Introduction: Navigating the Global Market for how much does a starter cost

In today’s rapidly evolving automotive landscape, understanding how much a starter costs is essential for international B2B buyers navigating the complexities of vehicle maintenance and repair. Whether you are sourcing parts for a fleet of vehicles in Nigeria or evaluating the best suppliers in Germany, the challenges of pricing transparency and quality assurance can be daunting. This guide is designed to demystify the various factors influencing starter costs, including types of starters, their applications, and essential supplier vetting criteria.

As we explore the cost spectrum—from budget-friendly aftermarket options to high-performance starters—we will provide actionable insights that empower you to make informed purchasing decisions. Our comprehensive analysis will cover not only the pricing variations based on vehicle type and regional labor costs but also the implications of choosing new versus remanufactured components. Moreover, we will highlight the importance of professional installation services versus DIY approaches, ensuring that you can effectively assess the total cost of ownership.

By equipping you with the knowledge to navigate this global market, this guide aims to enhance your procurement strategies and ultimately improve operational efficiency. From Africa to South America, the Middle East to Europe, understanding the nuances of starter pricing will enable you to forge stronger partnerships with suppliers and optimize your purchasing processes.

Índice

- Top 5 How Much Does A Starter Cost Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much does a starter cost

- Understanding how much does a starter cost Types and Variations

- Key Industrial Applications of how much does a starter cost

- 3 Common User Pain Points for ‘how much does a starter cost’ & Their Solutions

- Strategic Material Selection Guide for how much does a starter cost

- In-depth Look: Manufacturing Processes and Quality Assurance for how much does a starter cost

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does a starter cost’

- Comprehensive Cost and Pricing Analysis for how much does a starter cost Sourcing

- Alternatives Analysis: Comparing how much does a starter cost With Other Solutions

- Essential Technical Properties and Trade Terminology for how much does a starter cost

- Navigating Market Dynamics and Sourcing Trends in the how much does a starter cost Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much does a starter cost

- Strategic Sourcing Conclusion and Outlook for how much does a starter cost

- Aviso legal importante e termos de utilização

Understanding how much does a starter cost Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Iniciadores económicos | Aftermarket, budget-friendly, lower lifespan | Fleet vehicles, budget-conscious businesses | Prós: Económico; Contras: Tempo de vida mais curto, potenciais problemas de fiabilidade. |

| Arrancadores OEM | Original Equipment Manufacturer, higher quality | Luxury vehicles, brand-sensitive companies | Prós: Reliability, warranty; Contras: Custo mais elevado, disponibilidade limitada. |

| Arrancadores de alto desempenho | Enhanced durability and power, specialized design | Racing, performance vehicles | Prós: Desempenho superior; Contras: Caro, pode exigir uma instalação especializada. |

| Arrancadores Remanufacturados | Rebuilt with used parts, lower cost | Small businesses, cost-sensitive operations | Prós: Acessível; Contras: Uncertain lifespan, may lack warranty. |

| Remote Starters | Keyless entry, remote start capability | Luxury vehicle markets, tech-savvy buyers | Prós: Convenience, modern features; Contras: Higher installation complexity, potential compatibility issues. |

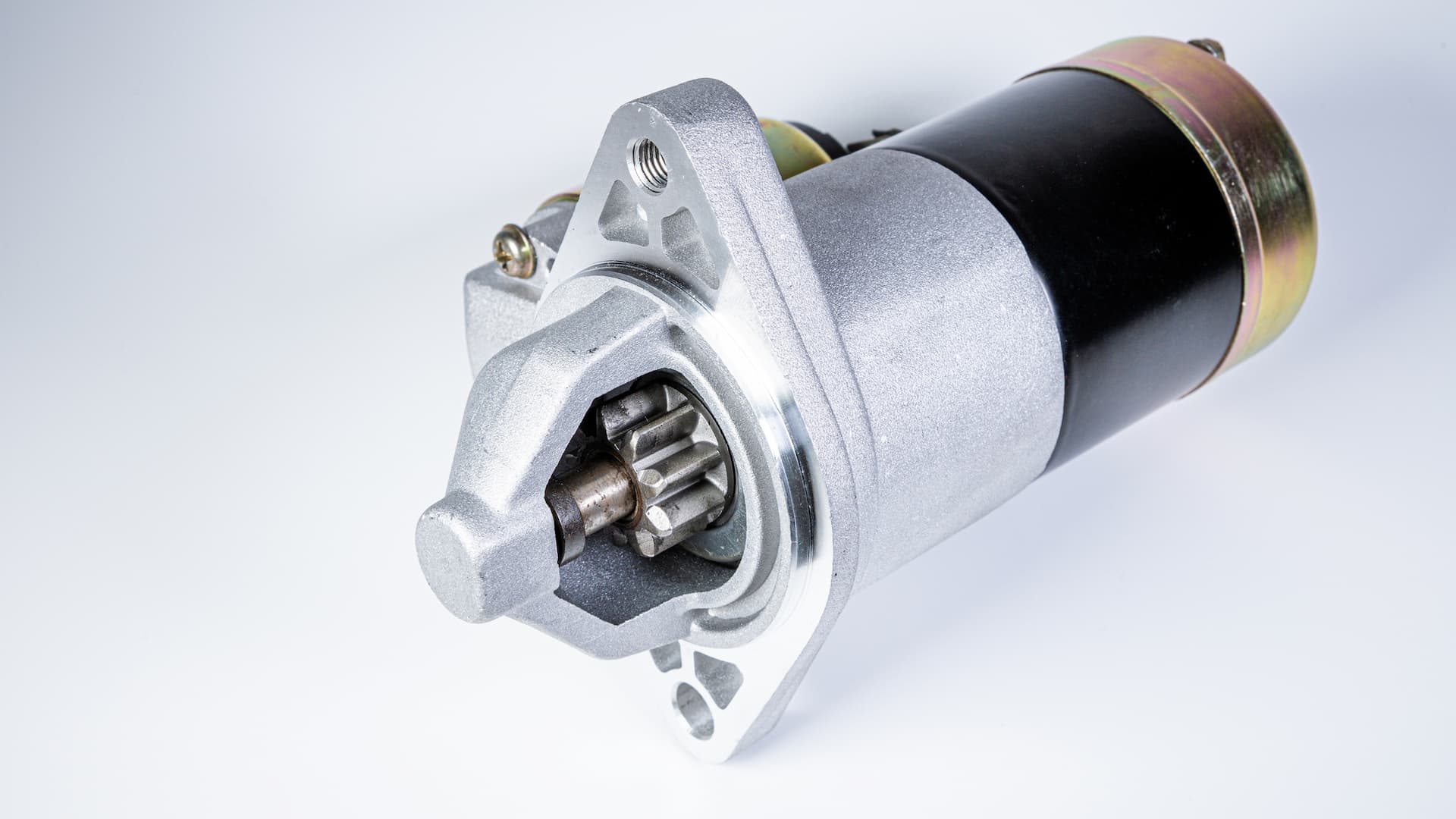

What Are the Characteristics of Economy Starters?

Economy starters are designed for cost-conscious buyers, often found in aftermarket options. They are typically priced between $75 and $200, making them attractive for fleet vehicles or businesses with limited budgets. While they provide a functional solution, their lifespan may be shorter compared to more premium options. B2B buyers should consider the balance between initial cost and long-term reliability.

Why Choose OEM Starters for Luxury Vehicles?

OEM starters are manufactured by the original vehicle maker, ensuring compatibility and reliability. Priced between $150 and $400, they are ideal for companies that prioritize brand integrity and performance, particularly in luxury vehicle markets. B2B buyers should weigh the benefits of guaranteed quality against the higher costs and potential availability issues, especially in regions with import restrictions.

What Are the Advantages of High-Performance Starters?

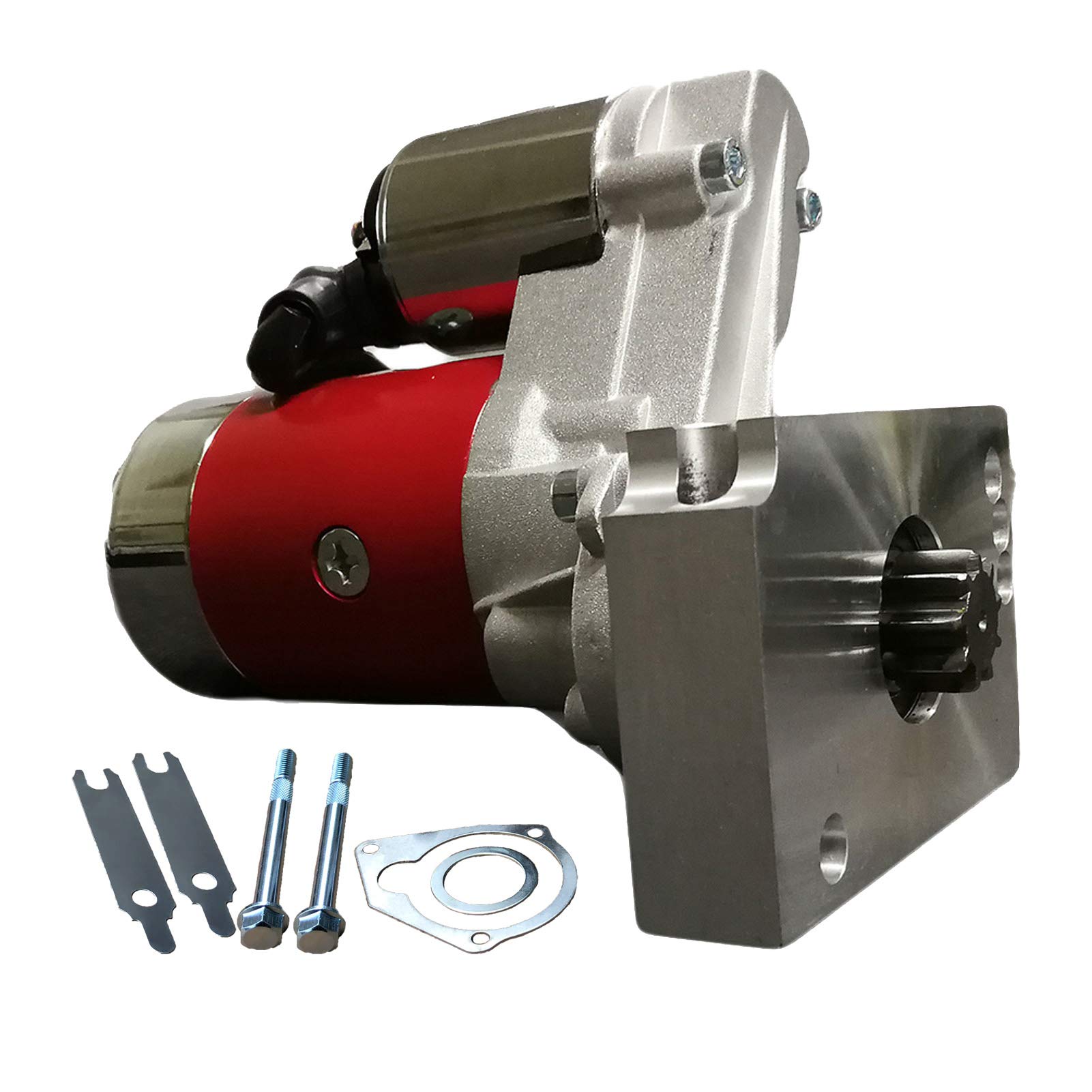

High-performance starters cater to racing and performance vehicle applications, offering enhanced durability and power. Typically ranging from $300 to over $1,000, these starters are designed for specialized installations. B2B buyers in the automotive racing sector should consider the value of performance enhancements against the investment, ensuring they align with their specific operational needs.

Illustrative image related to how much does a starter cost

How Do Remanufactured Starters Fit in the Market?

Remanufactured starters present a budget-friendly option for small businesses and cost-sensitive operations. Generally priced between $50 and $300, they are rebuilt from used parts, offering substantial savings. However, buyers should be cautious about the uncertain lifespan and potential lack of warranty. Evaluating the cost-benefit ratio is crucial for B2B purchasing decisions.

What Makes Remote Starters a Popular Choice?

Remote starters provide added convenience and modern features, appealing to tech-savvy buyers in the luxury vehicle market. While they offer keyless entry and remote start capabilities, they can be more complex to install and may present compatibility issues. B2B buyers should consider the added value of these features against the increased installation costs and technical requirements, ensuring alignment with their customer base’s preferences.

Key Industrial Applications of how much does a starter cost

| Indústria/Setor | Specific Application of how much does a starter cost | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Substituição de motores de arranque em veículos | Ensures reliable vehicle operation and minimizes downtime | Quality of parts (new vs. remanufactured), labor costs, warranty options |

| Serviços de transporte | Manutenção de frotas de veículos comerciais | Reduces unexpected breakdowns, improves operational efficiency | Opções de compra a granel, fiabilidade do fornecedor, disponibilidade regional |

| Agricultura | Starter replacements for farm equipment | Enhances productivity by minimizing equipment failure | Compatibility with various equipment brands, local sourcing, pricing |

| Mineração | Arrancadores para máquinas pesadas | Ensures continuous operation in demanding environments | Heavy-duty specifications, supplier support, maintenance services |

| Construção | Starters for construction machinery | Reduces project delays and enhances equipment reliability | Cost-effectiveness, part availability, warranty and service agreements |

How is ‘how much does a starter cost’ Applied in Automotive Repair?

In the automotive repair industry, understanding the cost of a starter is crucial for workshops and service centers. A reliable starter is essential for vehicle functionality, and knowing the price range helps mechanics provide accurate estimates to customers. Problems such as unexpected vehicle breakdowns can be mitigated by having quality starters on hand. International buyers, especially in regions like Africa and South America, should consider sourcing from reputable suppliers who offer both new and remanufactured starters, ensuring they meet local standards while optimizing costs.

What Role Does Starter Cost Play in Transportation Services?

For transportation service providers, managing a fleet involves regular maintenance, including starter replacements. Knowing how much a starter costs allows businesses to budget effectively and avoid unplanned expenses due to vehicle downtime. By investing in reliable starters, companies can enhance their operational efficiency and reduce the risk of delays in service delivery. Buyers in the Middle East and Europe should prioritize suppliers that offer bulk purchasing options and warranties, which can lead to significant savings and ensure consistent service levels.

How Does Starter Cost Affect Agricultural Operations?

In agriculture, the cost of starters for farm equipment is a critical factor in maintaining productivity. Equipment failures due to faulty starters can lead to costly downtime during peak seasons. Therefore, understanding the price range and sourcing quality parts is vital for farmers and agricultural businesses. Buyers, particularly in regions with developing infrastructure, should focus on suppliers that offer compatibility with various machinery brands and consider local sourcing to reduce shipping costs and delays.

Why is Understanding Starter Cost Important in Mining?

Mining operations rely heavily on heavy machinery, where starters play a key role in ensuring equipment runs smoothly. The cost of starters impacts overall operational efficiency and safety in high-demand environments. By investing in durable starters, mining companies can prevent costly operational interruptions. Buyers in this sector should evaluate suppliers based on heavy-duty specifications and the availability of maintenance support, especially in remote areas where equipment reliability is paramount.

What is the Impact of Starter Costs on Construction Projects?

In the construction industry, the reliability of machinery is crucial for project timelines. The cost of starters for construction equipment directly influences budget planning and project execution. By understanding the cost implications, construction firms can make informed decisions on equipment maintenance and replacements, reducing the risk of project delays. Buyers should consider the cost-effectiveness of parts, availability, and warranty agreements when sourcing starters, ensuring they can keep projects on track and within budget.

3 Common User Pain Points for ‘how much does a starter cost’ & Their Solutions

Scenario 1: Unpredictable Costs Leading to Budget Overruns

O problema: B2B buyers often face unpredictable costs when sourcing starters for their fleets or machinery. For instance, a company in Nigeria might have a limited budget set for maintenance, but upon requesting quotes, they find that the prices for starters can vary significantly. Factors such as vehicle type, the quality of the part (new vs. remanufactured), and regional supply chain issues can lead to discrepancies in costs, which can result in budget overruns and financial strain.

A solução: To mitigate these unpredictable costs, buyers should conduct thorough market research before making purchasing decisions. Start by gathering quotes from multiple suppliers, focusing on both local and international sources. Consider using online platforms that compare prices across different vendors. Additionally, establish relationships with trusted suppliers who can provide consistent pricing and quality assurance. It may also be beneficial to negotiate bulk purchasing agreements, which can lead to reduced per-unit costs. By understanding the factors that influence pricing—such as the specific make and model of vehicles or machinery—buyers can better predict costs and allocate their budgets more effectively.

Scenario 2: Difficulty in Assessing Quality vs. Cost

O problema: For international buyers, particularly those in South America or the Middle East, distinguishing between quality and cost can be a daunting task. A company might be tempted to opt for the lowest-priced starter, only to find that it fails prematurely, leading to additional costs for replacements and labor. This scenario not only affects the bottom line but can also disrupt operations, causing delays and frustration.

A solução: To navigate the quality versus cost dilemma, buyers should implement a systematic evaluation process for potential suppliers. Begin by assessing the reputation of the manufacturer, looking for reviews and testimonials from other B2B buyers. Request certifications that guarantee quality standards, such as ISO certifications or warranties. It may also be beneficial to explore remanufactured starters from reputable companies that offer a good balance between price and reliability. By investing time in evaluating the quality of starters, buyers can make informed decisions that reduce the risk of future failures and ensure smoother operations.

Scenario 3: Complex Installation Processes Leading to Increased Labor Costs

O problema: When sourcing starters, B2B buyers often underestimate the complexity of installation, especially for specialized or luxury vehicles. A company in Germany may find that the starter they purchased is not only more expensive than anticipated but also requires a lengthy installation process, significantly increasing labor costs. This can lead to frustration and unexpected expenses, straining the budget further.

A solução: To address the complexities of installation, buyers should prioritize sourcing starters that are compatible with their specific vehicles and equipment. Collaborate with experienced technicians to gain insights into which starters have straightforward installation processes. Additionally, consider investing in professional installation services that are bundled with the purchase, as this can provide a clearer understanding of total costs upfront. Providing training for in-house maintenance teams on starter installation and troubleshooting can also reduce reliance on external labor and minimize future costs. By taking these proactive steps, buyers can streamline the installation process, ultimately saving time and money.

Strategic Material Selection Guide for how much does a starter cost

What Materials Are Commonly Used in Starters and Their Cost Implications?

When considering the cost of starters, the materials used in their construction play a crucial role in determining performance, durability, and overall expense. Here, we analyze four common materials found in starters: steel, aluminum, copper, and plastic composites. Each material has unique properties that influence its suitability for different applications in the automotive sector.

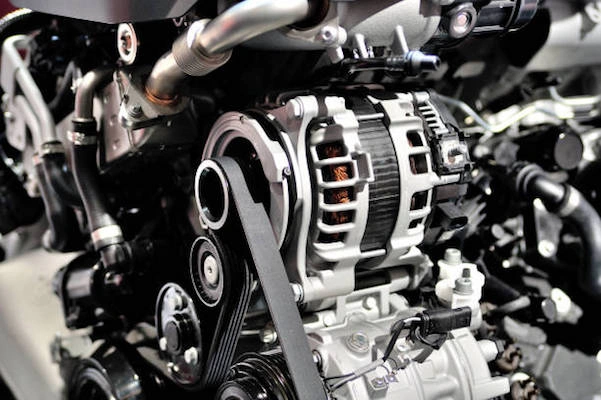

How Does Steel Impact Starter Performance and Cost?

Steel is a prevalent material in starter construction due to its strength and durability. It exhibits excellent temperature and pressure ratings, making it suitable for high-performance applications. Steel’s corrosion resistance can be enhanced through galvanization or coating, which is essential in regions with harsh weather conditions.

Prós: Steel starters are highly durable and can withstand significant wear and tear. They are also relatively cost-effective, making them a popular choice for budget-conscious buyers.

Contras: The weight of steel can be a disadvantage in performance vehicles where reducing weight is critical. Additionally, if not properly treated, steel can corrode over time, leading to potential failures.

Illustrative image related to how much does a starter cost

For international buyers, compliance with standards such as ASTM for steel grades is essential. In regions like Germany, adherence to DIN standards is critical for ensuring quality and performance.

Que papel desempenha o alumínio no fabrico de arrancadores?

Aluminum is increasingly used in starter construction due to its lightweight properties and good corrosion resistance. It can handle moderate temperature variations, making it suitable for various climates.

Prós: The lightweight nature of aluminum contributes to better fuel efficiency in vehicles. Its resistance to corrosion is advantageous in humid or coastal environments.

Contras: Aluminum starters may not be as durable as their steel counterparts, particularly under extreme conditions. They can also be more expensive to manufacture due to the complexities involved in processing aluminum.

Illustrative image related to how much does a starter cost

International buyers should consider the availability of aluminum and the associated costs in their regions. Compliance with local standards, such as JIS in Japan or ASTM in the U.S., is also crucial for ensuring product reliability.

How Does Copper Affect Starter Efficiency and Cost?

Copper is primarily used in the electrical components of starters, such as windings and connectors, due to its excellent conductivity. This property is vital for ensuring efficient power transfer from the battery to the starter motor.

Prós: Copper’s high conductivity results in faster engine cranking and improved performance. It also has good corrosion resistance, especially when treated.

Contras: The cost of copper can be significantly higher than other materials, impacting the overall price of starters. Additionally, copper components can be heavier, which may not be ideal for all vehicle types.

Illustrative image related to how much does a starter cost

For B2B buyers, understanding the fluctuating copper market is essential for budgeting. Compliance with electrical standards is also critical, particularly in regions with strict regulations.

What Are the Benefits of Using Plastic Composites in Starters?

Plastic composites are often used for non-structural components of starters, such as housings and covers. They are lightweight and can be molded into complex shapes, which can enhance design flexibility.

Prós: The primary advantage of plastic composites is their lightweight nature, which can help reduce overall vehicle weight. They are also resistant to corrosion and can be produced at a lower cost.

Illustrative image related to how much does a starter cost

Contras: Plastic composites may not offer the same level of durability as metals, particularly under high-stress conditions. They can also be less effective in extreme temperatures.

International buyers should be aware of the specific plastic grades and their compliance with standards like ASTM or ISO. Understanding the local market for plastic materials is also vital for sourcing.

Summary Table of Material Considerations for Starters

| Material | Typical Use Case for how much does a starter cost | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Aço | Structural components in starters | Elevada durabilidade | Can corrode if untreated | Médio |

| Alumínio | Caixas de arranque leves | Leve e resistente à corrosão | Menos durável do que o aço | Alto |

| Cobre | Enrolamentos eléctricos e conectores | Excelente condutividade | Custo elevado | Alto |

| Compósitos plásticos | Componentes não estruturais como caixas | Leve e económico | Menos durável sob tensão | Baixo |

This analysis provides a comprehensive overview of the materials commonly used in starter construction and their implications for cost and performance. International B2B buyers should consider these factors to make informed purchasing decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for how much does a starter cost

Quais são as principais fases do fabrico de arrancadores?

The manufacturing process of automotive starters involves several critical stages, each essential for ensuring the quality and reliability of the final product. Understanding these stages can help B2B buyers make informed decisions when sourcing starters from suppliers.

How Is Material Prepared for Starter Production?

The first step in the manufacturing process is material preparation. High-quality materials are vital for the durability and performance of starters. Common materials include:

Illustrative image related to how much does a starter cost

- Cobre: Utilizado para enrolamentos devido à sua excelente condutividade.

- Aço: Utilized for the casing and other structural components for strength.

- Alumínio: Often used for lightweight components, such as the starter’s housing.

Before production begins, raw materials undergo rigorous inspections to ensure they meet specified standards. This phase may involve chemical analysis and mechanical testing to verify material properties.

What Techniques Are Used in the Forming Process?

The forming process involves shaping the prepared materials into starter components. Key techniques include:

- Fundição sob pressão: Used for creating the starter housing and other complex shapes, allowing for high precision and reduced waste.

- Estampagem: Employed to create flat components such as brackets and mounting plates.

- Usinagem: Involves cutting and shaping parts to exact specifications, particularly for critical components like the armature and commutator.

These techniques ensure that each part fits together perfectly, which is crucial for the starter’s overall functionality.

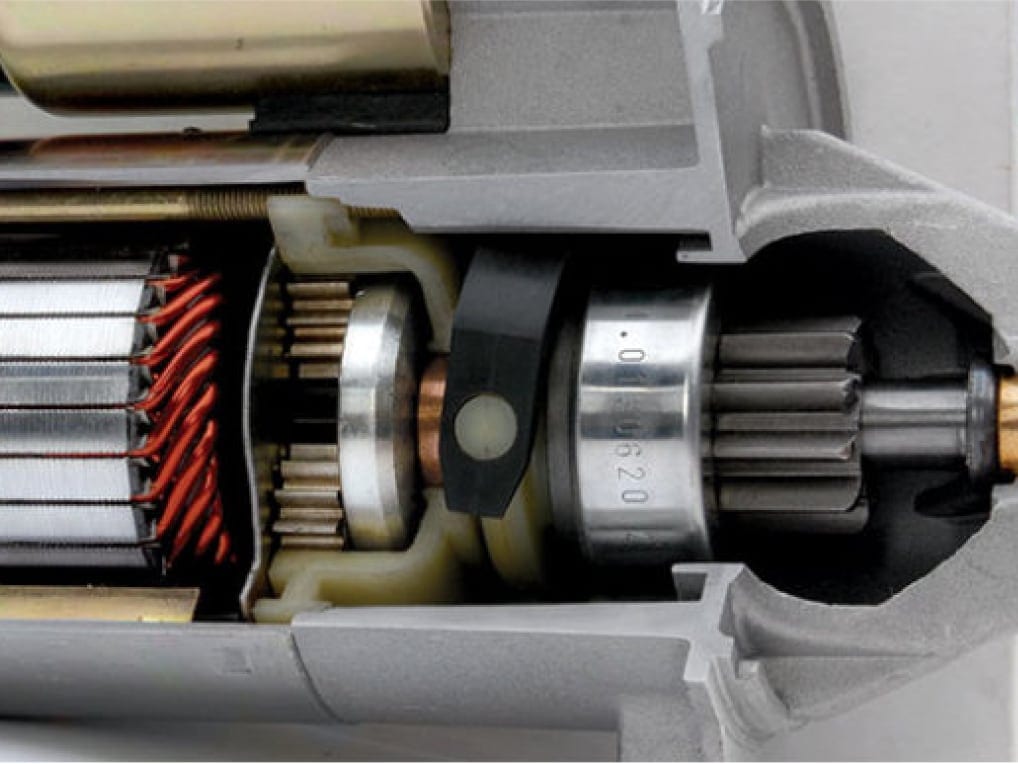

How Are Starters Assembled?

Once the components are formed, the assembly process begins. This stage typically includes:

- Integração de componentes: Individual parts, such as the motor, solenoid, and housing, are brought together.

- Cablagem: Electrical connections are made, ensuring that all components function cohesively.

- Testes durante a montagem: Some manufacturers conduct preliminary tests on components before final assembly to catch any defects early.

Efficient assembly lines often utilize automation to enhance precision and reduce labor costs while maintaining quality.

What Finishing Processes Are Commonly Applied?

After assembly, starters undergo finishing processes to ensure they meet aesthetic and functional standards. This can include:

- Tratamento de superfície: Techniques such as powder coating or galvanization protect components from corrosion and wear.

- Inspecções finais: Each starter is inspected for visual defects, ensuring that it meets both design and functional specifications.

Finishing processes are crucial for ensuring longevity and reliability, particularly in challenging environments.

What Quality Control Measures Are Employed in Starter Manufacturing?

Quality assurance is vital in the manufacturing of automotive starters, as failures can lead to significant safety issues and customer dissatisfaction. Key quality control (QC) measures include:

Que normas internacionais são relevantes para o fabrico de arrancadores?

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in the European market and API (American Petroleum Institute) standards for components used in specific applications may also apply.

Quais são os principais pontos de controlo de CQ no processo de fabrico?

Quality control checkpoints are integrated throughout the manufacturing process to ensure the highest standards. Common checkpoints include:

- Controlo de Qualidade de Entrada (IQC): Inspects raw materials upon delivery to ensure they meet required specifications.

- Controlo de qualidade em processo (IPQC): Conducts inspections during various stages of production, ensuring that any defects are identified and corrected immediately.

- Controlo de Qualidade Final (FQC): Involves comprehensive testing of the finished product to confirm that it functions correctly and meets performance specifications.

Que métodos de ensaio são habitualmente utilizados para arrancadores?

Various testing methods are employed to assess the functionality and reliability of starters. These may include:

- Testes elétricos: Measures resistance, continuity, and current draw to ensure proper electrical function.

- Testes mecânicos: Assesses the physical durability of components under simulated operational conditions.

- Ensaios ambientais: Evaluates how the starter performs under extreme temperatures, humidity, and vibration.

These tests are crucial for ensuring that the starters can withstand the conditions they will encounter in real-world applications.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

When sourcing starters, B2B buyers should consider several strategies to verify a supplier’s quality control measures:

- Auditorias a fornecedores: Conducting audits of the manufacturing facility can provide insights into the production processes and adherence to quality standards.

- Requesting QC Reports: Suppliers should be able to provide documentation of their QC processes, including results from testing and inspections.

- Inspeções por terceiros: Engaging independent inspection services can offer an unbiased assessment of the supplier’s quality control practices.

Quais são as nuances de controle de qualidade e certificação para compradores B2B internacionais?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential. Different markets may have specific regulatory requirements that suppliers must meet.

- Certificações regionais: Ensure that suppliers hold necessary certifications for your specific market. For example, CE marking is crucial for products sold in Europe, while other regions may have different compliance requirements.

- Language and Documentation: Ensure that all quality documentation is available in a language that is understandable for your team to avoid misinterpretations.

By thoroughly understanding the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing starters, ensuring they choose reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much does a starter cost’

In the competitive landscape of B2B procurement, understanding the costs associated with sourcing starters for vehicles is critical for making informed purchasing decisions. This guide provides a practical checklist for international buyers, ensuring a comprehensive evaluation of costs, suppliers, and products.

Passo 1: Identify Your Vehicle Requirements

Understanding the specific requirements of the vehicles you are servicing is vital. Different makes and models have unique starter specifications, which can significantly impact pricing. Additionally, consider whether you need standard, remanufactured, or high-performance starters based on your operational demands.

Illustrative image related to how much does a starter cost

Passo 2: Pesquisar preços de mercado

Gather information on the current market prices for starters. Prices can vary widely based on factors such as the type of starter (OEM vs. aftermarket), brand reputation, and geographic location. Analyze various suppliers to establish a baseline for what constitutes a competitive price in your region.

Passo 3: Evaluate Supplier Reputation

Before committing to a supplier, assess their market reputation. Look for reviews, testimonials, and ratings from previous clients, particularly those in your industry or geographic area. Reliable suppliers often have a track record of quality service and product reliability, which can save you time and money in the long run.

Passo 4: Verify Quality Certifications

Ensure that the starters you are considering meet industry standards and certifications. Certifications can indicate the quality and reliability of the products. Look for ISO certifications, compliance with local regulations, and any specific automotive industry standards that may apply.

Illustrative image related to how much does a starter cost

Passo 5: Pedir orçamentos pormenorizados

When you have shortlisted potential suppliers, request detailed quotes that break down all costs involved. This should include the price of the starter, shipping costs, potential tariffs, and any additional fees. A transparent quote allows for better comparison and negotiation with suppliers.

Passo 6: Consider Warranty and Return Policies

Review the warranty and return policies offered by suppliers. A robust warranty can provide peace of mind and protect your investment in case of product failure. Ensure that you understand the terms and conditions regarding returns, as this can affect your overall procurement strategy.

Passo 7: Assess Logistics and Delivery Times

Evaluate the logistics involved in sourcing starters, including delivery times and shipping methods. Reliable suppliers should provide clear timelines for product availability and shipping. Delays in receiving components can impact your operations, so it’s crucial to factor this into your decision-making process.

Illustrative image related to how much does a starter cost

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing starters, ensuring they select the right products at competitive prices while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for how much does a starter cost Sourcing

What Are the Key Cost Components for Sourcing a Starter?

When sourcing starters for vehicles, understanding the cost structure is crucial for B2B buyers. The main cost components include:

-

Materiais: The cost of raw materials such as copper, steel, and plastic used in the manufacturing process significantly impacts the final price. High-quality materials tend to increase durability but also elevate costs.

-

Trabalho: Labor costs vary depending on the region and skill level required for assembly. In countries with higher wage standards, labor costs will be a larger portion of the total price.

-

Custos indiretos de produção: This includes costs associated with the production facility, utilities, and administrative expenses. Efficient manufacturing processes can reduce these overhead costs.

-

Ferramentas: The initial investment in tooling for production can be substantial. Buyers may share this cost through larger orders, making it essential to consider volume when negotiating prices.

-

Controlo de Qualidade (QC): Rigorous QC processes ensure that starters meet industry standards and certifications. These processes add to the cost but can prevent future failures, saving buyers money in the long run.

-

Logística: Shipping and handling costs vary depending on the location of the supplier and the buyer. International shipments may incur additional fees such as tariffs and customs duties.

-

Margem: Suppliers will factor in their profit margin, which can vary based on competition and market demand. Understanding the typical margins in your target market can aid in negotiation.

What Influences the Price of Starters for International Buyers?

Several factors can influence the pricing of starters in international markets:

-

Volume/MOQ (Quantidade mínima de encomenda): Ordering in bulk can significantly reduce the per-unit cost. Establishing a long-term partnership with suppliers may lead to better pricing structures.

-

Especificações e personalização: Custom starters designed for specific vehicle models or performance requirements can lead to higher costs. Buyers should clearly outline their needs to avoid unnecessary expenses.

-

Materiais e certificações de qualidade: Starters made from premium materials or those that comply with international quality standards (like ISO certifications) often command higher prices. Buyers must balance quality against cost.

-

Fatores relacionados ao fornecedor: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the agreed Incoterms is essential as they define the responsibilities of buyers and sellers in shipping. This can significantly affect the total cost, especially in international transactions.

What Are the Best Practices for Negotiating Starter Prices?

B2B buyers can adopt several strategies to ensure cost-efficiency in sourcing starters:

-

Negotiate with Volume in Mind: Leverage your purchasing power by committing to larger orders. This can lead to discounts and more favorable payment terms.

-

Considere o custo total de propriedade (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, warranty claims, and potential downtime due to starter failures.

-

Pesquisar preços de mercado: Stay informed about market trends and competitor pricing. This knowledge can provide leverage during negotiations.

-

Explorar fornecedores locais: Depending on the region, sourcing from local suppliers may reduce shipping costs and lead times, improving overall efficiency.

-

Review Contracts Thoroughly: Pay close attention to payment terms, warranty conditions, and return policies. Favorable terms can mitigate risks associated with sourcing.

Conclusão

While the indicative price range for starters can vary greatly—from as low as $75 for economy models to over $1,000 for high-performance options—understanding the components of cost and the factors influencing pricing is essential for making informed purchasing decisions. By applying these insights and strategies, international B2B buyers can enhance their procurement processes, ensuring they secure high-quality starters at competitive prices.

Alternatives Analysis: Comparing how much does a starter cost With Other Solutions

Exploring Alternatives to Starter Costs: A Comparative Analysis

In the automotive sector, understanding the costs associated with a starter is crucial for B2B buyers, especially when considering alternatives that may serve similar functions. This analysis compares the cost and efficiency of traditional starter replacements against alternative solutions such as remote car starters and battery maintenance systems. Each option carries its own set of advantages and drawbacks that can significantly impact purchasing decisions.

| Aspecto comparativo | How Much Does A Starter Cost | Remote Car Starters | Battery Maintenance Systems |

|---|---|---|---|

| Desempenho | Essential for engine ignition | Enables starting from a distance; enhances convenience | Improves battery lifespan, indirectly aids starter performance |

| Custo | $100 – $600 (parts + labor) | $50 – $200 (parts only) | $20 – $100 (maintenance tools) |

| Facilidade de implementação | Requires professional installation; can be DIY | DIY installation possible; typically straightforward | Easy to implement; minimal technical skills required |

| Manutenção | Moderate; depends on part quality | Low; minimal upkeep needed | Regular checks recommended; periodic replacements of parts |

| Melhor caso de uso | Necessary for vehicle operation | Ideal for convenience; enhances user experience | Best for proactive battery care; prevents starter issues |

What Are the Advantages and Disadvantages of Remote Car Starters?

Remote car starters offer a modern solution for vehicle ignition, allowing users to start their engines from a distance. The primary advantage is convenience—owners can preheat or cool their vehicles before entering. However, while the initial cost is lower than that of a starter replacement, remote starters do not replace a faulty starter but rather complement it. Users must still ensure that the underlying starter system is functioning correctly; otherwise, they may encounter issues despite the convenience of remote ignition.

Illustrative image related to how much does a starter cost

How Do Battery Maintenance Systems Benefit Vehicle Owners?

Battery maintenance systems are designed to enhance battery performance and longevity. These systems can prevent starter issues by ensuring the battery remains charged and healthy, which is crucial for the starter’s operation. The upfront investment is minimal compared to starter replacements, and maintenance systems can be installed easily by most vehicle owners. However, these systems do not address existing starter problems; they are best utilized as preventative measures rather than solutions to current failures.

Conclusão: como os compradores B2B devem escolher a solução certa?

When determining the best solution for their needs, B2B buyers should consider various factors such as the specific vehicle application, budget constraints, and long-term maintenance plans. For immediate starter failures, direct replacement remains the most effective solution. However, for those seeking added convenience or a preventative approach, integrating remote car starters or battery maintenance systems can enhance the overall functionality and reliability of their vehicles. Ultimately, understanding the nuances of each option will enable buyers to make informed decisions tailored to their operational requirements.

Essential Technical Properties and Trade Terminology for how much does a starter cost

What Are the Key Technical Properties That Affect Starter Costs?

When evaluating the cost of a starter for automotive applications, several technical properties play a critical role in determining both price and performance. Understanding these properties can help B2B buyers make informed decisions.

1. Composição do material

The material used in the construction of a starter significantly impacts its durability and performance. Common materials include steel and aluminum, which provide strength and resistance to corrosion. High-quality materials ensure that the starter can withstand harsh operating conditions, which is particularly important for international buyers operating in diverse climates. Opting for starters made from premium materials may increase initial costs but often results in lower long-term maintenance expenses.

2. Especificações elétricas

Electrical specifications, including voltage ratings and amperage, are crucial for determining a starter’s compatibility with different vehicle systems. Most automotive starters operate on 12V systems, but variations exist for specific applications. Understanding the electrical requirements ensures that the starter can deliver the necessary power for efficient engine cranking. Buyers should prioritize starters that meet or exceed the OEM specifications for optimal performance.

3. Classificação de binário

The torque rating indicates the rotational force a starter can produce, which is essential for cranking an engine. A higher torque rating generally means better performance in cold weather or for larger engines. For B2B buyers, knowing the torque requirements of their specific vehicle models can help them select starters that will perform reliably under various conditions, reducing the risk of premature failure.

4. Especificações de peso e tamanho

The weight and size of a starter are critical factors that affect installation and compatibility. Starters must fit precisely within the vehicle’s engine compartment, and excessive weight can lead to handling issues. Buyers should consider the dimensions and weight specifications when sourcing starters to ensure they are suitable for their vehicle types, especially for fleets that may operate a variety of models.

Illustrative image related to how much does a starter cost

5. Warranty and Lifespan

A starter’s warranty and expected lifespan are vital for assessing its overall value. Typically, new starters come with warranties ranging from one to three years, while remanufactured starters may offer shorter warranty periods. Understanding the warranty terms can provide insight into the manufacturer’s confidence in their product and help B2B buyers calculate the total cost of ownership.

Quais são os termos comerciais comuns relacionados com os custos iniciais?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are key terms related to starter costs:

1. OEM (Fabricante de Equipamento Original)

OEM refers to parts made by the vehicle’s original manufacturer. These parts are often more expensive but are designed to meet specific performance standards. Buyers should weigh the benefits of OEM parts against aftermarket alternatives to determine the best fit for their needs.

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it can affect inventory management and procurement strategies. Buyers should negotiate MOQs that align with their purchasing capabilities.

3. RFQ (Pedido de Orçamento)

An RFQ is a formal process in which a buyer requests pricing and terms from suppliers for specific products. This document is essential for B2B transactions, allowing buyers to compare offers and negotiate better deals. Crafting a clear RFQ can streamline the procurement process.

Illustrative image related to how much does a starter cost

4. Incoterms (Termos Comerciais Internacionais)

Incoterms define the responsibilities of buyers and sellers in international shipping. Knowing these terms helps buyers understand shipping costs, delivery responsibilities, and risk management. Familiarity with Incoterms is vital for B2B transactions, especially for international buyers from diverse regions.

5. Peças de reposição

Aftermarket parts are components made by manufacturers other than the original equipment manufacturer. These parts can often be more affordable but may vary in quality and compatibility. B2B buyers should carefully assess aftermarket options to ensure they meet their performance and reliability standards.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing starters, ultimately leading to better performance and cost-effectiveness in their operations.

Navigating Market Dynamics and Sourcing Trends in the how much does a starter cost Sector

What Are the Current Market Trends Affecting Starter Costs?

The global market for automotive starters is witnessing significant changes driven by technological advancements and shifting consumer preferences. One of the primary drivers is the increasing demand for electric and hybrid vehicles, which often require specialized starter systems. This trend is particularly notable in regions like Europe and parts of South America, where governmental policies are increasingly favoring sustainable transportation solutions. Consequently, international B2B buyers must be aware of the evolving specifications for starters that cater to these new vehicle types.

Illustrative image related to how much does a starter cost

In addition, the rise of e-commerce platforms has transformed how businesses source starters. Buyers are now more inclined to procure parts directly from online suppliers, allowing for greater price transparency and competitive sourcing. For instance, buyers from Africa and the Middle East can leverage global platforms to access a wider array of products, including remanufactured starters that offer cost savings without sacrificing quality.

Moreover, the market is seeing a trend toward customization, where manufacturers are offering tailored solutions to meet specific needs. This shift is particularly relevant for B2B buyers looking for starters that fit unique vehicle models or performance specifications. As a result, understanding regional market dynamics and consumer preferences will be essential for making informed purchasing decisions.

How Does Sustainability Impact Sourcing for Starters?

Sustainability has become a critical consideration in the sourcing of automotive components, including starters. The environmental impact of traditional manufacturing processes has prompted many companies to seek more sustainable alternatives. Buyers are increasingly prioritizing suppliers that utilize eco-friendly materials and practices, such as recycling old starters or using biodegradable packaging.

Ethical sourcing is also gaining traction as consumers become more conscious of their purchasing decisions. B2B buyers are looking for suppliers that can provide certifications demonstrating sustainable practices, such as ISO 14001 for environmental management or other green certifications. This not only enhances the brand’s reputation but also aligns with global sustainability goals.

Moreover, the long-term benefits of sustainable sourcing can lead to cost savings. For instance, manufacturers that adopt energy-efficient production methods often pass on these savings to their customers, providing a compelling reason for international buyers to engage with responsible suppliers. As the market continues to evolve, integrating sustainability into the sourcing process will be essential for staying competitive.

How Has the Starter Market Evolved Over Time?

The automotive starter market has undergone significant evolution since its inception. Initially, starters were purely mechanical devices, but the introduction of electric starters in the early 20th century revolutionized vehicle ignition systems. This transition was pivotal, as it allowed for more reliable engine starts and improved vehicle performance.

Over the decades, advancements in technology have led to the development of more efficient and compact starter designs, including high-performance and lightweight options. The rise of electronic control systems in vehicles has further transformed starter technology, allowing for enhanced integration with other vehicle components.

Today, the market is not only focused on performance but also on sustainability and efficiency. With increasing regulations surrounding emissions and energy consumption, manufacturers are investing in research and development to create starters that meet stringent environmental standards. This evolution is crucial for international B2B buyers who must navigate a complex landscape of regulations and consumer expectations while sourcing high-quality starters.

Frequently Asked Questions (FAQs) for B2B Buyers of how much does a starter cost

-

How much does a starter cost for different vehicle types?

The cost of a starter can vary significantly depending on the vehicle type. For economy vehicles, aftermarket starters typically range from $75 to $200, while OEM (Original Equipment Manufacturer) starters can cost between $150 and $400. Luxury vehicles or high-performance models may see prices rise to $300 to $1,000 or more due to specialized parts and labor requirements. It’s essential to factor in the specific make and model of the vehicle when estimating costs. -

What factors affect the cost of a starter?

Several key factors influence starter costs, including the type of starter (new vs. remanufactured), the vehicle’s make and model, and labor rates for installation. New starters generally offer longer lifespans but come at a higher price, while remanufactured options can be more budget-friendly but may have a shorter service life. Additionally, if other components are damaged or require replacement, this can further increase overall costs. -

Qual é a quantidade mínima de encomenda (MOQ) para a aquisição de arrancadores a granel?

When sourcing starters for business purposes, the MOQ can vary widely by supplier and the specific type of starter. Typically, MOQs may range from 10 to 100 units, depending on the manufacturer and whether the order consists of standard or custom parts. It is advisable to communicate directly with suppliers to negotiate terms that suit your business needs, especially when considering import logistics. -

How can I vet suppliers for starters in international markets?

To vet suppliers effectively, start by reviewing their certifications and industry reputation. Look for references from other clients, especially those in your target region, and check if they comply with international quality standards. Utilize platforms like Alibaba or Global Sources to find verified suppliers and consult trade organizations for additional insights. Request samples to assess product quality before committing to a larger order. -

What payment terms should I negotiate when sourcing starters internationally?

Payment terms can vary based on the supplier and the nature of the transaction. Common options include advance payment, letters of credit, or payment upon delivery. For international transactions, it’s prudent to negotiate terms that protect your interests, such as partial payment upfront and the balance upon receipt of goods. Ensure clarity on currency exchange rates and additional fees to avoid unexpected costs. -

What quality assurance measures should I expect from starters suppliers?

Reputable suppliers should offer quality assurance measures, including product warranties and return policies. Look for suppliers that conduct rigorous testing on their starters to ensure they meet industry standards. Certifications like ISO 9001 can indicate a commitment to quality. Additionally, inquire about their production processes and whether they have protocols for defect management and customer feedback. -

What are the logistics considerations when importing starters?

Logistics considerations include shipping methods, customs duties, and lead times. Determine whether air freight or sea freight best suits your timeline and budget. Be aware of potential tariffs and import regulations in your country, as these can significantly impact costs. Work with a freight forwarder to navigate the complexities of international shipping and ensure timely delivery of your products. -

Can I customize starters for specific applications?

Yes, many manufacturers offer customization options for starters to meet specific application requirements. This may include modifications to size, voltage, or performance features. When discussing customization, provide detailed specifications and any particular performance expectations. Be prepared for potential minimum order quantities for customized parts and ensure clear communication regarding timelines and costs associated with modifications.

Top 5 How Much Does A Starter Cost Manufacturers & Suppliers List

1. Reddit - Custos de substituição do motor de arranque

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: Starter replacement, labor charges, diagnostics fees, OEM starter pricing, price variations by location, markup on parts.

2. Last Chance Auto Repairs – Starter Replacement Services

Domínio: últimareparosautomóveis.com

Registado: 2009 (16 anos)

Introdução: Starter Replacement Cost: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. Labor costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Common symptoms of a failing starter include: car won’t start, clicking noise, slow engine cranking, burning smell, intermittent starting issues. Factors affecting cost: Vehicle…

3. Facebook – Starter Replacement Cost

Domínio: facebook.com

Registado: 1997 (28 anos)

Introdução: custo para levar o carro à oficina e substituir o motor de arranque

4. CarParts.com – Car Starters

Domínio: carparts.com

Registado: 1999 (26 anos)

Introdução: Car Starters – Standard, Reverse Rotation from $75 | CarParts.com. Wide selection of high-quality replacement starters, both new and remanufactured. Guaranteed to fit. Fast shipping and hassle-free returns. Offers from best brands. Signs of a bad starter include engine not cranking, oil on the starter, and smoke from the vehicle.

5. Best Buy – Remote Car Starters

Domínio: bestbuy.com

Registada: 1994 (31 anos)

Introdução: Remote Car Starters available at Best Buy include 2179 items from brands such as Compustar, Viper, AVITAL, MPC, Start-X, and Car Keys Express. Features include 2-Way Paging, Keyless Entry, Self-Programmable, Panic Mode, App Compatibility, Remote Car Finder, and Automatic Incident Detection with G-Sensor. Products are sorted by best-selling and include discounts of 20% or more. Customer ratings are…

Strategic Sourcing Conclusion and Outlook for how much does a starter cost

In conclusion, understanding the cost of car starters is crucial for international B2B buyers looking to make informed purchasing decisions. Prices for starters can vary widely, influenced by factors such as vehicle type, brand, and whether you opt for new or remanufactured options. On average, buyers can expect to spend between $75 and $400 for parts alone, with additional labor costs ranging from $100 to $600, depending on the complexity of the installation.

Illustrative image related to how much does a starter cost

Strategic sourcing in this context is vital. By establishing strong relationships with reliable suppliers and manufacturers, businesses can secure better pricing, ensure quality, and improve supply chain efficiencies. This not only helps in reducing costs but also enhances the overall customer experience.

Looking ahead, as the automotive market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, staying abreast of market trends and supplier innovations will be essential. We encourage B2B buyers to actively engage with suppliers, request detailed quotes, and consider the long-term benefits of investing in quality starters. This proactive approach will empower your business to thrive in a competitive landscape.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.