Introdução: Navegando no mercado global de alternadores apex

No cenário competitivo do comércio global, o fornecimento de alternadores apex de alta qualidade representa um desafio significativo para os compradores B2B internacionais. Quer esteja a operar no sector automóvel no Brasil ou na indústria energética na Alemanha, a necessidade de alternadores fiáveis e eficientes é fundamental. Este guia serve como um recurso abrangente, explorando vários tipos de alternadores apex, suas aplicações em diferentes indústrias e as complexidades da verificação de fornecedores.

Os compradores obterão informações sobre os mais recentes avanços tecnológicos que distinguem os alternadores apex dos modelos tradicionais, garantindo que toma decisões informadas que melhoram a sua eficiência operacional. Além disso, iremos analisar as estruturas de preços, as opções de pagamento e as políticas de garantia, abordando as considerações de custos que são cruciais para as empresas em África, na América do Sul, no Médio Oriente e na Europa.

Ao equipá-lo com conhecimentos práticos e orientação estratégica, este guia permite-lhe navegar com confiança nas complexidades do aprovisionamento de alternadores apex. Com um enfoque na promoção da transparência e fiabilidade nas relações com os fornecedores, pode simplificar o seu processo de compra e, em última análise, gerar valor para a sua empresa.

Índice

- Lista dos 7 principais fabricantes e fornecedores de alternadores Apex

- Introdução: Navegando no mercado global de alternadores apex

- Compreender os tipos e as variações do alternador apex

- Principais aplicações industriais do alternador apex

- 3 Pontos de dor comuns dos utilizadores para ‘apex alternator’ e as suas soluções

- Guia de seleção de materiais estratégicos para o alternador apex

- Análise aprofundada: Processos de fabrico e garantia de qualidade para o alternador apex

- Guia prático de abastecimento: Uma lista de controlo passo a passo para ‘apex alternator’

- Análise exaustiva dos custos e dos preços para o fornecimento de alternadores apex

- Análise de alternativas: Comparação do alternador apex com outras soluções

- Propriedades técnicas essenciais e terminologia comercial para o alternador apex

- Navegar na dinâmica do mercado e nas tendências de abastecimento no sector dos alternadores de topo

- Perguntas mais frequentes (FAQs) para compradores B2B de alternador apex

- Conclusão sobre o aprovisionamento estratégico e perspectivas para o alternador apex

- Aviso legal importante e termos de utilização

Compreender os tipos e as variações do alternador apex

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Alternador de alto rendimento | Gama de 120 a 500 amperes, acabamentos personalizáveis | Máquinas pesadas, veículos especializados | Prós: Elevada potência de saída, personalizável; Contras: Custo inicial mais elevado, pode exigir conhecimentos específicos de instalação. |

| Alternador compacto | Pegada mais pequena, design leve | Automóvel, motociclos | Prós: Poupança de espaço, leveza; Contras: Capacidade de energia limitada, pode não ser adequada para aplicações de elevada exigência. |

| Alternador marítimo | Materiais resistentes à corrosão, design à prova de água | Embarcações marítimas, iates | Prós: Durável em condições adversas; Contras: Muitas vezes mais caro, é necessária uma manutenção especializada. |

| Alternador industrial | Concebida para um funcionamento contínuo, elevada durabilidade | Instalações de fabrico, equipamento industrial | Prós: Longa vida útil, desempenho fiável; Contras: Investimento inicial mais elevado, instalação potencialmente complexa. |

| Alternador personalizado | Especificações personalizadas com base nas necessidades do cliente | Mercados de nicho, veículos personalizados | Prós: Adaptação perfeita para aplicações específicas; Contras: Prazos de entrega mais longos, potencial para custos mais elevados. |

Quais são as principais caraterísticas dos alternadores de alto rendimento?

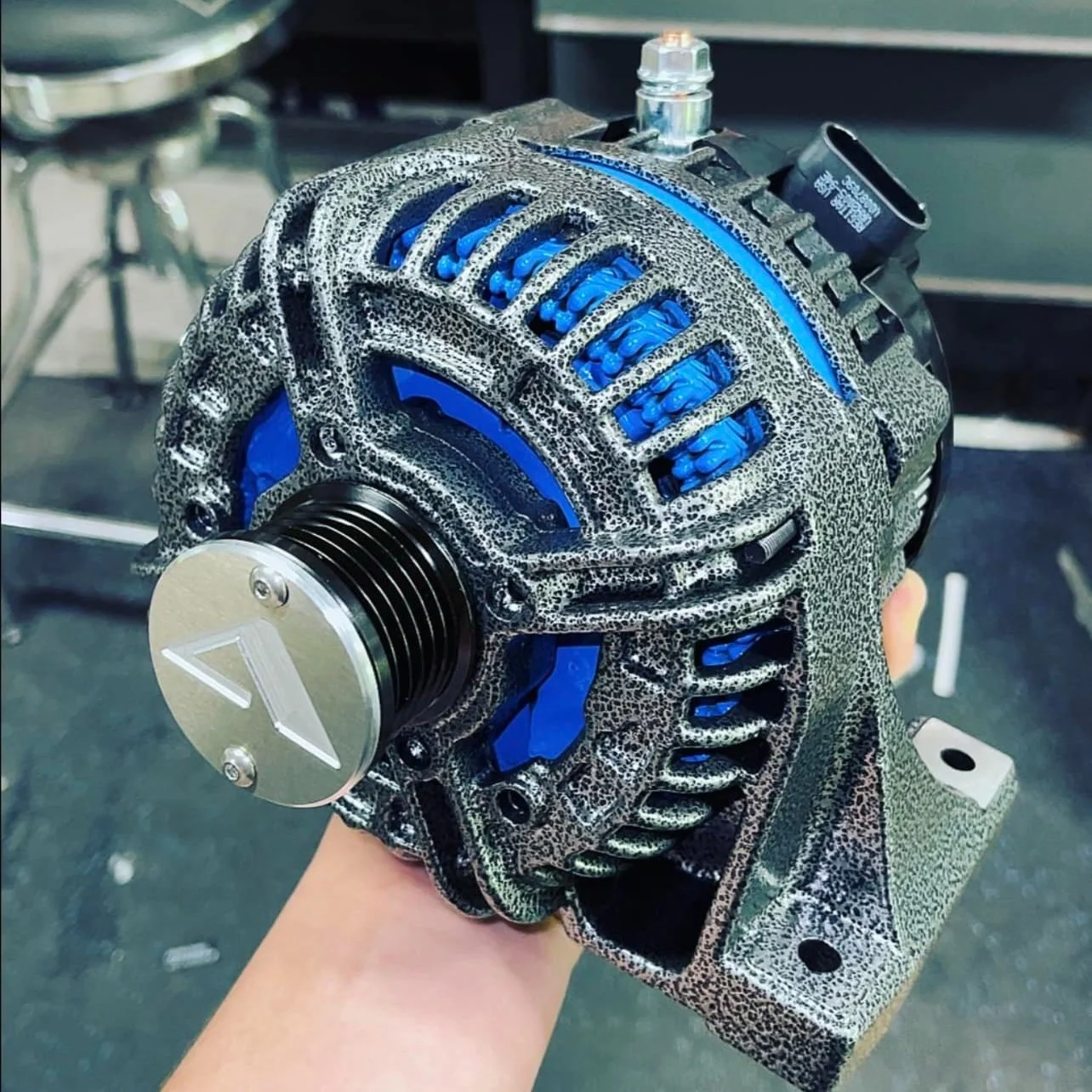

Os alternadores de alto rendimento são concebidos para fornecer uma potência significativa, normalmente entre 120 e 500 amperes. Este tipo de alternador é ideal para aplicações que exijam grandes necessidades eléctricas, tais como maquinaria pesada ou veículos especializados. Os compradores devem considerar os requisitos específicos de amperagem do seu veículo ou equipamento para garantir a compatibilidade. Além disso, as opções de personalização, como a correspondência de cores, podem melhorar o apelo estético sem comprometer a funcionalidade.

Como é que os alternadores compactos diferem dos outros tipos?

Os alternadores compactos são concebidos para aplicações em que o espaço é escasso, como em automóveis ou motociclos. Estas unidades são leves e de tamanho mais pequeno, o que facilita a sua instalação em espaços apertados. No entanto, a sua potência pode ser limitada em comparação com os modelos maiores. As empresas devem avaliar cuidadosamente as suas necessidades de energia, uma vez que a opção por um alternador compacto pode levar a um desempenho inferior em cenários de elevada procura.

O que torna os alternadores marítimos essenciais para aplicações marítimas?

Os alternadores marítimos são especificamente construídos para resistir a ambientes marítimos corrosivos, apresentando designs à prova de água e materiais resistentes à corrosão. São cruciais para embarcações marítimas e iates, garantindo um fornecimento de energia fiável em condições difíceis. Aquando da compra, os compradores B2B devem dar prioridade aos requisitos de durabilidade e manutenção, uma vez que os alternadores marítimos podem ter custos mais elevados devido à sua natureza especializada.

Porquê escolher alternadores industriais para as necessidades de fabrico?

Os alternadores industriais são construídos para funcionamento contínuo e elevada durabilidade, tornando-os adequados para fábricas e equipamento industrial pesado. O seu design robusto garante fiabilidade e uma longa vida útil, essenciais para empresas que dependem de uma alimentação eléctrica constante. No entanto, muitas vezes têm um custo inicial mais elevado e podem exigir uma instalação especializada. As empresas devem avaliar os benefícios a longo prazo em relação aos investimentos iniciais.

Como é que os alternadores personalizados beneficiam os mercados de nicho?

Os alternadores personalizados são concebidos para satisfazer os requisitos específicos de nichos de mercado ou veículos especializados. Esta personalização permite às empresas obter um ajuste perfeito para as suas aplicações únicas, melhorando a eficiência e o desempenho. No entanto, a contrapartida inclui prazos de entrega mais longos e custos potencialmente mais elevados. Os compradores B2B devem ponderar a necessidade de personalização em relação à urgência dos seus projectos para tomarem decisões informadas.

Principais aplicações industriais do alternador apex

| Indústria/Setor | Aplicação específica do alternador apex | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Automotivo | Veículos de alto desempenho | Potência eléctrica melhorada para sistemas avançados de veículos | Compatibilidade com modelos de veículos, requisitos de amperagem |

| Construção | Máquinas e equipamentos pesados | Alimentação eléctrica fiável para ferramentas e máquinas | Durabilidade, capacidade de carga e resistência ambiental |

| Energia renovável | Sistemas de energia solar | Conversão e armazenamento eficientes de energia | Requisitos de tensão, integração com sistemas existentes |

| Marinha | Barcos e iates | Energia consistente para sistemas de navegação e de bordo | Resistência à água, considerações de peso e especificações personalizadas |

| Agricultura | Máquinas agrícolas | Energia sustentada para equipamentos de irrigação e colheita | Robustez, necessidades de amperagem e termos de garantia |

Como é que o alternador de vértice é utilizado no sector automóvel?

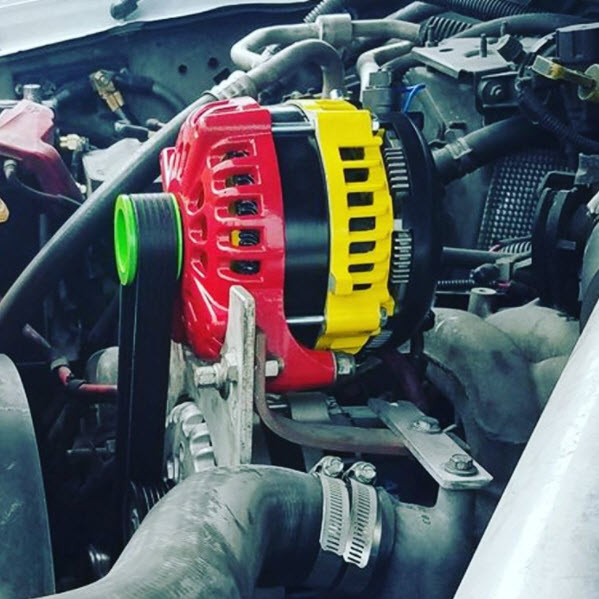

Na indústria automóvel, os alternadores apex são utilizados principalmente em veículos de alto desempenho, onde é crucial uma maior potência eléctrica. Estes alternadores podem fornecer entre 120 a 500 amperes, suportando sistemas avançados de veículos como sistemas de som, GPS e iluminação LED. Para os compradores internacionais, especialmente de regiões com normas eléctricas variáveis, é essencial garantir a compatibilidade com modelos de veículos específicos e requisitos de amperagem. Os alternadores Apex ajudam a resolver o problema da alimentação eléctrica inadequada, que pode levar a falhas no sistema e a um desempenho reduzido do veículo.

Que papel desempenha o alternador apex nos equipamentos de construção?

Na construção, os alternadores apex são vitais para máquinas e equipamentos pesados que requerem uma fonte de alimentação consistente e fiável. Estes alternadores podem ser integrados em escavadoras, gruas e outras máquinas, assegurando que as ferramentas funcionam eficientemente no local. A vantagem para as empresas de construção reside na redução do tempo de inatividade causado por falhas de energia. Os compradores devem considerar a durabilidade e a capacidade de carga dos alternadores, especialmente em condições de trabalho difíceis, juntamente com a sua resistência ambiental ao pó e à humidade.

Como é que o alternador apex melhora os sistemas de energias renováveis?

Em aplicações de energias renováveis, particularmente em sistemas de energia solar, os alternadores apex são utilizados para converter e armazenar energia de forma eficiente. Desempenham um papel fundamental na manutenção do equilíbrio elétrico necessário para os painéis solares e sistemas de baterias, assegurando um desempenho ótimo. Para os compradores B2B neste sector, é crucial compreender os requisitos de tensão e a forma como os alternadores se integram nos sistemas existentes. Esta aplicação aborda o desafio do armazenamento de energia e da eficiência de conversão, ajudando as empresas a maximizar os seus investimentos em energias renováveis.

Que vantagens oferece o alternador apex para as aplicações marítimas?

Na indústria marítima, os alternadores apex são essenciais para barcos e iates, fornecendo uma fonte de energia fiável para sistemas de navegação, iluminação e eletrónica a bordo. A saída eléctrica consistente garante que os sistemas críticos permaneçam operacionais, aumentando a segurança e a facilidade de utilização na água. Os compradores deste sector devem dar prioridade à resistência à água e às considerações de peso ao adquirirem alternadores, uma vez que estes factores têm um impacto significativo no desempenho e na eficiência da embarcação. Podem também ser necessárias especificações personalizadas para se adaptarem a aplicações marítimas específicas.

Como é que o alternador apex apoia as máquinas agrícolas?

Os alternadores Apex são cada vez mais utilizados em maquinaria agrícola para garantir uma alimentação eléctrica sustentada para equipamento de irrigação e colheita. Estes alternadores ajudam a otimizar a eficiência das operações agrícolas, permitindo práticas agrícolas atempadas e eficazes. Os compradores internacionais devem prestar atenção às necessidades de robustez e amperagem dos alternadores, uma vez que estas especificações influenciam diretamente o desempenho das máquinas agrícolas em diversas condições ambientais. Além disso, os termos da garantia podem assegurar a qualidade e a fiabilidade em aplicações agrícolas exigentes.

3 Pontos de dor comuns dos utilizadores para ‘apex alternator’ e as suas soluções

Cenário 1: Navegando por requisitos de alta potência para veículos especializados

O problema: Os compradores B2B enfrentam muitas vezes desafios no fornecimento de alternadores que possam satisfazer as necessidades específicas de energia de veículos especializados, tais como unidades de resposta a emergências ou camiões pesados. Estes veículos requerem frequentemente alternadores de alto rendimento, normalmente na ordem dos 300 a 500 amperes, para alimentar eficazmente numerosos sistemas e equipamentos electrónicos. Uma incompatibilidade entre os requisitos do veículo e as capacidades do alternador pode levar a problemas de desempenho, tempo de inatividade do veículo e aumento dos custos operacionais.

A solução: Para enfrentar este desafio, os compradores B2B devem realizar uma avaliação completa das necessidades eléctricas do seu veículo antes de adquirirem um alternador apex. Comece por consultar o manual de serviço do veículo ou contacte o fabricante para determinar os requisitos exactos de amperagem. Depois de estabelecer estas especificações, contacte fornecedores de renome que ofereçam alternadores de alto rendimento personalizados. A Apex Alternators, por exemplo, oferece opções adaptadas a necessidades específicas de potência, garantindo compatibilidade e desempenho. Além disso, solicitar um vídeo de teste de carga antes do envio pode servir como uma etapa de garantia de qualidade, confirmando que o alternador fornecerá a potência necessária.

Cenário 2: Preocupações com a fiabilidade e a durabilidade

O problema: Muitos compradores internacionais estão preocupados com a fiabilidade e a longevidade dos alternadores, particularmente em regiões com climas ou terrenos difíceis. Os alternadores que falham prematuramente podem resultar em reparações dispendiosas e tempos de inatividade inesperados, o que é particularmente prejudicial para as empresas que dependem de veículos para operações críticas, como a logística ou os serviços de emergência.

A solução: Para atenuar as preocupações relativas à durabilidade, os compradores devem dar prioridade ao fornecimento de alternadores fabricados com componentes de alta qualidade e processos de fabrico avançados. A Apex Alternators, por exemplo, dá ênfase à utilização de materiais de primeira qualidade concebidos para a longevidade. Os compradores devem também informar-se sobre as opções de garantia, uma vez que uma garantia robusta indica a confiança do fabricante na durabilidade do seu produto. Além disso, o estabelecimento de um calendário de manutenção que inclua verificações regulares do alternador pode ajudar a identificar potenciais problemas antes que estes conduzam a uma falha. Esta abordagem proactiva pode aumentar significativamente a fiabilidade do alternador ao longo do tempo.

Cenário 3: Gerir as necessidades e os custos de personalização

O problema: A personalização é muitas vezes um ponto problemático significativo para os compradores B2B, especialmente quando exigem cores ou modificações específicas para se adequarem à sua marca ou requisitos operacionais. As encomendas personalizadas podem originar confusão, custos acrescidos e prazos de entrega mais longos, o que torna fundamental que as empresas encontrem um equilíbrio entre a personalização e as restrições orçamentais.

A solução: Para gerir eficazmente as necessidades de personalização, os compradores devem comunicar claramente as suas especificações antecipadamente ao fabricante. Por exemplo, ao lidar com os alternadores Apex, fornecer o código exato da tinta para correspondência de cores pode simplificar o processo de personalização. Além disso, a compreensão da estrutura de preços - normalmente entre $300 e $700 - pode ajudar as empresas a efetuar um orçamento adequado. Os compradores devem também explorar os planos de pagamento oferecidos pelos fabricantes, o que pode aliviar os encargos financeiros das encomendas personalizadas. Por último, o estabelecimento de um calendário claro para a produção e entrega ajudará a definir expectativas realistas e a minimizar as perturbações nas operações. Ao adotar estes passos, as empresas podem atingir o nível de personalização desejado sem comprometer a qualidade ou o orçamento.

Guia de seleção de materiais estratégicos para o alternador apex

Que materiais são normalmente utilizados nos alternadores Apex?

Ao selecionar materiais para alternadores de vértice, é crucial compreender as propriedades, vantagens e limitações dos vários materiais. Este conhecimento ajuda os compradores B2B internacionais a tomar decisões informadas que se alinham com as suas necessidades operacionais e requisitos de conformidade.

Alumínio: Uma opção leve com elevada condutividade

O alumínio é uma escolha popular para caixas e componentes de alternadores devido à sua natureza leve e excelente condutividade eléctrica. Normalmente, tem uma temperatura nominal de até 150°C e oferece resistência moderada à corrosão, especialmente quando anodizado.

Prós: As principais vantagens do alumínio incluem o seu baixo peso, que aumenta a eficiência do combustível nos veículos, e a sua relação custo-eficácia em comparação com outros metais. Além disso, o alumínio é fácil de maquinar e fabricar, reduzindo a complexidade do fabrico.

Contras: No entanto, o alumínio é menos durável do que o aço e pode ser propenso a deformações sob tensão elevada. A sua resistência à corrosão é também limitada, a menos que seja tratada, o que pode aumentar os custos de fabrico.

Impacto na aplicação: O alumínio é adequado para aplicações em que a redução de peso é fundamental, como nos veículos de alto desempenho. No entanto, a sua menor resistência pode não ser ideal para aplicações pesadas.

Considerações para compradores internacionais: Os compradores em regiões como a Europa e o Médio Oriente devem assegurar o cumprimento de normas como a ASTM B221 para extrusões de alumínio. A preferência pelo alumínio pode variar em função das capacidades de fabrico locais e das condições ambientais.

Imagem ilustrativa relacionada com o alternador apex

Aço: O cavalo de batalha durável

O aço é outro material comum utilizado nos alternadores apex, particularmente para componentes que requerem elevada resistência e durabilidade. Pode suportar temperaturas superiores a 300°C e oferece uma excelente resistência à corrosão quando corretamente revestido.

Prós: A principal vantagem do aço é a sua robustez, tornando-o adequado para aplicações pesadas. É também relativamente barato e está amplamente disponível, o que pode reduzir os custos globais de produção.

Contras: Em contrapartida, o aço é mais pesado do que o alumínio, o que pode ter um impacto negativo na eficiência do combustível. Além disso, pode exigir processos de fabrico mais complexos, como a soldadura ou a maquinagem.

Impacto na aplicação: O aço é ideal para aplicações que exigem elevada resistência e durabilidade, como em veículos comerciais ou máquinas industriais. O seu peso pode ser um fator a considerar em aplicações orientadas para o desempenho.

Considerações para compradores internacionais: Os compradores devem estar cientes do cumprimento de normas como a DIN 17100 para o aço estrutural. Em regiões como o Brasil, o fornecimento local de aço pode também afetar os custos e os prazos de entrega.

Cobre: O condutor elétrico

O cobre é frequentemente utilizado para enrolamentos e ligações em alternadores devido à sua superior condutividade eléctrica. Pode suportar temperaturas elevadas, normalmente até 200°C, e tem uma excelente resistência à corrosão quando isolado.

Prós: A principal vantagem do cobre é a sua excelente condutividade, que aumenta a eficiência do alternador. É também muito durável e resistente à fadiga, o que o torna adequado para uma utilização a longo prazo.

Contras: A principal desvantagem é o seu elevado custo em comparação com o alumínio e o aço. Além disso, o cobre é mais pesado, o que pode ser uma desvantagem em aplicações sensíveis ao peso.

Impacto na aplicação: O cobre é essencial para aplicações que requerem uma elevada eficiência eléctrica, como em veículos eléctricos ou sistemas de alto desempenho. No entanto, o seu peso e custo podem limitar a sua utilização em projectos sensíveis ao orçamento.

Considerações para compradores internacionais: O cumprimento de normas como a ASTM B170 para o fio de cobre é essencial. Os compradores em África e na América do Sul podem também ter de considerar a disponibilidade e as flutuações de custo do cobre nas suas regiões.

Imagem ilustrativa relacionada com o alternador apex

Materiais compostos: O futuro do design de alternadores

Os materiais compósitos estão a ser cada vez mais explorados para aplicações em alternadores devido às suas propriedades únicas. Estes materiais podem oferecer elevadas relações força/peso e uma excelente resistência à corrosão.

Prós: A principal vantagem dos materiais compósitos é a sua leveza, que pode melhorar significativamente o desempenho do veículo. Além disso, oferecem uma resistência superior aos factores ambientais, aumentando a longevidade do alternador.

Contras: No entanto, o fabrico dos compósitos pode ser dispendioso e pode exigir processos especializados para o seu fabrico. As suas propriedades mecânicas podem também variar muito em função da formulação específica utilizada.

Impacto na aplicação: Os compósitos são ideais para aplicações de elevado desempenho em que a redução de peso é fundamental. No entanto, o seu custo pode limitar a adoção em mercados mais tradicionais.

Imagem ilustrativa relacionada com o alternador apex

Considerações para compradores internacionais: Os compradores devem estar conscientes da evolução das normas aplicáveis aos materiais compósitos, que podem não estar tão estabelecidas como as aplicáveis aos metais. Regiões como a Europa podem ter regulamentos específicos relativos à utilização de materiais compósitos em aplicações automóveis.

Tabela de resumo da seleção de materiais para os alternadores Apex

| Material | Caso de uso típico para o alternador apex | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Caixas e componentes leves | Leve e económico | Menor durabilidade em comparação com o aço | Médio |

| Aço | Componentes resistentes | Alta resistência e durabilidade | Mais pesado, o que afecta a eficiência do combustível | Baixo |

| Cobre | Enrolamentos e ligações elétricas | Condutividade elétrica superior | Custo e peso elevados | Alto |

| Compósito | Aplicações de alto desempenho | Leve e resistente à corrosão | Caro e complexo de fabricar | Alto |

Este guia de seleção de materiais fornece uma visão geral abrangente dos materiais normalmente utilizados nos alternadores apex, permitindo que os compradores B2B internacionais tomem decisões informadas que se alinham com as suas necessidades operacionais e requisitos de conformidade.

Análise aprofundada: Processos de fabrico e garantia de qualidade para o alternador apex

Quais são as principais etapas do processo de fabrico dos alternadores Apex?

O fabrico dos alternadores Apex envolve uma série de fases meticulosamente planeadas, cada uma delas concebida para garantir que o produto final cumpre os padrões de elevado desempenho. As fases principais incluem a preparação do material, a moldagem, a montagem e o acabamento.

Como é que o material é preparado para os alternadores Apex?

A fase inicial do fabrico dos alternadores Apex começa com a seleção cuidadosa de matérias-primas de alta qualidade. Os componentes incluem frequentemente fio de cobre para os enrolamentos, ligas duráveis para a caixa e outras peças essenciais que contribuem para a eficiência e longevidade do alternador.

Imagem ilustrativa relacionada com o alternador apex

Uma vez obtidos os materiais, estes são submetidos a rigorosos controlos de qualidade para garantir que cumprem as especificações exigidas. Isto inclui a avaliação da pureza dos metais e a integridade dos materiais de isolamento. A documentação correta das certificações dos materiais é essencial, especialmente para os compradores internacionais que podem exigir o cumprimento de normas específicas.

Que técnicas são empregues na formação de alternadores Apex?

A fase de moldagem envolve a transformação das matérias-primas em componentes utilizáveis. Técnicas como a estampagem, a maquinagem e o forjamento são normalmente utilizadas para criar peças como o estator e o rotor.

A precisão é crucial nesta fase; as máquinas CNC (Controlo Numérico Computadorizado) são frequentemente utilizadas para garantir que cada peça é fabricada de acordo com especificações exactas. Este nível de precisão é vital para o desempenho global do alternador, uma vez que qualquer desvio pode afetar a sua eficiência e fiabilidade.

Como funciona o processo de montagem dos alternadores Apex?

Após a fase de moldagem, o processo de montagem decorre num ambiente limpo e controlado. Técnicos qualificados montam os vários componentes, incluindo o rotor, o estator e o regulador de tensão.

Durante a montagem, cada alternador é submetido a várias verificações para garantir o ajuste e o funcionamento corretos. Isto inclui a verificação do alinhamento do rotor e do estator, que é crucial para uma conversão de energia óptima.

Que técnicas de acabamento são aplicadas aos alternadores Apex?

A fase de acabamento envolve vários processos destinados a melhorar a durabilidade e o aspeto dos alternadores. Pode incluir pintura, revestimento para resistência à corrosão e controlos de qualidade para detetar defeitos estéticos.

Podem ser utilizadas técnicas especializadas, como o revestimento a pó, para garantir um acabamento robusto que resista aos factores ambientais, o que é particularmente importante para os mercados internacionais, onde as condições podem variar significativamente.

Como é que a garantia de qualidade é integrada em todo o processo de fabrico?

A garantia de qualidade é um componente crítico no fabrico dos alternadores Apex, assegurando que cada unidade cumpre as normas internacionais e as expectativas dos clientes.

Que normas internacionais se aplicam aos alternadores Apex?

Os alternadores Apex são fabricados em conformidade com várias normas de qualidade internacionais, incluindo a ISO 9001, que define os critérios para um sistema de gestão da qualidade. Esta certificação demonstra que o fabricante fornece consistentemente produtos que cumprem os requisitos regulamentares e do cliente.

Imagem ilustrativa relacionada com o alternador apex

Para além da ISO 9001, a conformidade com a marcação CE (Conformité Européenne) é essencial para a venda de produtos nos mercados europeus, garantindo normas de segurança, saúde e proteção ambiental. Outras certificações relevantes podem incluir as normas API (American Petroleum Institute) para aplicações industriais específicas.

Quais são os principais pontos de verificação do controlo de qualidade no processo de fabrico?

Os pontos de verificação do controlo de qualidade (CQ) estão estrategicamente colocados ao longo do processo de fabrico para detetar defeitos precocemente e garantir que o produto final é da mais elevada qualidade.

-

Controlo de Qualidade de Entrada (IQC): Esta fase avalia as matérias-primas e os componentes aquando da sua receção para garantir que cumprem as especificações predefinidas.

-

Controlo de qualidade em processo (IPQC): As verificações contínuas durante o processo de fabrico ajudam a identificar e a retificar problemas em tempo real. Isto inclui a monitorização das tolerâncias durante a maquinagem e a verificação da precisão da montagem.

-

Controlo de Qualidade Final (FQC): Antes da expedição, cada alternador é submetido a uma inspeção exaustiva, que pode incluir testes de carga e avaliações de desempenho para verificar se cumpre as normas operacionais.

Que métodos de ensaio comuns são utilizados para os alternadores Apex?

Para validar o desempenho e a fiabilidade dos alternadores, são utilizados vários métodos de ensaio. Estes podem incluir:

- Teste de carga: Assegurar que o alternador pode gerir a sua potência nominal em diferentes condições.

- Testes térmicos: Avaliar o desempenho do alternador a diferentes temperaturas, crucial para regiões com climas extremos.

- Teste de vibração: Avaliar a durabilidade do alternador sob tensão operacional para prever a sua duração de vida.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

Para os compradores B2B internacionais, especialmente os de África, América do Sul, Médio Oriente e Europa, a verificação do controlo de qualidade do fornecedor é fundamental. Eis algumas estratégias eficazes:

-

Auditorias a fornecedores: A realização de auditorias regulares às instalações de fabrico pode fornecer informações sobre os processos de qualidade em vigor. Isto inclui a revisão da documentação, dos processos e da conformidade com as normas.

-

Pedido de relatórios de qualidade: Os fornecedores devem ser capazes de fornecer relatórios de qualidade detalhados, incluindo resultados de inspecções e certificações de testes.

-

Inspeções por terceiros: A contratação de agências de inspeção de terceiros pode oferecer uma avaliação imparcial dos processos de fabrico e da qualidade do produto, garantindo que o fornecedor cumpre as normas internacionais.

Quais são as nuances das certificações de controlo de qualidade para compradores internacionais B2B?

Ao lidar com fornecedores internacionais, é essencial compreender que as certificações de controlo de qualidade podem variar em termos de importância e aplicação nas diferentes regiões.

-

Diferenças regulamentares: Alguns países podem ter regulamentos mais rigorosos do que outros, necessitando de certificações adicionais ou verificações de conformidade. Por exemplo, os produtos vendidos na União Europeia têm de cumprir os requisitos da marcação CE, que podem não ser tão rigorosos noutros mercados.

-

Considerações culturais: Compreender as práticas comerciais e as nuances culturais dos fornecedores de diferentes regiões pode facilitar uma melhor comunicação e expectativas em relação à garantia de qualidade.

Ao concentrarem-se nestes processos de fabrico e práticas de garantia de qualidade, os compradores B2B podem garantir que estão a adquirir alternadores Apex de alta qualidade que satisfazem as suas necessidades específicas e cumprem as normas internacionais.

Guia prático de abastecimento: Uma lista de controlo passo a passo para ‘apex alternator’

No mercado competitivo de hoje, o fornecimento de alternadores apex de alta qualidade requer uma abordagem estratégica para garantir um desempenho e fiabilidade óptimos. Este guia ajudará os compradores B2B a navegar eficazmente no processo de aquisição, permitindo-lhes tomar decisões informadas.

Passo 1: Defina as suas especificações técnicas

Antes de iniciar o processo de aprovisionamento, é essencial delinear os requisitos técnicos específicos para os alternadores de que necessita. Determine factores como a amperagem (que varia entre 120 e 500 amperes), a compatibilidade com vários modelos de veículos e quaisquer personalizações necessárias, como a correspondência de cores. Especificações claramente definidas simplificarão o processo de seleção do fornecedor e garantirão que recebe o produto certo para as suas necessidades.

Passo 2: Pesquisar potenciais fornecedores

Efetuar uma pesquisa aprofundada sobre os fornecedores especializados em alternadores apex. Procure fabricantes com um historial comprovado de fornecimento de produtos de alta qualidade. Considere o seguinte:

– Reputação no sector: Consulte as análises em linha e os testemunhos de outros compradores B2B.

– Experiência: Concentre-se nos fornecedores com uma vasta experiência na sua região de mercado específica, como a África, a América do Sul, o Médio Oriente ou a Europa.

Passo 3: Avaliar as certificações dos fornecedores

Assegurar-se de que os seus potenciais fornecedores possuem certificações relevantes é crucial para a garantia de qualidade. As certificações podem indicar o cumprimento de normas de qualidade internacionais e regulamentos de segurança. Verifique o seguinte:

– Certificações ISO: Procure certificações ISO 9001 ou similares que demonstrem um compromisso com a gestão da qualidade.

– Conformidade local: Certifique-se de que os fornecedores cumprem quaisquer regulamentos regionais aplicáveis aos alternadores no seu mercado-alvo.

Passo 4: Pedir orçamentos pormenorizados

Depois de ter selecionado os potenciais fornecedores, solicite orçamentos detalhados que incluam preços, condições de pagamento e informações sobre garantias. Um orçamento completo ajudá-lo-á a comparar as opções de forma eficaz. Preste atenção a:

– Estrutura de preços: Perceber se o preço varia com base em personalizações ou encomendas em massa.

– Condições de garantia: Procure garantias que cubram não só o produto, mas também quaisquer custos de mão de obra associados.

Passo 5: Rever as opções de envio e entrega

Discuta as opções de envio e entrega com os fornecedores selecionados. Uma logística eficiente é crucial para minimizar o tempo de inatividade nas suas operações. Considere:

– Custos de envio: Certifique-se de que tem conhecimento de todas as taxas de envio e das responsabilidades de ambas as partes.

– Prazos de entrega: Confirmar os prazos de entrega para evitar atrasos que possam afetar as operações da sua empresa.

Imagem ilustrativa relacionada com o alternador apex

Passo 6: Efetuar um controlo de garantia de qualidade

Antes de finalizar a sua encomenda, solicite um vídeo de teste de carga ou documentação semelhante para verificar o desempenho do alternador. Este passo é vital para garantir que o produto cumpre as suas especificações e normas de qualidade. Procurar:

– Métricas de desempenho: Assegurar-se de que o alternador funciona dentro da gama de amperagem especificada.

– Documentação de teste: Solicitar provas dos controlos de qualidade efectuados durante a produção.

Passo 7: Estabeleça um plano de comunicação

Uma comunicação eficaz com o seu fornecedor é essencial durante todo o processo de aprovisionamento. Estabeleça um ponto de contacto claro e defina expectativas para actualizações sobre o estado da encomenda e quaisquer problemas potenciais. Considerar:

– Actualizações regulares: Agende check-ins para se manter informado sobre o progresso da sua encomenda.

– Mecanismo de feedback: Implementar um sistema para abordar quaisquer preocupações ou ajustamentos necessários durante o processo de aprovisionamento.

Seguindo esta lista de verificação, os compradores B2B podem navegar com confiança na aquisição de alternadores apex, garantindo que escolhem as melhores opções para as suas necessidades operacionais.

Imagem ilustrativa relacionada com o alternador apex

Análise exaustiva dos custos e dos preços para o fornecimento de alternadores apex

Analisar a estrutura de custos e os preços dos alternadores apex é essencial para os compradores B2B internacionais que procuram tomar decisões de aprovisionamento informadas. Compreender os componentes que contribuem para o custo global pode ajudar os compradores a negociar melhores preços e a otimizar a sua estratégia de aquisição.

Quais são os principais componentes de custo dos alternadores Apex?

-

Materiais: A qualidade dos materiais utilizados no fabrico dos alternadores apex influencia significativamente o preço. Os componentes de alta qualidade, como os enrolamentos de cobre, as carcaças duráveis e os sistemas electrónicos avançados, melhoram o desempenho e a longevidade, mas também aumentam o custo. Os compradores devem informar-se sobre os materiais específicos utilizados e a sua origem para garantir que cumprem as normas da indústria.

-

Trabalho: Os custos de mão de obra variam consoante o local de fabrico e o nível de competência necessário para a montagem. Em regiões com custos de mão de obra mais baixos, como partes da América do Sul ou de África, os fabricantes podem oferecer preços competitivos. No entanto, pode ser necessária mão de obra altamente qualificada para alternadores personalizados ou de alto rendimento, o que pode aumentar os custos.

-

Custos indiretos de produção: Inclui as despesas relacionadas com as operações da fábrica, os serviços públicos e a manutenção do equipamento. Processos de produção eficientes podem reduzir os custos gerais, permitindo que os fornecedores ofereçam preços mais competitivos. Os compradores devem ter em conta a capacidade de produção e a eficiência do fornecedor ao avaliarem os preços.

-

Ferramentas: Os alternadores personalizados requerem frequentemente ferramentas especializadas, o que pode representar um custo inicial significativo para os fabricantes. Estes custos são normalmente incluídos no preço dos alternadores, especialmente no caso de encomendas de baixo volume. Os compradores devem avaliar as capacidades de ferramentas dos potenciais fornecedores e discutir a forma como estes custos se reflectirão nos preços.

-

Controlo de Qualidade (QC): A implementação de processos rigorosos de controlo de qualidade garante que os alternadores cumprem as normas de desempenho. Isto pode implicar testes de capacidade de carga e de durabilidade, o que pode aumentar o custo global. Os compradores devem solicitar informações sobre os procedimentos de CQ utilizados pelos fornecedores para garantir a fiabilidade do produto.

-

Logística: Os custos de envio podem variar muito em função do destino, dos métodos de envio selecionados e de quaisquer tarifas ou direitos de importação aplicáveis. Os compradores devem esclarecer os Incoterms com os fornecedores para compreender quem assume a responsabilidade pelos custos e riscos de envio.

-

Margem: Normalmente, os fornecedores incluem uma margem nos seus preços para cobrir os seus custos e gerar lucro. Compreender as margens padrão do sector pode ajudar os compradores a negociar de forma mais eficaz.

O que influencia os preços dos alternadores Apex?

Vários factores podem influenciar o preço dos alternadores apex para além da estrutura básica de custos:

-

Volume/MOQ: As encomendas maiores conduzem frequentemente a custos unitários mais baixos. Os compradores devem considerar a possibilidade de combinar encomendas com outras empresas para atingir as quantidades mínimas de encomenda (MOQ) e obter melhores preços.

-

Especificações/Personalização: Os alternadores personalizados, adaptados a requisitos específicos do veículo ou a normas de desempenho, podem implicar custos adicionais. Os compradores devem ponderar os benefícios da personalização em relação aos aumentos de preço.

-

Qualidade e certificações: Os alternadores que cumprem certificações específicas do sector (por exemplo, ISO, CE) podem ter preços mais elevados devido aos testes adicionais e à conformidade exigida. Os compradores devem avaliar a importância das certificações na sua decisão de compra.

-

Fatores relacionados ao fornecedor: A reputação e a fiabilidade do fornecedor também podem influenciar os preços. Os fornecedores estabelecidos com registos comprovados podem cobrar preços mais elevados, mas oferecem melhores garantias e apoio ao cliente.

Que dicas podem ajudar os compradores B2B internacionais a otimizar os custos?

-

Negocie com sabedoria: Não hesite em negociar preços, especialmente para encomendas maiores. Discuta possíveis descontos para compras em grandes quantidades ou parcerias a longo prazo.

-

Considere o custo total de propriedade (TCO): Avalie não só o preço de compra inicial, mas também os custos a longo prazo associados à manutenção, garantias e potenciais períodos de inatividade.

-

Esteja ciente das nuances dos preços: As diferentes regiões podem ter estruturas de preços variáveis influenciadas pelas condições económicas locais, tarifas e flutuações cambiais. Os compradores em África, na América do Sul, no Médio Oriente e na Europa devem realizar uma pesquisa de mercado aprofundada para compreender estas nuances.

-

Solicite cotações de vários fornecedores: A comparação de cotações de diferentes fornecedores pode fornecer informações sobre os preços de mercado e ajudar a identificar o melhor valor.

Em conclusão, compreender a estrutura de custos abrangente e a dinâmica de preços dos alternadores apex é vital para os compradores B2B. Ao considerar todos os componentes de custos, os influenciadores de preços e ao empregar tácticas de negociação estratégicas, os compradores podem otimizar as suas decisões de aprovisionamento e melhorar a eficiência da sua cadeia de fornecimento.

Análise de alternativas: Comparação do alternador apex com outras soluções

Compreender as alternativas em alternadores de alto rendimento

Ao considerar alternadores de alto rendimento para aplicações industriais ou automóveis, é essencial que os compradores B2B avaliem várias alternativas para garantir que selecionam a melhor solução para as suas necessidades. A escolha certa pode afetar o desempenho, a relação custo-eficácia e a fiabilidade a longo prazo. Esta secção compara o Alternador Apex com duas alternativas viáveis: o Alternador de Alto Rendimento da Bosch e o Alternador Mechman, centrando-se no desempenho, custo, facilidade de implementação, manutenção e melhores casos de utilização.

| Aspecto comparativo | Alternador Apex | Alternador de alto rendimento Bosch | Alternador Mechman |

|---|---|---|---|

| Desempenho | 120 a 500 amperes; elevada fiabilidade | 150 a 400 amperes; design robusto | 200 a 350 amperes; saída eficiente |

| Custo | $300 - $700 | $350 - $800 | $400 - $750 |

| Facilidade de implementação | Personalizável; instalação simples | Ajuste padrão; são necessárias modificações mínimas | Opções de personalização disponíveis |

| Manutenção | Manutenção reduzida; garantia de 1 ano | Moderado; requer verificações periódicas | Manutenção reduzida; boa durabilidade |

| Melhor caso de uso | Aplicações automóveis de elevada procura | Veículos comerciais e frotas | Veículos de alta performance e todo-o-terreno |

Quais são as vantagens e desvantagens do alternador de alto rendimento da Bosch?

O alternador de alto rendimento da Bosch é conhecido pelo seu design robusto e fiabilidade, o que o torna uma escolha popular entre os operadores de veículos comerciais. Com uma gama de desempenho de 150 a 400 amperes, destina-se a aplicações pesadas. No entanto, o custo pode ser ligeiramente superior ao do Alternador Apex e, embora a instalação seja geralmente simples, podem ser necessárias algumas modificações, dependendo do modelo do veículo. A manutenção é moderada, uma vez que requer verificações periódicas para garantir um desempenho ótimo, o que pode ser uma consideração para frotas com tempo de inatividade limitado.

Como é que o alternador Mechman se compara?

O Alternador Mechman oferece uma forte gama de desempenho de 200 a 350 amperes, tornando-o adequado para veículos de desempenho e aplicações todo-o-terreno. Destaca-se pelo seu rendimento eficiente e durabilidade, garantindo um desempenho duradouro mesmo em condições exigentes. Embora seja ligeiramente mais caro do que o Alternador Apex, o investimento pode ser justificado para os compradores que necessitam de um elevado desempenho. Estão disponíveis opções de personalização, mas a instalação pode exigir alguns conhecimentos técnicos. A manutenção é geralmente baixa, o que o torna uma opção atractiva para os compradores que procuram fiabilidade.

Como escolher o alternador de alto rendimento certo para as suas necessidades

Em conclusão, a escolha do alternador certo depende dos seus requisitos específicos, incluindo as exigências de potência da sua aplicação, as restrições orçamentais e as capacidades de manutenção. O alternador Apex é ideal para quem procura uma solução personalizável e de elevado desempenho a um preço competitivo. Por outro lado, o Alternador Bosch High Output é adequado para aplicações comerciais que exigem fiabilidade, enquanto o Alternador Mechman se destaca em ambientes orientados para o desempenho. Ao avaliar cuidadosamente estas alternativas em função das suas necessidades operacionais, pode tomar uma decisão informada que melhore a eficiência e a fiabilidade do seu veículo.

Propriedades técnicas essenciais e terminologia comercial para o alternador apex

Quais são as caraterísticas técnicas essenciais dos alternadores Apex?

A compreensão das especificações técnicas dos alternadores apex é crucial para os compradores B2B que procuram soluções de energia fiáveis. Aqui estão as principais propriedades que definem o seu desempenho e adequação a várias aplicações:

-

Amperagem de saída

Os alternadores Apex variam normalmente entre 120 amperes e 500 amperes, com modelos de maior potência para veículos com maiores exigências de energia. Selecionar a amperagem adequada é vital para garantir que todos os componentes eléctricos funcionam eficientemente, especialmente em aplicações comerciais e industriais. Uma potência mais elevada também suporta acessórios e sistemas adicionais que podem ser instalados no veículo. -

Grau do material

A qualidade dos materiais utilizados na construção de um alternador afecta diretamente a sua longevidade e desempenho. O alumínio e o cobre de alta qualidade são normalmente utilizados devido à sua excelente condutividade e resistência à corrosão. Os compradores B2B devem dar prioridade aos alternadores fabricados com estes materiais para garantir durabilidade e fiabilidade em ambientes exigentes. -

Teste de carga

Antes do envio, os alternadores apex podem ser submetidos a testes de carga, que verificam a sua potência nominal e funcionalidade. Este processo é essencial para os compradores B2B, uma vez que garante que o produto cumpre as normas de desempenho especificadas. Solicitar um vídeo de teste de carga também pode ajudar a criar confiança com os fornecedores, garantindo que o produto entregue está totalmente operacional e é capaz de suportar as cargas previstas. -

Garantia e política de devolução

Os alternadores Apex são normalmente fornecidos com uma garantia de um ano, o que é um fator crítico para os compradores B2B. Uma garantia não só protege o investimento como também significa a confiança do fabricante no seu produto. Compreender a política de devolução é igualmente importante, uma vez que descreve os procedimentos em caso de defeitos ou insatisfação, assegurando que os compradores podem gerir os riscos de forma eficaz. -

Personalização

Muitos alternadores apex oferecem correspondência de cores personalizada e outras especificações adaptadas às necessidades do cliente. Esta flexibilidade pode ser uma vantagem significativa para as empresas que procuram manter a consistência da marca na sua frota ou equipamento. Compreender como tirar partido das opções personalizadas pode aumentar a satisfação do comprador e a eficiência operacional.

Que terminologia comercial devem os compradores B2B saber sobre os alternadores Apex?

A familiaridade com o jargão do sector é vital para uma comunicação e negociação eficazes na aquisição de alternadores apex. Eis alguns termos comuns que os compradores devem compreender:

-

OEM (Fabricante de Equipamento Original)

Um OEM refere-se ao fabricante original do alternador ou dos seus componentes. A compra a um OEM garante frequentemente que o produto cumpre as especificações necessárias para o desempenho e compatibilidade, o que é crucial para as empresas que dependem de peças de alta qualidade. -

MOQ (Quantidade mínima de encomenda)

O MOQ indica o número mais pequeno de unidades que um fornecedor está disposto a vender numa única encomenda. Compreender o MOQ é essencial para os compradores, uma vez que afecta a gestão do inventário e as considerações orçamentais. Os fornecedores podem ter diferentes MOQs com base nas suas capacidades de produção e na procura do mercado. -

RFQ (Pedido de Orçamento)

Um RFQ é um documento formal emitido pelos compradores para solicitar cotações de preços aos fornecedores. Este processo ajuda os compradores a comparar preços, termos e condições de diferentes fornecedores, facilitando a tomada de decisões informadas. A elaboração de um RFQ claro pode levar a melhores preços e condições. -

Incoterms (Termos Comerciais Internacionais)

Os Incoterms são termos comerciais normalizados que definem as responsabilidades dos compradores e vendedores em transacções internacionais. A familiaridade com estes termos é vital para que os compradores B2B compreendam as responsabilidades de envio, os custos e a gestão de riscos durante o processo de aquisição. -

Prazo de entrega

O prazo de entrega refere-se ao período entre a encomenda e a receção do produto. Conhecer o prazo de entrega previsto para os alternadores apex é crucial para planear e garantir que os projectos se mantêm dentro do prazo. Os compradores devem comunicar claramente os seus prazos aos fornecedores para alinhar as expectativas.

A compreensão destas propriedades técnicas e da terminologia comercial permitirá que os compradores B2B tomem decisões de compra informadas, assegurando que selecionam os alternadores apex adequados às suas necessidades específicas, enquanto navegam com confiança no processo de aquisição.

Navegar na dinâmica do mercado e nas tendências de abastecimento no sector dos alternadores de topo

Quais são as actuais dinâmicas de mercado e as principais tendências que afectam o sector dos alternadores Apex?

O mercado global de alternadores de pico está a registar um crescimento significativo, impulsionado pela procura crescente de sistemas eléctricos de alta potência em várias indústrias, incluindo os sectores automóvel, marítimo e das energias renováveis. As principais tendências que moldam este panorama incluem avanços na tecnologia, com os fabricantes a concentrarem-se no desenvolvimento de alternadores mais eficientes, duráveis e personalizáveis. Os compradores B2B internacionais, particularmente em regiões como a África, a América do Sul, o Médio Oriente e a Europa, procuram cada vez mais produtos de alta qualidade e fiáveis que possam suportar diversas condições operacionais.

As tecnologias emergentes, como a monitorização digital e o diagnóstico inteligente, estão a tornar-se parte integrante das decisões de aprovisionamento. Estas inovações permitem o acompanhamento do desempenho em tempo real e a manutenção preditiva, reduzindo assim o tempo de inatividade e os custos de manutenção. Além disso, a tendência para os veículos eléctricos (VE) está a influenciar o mercado dos alternadores, uma vez que os fabricantes adaptam os seus produtos para satisfazer as necessidades em evolução dos sistemas híbridos e eléctricos. A gama média de preços dos alternadores apex, normalmente entre $300 e $700, mantém-se competitiva, permitindo às empresas explorar opções de pagamento flexíveis, melhorando a acessibilidade para os compradores internacionais.

Como é que a sustentabilidade e as práticas de fornecimento ético estão a moldar a indústria de alternadores Apex?

A sustentabilidade está a tornar-se cada vez mais um fator crítico para os compradores B2B no sector dos alternadores de topo. Com o aumento da consciencialização global para as questões ambientais, as empresas estão a dar prioridade ao fornecimento ético e à minimização da sua pegada ecológica. A produção de alternadores de pico envolve vários materiais, e o seu fornecimento responsável pode reduzir significativamente o impacto ambiental. Os fabricantes estão a ser instados a adotar materiais e processos de produção mais ecológicos, como a utilização de metais reciclados e revestimentos amigos do ambiente.

Além disso, certificações como a ISO 14001 para sistemas de gestão ambiental e a adesão aos princípios da economia circular estão a ganhar força. Estas certificações não só garantem aos compradores práticas éticas, como também melhoram a reputação da marca. Os compradores B2B são aconselhados a procurar fornecedores que demonstrem um compromisso com práticas sustentáveis, uma vez que tal pode conduzir a uma cadeia de abastecimento mais resistente e a uma maior fidelização dos clientes.

Qual é a breve evolução e história do alternador Apex?

O alternador apex evoluiu significativamente desde a sua criação, passando de modelos tradicionais de baixo rendimento para os modelos de alto desempenho disponíveis atualmente. Os primeiros alternadores centravam-se principalmente na produção eléctrica básica, muitas vezes com dificuldades em satisfazer as exigências crescentes dos veículos e máquinas modernos. Ao longo dos anos, os avanços na ciência dos materiais e na engenharia eléctrica conduziram ao desenvolvimento de alternadores de alto rendimento capazes de fornecer 120 a 500 amperes, atendendo a uma variedade de aplicações.

Esta evolução tem sido impulsionada por uma ênfase crescente na personalização e no desempenho, com os fabricantes a oferecerem agora soluções à medida para satisfazer os requisitos específicos dos clientes. À medida que o mercado continua a amadurecer, a ênfase na fiabilidade, eficiência e sustentabilidade irá provavelmente moldar o futuro dos alternadores apex, garantindo que continuam a ser um componente vital em vários sectores em todo o mundo.

Perguntas mais frequentes (FAQs) para compradores B2B de alternador apex

-

Como é que posso garantir a qualidade de um alternador apex antes de o comprar?

Para garantir a qualidade de um alternador apex, solicite especificações pormenorizadas, incluindo as potências em ampères e os materiais utilizados. É aconselhável pedir um vídeo de teste de carga que demonstre a potência nominal e a funcionalidade do alternador antes do envio. Além disso, verifique se o fabricante fornece uma garantia e apoio pós-venda. A realização de auditorias a fornecedores e a análise de testemunhos de clientes podem ajudar a avaliar a fiabilidade do fornecedor. -

Que opções de personalização estão disponíveis para os alternadores apex?

Os alternadores Apex podem ser personalizados para atender a requisitos específicos, incluindo classificações de ampères que variam de 120 a 500 ampères. Os compradores também podem solicitar a correspondência de cores, fornecendo um código de pintura. Discutir as opções de personalização com o fornecedor antes da encomenda é crucial para garantir que o produto satisfaz as suas necessidades específicas de aplicação e preferências estéticas. -

Que condições de pagamento posso esperar ao adquirir alternadores apex?

As condições de pagamento dos alternadores apex podem variar consoante o fornecedor, mas muitos oferecem opções flexíveis, incluindo planos de pagamento adaptados ao seu orçamento. Normalmente, o pagamento total é exigido antes do envio. Certifique-se de que esclarece quaisquer taxas adicionais para personalização ou custos de envio. Compreender as condições de pagamento antecipadamente ajudará na elaboração do orçamento e no planeamento financeiro. -

Qual é a quantidade mínima de encomenda (MOQ) para os alternadores apex?

A quantidade mínima de encomenda (MOQ) para alternadores apex pode variar consoante os fornecedores. Alguns podem aceitar pequenas encomendas para efeitos de teste, enquanto outros podem exigir quantidades maiores para cumprir as encomendas de forma económica. É aconselhável discutir a quantidade mínima de encomenda com os potenciais fornecedores para garantir que está de acordo com a sua estratégia e capacidade de compra. -

Como é que posso verificar os fornecedores de alternadores apex no comércio internacional?

Ao examinar os fornecedores de alternadores apex, reveja as suas credenciais, certificações e experiência no sector. Solicite referências de clientes anteriores e verifique as revisões online. Estabeleça uma comunicação direta para avaliar a sua capacidade de resposta e disponibilidade para fornecer a documentação necessária. Também é benéfico considerar fornecedores com um historial comprovado de exportação para a sua região. -

Que considerações logísticas devo ter em conta ao importar alternadores apex?

A logística desempenha um papel crucial no processo de importação de alternadores apex. Considere os métodos de envio, os tempos de trânsito e os regulamentos alfandegários específicos do seu país. A colaboração com um transitário pode agilizar o processo e ajudar a lidar com eventuais direitos de importação. Certifique-se de que o fornecedor fornece embalagens e etiquetas claras para facilitar o desalfandegamento. -

Quais são os problemas mais comuns com os alternadores apex e como podem ser resolvidos?

Os problemas comuns dos alternadores apex podem incluir inconsistências de desempenho ou dificuldades de instalação. Para resolver estes problemas, assegure uma instalação correta seguindo as orientações do fabricante. As verificações de manutenção regulares também podem evitar problemas. Se surgirem problemas, contacte o fornecedor para obter apoio na resolução de problemas e utilize a garantia para substituições, se necessário. -

Quais são as políticas de garantia dos alternadores apex?

As políticas de garantia para os alternadores apex cobrem normalmente os defeitos de materiais e de fabrico durante um período especificado, frequentemente um ano. É importante clarificar os termos da garantia com o fornecedor, incluindo o processo de apresentação de reclamações e quaisquer exclusões. Compreender a política de garantia ajudará a proteger o seu investimento e a assegurar que tem recurso em caso de falhas do produto.

Lista dos 7 principais fabricantes e fornecedores de alternadores Apex

1. Apex - Alternadores de alto rendimento

Domínio: apexhighoutputalternators.com

Registada: 2016 (9 anos)

Introdução: A Apex Alternators oferece alternadores personalizados de alta potência que variam entre 120 amperes e 500 amperes, utilizando a mais recente tecnologia para fiabilidade. Os clientes podem solicitar cores de pintura específicas utilizando o seu código de pintura. Os alternadores são construídos com peças de alta qualidade para durabilidade e desempenho. Pode ser fornecido um vídeo de teste de carga antes do envio para demonstrar a funcionalidade. Os preços variam de $300 a...

2. Burrell Defense - Alternador SMG

Domínio: apexlegends.fandom.com

Registado: 1996 (29 anos)

Introdução: {“name”: “Alternator SMG”, “tipo”: “Submetralhadora”, “tipo de munição”: “Rodas leves”, “modos de disparo”: “Auto”, “fabricante”: “Burrell Defense”, “attachment_slots”: “Vários”, “danos”: {“corpo”: 16, “cabeça”: 19, “pernas”: 13}, “damage_multipliers”: {“cabeça”: 1.25, “pernas”: 0.8}, “technical_stats”: {“RPM”: 600, “DPS”: 160, “magazine_sizes”: [19, 23, 26, 27], “tempos_de_recarga”: {“tática”: [1.9, 1.84, 1.77, 1.71...

3. GMK Audio - Alternadores de alto rendimento Apex

Domínio: gmkaudio.com

Registado: 2024 (1 ano)

Introdução: Alternadores de alto rendimento Apex concebidos para um desempenho e fiabilidade máximos. Inclui tecnologia avançada de gancho de cabelo para um rendimento elétrico e eficiência superiores. Díodos: 60 amperes em caixas pequenas, 100 amperes em caixas grandes (em comparação com os 25 amperes e 50 amperes da concorrência). Rectificadores de ponte dupla para um arrefecimento eficiente e durabilidade. Estatores de gancho de cabelo OEM, soldados e soldados à mão para maior fiabilidade, com estágios de 6 fases...

4. Harry's - 240 Amp para Honda Civic 2018

Domínio: facebook.com

Registado: 1997 (28 anos)

Introdução: Esta empresa, Harry's - 240 Amp for 2018 Honda Civic, é uma entidade notável no mercado. Para obter detalhes específicos do produto, é recomendável visitar seu site diretamente.

5. Alternadores Apex - Modelos de alto rendimento

Domínio: sitejabber.com

Registada: 2008 (17 anos)

Introdução: A Apex Alternators oferece alternadores de alta potência, incluindo modelos como um alternador de 370 amperes e um alternador de 350-360 amperes. Os clientes relataram problemas com o facto de os produtos não funcionarem como anunciado, com queixas sobre a saída de tensão incorrecta (carregando apenas a 12,8-13,4 volts em vez dos 14,8 volts esperados), recebendo o alternador errado e um mau serviço ao cliente. A empresa tem uma classificação baixa ...

6. Apex Legends - Alternador SMG

Domínio: apexlegends.wiki.gg

Introdução: A Alternator SMG é uma submetralhadora em Apex Legends. Tem um design único e é conhecida pela sua elevada cadência de tiro e precisão. A arma usa munição leve e tem um carregador de tamanho moderado. É eficaz a curta e média distância, o que a torna uma escolha versátil para os jogadores. A Alternator pode ser equipada com vários acessórios para melhorar o seu desempenho.

7. Reddit - Alternador SMG

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: Alternator é uma submetralhadora (SMG) em Apex Legends. Os jogadores têm opiniões divergentes sobre ela, destacando a sua eficácia ao largar e a sua capacidade de guardar acessórios. Alguns jogadores preferem-na pela sua precisão de tiro na anca e velocidade de disparo controlável, enquanto outros acham que é ofuscada por outras submetralhadoras como a R99 e a R301 em cenários de jogo intermédios e finais. É considerada boa para principiantes, mas pode não aguentar ...

Conclusão sobre o aprovisionamento estratégico e perspectivas para o alternador apex

No atual cenário competitivo, o fornecimento estratégico de alternadores de topo é vital para as empresas que procuram melhorar a sua eficiência operacional e fiabilidade. Ao dar prioridade à qualidade e ao desempenho, os compradores internacionais B2B podem garantir que investem em alternadores de alto rendimento que satisfazem as suas necessidades específicas, quer para aplicações automóveis quer para utilização industrial. As opções de personalização disponíveis, tais como a variação da amperagem e a correspondência de cores, permitem às empresas adaptar soluções que se alinham com a sua marca e requisitos operacionais.

Além disso, a acessibilidade dos alternadores apex, combinada com planos de pagamento flexíveis e garantias robustas, sublinha o valor da parceria com fornecedores de renome. Esta abordagem não só reduz os riscos associados à falha do produto, como também promove relações a longo prazo que podem levar a melhores preços e condições de serviço no futuro.

Imagem ilustrativa relacionada com o alternador apex

Olhando para o futuro, é imperativo que os compradores de regiões como a África, a América do Sul, o Médio Oriente e a Europa se envolvam proactivamente com os fornecedores. Ao fazê-lo, podem assegurar os melhores negócios e garantir que têm acesso à tecnologia mais recente. Dê o próximo passo para otimizar a sua estratégia de aprovisionamento - estabeleça contacto com os fornecedores para explorar o potencial dos alternadores apex e elevar as suas operações comerciais.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.