Introduction: Navigating the Global Market for para q sirve el alternador

In today’s competitive landscape, international B2B buyers face the challenge of sourcing reliable components, such as alternators, which are crucial for vehicle performance and operational efficiency. Understanding para qué sirve el alternador is essential for making informed purchasing decisions that can impact supply chain effectiveness and end-user satisfaction. This guide offers a comprehensive overview of the alternator’s functionality, types, and applications across various industries, providing insights into the critical role these components play in modern vehicles.

The guide delves into key aspects such as the mechanisms of alternators, their compatibility with different vehicle systems, and the importance of sourcing from reputable suppliers. It also addresses the nuances of supplier vetting, ensuring that buyers from regions like Africa, South America, the Middle East, and Europe—including markets like Saudi Arabia and Nigeria—can confidently engage with potential partners. Additionally, we will explore cost considerations, maintenance practices, and common issues related to alternator performance.

By equipping B2B buyers with actionable insights and best practices, this guide aims to empower them to navigate the complexities of the global market for alternators effectively. Whether you are looking to enhance your vehicle fleet or improve operational efficiencies, understanding the intricacies of alternators will enable you to make strategic decisions that drive success.

Índice

- Top 2 Para Q Sirve El Alternador Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for para q sirve el alternador

- Understanding para q sirve el alternador Types and Variations

- Key Industrial Applications of para q sirve el alternador

- 3 Common User Pain Points for ‘para q sirve el alternador’ & Their Solutions

- Strategic Material Selection Guide for para q sirve el alternador

- In-depth Look: Manufacturing Processes and Quality Assurance for para q sirve el alternador

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘para q sirve el alternador’

- Comprehensive Cost and Pricing Analysis for para q sirve el alternador Sourcing

- Alternatives Analysis: Comparing para q sirve el alternador With Other Solutions

- Essential Technical Properties and Trade Terminology for para q sirve el alternador

- Navigating Market Dynamics and Sourcing Trends in the para q sirve el alternador Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of para q sirve el alternador

- Strategic Sourcing Conclusion and Outlook for para q sirve el alternador

- Aviso legal importante e termos de utilização

Understanding para q sirve el alternador Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Alternador padrão | Converts mechanical energy to electrical; common in vehicles. | Automotive manufacturing, fleet management | Pros: Widely available, cost-effective. Cons: Limited to standard applications. |

| Alternador de alta potência | Produces higher voltage and current for power-hungry devices. | Veículos de alto desempenho, maquinaria pesada | Pros: Supports advanced electronics. Cons: Higher cost, may require modifications. |

| Alternador marítimo | Designed for harsh marine environments; corrosion-resistant. | Embarcações marítimas, barcos de pesca | Pros: Durable, reliable in wet conditions. Cons: More expensive, specialized parts. |

| Alternador a diesel | Built to handle the demands of diesel engines; robust design. | Commercial trucks, industrial applications | Pros: High durability, efficiency. Cons: Heavier, potentially higher maintenance. |

| Renewable Energy Alternator | Optimized for wind and solar energy systems; eco-friendly design. | Renewable energy projects, off-grid applications | Pros: Supports sustainability, often low maintenance. Cons: Initial investment can be high. |

Quais são as principais caraterísticas dos alternadores standard?

Standard alternators are the most common type found in vehicles. They efficiently convert mechanical energy from the engine into electrical energy, which powers the vehicle’s electrical systems while simultaneously recharging the battery. For B2B buyers, these alternators are ideal for automotive manufacturing and fleet management due to their widespread availability and cost-effectiveness. However, they may not meet the needs of vehicles with specialized electrical demands.

Como é que os alternadores de alto rendimento diferem dos modelos padrão?

High-output alternators are designed to produce greater voltage and current, making them suitable for vehicles with advanced electronic systems, such as performance cars or heavy machinery. These alternators can support additional accessories like high-powered sound systems or aftermarket lighting. B2B buyers should consider these for applications requiring enhanced electrical capacity, although they come at a higher cost and may necessitate modifications to the vehicle’s electrical system.

O que torna os alternadores marítimos únicos?

Marine alternators are specifically engineered to withstand the harsh conditions of marine environments, featuring corrosion-resistant materials and designs. They are crucial for powering the electrical systems of boats and ships, ensuring reliability in wet conditions. For businesses in the marine sector, investing in high-quality marine alternators is essential for operational efficiency, though they typically carry a higher price tag due to their specialized construction.

Why Are Diesel Alternators Important for Heavy-Duty Applications?

Diesel alternators are built to meet the high demands of diesel engines, offering robust performance and efficiency. They are commonly used in commercial trucks and industrial machinery, where reliability and durability are paramount. B2B buyers should prioritize these alternators for heavy-duty applications, understanding that while they may be heavier and require more maintenance, their efficiency and longevity can justify the investment.

How Do Renewable Energy Alternators Support Sustainable Practices?

Renewable energy alternators are tailored for integration with wind and solar energy systems, promoting eco-friendly energy solutions. These alternators are often low maintenance and designed to operate efficiently in off-grid applications. For businesses focused on sustainability, investing in renewable energy alternators can enhance their green credentials, although the initial investment may be higher compared to conventional alternators.

Key Industrial Applications of para q sirve el alternador

| Indústria/Setor | Specific Application of para q sirve el alternador | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Automotivo | Powering vehicle electrical systems during operation | Ensures reliable vehicle functionality and customer satisfaction | Quality certifications, compatibility with vehicle models, after-sales support |

| Equipamento de construção | Supplying electricity for heavy machinery and tools | Enhances operational efficiency and reliability on job sites | Durability in harsh environments, maintenance services, warranty options |

| Energia renovável | Integrating with hybrid systems for energy conversion | Supports sustainable energy solutions and reduces operational costs | Efficiency ratings, adaptability to different energy sources, supplier reputation |

| Indústria naval | Providing power for onboard systems in vessels | Improves safety and operational reliability at sea | Corrosion resistance, compliance with marine standards, size and weight specifications |

| Máquinas agrícolas | Powering irrigation and automated farming equipment | Increases productivity and operational efficiency in farming | Voltage requirements, environmental resilience, local sourcing options |

How Does the Automotive Industry Utilize ‘para q sirve el alternador’?

In the automotive sector, the alternator plays a crucial role by supplying electricity to a vehicle’s electrical systems while the engine is running. This ensures that critical components such as lights, infotainment systems, and electronic controls function reliably. For international B2B buyers, especially in regions like Africa and South America, sourcing high-quality alternators that meet specific vehicle model requirements is essential. Buyers must also consider after-sales support and warranty options to ensure long-term reliability and customer satisfaction.

What Role Does the Alternator Play in Construction Equipment?

In construction, alternators are vital for powering heavy machinery and tools, providing the necessary electricity to operate equipment like excavators and cranes. This application enhances operational efficiency and reliability, crucial for meeting project deadlines. B2B buyers in this sector must prioritize sourcing alternators that can withstand harsh environmental conditions and offer maintenance services, ensuring minimal downtime on job sites.

How is ‘para q sirve el alternador’ Applied in Renewable Energy Systems?

The renewable energy sector increasingly incorporates alternators in hybrid systems to convert mechanical energy into electricity, facilitating energy storage and management. This integration supports sustainable energy solutions and helps reduce operational costs. Buyers in this industry should focus on sourcing alternators with high efficiency ratings and adaptability to various energy sources, ensuring compatibility with their renewable energy projects.

Why is the Alternator Important in the Marine Industry?

In the marine industry, alternators provide essential power for onboard systems, ensuring operational reliability and safety at sea. They power navigation systems, communication devices, and other critical equipment on vessels. For B2B buyers in this field, sourcing alternators that are corrosion-resistant and compliant with marine standards is crucial, as these factors significantly impact performance and longevity in a marine environment.

How Does the Agricultural Sector Benefit from Alternators?

In agriculture, alternators are used to power irrigation systems and automated farming equipment, which significantly increases productivity and operational efficiency. This application is particularly beneficial in regions with limited access to reliable power sources. Buyers in this sector should consider voltage requirements and environmental resilience when sourcing alternators, as these factors directly affect the effectiveness of agricultural operations.

3 Common User Pain Points for ‘para q sirve el alternador’ & Their Solutions

Scenario 1: Ensuring Reliable Vehicle Performance with Alternators

O problema: B2B buyers in the automotive sector often grapple with ensuring that their fleet operates smoothly. A malfunctioning alternator can lead to unexpected vehicle breakdowns, which directly affects operational efficiency and increases maintenance costs. For businesses that rely on transportation, such as logistics and delivery services, these disruptions can lead to delays, loss of revenue, and decreased customer satisfaction. Understanding the critical role of the alternator in maintaining battery charge and supplying power to electrical systems is essential, yet many buyers overlook its importance during procurement.

A solução: To mitigate this risk, B2B buyers should prioritize sourcing high-quality alternators that meet or exceed OEM specifications. When evaluating alternators, consider factors such as compatibility with specific vehicle models, reliability ratings, and warranty offerings. It’s advisable to partner with reputable suppliers known for their expertise in automotive components. Regular training for fleet maintenance teams on identifying early signs of alternator failure—like dimming lights or difficulty starting the vehicle—can also enhance operational reliability. Implementing a proactive maintenance schedule that includes regular inspections of the alternators can help identify issues before they escalate, ensuring your fleet remains operational and efficient.

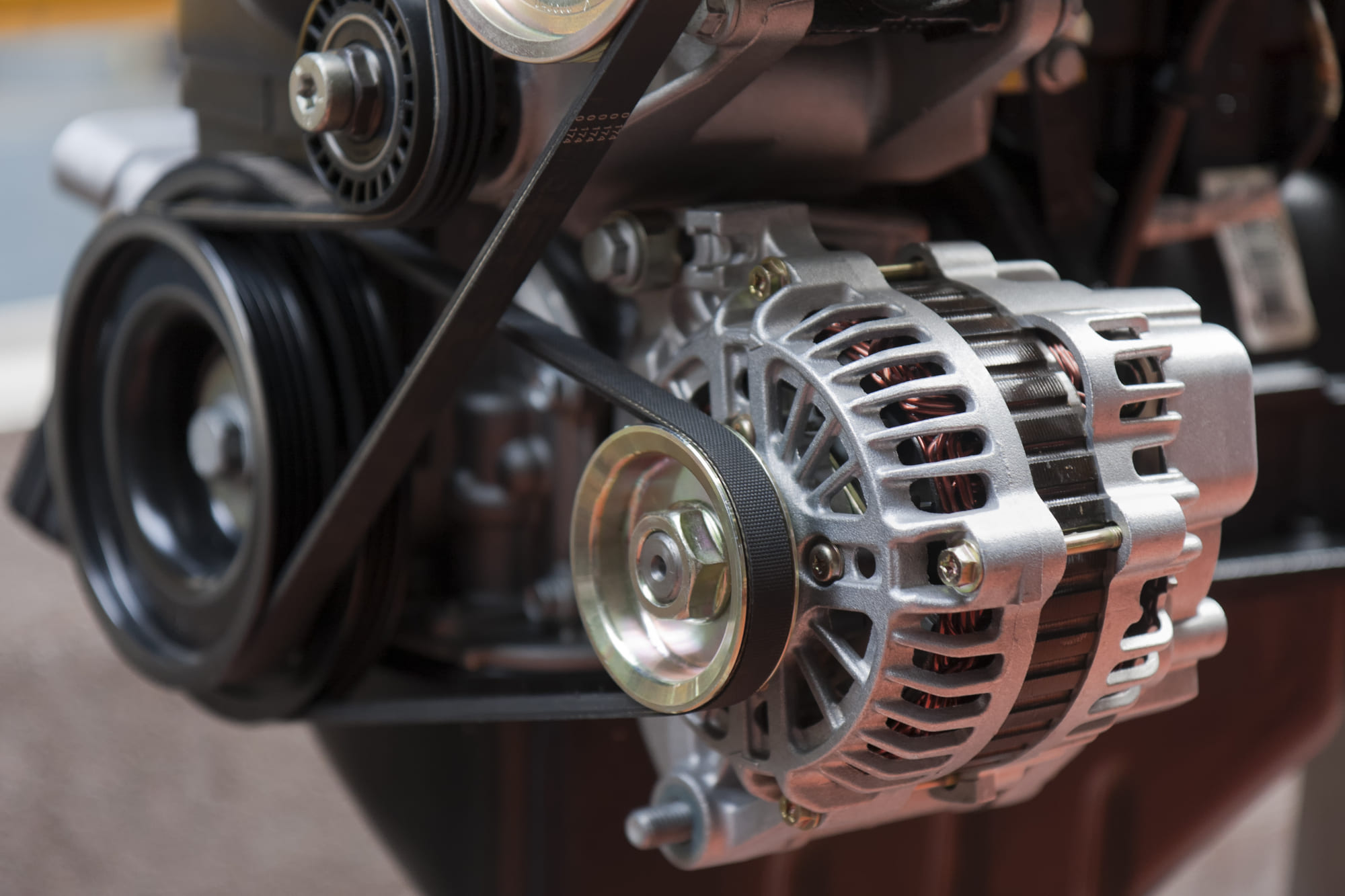

Illustrative image related to para q sirve el alternador

Scenario 2: Cost-Effective Solutions for Alternator Failures

O problema: Many businesses face the challenge of balancing cost and quality when it comes to replacing alternators. Lower-cost options may seem appealing, but they often lead to more frequent failures, resulting in increased long-term costs. B2B buyers may find themselves caught in a cycle of purchasing cheap alternators that fail prematurely, leading to unplanned maintenance costs and downtime, which can severely affect their bottom line.

A solução: To address this issue, it is crucial to invest in high-quality alternators that provide longevity and reliability. Buyers should conduct thorough market research to identify suppliers that offer a balance of competitive pricing and high-quality products. Seeking out suppliers that provide detailed specifications and performance data can help ensure that the chosen alternators are built to last. Additionally, consider negotiating bulk purchasing agreements with suppliers, as this can often lead to reduced costs per unit while maintaining quality. Implementing a robust warranty program can also provide peace of mind and protection against early failures, ensuring that your investment is sound.

Scenario 3: Navigating Technical Challenges with Alternator Specifications

O problema: B2B buyers often encounter difficulties when trying to understand the technical specifications of alternators, leading to mismatches with vehicle requirements. This lack of clarity can result in purchasing the wrong alternator, causing delays and additional costs in returns or replacements. For companies that rely on specific vehicle performance metrics, such as those in the construction or agricultural sectors, understanding these specifications is vital for operational success.

A solução: To navigate these technical challenges effectively, B2B buyers should establish a comprehensive understanding of the specific electrical needs of their vehicle fleet. Engaging with technical experts or engineers who specialize in automotive electrical systems can provide valuable insights into the required specifications for alternators. Utilizing resources such as detailed product catalogs and technical datasheets from manufacturers can also aid in making informed decisions. Moreover, consider investing in training for procurement teams to enhance their technical knowledge regarding alternator specifications. This will empower them to ask the right questions when sourcing products, ensuring that they select the correct alternators that align with their operational requirements and improve overall fleet performance.

Strategic Material Selection Guide for para q sirve el alternador

What Are the Key Materials Used in Alternators and Their Properties?

When selecting materials for alternators, it is crucial to consider their performance characteristics, cost, and suitability for specific applications. This section analyzes four common materials used in alternator manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Cobre

Principais propriedades:

Copper is known for its excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It can operate effectively at high temperatures, making it suitable for the demanding environments found in automotive applications.

Prós e contras:

The primary advantage of copper is its superior conductivity, which enhances the efficiency of the alternator. However, copper is relatively expensive compared to other materials, which can increase manufacturing costs. Additionally, its weight may be a consideration in applications where weight reduction is critical.

Impacto na aplicação:

Copper is commonly used in windings and connectors within the alternator, ensuring efficient energy transfer. Its compatibility with various automotive electrical systems makes it a preferred choice.

Considerações para compradores internacionais:

Buyers from regions like Africa and the Middle East should ensure compliance with international standards such as ASTM B170 for copper wire. Additionally, the fluctuating price of copper can impact budgeting for projects.

2. Alumínio

Principais propriedades:

Aluminum is lightweight, resistant to corrosion, and has good thermal conductivity. It can operate at moderate temperatures and is often used in components where weight savings are essential.

Prós e contras:

The lightweight nature of aluminum can lead to improved fuel efficiency in vehicles, making it an attractive option. However, aluminum’s lower electrical conductivity compared to copper can limit its effectiveness in certain applications. Additionally, it can be more challenging to work with in terms of manufacturing processes.

Impacto na aplicação:

Aluminum is often used in the casing and structural components of alternators. Its corrosion resistance makes it suitable for environments with high humidity or exposure to road salt.

Considerações para compradores internacionais:

International buyers should be aware of the standards for aluminum alloys, such as ASTM B221. Additionally, the availability of aluminum can vary by region, impacting supply chains.

3. Aço

Principais propriedades:

Steel is known for its strength, durability, and resistance to wear. It can withstand high pressures and is often used in components that require structural integrity.

Prós e contras:

The primary advantage of steel is its robustness, which ensures longevity and reliability in alternator applications. However, steel is heavier than aluminum and copper, which may not be ideal for all automotive designs. It is also susceptible to corrosion unless properly treated.

Impacto na aplicação:

Steel is typically used in the alternator housing and support structures, providing the necessary strength to protect internal components. Its compatibility with various automotive environments makes it a reliable choice.

Illustrative image related to para q sirve el alternador

Considerações para compradores internacionais:

Buyers should consider compliance with standards like ASTM A36 for structural steel. Additionally, the weight of steel components may influence shipping costs and logistics in regions like South America and Europe.

4. Compósitos plásticos

Principais propriedades:

Plastic composites are lightweight, resistant to corrosion, and can be molded into complex shapes. They can operate at moderate temperatures and provide electrical insulation.

Prós e contras:

The main advantage of plastic composites is their versatility in design and weight savings. However, they may not be suitable for high-temperature applications and can have lower mechanical strength compared to metals.

Impacto na aplicação:

Plastic composites are often used in non-structural components of alternators, such as covers and insulators, where weight reduction is beneficial. Their insulation properties also help in preventing electrical shorts.

Considerações para compradores internacionais:

International buyers should ensure that the plastic materials used comply with standards such as ASTM D638 for tensile properties. The availability of specific composites may vary by region, impacting sourcing strategies.

Illustrative image related to para q sirve el alternador

Tabela resumida da seleção de materiais para alternadores

| Material | Typical Use Case for para q sirve el alternador | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Enrolamentos e conectores | Condutividade elétrica superior | Custo e peso mais elevados | Alto |

| Alumínio | Casing and structural components | Leve e resistente à corrosão | Condutividade inferior à do cobre | Médio |

| Aço | Housing and support structures | Alta resistência e durabilidade | Mais pesado e suscetível à corrosão | Médio |

| Compósitos plásticos | Non-structural components (covers, insulators) | Leve e versátil | Lower mechanical strength and temperature limits | Baixo |

This analysis provides B2B buyers with a comprehensive overview of materials used in alternators, enabling informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for para q sirve el alternador

What Are the Key Manufacturing Processes for Alternators?

Manufacturing alternators involves several critical stages that ensure the production of high-quality components essential for vehicle electrical systems. Here’s a breakdown of the typical manufacturing processes:

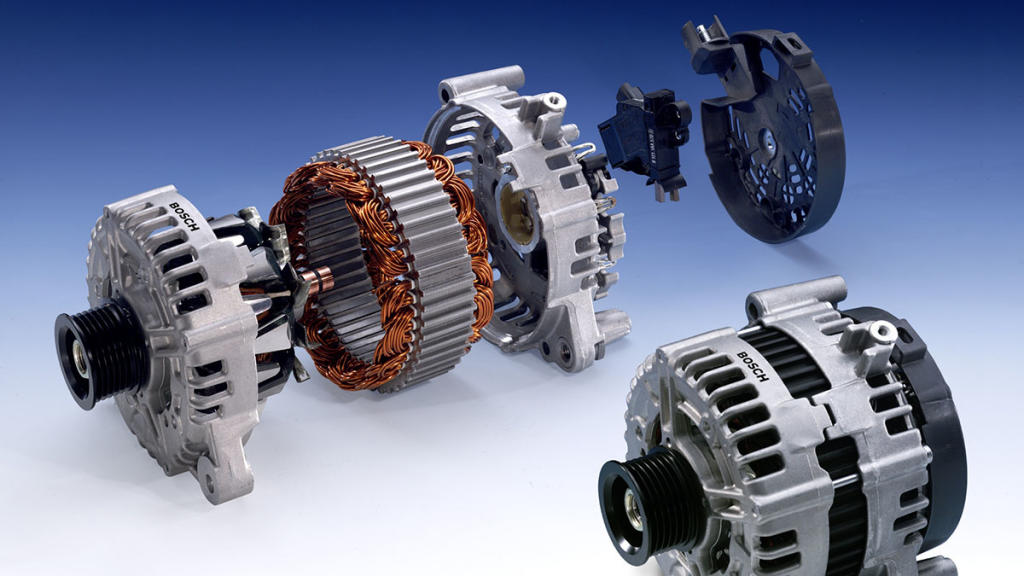

Quais são as principais fases de fabrico dos alternadores?

-

Preparação do material

– The first step in alternator manufacturing is sourcing and preparing raw materials, primarily high-grade steel for the rotor and stator, copper wire for the windings, and various polymers for insulation.

– Quality control begins at this stage, where materials are inspected for purity, tensile strength, and electrical conductivity, ensuring they meet industry standards. -

Formando

– Estampagem: The steel is stamped into various shapes, including the stator and rotor cores. This process requires precision to maintain the tolerances necessary for efficient operation.

– Enrolamento: Copper wire is wound around the stator and rotor to create the electromagnetic fields necessary for the alternator to function. Automated winding machines are often used to ensure uniformity and reduce labor costs. -

Montagem

– The components are assembled in a clean environment to prevent contamination. This includes mounting the rotor onto the shaft, securing the stator, and installing the rectifier and voltage regulator.

– Advanced robotics and automated systems are frequently utilized to enhance precision and efficiency during assembly. -

Acabamento

– After assembly, alternators undergo finishing processes, which may include surface treatments to prevent corrosion and improve durability.

– Components are often painted or coated with protective finishes to enhance longevity and aesthetic appeal.

Como é implementada a garantia de qualidade no fabrico de alternadores?

Quality assurance in alternator manufacturing is paramount to ensure reliability and performance, especially for B2B buyers who depend on these components for their vehicles.

Which International Standards Apply to Alternator Manufacturing?

-

ISO 9001

– This international standard outlines the criteria for a quality management system. Manufacturers must demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

– Compliance with ISO 9001 ensures that processes are standardized, documented, and continuously improved. -

Marcação CE

– In Europe, alternators must comply with the CE marking requirements, indicating conformity with health, safety, and environmental protection standards. -

Padrões API

– For certain applications, particularly in automotive and industrial sectors, adhering to API (American Petroleum Institute) standards can be crucial, especially for alternators used in oilfield services or heavy machinery.

Quais são os principais pontos de verificação do controlo de qualidade na fabricação de alternadores?

Quality control is integrated at various stages of the manufacturing process to ensure that each alternator meets rigorous performance standards.

-

Controlo de Qualidade de Entrada (IQC)

– At the material preparation stage, suppliers must provide documentation proving that raw materials meet specified standards. Random sampling is conducted to test material properties. -

Controlo de qualidade em processo (IPQC)

– During the forming and assembly stages, continuous monitoring is essential. This includes checking the dimensions of stamped parts, the integrity of windings, and proper assembly alignment.

– Use of automated inspection systems can enhance detection of defects. -

Controlo de Qualidade Final (FQC)

– Once the alternator is assembled, it undergoes thorough testing. Common tests include:- Electrical performance tests to verify voltage output and efficiency.

- Mechanical tests to check vibration resistance and durability.

- Environmental tests to assess performance under extreme conditions.

Como os compradores B2B podem verificar as práticas de controlo de qualidade dos fornecedores?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability.

-

Auditorias a fornecedores

– Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can involve reviewing documentation, inspecting the production floor, and evaluating compliance with ISO standards. -

Relatórios de qualidade

– Requesting detailed quality reports from suppliers can provide transparency regarding their processes. These reports should include data on defect rates, compliance with international standards, and results from testing procedures. -

Inspeções por terceiros

– Engaging third-party inspection services can serve as an unbiased means of verifying the quality of products before they are shipped. These inspectors can assess compliance with specific standards and provide certification.

Que nuances devem os compradores internacionais considerar relativamente ao controlo de qualidade?

-

Cultural and Regulatory Differences

– Buyers must be aware of the varying regulations and quality expectations in different regions. For instance, compliance with European standards may differ significantly from those in Africa or the Middle East. -

Supply Chain Challenges

– International logistics can introduce risks that affect product quality. Buyers should ensure that suppliers have robust processes to mitigate these risks, such as maintaining control over the supply chain and ensuring proper storage conditions. -

Communication and Relationship Management

– Building strong relationships with suppliers can enhance transparency and foster collaboration on quality initiatives. Regular communication can also help address any concerns promptly.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing alternators, ensuring they receive reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘para q sirve el alternador’

Introdução

This guide serves as a practical checklist for B2B buyers aiming to procure alternators, essential components in automotive systems. Understanding the importance of alternators and the steps involved in sourcing them can enhance operational efficiency and ensure reliable vehicle performance.

Passo 1: Defina as suas especificações técnicas

Before initiating the procurement process, clearly outline the technical specifications required for the alternators. Consider factors such as voltage output, power rating, and compatibility with existing vehicle models. This clarity will help you communicate effectively with suppliers and ensure that you acquire the right components for your needs.

Illustrative image related to para q sirve el alternador

Passo 2: Pesquisa e identificação de fornecedores fiáveis

Conduct thorough research to identify potential suppliers of alternators. Look for suppliers with a proven track record in your target market, particularly those familiar with the specific automotive requirements in regions like Africa, South America, the Middle East, and Europe. Utilize platforms such as trade shows, industry directories, and referrals to compile a list of reputable manufacturers and distributors.

Passo 3: Avaliar certificações de fornecedores e normas de qualidade

It’s essential to verify that potential suppliers meet relevant industry certifications and quality standards. Look for certifications such as ISO 9001 or specific automotive quality certifications that ensure adherence to international standards. This step is crucial for ensuring that the alternators you source are reliable and meet safety regulations.

Passo 4: Request Product Samples and Technical Documentation

Before making a bulk purchase, request samples and comprehensive technical documentation from your shortlisted suppliers. Analyzing product samples allows you to assess the quality and performance of the alternators firsthand. Additionally, technical documentation provides insights into specifications, installation guidelines, and maintenance requirements, which are vital for informed decision-making.

Passo 5: Avalie os preços e as condições de pagamento

Evaluate the pricing structures and payment terms offered by each supplier. Request detailed quotes that outline costs for different models, shipping, and any additional fees. Understanding the financial aspects will help you compare suppliers effectively and negotiate better terms, ensuring you stay within budget while securing quality products.

Passo 6: Inquire About Warranty and After-Sales Support

Ensure that suppliers offer robust warranty policies and after-sales support for the alternators. A solid warranty indicates the manufacturer’s confidence in their product, while effective after-sales support can assist you in resolving any issues that may arise post-purchase. Clarify the terms of support, including the duration of the warranty and the process for claims.

Passo 7: Finalize Contracts and Delivery Timelines

Once you’ve selected a supplier, finalize the contracts, ensuring all terms are clearly outlined, including delivery timelines, payment schedules, and return policies. This step is vital to mitigate risks and establish a clear understanding between both parties regarding expectations and responsibilities. Confirm that the delivery timelines align with your operational needs to prevent disruptions in your supply chain.

By following this checklist, B2B buyers can effectively navigate the procurement process for alternators, ensuring that they source high-quality components that meet their specific needs and enhance their operational capabilities.

Comprehensive Cost and Pricing Analysis for para q sirve el alternador Sourcing

Quais são os principais componentes de custo para o fornecimento de alternadores?

When analyzing the cost structure for sourcing alternators, several critical components come into play. The main cost components include:

-

Materiais: The primary materials for alternators include copper wire for windings, aluminum or steel for casings, and various electronic components such as diodes and rectifiers. Fluctuations in global commodity prices can significantly impact costs, especially for copper and aluminum.

-

Trabalho: Labor costs vary widely by region. In countries with lower labor costs, such as those in parts of Africa and South America, manufacturers might achieve lower overall production costs. However, in Europe and the Middle East, labor costs can be higher, impacting the final pricing.

-

Custos indiretos de produção: This encompasses costs related to factory operations, including utilities, maintenance, and administrative expenses. Efficient production processes can help minimize these costs, which is crucial for competitive pricing.

-

Ferramentas: Initial setup and tooling costs can be substantial, particularly for customized alternators. These costs are amortized over the production volume, meaning higher initial investments can lead to lower unit costs at scale.

-

Controlo de Qualidade (QC): Implementing robust QC processes ensures the reliability and performance of alternators. However, this adds to the overall cost structure. Buyers should consider suppliers that balance quality with cost-effectiveness.

-

Logística: Transportation and handling costs are significant, especially for international shipments. Factors such as shipping methods, distances, and customs duties can affect the total cost of ownership.

-

Margem: Suppliers typically add a margin to cover their costs and profit. Understanding the market dynamics can help buyers negotiate better pricing.

What Influences the Pricing of Alternators?

Pricing for alternators is influenced by multiple factors that international B2B buyers must consider:

-

Volume/MOQ: Bulk purchases often lead to significant discounts. Establishing a minimum order quantity (MOQ) can facilitate better pricing, making it essential for buyers to assess their needs accurately.

-

Especificações e personalização: Custom alternators with specific features or higher performance standards generally incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materiais e certificações de qualidade: High-quality materials and certifications (e.g., ISO, CE) can increase costs. However, investing in certified products often results in lower failure rates and better long-term performance.

-

Fatores relacionados ao fornecedor: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects the distribution of costs and risks between buyers and suppliers. Understanding these terms can help buyers manage logistics costs effectively.

What Are Essential Buyer Tips for Cost-Efficiency in Alternator Sourcing?

To ensure cost-efficient sourcing of alternators, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negociar termos: Always negotiate prices, payment terms, and delivery schedules. Suppliers may be willing to offer discounts or flexible payment plans to secure large orders.

-

Avalie o custo total de propriedade (TCO): Look beyond the initial purchase price. Consider the long-term implications of maintenance, durability, and performance to determine the true cost of the alternators.

-

Stay Informed on Pricing Trends: Monitor global material prices and market conditions to make informed purchasing decisions. Understanding market trends can help in timing purchases to secure better pricing.

-

Considere fornecedores locais: Sourcing from local suppliers can reduce logistics costs and lead times, enhancing overall supply chain efficiency.

-

Investigate Alternative Products: Explore different brands and product lines to find cost-effective solutions without compromising quality.

Conclusão

Understanding the cost components and pricing influencers for alternators is crucial for international B2B buyers. By focusing on negotiation strategies, evaluating total cost of ownership, and staying informed about market trends, buyers can make strategic decisions that enhance their procurement process. It is essential to approach sourcing with a comprehensive strategy that balances cost, quality, and reliability.

Disclaimer: Prices and availability are subject to change based on market conditions and supplier negotiations. Always verify current pricing and terms with suppliers.

Alternatives Analysis: Comparing para q sirve el alternador With Other Solutions

Exploring Alternative Solutions to the Alternator

In the automotive sector, the alternator plays a pivotal role in generating electricity and recharging the battery during vehicle operation. However, as technology evolves, alternative solutions emerge that can serve similar purposes. This analysis aims to compare the traditional alternator with alternative power generation technologies, highlighting their unique attributes and suitability for various applications.

| Aspecto comparativo | Para Q Sirve El Alternador | Alternative 1 Name (Generator) | Alternative 2 Name (Solar Power System) |

|---|---|---|---|

| Desempenho | High efficiency in converting mechanical energy to electrical energy while the engine runs. | Reliable power generation but dependent on fuel type and engine size. | Limited by sunlight availability; efficiency varies by location and weather. |

| Custo | Moderate initial cost; long-term savings due to durability. | Initial investment can be high; ongoing fuel costs. | Higher upfront cost for installation; potential savings on energy bills over time. |

| Facilidade de implementação | Generally easy to install and integrate into existing systems. | May require specialized installation, depending on the size and type. | Complex installation; requires space for panels and battery systems. |

| Manutenção | Requires periodic checks; relatively low maintenance. | Regular maintenance needed for fuel systems and engine. | Minimal maintenance after installation; battery replacement may be required. |

| Melhor caso de uso | Ideal for conventional vehicles and hybrid models. | Best suited for remote areas lacking electrical infrastructure. | Excellent for eco-conscious users and locations with abundant sunlight. |

Generator: An Alternative to the Alternator

Generators serve as a traditional alternative to alternators, converting fuel into electrical energy. They are particularly useful in situations where continuous power is required, such as in remote construction sites or during power outages. The main advantage of generators is their ability to provide a reliable power source independent of the vehicle’s engine. However, they come with ongoing fuel costs and require regular maintenance to ensure optimal performance. Additionally, their portability can be limited, making them less suitable for everyday vehicle use.

Illustrative image related to para q sirve el alternador

Solar Power System: A Sustainable Choice

Solar power systems represent a modern alternative to traditional power generation methods, utilizing solar panels to convert sunlight into electricity. This technology is particularly appealing to eco-conscious consumers and businesses looking to reduce their carbon footprint. While solar systems can provide significant savings on energy costs over time, their effectiveness is heavily reliant on geographic and climatic conditions. The initial investment can be substantial, and the installation process is often more complex compared to traditional alternators. However, once set up, solar systems require minimal maintenance and can offer a sustainable energy solution.

Fazer a escolha certa para as suas necessidades

When considering the right power generation solution for your vehicle or operation, it is essential to evaluate your specific requirements, including performance needs, budget constraints, and maintenance capabilities. The traditional alternator remains a robust choice for most vehicles, especially for those that require consistent electrical output while the engine is running. However, alternatives like generators and solar power systems offer unique benefits that may align better with specific use cases, such as off-grid applications or sustainable energy initiatives. By carefully weighing these factors, B2B buyers can make informed decisions that best suit their operational needs and long-term objectives.

Essential Technical Properties and Trade Terminology for para q sirve el alternador

What Are the Critical Technical Properties of an Alternator?

When evaluating an alternator for your business needs, understanding its technical specifications is crucial. Here are some essential properties to consider:

1. Tensão de saída e classificação de corrente

The output voltage of an alternator typically ranges from 12V to 24V, with current ratings that can vary from 30A to over 200A. This specification is critical because it determines the alternator’s ability to power various electrical components in vehicles. For B2B buyers, knowing the correct voltage and current ratings ensures compatibility with the vehicle’s electrical system and prevents potential damage to sensitive electronics.

Illustrative image related to para q sirve el alternador

2. Classificação de eficiência

Efficiency ratings indicate how effectively an alternator converts mechanical energy into electrical energy. Higher efficiency (often above 70%) means less energy is wasted as heat, which is particularly important for electric vehicle applications. For businesses focusing on sustainability and reducing operating costs, selecting a high-efficiency alternator can lead to significant long-term savings.

3. Mecanismo de arrefecimento

Alternators can be air-cooled or liquid-cooled. Air-cooled systems are simpler and more common, while liquid-cooled designs can handle higher loads without overheating. Understanding the cooling mechanism is essential for businesses operating in extreme environments or requiring high-performance vehicles, as it impacts reliability and maintenance needs.

4. Grau do material

The materials used in the construction of an alternator, such as copper for wiring and aluminum for the housing, influence its durability and performance. Copper is preferred for its conductivity, while aluminum is valued for its lightweight properties. For B2B buyers, selecting alternators with high-quality materials ensures longevity and reduces the frequency of replacements, ultimately lowering operational costs.

5. Tipo e dimensões de montagem

Alternators come in various mounting styles, including side-mounted and front-mounted, with specific dimensions that must fit the vehicle’s engine bay. Accurate measurements are vital to avoid installation issues. Buyers should consider the mounting type when sourcing alternators to ensure a seamless fit and functionality.

Illustrative image related to para q sirve el alternador

Quais são os termos comerciais comuns relacionados com alternadores?

Understanding industry terminology is essential for effective communication and negotiation in the B2B sector. Here are some common terms related to alternators:

1. OEM (Fabricante de Equipamento Original)

OEM refers to products made by the original manufacturer of a vehicle. In the context of alternators, sourcing OEM parts ensures compatibility and quality. Businesses often prefer OEM alternators for their reliability and adherence to manufacturer specifications.

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is critical for businesses to manage inventory costs and ensure sufficient supply without overstocking. Negotiating lower MOQs can enhance cash flow and flexibility for smaller businesses.

3. RFQ (Pedido de Orçamento)

An RFQ is a document sent to suppliers to obtain pricing and terms for specific products. For B2B buyers, sending an RFQ for alternators allows for comparison of prices, delivery times, and terms, helping make informed purchasing decisions.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms are a set of international rules defining the responsibilities of buyers and sellers in shipping goods. Understanding these terms helps businesses clarify shipping costs, risks, and responsibilities when procuring alternators from international suppliers.

Illustrative image related to para q sirve el alternador

5. Peças de reposição

Aftermarket parts are components made by manufacturers other than the original vehicle manufacturer. While often less expensive, they may vary in quality and compatibility. Businesses should weigh the cost savings against potential risks when considering aftermarket alternators.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing alternators, ultimately enhancing their operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the para q sirve el alternador Sector

What Are the Key Market Dynamics and Trends in the Alternator Sector?

The alternator market is shaped by several global drivers that influence B2B sourcing strategies. The increasing demand for energy-efficient vehicles, coupled with advancements in automotive technology, has led to a surge in the production and innovation of alternators. B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing components that not only meet quality standards but also enhance vehicle performance and efficiency.

Emerging trends include the integration of smart technologies in alternators, enabling features such as real-time monitoring and predictive maintenance. These innovations can significantly reduce operational costs and enhance the lifespan of the vehicle’s electrical system. Additionally, the rise of electric vehicles (EVs) is reshaping the alternator market, as manufacturers pivot towards hybrid and fully electric models. As a result, B2B buyers must stay informed about the latest technological advancements and evaluate suppliers based on their ability to deliver innovative solutions.

Supply chain dynamics are also evolving, with an increased focus on localized sourcing. Buyers are now seeking suppliers who can provide rapid delivery and flexibility in production, particularly in response to fluctuating market demands. This trend is particularly relevant in regions like Nigeria and Saudi Arabia, where infrastructure development and automotive growth are accelerating.

Como é que a sustentabilidade e o fornecimento ético podem afetar a cadeia de fornecimento de alternadores?

Sustainability is becoming a critical consideration in the alternator sector, with B2B buyers increasingly prioritizing environmentally friendly practices. The production of alternators can have significant environmental impacts, including carbon emissions and resource depletion. Therefore, sourcing alternators from manufacturers that adhere to sustainable practices is essential for reducing a company’s carbon footprint.

Ethical sourcing is also gaining traction, as businesses recognize the importance of transparent supply chains. Buyers are looking for suppliers who can demonstrate responsible labor practices and compliance with international standards. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming prerequisites for suppliers in the alternator market.

Moreover, the use of ‘green’ materials, such as recyclable metals and eco-friendly packaging, is increasingly important. B2B buyers should engage with suppliers who prioritize sustainable materials in their production processes, as this not only supports environmental goals but can also enhance the brand reputation of the buying company.

Como é que o mercado dos alternadores evoluiu ao longo do tempo?

The evolution of the alternator market reflects broader changes in automotive technology and consumer preferences. Initially, alternators were primarily mechanical devices designed to convert engine motion into electrical energy. Over the decades, advancements in materials and electronic systems have transformed alternators into sophisticated components capable of enhancing vehicle efficiency and performance.

The shift from traditional combustion engines to hybrid and electric vehicles has prompted manufacturers to innovate further, leading to the development of compact and lightweight alternators that meet the demands of modern vehicles. This evolution is significant for B2B buyers, as it underscores the need to source from suppliers who are not only aware of these trends but are also capable of delivering cutting-edge products that align with future automotive technologies.

In summary, understanding market dynamics, prioritizing sustainability, and recognizing the historical context of alternators are essential for B2B buyers looking to make informed sourcing decisions in this evolving sector.

Frequently Asked Questions (FAQs) for B2B Buyers of para q sirve el alternador

-

How does an alternator work in a vehicle?

The alternator operates by converting mechanical energy from the engine into electrical energy. When the engine runs, it drives a belt connected to the alternator, causing its rotor to spin within a magnetic field. This action generates alternating current (AC), which is then converted into direct current (DC) by a rectifier. This DC power is essential for charging the battery and powering the vehicle’s electrical systems, including lights, audio systems, and climate control. -

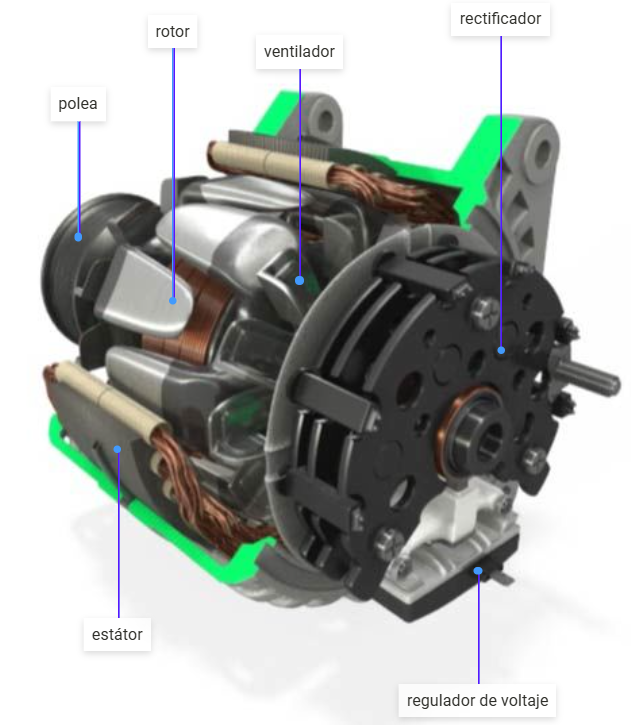

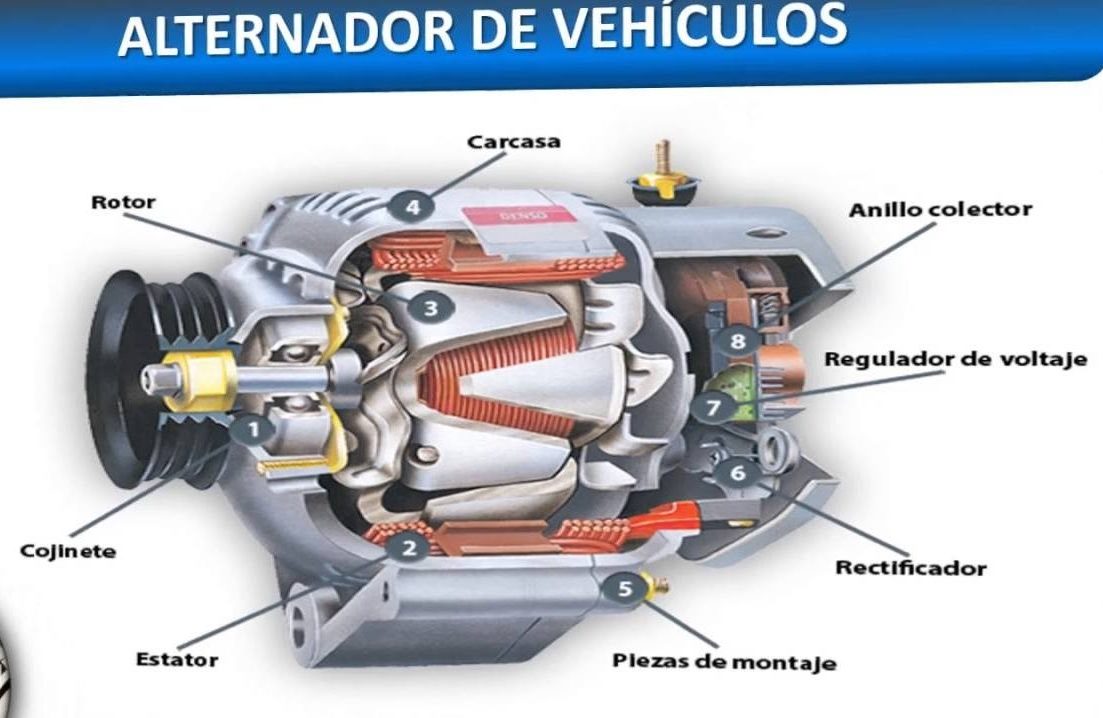

What are the key components of an alternator?

An alternator comprises several critical components: the rotor, stator, rectifier, voltage regulator, and cooling fan. The rotor generates a magnetic field, while the stator contains wire coils that capture the induced current. The rectifier converts AC to DC, and the voltage regulator ensures a stable output voltage to prevent overcharging the battery. Understanding these components helps in selecting the right alternator for your needs. -

What are the signs of a failing alternator?

Indicators of a failing alternator include dimming or flickering headlights, difficulty starting the vehicle, warning lights on the dashboard, unusual noises such as grinding or whining, and a dead battery. If any of these symptoms occur, it’s crucial to have the alternator inspected and potentially replaced to avoid vehicle breakdowns and ensure reliable operation. -

What should I consider when sourcing alternators for my business?

When sourcing alternators, consider factors such as the supplier’s reputation, product quality, and compliance with international standards. It’s also essential to evaluate the supplier’s ability to provide customization options, warranty terms, and after-sales support. Additionally, assess their logistics capabilities to ensure timely delivery, especially if you’re operating in regions with specific import regulations. -

What are common payment terms in B2B alternator transactions?

Payment terms can vary widely among suppliers. Common arrangements include advance payment, net 30 or 60 days, and payment upon delivery. It’s advisable to negotiate terms that align with your cash flow needs while considering the supplier’s policies. Always clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms, to avoid any transaction issues. -

Como é que posso garantir a qualidade dos alternadores que compro?

To ensure quality, request certifications that verify compliance with industry standards, such as ISO or CE. Consider conducting quality assurance checks, including product samples before bulk ordering. Engaging in supplier audits and visiting manufacturing facilities can also provide insight into production processes and quality control measures. Establishing a clear return policy can further protect your investment. -

Qual é a quantidade mínima de encomenda (MOQ) para alternadores?

Minimum order quantities can vary significantly based on the supplier and the specific alternator model. Typically, MOQs can range from a few units to several hundred. When negotiating, clarify if the MOQ affects pricing and shipping costs. Some suppliers may offer flexibility for first-time buyers or smaller businesses, so it’s beneficial to communicate your needs upfront. -

How can I streamline logistics for importing alternators?

To streamline logistics, work with suppliers who have experience in international shipping and can provide comprehensive shipping solutions. Establish clear communication regarding shipping schedules, customs documentation, and delivery timelines. Using freight forwarders can also help navigate complex logistics. Ensure that your supplier understands the import regulations for your region to avoid delays at customs.

Top 2 Para Q Sirve El Alternador Manufacturers & Suppliers List

1. Kia – Alternador

Domínio: kia.com

Registado: 1996 (29 anos)

Introdução: Un alternador es un componente esencial en vehículos con motor de combustión, encargado de convertir energía química en energía eléctrica para cargar la batería y alimentar otros componentes eléctricos. Funciona en conjunto con la batería y el regulador de voltaje, generando corriente alterna que se transforma en corriente continua para cargar la batería. Los alternadores suelen durar entre 7 y 10…

2. Race – Alternador de Coche

Domínio: race.es

Introdução: El alternador es un componente del coche que produce electricidad y la acumula en la batería. Funciona mediante el giro rotativo del motor, generando electricidad alterna que se convierte en continua de 12 voltios a través de una placa de diodos. El voltaje generado debe mantenerse entre 13,5 V y 14,5 V. En coches antiguos, el alternador era una pieza independiente, mientras que en coches modernos…

Strategic Sourcing Conclusion and Outlook for para q sirve el alternador

What Are the Key Takeaways for B2B Buyers Regarding Alternators?

In summary, understanding the vital role of alternators in vehicle operations is crucial for B2B buyers across various industries. Alternators are essential components that convert mechanical energy into electrical energy, ensuring that all electrical systems in a vehicle function efficiently. This knowledge can guide procurement strategies, enabling businesses to source high-quality, reliable alternators that meet their operational needs.

How Can Strategic Sourcing Enhance Your Supply Chain?

Strategic sourcing of alternators not only ensures operational reliability but also fosters cost-effectiveness and sustainability. By partnering with reputable manufacturers and suppliers, businesses can secure products that comply with international quality standards, ultimately enhancing vehicle performance and reducing maintenance costs.

O que se segue para os compradores B2B internacionais?

As markets evolve, the demand for efficient automotive components continues to grow. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should leverage this opportunity to strengthen their supply chains. Engage with trusted suppliers, explore innovative technologies, and prioritize sustainable practices. By doing so, you can position your business for success in a competitive landscape.

Illustrative image related to para q sirve el alternador

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.