Introduction: Navigating the Global Market for starter motor

In the ever-evolving automotive landscape, sourcing reliable starter motors presents a significant challenge for international B2B buyers. The starter motor plays a critical role in vehicle functionality, acting as the first step in the engine’s ignition process. Understanding the various types, applications, and performance metrics of starter motors is essential for making informed purchasing decisions. This guide serves as a comprehensive resource, addressing everything from the different starter motor types suited for diverse vehicle applications to strategies for supplier vetting and cost considerations.

As businesses in regions like Africa, South America, the Middle East, and Europe (notably countries like Saudi Arabia and Germany) navigate their unique market dynamics, the importance of selecting the right starter motor cannot be overstated. Factors such as local regulations, market demand, and logistical challenges can complicate the sourcing process. By equipping buyers with in-depth insights into product specifications, compatibility issues, and maintenance requirements, this guide empowers them to make strategic decisions that enhance operational efficiency and reduce downtime.

Whether you are a fleet manager looking to optimize vehicle performance or a parts distributor aiming to expand your inventory, understanding the global market for starter motors is crucial. This guide is your gateway to mastering the complexities of starter motor procurement, ensuring that you remain competitive and informed in a rapidly changing environment.

Índice

- Top 5 Starter Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter motor

- Understanding starter motor Types and Variations

- Key Industrial Applications of starter motor

- 3 Common User Pain Points for ‘starter motor’ & Their Solutions

- Strategic Material Selection Guide for starter motor

- In-depth Look: Manufacturing Processes and Quality Assurance for starter motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor’

- Comprehensive Cost and Pricing Analysis for starter motor Sourcing

- Alternatives Analysis: Comparing starter motor With Other Solutions

- Essential Technical Properties and Trade Terminology for starter motor

- Navigating Market Dynamics and Sourcing Trends in the starter motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter motor

- Strategic Sourcing Conclusion and Outlook for starter motor

- Aviso legal importante e termos de utilização

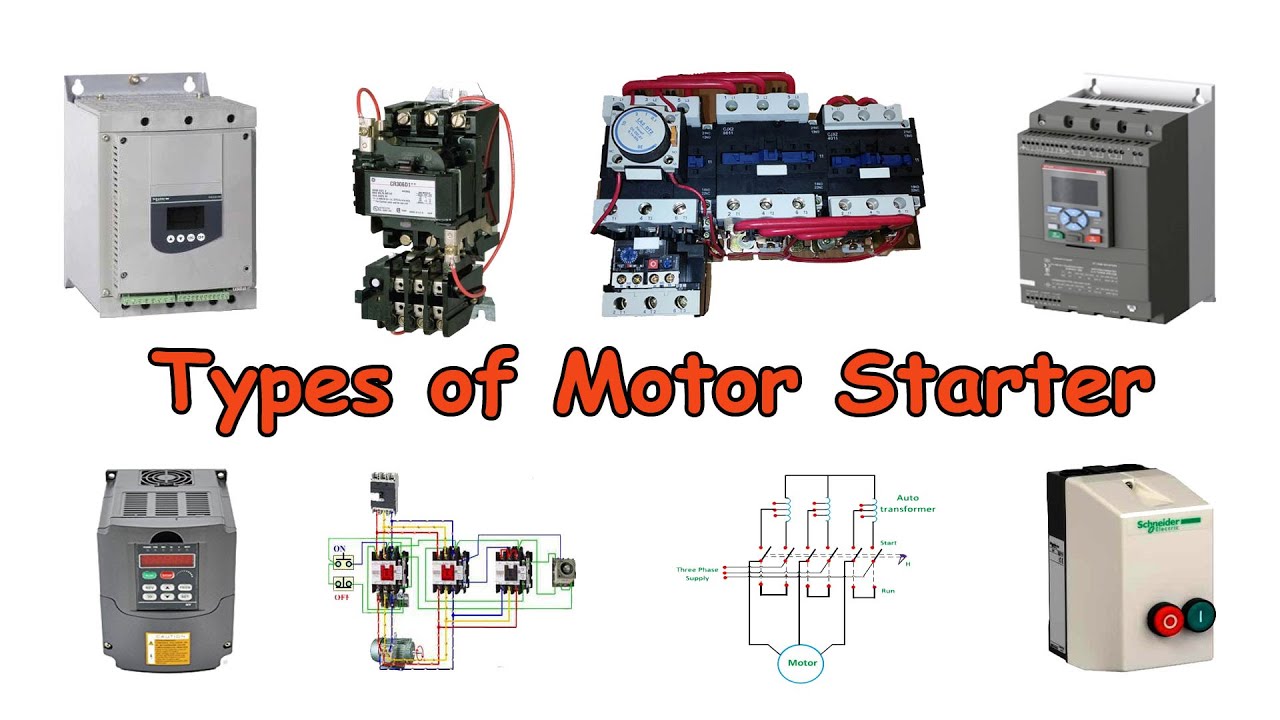

Understanding starter motor Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Motor de arranque com redução de engrenagem | Utilizes a gear reduction system for higher torque | Heavy-duty vehicles, construction | Prós: High torque, efficient for large engines. Contras: Bulkier, may require more maintenance. |

| Arrancador de Íman Permanente | Compact design using permanent magnets | Automóvel, motociclos | Prós: Lightweight, reliable, and cost-effective. Contras: Less torque compared to gear reduction types. |

| Solenoide de arranque | Integrates solenoid for engaging the starter gear | Commercial vehicles, marine engines | Prós: Simple design, easy to install. Contras: Vulnerable to electrical failures. |

| Arrancador de alto desempenho | Designed for racing and high-performance engines | Racing cars, high-performance vehicles | Prós: Enhanced durability and speed. Contras: Custo mais elevado, pode não ser adequado para utilização quotidiana. |

| Diesel Starter Motor | Designed specifically for diesel engines | Heavy-duty trucks, agricultural equipment | Prós: Optimized for high compression engines. Contras: Heavier, more complex electrical requirements. |

What Are the Characteristics of Gear Reduction Starters?

Gear reduction starters are engineered to deliver high torque output, making them ideal for heavy-duty applications such as construction vehicles and large machinery. They utilize a gear system that multiplies the torque provided by the motor, allowing for easier starts of larger engines. When considering a gear reduction starter, B2B buyers should evaluate the compatibility with their engine specifications and the potential need for increased maintenance due to their complexity.

How Do Permanent Magnet Starters Differ from Other Types?

Permanent magnet starters are characterized by their compact design and the use of permanent magnets to generate the necessary electromagnetic field. This type of starter is commonly used in automotive applications and motorcycles, where space and weight are critical factors. For B2B buyers, the primary considerations should include the starter’s weight, reliability, and cost-effectiveness, especially for mass-produced vehicles.

Why Choose Solenoid Starters for Commercial Vehicles?

Solenoid starters are known for their straightforward design, which includes a solenoid that engages the starter gear when activated. This type is frequently used in commercial vehicles and marine engines due to its ease of installation and maintenance. Buyers should consider the electrical system’s compatibility and the potential for solenoid-related failures, which can impact operational efficiency.

What Makes High-Performance Starters Suitable for Racing?

High-performance starters are tailored for racing and high-performance vehicles, providing enhanced durability and quicker engagement times. These starters are built to withstand extreme conditions and are often lighter than traditional models. B2B buyers in the racing industry should assess the starter’s specifications against their engine requirements and weigh the benefits of speed and reliability against the higher investment costs.

How Are Diesel Starter Motors Designed for Heavy-Duty Applications?

Diesel starter motors are specifically designed to meet the demands of high-compression diesel engines found in heavy-duty trucks and agricultural equipment. They are built to handle the increased starting loads that diesel engines require. Buyers should focus on the starter’s compatibility with their specific diesel engines and consider the potential for higher wear rates due to the demanding nature of these applications.

Key Industrial Applications of starter motor

| Indústria/Setor | Specific Application of Starter Motor | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Fabricação Automotiva | Engine Assembly in Vehicles | Ensures reliable vehicle startups, enhancing production efficiency. | Quality control standards, compatibility with various engine types. |

| Equipamento de construção | Cranking Diesel Engines in Heavy Machinery | Facilitates efficient operation of heavy equipment, reducing downtime. | Durability under harsh conditions, ease of installation. |

| Indústria naval | Starting Marine Engines | Provides reliable engine starts for boats and vessels, critical for safety. | Corrosion resistance, compliance with maritime regulations. |

| Máquinas agrícolas | Ignition of Tractors and Harvesters | Ensures operational readiness, vital for timely agricultural activities. | High torque performance, ability to function in extreme weather. |

| Produção de energia | Starting Backup Generators | Guarantees immediate power availability during outages, enhancing reliability. | Sourcing from reputable manufacturers, ensuring voltage compatibility. |

Como é que o motor de arranque é utilizado no fabrico de automóveis?

In automotive manufacturing, starter motors are integral to the assembly of vehicles. They are used to crank the engine during the initial startup process, ensuring that the vehicle can start reliably every time. This reliability is critical in a production environment where efficiency is paramount. Buyers in this sector must consider sourcing starter motors that meet strict quality control standards and are compatible with various engine types, especially with the diverse automotive markets in Europe and South America.

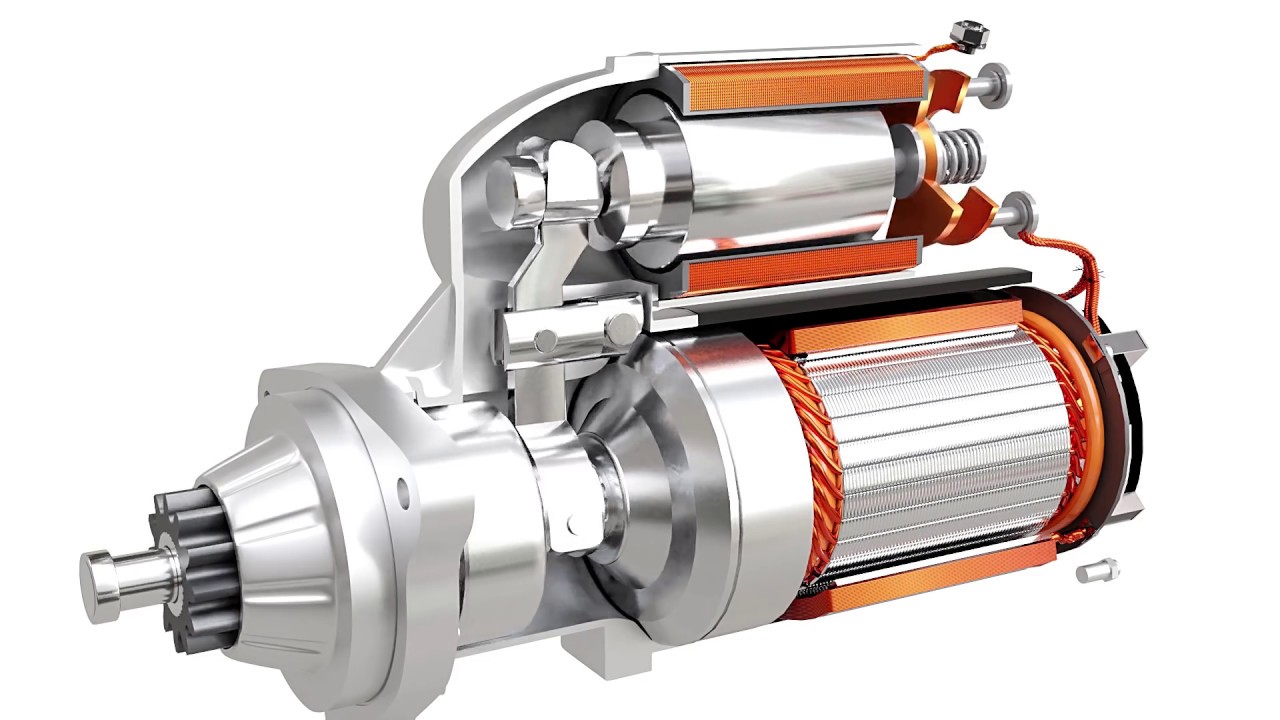

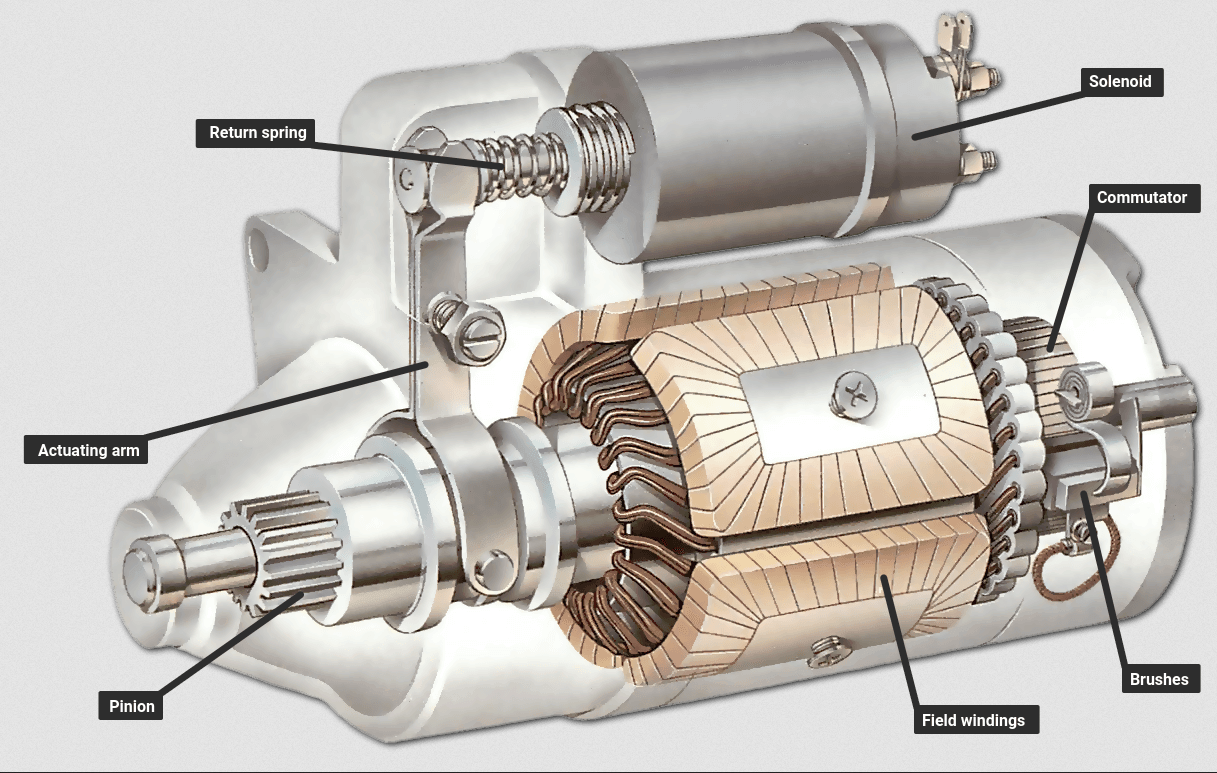

Illustrative image related to starter motor

What Role Does the Starter Motor Play in Construction Equipment?

Starter motors are essential for cranking diesel engines in construction machinery, such as excavators and bulldozers. These machines operate under challenging conditions, and a reliable starter motor ensures that heavy equipment can be operational without delays. For businesses in the construction sector, sourcing durable starter motors that can withstand extreme temperatures and vibrations is crucial. Additionally, ease of installation is a significant consideration to minimize downtime during equipment servicing.

How Does the Starter Motor Benefit the Marine Industry?

In the marine industry, starter motors are vital for starting engines on boats and vessels. A reliable starter motor is essential for safety, as it ensures that the engine can start promptly, particularly in emergency situations. Marine buyers need to focus on sourcing starter motors that offer corrosion resistance and comply with maritime regulations, especially in regions like the Middle East where environmental conditions can be harsh. The reliability of these components can significantly influence operational safety and efficiency at sea.

Why is the Starter Motor Important for Agricultural Machinery?

Starter motors are crucial for the ignition of tractors and harvesters, which are indispensable in agricultural operations. These motors ensure that machinery starts promptly, allowing farmers to perform tasks on schedule, which is vital during planting and harvesting seasons. Buyers in the agricultural sector should prioritize high torque performance in starter motors, as well as their ability to function effectively in extreme weather conditions typical of many regions in Africa and South America.

What is the Importance of Starter Motors in Power Generation?

In power generation, starter motors are used to initiate backup generators, providing critical power during outages. Their reliability directly impacts the effectiveness of emergency power systems, making them essential for businesses that require uninterrupted power supply. When sourcing starter motors for this application, companies should ensure they are from reputable manufacturers and that they meet specific voltage compatibility requirements to align with their generator systems, particularly in regions with varying electrical standards.

3 Common User Pain Points for ‘starter motor’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Starter Motors

O problema: B2B buyers, especially those in regions with limited access to automotive parts, often struggle to source high-quality starter motors for various vehicle models. This can lead to delays in repairs and increased operational costs, particularly for fleet operators who rely on prompt vehicle maintenance. Unscrupulous suppliers may offer low-quality or counterfeit products, further complicating the purchasing decision.

A solução: To navigate this challenge, buyers should establish relationships with reputable suppliers who provide verifiable product certifications and warranties. When sourcing starter motors, consider utilizing platforms that specialize in automotive parts and offer a wide range of OEM (Original Equipment Manufacturer) products. It’s essential to review supplier ratings and customer feedback to ensure reliability. Additionally, building a network with other businesses in the automotive sector can yield recommendations for trustworthy suppliers. Conducting due diligence in the sourcing process, such as requesting product samples or specifications, can further ensure that the starter motors meet performance standards.

Scenario 2: Misalignment Between Starter Motor Specifications and Vehicle Requirements

O problema: Another significant pain point for B2B buyers arises when the starter motors ordered do not align with the specific requirements of their vehicles. This misalignment can stem from unclear specifications or changes in vehicle designs that are not reflected in the parts catalog. Such discrepancies can lead to wasted time and resources, as well as frustration during the installation process.

A solução: To mitigate this issue, it is crucial for buyers to invest time in understanding the specifications of the starter motors required for their fleet or inventory. This includes paying close attention to the vehicle make, model, and engine type. Buyers should leverage detailed databases and technical manuals that provide comprehensive information about compatible parts. Furthermore, engaging with manufacturers or suppliers who offer technical support can help clarify any uncertainties regarding compatibility. Utilizing digital tools or inventory management systems that track vehicle specifications can also streamline the ordering process, ensuring that the correct starter motors are sourced every time.

Illustrative image related to starter motor

Scenario 3: Performance Issues and Unanticipated Failures of Starter Motors

O problema: Performance issues, such as starter motors failing prematurely or not operating efficiently, can lead to significant downtime for businesses that depend on their vehicles. These failures may be attributed to factors such as poor-quality parts, inadequate maintenance, or incorrect installation. For fleet operators, this can result in lost revenue and diminished service quality, creating a ripple effect on their operations.

A solução: To address performance-related concerns, buyers should prioritize regular maintenance and service checks for their vehicles, focusing specifically on the starter motor. Implementing a proactive maintenance schedule that includes inspections of the electrical systems, battery, and starter motor can help identify potential issues before they lead to failure. Moreover, when purchasing starter motors, opt for products that come with strong warranties and proven track records of durability. Establishing partnerships with experienced mechanics who can provide proper installation and maintenance advice is also beneficial. Additionally, investing in training for in-house technicians on the latest automotive technologies and maintenance practices can enhance overall vehicle reliability and performance, reducing the likelihood of unexpected failures.

Strategic Material Selection Guide for starter motor

Quais materiais são normalmente usados em motores de arranque?

When selecting materials for starter motors, it is essential to consider their properties, advantages, disadvantages, and the specific needs of international markets. Here, we analyze four common materials used in the construction of starter motors: steel, aluminum, copper, and plastic.

Illustrative image related to starter motor

Qual o desempenho do aço em aplicações de motores de arranque?

Steel is a prevalent choice for various components in starter motors due to its high strength and durability. It typically offers excellent temperature and pressure ratings, making it suitable for the demanding environment of an automotive engine. Steel’s corrosion resistance can vary; however, when treated or coated, it can withstand harsh conditions.

Prós: Steel provides robust mechanical properties, ensuring longevity and reliability. It is relatively cost-effective and widely available, making it a preferred choice for manufacturers.

Contras: The weight of steel can be a drawback, affecting fuel efficiency in vehicles. Additionally, the manufacturing complexity can increase if intricate designs are required.

Impacto na aplicação: Steel components are compatible with high-pressure applications, making them ideal for starter motors that need to engage quickly and effectively.

Considerações para compradores internacionais: Buyers in regions like Europe and the Middle East should ensure compliance with relevant standards such as DIN and ASTM, particularly regarding corrosion resistance and mechanical properties.

Illustrative image related to starter motor

What Role Does Aluminum Play in Starter Motors?

Aluminum is often used in starter motor housings and components due to its lightweight nature and good thermal conductivity. It can handle moderate temperature ranges effectively, making it suitable for automotive applications.

Prós: The primary advantage of aluminum is its weight reduction, which can enhance vehicle performance and fuel efficiency. It also offers good resistance to corrosion, especially when anodized.

Contras: Aluminum can be more expensive than steel and may require specialized manufacturing processes, which can increase production costs. Its mechanical strength is generally lower than that of steel, which could be a concern in high-stress applications.

Impacto na aplicação: Aluminum is suitable for parts that need to dissipate heat quickly, such as housings that surround electrical components.

Considerações para compradores internacionais: Buyers should be aware of the specific alloys used, as some may not meet the necessary performance standards in extreme temperatures, particularly in regions like Africa or South America.

Why Is Copper Important in Starter Motors?

Copper is primarily used in the electrical components of starter motors, such as windings and connectors, due to its excellent electrical conductivity. It can handle high current loads, which is critical for the starter motor’s performance.

Prós: The high conductivity of copper ensures efficient power transfer, reducing energy loss and improving overall performance. It is also relatively easy to work with during manufacturing.

Contras: Copper is prone to corrosion, particularly in humid environments, which can lead to electrical failures over time. Additionally, it is more expensive than other conductive materials like aluminum.

Illustrative image related to starter motor

Impacto na aplicação: Copper’s compatibility with high electrical loads makes it essential for the effective operation of starter motors.

Considerações para compradores internacionais: Buyers must consider the environmental conditions in their regions, as corrosion-resistant coatings may be necessary in humid climates, especially in parts of Africa and South America.

How Is Plastic Used in Starter Motor Components?

Plastic is increasingly being used for non-structural components in starter motors, such as housings for electrical connectors or insulation parts. It offers good electrical insulation properties and can be manufactured in various shapes and sizes.

Illustrative image related to starter motor

Prós: The lightweight nature of plastic contributes to overall vehicle weight reduction. It is also cost-effective and can be produced in high volumes with relative ease.

Contras: Plastic components may not withstand high temperatures or mechanical stress as well as metals, which can limit their application in critical areas.

Impacto na aplicação: Plastic is suitable for components that require electrical insulation and are not subjected to high mechanical loads.

Considerações para compradores internacionais: Buyers should ensure that the plastics used are compliant with automotive standards, particularly regarding heat resistance and durability, especially in regions with extreme temperatures.

Illustrative image related to starter motor

Tabela resumida da seleção de materiais para motores de arranque

| Material | Typical Use Case for starter motor | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Aço | Componentes estruturais | Alta resistência e durabilidade | Heavier weight | Médio |

| Alumínio | Componentes de alojamento e leves | Leve e resistente à corrosão | Resistência mecânica inferior à do aço | Alto |

| Cobre | Enrolamentos eléctricos e conectores | Excelente condutividade elétrica | Suscetível à corrosão | Alto |

| Plástico | Isolamento e peças não estruturais | Leve e económico | Limited heat and stress resistance | Baixo |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for starter motors, considering performance, cost, and regional compliance factors.

In-depth Look: Manufacturing Processes and Quality Assurance for starter motor

Quais são as principais etapas do processo de fabrico de motores de arranque?

The manufacturing process of starter motors involves several critical stages that ensure the final product meets the stringent performance and reliability standards required in automotive applications. The main stages include material preparation, forming, assembly, and finishing.

Preparação do material

The initial stage involves selecting high-quality raw materials, such as steel for the housing, copper for windings, and various alloys for gears and components. These materials are subjected to rigorous testing to confirm their mechanical properties, electrical conductivity, and thermal resistance. Ensuring the right specifications at this stage is crucial for the durability and functionality of the starter motor.

Técnicas de conformação

Once materials are prepared, they undergo various forming processes. Techniques such as stamping, forging, and machining are commonly used to shape the metal components of the starter motor. Precision is essential in this stage, as any deviations can lead to malfunction. CNC (Computer Numerical Control) machining is often employed to achieve high accuracy and repeatability in producing intricate parts like the rotor and stator.

Processo de montagem

The assembly phase is where various components come together. This includes the insertion of windings into the stator, assembly of the rotor, and integration of solenoids and gears. Automated assembly lines are frequently utilized to enhance efficiency and minimize human error. Each assembly step is carefully documented to maintain traceability, which is vital for quality control and regulatory compliance.

Técnicas de acabamento

Finally, finishing techniques such as painting, coating, and surface treatment are applied to enhance corrosion resistance and aesthetic appeal. This stage may also involve the application of thermal and electrical insulation materials. Quality checks are performed at each step to ensure that the finished products meet both functional and aesthetic criteria.

Como é implementada a garantia de qualidade no fabrico de motores de arranque?

Quality assurance (QA) is integral to the manufacturing of starter motors, ensuring that each unit produced meets or exceeds industry standards. Several international and industry-specific standards guide these processes.

Illustrative image related to starter motor

Normas internacionais

ISO 9001 is the most widely recognized standard for quality management systems. Adhering to ISO 9001 helps manufacturers implement systematic processes that improve efficiency and customer satisfaction. Compliance with CE marking requirements is also essential for products sold in Europe, signifying conformity with health, safety, and environmental protection standards.

Normas específicas do sector

In addition to general quality standards, specific regulations such as API (American Petroleum Institute) may apply, especially for starter motors used in automotive and industrial applications. Compliance with these standards ensures that products meet the necessary performance benchmarks.

What Are the Key Quality Control Checkpoints in Starter Motor Production?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure consistency. Common checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Controlo de Qualidade de Entrada (IQC)

At this stage, raw materials and components are inspected upon arrival. Suppliers must provide certificates of compliance, and any discrepancies are addressed before materials enter the production line.

Controlo de qualidade em processo (IPQC)

During the manufacturing process, periodic inspections are conducted to monitor the assembly and fabrication of components. This includes dimensional checks, functionality tests, and visual inspections to catch any defects early.

Controlo de Qualidade Final (FQC)

Once the starter motors are fully assembled, they undergo rigorous testing. This may include performance testing, electrical testing, and thermal cycling to simulate real-world conditions. The results are documented and analyzed to ensure all units meet required specifications.

What Testing Methods Are Commonly Used to Ensure Starter Motor Quality?

Various testing methods are employed to validate the performance and reliability of starter motors. These methods can include:

- Testes elétricos: Assessing the electrical resistance and current draw to ensure optimal performance.

- Testes funcionais: Running the starter motor in a controlled environment to evaluate its operational efficiency.

- Testes térmicos: Simulating extreme temperatures to ensure the motor can withstand high-stress conditions.

- Ensaios de vibração: Subjecting the motor to vibrations to ensure durability in real-world applications.

Como podem os compradores B2B verificar os processos de controlo de qualidade dos fornecedores?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

Illustrative image related to starter motor

Auditorias a fornecedores

Conducting regular audits of suppliers can provide insight into their manufacturing practices and quality assurance measures. Audits should focus on compliance with international standards, adherence to documented processes, and the effectiveness of their QC checkpoints.

Relatórios de qualidade

Requesting quality assurance reports can offer a glimpse into the supplier’s QA processes. These reports should detail testing methods, results, and any corrective actions taken in response to defects.

Inspeções por terceiros

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control. These agencies can perform on-site inspections and testing to verify that products meet specified standards before shipment.

Quais são as nuances do controlo de qualidade para compradores B2B internacionais?

Navigating quality control nuances can be particularly challenging for international B2B buyers. Different regions may have varying standards, and understanding these differences is vital. For instance, compliance with EU regulations may differ significantly from those in the Middle East or South America.

Buyers should familiarize themselves with local regulations and standards relevant to their markets. Additionally, establishing clear communication with suppliers about quality expectations and compliance requirements can help mitigate risks associated with subpar products.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for starter motors is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they procure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor’

To assist B2B buyers in the procurement of starter motors, this practical sourcing guide provides a structured checklist that ensures informed decision-making. This guide addresses critical aspects from technical specifications to supplier evaluation, tailored specifically for international buyers, including those from Africa, South America, the Middle East, and Europe.

Passo 1: Defina as suas especificações técnicas

Start by clearly outlining the technical specifications required for the starter motors you intend to procure. Consider factors such as voltage requirements, compatibility with specific vehicle models, and any certifications needed for your market. This clarity will streamline your search and ensure that you only engage with suppliers who can meet your specific needs.

Passo 2: Pesquisar tendências e padrões de mercado

Understanding current market trends and industry standards is essential. Look into recent advancements in starter motor technology, such as improved energy efficiency or durability. Additionally, familiarize yourself with regional standards and regulations that may affect your purchase, particularly if you are sourcing from different continents.

Passo 3: Avalie potenciais fornecedores

Before making a commitment, thoroughly vet potential suppliers. Request comprehensive company profiles, including their manufacturing capabilities and quality control processes. Seek references from other businesses in your industry to gauge supplier reliability. This due diligence is vital to ensuring that you partner with a reputable source.

Passo 4: Solicitar amostras para teste

Always request samples of starter motors before finalizing your order. Testing samples allows you to assess quality, performance, and compatibility with your vehicles. This step is crucial to mitigate risks associated with bulk purchases, ensuring that the products meet your specifications and performance expectations.

Passo 5: Verificar as certificações dos fornecedores

Ensure that suppliers possess the necessary certifications relevant to your market. Look for ISO certifications, compliance with local regulations, and any industry-specific certifications that may apply. Valid certifications are indicative of a supplier’s commitment to quality and can help avoid future compliance issues.

Passo 6: Avalie os preços e as condições de pagamento

Analyze the pricing structures offered by various suppliers, but don’t base your decision solely on cost. Consider payment terms, bulk purchase discounts, and shipping costs. A supplier offering competitive pricing might have hidden costs that could impact your overall expenditure, so clarity in this area is essential.

Passo 7: Estabeleça um plano de comunicação

Once you have selected a supplier, establish a clear communication plan. Define points of contact, preferred communication channels, and response time expectations. Effective communication is crucial for addressing potential issues quickly and ensuring a smooth procurement process.

By following these steps, B2B buyers can make informed decisions when sourcing starter motors, ultimately leading to successful procurement outcomes and long-term supplier relationships.

Comprehensive Cost and Pricing Analysis for starter motor Sourcing

What Are the Key Cost Components for Starter Motor Sourcing?

When sourcing starter motors, several cost components must be considered to understand the overall pricing structure. These include:

Illustrative image related to starter motor

-

Materiais: The quality of raw materials used in manufacturing starter motors directly affects costs. Common materials include steel, copper, and various plastics. Higher-quality materials may incur increased costs but can lead to better performance and longevity.

-

Trabalho: Labor costs encompass wages for skilled workers who assemble the motors and conduct quality assurance checks. Regions with higher labor costs may see a significant impact on overall pricing.

-

Custos indiretos de produção: This includes costs related to factory operations, such as utilities, equipment maintenance, and indirect labor. Efficient production processes can help minimize these costs.

-

Ferramentas: The initial investment in specialized tools and molds required for production can be substantial. These costs are often amortized over large production runs, making them less significant on a per-unit basis for bulk orders.

-

Controlo de Qualidade (QC): Rigorous quality control processes ensure that starter motors meet industry standards and specifications. While this adds to the cost, it can reduce returns and warranty claims.

-

Logística: Transportation and handling costs for delivering starter motors from the manufacturer to the buyer can vary greatly depending on distance, shipping methods, and import duties.

-

Margem: Suppliers will add a profit margin to cover their operational costs and risks. Understanding the typical margin in the market can help buyers gauge pricing fairness.

How Do Price Influencers Impact Starter Motor Costs?

Several factors influence the final price of starter motors, which buyers should consider:

-

Volume e quantidade mínima de encomenda (MOQ): Bulk orders often lead to reduced per-unit costs. Negotiating favorable MOQs can result in significant savings.

-

Especificações e personalização: Customized starter motors designed for specific vehicle models may incur higher costs due to unique tooling and material requirements. Standardized models typically offer more competitive pricing.

-

Qualidade dos materiais e certificações: Motors made from premium materials or those that comply with specific international standards (such as ISO certifications) can command higher prices. Buyers should assess whether these certifications are necessary for their operations.

-

Fatores relacionados ao fornecedor: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding the terms of trade (Incoterms) can significantly impact overall costs. For instance, FOB (Free on Board) shipping may involve different responsibilities and costs compared to CIF (Cost, Insurance, and Freight).

What Are the Best Buyer Tips for Cost-Efficient Starter Motor Sourcing?

To navigate the complexities of sourcing starter motors effectively, consider the following tips:

-

Negocie com sabedoria: Establishing strong relationships with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate on both price and payment terms, especially for larger orders.

-

Foco no custo total de propriedade (TCO): Evaluate the long-term value of starter motors rather than just the upfront cost. Consider factors such as durability, warranty, and maintenance requirements, as these can significantly impact TCO.

-

Compreenda as nuances dos preços nos mercados internacionais: Different regions may have varying pricing strategies due to local economic conditions, tariffs, and demand. For instance, buyers in Africa and South America may face different challenges compared to those in Europe, affecting their negotiation strategies.

-

Mantenha-se informado sobre as tendências do mercado: Regularly review market conditions and technological advancements that may impact starter motor pricing. Awareness of emerging trends can provide leverage during negotiations.

Isenção de responsabilidade sobre preços indicativos

It is essential to note that prices for starter motors can fluctuate based on numerous variables, including market demand, geopolitical factors, and supply chain dynamics. Therefore, the prices mentioned in various references should be viewed as indicative rather than fixed. Always obtain quotes from multiple suppliers to ensure competitive pricing aligned with current market conditions.

Alternatives Analysis: Comparing starter motor With Other Solutions

Exploring Alternatives to the Starter Motor: A Comprehensive Comparison

In the automotive industry, the starter motor plays a crucial role in initiating the combustion process within internal combustion engines. However, as technology evolves, several alternative solutions have emerged that may serve similar functions or complement the starter motor’s capabilities. This analysis compares the traditional starter motor with two notable alternatives: the Gerador de arranque integrado (ISG) e Battery Electric Vehicle (BEV) Systems.

| Aspecto comparativo | Motor de arranque | Gerador de arranque integrado (ISG) | Battery Electric Vehicle (BEV) Systems |

|---|---|---|---|

| Desempenho | Reliable for conventional engines; starts engines quickly. | Combines starter and alternator functions; improves fuel efficiency. | Provides instant torque; silent operation. |

| Custo | Generally low replacement cost (£230-£384). | Higher initial cost due to complexity. | High upfront investment; long-term savings on fuel. |

| Facilidade de implementação | Simple installation in traditional vehicles. | Requires integration into hybrid systems; more complex. | Needs specialized infrastructure and charging stations. |

| Manutenção | Regular checks needed; can last 100,000-150,000 miles. | Lower maintenance due to fewer moving parts. | Minimal maintenance; battery replacement is costly. |

| Melhor caso de uso | Ideal for conventional petrol and diesel vehicles. | Best for hybrid vehicles seeking efficiency. | Perfect for fully electric vehicles with zero emissions. |

Understanding Integrated Starter Generators (ISG)

The Integrated Starter Generator (ISG) merges the functions of a starter motor and an alternator into a single unit. This innovative solution is particularly beneficial for hybrid vehicles, as it enhances fuel efficiency by enabling regenerative braking and allowing the engine to shut off during idling. The ISG system can provide a seamless transition between electric and combustion power, reducing emissions and improving overall vehicle performance. However, the complexity and higher cost of installation can be a deterrent for some buyers, especially in markets where conventional vehicles remain prevalent.

Evaluating Battery Electric Vehicle (BEV) Systems

Battery Electric Vehicle (BEV) systems represent a significant shift away from traditional starter motor technology. BEVs utilize electric motors powered by rechargeable batteries, delivering instant torque and a quiet driving experience. The reduction in mechanical components means that BEVs require less maintenance compared to internal combustion engines. However, the higher initial investment and the need for charging infrastructure can present challenges, particularly in regions where electric vehicle adoption is still growing. Despite these challenges, the long-term operational cost savings and environmental benefits make BEVs an appealing option for forward-thinking businesses.

Conclusão: Fazer a escolha certa para a sua empresa

When selecting the right solution for starting vehicle engines, B2B buyers must consider several factors, including performance needs, budget constraints, and long-term maintenance requirements. While the traditional starter motor remains a solid choice for conventional vehicles, alternatives like Integrated Starter Generators and Battery Electric Vehicle systems offer distinct advantages in efficiency and sustainability. By assessing the specific operational context—whether it be for a fleet of traditional vehicles or a transition towards hybrid and electric options—buyers can make informed decisions that align with their strategic objectives and market trends.

Essential Technical Properties and Trade Terminology for starter motor

Quais são as principais propriedades técnicas de um motor de arranque?

When sourcing starter motors for automotive applications, understanding critical technical specifications is essential. These properties not only influence performance but also affect the overall reliability of the vehicle. Here are some of the key specifications to consider:

1. Grau do material

The materials used in the construction of starter motors—such as steel for the housing and copper for the windings—are crucial for durability and efficiency. High-grade materials can withstand wear and tear, ensuring longer service life. For B2B buyers, selecting starters with superior materials can reduce replacement frequency and maintenance costs.

Illustrative image related to starter motor

2. Classificação de binário

Torque rating indicates the amount of rotational force the starter motor can generate. This is critical for ensuring that the motor can effectively crank the engine under various conditions. A higher torque rating can be particularly important for vehicles with larger engines or those operating in extreme environments, making it a key factor for buyers in regions with diverse climates.

3. Tensão nominal

Most starter motors operate on a standard voltage—typically 12V for passenger vehicles and 24V for heavy-duty applications. Ensuring compatibility with vehicle electrical systems is vital to prevent failures. Buyers should verify the voltage requirements to ensure optimal performance and avoid electrical mishaps.

4. Consumo de corrente

The current draw of a starter motor during operation is another important specification. A lower current draw can minimize the load on the vehicle’s electrical system, enhancing battery life. For businesses, understanding current draw is essential for ensuring compatibility with existing vehicle systems and maximizing operational efficiency.

5. Gama de temperaturas operacionais

The operational temperature range specifies the conditions under which the starter motor can function effectively. Motors designed to operate in extreme temperatures (both hot and cold) will be more reliable in varied climates, which is particularly relevant for buyers in regions like Africa and the Middle East where temperature fluctuations can be significant.

6. Lifetime Rating

The lifetime rating, often expressed in miles or hours of operation, indicates how long a starter motor is expected to last under normal conditions. Understanding this rating helps buyers assess the value and return on investment of the starter motor, guiding purchasing decisions based on vehicle usage and maintenance strategies.

Quais são os termos comerciais comuns associados aos motores de arranque?

Familiarity with industry jargon is crucial for effective communication and negotiation in the procurement of starter motors. Here are some common terms that B2B buyers should know:

1. OEM (Fabricante de Equipamento Original)

OEM refers to parts that are made by the vehicle manufacturer or an authorized company. Sourcing OEM starter motors ensures compatibility and adherence to quality standards, which can be a critical selling point for distributors and repair shops.

Illustrative image related to starter motor

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for businesses to manage inventory and cash flow effectively. Buyers should negotiate MOQs to align with their purchasing needs and storage capabilities.

3. RFQ (Pedido de Orçamento)

An RFQ is a document that businesses use to solicit price proposals from suppliers. It typically includes specifications, quantities, and delivery terms. Submitting an RFQ allows buyers to compare offers and negotiate better terms, which is essential for cost management.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariff responsibilities. Understanding these terms helps buyers manage shipping logistics and avoid unexpected costs, especially when sourcing starter motors from international suppliers.

5. Mercado pós-venda

The aftermarket refers to parts and accessories that are not sourced from the original manufacturer. Many businesses focus on aftermarket starter motors for cost-effective solutions. Understanding this market segment allows buyers to explore alternative options that may offer competitive pricing without sacrificing quality.

6. Prazo de entrega

Lead time is the duration between placing an order and receiving the product. Knowing lead times is essential for inventory management and ensuring that vehicle repairs or assembly schedules are not disrupted. Buyers should inquire about lead times when negotiating contracts to ensure timely delivery.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing starter motors, ultimately leading to better performance, reliability, and cost-efficiency in their operations.

Navigating Market Dynamics and Sourcing Trends in the starter motor Sector

What Are the Key Drivers Shaping the Global Starter Motor Market?

The global starter motor market is experiencing significant growth, driven by several key factors. First, the increasing demand for vehicles, particularly in emerging markets such as Africa and South America, is propelling the need for reliable starter motors. As urbanization accelerates, more consumers are seeking personal and commercial vehicles, leading to a higher production volume of starter motors. Additionally, advancements in automotive technology, including the rise of electric vehicles (EVs) and hybrid models, are shaping sourcing trends. Manufacturers are increasingly focusing on lightweight materials and efficient designs to enhance performance and fuel economy, making it essential for B2B buyers to stay informed about these innovations.

Another emerging trend is the integration of smart technology in automotive components. Smart starter motors equipped with IoT capabilities allow for better diagnostics and predictive maintenance, providing B2B buyers with valuable data to optimize fleet management. In regions like the Middle East and Europe, regulatory changes aimed at reducing carbon emissions are further influencing market dynamics, pushing manufacturers to innovate and adapt to stricter environmental standards.

How Can Sustainability and Ethical Sourcing Impact the Starter Motor Supply Chain?

Sustainability has become a crucial consideration in the starter motor sector, influencing sourcing decisions for B2B buyers. The environmental impact of manufacturing processes and the materials used in starter motors is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and reducing waste during production. The adoption of ‘green’ certifications, such as ISO 14001, can significantly enhance a supplier’s credibility, making them more attractive to environmentally-conscious buyers.

Ethical sourcing is also gaining traction, as companies strive to ensure transparency in their supply chains. This includes verifying that raw materials are sourced responsibly and that labor practices adhere to international standards. For B2B buyers, establishing relationships with suppliers who prioritize ethical practices not only mitigates risks but also enhances brand reputation. In regions like Europe, where consumers are increasingly aware of sustainability issues, aligning with ethical suppliers can lead to competitive advantages in the marketplace.

What Is the Historical Context of Starter Motors in the Automotive Industry?

The starter motor has evolved significantly since its inception in the early 20th century. Initially, vehicles relied on hand-crank methods to start their engines, which were cumbersome and required considerable physical effort. The introduction of the electric starter motor in the 1910s revolutionized the automotive industry, enhancing convenience and reliability. As vehicle technology progressed, starter motors became more compact and efficient, leading to innovations such as the gear-reduction starter and solenoid designs.

Today, the starter motor is an integral component of modern vehicles, essential for both traditional internal combustion engines and emerging electric vehicles. Understanding the historical evolution of starter motors provides valuable context for B2B buyers, highlighting the importance of innovation in sourcing decisions and the ongoing transformation of the automotive landscape. As the industry continues to evolve, staying abreast of technological advancements and sourcing trends will be crucial for maintaining a competitive edge in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of starter motor

-

Como posso resolver problemas com um motor de arranque avariado?

To address a faulty starter motor, first conduct a thorough diagnostic check. Listen for clicking sounds when attempting to start the engine, as this may indicate electrical issues. Ensure the battery is fully charged and all connections are secure. If the starter motor continues to malfunction, consider contacting a qualified technician for further inspection. It may require replacement or repair of components like the solenoid or wiring. Regular maintenance can prevent issues, so schedule periodic checks as part of your vehicle service routine. -

What is the best starter motor for heavy-duty applications?

For heavy-duty applications, look for starter motors that are specifically designed for high-torque performance and durability. Brands like Bosch, Denso, and Delco Remy offer models tailored for commercial vehicles and industrial equipment. Ensure the starter motor meets the specifications of your engine, including voltage and amperage requirements. Consider consulting with suppliers who specialize in heavy-duty parts to find a model that provides reliability under demanding conditions, as this can significantly affect operational efficiency. -

What factors should I consider when vetting a starter motor supplier?

When vetting a starter motor supplier, prioritize their reputation in the industry. Look for suppliers with a proven track record in quality assurance and customer service. Verify certifications and compliance with international standards, such as ISO. Additionally, assess their ability to provide technical support and after-sales service. Request references or testimonials from other clients to gauge their reliability. It’s also beneficial to evaluate their logistics capabilities to ensure timely delivery to your location. -

Quais são as quantidades mínimas de encomenda (MOQ) para motores de arranque?

Minimum order quantities (MOQ) for starter motors can vary significantly between suppliers. Typically, MOQs range from 10 to 100 units, depending on the manufacturer and the specific model. Some suppliers may offer flexibility for smaller orders, especially for first-time customers or trial purchases. Always discuss your requirements with the supplier to negotiate terms that suit your business needs, especially if you are testing new products or entering a new market. -

What payment terms are commonly accepted when purchasing starter motors internationally?

Payment terms for international purchases of starter motors usually vary by supplier and the buyer’s location. Common options include letters of credit, advance payments, and net 30 or net 60 terms. Always clarify payment methods upfront, including any associated fees for currency exchange or international transactions. Establishing a secure payment method, such as PayPal or escrow services, can help mitigate risks. It’s advisable to review the supplier’s credit terms and negotiate favorable conditions to support your cash flow. -

How do I ensure quality assurance when sourcing starter motors?

To ensure quality assurance when sourcing starter motors, request detailed specifications and compliance certifications from the supplier. Look for products that meet international standards, such as ISO and SAE. Ask about their quality control processes, including testing methods for performance and durability. Consider requesting samples or visiting the supplier’s facility for firsthand assessment. Establish a clear return policy in case the products do not meet agreed standards, which can safeguard your investment. -

What logistics considerations should I keep in mind for importing starter motors?

When importing starter motors, consider logistics factors such as shipping methods, lead times, and customs clearance processes. Choose a reliable freight forwarder experienced in handling automotive parts to navigate potential challenges. Understand the import regulations in your country, including tariffs and duties, to avoid unexpected costs. Ensure that the supplier provides proper documentation, including invoices and packing lists, to facilitate smooth customs processing. Planning ahead can help minimize delays and ensure timely delivery to your operations. -

Os motores de arranque podem ser personalizados para aplicações específicas?

Yes, many manufacturers offer customization options for starter motors to fit specific applications. Customization can include alterations in size, voltage, and torque specifications. When seeking a customized solution, communicate your exact requirements to the supplier, including the intended use and environmental conditions. Collaborate with their engineering team to develop a product that meets your performance criteria. Keep in mind that custom orders may have longer lead times and higher costs, so plan accordingly.

Top 5 Starter Motor Manufacturers & Suppliers List

1. RAC - Motores de arranque

Domínio: rac.co.uk

Registado: 1996 (29 anos)

Introdução: Starter motor is an essential electric component in internal combustion vehicles that initiates engine rotation when the ignition is engaged. It works by receiving an electrical signal that activates the starter solenoid, sending a charge to the battery and engaging the starter motor to crank the engine. Common causes of starter motor failure include broken solenoid, mechanical issues, electrical …

2. Haynes - Motor de arranque

Domínio: us.haynes.com

Registado: 1996 (29 anos)

Introdução: Esta empresa, Haynes - Starter Motor, é uma entidade notável no mercado. Para obter detalhes específicos do produto, recomenda-se visitar diretamente o seu website.

3. Samarin – Starter Motor Solutions

Domínio: samarins.com

Registada: 2000 (25 anos)

Introdução: The starter motor is an electric motor that turns over or ‘cranks’ the engine to start. It consists of a powerful DC electric motor and a starter solenoid. The starter motor is powered by the car’s main 12-volt battery and requires a high electric current to operate. Symptoms of a bad starter motor include a single click or no response when attempting to start the car, or the starter motor running…

4. Auto Electro – Starter Motors

Domínio: autoelectro.pt

Registado: 1999 (26 anos)

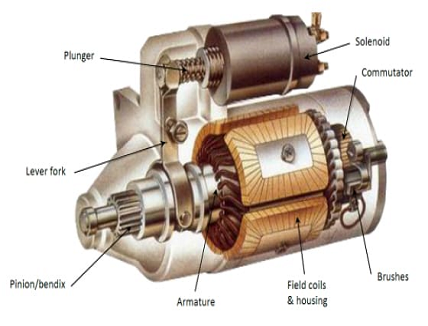

Introdução: Starter motors are essential components in vehicles, responsible for turning the engine over during ignition. Key components include: 1. Armature: An electromagnet mounted on the drive shaft, made of laminated soft iron core with conductor loops. 2. Commutator: A section of the shaft that conducts electricity through brushes, made of two plates attached to the armature axle. 3. Brushes: Conduct el…

5. The AA – Starter Motor Issues

Domínio: theaa.com

Registado: 1997 (28 anos)

Introdução: Common starter motor problems include: 1. Engine won’t start – A faulty starter motor can prevent the engine from starting, often indicated by no response or a clicking noise when the key is turned. 2. Clicking noise – This suggests the starter motor is trying to engage but lacks sufficient power, possibly due to a weak battery or poor electrical connections. 3. Starter motor doesn’t turn – This c…

Strategic Sourcing Conclusion and Outlook for starter motor

The landscape of starter motor sourcing is increasingly complex, driven by technological advancements and the evolving needs of the automotive sector. For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of starter motor procurement is crucial. Key takeaways include the importance of assessing supplier reliability, the need for quality assurance, and the benefits of strategic partnerships that enhance supply chain efficiency.

Strategic sourcing not only mitigates risks but also fosters innovation, allowing businesses to adapt to changing market demands. By investing in high-quality starter motors and reliable suppliers, companies can ensure seamless operations and customer satisfaction.

Looking ahead, it is essential for B2B buyers to stay informed about emerging technologies and trends within the starter motor market. Engaging with suppliers who prioritize sustainability and technological advancement will be pivotal in navigating future challenges. Embrace the opportunity to enhance your sourcing strategy today—your choice of starter motor suppliers can significantly impact your operational success in the global marketplace.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.