Introduction: Navigating the Global Market for starter location

Navigating the global market for starter location presents a unique challenge for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. Sourcing reliable starter motors, essential components that initiate engine function, requires a nuanced understanding of the various types available, their applications across different vehicle models, and the intricacies of supplier vetting. With a diverse array of manufacturers and specifications, making informed purchasing decisions can be daunting.

This comprehensive guide aims to demystify the process of identifying the right starter location for your specific needs. We will explore the different types of starters, their applications in various automotive contexts, and critical factors to consider when evaluating suppliers. Additionally, we will delve into cost considerations, ensuring you understand the financial implications of your choices.

By providing actionable insights and detailed information, this guide empowers B2B buyers to navigate the complexities of the starter motor market confidently. Whether you’re a buyer from Nigeria seeking reliable automotive parts or a procurement manager in Saudi Arabia looking to streamline your supply chain, this resource is designed to enhance your decision-making process and optimize your sourcing strategy. With the right knowledge at your fingertips, you can ensure your operations run smoothly and efficiently.

Índice

- Top 1 Starter Location Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter location

- Understanding starter location Types and Variations

- Key Industrial Applications of starter location

- 3 Common User Pain Points for ‘starter location’ & Their Solutions

- Strategic Material Selection Guide for starter location

- In-depth Look: Manufacturing Processes and Quality Assurance for starter location

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter location’

- Comprehensive Cost and Pricing Analysis for starter location Sourcing

- Alternatives Analysis: Comparing starter location With Other Solutions

- Essential Technical Properties and Trade Terminology for starter location

- Navigating Market Dynamics and Sourcing Trends in the starter location Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter location

- Strategic Sourcing Conclusion and Outlook for starter location

- Aviso legal importante e termos de utilização

Understanding starter location Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Underhood Starter | Located near the engine, often on the top or side | Light-duty vehicles, small engines | Prós: Easier access for replacement. Contras: Limited to specific vehicle models. |

| Bell Housing Starter | Positioned at the transmission bell housing | Heavy-duty trucks, larger vehicles | Prós: High torque capacity for larger engines. Contras: More complex installation process. |

| Front-mounted Starter | Accessible from the front of the vehicle | Sports cars, performance vehicles | Prós: Improved airflow for cooling. Contras: May require front-end disassembly for access. |

| Side-mounted Starter | Mounted on the side of the engine block | Various vehicle types | Prós: Versatile placement options. Contras: Accessibility can vary based on vehicle design. |

| Rear-mounted Starter | Positioned towards the rear of the engine | Specialty vehicles, some SUVs | Prós: Optimizes weight distribution. Contras: Difficult access for maintenance. |

What Are the Characteristics of Underhood Starters?

Underhood starters are typically found in light-duty vehicles and smaller engines. Their location near the top or side of the engine allows for easier access during maintenance or replacement. B2B buyers focusing on light-duty vehicle fleets may prefer this type due to the reduced labor costs associated with simpler installations. However, the range of compatible vehicles is limited, which can restrict options for buyers looking for bulk purchases.

How Do Bell Housing Starters Differ from Other Types?

Bell housing starters are installed at the transmission bell housing and are common in heavy-duty trucks and larger vehicles. They are designed to provide high torque, making them ideal for heavy loads and demanding conditions. For B2B buyers, this type is suitable for industries that require robust performance, such as construction or logistics. However, the installation process can be more complex, potentially increasing labor costs.

Why Choose Front-mounted Starters for Performance Vehicles?

Front-mounted starters are often used in sports cars and performance vehicles, where they benefit from improved airflow for cooling. This design can enhance performance, making it appealing for B2B buyers in the automotive aftermarket or racing sectors. However, the need for front-end disassembly to access the starter can complicate maintenance, which may deter some buyers.

What Are the Advantages of Side-mounted Starters?

Side-mounted starters are versatile and can be found in a variety of vehicle types. Their location on the side of the engine block allows for flexible placement options, which can be advantageous in custom vehicle builds. B2B buyers in manufacturing or specialty vehicle production may find this type beneficial. However, accessibility can vary significantly between different vehicle designs, which could impact maintenance efficiency.

When Should You Consider Rear-mounted Starters?

Rear-mounted starters are typically found toward the back of the engine and are more common in specialty vehicles and some SUVs. This configuration can optimize weight distribution, which can enhance vehicle handling. For B2B buyers, particularly those in the specialty vehicle market, this type can be advantageous. However, the difficulty of access for maintenance can be a significant drawback, necessitating careful consideration of serviceability when making purchasing decisions.

Key Industrial Applications of starter location

| Indústria/Setor | Specific Application of starter location | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Fabricação Automotiva | Design and assembly of starter motors in vehicles | Aumenta a fiabilidade e o desempenho do veículo | Quality certifications, compatibility with various vehicle models |

| Maquinaria pesada | Integration of starters in construction and agricultural equipment | Ensures reliable operation in demanding environments | Durability under extreme conditions, availability of replacement parts |

| Energia renovável | Starter systems for wind turbines and solar tracking systems | Improves efficiency and operational uptime | Supplier expertise in renewable technologies, adaptability to local conditions |

| Transporte | Starter solutions for commercial vehicles and fleets | Reduz o tempo de inatividade e os custos de manutenção | Bulk purchasing options, warranty and support services |

| Indústria naval | Starter applications in boats and ships | Enhances safety and reliability in marine operations | Compliance with maritime regulations, resistance to corrosion |

How Is ‘Starter Location’ Used in Automotive Manufacturing?

In the automotive manufacturing sector, the starter location is critical for the design and assembly of starter motors in vehicles. Proper placement ensures optimal functionality, contributing to vehicle reliability and performance. International B2B buyers, especially in regions like Africa and South America, must consider the compatibility of starter motors with various vehicle models. Quality certifications and supplier reputation are vital to ensure that the starters meet industry standards, ultimately enhancing the end product’s reliability.

What Role Does ‘Starter Location’ Play in Heavy Machinery?

In heavy machinery, the starter location is pivotal for integrating starters into construction and agricultural equipment. These environments often demand high reliability due to the rigorous operational conditions. A well-placed starter ensures that machinery can start efficiently, reducing downtime in critical operations. Buyers in regions like the Middle East need to focus on sourcing durable starters that can withstand extreme conditions, along with the availability of replacement parts to minimize operational disruptions.

How Is ‘Starter Location’ Relevant in Renewable Energy Applications?

Starter systems in renewable energy applications, such as wind turbines and solar tracking systems, utilize strategic starter locations for improved efficiency and operational uptime. These systems require reliable starting mechanisms to harness energy effectively. For B2B buyers in Europe, sourcing from suppliers with expertise in renewable technologies is essential. Additionally, adaptability to local environmental conditions ensures that the starters function optimally, contributing to the overall sustainability goals of the projects.

How Does ‘Starter Location’ Benefit the Transportation Sector?

In the transportation sector, starter solutions are crucial for commercial vehicles and fleets. Proper starter location contributes to reduced downtime and lower maintenance costs, which are significant factors for fleet operators. Buyers, particularly in emerging markets like Nigeria and Saudi Arabia, should seek bulk purchasing options to benefit from economies of scale. Warranty and support services from suppliers can further enhance value, ensuring that fleets remain operational and cost-effective.

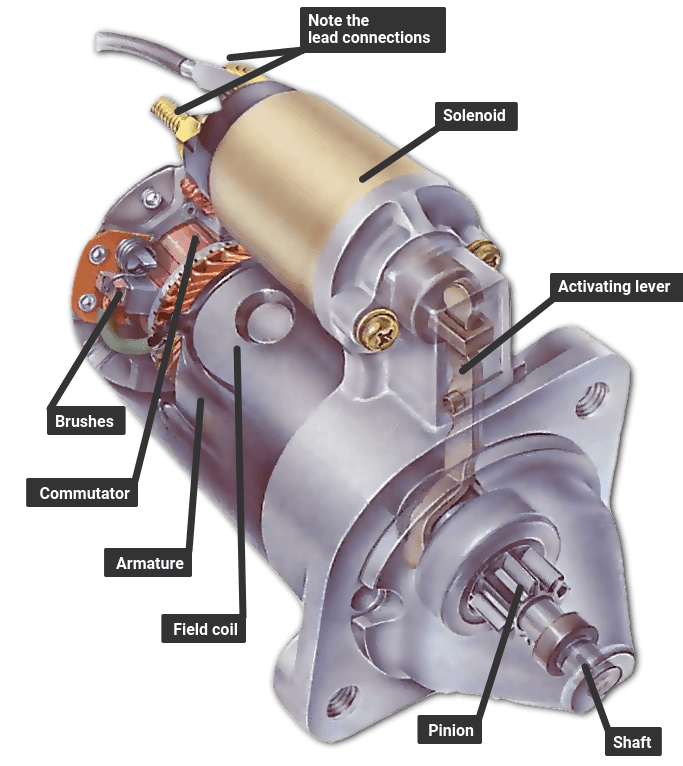

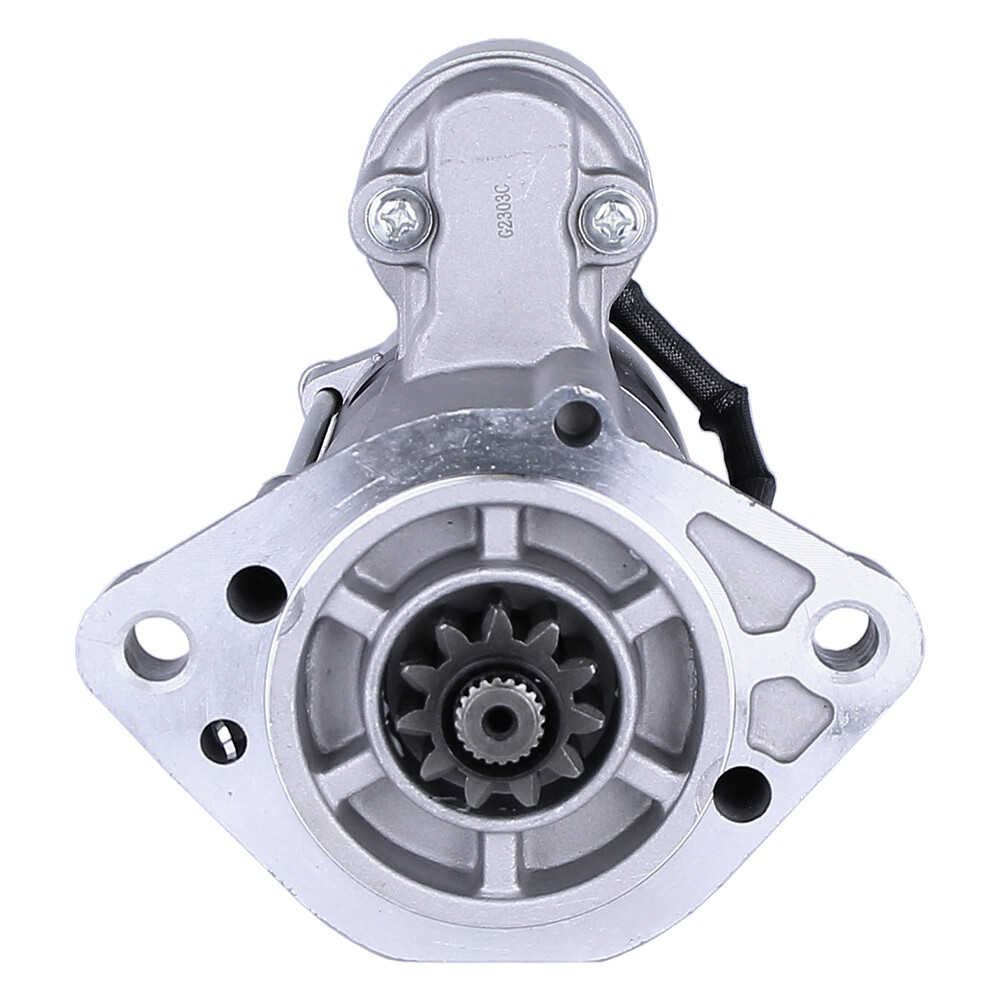

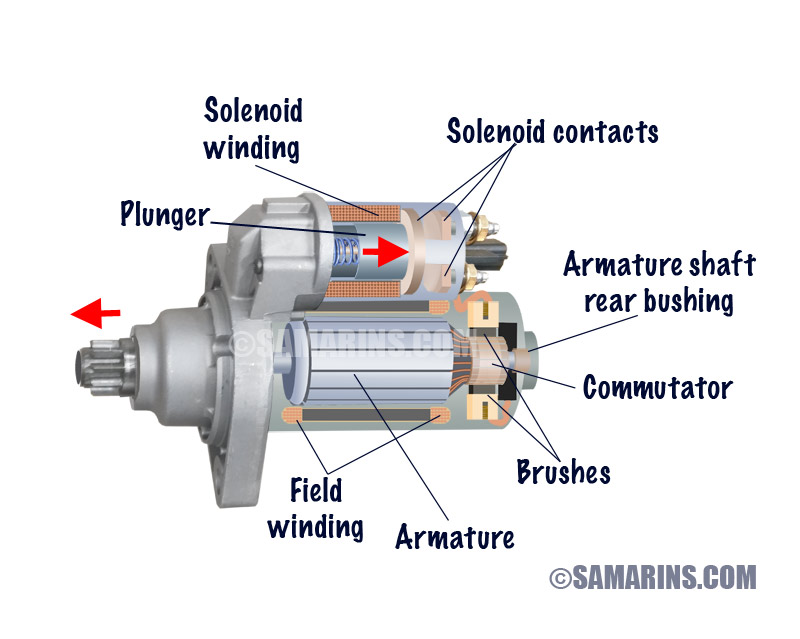

Illustrative image related to starter location

Why Is ‘Starter Location’ Important in the Marine Industry?

In the marine industry, the starter location is essential for ensuring reliable operation in boats and ships. A well-placed starter contributes to enhanced safety and reliability, which are critical in maritime operations. International B2B buyers need to consider suppliers that comply with maritime regulations and offer products resistant to corrosion. This focus on quality and compliance ensures that marine vessels operate efficiently, reducing the risk of failures at sea.

3 Common User Pain Points for ‘starter location’ & Their Solutions

Scenario 1: Confusion Over Starter Location in Diverse Vehicle Models

O problema: International B2B buyers often face challenges when trying to identify the starter location in various vehicle models, especially when dealing with a mixed fleet. For instance, a mechanic in Nigeria servicing a fleet of vehicles from different manufacturers may struggle to locate the starter motor due to variations in design and placement. This confusion can lead to increased downtime, inefficient repairs, and potential customer dissatisfaction, which is detrimental in a competitive market.

A solução: To mitigate this issue, it’s crucial to leverage comprehensive vehicle repair manuals or digital databases that offer detailed schematics for a wide range of vehicle models. Buyers should invest in a subscription to a reputable repair information service that provides access to diagrams, troubleshooting guides, and specifications for starters across multiple brands. Additionally, creating a centralized repository of vehicle specifications within their operations can streamline the repair process. Training mechanics on the unique features of each vehicle type will also enhance their efficiency in locating starters quickly and accurately, reducing overall service time.

Scenario 2: Misdiagnosis Leading to Unnecessary Starter Replacements

O problema: A common pain point for B2B buyers is the misdiagnosis of starter issues, leading to unnecessary replacements. For instance, a fleet operator in Saudi Arabia may replace starters based on symptoms like clicking noises or slow cranking, without considering other underlying issues such as battery health or faulty wiring. This not only incurs additional costs but also affects the reliability of the fleet, resulting in budget overruns and potential loss of business.

A solução: To avoid misdiagnosis, it’s essential to implement a systematic diagnostic protocol before concluding that a starter replacement is necessary. Buyers should invest in diagnostic tools that can assess battery voltage, check electrical connections, and identify faults in the ignition system. Training technicians on how to interpret diagnostic codes and perform thorough inspections will ensure that they can accurately identify the root cause of the problem. This proactive approach will save costs in the long run and improve the overall reliability of the fleet.

Scenario 3: Difficulty in Sourcing Quality Starters for Diverse Markets

O problema: International buyers often struggle to source high-quality starter motors that meet the diverse requirements of different regions. For example, a distributor in South America may find it challenging to procure starters that comply with local standards and offer reliable performance in varying climate conditions. This can lead to subpar product offerings, warranty claims, and a tarnished reputation in the market.

A solução: Establishing strong relationships with reputable manufacturers and suppliers who understand the specific needs of different markets is vital. Buyers should conduct thorough research to identify suppliers that specialize in starters suited for their regional climates and vehicle types. Additionally, implementing quality control measures, such as requesting samples and conducting performance tests, can help ensure that the starters sourced meet the necessary standards. Joining industry associations or forums can also provide insights into reliable suppliers and trends, enabling buyers to make informed purchasing decisions that enhance their product offerings and customer satisfaction.

Strategic Material Selection Guide for starter location

What Are the Key Materials for Starter Locations in Automotive Applications?

When selecting materials for starter locations in automotive applications, it is essential to consider various factors such as durability, resistance to environmental conditions, and compatibility with different vehicle types. Below are analyses of four common materials used in starter locations, focusing on their properties, pros and cons, and implications for international B2B buyers.

Steel: The Traditional Choice for Starter Locations

Principais propriedades: Steel is known for its high tensile strength and ability to withstand significant mechanical stress, making it suitable for starter applications. It typically has a temperature rating of up to 300°C and can handle high-pressure environments.

Illustrative image related to starter location

Prós e contras: Steel is durable and cost-effective, with a relatively low manufacturing complexity. However, it is prone to corrosion if not properly coated or treated, which can lead to premature failure in harsh environments.

Impacto na aplicação: Steel’s strength makes it ideal for heavy-duty applications, but its susceptibility to corrosion can be a limitation in humid or saline environments, such as coastal regions in Africa and South America.

Considerações para compradores internacionais: Buyers should ensure compliance with international standards such as ASTM A36 or DIN 17100 for structural steel. Coatings or treatments may be necessary to enhance corrosion resistance, especially in regions with high humidity or salt exposure.

Alumínio: uma alternativa leve

Principais propriedades: Aluminum is lightweight and has excellent corrosion resistance due to its natural oxide layer. It can operate effectively at temperatures ranging from -50°C to 150°C.

Prós e contras: The main advantage of aluminum is its weight reduction, which can improve overall vehicle efficiency. However, it is generally more expensive than steel and may require more complex manufacturing processes, such as die casting or extrusion.

Illustrative image related to starter location

Impacto na aplicação: Aluminum is suitable for applications where weight savings are critical, but its lower strength compared to steel may limit its use in high-stress environments.

Considerações para compradores internacionais: Aluminum components must comply with standards such as ASTM B221 or DIN 1725. Buyers should also consider the availability of aluminum recycling programs in their regions to enhance sustainability.

Plastic Composites: The Modern Solution

Principais propriedades: Plastic composites are lightweight and can be engineered to have specific thermal and chemical resistance properties. They can typically handle temperatures up to 120°C.

Prós e contras: The primary advantage of plastic composites is their resistance to corrosion and chemical exposure, making them ideal for diverse environments. However, they may not offer the same mechanical strength as metals and can be more expensive to produce.

Impacto na aplicação: These materials are particularly beneficial in environments where exposure to chemicals or moisture is a concern, such as in automotive applications in tropical climates.

Considerações para compradores internacionais: Compliance with standards such as ASTM D638 for tensile properties is essential. Buyers should also assess the availability of these materials in their local markets, as sourcing can vary significantly by region.

Cobre: O condutor elétrico

Principais propriedades: Copper is an excellent conductor of electricity and has a high melting point of approximately 1,085°C. It is also resistant to corrosion, especially when alloyed with tin or nickel.

Prós e contras: The key advantage of copper is its superior electrical conductivity, making it ideal for starter motors. However, it is significantly more expensive than steel and aluminum, and its weight can be a disadvantage in weight-sensitive applications.

Impacto na aplicação: Copper is essential in starter motor electrical connections, ensuring efficient power transfer. Its high cost may limit its use to critical components rather than structural applications.

Considerações para compradores internacionais: Buyers should ensure compliance with standards such as ASTM B170 for copper wire. They should also consider the impact of fluctuating copper prices on overall project budgets.

Summary Table of Material Selection for Starter Locations

| Material | Typical Use Case for Starter Location | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Aço | Componentes estruturais | Alta resistência e durabilidade | Suscetível à corrosão | Baixo |

| Alumínio | Lightweight structural parts | Excelente resistência à corrosão | Custo mais elevado e complexidade de fabrico | Médio |

| Compósitos plásticos | Housing and protective covers | Resistant to chemicals and moisture | Menor resistência mecânica | Médio |

| Cobre | Electrical connections | Condutividade elétrica superior | Custo e peso elevados | Alto |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions about materials for starter locations, considering both performance and regional factors.

In-depth Look: Manufacturing Processes and Quality Assurance for starter location

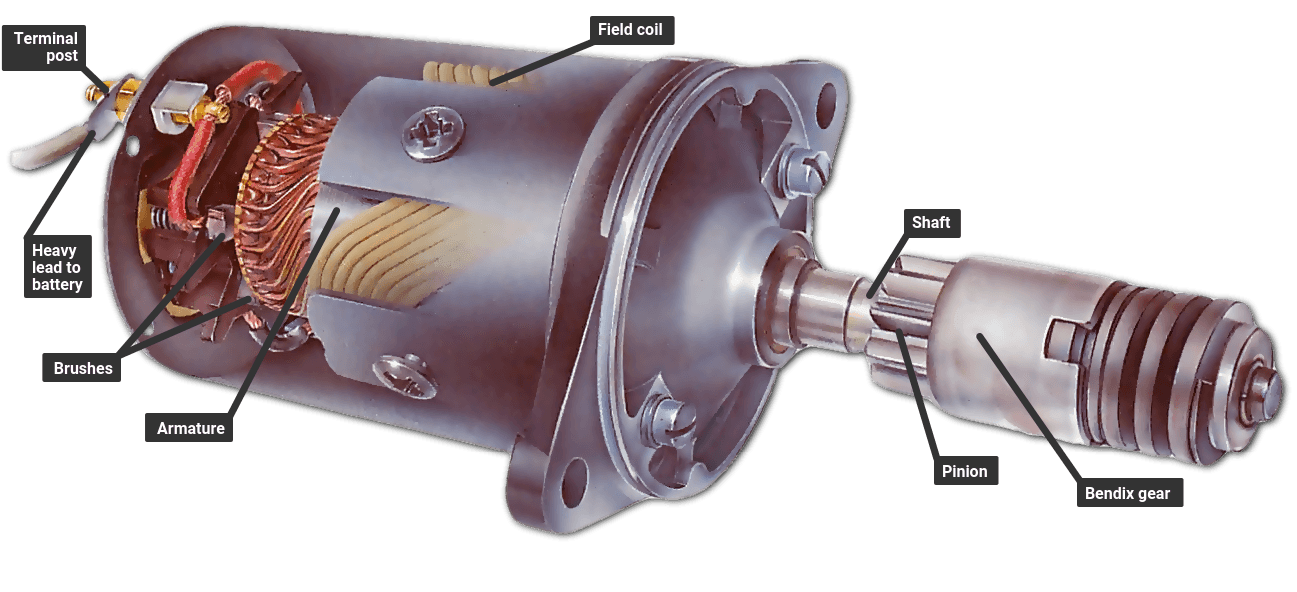

Quais são os principais processos de fabrico dos motores de arranque?

The manufacturing of starter motors involves a series of well-defined stages that ensure the final product meets industry standards for performance and durability. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to starter location

How Does Material Preparation Work for Starter Motors?

Material preparation is the first step in the manufacturing process. This includes selecting high-quality raw materials such as copper for electrical components, steel for the casing, and various alloys for durability. Suppliers must ensure that materials meet specific industry standards, which can include tensile strength, conductivity, and corrosion resistance. Quality checks at this stage are crucial, as subpar materials can lead to failures in the final product.

What Techniques Are Used in the Forming Stage of Starter Manufacturing?

Once materials are prepared, the forming stage begins. Techniques such as stamping, machining, and die-casting are commonly employed to shape the components of the starter motor. For example, steel casings are often stamped to form precise shapes that fit together seamlessly during assembly. Advanced techniques like computer numerical control (CNC) machining ensure high precision, which is vital for the starter’s performance.

How Is Assembly Performed in Starter Motor Manufacturing?

The assembly process is where all formed components come together. This typically involves several steps:

- Montagem de componentes: Individual parts such as the motor housing, rotor, and solenoid are assembled.

- Cablagem: Electrical connections are established, often requiring skilled technicians to ensure that wiring meets electrical safety standards.

- Testing for Fit and Function: During assembly, components are tested for fit and function. This can include initial electrical tests to ensure proper connectivity.

Quality control checks during this stage are critical, as any misalignment can lead to operational failures.

What Finishing Processes Are Involved in Starter Motor Production?

Finishing processes enhance the durability and aesthetic appeal of starter motors. This may include painting or coating to prevent corrosion, as well as final assembly checks. Finishing techniques such as passivation for metal parts can improve resistance to oxidation. Additionally, manufacturers may apply labels and branding, ensuring they meet international standards for product identification.

Illustrative image related to starter location

Que normas de garantia de qualidade são relevantes para os motores de arranque?

Quality assurance is vital in ensuring that starter motors are reliable and meet customer expectations. International standards like ISO 9001 provide a framework for quality management systems, focusing on continuous improvement and customer satisfaction. Industry-specific standards, such as CE marking in Europe or API standards in the automotive sector, help ensure compliance with safety and environmental regulations.

Como é que os pontos de controlo de qualidade são integrados no processo de fabrico?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify defects early. Key QC checkpoints include:

- Controlo de Qualidade de Entrada (IQC): As matérias-primas são inspecionadas à chegada para garantir que cumprem as especificações.

- Controlo de qualidade em processo (IPQC): Ongoing inspections during the manufacturing process help catch defects before they progress.

- Controlo de Qualidade Final (FQC): The finished product undergoes rigorous testing for performance and safety standards.

These checkpoints help maintain a high level of quality throughout the production process.

Quais são os métodos de teste comuns utilizados para motores de arranque?

Testing methods for starter motors can vary but typically include:

- Testes elétricos: Ensures that the motor operates within specified voltage and current parameters.

- Testes mecânicos: Evaluates the structural integrity and performance under load conditions.

- Ensaios ambientais: Assesses the motor’s performance in various environmental conditions, such as extreme temperatures or humidity.

Documentation of these tests is essential for B2B buyers to verify compliance with quality standards.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Buyers can take several steps:

- Realizar auditorias: Regular audits of supplier facilities can help ensure compliance with quality standards.

- Solicitar relatórios de qualidade: Suppliers should provide detailed reports on their quality control processes, including test results and compliance certifications.

- Contrate inspetores terceirizados: Independent inspections can provide unbiased verification of a supplier’s quality practices and product performance.

What Quality Control Considerations Should International Buyers Be Aware Of?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider several nuances in quality control:

- Compreender as normas locais: Different regions may have varying standards for quality assurance. Familiarity with local regulations and certifications can help buyers make informed decisions.

- Cultural Differences in Quality Practices: Buyers should be aware that quality management practices can differ significantly across cultures. Open communication with suppliers is essential to ensure mutual understanding of quality expectations.

- Shipping and Logistics Challenges: Ensure that quality is maintained during shipping, as transportation can introduce risks to product integrity. Consider suppliers who have robust logistics processes in place.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance for B2B Buyers

For B2B buyers, understanding the manufacturing processes and quality assurance practices related to starter motors is essential for making informed purchasing decisions. By focusing on these aspects, buyers can ensure they are sourcing high-quality products that meet their operational needs and comply with international standards. Engaging with suppliers who prioritize quality at every stage of production will lead to better performance and reliability in their starter motors.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter location’

In the competitive landscape of international B2B procurement, sourcing starter locations for automotive applications requires a strategic approach. This guide provides a clear, step-by-step checklist to help you navigate the complexities of finding reliable suppliers and ensuring quality products.

Passo 1: Defina as suas especificações técnicas

Before initiating the sourcing process, it’s vital to establish precise technical specifications for the starter location. Identify the specific vehicle models, engine types, and performance requirements that the starters must meet. This clarity will help you communicate your needs effectively to potential suppliers and ensure compatibility with your products.

Passo 2: Realizar pesquisa de mercado

Understanding the market landscape is essential. Research the current trends in starter technology, including innovations in efficiency and durability. Look for insights on regional preferences and standards, especially if you are targeting specific areas like Africa or the Middle East, where local regulations may influence your choices.

Passo 3: Avalie potenciais fornecedores

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Focus on the following:

– Processos de garantia de qualidade: Ensure suppliers have robust quality control measures in place.

– Delivery Capabilities: Assess their ability to meet your delivery timelines, particularly if you are working on a tight schedule.

Passo 4: Verificar certificações e conformidade

Confirm that potential suppliers hold the necessary certifications relevant to the automotive industry. This may include ISO certifications or compliance with local automotive standards. Compliance ensures that the starters meet safety and performance benchmarks, reducing the risk of future liabilities.

Passo 5: Solicitar amostras para teste

Before finalizing any contracts, request samples of the starters to conduct your own testing. Evaluate the quality, compatibility, and performance under real-world conditions. This step is critical to ensure that the product meets your technical specifications and operational needs.

Passo 6: Negociar preços e condições

Once you have identified a suitable supplier, engage in negotiations to establish favorable pricing and terms. Consider factors such as:

– Descontos para compras em massa: These can significantly reduce your overall costs.

– Condições de pagamento: Clarify payment schedules and conditions to manage cash flow effectively.

Passo 7: Estabeleça um plano de comunicação

Effective communication with your supplier is essential for a successful partnership. Develop a clear communication plan that outlines:

– Actualizações regulares: Schedule periodic check-ins to discuss order statuses and any potential issues.

– Mecanismo de feedback: Implement a system for providing feedback on product performance and service quality, facilitating continuous improvement.

By following these steps, B2B buyers can streamline their procurement process for starter locations, ensuring they source high-quality products that meet their operational demands while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for starter location Sourcing

What Are the Key Cost Components in Starter Location Sourcing?

Understanding the cost structure involved in sourcing starter locations is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materiais are a significant part of the cost, often influenced by the type and quality of materials used in manufacturing the starter motors. For instance, high-quality copper or specialized alloys can increase costs but improve performance and durability.

Custos de mão de obra vary significantly by region. Countries with lower labor costs may offer competitive pricing, but this can sometimes lead to quality trade-offs. Additionally, despesas gerais de fabrico encompasses the expenses related to running production facilities, including utilities, rent, and equipment maintenance, which can vary based on local economic conditions.

Custos de ferramentas are also essential, particularly for custom starter designs. These costs can escalate if specialized equipment is required. Effective QC processes ensure that the final product meets required specifications, which can add to costs but ultimately reduce returns and warranty claims.

Logistics costs must be factored in, particularly for international shipments. Costs related to shipping, handling, and customs duties can add significantly to the overall expenditure. Lastly, the margem that suppliers include varies based on their market positioning and perceived value of their products.

How Do Price Influencers Affect Starter Location Sourcing?

Several factors influence the pricing of starter locations. Volume ou quantidade mínima de encomenda (MOQ) is a primary driver; larger orders typically attract lower per-unit costs due to economies of scale. Buyers should negotiate for favorable MOQs to optimize pricing.

Illustrative image related to starter location

Especificações e personalização also play a crucial role. Customized products often incur higher costs due to the additional design and manufacturing processes involved. Thus, buyers should assess whether standard products can meet their needs to avoid unnecessary expenses.

The quality of materials directly impacts pricing. High-quality or certified materials may come at a premium but can enhance the starter’s longevity and reliability, offering better value in the long term. Buyers should inquire about quality certifications to ensure they receive products that meet their operational standards.

Factores do fornecedor, such as reputation and reliability, can also influence price. Established suppliers may charge higher prices due to their proven track record, while newer entrants might offer lower prices to gain market share.

Compreensão Incoterms is critical for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping and logistics, impacting overall costs. Familiarity with these terms can lead to more strategic negotiations and cost savings.

What Are the Buyer Tips for Cost-Efficiency in Sourcing Starter Locations?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, cost-efficiency in sourcing starter locations involves several strategies. Begin with negotiation; leverage volume purchases to secure better pricing. Establishing long-term relationships with suppliers can also lead to favorable terms and discounts.

Considerar o Custo total de propriedade (TCO) rather than just the upfront price. This includes maintenance, expected lifespan, and performance of the starter motor. A higher initial investment in a quality product may yield lower long-term costs due to reduced failure rates and maintenance needs.

Buyers should also be aware of the nuances de preços for international transactions. Factors like currency fluctuations, local taxes, and tariffs can significantly impact final costs. Engaging local experts or consultants can provide insights into market conditions and help navigate these complexities.

Illustrative image related to starter location

Lastly, always request indicative prices from multiple suppliers to compare offers effectively. This practice not only ensures competitive pricing but also provides leverage in negotiations.

By understanding these cost structures and pricing influencers, B2B buyers can make informed decisions that enhance their procurement strategies while minimizing expenses.

Alternatives Analysis: Comparing starter location With Other Solutions

Understanding the Importance of Alternative Solutions

In the automotive sector, particularly for B2B buyers in regions such as Africa, South America, the Middle East, and Europe, evaluating various solutions is crucial for optimizing vehicle performance and reliability. While the starter location plays a significant role in the functionality of a vehicle’s starting system, alternative methods and technologies can also be considered. This analysis compares the traditional starter location with two viable alternatives: Push-Button Start Systems e Sistemas de arranque à distância.

Tabela comparativa

| Aspecto comparativo | Starter Location | Push-Button Start Systems | Sistemas de arranque à distância |

|---|---|---|---|

| Desempenho | Essential for engine ignition | High reliability, quick ignition | Convenient but dependent on range |

| Custo | Moderate (parts $100-$400) | Higher upfront cost ($200-$600) | Varies ($150-$500), installation may add costs |

| Facilidade de implementação | Requires mechanical skill | Moderate, often needs professional installation | Easy installation for DIY; professional recommended for complex systems |

| Manutenção | Necessidade de controlos regulares | Minimal, but check battery health | Battery maintenance critical; may require software updates |

| Melhor caso de uso | Standard vehicles, reliable choice | Luxury and modern vehicles | Convenience in extreme weather |

Discriminação detalhada das alternativas

What Are Push-Button Start Systems and Their Advantages?

Push-button start systems represent a modern evolution in vehicle ignition technology. These systems allow drivers to start their vehicles with the simple push of a button, eliminating the need for a traditional key. The main advantages include enhanced convenience and security, as the key fob must be within the vehicle to start it. However, the initial investment can be substantial, and installation often requires professional assistance, which could increase costs. Additionally, if the key fob’s battery dies, it can complicate the starting process.

How Do Remote Start Systems Work and What Are Their Benefits?

Remote start systems provide the ability to start a vehicle from a distance, typically using a key fob or smartphone app. This technology is particularly useful in regions with extreme weather conditions, allowing drivers to pre-condition their vehicles before entering. The convenience factor is significant, especially in commercial fleets where multiple vehicles may be in use. However, the effectiveness of remote start systems can depend on the range, and maintenance is crucial, as the systems rely on battery health and may require software updates. Installation can also vary in complexity, making it important to choose a system that fits the vehicle’s specifications.

Conclusão: Como escolher a solução certa para as suas necessidades

For B2B buyers, the decision between starter location and alternative solutions like push-button or remote start systems should be guided by specific operational needs and vehicle types. If reliability and cost-effectiveness are the priorities, maintaining the traditional starter location may be the best choice. However, for businesses looking to enhance user experience and convenience, investing in push-button or remote start systems could provide significant benefits. Ultimately, assessing the unique demands of your fleet or vehicles, including maintenance capabilities and budget considerations, will lead to the most informed decision.

Essential Technical Properties and Trade Terminology for starter location

What Are the Key Technical Properties of a Starter Location?

Understanding the technical properties associated with starter locations is vital for ensuring compatibility, reliability, and performance in automotive applications. Here are some critical specifications to consider:

1. Grau do material

The material grade of the starter motor housing typically involves aluminum or high-grade steel. Aluminum is lightweight and resistant to corrosion, while steel offers durability and strength. Selecting the appropriate material is crucial for ensuring the longevity of the starter, especially in harsh environments prevalent in regions like Africa and the Middle East.

Illustrative image related to starter location

2. Especificações de binário

Torque specifications are vital for ensuring that the starter motor is securely fastened to the engine block. This specification often ranges from 10 to 25 ft-lbs, depending on the vehicle model. Proper torque is essential to prevent loosening over time, which can lead to starter failure and costly repairs.

3. Resistência elétrica

The electrical resistance of the starter solenoid and motor windings impacts the efficiency of the starter. Lower resistance values are preferable as they allow for better electrical flow, reducing the risk of overheating and failure. This property is particularly important in hot climates where high temperatures can exacerbate electrical issues.

4. Configuração de montagem

The mounting configuration refers to how the starter is installed in the vehicle. This can vary significantly between models, affecting accessibility and ease of replacement. Understanding the specific mounting requirements helps in planning maintenance and replacement schedules efficiently.

5. Tensão nominal

Most automotive starters operate on a 12-volt system. However, some heavy-duty applications may require 24 volts. Understanding the voltage rating is critical for compatibility with the vehicle’s electrical system and ensures optimal performance.

6. Cranking Amps

Cranking amps (CA) indicate the starter’s ability to start the engine under normal conditions. A higher CA rating is necessary for larger engines or in colder climates where more power is required to turn over the engine. B2B buyers should consider the engine size and typical operating conditions when selecting starters.

Illustrative image related to starter location

Quais são os termos comerciais comuns relacionados à localização inicial?

Familiarity with industry terminology can enhance communication and efficiency in the procurement process. Here are several important trade terms:

1. OEM (Fabricante de Equipamento Original)

OEM refers to parts produced by the vehicle manufacturer or a certified supplier. Purchasing OEM starters ensures compatibility and reliability, which is essential for B2B buyers looking for quality assurance in their supply chains.

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for international buyers, as it affects inventory management and cash flow. B2B buyers should negotiate MOQs that align with their operational needs.

3. RFQ (Pedido de Orçamento)

An RFQ is a document sent to suppliers requesting a price quote for specific products. This process allows buyers to compare prices and terms from multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is critical for B2B buyers to manage shipping costs, risk, and delivery timelines effectively. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight).

5. Prazo de entrega

Lead time refers to the time from placing an order to receiving the product. In the automotive industry, lead times can vary significantly based on supplier location and inventory levels. Buyers must account for lead times to ensure timely delivery and minimize disruptions.

6. Garantia

A warranty is a guarantee provided by the manufacturer regarding the quality and durability of the starter. Understanding warranty terms is essential for B2B buyers to mitigate risks associated with product failure and to ensure they are covered for potential defects.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs, particularly in diverse and demanding markets.

Navigating Market Dynamics and Sourcing Trends in the starter location Sector

What Are the Current Market Dynamics and Key Trends in the Starter Location Sector?

The global market for starter motors is witnessing significant transformation driven by technological advancements and evolving consumer preferences. International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, should be aware of several key trends. First, the integration of smart technologies, such as IoT and AI, is enhancing diagnostic capabilities, allowing for predictive maintenance and reducing downtime. This trend is particularly relevant for businesses looking to optimize fleet operations and reduce operational costs.

Additionally, the rise of electric vehicles (EVs) is reshaping the starter motor market, with manufacturers increasingly developing components that cater to hybrid and fully electric systems. As countries push for greener transportation solutions, B2B buyers must consider suppliers that can adapt to these changes and provide innovative products that meet the demands of the evolving automotive landscape.

Moreover, the globalization of supply chains has led to increased competition, driving down prices while also presenting challenges related to sourcing reliability and lead times. B2B buyers must navigate these dynamics by establishing strong relationships with suppliers who can ensure timely delivery and quality assurance, particularly in emerging markets where logistics can be unpredictable.

How Can Sustainability and Ethical Sourcing Impact Your B2B Buying Decisions in the Starter Location Sector?

Sustainability is becoming a crucial factor for B2B buyers, as environmental concerns shape consumer behavior and regulatory frameworks across various regions. The production and disposal of starter motors can have significant environmental impacts, including resource depletion and waste generation. As such, buyers should prioritize suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing waste throughout the manufacturing process.

Ethical sourcing is also gaining traction in the starter location sector. Buyers should seek suppliers who uphold fair labor practices and maintain transparency in their supply chains. Certifications such as ISO 14001 for environmental management and SA8000 for social accountability can serve as indicators of a supplier’s commitment to ethical standards.

By choosing suppliers with robust sustainability credentials, B2B buyers not only contribute to a healthier planet but also enhance their brand reputation and meet the growing demand for environmentally responsible products. This alignment with sustainable practices can be a differentiating factor in competitive markets, particularly in regions like Europe, where regulatory scrutiny is increasingly stringent.

How Has the Starter Location Sector Evolved Over Time?

The starter location sector has evolved significantly over the past few decades, transitioning from mechanical to electrical systems that offer greater efficiency and reliability. Initially, starters were simple devices relying on direct mechanical engagement, but advancements in electric motor technology have led to the development of high-torque starters that enhance engine performance.

Illustrative image related to starter location

In recent years, the integration of electronics has further refined starter functionality, allowing for features such as remote start and advanced diagnostic capabilities. This evolution has not only improved the user experience but has also catered to the growing demand for electric and hybrid vehicles, positioning the starter location sector at the forefront of automotive innovation.

As the market continues to adapt to technological advancements and sustainability demands, B2B buyers in regions such as Africa and South America should remain vigilant about these trends to make informed purchasing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of starter location

-

How do I identify the location of a starter motor in different vehicle models?

Identifying the starter motor’s location can vary significantly between different vehicle makes and models. Typically, the starter is mounted near the engine block, often on the transmission bell housing. To locate it, refer to the vehicle’s service manual or use online repair guides specific to your model. Visual aids, such as diagrams or videos, can be particularly helpful. If you’re sourcing parts internationally, ensure your supplier provides accurate specifications to avoid compatibility issues. -

What are common signs indicating a starter motor is failing?

A failing starter motor often exhibits several telltale signs. Common indicators include slow or labored cranking, a clicking noise when turning the key, or the engine not starting at all. Additionally, a burning smell or unusual noises during cranking can signal a problem. Addressing these symptoms promptly can prevent more extensive vehicle damage and ensure timely sourcing of replacement parts from your suppliers. -

What factors should I consider when sourcing starter motors for international trade?

When sourcing starter motors internationally, consider factors such as the supplier’s reputation, product quality, compliance with international standards, and warranty offerings. Evaluate the logistics involved, including shipping times and costs. It’s also crucial to verify the supplier’s ability to provide parts compatible with your specific vehicle models, as well as their experience with international buyers, particularly in your target regions like Africa or South America. -

How can I ensure the quality of starter motors from overseas suppliers?

To ensure quality, conduct thorough due diligence on potential suppliers. Request certifications and quality assurance documents, and seek out customer reviews or testimonials. Consider visiting manufacturing facilities if feasible, or using third-party inspection services to evaluate product quality before shipment. Establish clear quality control criteria, including performance benchmarks, to ensure the starter motors meet your operational standards. -

What is the typical minimum order quantity (MOQ) for starter motors when sourcing internationally?

Minimum order quantities (MOQs) for starter motors can vary widely depending on the supplier and the specific product. Generally, MOQs can range from as low as 10 units to several hundred. Discuss your needs with potential suppliers and negotiate terms that accommodate your business requirements. Smaller businesses may benefit from grouping orders with other buyers to meet MOQ thresholds. -

What payment terms are commonly used in international B2B transactions for automotive parts?

Common payment terms in international B2B transactions for automotive parts include letters of credit, advance payments, and net payment terms (such as 30, 60, or 90 days). It’s essential to establish clear payment agreements before finalizing orders to mitigate risks. Consider using escrow services for high-value transactions to protect both parties until the goods are delivered and inspected. -

How can I facilitate the logistics of importing starter motors from overseas?

To facilitate logistics, partner with reliable freight forwarders who have experience in automotive parts shipping. Understand the import regulations and tariffs applicable in your region to avoid delays. Ensure proper documentation, including bills of lading and customs declarations, is prepared in advance. Consider using a just-in-time inventory strategy to reduce storage costs while ensuring timely deliveries. -

What customization options should I discuss with my starter motor supplier?

When sourcing starter motors, inquire about customization options such as voltage specifications, size variations, and specific design features tailored to your vehicle models. Discuss the potential for branded packaging or labeling to enhance your market presence. Customization can help differentiate your offerings and meet specific requirements of your target markets, ensuring better alignment with customer expectations.

Top 1 Starter Location Manufacturers & Suppliers List

1. Honda Accord – Starter Location Guide

Domínio: 2carpros.com

Registado: 1999 (26 anos)

Introdução: 1995 Honda Accord, 234,575 miles; Starter location needed; 4-cylinder or V6 engine options; Starter motor is a high torque motor with a small pinion gear contacting the flywheel; Starter solenoid initiates electrical connection; Replacement instructions available; Related issues include starter not turning engine over and car not starting.

Strategic Sourcing Conclusion and Outlook for starter location

In the competitive landscape of automotive parts sourcing, understanding the strategic sourcing of starter locations is pivotal for international buyers. By leveraging insights into starter motor positioning, B2B buyers can enhance their procurement strategies, ensuring timely access to quality components while minimizing operational disruptions. The location of the starter not only impacts replacement efficiency but also influences the overall maintenance costs and vehicle performance.

As businesses expand into emerging markets across Africa, South America, the Middle East, and Europe, the importance of establishing reliable supply chains becomes increasingly evident. Buyers must prioritize partnerships with suppliers who understand the nuances of regional vehicle specifications and can provide tailored solutions. This proactive approach to sourcing can lead to significant cost savings and improved service delivery.

Looking ahead, the global automotive market is poised for growth, driven by advancements in technology and shifting consumer demands. Now is the opportune time for B2B buyers to invest in strategic sourcing practices that align with future trends. Embrace the potential of your sourcing strategy today—partner with reliable suppliers to secure your competitive edge in this dynamic marketplace.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.