Introduction: Navigating the Global Market for alternator parts diagram

In the ever-evolving automotive industry, sourcing reliable alternator parts diagrams poses a significant challenge for international B2B buyers. Understanding the intricate components and functionality of alternators is crucial for making informed purchasing decisions that can impact operational efficiency and maintenance costs. This comprehensive guide delves into the various types of alternator parts diagrams, their applications across different vehicle models, and the importance of selecting high-quality components from reputable suppliers.

As we navigate this complex landscape, we will also discuss effective strategies for vetting suppliers, evaluating costs, and ensuring compliance with international standards, particularly for markets in Africa, South America, the Middle East, and Europe, including key countries like Saudi Arabia and Germany. By equipping decision-makers with the knowledge necessary to interpret alternator parts diagrams, this guide empowers them to make sound investments in components that enhance vehicle performance and longevity.

With a clear focus on actionable insights, we aim to simplify the procurement process, enabling buyers to identify and source the right alternator parts with confidence. Whether you’re looking to optimize your supply chain or improve your technical understanding of alternators, this guide is your essential resource for navigating the global market effectively.

Índice

- Top 5 Alternator Parts Diagram Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator parts diagram

- Understanding alternator parts diagram Types and Variations

- Key Industrial Applications of alternator parts diagram

- 3 Common User Pain Points for ‘alternator parts diagram’ & Their Solutions

- Strategic Material Selection Guide for alternator parts diagram

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator parts diagram

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator parts diagram’

- Comprehensive Cost and Pricing Analysis for alternator parts diagram Sourcing

- Alternatives Analysis: Comparing alternator parts diagram With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator parts diagram

- Navigating Market Dynamics and Sourcing Trends in the alternator parts diagram Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator parts diagram

- Strategic Sourcing Conclusion and Outlook for alternator parts diagram

- Aviso legal importante e termos de utilização

Understanding alternator parts diagram Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Basic Alternator Diagram | Simplistic representation; shows core components | Automotive repairs, educational purposes | Prós: Easy to understand; useful for training. Contras: Lacks detail for advanced diagnostics. |

| Electrical Wiring Diagram | Detailed circuitry connections and terminals | Electrical engineering, automotive design | Prós: Comprehensive; ideal for troubleshooting. Contras: Pode ser complexo para iniciantes. |

| Functional Flow Diagram | Illustrates operational processes of alternator | Technical training, engineering analysis | Prós: Clarifies function; great for process understanding. Contras: May require prior knowledge to interpret. |

| 3D Alternator Model Diagram | Interactive visual model; shows spatial relationships | Manufacturing, design prototyping | Prós: Engaging; enhances comprehension of spatial dynamics. Contras: Requires advanced software to view. |

| Maintenance and Repair Diagram | Focused on disassembly and repair instructions | Automotive service centers, DIY mechanics | Prós: Practical; aids in repair processes. Contras: Limited to specific models or types. |

What Are the Characteristics of a Basic Alternator Diagram?

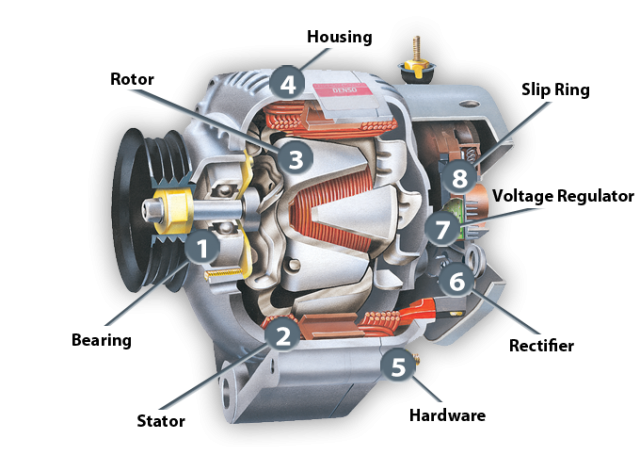

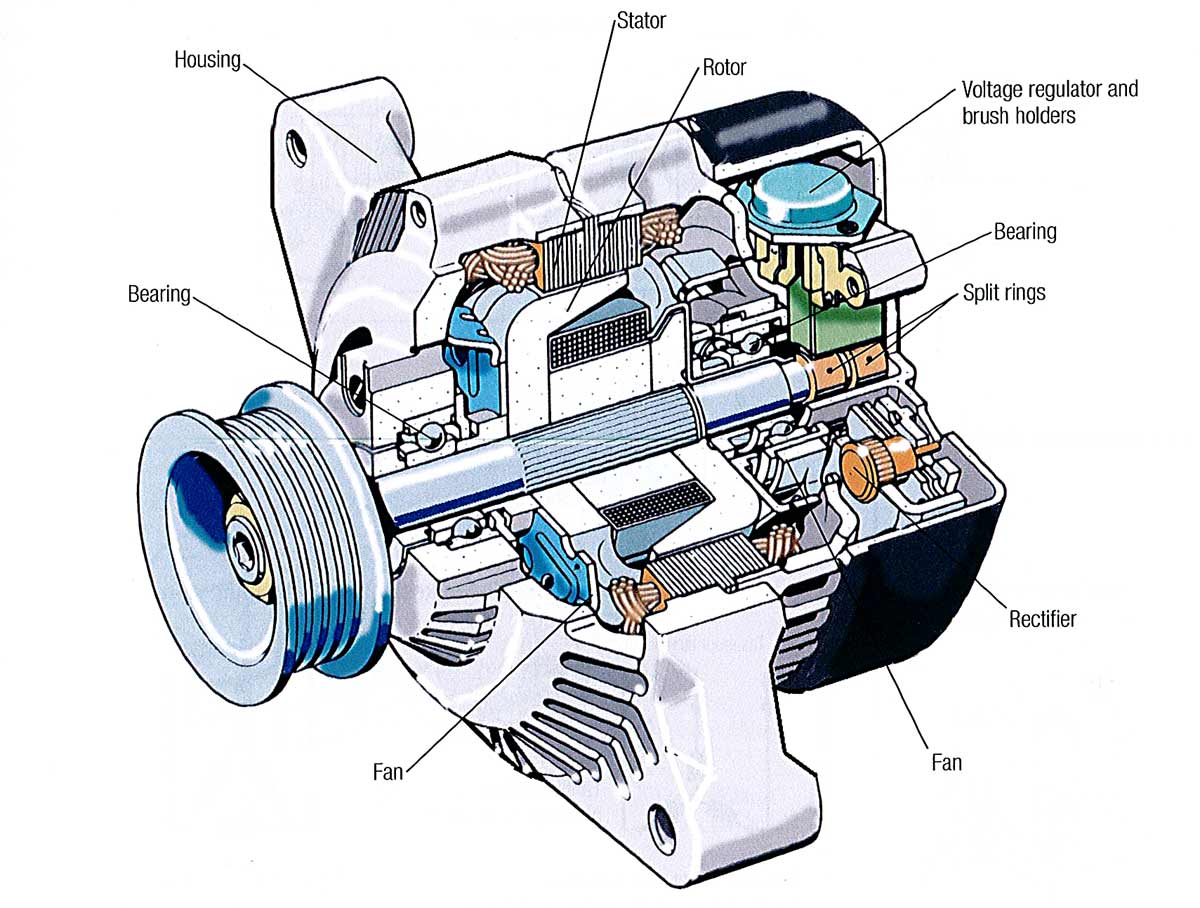

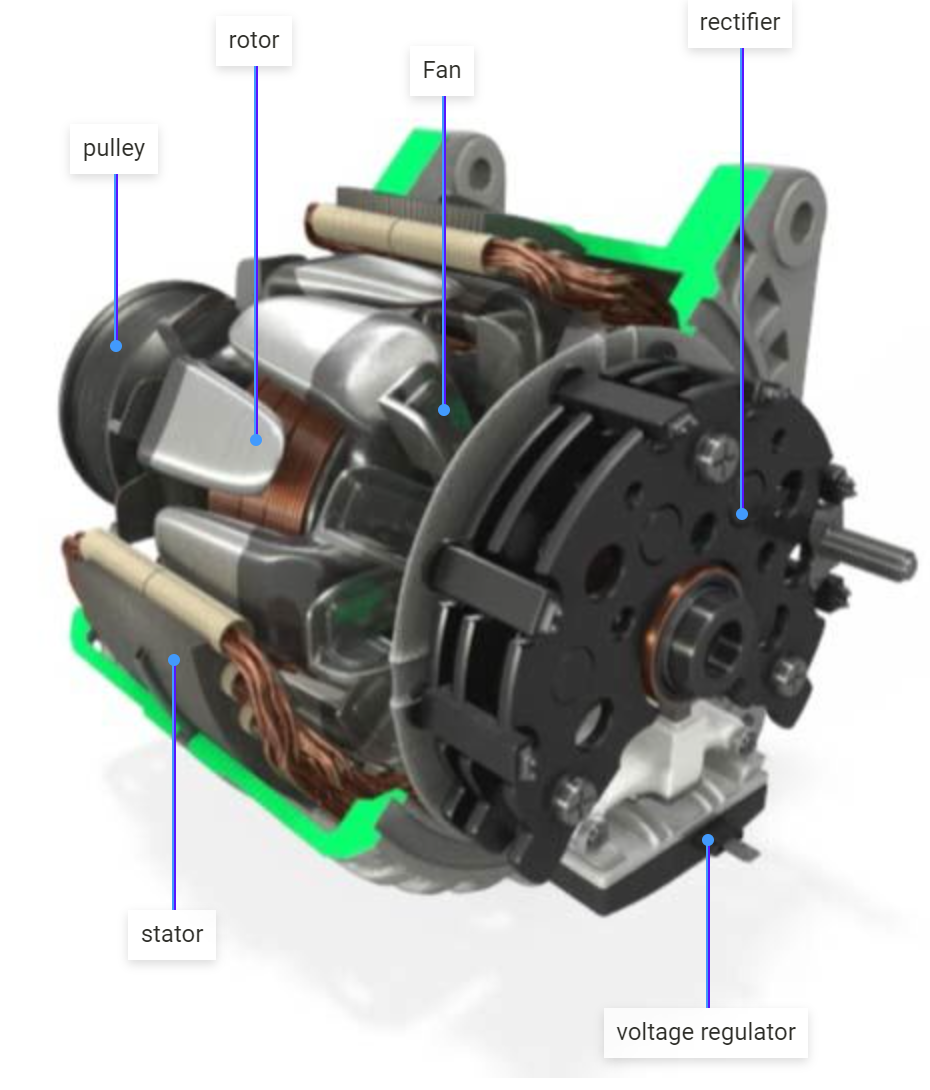

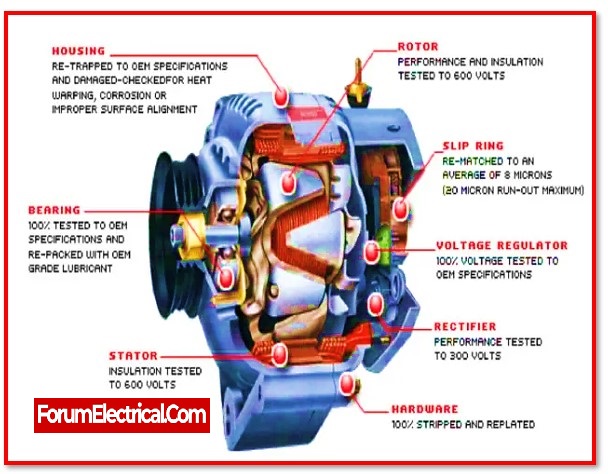

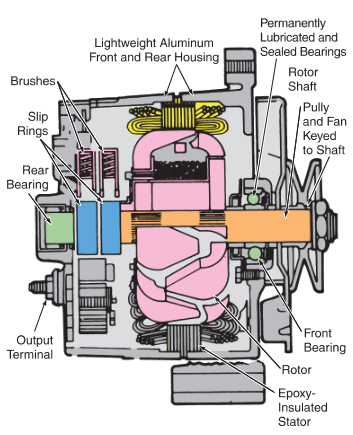

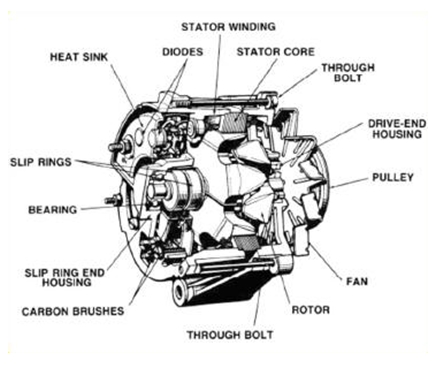

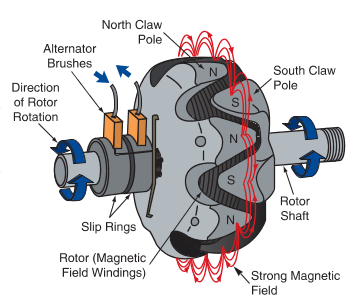

The Basic Alternator Diagram is a straightforward representation that highlights the essential components, such as the rotor, stator, and rectifier. This type is particularly suitable for educational settings and initial training for automotive technicians. B2B buyers, especially in the automotive repair sector, can leverage this diagram to train new employees or explain fundamental concepts to clients. However, its simplicity can be a limitation for advanced diagnostics and troubleshooting.

How Does an Electrical Wiring Diagram Benefit B2B Buyers?

The Electrical Wiring Diagram provides a comprehensive view of the circuitry and connections within an alternator. It outlines critical terminals and their functions, making it invaluable for electrical engineers and automotive designers. This type of diagram is essential for troubleshooting complex electrical issues and ensuring proper installation in new designs. However, its complexity may pose a challenge for those without a technical background, making it less accessible for some buyers.

Why Choose a Functional Flow Diagram?

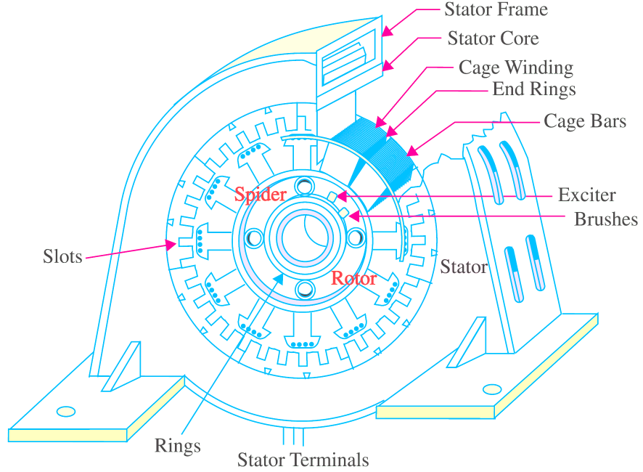

The Functional Flow Diagram illustrates the operational processes of an alternator, detailing how mechanical energy is converted to electrical energy. This type is particularly beneficial for technical training and engineering analysis, as it helps users understand the sequence of operations. B2B buyers in training and development sectors will find this diagram useful for enhancing workforce competency. However, it may require a foundational knowledge of electrical systems to interpret effectively.

What Are the Advantages of 3D Alternator Model Diagrams?

3D Alternator Model Diagrams offer an interactive visual representation, showcasing the spatial relationships between various components. This type is particularly advantageous for manufacturers and design prototyping, as it allows for a better understanding of how parts fit together. B2B buyers can use these models to enhance presentations and training materials. However, accessing these diagrams often requires advanced software, which could be a barrier for some organizations.

How Do Maintenance and Repair Diagrams Support Automotive Service Centers?

Maintenance and Repair Diagrams focus on disassembly and repair processes, providing step-by-step instructions for servicing alternators. This type is crucial for automotive service centers and DIY mechanics who need practical guidance. B2B buyers in these sectors can utilize these diagrams to streamline repair processes and improve service efficiency. However, these diagrams may be limited to specific alternator models, reducing their applicability across different brands or types.

Key Industrial Applications of alternator parts diagram

| Indústria/Setor | Specific Application of alternator parts diagram | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Automotivo | Understanding alternator functionality in vehicle design | Enhances vehicle reliability and electrical system efficiency | Quality of components, compatibility with vehicle models, and supplier reputation |

| Energia renovável | Design and integration of alternators in wind turbines | Increases energy conversion efficiency and system reliability | Compliance with energy regulations, durability in harsh environments, and technical support |

| Indústria naval | Power generation systems in boats and ships | Ensures consistent electrical supply for navigation and safety | Resistance to corrosion, weight considerations, and service availability |

| Equipamento de construção | Electrical systems in heavy machinery and generators | Melhora a eficiência operacional e reduz o tempo de inatividade | Performance under extreme conditions, ease of maintenance, and sourcing local parts |

| Agricultura | Alternators in irrigation systems and farm machinery | Enhances productivity and reliability of farming operations | Adaptability to various energy sources, availability of spare parts, and technical support |

How Is the Alternator Parts Diagram Used in the Automotive Industry?

In the automotive sector, the alternator parts diagram is crucial for engineers and designers in understanding how to integrate these components into vehicle electrical systems. It helps in troubleshooting and maintaining the alternator, ensuring that vehicles operate efficiently and reliably. For international B2B buyers, especially in regions like Africa and Europe, sourcing high-quality alternator parts is essential to meet diverse vehicle specifications and local regulations.

What Role Does the Alternator Parts Diagram Play in Renewable Energy Applications?

In renewable energy, particularly in wind turbine design, the alternator parts diagram aids engineers in optimizing the electrical generation process. By understanding the components and their functions, businesses can enhance energy conversion efficiency and reliability. Buyers in South America and the Middle East should consider sourcing durable components that can withstand harsh environmental conditions while ensuring compliance with energy regulations.

How Is the Alternator Parts Diagram Beneficial for the Marine Industry?

The marine industry relies on alternators for power generation in boats and ships. The alternator parts diagram provides insights into component functionality, which is critical for ensuring a consistent electrical supply for navigation systems and safety equipment. B2B buyers from Europe and Africa must prioritize corrosion-resistant materials and reliable suppliers to guarantee longevity and performance in marine environments.

Why Is the Alternator Parts Diagram Important for Construction Equipment?

In construction, alternators are integral to the electrical systems of heavy machinery and generators. The parts diagram assists manufacturers in designing robust systems that improve operational efficiency and minimize downtime. For B2B buyers, sourcing reliable alternator components that can perform under extreme conditions is vital, as is the availability of local spare parts to facilitate maintenance.

What Is the Significance of the Alternator Parts Diagram in Agricultural Machinery?

The agricultural sector utilizes alternators in irrigation systems and various farm machinery. Understanding the parts diagram helps manufacturers and engineers design systems that enhance productivity and reliability. International buyers, particularly in emerging markets, need to focus on sourcing adaptable components that work with different energy sources and ensure the availability of technical support for maintenance and troubleshooting.

3 Common User Pain Points for ‘alternator parts diagram’ & Their Solutions

Scenario 1: Difficulty in Understanding Alternator Functionality Through Diagrams

O problema: Many B2B buyers, particularly those in emerging markets, struggle to comprehend the complex diagrams associated with alternator parts. This confusion often arises from the lack of accompanying explanations, leading to misinterpretations of critical components such as the rotor, stator, and voltage regulator. As a result, buyers may order incorrect parts, leading to costly delays in repairs and increased operational downtime for their fleets. This is especially pertinent for automotive repair shops in regions where technical training resources are scarce.

A solução: To effectively utilize alternator parts diagrams, B2B buyers should seek out comprehensive educational resources that combine visual aids with clear, detailed explanations of each component’s function. Suppliers can enhance their product offerings by providing labeled diagrams alongside step-by-step guides that outline the operation of each part. Additionally, incorporating multimedia resources like instructional videos can further bridge the knowledge gap. Buyers should prioritize suppliers who invest in educational content, as this not only aids in proper part selection but also fosters long-term partnerships built on trust and understanding.

Scenario 2: Inadequate Technical Support for Sourcing Correct Parts

O problema: B2B buyers often face challenges when sourcing the right alternator parts due to inadequate technical support from suppliers. This is particularly frustrating for automotive workshops that may not have in-house expertise to interpret diagrams or identify the correct specifications. Miscommunication about part specifications can lead to the procurement of incompatible components, causing unnecessary delays and financial losses.

A solução: To address this pain point, buyers should seek suppliers that offer dedicated technical support services, including a knowledgeable customer service team that can assist with interpreting alternator diagrams. Engaging in a collaborative relationship where buyers can discuss their specific needs and receive tailored guidance can significantly improve the sourcing process. Furthermore, utilizing platforms that allow for real-time chat or video consultations can facilitate clearer communication and ensure that the correct parts are ordered efficiently. Buyers should also consider attending training workshops or webinars offered by suppliers to enhance their understanding of alternator systems and components.

Scenario 3: Complications in Installation Due to Lack of Clarity in Diagrams

O problema: Even after successfully sourcing the correct alternator parts, many B2B buyers encounter difficulties during the installation process due to unclear diagrams. This is often the case when diagrams do not include installation steps or when they lack context about how components fit together within the larger system. Such challenges can lead to improper installation, resulting in further mechanical issues and increased maintenance costs.

A solução: To overcome installation complications, buyers should look for suppliers who provide comprehensive installation guides that accompany their alternator parts diagrams. These guides should include not only diagrams but also written instructions, troubleshooting tips, and safety precautions. Additionally, suppliers can enhance the installation experience by offering webinars or hands-on training sessions that demonstrate the installation process in real-time. Buyers should also consider investing in diagnostic tools that can help verify correct installation and functionality post-installation. By prioritizing suppliers that support the entire lifecycle of the product, from sourcing to installation, buyers can ensure smoother operations and reduced downtime.

Strategic Material Selection Guide for alternator parts diagram

What Materials Are Commonly Used in Alternator Parts?

In the manufacturing of alternator parts, material selection is pivotal for ensuring performance, durability, and cost-effectiveness. Here, we analyze four common materials used in alternators, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Como o alumínio beneficia os componentes do alternador?

Aluminum is frequently used for the housing and structural components of alternators due to its lightweight and non-magnetic properties. Key properties include excellent thermal conductivity, a temperature rating of up to 150°C, and good corrosion resistance when anodized.

Prós: Aluminum’s lightweight nature leads to reduced overall vehicle weight, enhancing fuel efficiency. It is also relatively inexpensive and easy to manufacture, allowing for cost-effective production.

Contras: While aluminum is durable, it can be less resistant to mechanical wear compared to other metals like steel. It may require additional coatings to enhance corrosion resistance in harsh environments.

Impacto na aplicação: Aluminum is suitable for environments where heat dissipation is critical, making it ideal for alternator housings. However, in regions with high humidity or saline conditions, additional protective measures may be necessary.

Considerations for B2B Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as DIN and ASTM for aluminum alloys. The preference for lightweight materials is growing, particularly in automotive applications.

Why is Copper Essential for Electrical Components?

Copper is a primary material for windings and electrical connections in alternators due to its excellent electrical conductivity, with a conductivity rating of 97% IACS. It also has a high melting point (1,984°F or 1,085°C) and good corrosion resistance.

Prós: Copper’s superior conductivity enhances the efficiency of power generation, making it ideal for applications requiring high electrical performance. Its ductility allows for easy shaping during manufacturing.

Contras: The primary drawback is its cost, as copper is significantly more expensive than aluminum. Additionally, copper is heavier, which may not align with the trend towards lightweight automotive components.

Impacto na aplicação: Copper is essential for high-performance applications where electrical efficiency is paramount. However, its weight may be a consideration for designs focused on reducing overall vehicle mass.

Considerations for B2B Buyers: Buyers should be aware of fluctuating copper prices and consider sourcing strategies. Compliance with international standards for electrical components is also critical.

How Does Steel Contribute to Durability in Alternators?

Steel is often used for components that require high strength, such as the rotor shaft and internal supports. It offers high tensile strength and can withstand significant mechanical stress, with a temperature rating of up to 300°C.

Prós: Steel’s durability ensures longevity and reliability in demanding applications. It can be treated for additional corrosion resistance, enhancing its suitability for various environments.

Contras: Steel is heavier than aluminum and copper, which may not be ideal for lightweight applications. It is also more prone to corrosion unless properly coated or treated.

Illustrative image related to alternator parts diagram

Impacto na aplicação: Steel is suitable for components that experience high mechanical stress but may require additional treatments for corrosion resistance in humid or saline environments.

Considerations for B2B Buyers: Buyers should ensure that steel components meet international standards such as ASTM or JIS for quality assurance. The choice of steel grade can impact performance and cost.

Qual é o papel do plástico no design do alternador?

Plastics are increasingly used in non-structural components such as covers and insulators due to their lightweight and insulating properties. Commonly used plastics include nylon and polypropylene.

Prós: Plastics are lightweight, cost-effective, and can be molded into complex shapes, allowing for innovative designs. They also offer good electrical insulation properties.

Contras: Plastics may not withstand high temperatures as well as metals, with a typical upper limit of around 120°C. They can also be less durable under mechanical stress.

Impacto na aplicação: Plastics are suitable for applications where weight reduction is crucial, but their limitations in temperature and mechanical strength must be considered.

Considerations for B2B Buyers: Buyers should evaluate the plastic grades used to ensure compliance with relevant standards and consider the environmental impact of plastic materials in their sourcing decisions.

Summary of Material Selection for Alternator Parts

| Material | Typical Use Case for alternator parts diagram | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Componentes estruturais e de alojamento | Leve e com boa condutividade térmica | Less resistant to mechanical wear | Baixo |

| Cobre | Enrolamentos elétricos e ligações | Excelente condutividade elétrica | High cost and heavier than aluminum | Alto |

| Aço | Rotor shaft and internal supports | Alta resistência e durabilidade | Mais pesado e propenso à corrosão | Médio |

| Plástico | Non-structural components (covers) | Leve e económico | Limited temperature and mechanical strength | Baixo |

This guide serves as a comprehensive overview for international B2B buyers, helping them make informed decisions regarding material selection for alternator parts in various applications.

Illustrative image related to alternator parts diagram

In-depth Look: Manufacturing Processes and Quality Assurance for alternator parts diagram

Quais são as principais fases do processo de fabrico de peças de alternador?

Understanding the manufacturing process of alternator parts is crucial for B2B buyers, particularly those in international markets. The process typically involves several stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the quality and reliability of the final product.

How Is Material Prepared for Alternator Parts?

The first step in manufacturing alternator components is material preparation. Common materials include aluminum for the housing, copper for the windings, and various alloys for internal components. These materials are selected based on their electrical conductivity, thermal properties, and mechanical strength.

Once sourced, materials undergo inspection to ensure compliance with specifications. This may involve chemical composition analysis and physical property testing. Materials that pass inspection are then cut or shaped to the required dimensions, often using CNC (Computer Numerical Control) machining for precision.

Que técnicas são utilizadas na formação de componentes do alternador?

The forming stage involves shaping raw materials into specific components. Techniques such as die-casting, stamping, and extrusion are commonly employed. For example, aluminum housings are often produced through die-casting, which allows for complex shapes while maintaining structural integrity.

In this phase, quality control measures are implemented to monitor dimensional accuracy and surface finish. Automated systems may be used to detect defects early in the process, reducing waste and ensuring only high-quality parts proceed to the assembly stage.

Illustrative image related to alternator parts diagram

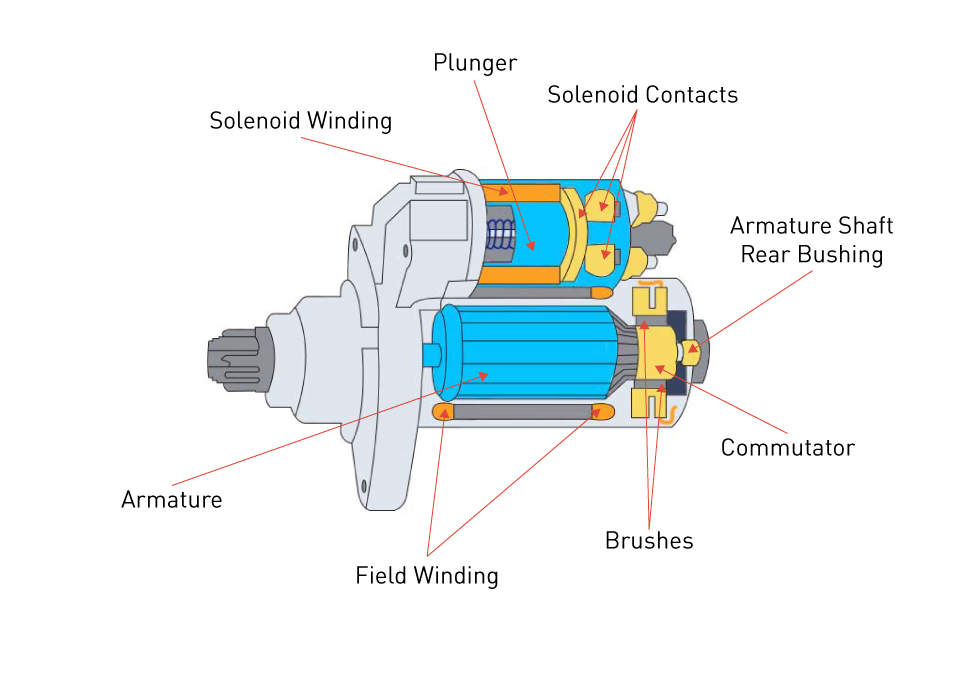

How Are Alternator Parts Assembled?

The assembly stage is critical for the performance of the alternator. Components such as the rotor, stator, rectifier, and voltage regulator are brought together in a controlled environment. Skilled technicians or automated assembly lines ensure that parts are aligned and fitted correctly, which is essential for the alternator’s efficiency and longevity.

During assembly, multiple quality checkpoints are established. These may include functional tests to verify that electrical connections are secure and that moving parts are free from obstruction. Effective assembly practices help minimize the risk of defects in the final product.

What Finishing Processes Are Applied to Alternator Parts?

Finishing processes enhance the durability and aesthetic appeal of alternator components. This stage may involve anodizing aluminum housings to improve corrosion resistance or applying protective coatings to internal parts. Finishing also includes rigorous cleaning procedures to remove contaminants that could affect performance.

Quality assurance during the finishing stage includes visual inspections and testing for adherence to surface finish specifications. This is crucial for international buyers who often have stringent requirements regarding product appearance and performance.

Que normas de garantia de qualidade são relevantes para o fabrico de alternadores?

Quality assurance in alternator manufacturing is governed by both international and industry-specific standards. ISO 9001 is a widely recognized quality management system standard that ensures consistent quality across manufacturing processes. Compliance with this standard is crucial for B2B buyers looking for reliability in their supply chains.

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the application of the alternator. For instance, automotive alternators must meet stringent safety and performance regulations, which vary by region.

Quais são os principais pontos de verificação do controlo de qualidade na fabricação de alternadores?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that products meet the required specifications. These checkpoints typically include:

-

Controlo de Qualidade de Entrada (IQC): This involves inspecting raw materials before they enter the production process. Any materials that do not meet the specified criteria are rejected.

-

Controlo de qualidade em processo (IPQC): During the manufacturing stages, operators conduct regular checks to monitor dimensions and functional properties. This helps identify any deviations from standards early in the process.

-

Controlo de Qualidade Final (FQC): After assembly, the complete alternator undergoes testing to verify its performance. This may include electrical testing, thermal cycling, and load testing to ensure it meets operational specifications.

What Common Testing Methods Are Used for Alternator Quality Assurance?

Several testing methods are commonly employed to verify the quality and functionality of alternators. These include:

-

Testes elétricos: This checks the alternator’s output voltage and current under various loads to ensure it meets specifications.

-

Testes térmicos: Alternators are subjected to high and low-temperature environments to evaluate their performance under extreme conditions.

-

Teste de vibração: This simulates real-world operational conditions to ensure that components can withstand the stresses of vehicle operation.

-

Leak Testing: For alternators with liquid cooling systems, ensuring that there are no leaks is critical for performance and longevity.

Como os compradores B2B podem verificar as práticas de controlo de qualidade dos fornecedores?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure the reliability of alternator parts. Here are some effective strategies:

-

Auditorias a fornecedores: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This includes reviewing documentation, inspecting facilities, and talking to quality assurance personnel.

-

Pedido de relatórios de qualidade: Suppliers should provide detailed quality reports that outline their testing methods, results, and compliance with relevant standards. This documentation serves as a valuable resource for evaluating supplier reliability.

-

Inspeções por terceiros: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These organizations often conduct random inspections and tests to validate the quality of the products.

What Are the Quality Control Considerations for International Buyers in Different Regions?

Quality control nuances can vary significantly by region. Buyers from Africa, South America, the Middle East, and Europe should be aware of specific considerations:

Illustrative image related to alternator parts diagram

-

Regulamentos regionais: Different countries have unique regulations regarding electrical components. It is essential to understand these requirements to ensure compliance and avoid potential issues during customs clearance.

-

Diferenças culturais nos padrões de qualidade: Expectations regarding quality and testing can vary. For instance, European buyers may have stricter quality demands compared to those in other regions. Understanding these cultural nuances can help in establishing effective communication with suppliers.

-

Desafios da logística e da cadeia de abastecimento: International shipping and logistics can impact product quality. Buyers should consider how products are packaged and transported to minimize risks such as damage during transit.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing alternator parts, ensuring reliability and performance in their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator parts diagram’

To assist B2B buyers in procuring high-quality alternator parts diagrams, this guide offers a practical checklist that emphasizes key actions and considerations. By following these steps, you can ensure that you select the right diagrams that meet your technical and operational needs.

Passo 1: Defina as suas especificações técnicas

Establish clear specifications for the alternator parts diagram you require. This includes the type of vehicle or equipment the alternator will serve and any specific components that must be illustrated, such as the rotor, stator, or rectifier. Precise specifications will help you communicate effectively with suppliers and ensure that the diagrams meet your operational requirements.

Passo 2: Identificar fornecedores de renome

Research potential suppliers who specialize in automotive diagrams and components. Look for companies with established reputations in the industry, particularly those that cater to your target regions, such as Africa, South America, the Middle East, and Europe. A supplier’s reputation can often be gauged through customer reviews, industry certifications, and their history of service.

Passo 3: Avaliar as certificações dos fornecedores

Before committing to a supplier, verify their certifications. Look for quality assurance certifications such as ISO 9001, which indicates a commitment to quality management practices. Additionally, check if they comply with local and international automotive standards, ensuring that the diagrams and parts meet required safety and performance criteria.

Illustrative image related to alternator parts diagram

Passo 4: Request Samples and References

Ask suppliers for sample diagrams and references from previous clients. This will provide insight into the quality and accuracy of their diagrams. Pay attention to the clarity of the diagrams, as well as any accompanying documentation that explains the components and their functions. Having references from clients in similar industries can further validate the supplier’s reliability.

Passo 5: Confirm Technical Support and Resources

Ensure that the supplier offers adequate technical support and resources. This is crucial for understanding the diagrams and troubleshooting any issues that may arise. Inquire about the availability of customer service, technical manuals, and online resources that can assist your team in utilizing the diagrams effectively.

Passo 6: Assess Customization Options

Determine if the supplier can provide customized diagrams tailored to your specific needs. Customization may be necessary if you require modifications to standard diagrams to fit unique equipment or operational requirements. Discuss any potential costs and timelines for customization upfront to avoid surprises later.

Passo 7: Negociar termos e condições

Finally, negotiate the terms and conditions of the purchase, including pricing, delivery timelines, and warranty information. Clearly outline expectations regarding revisions, returns, and support after the sale. A transparent agreement can help prevent misunderstandings and ensure a smooth procurement process.

By following this step-by-step checklist, B2B buyers can effectively source high-quality alternator parts diagrams that meet their technical needs and operational standards.

Comprehensive Cost and Pricing Analysis for alternator parts diagram Sourcing

What Are the Key Cost Components in Sourcing Alternator Parts Diagrams?

When sourcing alternator parts diagrams, understanding the cost structure is crucial for B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materiais: The primary materials used in alternator components include aluminum for the housing, copper for windings, and various plastics for insulation. Prices can fluctuate based on global market conditions, affecting overall costs.

-

Trabalho: Labor costs vary by region. For example, labor in developing regions, such as parts of Africa and South America, may be lower than in Europe, impacting the overall pricing structure. Skilled labor for assembly and quality assurance is essential to ensure product reliability.

-

Custos indiretos de produção: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce these costs, which can be a point of negotiation for buyers.

-

Ferramentas: Tooling costs can be significant, especially for customized parts. The design and production of specialized tools can require a substantial upfront investment, influencing pricing.

-

Controlo de qualidade: Ensuring that alternator parts meet international standards is critical. This includes inspections and certifications, which can increase costs but are necessary for maintaining quality and compliance.

-

Logística: Shipping costs can vary greatly based on the Incoterms agreed upon. Costs associated with storage, transportation, and customs clearance should be factored into the total cost.

-

Margem: Suppliers typically add a markup to cover their costs and desired profit. Understanding the typical margins in the industry can help buyers negotiate better prices.

How Do Price Influencers Impact Alternator Parts Diagram Sourcing?

Several factors can influence the pricing of alternator parts diagrams, which international buyers should consider:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Minimum order quantities (MOQs) can also affect pricing. Buyers should assess their needs and negotiate for better rates on bulk purchases.

-

Especificações e personalização: Unique specifications or custom designs can increase costs significantly. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materiais: The choice of materials can have a direct impact on cost. High-quality materials may incur higher upfront costs but can lead to better performance and longevity.

-

Qualidade e certificações: Products that meet higher quality standards or come with certifications may be priced higher. However, this investment can lead to reduced failure rates and lower Total Cost of Ownership (TCO).

-

Fatores relacionados ao fornecedor: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge a premium for their products due to their track record and quality assurance processes.

-

Incoterms: The agreed-upon Incoterms (e.g., FOB, CIF) will determine who bears the shipping costs and risks, impacting the final price. Understanding these terms is crucial for accurate budgeting.

What Buyer Tips Can Enhance Cost-Efficiency in Alternator Parts Diagram Sourcing?

B2B buyers can employ several strategies to enhance cost-efficiency:

-

Negociação: Engage in open discussions with suppliers about pricing and terms. Leverage your purchasing power, especially if ordering in bulk, to negotiate better rates.

-

Análise de custo-benefício: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as maintenance, longevity, and performance to make informed decisions.

-

Pesquisa de mercado: Understand the market trends and pricing benchmarks for alternator parts. This knowledge can empower buyers to negotiate effectively and recognize fair pricing.

-

Relações com fornecedores: Building long-term relationships with reliable suppliers can lead to better pricing and terms over time. Trust and communication can facilitate smoother transactions.

-

Global Sourcing: Consider sourcing from various regions to capitalize on cost advantages. For instance, suppliers from Africa or South America may offer competitive pricing compared to European suppliers.

Isenção de responsabilidade sobre preços

It is important to note that the prices associated with alternator parts diagrams can fluctuate based on market conditions, demand, and other external factors. Buyers should conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing alternator parts diagram With Other Solutions

Exploring Alternatives: What Are the Best Solutions to the Alternator Parts Diagram?

In the automotive and industrial sectors, understanding the components and functionality of systems like alternators is crucial. While the alternator parts diagram serves as a valuable tool for visualizing these elements, several alternative solutions and methods can also meet the needs of B2B buyers. This section analyzes the effectiveness of the alternator parts diagram compared to other approaches, helping decision-makers make informed choices.

Illustrative image related to alternator parts diagram

| Aspecto comparativo | Alternator Parts Diagram | Modelos CAD 3D | Interactive Software Tools |

|---|---|---|---|

| Desempenho | High clarity in component layout | Offers dynamic visualization | Provides real-time simulations |

| Custo | Generally low-cost | Moderate cost (software licenses) | High cost (software development) |

| Facilidade de implementação | Fácil de criar e partilhar | Requires software expertise | Requires training and setup |

| Manutenção | Low maintenance | Actualizações de software necessárias | Regular updates and IT support |

| Melhor caso de uso | Educational and technical reference | Design and engineering phases | Training and operational simulations |

What Are the Benefits of 3D CAD Models Compared to an Alternator Parts Diagram?

3D CAD models provide an advanced visualization of alternator components, allowing users to rotate and manipulate the model in a virtual space. This interactivity helps engineers and designers understand spatial relationships and component interactions more effectively than static diagrams. However, the cost of acquiring CAD software and the need for specialized training can be a barrier for some businesses. Additionally, while CAD models excel in design, they may not be as effective for educational purposes compared to simplified diagrams.

How Do Interactive Software Tools Compare to the Alternator Parts Diagram?

Interactive software tools offer a dynamic approach to learning and understanding alternators through real-time simulations. These tools can mimic the operational aspects of an alternator, showing how components work together under different conditions. While they provide a more engaging learning experience, the complexity and high cost of developing and maintaining such software can deter some B2B buyers. Moreover, users may require training to maximize the software’s capabilities, which can add to the overall investment.

Conclusion: How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting a solution for understanding alternator components, B2B buyers should consider their specific needs, budget constraints, and the required level of detail. The alternator parts diagram is ideal for educational and quick reference needs, while 3D CAD models and interactive software tools are more suited for design and engineering applications. By assessing the advantages and limitations of each alternative, businesses can choose the most effective solution that aligns with their operational goals and technical requirements.

Essential Technical Properties and Trade Terminology for alternator parts diagram

Quais são as principais propriedades técnicas das peças do alternador?

When engaging in the procurement of alternator parts, understanding specific technical properties is crucial for ensuring quality and compatibility. Here are some essential specifications:

1. Classe do material

Alternators are typically constructed from aluminum or steel due to their strength-to-weight ratio and resistance to corrosion. Aluminum is favored for its lightweight properties, while steel provides durability. For B2B buyers, selecting the appropriate material grade can impact the longevity and performance of the alternator, influencing maintenance costs and operational efficiency.

2. Níveis de tolerância

Tolerance refers to the acceptable range of variation in dimensions of alternator parts, such as the rotor and stator. Precision in manufacturing ensures that components fit together correctly, which is vital for performance and safety. Inaccurate tolerances can lead to mechanical failure, making it imperative for buyers to understand the specifications that meet their operational needs.

3. Tensão nominal

The voltage rating of an alternator indicates the maximum electrical output it can safely deliver. This is typically measured in volts (V). B2B buyers must match this rating with the electrical requirements of their vehicles or systems to avoid underperformance or damage. Selecting the correct voltage rating is essential for ensuring that the alternator meets the power demands of various electrical components.

4. Cooling Efficiency

Effective cooling mechanisms, such as internal fans or heat sinks, are critical for maintaining the alternator’s performance under load. High temperatures can lead to premature failure of components like the rectifier and voltage regulator. Buyers should assess cooling efficiency as part of their purchasing criteria to ensure optimal performance in high-temperature environments.

5. Output Current

The output current, measured in amperes (A), indicates the amount of electrical current the alternator can produce. This specification is vital for B2B buyers to ensure that the alternator can adequately power all electrical systems in the vehicle. Insufficient output can lead to battery drain and failure of electrical components.

What Are Common Trade Terms Related to Alternator Parts?

Understanding industry jargon can enhance communication and negotiation processes in B2B transactions. Here are several key terms:

1. OEM (Fabricante de Equipamento Original)

This term refers to companies that produce parts that are used in the manufacturing of a vehicle. When sourcing alternator parts, opting for OEM components can ensure compatibility and reliability, as they are designed to meet the specifications set by the vehicle manufacturer.

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and procurement costs. Buyers should negotiate MOQs that align with their operational needs and storage capabilities.

Illustrative image related to alternator parts diagram

3. RFQ (Pedido de Cotação)

An RFQ is a document sent to suppliers asking for price estimates for specific products or services. For B2B buyers, issuing an RFQ allows for comparison of prices and terms, facilitating informed decision-making when sourcing alternator parts.

4. Incoterms

Incoterms (International Commercial Terms) are internationally recognized rules that define the responsibilities of sellers and buyers in shipping transactions. Familiarity with Incoterms is vital for B2B buyers as they determine who is responsible for shipping costs, insurance, and liability during transit, impacting overall procurement expenses.

5. Mercado de reposição

Aftermarket refers to parts and accessories not made by the original manufacturer. While often less expensive, aftermarket parts can vary significantly in quality. B2B buyers should assess the reliability and warranty options associated with aftermarket alternators to ensure they meet operational standards.

Illustrative image related to alternator parts diagram

Understanding these properties and terms will empower B2B buyers to make informed decisions, ultimately leading to enhanced operational efficiency and reduced costs in managing alternator components.

Navigating Market Dynamics and Sourcing Trends in the alternator parts diagram Sector

Market Overview & Key Trends: What Drives the Alternator Parts Diagram Sector?

The alternator parts diagram sector is experiencing significant growth driven by several global factors. As the automotive industry shifts towards electrification, the demand for advanced alternator designs and components has surged. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality alternator parts that can withstand the rigors of modern engines. The rise of electric vehicles (EVs) is also reshaping market dynamics, prompting manufacturers to innovate with more efficient alternator systems that integrate seamlessly with hybrid and fully electric powertrains.

Emerging technologies such as 3D printing and IoT are transforming sourcing strategies. These innovations allow manufacturers to produce components with improved precision and reduced waste, which is appealing to cost-sensitive markets. Moreover, digital platforms for sourcing and procurement are gaining traction, enabling international buyers to access a wider range of suppliers and negotiate better terms. In regions like Saudi Arabia and Germany, where automotive standards are stringent, the ability to visualize alternator components through detailed diagrams becomes essential for compliance and quality assurance.

Additionally, the push for enhanced performance and fuel efficiency is leading to an increased focus on lightweight materials and advanced cooling technologies in alternator design. B2B buyers are prioritizing suppliers who can provide comprehensive technical documentation, including detailed alternator parts diagrams, to facilitate informed purchasing decisions and ensure compatibility with existing systems.

How Can Sustainability & Ethical Sourcing Impact the Alternator Parts Diagram Sector?

Sustainability is becoming a cornerstone of B2B sourcing strategies in the alternator parts diagram sector. As environmental regulations tighten globally, buyers are increasingly scrutinizing the ecological impact of their supply chains. This trend is particularly pronounced in Europe, where consumers and businesses alike prioritize suppliers that adopt sustainable practices. For instance, manufacturers are encouraged to use recyclable materials and energy-efficient production methods, which not only reduce waste but also lower production costs in the long run.

The importance of ethical sourcing cannot be overstated. B2B buyers are now more aware of the social implications of their procurement choices, seeking partners who uphold fair labor practices and transparency throughout the supply chain. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming critical benchmarks for evaluating potential suppliers.

Moreover, the adoption of “green” materials in alternator production, such as biodegradable lubricants and non-toxic coatings, is gaining traction. These innovations not only help manufacturers comply with environmental regulations but also appeal to eco-conscious buyers. By prioritizing sustainability and ethical sourcing, businesses can enhance their brand reputation and align with the values of a growing segment of environmentally aware consumers.

What is the Brief Evolution/History of the Alternator Parts Diagram Sector?

The alternator parts diagram sector has evolved significantly since the introduction of the alternator in the early 20th century. Initially designed to charge vehicle batteries and power electrical systems, early alternators were bulky and inefficient. Over the decades, advancements in materials and engineering led to the development of smaller, more efficient designs, including the modern lightweight aluminum housing and integrated cooling systems.

The integration of electronic components in the 1980s marked a pivotal shift, allowing for improved voltage regulation and the emergence of smart alternators capable of communicating with vehicle systems. This evolution necessitated detailed alternator parts diagrams, which became essential for manufacturers and repair technicians alike to understand complex systems and ensure proper installation and maintenance.

Today, as the automotive industry embraces electrification, the alternator parts diagram sector is poised for further transformation. With increasing emphasis on performance, efficiency, and sustainability, the demand for detailed, accurate diagrams will continue to grow, providing vital support for B2B buyers navigating this dynamic market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator parts diagram

-

How do I identify the right alternator parts diagram for my needs?

To identify the appropriate alternator parts diagram, first, determine the specific make and model of the vehicle or equipment you are sourcing for. Manufacturers often provide detailed diagrams that include part numbers, which can help ensure compatibility. Additionally, consult with suppliers who specialize in alternators, as they can provide insights and diagrams tailored to your requirements. Cross-referencing these diagrams with the actual alternator can help confirm that you are sourcing the correct parts. -

What are the key components to look for in an alternator parts diagram?

An effective alternator parts diagram should clearly illustrate essential components such as the rotor, stator, rectifier, voltage regulator, and cooling fan. It should also indicate the connections for the D-, B+, and D+ terminals. Understanding these components will aid in troubleshooting, maintenance, and replacement processes. If the diagram includes annotations or part numbers, it can facilitate easier ordering from suppliers. -

How can I ensure the quality of alternator parts when sourcing internationally?

To ensure the quality of alternator parts from international suppliers, conduct thorough research on the supplier’s reputation and history. Look for certifications such as ISO or similar quality assurance standards. Request samples or detailed product specifications before placing larger orders. Additionally, consider utilizing third-party inspection services to verify the quality and compliance of the parts before shipment. -

What are the common payment terms for B2B transactions in alternator parts sourcing?

Payment terms can vary widely among suppliers, but common practices include upfront payment, 30% deposit with the balance upon delivery, or payment through letters of credit. It is crucial to clarify these terms before finalizing any agreement. In international transactions, ensure that payment methods comply with regulations in both your country and the supplier’s country, and consider options that provide security for both parties. -

What is the minimum order quantity (MOQ) typically required for alternator parts?

Minimum order quantities (MOQs) for alternator parts can differ based on the supplier and the type of parts being ordered. Generally, MOQs can range from 50 to 500 units, depending on the part’s demand and the supplier’s production capabilities. It’s advisable to discuss MOQs directly with suppliers, as some may be flexible, especially for new customers or bulk orders. -

How can I customize alternator parts for specific applications?

Customization of alternator parts typically involves collaborating closely with your supplier. Provide detailed specifications, including dimensions, materials, and any specific performance requirements. Some manufacturers may offer design services or modifications based on your needs. Be prepared to discuss lead times and costs associated with custom parts, as these can vary significantly. -

What logistics considerations should I keep in mind when sourcing alternator parts internationally?

When sourcing alternator parts internationally, consider shipping methods, customs regulations, and potential tariffs or duties. Choose a reliable logistics partner who understands the nuances of international shipping. Ensure that your supplier can provide the necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance. Additionally, factor in delivery times and choose shipping options that align with your project timelines. -

How do I handle warranty and return issues for alternator parts?

When sourcing alternator parts, inquire about the warranty policy and return procedures upfront. Understand the duration of the warranty, what it covers, and the process for claims. Maintain clear communication with your supplier regarding any defects or issues with the parts upon receipt. Document any problems and follow the supplier’s return policy meticulously to ensure a smooth resolution.

Top 5 Alternator Parts Diagram Manufacturers & Suppliers List

1. Electude – Noções básicas sobre alternadores

Domínio: electude.com

Registado: 2005 (20 anos)

Introdução: An alternator is a crucial automotive component that converts mechanical energy into electrical energy, generating power for the vehicle’s electrical systems and battery. Key components include:

– Polia: transfere a energia mecânica do motor.

– Rotor: Cria o campo magnético para gerar corrente alternada.

– Estator: A parte estática onde a tensão é gerada.

– Rectifier: Converts a…

2. HowStuffWorks – Alternadores

Domínio: auto.howstuffworks.com

Registado: 1998 (27 anos)

Introdução: Os alternadores são pequenos e leves, aproximadamente do tamanho de um coco, construídos com uma carcaça externa de alumínio para dissipação de calor e não magnetização. Os componentes principais incluem:

– Polia de transmissão fixada ao eixo do rotor, convertendo energia mecânica em energia elétrica.

– Terminais: Terminal S (deteta a tensão da bateria), terminal IG (interruptor de ignição para o regulador de tensão), terminal L (fecha c...

3. Pinterest – Exploded View of an Alternator

4. Facebook – Automotive Alternator Diagram

Domínio: facebook.com

Registado: 1997 (28 anos)

Introdução: Detailed diagram of an automotive alternator and its main components.

5. Scribd – Automotive Alternator Key Parts

Domínio: scribd.com

Registada: 2006 (19 anos)

Introdução: The document discusses the main parts and functions of an automotive alternator, describing 8 key parts: 1) the pulley that rotates the rotor assembly via the engine belt, 2) the housing that protects internal components, 3) bearings that allow the rotor to spin freely, 4) the rotor assembly that generates a magnetic field, 5) the stator assembly that uses this field to generate electricity, 6) th…

Strategic Sourcing Conclusion and Outlook for alternator parts diagram

In conclusion, the strategic sourcing of alternator parts is vital for maintaining the efficiency and reliability of automotive systems across diverse markets. Understanding the intricate components of an alternator, such as the rotor, stator, and voltage regulator, allows international buyers to make informed purchasing decisions. By prioritizing quality and compatibility, businesses can minimize operational disruptions and enhance vehicle performance.

Illustrative image related to alternator parts diagram

As global supply chains evolve, sourcing from reputable manufacturers is essential to ensure not only product quality but also adherence to regional standards. Buyers from regions such as Africa, South America, the Middle East, and Europe should leverage the insights provided in this guide to identify key suppliers that align with their operational needs and budget constraints.

Looking ahead, the demand for high-quality alternator parts will only grow as the automotive industry increasingly focuses on sustainability and efficiency. Engaging with reliable suppliers and fostering long-term partnerships will be crucial. We encourage international B2B buyers to take proactive steps towards optimizing their sourcing strategies, ensuring they remain competitive in an ever-changing market landscape.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.