters in construction vehicles can prevent machinery failures that could delay projects. When sourcing parts, it is essential to find suppliers with a strong reputation for quality components specifically designed for construction equipment, ensuring that operations remain uninterrupted and projects are completed on time.

3 Common User Pain Points for ‘how to know you have a bad starter’ & Their Solutions

Scenario 1: Understanding the Signs of a Failing Starter Motor

O problema: B2B buyers, particularly fleet managers and automotive service providers, often face the challenge of diagnosing starter motor issues amidst a myriad of potential vehicle problems. When a vehicle fails to start, it can lead to significant downtime, impacting service delivery and operational efficiency. Without a clear understanding of the symptoms of a bad starter, buyers may waste time and resources on unnecessary diagnostics or repairs, leading to frustration and financial loss.

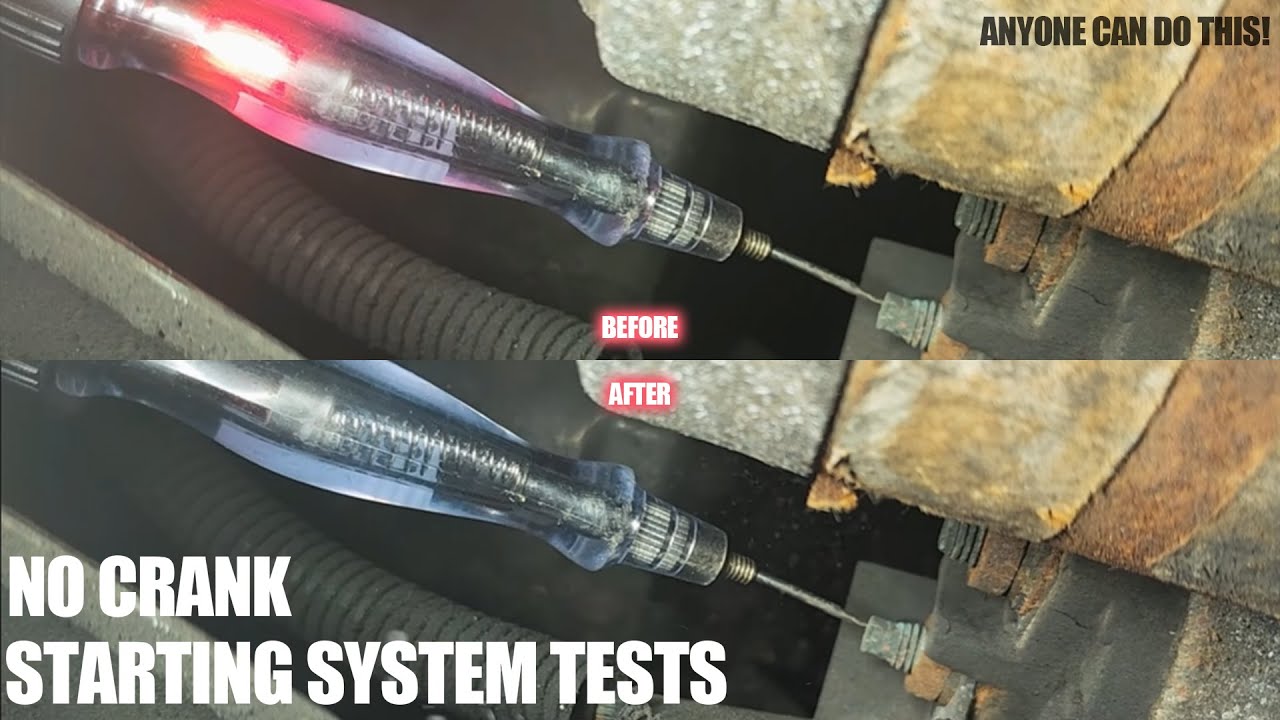

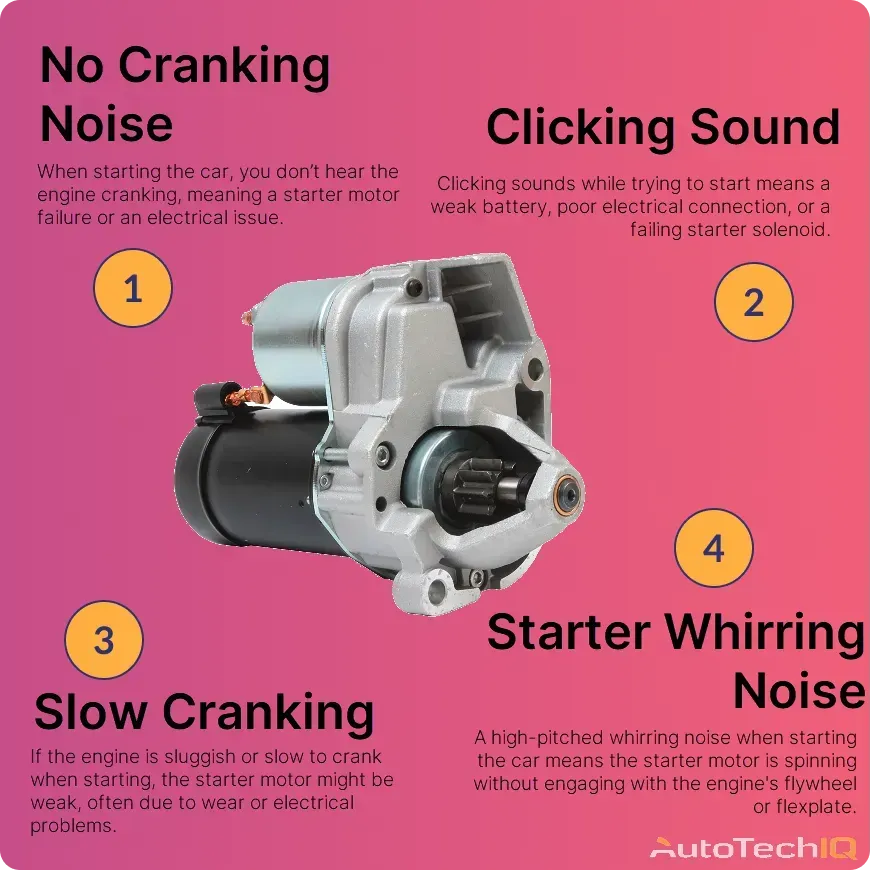

A solução: To effectively identify a bad starter, B2B buyers should familiarize themselves with the key symptoms. Common signs include a clicking noise when the ignition is turned, slow cranking of the engine, and dashboard warning lights illuminating without the engine starting. Fleet managers can implement a checklist for their technicians to follow during routine inspections. This checklist should include visual inspections of the starter and battery connections, testing battery voltage, and listening for abnormal sounds when attempting to start the vehicle. By establishing a systematic approach to diagnosing starter issues, companies can reduce downtime and ensure timely repairs.

Scenario 2: Cost Implications of Starter Failures

O problema: For B2B buyers managing automotive fleets, the financial implications of starter motor failures can be significant. The cost of replacing a starter can range from $300 to $600, depending on the vehicle model and labor costs. Additionally, if the problem is misdiagnosed, companies may incur further costs from unnecessary repairs or even additional breakdowns, leading to further operational delays and lost revenue.

A solução: To mitigate these costs, businesses should invest in training their maintenance staff on the correct diagnostic procedures for starter issues. This includes utilizing tools like voltmeters to distinguish between battery and starter problems accurately. Establishing a strong relationship with reputable parts suppliers can also help buyers secure quality starters at competitive prices, reducing the likelihood of premature failures. By keeping a well-maintained inventory of essential parts and performing regular maintenance checks, businesses can preemptively address potential issues before they escalate into costly repairs.

Scenario 3: Managing Unforeseen Downtime Due to Starter Issues

O problema: Unforeseen starter failures can lead to significant downtime, disrupting service schedules and causing customer dissatisfaction. For B2B buyers in sectors like logistics or transportation, a single vehicle breakdown can have a ripple effect, delaying deliveries and impacting service commitments. The unpredictability of starter failures can leave buyers scrambling for quick fixes, which may not always be feasible.

A solução: To manage unforeseen downtime effectively, businesses should develop a proactive maintenance strategy that includes regular checks of the starter system, including the battery and electrical connections. Implementing a vehicle health monitoring system can provide real-time data on vehicle performance, allowing fleet managers to anticipate starter issues before they lead to breakdowns. Furthermore, establishing partnerships with local mechanics or roadside assistance services can ensure rapid response times for repairs, minimizing downtime. By being proactive and prepared, businesses can maintain smoother operations and uphold their service commitments.

Strategic Material Selection Guide for how to know you have a bad starter

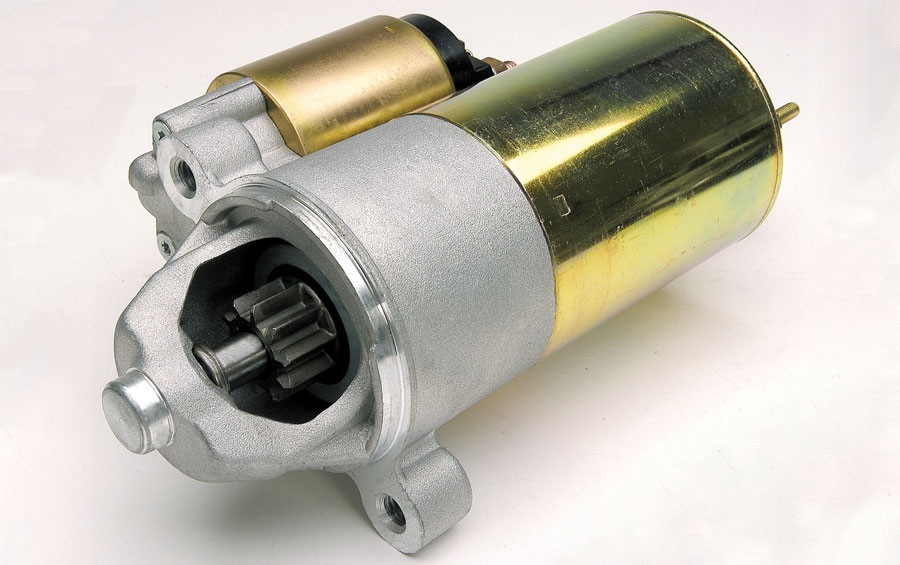

What Materials Are Commonly Used in Starters and How Do They Affect Performance?

When assessing the materials used in starters, it is crucial to consider their properties and how they affect the overall performance of the starter system. Here, we analyze four common materials: copper, aluminum, steel, and plastic composites. Each material has unique properties that can influence the functionality and reliability of starters in various applications.

How Does Copper Impact Starter Performance?

Copper is widely used in starter components, particularly in wiring and connectors due to its excellent electrical conductivity. It can handle high temperatures and has a high melting point, making it suitable for the heat generated during engine starts.

Prós: Copper’s high conductivity ensures efficient power transfer, reducing energy loss. It is also resistant to corrosion, which is critical for maintaining performance over time.

Contras: However, copper is relatively expensive compared to other metals, which can increase the overall cost of starter components. Additionally, its weight can be a disadvantage in applications where reducing weight is essential.

Impacto na aplicação: In environments with high humidity or exposure to corrosive elements, copper’s resistance to corrosion becomes a significant advantage. However, buyers in regions with limited access to high-quality copper may face challenges in sourcing reliable components.

Illustrative image related to how to know you have a bad starter

Que papel desempenha o alumínio nos arrancadores?

Aluminum is another common material used in starter construction, particularly for housings and casings. It is lightweight and has good thermal conductivity, which helps dissipate heat generated during operation.

Prós: The lightweight nature of aluminum contributes to overall vehicle efficiency, making it a preferred choice for modern automotive designs. Its resistance to corrosion also makes it suitable for various environments.

Contras: On the downside, aluminum has lower tensile strength compared to steel, which may lead to durability issues in high-stress applications. Additionally, its thermal expansion properties can lead to misalignment in some designs.

Impacto na aplicação: In warmer climates, aluminum’s ability to dissipate heat can improve starter performance. However, international buyers must ensure compliance with local standards, as aluminum components may require specific treatments to enhance durability.

Why Is Steel Preferred for Certain Starter Components?

Steel is often used in starter gears and shafts due to its high strength and durability. It can withstand significant mechanical stress, making it suitable for high-performance applications.

Prós: Steel’s robustness ensures longevity and reliability, especially in demanding environments. It is also cost-effective compared to other metals, which can be advantageous for bulk purchasing.

Contras: However, steel is susceptible to corrosion if not properly treated or coated, which can lead to premature failure in harsh conditions. Its weight can also be a disadvantage in applications where minimizing mass is critical.

Illustrative image related to how to know you have a bad starter

Impacto na aplicação: In regions with high levels of moisture or corrosive environments, steel components may require additional protective coatings to enhance their lifespan. Buyers should consider the local climate when selecting steel components.

How Do Plastic Composites Enhance Starter Systems?

Plastic composites are increasingly used in starter systems for non-structural components due to their lightweight and insulating properties.

Prós: These materials can reduce overall weight, improving fuel efficiency. They also offer excellent resistance to electrical insulation, preventing short circuits.

Contras: However, plastic composites may not withstand high temperatures as effectively as metals, which can limit their use in certain applications. Their long-term durability under mechanical stress is also a concern.

Impacto na aplicação: In regions with high temperatures, the choice of plastic composite must be carefully considered to avoid degradation. Compliance with international standards for automotive components is essential for ensuring reliability.

Quadro resumo da seleção de materiais para arrancadores

| Material | Typical Use Case for how to know you have a bad starter | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Wiring and connectors in starters | Excelente condutividade elétrica | Custo elevado, maior peso | Alto |

| Alumínio | Housings and casings for starters | Leve, resistente à corrosão | Menor resistência à tração | Médio |

| Aço | Gears and shafts in starters | Alta resistência e durabilidade | Suscetível à corrosão | Baixo |

| Compósitos plásticos | Componentes não estruturais em arrancadores | Leve, bom isolamento elétrico | Resistência limitada à temperatura | Médio |

This guide provides actionable insights for international B2B buyers, helping them make informed decisions based on material properties, advantages, and limitations, while considering regional compliance and standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how to know you have a bad starter

Quais são as principais etapas do processo de fabrico de arrancadores?

Understanding the manufacturing process of starters is crucial for B2B buyers. The process generally consists of four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Starter Production?

The first step in starter manufacturing involves sourcing high-quality raw materials. Common materials include high-grade steel for the casing, copper for the windings, and durable plastics for insulation. Suppliers should provide certifications that the materials meet relevant international standards, ensuring they can withstand the operational demands placed on starters.

Once materials are acquired, they undergo various treatments, such as heat treating and coating, to enhance their strength and resistance to environmental factors. This stage is critical as the quality of raw materials directly impacts the performance and longevity of the starter.

What Forming Techniques Are Used in Starter Manufacturing?

The forming stage involves shaping the prepared materials into specific components of the starter. Key techniques include:

-

Usinagem: Precision machining is employed to create intricate parts such as the starter motor housing and the pinion gear. This ensures a perfect fit and minimizes the risk of mechanical failure.

-

Estampagem: Metal stamping is often used to produce flat components quickly and efficiently. This method allows for high-volume production while maintaining consistent quality.

-

Moldagem por injeção: For plastic components, injection molding provides a cost-effective way to produce complex shapes with high precision. The resulting parts are lightweight yet durable, contributing to the overall efficiency of the starter.

Each of these techniques should adhere to established quality standards to ensure that components will function reliably under various conditions.

How Does the Assembly Process Work for Starters?

After the components are formed, they move to the assembly stage. Here, skilled workers or automated systems assemble the starter using advanced techniques. The key focus during assembly is to maintain tolerances and ensure that each part fits together correctly.

Assembly typically involves:

- Cablagem: Connecting electrical components to ensure proper current flow.

- Securing Components: Using fasteners and adhesives to hold parts together, ensuring durability and reliability.

- Controlos de qualidade: Conducting in-process quality control checks to catch any defects early.

The assembly process is vital, as improper assembly can lead to premature starter failure, impacting customer satisfaction and brand reputation.

Que técnicas de acabamento são aplicadas aos starters?

Finishing processes aim to enhance the performance and aesthetic appeal of starters. Common finishing techniques include:

-

Revestimento: Applying protective coatings to prevent corrosion and wear, especially important for starters that may be exposed to harsh environments.

-

Testes: Each starter undergoes rigorous testing to verify its performance. This includes checking for electrical continuity, torque output, and thermal stability.

-

Embalagem: Finally, starters are packaged in protective materials to prevent damage during shipping and handling.

These finishing touches not only improve the product’s lifespan but also ensure that it meets the expectations of B2B buyers regarding quality and reliability.

What Are the Quality Assurance Measures in Starter Manufacturing?

Quality assurance (QA) is crucial in ensuring that starters meet the required standards. Here’s a breakdown of the QA processes typically involved:

How Are International Standards Like ISO 9001 Relevant to Starter Manufacturing?

ISO 9001 is an international standard that specifies requirements for a quality management system (QMS). Manufacturers that adhere to ISO 9001 demonstrate their commitment to consistent quality and customer satisfaction.

For B2B buyers, verifying a supplier’s ISO 9001 certification can provide assurance that the manufacturer follows systematic procedures for quality control, including regular audits and continuous improvement initiatives.

Illustrative image related to how to know you have a bad starter

Quais são os principais pontos de verificação do controlo de qualidade na produção de arrancadores?

Quality control checkpoints are essential at various stages of the manufacturing process to ensure that defects are caught early. Key checkpoints include:

-

Controlo de Qualidade de Entrada (IQC): Inspeção das matérias-primas à chegada para garantir a sua conformidade com as especificações.

-

Controlo de qualidade em processo (IPQC): Monitoring the manufacturing process to detect any deviations from quality standards during production.

-

Controlo de Qualidade Final (FQC): Conducting thorough inspections of finished products to verify that they meet performance and safety standards before shipping.

Each checkpoint serves as a safeguard to maintain the integrity of the final product.

Que métodos de teste comuns são utilizados para arrancadores?

Testing methods play a significant role in quality assurance. Common methods include:

-

Testes funcionais: Verifying that the starter operates correctly under simulated conditions.

-

Testes elétricos: Measuring parameters like resistance and current flow to ensure electrical components function as intended.

-

Teste de durabilidade: Assessing the starter’s performance under extreme conditions, including temperature fluctuations and vibrations.

B2B buyers should inquire about these testing methods to understand the level of quality assurance their suppliers implement.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are some effective ways to do this:

What Should B2B Buyers Look for in Supplier Audits and Reports?

Conducting supplier audits is an effective method for assessing quality control practices. Buyers should:

-

Request Audit Reports: Suppliers should provide recent audit reports, demonstrating compliance with international standards and internal quality measures.

-

Review Performance Metrics: Key performance indicators (KPIs) related to defect rates and customer satisfaction can provide insights into a supplier’s reliability.

Why Are Third-Party Inspections Important for Quality Assurance?

Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can conduct audits and inspections to verify that manufacturing processes align with claimed quality standards. This is particularly important for B2B buyers who may face challenges in visiting suppliers in different regions.

Quais são as nuances do controlo de qualidade para compradores B2B internacionais?

International buyers should be aware of regional differences in quality standards and regulations. For example, CE marking is mandatory for products sold in the European Economic Area, while API standards may apply to products used in the oil and gas sector. Understanding these nuances ensures that buyers select suppliers who comply with the necessary certifications for their markets.

By being informed about the manufacturing processes and quality assurance measures, B2B buyers can make better purchasing decisions, ensuring they procure reliable and high-quality starters for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know you have a bad starter’

In the realm of automotive maintenance, understanding the signs of a bad starter is crucial for ensuring the reliability of your vehicle fleet. This guide offers a step-by-step checklist for B2B buyers, helping you identify potential starter issues and effectively source the necessary components or services.

Illustrative image related to how to know you have a bad starter

Passo 1: Recognize Common Symptoms of Starter Failure

Identifying the symptoms of a failing starter is the first step towards effective procurement. Look for signs such as dashboard lights illuminating without the engine cranking, a clicking sound when attempting to start, or slow cranking of the engine. These indicators can help you determine whether your current starter needs replacement or repair.

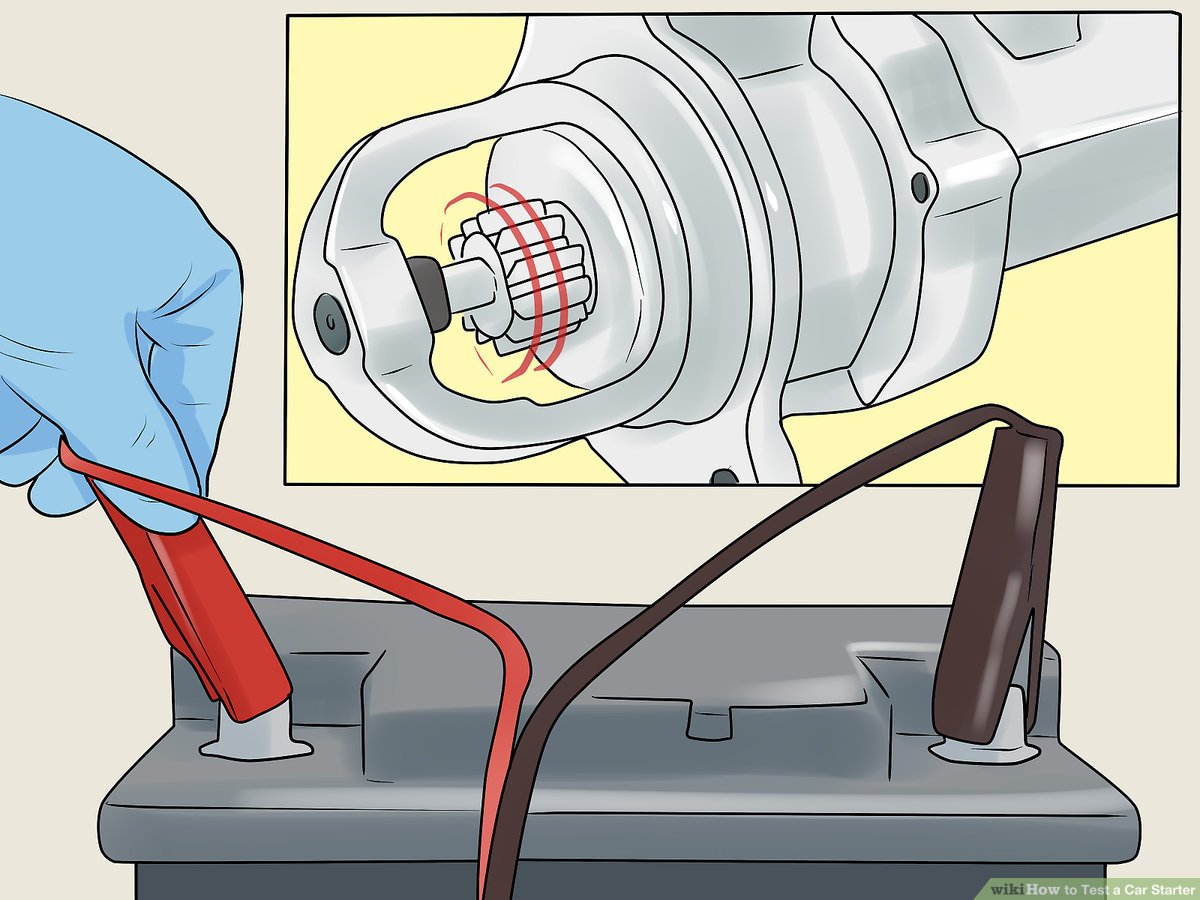

Passo 2: Conduct a Preliminary Diagnostic Test

Before sourcing a new starter, perform a preliminary diagnostic test to confirm the starter’s condition. Use a voltmeter to check the battery voltage; a reading below 12.3 volts often indicates a battery issue rather than a starter failure. This step is critical to avoid unnecessary purchases, ensuring you source only what is needed.

Passo 3: Evaluate Supplier Credentials and Experience

When sourcing replacement starters, it is vital to assess supplier credentials and experience. Look for suppliers with a proven track record in the automotive sector, especially those familiar with your specific vehicle models. Verify their certifications and request references from other clients in your region to ensure reliability and quality.

Passo 4: Compare Product Quality and Specifications

Not all starters are created equal, and product quality can vary significantly among suppliers. Review specifications such as power ratings, compatibility with your vehicle models, and warranty terms. Prioritize suppliers that provide detailed product information, as this can help prevent future failures and ensure long-term reliability.

Illustrative image related to how to know you have a bad starter

Passo 5: Inquire About Return Policies and Warranty Terms

Understanding a supplier’s return policies and warranty terms is crucial when sourcing starters. A solid warranty can provide peace of mind, indicating that the supplier stands behind their product quality. Ensure that the return policy allows for exchanges or refunds in case the starter does not meet your expectations or specifications.

Passo 6: Avaliar a logística e as opções de entrega

Consider the logistics involved in your purchase, including delivery times and shipping costs. For international buyers, it’s essential to understand the potential delays and customs processes that may affect the timely arrival of your starter. Choose suppliers that offer reliable shipping methods and transparent delivery timelines.

Passo 7: Stay Informed on Maintenance Practices

Finally, educate yourself and your team on best practices for maintaining starters to extend their life and prevent future issues. Regular checks on electrical connections, battery health, and oil leaks can mitigate risks of starter failure. This knowledge will not only help in maintaining your vehicles but also guide your sourcing decisions in the future.

By following this checklist, B2B buyers can make informed decisions when sourcing starters, ensuring their fleets remain operational and efficient.

Comprehensive Cost and Pricing Analysis for how to know you have a bad starter Sourcing

Understanding the costs associated with sourcing parts for diagnosing and addressing starter issues is crucial for B2B buyers. The analysis of the cost structure and pricing can help you make informed decisions, especially when navigating international markets.

What Are the Key Cost Components for Sourcing Starter Parts?

-

Materiais: The primary material cost for starters includes metals such as copper and aluminum, along with plastic and rubber components. The quality of these materials can significantly affect the durability and performance of the starter, impacting your overall costs.

-

Trabalho: Labor costs encompass the wages for skilled workers involved in manufacturing, assembly, and quality control processes. In regions with higher labor costs, like parts of Europe, this can lead to increased prices, whereas sourcing from countries with lower labor costs may offer savings.

-

Custos indiretos de produção: This includes costs related to utilities, rent, and equipment maintenance necessary for production. Overhead can vary widely based on the manufacturing facility’s location and efficiency.

-

Ferramentas: Initial tooling costs can be substantial, particularly for custom starters or those requiring specific configurations. These costs are generally amortized over production runs, making volume purchases more cost-effective.

-

Controlo de Qualidade (QC): Ensuring the reliability of starters involves rigorous QC measures, which can increase initial costs but reduce long-term risks associated with product failures.

-

Logística: Shipping and handling costs can vary significantly depending on the distance, mode of transport, and any tariffs or duties applied. For international buyers, understanding Incoterms is essential to gauge who bears these costs.

-

Margem: Suppliers typically apply a margin to cover their operating costs and profit. This margin can fluctuate based on market demand, competition, and the supplier’s positioning.

What Influences the Price of Starters?

-

Volume e quantidade mínima de encomenda (MOQ): Larger order volumes usually lead to lower per-unit costs due to economies of scale. Negotiating MOQs can help secure better pricing, especially for bulk purchases.

-

Especificações e personalização: Custom-built starters to meet specific vehicle requirements can incur higher costs. Be prepared to provide detailed specifications to get accurate pricing.

-

Qualidade dos materiais e certificações: Higher quality and certified materials can increase costs but are often justified by better performance and longevity. International buyers should verify supplier certifications to ensure compliance with local regulations.

-

Fatores relacionados ao fornecedor: The reliability, reputation, and financial stability of suppliers can influence pricing. Established suppliers may offer better warranties or support services, potentially offsetting higher initial costs.

-

Incoterms: Understanding Incoterms can help clarify shipping responsibilities and costs. For instance, choosing Ex-Works (EXW) might minimize initial costs but could lead to higher logistics expenses later.

What Are Effective Buyer Tips for Sourcing Starters?

-

Negocie com sabedoria: Leverage volume commitments or long-term contracts to negotiate better pricing. Building relationships with suppliers can also lead to favorable terms.

-

Foco na eficiência de custos: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront costs. A higher-quality starter may reduce maintenance and replacement costs over time.

-

Compreenda as nuances dos preços nos mercados internacionais: Different regions may have varying market dynamics. For instance, in Africa and South America, currency fluctuations can impact pricing. Consider local economic conditions when sourcing.

-

Realizar pesquisa de mercado: Keep abreast of market trends and competitor pricing. This knowledge will empower you during negotiations and help you identify the best sourcing opportunities.

-

Seek Local Suppliers When Possible: Sourcing locally can reduce logistics costs and lead times, particularly in regions like Nigeria and Brazil, where importing can be complex and costly.

Isenção de responsabilidade para preços indicativos

Prices for starters can fluctuate based on the factors mentioned above. It is advisable to obtain multiple quotes and conduct thorough due diligence before finalizing purchases.

Alternatives Analysis: Comparing how to know you have a bad starter With Other Solutions

Exploring Alternative Methods for Diagnosing Starter Issues

When dealing with automotive issues, particularly in commercial fleets or service vehicles, understanding how to accurately diagnose a bad starter is crucial. However, various alternative methods and technologies exist that can assist in identifying starter problems or similar issues. Below, we compare the traditional approach of determining a bad starter against other viable diagnostic solutions.

| Aspecto comparativo | How To Know You Have A Bad Starter | Ferramenta de diagnóstico | Testador de baterias |

|---|---|---|---|

| Desempenho | Reliable diagnosis through symptoms | High accuracy; provides codes for multiple issues | Quick battery health check |

| Custo | Minimal (DIY approach) | Moderado ($50 - $200) | Low ($10 – $50) |

| Facilidade de implementação | Requires some mechanical knowledge | User-friendly; minimal training needed | Very easy; plug-and-play |

| Manutenção | Regular checks recommended | Actualizações de software necessárias | Low maintenance; check as needed |

| Melhor caso de uso | When symptoms are clear | Comprehensive diagnostics for multiple systems | Quick battery assessments |

What Are the Pros and Cons of Using a Diagnostic Scan Tool?

A diagnostic scan tool offers a modern and efficient approach to vehicle troubleshooting. This device connects to the vehicle’s onboard computer to retrieve error codes and diagnostic information.

Illustrative image related to how to know you have a bad starter

Prós:

– Provides a comprehensive overview of vehicle health, allowing for the diagnosis of multiple issues beyond just the starter.

– User-friendly interfaces make them accessible even to those with limited technical knowledge.

Contras:

– Can be costly for businesses with a limited budget, especially if multiple vehicles need to be serviced.

– May require updates or additional training to maximize effectiveness, which can lead to added costs.

How Does a Battery Tester Compare as an Alternative?

A battery tester is a simple yet effective tool that measures the health of a vehicle’s battery. It can quickly determine if a battery is weak, which could be mistaken for starter issues.

Prós:

– Low cost and easy to use, making it an ideal tool for quick assessments.

– Provides immediate results, which can help in making quick decisions about whether to replace the battery or check the starter.

Illustrative image related to how to know you have a bad starter

Contras:

– Limited in scope; it cannot diagnose starter issues directly but only assesses battery health.

– If the battery is functioning well, it may lead to further troubleshooting and time spent on the starter without definitive results.

Conclusão: Como é que os compradores B2B devem escolher a solução de diagnóstico correta?

For B2B buyers in the automotive sector, selecting the right diagnostic tool is essential for efficient fleet management and vehicle maintenance. The decision should be based on specific needs, including budget constraints, the complexity of vehicle issues, and the level of technical expertise available. For those who frequently encounter starting issues, investing in a diagnostic scan tool may provide the most comprehensive solution. However, for quick assessments, a battery tester is a cost-effective and easy-to-use option. Ultimately, understanding the strengths and limitations of each method will empower buyers to make informed decisions that enhance operational efficiency and reduce downtime.

Essential Technical Properties and Trade Terminology for how to know you have a bad starter

What Are the Critical Technical Properties to Identify a Bad Starter?

-

Grau do material

The material used in a starter motor is crucial for its durability and performance. High-grade materials, such as aluminum or reinforced plastics, ensure resistance to heat and corrosion. In B2B transactions, specifying material grade helps buyers ensure they are purchasing starters that can withstand harsh operating conditions, particularly in regions with extreme climates like Africa and South America. -

Resistência elétrica

The electrical resistance of the starter motor’s windings affects its efficiency. A low resistance allows for a higher current flow, enhancing the starter’s ability to crank the engine. For buyers, understanding electrical resistance specifications is vital to ensure compatibility with the vehicle’s electrical system, preventing failures that can lead to costly downtime. -

Saída de binário

Torque output is a measure of the starter’s ability to turn the engine over. A starter with insufficient torque may struggle to initiate the engine, particularly in cold weather or high-compression engines. B2B buyers must pay attention to torque ratings to select starters that meet the demands of specific vehicle models, enhancing reliability and performance. -

Amperagem de arranque (CA)

Cranking amperage indicates the amount of current the starter draws to start the engine. A higher CA rating is typically required for larger engines or vehicles in colder climates. Knowing the CA specification is essential for B2B buyers to ensure that the starter can handle the starting requirements of the intended vehicle, avoiding premature failure. -

Níveis de tolerância

Tolerance levels refer to the allowable variations in the starter’s dimensions and performance characteristics. Tight tolerances ensure that components fit together correctly, reducing the risk of mechanical failure. For international buyers, understanding tolerance specifications is crucial for ensuring compatibility with various vehicle models and avoiding costly returns.

Which Trade Terminology is Essential for B2B Transactions Regarding Starters?

-

OEM (Fabricante de Equipamento Original)

OEM refers to parts made by the original manufacturer of the vehicle. In the context of starters, using OEM parts ensures compatibility and reliability. B2B buyers often prefer OEM starters to maintain warranty coverage and guarantee quality. -

MOQ (Quantidade mínima de encomenda)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to manage inventory effectively and negotiate bulk purchase agreements. It also impacts cash flow and storage considerations. -

RFQ (Pedido de Orçamento)

An RFQ is a formal process where buyers request pricing and terms from suppliers. For starters, submitting an RFQ helps buyers compare options and negotiate better deals. This terminology is vital in B2B transactions to ensure clarity and competitiveness. -

Incoterms (Termos Comerciais Internacionais)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade, such as delivery points and shipping costs. Familiarity with Incoterms helps B2B buyers understand their obligations in the shipping process, reducing risks of disputes. -

Prazo de entrega

Lead time refers to the time taken from placing an order to receiving the product. In the context of starters, understanding lead times is essential for B2B buyers to manage their supply chains and ensure timely vehicle maintenance or production schedules. -

Período de garantia

The warranty period specifies the duration a product is guaranteed against defects. For starters, a longer warranty can indicate higher confidence in product quality. B2B buyers should consider warranty terms when evaluating suppliers, as this can affect long-term operational costs.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select high-quality starters that meet their operational needs while navigating international procurement complexities.

Navigating Market Dynamics and Sourcing Trends in the how to know you have a bad starter Sector

What Are the Current Market Dynamics and Key Trends in the Starter Sector?

The global automotive market is witnessing significant shifts driven by technological advancements and evolving consumer preferences. For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. One of the main drivers in the starter sector is the increasing demand for electric vehicles (EVs). As manufacturers pivot towards sustainable transport solutions, the traditional starter systems are evolving to accommodate new technologies, including integrated starter generators in hybrid and electric vehicles.

Illustrative image related to how to know you have a bad starter

Moreover, there is a growing trend towards digitalization in supply chain management. B2B buyers are leveraging technology to enhance their sourcing processes, employing platforms that facilitate real-time inventory tracking and predictive analytics. This enables companies to optimize their procurement strategies, ensuring they can respond swiftly to market demands. Additionally, the rise of e-commerce is transforming how parts are sourced, making it easier for international buyers to access components from various suppliers globally.

In regions like Nigeria and Brazil, local automotive markets are expanding, driven by a burgeoning middle class and increased vehicle ownership. This creates opportunities for suppliers who can offer reliable starter systems, as well as aftermarket parts and services. Furthermore, the implementation of stringent regulations regarding emissions is pushing manufacturers to innovate and comply with environmental standards, thereby impacting starter design and functionality.

How Is Sustainability and Ethical Sourcing Impacting the Starter Sector?

Sustainability is becoming a cornerstone of business practices in the automotive sector, influencing how components like starters are produced and sourced. As environmental concerns rise, B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices. This includes sourcing materials that are recycled or have lower environmental impacts, such as metals that are responsibly mined and processed.

Ethical supply chains are also gaining traction, as companies recognize the importance of transparency in sourcing. B2B buyers are looking for partners who can provide certifications for ethical practices, ensuring that their products, including starter systems, are manufactured under fair labor conditions and with minimal environmental harm. This demand is not just a trend; it is becoming a competitive advantage for suppliers who can demonstrate their commitment to sustainability.

Furthermore, the integration of “green” certifications into the sourcing process is critical. Buyers are increasingly seeking suppliers who can provide evidence of adherence to environmental standards, such as ISO 14001 or similar frameworks. These certifications not only enhance credibility but also align with the corporate social responsibility goals of many organizations, making them more attractive to international buyers.

What Is the Historical Context Behind Current Starter Technologies?

The evolution of starter systems has been closely tied to advancements in automotive technology. Initially, starters were purely mechanical devices, but with the introduction of electrical systems in vehicles, they transformed into electric motors powered by batteries. This change significantly improved reliability and ease of use, allowing for a seamless ignition process.

Over the decades, as vehicle technology progressed, starters have adapted to meet the demands of more complex engine systems. The introduction of smart starters that integrate with vehicle computers has further enhanced functionality, enabling features like stop-start systems that improve fuel efficiency. This historical context is vital for B2B buyers, as it highlights the importance of sourcing from manufacturers that understand both traditional and modern starter technologies, ensuring compatibility and performance in an evolving market.

In conclusion, as the starter sector continues to evolve, international B2B buyers must stay informed about market dynamics, sustainability practices, and the historical context of starter technology to make informed sourcing decisions.

Illustrative image related to how to know you have a bad starter

Frequently Asked Questions (FAQs) for B2B Buyers of how to know you have a bad starter

-

How can I identify a bad starter in my vehicle?

Identifying a bad starter typically involves observing specific symptoms. Common signs include a clicking noise when turning the key, the engine failing to crank, or slow cranking when you attempt to start the vehicle. You may also notice dashboard warning lights illuminating without the engine starting. If you experience any of these issues, it’s advisable to have your starter and associated components inspected by a qualified mechanic. -

What are the potential costs associated with replacing a bad starter?

The cost of replacing a starter can vary significantly based on the vehicle type and labor charges in your region. Generally, you can expect to pay between $300 and $600 for parts and labor. It’s essential to obtain quotes from multiple suppliers or mechanics to ensure competitive pricing, especially when sourcing parts internationally. Be sure to factor in shipping and import duties if you are purchasing from abroad. -

Posso dar o arranque ao meu veículo se o motor de arranque estiver a funcionar mal?

Jump-starting a vehicle with a bad starter is unlikely to resolve the issue. While a jump-start provides additional power to the battery, it does not fix problems within the starter motor itself. If you suspect a starter issue, it’s best to conduct a thorough diagnosis or consult with a mechanic to determine the exact cause of the starting problem. -

What should I consider when sourcing starters from international suppliers?

When sourcing starters internationally, consider the supplier’s reputation, product quality, and compliance with local standards. Check for certifications and customer reviews to gauge reliability. Additionally, inquire about warranty terms and after-sales support. Make sure the supplier can provide necessary documentation for customs clearance, which is crucial for smooth logistics. -

Como posso garantir a qualidade das entradas que adquiro?

To ensure quality, vet potential suppliers by requesting product samples and certifications, such as ISO standards. Conduct factory audits if possible or work with third-party inspection services to verify the quality before shipment. Additionally, establish a clear quality assurance process that includes testing upon receipt to confirm that the products meet your specifications. -

What are the typical minimum order quantities (MOQ) for starters from suppliers?

Minimum order quantities can vary widely among suppliers. Some manufacturers may require MOQs ranging from 50 to several hundred units, depending on their production capacity and the type of starter. It’s essential to discuss MOQs upfront and negotiate terms that suit your business needs, especially if you are a smaller buyer or testing a new market. -

What payment terms should I negotiate when purchasing starters?

When negotiating payment terms, aim for conditions that balance your cash flow needs with the supplier’s requirements. Common terms include a percentage upfront (20-30%) with the remainder due upon delivery or net 30/60 days. Consider using escrow services for large orders to protect your investment and ensure that the product meets your expectations before full payment is released. -

What logistics considerations are important when importing starters?

Logistics considerations include choosing reliable shipping methods, understanding customs regulations, and managing import duties. Ensure that the supplier provides all necessary documentation, such as invoices and certificates of origin, to facilitate customs clearance. Plan for potential delays by allowing extra time for shipping and customs processing, and consider using a freight forwarder with experience in automotive parts to streamline the process.

A Look at How To Know You Have A Bad Starter Manufacturers & Suppliers

Could not verify enough suppliers for how to know you have a bad starter to create a list at this time.

Strategic Sourcing Conclusion and Outlook for how to know you have a bad starter

Understanding the signs of a failing starter is crucial for maintaining operational efficiency and minimizing downtime. Key indicators such as dashboard warning lights, clicking sounds, or slow cranking can help diagnose starter issues early, allowing you to take proactive measures. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, sourcing high-quality replacement parts is essential to ensure your vehicles remain reliable.

Strategic sourcing plays a vital role in this process. By establishing relationships with reputable suppliers, you can secure quality starters and related components that enhance the longevity of your fleet. Regular maintenance and monitoring of your starter system, including checking electrical connections and addressing any oil leaks, can prevent unexpected failures.

Illustrative image related to how to know you have a bad starter

As you navigate the complexities of sourcing automotive parts, prioritize suppliers who offer robust warranties and customer support. This not only safeguards your investment but also ensures that you have the resources needed to address any potential issues swiftly. Embrace this opportunity to enhance your operational resilience and keep your fleet running smoothly. Invest in quality today for a more reliable tomorrow.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.