Introduction: Navigating the Global Market for how much is an alternator

Navigating the global market for understanding how much an alternator costs can be a complex endeavor for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With the alternator being a critical component in vehicle electrical systems, sourcing reliable and cost-effective options is essential for maintaining fleet operations and ensuring customer satisfaction. This guide offers a comprehensive overview of the various types of alternators available, their applications across different vehicle models, and the factors influencing their prices.

Buyers will gain insights into the intricacies of supplier vetting, including how to assess quality and warranty offerings, which can significantly impact long-term operational costs. Additionally, we will delve into the average replacement costs, highlighting potential discrepancies between OEM and aftermarket parts. By equipping international B2B buyers with actionable knowledge, this guide empowers them to make informed purchasing decisions that align with their specific operational needs and budget constraints.

Understanding the nuances of alternator pricing not only aids in cost management but also enhances the overall efficiency of automotive operations. This guide serves as an essential resource for businesses looking to navigate the complexities of the alternator market effectively, ensuring that they can source quality components that meet their performance requirements without exceeding their financial limits.

Índice

- A Look at How Much Is An Alternator Manufacturers & Suppliers

- Introduction: Navigating the Global Market for how much is an alternator

- Understanding how much is an alternator Types and Variations

- Key Industrial Applications of how much is an alternator

- 3 Common User Pain Points for ‘how much is an alternator’ & Their Solutions

- Strategic Material Selection Guide for how much is an alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for how much is an alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much is an alternator’

- Comprehensive Cost and Pricing Analysis for how much is an alternator Sourcing

- Alternatives Analysis: Comparing how much is an alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for how much is an alternator

- Navigating Market Dynamics and Sourcing Trends in the how much is an alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much is an alternator

- Strategic Sourcing Conclusion and Outlook for how much is an alternator

- Aviso legal importante e termos de utilização

Understanding how much is an alternator Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Novos alternadores | Brand new, OEM quality, often comes with a warranty | Gestão de frotas, oficinas de reparação automóvel | Prós: Reliable performance, warranty included. Contras: Custo inicial mais elevado. |

| Alternadores remanufaturados | Rebuilt from used units, tested for quality | Cost-sensitive repairs, automotive shops | Prós: Cost-effective, environmentally friendly. Contras: Potencial variabilidade na qualidade. |

| Alternadores de alta potência | Higher amperage output for vehicles with extensive electrical needs | Veículos de alto desempenho, construções personalizadas | Prós: Suporta acessórios eléctricos adicionais. Contras: May require additional modifications. |

| Alternadores de um fio | Simplified wiring design, often used in older models | Classic car restorations, vintage vehicles | Prós: Easy installation, lower cost. Contras: Compatibilidade limitada com veículos modernos. |

| Alternadores de dupla voltagem | Capable of operating at both 12V and 24V | Veículos comerciais, máquinas pesadas | Prós: Versatile application, suitable for various vehicle types. Contras: More complex and potentially higher cost. |

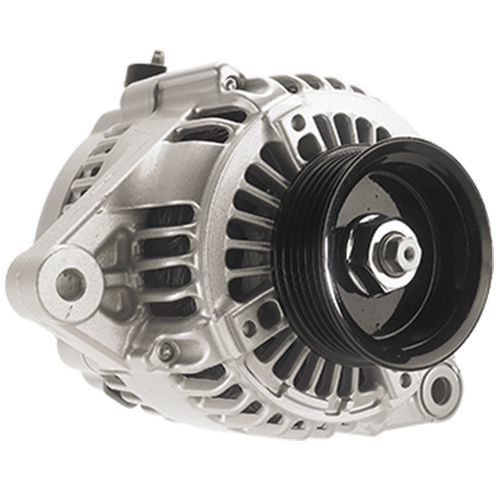

Quais são as principais caraterísticas dos novos alternadores?

New alternators are manufactured to meet original equipment specifications and typically come with a warranty. They are ideal for businesses that prioritize reliability and performance, such as fleet management companies and automotive repair shops. When purchasing, consider the specific vehicle make and model to ensure compatibility. Although they come at a higher initial cost, the assurance of quality and longevity can justify the investment for many B2B buyers.

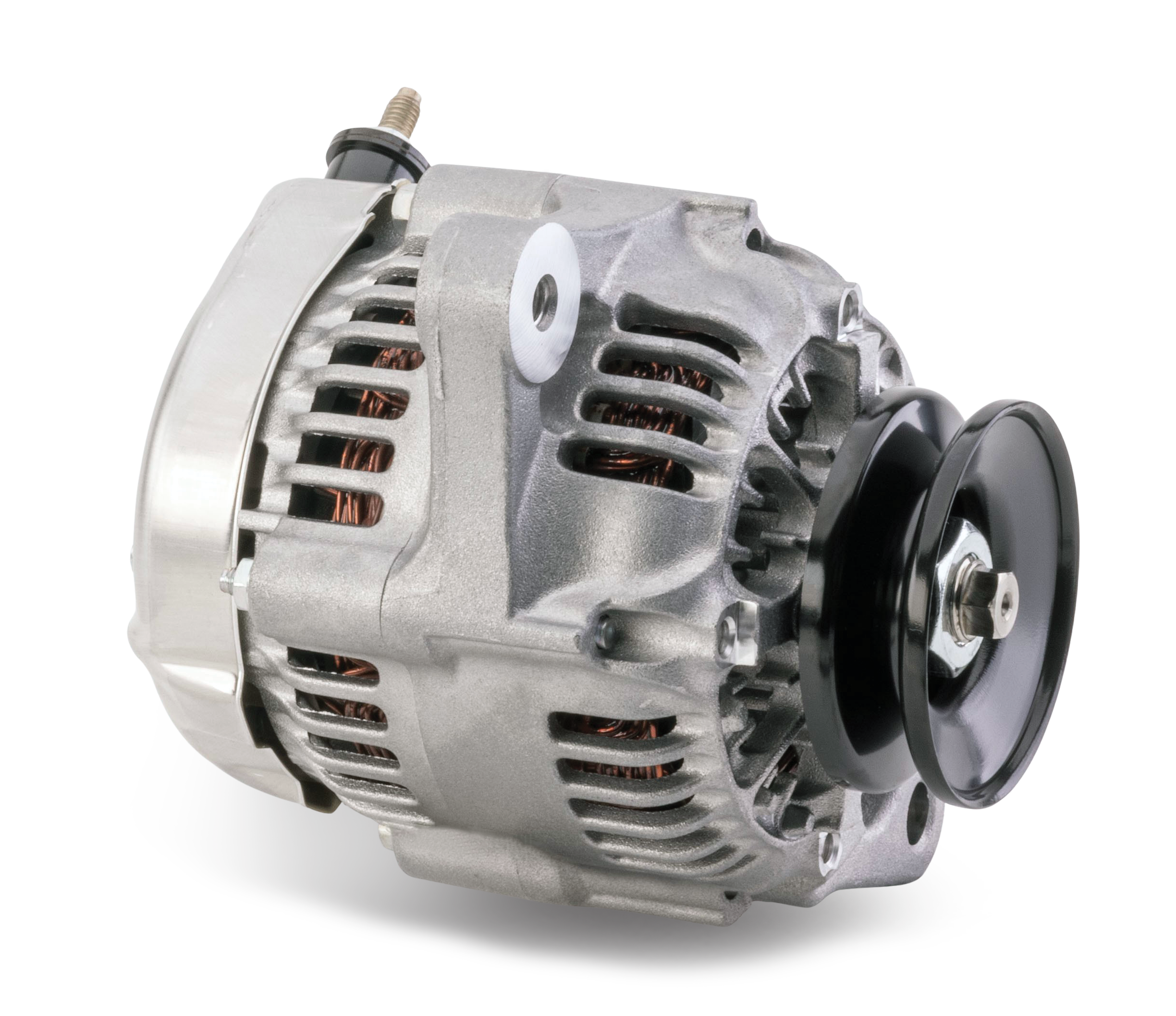

How Do Remanufactured Alternators Serve B2B Needs?

Remanufactured alternators are rebuilt from used units, tested to meet quality standards before resale. They are a popular choice for cost-sensitive repairs in automotive shops, providing a balance between price and performance. Buyers should evaluate the reputation of the remanufacturer and warranty offered, as quality can vary. This option is not only budget-friendly but also environmentally sustainable, appealing to businesses focused on reducing waste.

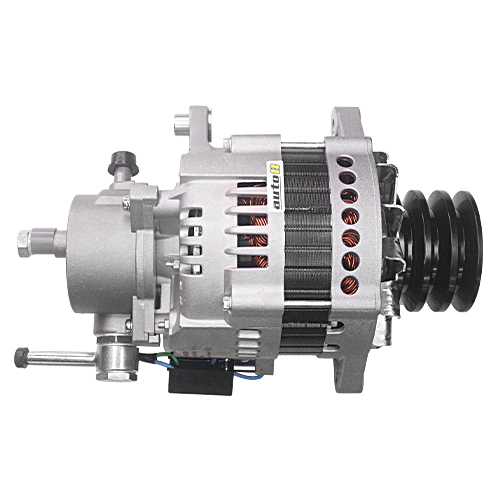

Why Choose High-Output Alternators for Performance Applications?

High-output alternators are designed to provide greater amperage, catering to vehicles with extensive electrical needs, such as performance cars and custom builds. They are ideal for businesses involved in aftermarket modifications or racing. When purchasing, consider the specific electrical demands of the vehicle to avoid overloading. While they offer enhanced performance, buyers should also be aware of potential installation complexities and higher costs.

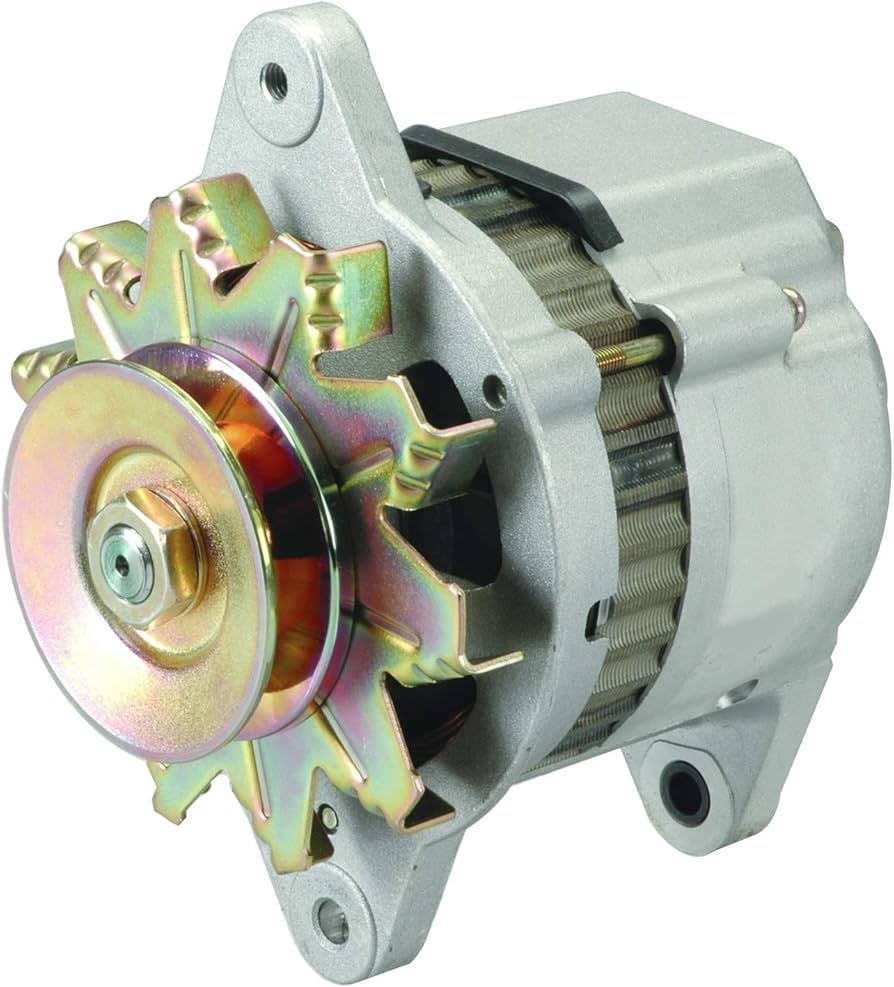

Quais são as vantagens dos alternadores de um só fio?

One-wire alternators are characterized by their simplified wiring system, making them an excellent choice for older vehicles or classic car restorations. They are easy to install and generally more affordable, appealing to businesses focused on vintage car maintenance. However, compatibility with modern vehicles is limited, so buyers should ensure they are suited to their specific applications. This type is particularly advantageous for small repair shops specializing in classic vehicles.

How Do Dual-Voltage Alternators Fit into Commercial Applications?

Dual-voltage alternators can operate at both 12V and 24V, making them versatile for various commercial applications, including heavy machinery and commercial vehicles. Businesses in the construction and transportation sectors can benefit from their adaptability. When considering a dual-voltage alternator, buyers should evaluate the complexity of installation and potential costs, as they may be higher than standard options. Their versatility, however, can make them a worthwhile investment for companies managing diverse fleets.

Key Industrial Applications of how much is an alternator

| Indústria/Setor | Specific Application of how much is an alternator | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Fabricação Automotiva | Production of vehicles requiring reliable alternators | Ensures optimal electrical performance and vehicle longevity | Compatibility with vehicle specifications; OEM vs aftermarket options |

| Energia renovável | Wind turbine generators for power conversion | Converts mechanical energy to electrical energy, improving efficiency | Quality of components; local sourcing for reduced shipping costs |

| Mineração | Heavy machinery and vehicles in harsh conditions | Maintains operational efficiency, reducing downtime | Durability under extreme conditions; availability of parts for maintenance |

| Transporte e Logística | Fleet vehicles for reliable power supply | Enhances fleet reliability, reducing operational costs | Bulk purchasing agreements; warranty and service options |

| Agricultura | Tractors and farming equipment for energy supply | Aumenta a produtividade, garantindo a fiabilidade do equipamento | Sourcing from reputable suppliers; understanding regional electrical standards |

How is an Alternator Critical in the Automotive Manufacturing Sector?

In automotive manufacturing, alternators are essential components that ensure vehicles operate efficiently. They convert mechanical energy from the engine into electrical energy, powering various electrical systems and recharging the battery. For international B2B buyers, particularly those in regions like Africa and South America, sourcing alternators that meet specific vehicle requirements is crucial. Factors such as compatibility with the vehicle’s make, model, and electrical demands must be considered to prevent operational issues and enhance vehicle longevity.

What Role Does an Alternator Play in Renewable Energy Applications?

In the renewable energy sector, particularly in wind turbine generators, alternators are vital for converting mechanical energy into electrical energy. This conversion is crucial for energy efficiency and sustainability. Buyers in this sector must focus on sourcing high-quality alternators that can withstand varying environmental conditions. Local sourcing can also minimize shipping costs and enhance supply chain efficiency, which is particularly important in regions like the Middle East and Europe where renewable energy initiatives are expanding.

How Do Alternators Support the Mining Industry?

The mining industry relies heavily on robust machinery and vehicles that can operate under extreme conditions. Alternators in these vehicles ensure that electrical systems function reliably, minimizing downtime and enhancing productivity. For B2B buyers, it is essential to consider the durability and performance of alternators in harsh environments. Sourcing alternators that can withstand dust, moisture, and vibration will directly impact operational efficiency and maintenance costs.

In What Ways are Alternators Essential for Transportation and Logistics?

In the transportation and logistics sector, fleet vehicles depend on reliable alternators to maintain electrical systems, which is critical for overall fleet performance. A well-functioning alternator reduces the risk of breakdowns and operational disruptions, ultimately saving costs. B2B buyers should explore bulk purchasing agreements to secure favorable pricing and ensure consistent supply. Additionally, understanding warranty and service options can provide peace of mind regarding long-term maintenance.

Why are Alternators Important in Agriculture?

Agricultural machinery, such as tractors, heavily relies on alternators for efficient energy supply. These components ensure that equipment operates smoothly, which is essential for maximizing productivity in farming operations. Buyers in the agricultural sector should prioritize sourcing from reputable suppliers to ensure quality and compatibility with regional electrical standards. This approach not only enhances equipment reliability but also supports sustainable agricultural practices in regions like Africa and South America.

3 Common User Pain Points for ‘how much is an alternator’ & Their Solutions

Scenario 1: Navigating Price Variability in Alternator Sourcing

O problema: B2B buyers often face significant variability in the cost of alternators, which can lead to confusion and budgeting challenges. For instance, a fleet manager in a logistics company may receive quotes ranging from $100 to $1,000 for what appears to be the same part. This discrepancy can arise from various factors such as brand differences, quality of materials, and whether the alternator is new or remanufactured. Without a clear understanding of these variables, buyers might either overpay for a subpar product or risk purchasing a low-quality part that could lead to further operational issues.

A solução: To effectively navigate the price variability of alternators, B2B buyers should establish a standardized criteria checklist that includes specifications such as the vehicle’s make, model, and year, as well as the required amperage and warranty options. Collaborating with trusted suppliers who can provide detailed product comparisons can also prove beneficial. Additionally, buyers should consider investing in a high-quality aftermarket or OEM alternator that aligns with their operational needs and budget. By negotiating bulk purchase agreements, buyers can secure better pricing and ensure that they are getting the right part at a competitive rate.

Scenario 2: Understanding the Long-Term Costs Associated with Alternator Failure

O problema: A common oversight among B2B buyers is focusing solely on the upfront cost of an alternator without considering the long-term implications of a poor-quality purchase. For instance, an automotive service center may opt for the cheapest alternator available, only to find that it fails within a year, leading to additional labor costs and lost business due to vehicle downtime. This short-sighted approach can dramatically affect operational efficiency and profitability.

A solução: To mitigate the risk of purchasing low-quality alternators, buyers should conduct a thorough analysis of the total cost of ownership (TCO). This analysis should encompass not only the initial purchase price but also potential future costs associated with repairs, labor, and lost revenue from downtime. Investing in a high-quality alternator with a robust warranty can ultimately save money in the long run. Additionally, establishing relationships with reputable suppliers who provide comprehensive product support and warranties can enhance the reliability of the purchase, ensuring fewer interruptions in service.

Scenario 3: Difficulty in Identifying Signs of Alternator Malfunction

O problema: B2B buyers in the automotive sector often struggle to identify early warning signs of alternator failure, which can lead to unexpected breakdowns and costly repairs. For example, a fleet operator may overlook subtle symptoms like dimming headlights or unusual noises, resulting in a complete alternator failure and significant downtime for their vehicles. This not only impacts productivity but also strains client relationships due to delays.

A solução: To address this challenge, B2B buyers should implement a proactive maintenance program that includes regular inspections of the electrical systems in their vehicles. Providing training for technicians on the common signs of alternator issues—such as fluctuating dashboard lights, burning smells, and erratic electrical performance—can empower teams to act before problems escalate. Additionally, utilizing diagnostic tools to routinely check alternator performance can help detect potential issues early. Establishing a relationship with a reliable parts supplier for quick replacements can further reduce downtime and ensure that operations run smoothly.

Strategic Material Selection Guide for how much is an alternator

Quais são os materiais mais comuns utilizados nos alternadores?

When considering the manufacturing and replacement of alternators, several materials play crucial roles in determining performance, durability, and cost. Understanding the properties and applications of these materials is essential for B2B buyers, particularly in international markets.

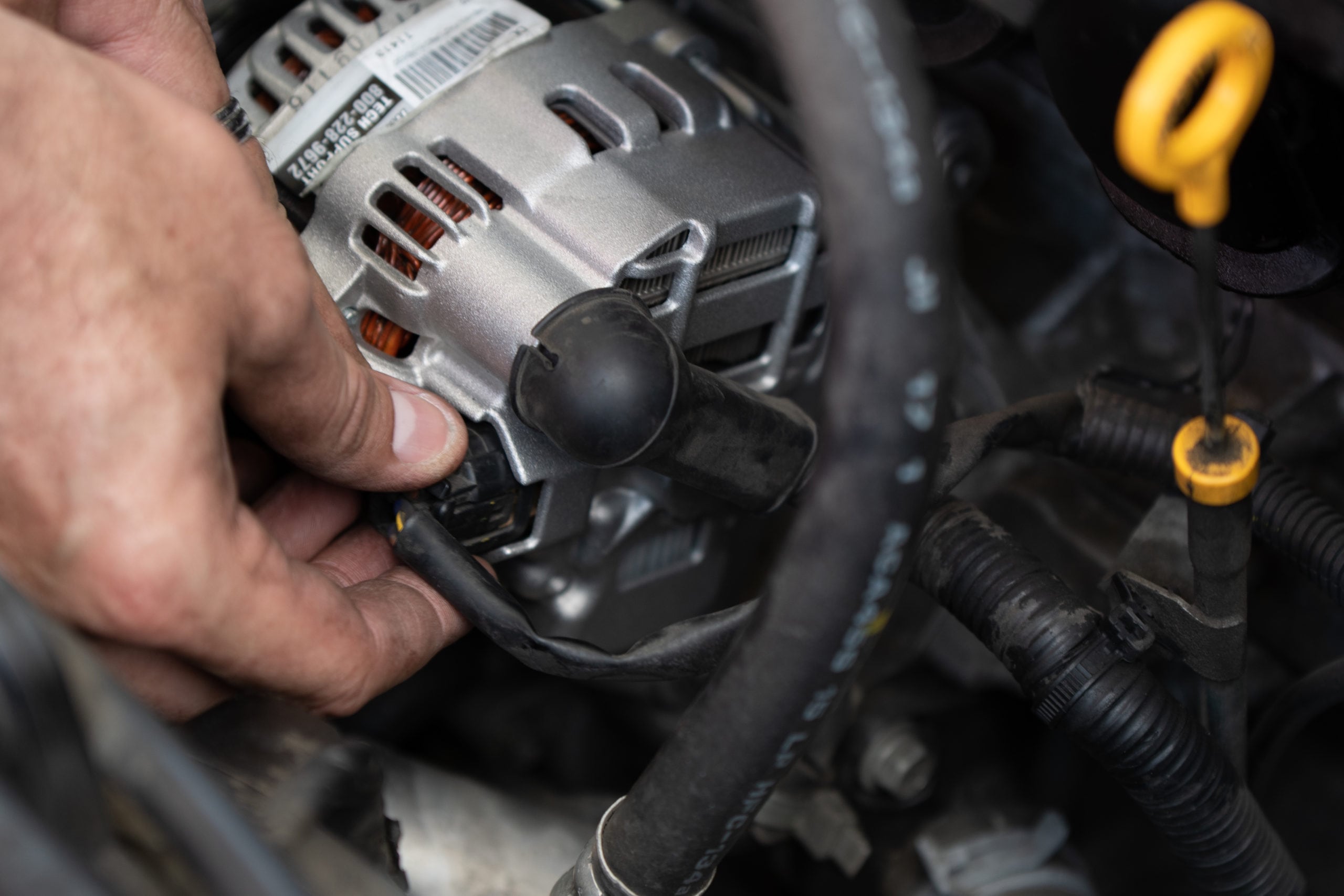

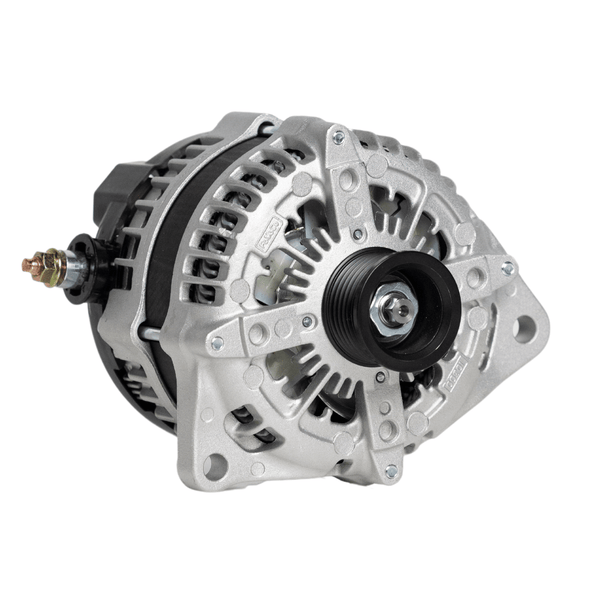

Illustrative image related to how much is an alternator

Quais são as principais propriedades do cobre nos alternadores?

Copper is a primary material in alternators, particularly in the windings. It boasts excellent electrical conductivity, which is vital for efficient energy transfer. Copper also has a high melting point, making it suitable for high-temperature environments. Its corrosion resistance is moderate; while it can oxidize over time, protective coatings can mitigate this.

Prós e contras: The main advantage of copper is its superior conductivity, which enhances the alternator’s efficiency. However, it is relatively expensive compared to alternatives like aluminum, which can increase overall production costs. Additionally, the manufacturing process can be complex due to the need for precise winding techniques.

Impacto na aplicação: Copper’s compatibility with high electrical loads makes it ideal for modern vehicles that require significant power for various electronics. However, the presence of copper can raise concerns about theft in some regions, necessitating enhanced security measures.

Como é que o alumínio se compara aos componentes do alternador?

Aluminum is increasingly used in alternator housings and some winding applications due to its lightweight nature and good conductivity, albeit lower than copper. It has a lower melting point than copper but offers excellent corrosion resistance, especially when anodized.

Illustrative image related to how much is an alternator

Prós e contras: The lightweight nature of aluminum reduces the overall weight of the alternator, which can improve fuel efficiency in vehicles. However, its lower conductivity means that larger cross-sectional areas are required to achieve the same performance as copper, potentially complicating design and manufacturing.

Impacto na aplicação: Aluminum is particularly advantageous in regions with high humidity or corrosive environments, as its resistance to corrosion prolongs the lifespan of the alternator. International buyers should consider local climate conditions when selecting materials.

Qual é o papel do aço na fabricação de alternadores?

Steel is primarily used in the structural components of alternators, such as the frame and mounting brackets. It provides strength and durability, with a high tensile strength rating, making it suitable for heavy-duty applications.

Illustrative image related to how much is an alternator

Prós e contras: The main advantage of steel is its strength and availability, making it a cost-effective choice for structural components. However, it is heavier than both copper and aluminum, which may negatively impact vehicle performance. Additionally, steel is susceptible to rust if not adequately treated.

Impacto na aplicação: Steel’s durability makes it suitable for rugged applications, particularly in commercial vehicles operating in demanding environments. Buyers should ensure that the steel used complies with international standards to guarantee quality and performance.

How Do Plastics and Composites Enhance Alternator Design?

Plastics and composites are often used for insulation and housing components in alternators. They offer excellent electrical insulation properties and can be engineered for specific temperature and chemical resistance.

Illustrative image related to how much is an alternator

Prós e contras: The lightweight nature of plastics and composites can significantly reduce the overall weight of the alternator. However, their mechanical strength is generally lower than metals, which can limit their use in structural applications. Additionally, the cost of high-performance composites can be significant.

Impacto na aplicação: In regions with high humidity or exposure to chemicals, using plastics can enhance the longevity of alternators. Buyers should look for materials that meet relevant international standards for insulation and thermal resistance.

Quadro resumo das considerações materiais

| Material | Typical Use Case for how much is an alternator | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Enrolamentos e ligações elétricas | Excelente condutividade elétrica | Custo mais elevado em comparação com as alternativas | Alto |

| Alumínio | Caixas e alguns enrolamentos | Leve e resistente à corrosão | Condutividade inferior à do cobre | Médio |

| Aço | Componentes estruturais | Alta resistência e durabilidade | Mais pesado e com tendência para a ferrugem | Baixo |

| Plastics/Composites | Componentes de isolamento e habitação | Leve e com bom isolamento | Menor resistência mecânica | Médio |

Understanding these materials and their implications can help B2B buyers make informed decisions when sourcing alternators, ensuring they select components that meet their performance needs while considering cost and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for how much is an alternator

Quais são as principais fases de fabrico de um alternador?

The manufacturing process of an alternator is intricate, involving several key stages that ensure the final product meets performance and reliability standards. These stages typically include material preparation, forming, assembly, and finishing.

Como é que o material é preparado para o fabrico de alternadores?

Material preparation is crucial for producing high-quality alternators. The primary materials used in alternators include copper for windings, steel for housings, and aluminum for the rotor. Manufacturers begin by sourcing raw materials that meet specific metallurgical standards. This may involve testing the material for conductivity, strength, and corrosion resistance.

Illustrative image related to how much is an alternator

Once sourced, the materials are cut into required shapes and sizes using precision machining techniques. This ensures that all components can fit together seamlessly during assembly, which is vital for maintaining the alternator’s efficiency and longevity.

Que técnicas de conformação são utilizadas na produção de alternadores?

The forming stage involves shaping the prepared materials into functional components. Common techniques include stamping, forging, and die-casting.

-

Estampagem: This method is often used for creating the alternator’s housing and other flat components. High-pressure stamping machines shape sheets of metal into the desired form, ensuring uniform thickness and strength.

-

Forjamento: For components requiring high durability, such as the rotor, forging processes are utilized. This involves shaping heated metal under pressure to enhance its structural integrity.

-

Fundição injectada: Aluminum components, including the rotor and housing, are often produced through die-casting. This technique allows for complex shapes to be manufactured with tight tolerances, improving the alternator’s overall performance.

Como é conduzido o processo de montagem dos alternadores?

The assembly process is where all individual components come together to form the complete alternator. This stage typically involves several sub-processes, including the installation of the rotor, stator, and rectifier.

-

Rotors and Stators: The rotor is placed inside the stator, and the necessary electrical connections are made. Precision is critical here, as any misalignment can lead to inefficiencies or failures.

-

Rectifier Assembly: The rectifier converts alternating current (AC) generated by the rotor into direct current (DC) needed for vehicle operation. This component must be assembled with strict adherence to electrical standards to ensure reliable performance.

-

Montagem final: After the electrical components are installed, the alternator is fully assembled, including the installation of bearings and other moving parts. Quality checks are conducted throughout to ensure that each assembly meets specifications.

Que processos de acabamento são aplicados aos alternadores?

Finishing processes enhance the durability and aesthetics of alternators. These typically include surface treatments, coating, and final inspections.

-

Tratamentos de superfície: Components may undergo processes such as anodizing or powder coating to improve corrosion resistance and enhance appearance.

-

Inspecções de qualidade: Each finished alternator undergoes rigorous testing to confirm it meets operational standards. This includes checking for electrical output, noise levels, and physical defects.

What Quality Assurance Measures Are In Place for Alternators?

Quality assurance is critical in the manufacturing of alternators, ensuring that they meet international standards and customer expectations.

Illustrative image related to how much is an alternator

Quais normas internacionais são relevantes para a fabricação de alternadores?

Manufacturers often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO standards helps ensure that manufacturing processes are efficient and produce consistent, high-quality products.

In addition to ISO certifications, specific industry standards such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the intended use of the alternators, especially in automotive and industrial applications.

Quais são os principais pontos de verificação do controlo de qualidade na produção de alternadores?

Quality control (QC) checkpoints are integral to the manufacturing process. Common QC stages include:

-

Controlo de Qualidade de Entrada (IQC): This involves inspecting raw materials before they are used in production. Ensuring that materials meet predetermined specifications prevents defects in the final product.

-

Controlo de qualidade em processo (IPQC): During the manufacturing process, various checkpoints are established to monitor parameters such as dimensions, weight, and electrical characteristics. Any deviations are addressed immediately to prevent them from affecting the overall production batch.

-

Controlo de Qualidade Final (FQC): After assembly, each alternator undergoes final inspections and testing. This may include electrical output tests, noise tests, and visual inspections for any cosmetic defects.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, it is essential to verify the quality control processes of suppliers. Here are several strategies:

-

Auditorias a fornecedores: Conducting regular audits of suppliers can provide insights into their manufacturing practices and quality control measures. This helps buyers assess compliance with international standards and quality expectations.

-

Relatórios de qualidade: Requesting detailed quality reports from suppliers can reveal their testing methods and results. This transparency is crucial for building trust and ensuring the reliability of products.

-

Inspeções por terceiros: Engaging third-party inspection services can offer unbiased evaluations of the supplier’s manufacturing processes and product quality. This step is particularly important for buyers operating in regions with stringent regulatory requirements.

What Are the Quality Certification Nuances for International B2B Buyers?

B2B buyers must be aware of the nuances related to quality certifications when sourcing alternators from international suppliers. Different regions may have varying standards for quality and safety, which can affect compliance.

-

Certificações regionais: Buyers should familiarize themselves with regional certifications that may be necessary for importing alternators, such as the GCC certification in the Middle East or CE marking in Europe.

-

Documentation and Compliance: Ensuring that suppliers provide all necessary documentation, including certificates of conformity and quality assurance reports, can facilitate smoother trade processes and compliance with local regulations.

By understanding the manufacturing processes and quality assurance measures associated with alternators, B2B buyers can make informed decisions when sourcing these critical components, ultimately leading to improved operational efficiency and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much is an alternator’

In the competitive landscape of automotive parts procurement, understanding the cost and specifics of alternators is essential for B2B buyers. This guide serves as a practical checklist to help you navigate the sourcing process effectively, ensuring that you make informed decisions that align with your operational needs and budget constraints.

Passo 1: Defina as suas especificações técnicas

Before sourcing an alternator, it’s crucial to clearly define the technical specifications required for your application. This includes the year, make, model, and engine size of the vehicles you are servicing. Identifying these specifications ensures compatibility and optimal performance, preventing costly mistakes.

- Requisitos de amperagem: Determine the amperage your vehicles require. Higher amperage alternators often contain more valuable materials, affecting cost.

- Mounting Style and Electrical Connections: Ensure that the alternator’s mounting style and type of electrical connections match your vehicle specifications.

Passo 2: Pesquisar preços de mercado

Investigating the market price range for alternators is vital for budget planning. Prices can vary significantly based on brand, quality, and type (new vs. remanufactured).

Illustrative image related to how much is an alternator

- Average Cost Range: Expect prices to range from $100 to $1,000, depending on the specifications and quality.

- Considerar o custo total de propriedade: Factor in potential shipping and handling fees, especially for international procurement.

Passo 3: Avalie potenciais fornecedores

A thorough evaluation of potential suppliers is essential to ensure reliability and quality. Look for suppliers with a proven track record in the automotive parts industry.

- Solicitar documentação: Ask for company profiles, certifications, and case studies. This will help you gauge their credibility and experience.

- Assess Customer Reviews: Look for feedback from other B2B clients in similar markets to understand their satisfaction levels.

Passo 4: Verify Warranty and Return Policies

Warranties can significantly affect the overall value of your purchase. Ensure that the alternators come with a warranty that meets your needs.

- Length of Warranty: A longer warranty may indicate higher quality. Consider options with lifetime warranties for added security.

- Política de devolução: Understand the terms for returns or exchanges in case the alternator does not meet your specifications or fails prematurely.

Passo 5: Check for Compliance with Local Standards

Compliance with local automotive and safety standards is non-negotiable. Verify that the alternators you plan to purchase meet these regulations.

- Normas internacionais: Ensure that products comply with relevant international standards, especially if you’re sourcing from different regions.

- Verificação da certificação: Request certifications from suppliers to confirm compliance with local regulations, which can prevent future liabilities.

Passo 6: Avaliar a logística e as opções de entrega

Logistics can impact the overall procurement process, especially for international buyers. Assess your delivery options to ensure timely receipt of the alternators.

Illustrative image related to how much is an alternator

- Shipping Methods: Evaluate different shipping options and their costs. Air freight may be quicker but more expensive, while sea freight is economical but slower.

- Supplier Location: Consider the supplier’s location relative to your operation. Closer suppliers may reduce shipping costs and lead times.

Passo 7: Finalizar o contrato de compra e venda

Once you’ve completed your research and evaluations, it’s time to finalize the purchase agreement. Ensure that all terms are clearly outlined to avoid misunderstandings.

- Condições de pagamento: Discuss payment options, including upfront payments, deposits, or credit terms.

- Delivery Schedule: Confirm a clear delivery schedule that aligns with your operational needs.

By following these steps, B2B buyers can confidently navigate the procurement process for alternators, ensuring that they secure quality products at competitive prices while minimizing risks.

Comprehensive Cost and Pricing Analysis for how much is an alternator Sourcing

Understanding the cost structure and pricing for sourcing alternators is crucial for B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. This analysis will break down the cost components, price influencers, and provide valuable buyer tips for effective procurement.

Illustrative image related to how much is an alternator

What Are the Key Cost Components Involved in Alternator Sourcing?

-

Materiais: The primary materials used in alternators include copper for windings, steel for housings, and various types of plastics and rubber for insulation and mounts. The quality and source of these materials can significantly influence the overall cost. For instance, high-quality copper will increase the price but may enhance durability and performance.

-

Trabalho: Labor costs vary by region and the complexity of the alternator design. In regions with higher labor costs, such as Europe, the total manufacturing cost may increase. Conversely, sourcing from areas with lower labor costs, such as certain parts of Asia, can provide significant savings.

-

Custos indiretos de produção: This includes costs related to facility maintenance, utilities, and indirect labor. Efficient manufacturing processes can reduce overhead costs, making it essential for buyers to assess potential suppliers’ operational efficiencies.

-

Ferramentas: Custom tooling for specific alternator designs can be a significant upfront cost. If a buyer requires unique specifications, they should factor in these costs, which can vary greatly depending on the complexity of the tooling required.

-

Controlo de Qualidade (QC): Ensuring that alternators meet specific performance and safety standards can add to the overall cost. Buyers should consider suppliers who invest in rigorous QC processes, as this can prevent costly returns and failures in the field.

-

Logística: Transportation and handling fees can vary widely based on the shipping distance and method. International buyers should be aware of additional costs related to customs, duties, and insurance, which can impact the total cost.

-

Margem: Suppliers will typically add a margin to cover their operational costs and profit. Understanding the market dynamics and average margins in the alternator industry can aid buyers in negotiating better prices.

What Influences the Pricing of Alternators for International Buyers?

-

Volume/MOQ: Bulk purchases can lead to significant discounts. Buyers should negotiate minimum order quantities (MOQs) that align with their inventory needs while maximizing cost efficiency.

-

Especificações e personalização: Custom alternators designed for specific vehicle models or unique operational requirements may carry a premium price. Buyers should clearly communicate their needs to avoid unforeseen costs.

-

Qualidade dos materiais e certificações: Alternators with higher quality materials and certifications (such as ISO or OEM standards) often come at a higher price but can provide better performance and reliability, reducing the total cost of ownership in the long run.

-

Fatores relacionados ao fornecedor: The reputation and reliability of suppliers can greatly impact pricing. Established suppliers with proven track records may charge more, but they often provide superior quality and service.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) used in the transaction is vital for international buyers. These terms define the responsibilities of buyers and sellers in shipping costs, risk, and insurance.

What Are the Best Negotiation Tips for Alternator Sourcing?

-

Pesquisar preços de mercado: Familiarize yourself with the prevailing market rates for alternators in your target region to strengthen your negotiation position.

-

Aproveite os relacionamentos: Building long-term relationships with suppliers can lead to better pricing, especially for repeat purchases.

-

Considerar o custo total de propriedade: When evaluating prices, consider not just the upfront cost but also the long-term implications, including durability, warranty, and maintenance costs.

-

Negociar condições de pagamento: Flexible payment terms can improve cash flow and provide room for negotiation on pricing.

Conclusão

Sourcing alternators involves a complex interplay of various cost components and pricing influencers. By understanding these elements, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always approach sourcing with a strategic mindset, and consider the total cost of ownership when evaluating suppliers.

Alternatives Analysis: Comparing how much is an alternator With Other Solutions

When evaluating the costs and benefits of an alternator, it’s essential to consider alternative solutions that may fulfill similar functions in automotive electrical systems. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and specific application needs.

| Aspecto comparativo | How Much Is An Alternator | Sistemas de energia solar | Battery Backup Systems |

|---|---|---|---|

| Desempenho | Reliable power generation for vehicle electrical systems. | Provides renewable energy; effective in sunny climates. | Offers temporary power supply during outages. |

| Custo | $100 – $1,000 for parts and labor. | Initial setup costs can be high ($5,000 – $30,000), but long-term savings on electricity. | Typically $200 – $1,500 for standard systems, depending on capacity. |

| Facilidade de implementação | Generally straightforward; requires professional installation. | Complex installation; may need permits and adjustments to existing systems. | Easier to install; often plug-and-play options available. |

| Manutenção | Moderate; periodic checks needed, especially for older models. | Low maintenance; occasional panel cleaning needed. | Moderate; batteries require monitoring and eventual replacement. |

| Melhor caso de uso | Best for standard vehicles requiring reliable electrical systems. | Ideal for off-grid applications or supplemental power in sunny regions. | Suitable for emergency power needs or backup for critical systems. |

What Are the Pros and Cons of Solar Power Systems as an Alternative to Alternators?

Solar power systems harness renewable energy, making them an environmentally friendly alternative. They are particularly effective in regions with abundant sunlight, providing a sustainable energy source for various applications, including vehicles. However, the initial setup costs can be significantly higher than purchasing an alternator, and installation may require specialized knowledge and permits. Solar systems also involve a more complex integration process into existing vehicles, which can deter some buyers.

How Do Battery Backup Systems Compare with Alternators?

Battery backup systems serve as a reliable alternative, especially for temporary power needs. They are commonly used in residential settings to provide electricity during outages. The cost of these systems is generally lower than that of solar power systems but can still be significant depending on capacity. Battery backups are easier to install than solar systems, often requiring minimal setup. However, they do not provide continuous power like an alternator, making them less suitable for regular vehicle operation.

Como é que os compradores B2B podem escolher a solução certa para as suas necessidades?

When selecting the right solution, B2B buyers should assess their specific requirements, such as the intended application, budget constraints, and long-term operational costs. For standard vehicle needs, an alternator remains the most reliable choice, delivering consistent power. In contrast, solar power systems may be more suitable for those seeking sustainable energy solutions, while battery backup systems can effectively address temporary power shortages. Understanding these alternatives’ performance, cost, and ease of implementation will help buyers make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for how much is an alternator

What Are the Critical Technical Properties of an Alternator?

When evaluating the cost and suitability of an alternator, it is crucial to consider several technical specifications that can impact performance, compatibility, and overall value. Here are some of the most important properties to understand:

1. Classificação da amperagem

The amperage rating indicates the electrical output capacity of the alternator. It’s essential for determining whether the alternator can support the electrical demands of a vehicle. For B2B buyers, selecting an alternator with the correct amperage is vital to ensure that all vehicle systems function properly without risk of failure. A mismatch could lead to underperformance or damage to electrical components.

2. Mounting Style

Alternators come with various mounting styles designed to fit specific vehicle models. Understanding the mounting style is crucial for ensuring compatibility with the vehicle’s engine bay. For B2B buyers, incorrect mounting can lead to additional costs due to the need for modifications or replacement, making it imperative to verify this specification during procurement.

3. Voltage Output

Alternators typically produce a voltage output between 13.5 to 14.5 volts. This range is crucial for charging the battery and powering the vehicle’s electrical systems. B2B buyers should ensure that the alternator’s voltage output aligns with the requirements of their specific vehicle models to avoid potential electrical failures.

4. Warranty Period

The warranty period offered with an alternator can vary significantly. A longer warranty often indicates higher confidence in the product’s durability and quality. For businesses, a robust warranty can also reduce the total cost of ownership by minimizing future repair or replacement expenses, making it a critical consideration in the purchasing decision.

5. Core Availability

Many alternators are available as remanufactured units, which depend on the availability of cores for rebuilding. The rarity of specific alternators can affect pricing and lead times. B2B buyers should assess core availability to avoid delays in procurement and to understand the pricing dynamics associated with remanufactured parts.

Illustrative image related to how much is an alternator

What Are Common Trade Terminology and Their Importance?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some key terms related to alternator procurement:

1. OEM (Fabricante de Equipamento Original)

OEM refers to parts made by the same manufacturer that produced the original components of the vehicle. Purchasing OEM parts ensures compatibility and quality, which is critical for maintaining vehicle performance. B2B buyers often prefer OEM parts for their reliability, especially in high-stakes applications.

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory costs effectively. It helps in forecasting demand and negotiating better pricing, especially when dealing with bulk purchases.

3. RFQ (Pedido de Cotação)

An RFQ is a document sent to suppliers to solicit pricing for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process and facilitate comparisons between multiple suppliers, ensuring competitive pricing and favorable terms.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers to manage risk and costs associated with logistics. It ensures clarity in the delivery process, which is essential for smooth operations.

Illustrative image related to how much is an alternator

5. Mercado de reposição

The aftermarket refers to parts and accessories that are not sourced from the OEM but are produced by third-party manufacturers. While aftermarket parts can be more cost-effective, B2B buyers need to assess quality and compatibility carefully, as these factors can influence vehicle performance and safety.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring that they procure the right alternators for their operational needs while optimizing costs and maintaining quality.

Navigating Market Dynamics and Sourcing Trends in the how much is an alternator Sector

Quais são as principais tendências de mercado que influenciam o sector dos alternadores?

The global alternator market is witnessing significant transformation driven by technological advancements, evolving consumer preferences, and increasing vehicle electrification. With the automotive industry shifting toward electric and hybrid vehicles, the demand for high-efficiency alternators is on the rise. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must stay abreast of these trends to capitalize on emerging opportunities.

One notable trend is the increasing adoption of remanufactured alternators, which offer cost savings and are seen as environmentally friendly. This shift is particularly relevant in developing regions where budget constraints are significant. Additionally, the rise of e-commerce platforms has streamlined sourcing processes, allowing buyers to access a broader range of products at competitive prices. B2B buyers are increasingly leveraging digital tools to compare suppliers, assess product quality, and negotiate prices effectively.

Moreover, as vehicle technology continues to advance, the complexity of alternators is increasing, necessitating specialized knowledge for proper sourcing. Buyers must consider factors such as the alternator’s amperage, compatibility with vehicle models, and warranty options to make informed purchasing decisions. Understanding these market dynamics is essential for buyers looking to optimize their procurement strategies and ensure the reliability of their automotive electrical systems.

Illustrative image related to how much is an alternator

How Does Sustainability Affect Sourcing Practices for Alternators?

The importance of sustainability in sourcing practices cannot be overstated, especially in the automotive sector. As global awareness of environmental issues rises, B2B buyers are increasingly prioritizing sustainability in their procurement processes. The alternator sector is not immune to this trend; buyers are looking for suppliers who adopt environmentally friendly practices and materials.

Ethical sourcing is becoming a key consideration, with companies facing pressure to ensure their supply chains are free from exploitation and environmentally damaging practices. This includes the responsible sourcing of materials used in alternators, such as copper and aluminum, which have significant environmental footprints. Buyers should seek suppliers with certifications that demonstrate adherence to sustainable practices, such as ISO 14001 for environmental management or certifications related to recycled materials.

Moreover, the demand for ‘green’ products is influencing manufacturing processes, prompting suppliers to innovate and develop alternators with lower energy consumption and improved recyclability. Buyers who align their sourcing strategies with sustainability goals not only contribute to environmental preservation but also enhance their brand reputation and appeal to eco-conscious consumers.

Que desenvolvimentos históricos moldaram o mercado de alternadores?

The evolution of alternators dates back to the early 20th century when vehicles relied primarily on direct current (DC) generators. The introduction of the alternator in the 1960s marked a significant turning point, offering improved efficiency and reliability. As automotive technology advanced, so did the design and functionality of alternators, leading to the development of high-output models that could support the growing number of electrical components in modern vehicles.

Over the decades, the alternator’s role has expanded beyond merely charging the battery; it now powers an array of systems from infotainment to safety features. This evolution reflects broader trends in vehicle electrification and the increasing complexity of automotive electrical systems. Understanding this historical context provides B2B buyers with insights into the future direction of the alternator market, helping them make informed decisions about sourcing and procurement strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of how much is an alternator

-

How much does an alternator typically cost for B2B buyers?

The cost of an alternator can vary significantly based on factors such as the vehicle’s make, model, and year, as well as the alternator’s specifications like amperage and mounting style. Generally, prices range from $100 to $1,000. For bulk purchases, buyers can often negotiate better pricing with suppliers. It is advisable to consider the warranty and quality of the alternators, as these factors can impact long-term value and reliability. -

Que factores influenciam o preço de um alternador?

Several factors affect the price of an alternator, including its amperage rating, manufacturing materials, and whether it is new or remanufactured. Additionally, the complexity of the alternator’s design, such as the number of electrical connections and mounting styles, can impact costs. Buyers should also account for shipping and import duties when sourcing alternators internationally, which can further influence the overall price. -

What are the signs that an alternator needs replacement?

Key indicators that an alternator may need replacement include dimming headlights, electrical system malfunctions, unusual noises from the engine, and warning lights on the dashboard. If a vehicle frequently experiences dead batteries or stalling, these may also signal a failing alternator. For B2B buyers, understanding these signs can aid in timely replacements, reducing downtime and maintenance costs. -

Como é que posso verificar os fornecedores de alternadores nos mercados internacionais?

To vet suppliers effectively, start by checking their reputation through customer reviews and industry ratings. Request certifications that demonstrate compliance with international standards. Conducting background checks on the supplier’s history and financial stability is also essential. Engaging in direct communication and requesting samples can provide insight into the quality of their products, ensuring they meet your specifications before committing to larger orders. -

What are the minimum order quantities (MOQs) for alternators when sourcing internationally?

Minimum order quantities can vary widely depending on the supplier and the type of alternator. Typically, MOQs range from 10 to 100 units for bulk orders. It’s crucial for buyers to clarify these terms upfront to ensure they align with their inventory needs. Some suppliers may offer flexibility on MOQs for first-time buyers or for specific promotional items, so it’s worth negotiating these terms. -

What payment terms should I consider when purchasing alternators?

When negotiating payment terms, consider options such as advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60 days). Ensure that you understand the currency exchange rates and transaction fees if dealing internationally. Establishing clear terms can help manage cash flow and mitigate risks associated with international trade. Always document payment agreements in writing to avoid disputes later. -

How important is quality assurance (QA) when sourcing alternators?

Quality assurance is critical when sourcing alternators, as subpar products can lead to increased returns and customer dissatisfaction. Ensure that suppliers adhere to recognized quality standards, such as ISO certifications. Request documentation of QA processes, including testing methods and failure rates. By prioritizing QA, buyers can enhance their product offerings and build long-term relationships with customers. -

Que considerações logísticas devo ter em mente ao importar alternadores?

Logistics considerations include shipping methods, transit times, and customs clearance processes. Choose a reliable freight forwarder experienced in automotive parts to navigate international shipping efficiently. Understand the import regulations and tariffs in your country to avoid unexpected costs. Additionally, consider warehousing options for managing inventory after arrival, which can streamline distribution to your customers.

A Look at How Much Is An Alternator Manufacturers & Suppliers

Could not verify enough suppliers for how much is an alternator to create a list at this time.

Strategic Sourcing Conclusion and Outlook for how much is an alternator

In conclusion, understanding the factors influencing the cost of alternators is crucial for international B2B buyers. Prices can vary significantly based on vehicle specifications, alternator types, and geographical factors. The average cost for replacement ranges from $100 to $1,000, with labor typically adding another $120 to $200. As such, strategic sourcing becomes essential—not only to ensure the procurement of high-quality components but also to mitigate the risks associated with subpar aftermarket parts.

Illustrative image related to how much is an alternator

B2B buyers in regions like Africa, South America, the Middle East, and Europe should prioritize suppliers who provide comprehensive warranties and high-quality products. Engaging with reputable manufacturers and distributors can lead to better pricing models and reliability in supply chains, especially as the demand for automotive parts continues to rise.

Looking forward, establishing robust relationships with trusted suppliers will be pivotal in navigating the complexities of the automotive parts market. As you plan your sourcing strategies, consider leveraging local suppliers and exploring remanufactured options to enhance cost-efficiency without compromising on quality. Embrace this opportunity to secure a competitive edge in your market.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.