Introduction: Navigating the Global Market for self motor parts

In an increasingly competitive global market, sourcing self motor parts presents a unique set of challenges for international B2B buyers. With diverse applications ranging from automotive to industrial machinery, the complexity of selecting the right components can be daunting. This guide aims to simplify the process of navigating the vast landscape of self motor parts by providing insights into various types, applications, and essential factors to consider when making purchasing decisions.

Buyers will learn about the nuances of new versus remanufactured parts, the importance of kW ratings, and how to assess supplier reliability. Furthermore, we will explore cost considerations, including bulk purchasing strategies and potential logistical hurdles that may arise when sourcing from different regions, particularly in Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia.

By leveraging the information presented in this comprehensive guide, B2B buyers will be empowered to make informed choices that align with their operational needs and budget constraints. Whether you are looking to enhance your supply chain efficiency or ensure compliance with regional standards, this resource serves as a vital tool in optimizing your procurement process for self motor parts.

Índice

- Top 4 Self Motor Parts Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for self motor parts

- Understanding self motor parts Types and Variations

- Key Industrial Applications of self motor parts

- 3 Common User Pain Points for ‘self motor parts’ & Their Solutions

- Strategic Material Selection Guide for self motor parts

- In-depth Look: Manufacturing Processes and Quality Assurance for self motor parts

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘self motor parts’

- Comprehensive Cost and Pricing Analysis for self motor parts Sourcing

- Alternatives Analysis: Comparing self motor parts With Other Solutions

- Essential Technical Properties and Trade Terminology for self motor parts

- Navigating Market Dynamics and Sourcing Trends in the self motor parts Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of self motor parts

- Strategic Sourcing Conclusion and Outlook for self motor parts

- Aviso legal importante e termos de utilização

Understanding self motor parts Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Starter Motors | Varying kW ratings, voltage options (6V, 12V, 24V), and rotation direction | Automotivo, Máquinas Pesadas | Prós: Wide range of options; Contras: Compatibility issues can arise. |

| Alternators | Converts mechanical energy to electrical energy; varying output capacities | Automotive, Marine, Industrial | Prós: Reliable power generation; Contras: Maintenance can be complex. |

| Gear Reduction Motors | Enhanced torque output, compact design, and specific gear ratios | Robotics, Automation, Aerospace | Prós: High efficiency; Contras: Custo inicial mais elevado. |

| Permanent Magnet Motors | Compact, lightweight, and high efficiency | Electric Vehicles, HVAC Systems | Prós: Energy-efficient; Contras: Sensitive to temperature changes. |

| Wound Field Motors | Uses electromagnetic coils for torque generation; customizable designs | Industrial Equipment, Power Tools | Prós: High torque capabilities; Contras: Requires more maintenance. |

What are the Key Characteristics of Starter Motors for B2B Buyers?

Starter motors are essential for initiating the engine’s operation in various vehicles and machinery. They come in multiple configurations, including different kW ratings and voltage specifications, which makes them suitable for diverse applications, from passenger vehicles to heavy machinery. Buyers should consider compatibility with existing systems, as well as the quality of components, since reliability is crucial in minimizing downtime.

How Do Alternators Function and Where are They Used?

Alternators are vital components that convert mechanical energy into electrical energy, providing power to a vehicle’s electrical systems and charging the battery. They are commonly used in automotive applications, marine vessels, and industrial settings. B2B buyers should focus on the output capacity and efficiency ratings when selecting alternators, as these factors can significantly impact operational costs and performance.

What Advantages Do Gear Reduction Motors Offer?

Gear reduction motors are designed to provide higher torque output while maintaining a compact size. They are widely used in applications such as robotics, automation, and aerospace, where space is limited but power requirements are high. When purchasing gear reduction motors, companies should evaluate the gear ratios and efficiency to ensure optimal performance in their specific applications.

Why Choose Permanent Magnet Motors?

Permanent magnet motors are known for their lightweight and compact design, offering high efficiency and performance. They are increasingly utilized in electric vehicles and HVAC systems due to their energy-saving capabilities. Buyers should consider the motor’s temperature tolerance and application-specific requirements, as these factors can influence long-term reliability and efficiency.

What are the Key Considerations for Wound Field Motors?

Wound field motors use electromagnetic coils to generate torque and can be customized for various applications, making them suitable for industrial equipment and power tools. They provide high torque capabilities but require more maintenance than other motor types. Buyers should assess the specific application needs, maintenance requirements, and overall cost-effectiveness when considering wound field motors for their operations.

Key Industrial Applications of self motor parts

| Indústria/Setor | Specific Application of self motor parts | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Automotivo | Starter motors for vehicle ignition systems | Ensures reliable vehicle start, reducing downtime | Quality certifications, compatibility with vehicle models |

| Equipamento industrial | Motors for conveyor systems | Enhances production efficiency and reliability | Power ratings, durability, and maintenance requirements |

| Agricultura | Electric motors in irrigation systems | Increases water management efficiency | Voltage specifications, environmental resistance |

| Energia renovável | Motors in wind turbine generators | Supports sustainable energy production | Efficiency ratings, sourcing from certified manufacturers |

| Marinha | Motors for propulsion in boats and ships | Enhances performance and fuel efficiency | Marine-grade materials, compliance with safety standards |

How Are Self Motor Parts Used in the Automotive Industry?

In the automotive sector, self motor parts, particularly starter motors, are crucial for vehicle ignition systems. They provide the necessary torque to start the engine, ensuring reliability and minimizing downtime. For international buyers, especially in regions like Africa and the Middle East, sourcing high-quality starter motors that meet specific vehicle model compatibility is essential. Additionally, buyers should prioritize suppliers with quality certifications to ensure performance and longevity.

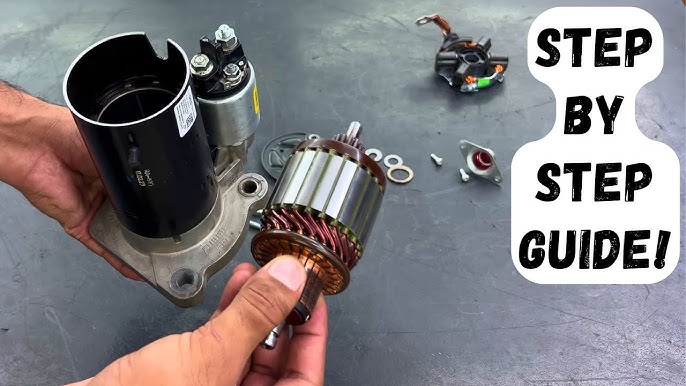

Illustrative image related to self motor parts

What Role Do Self Motor Parts Play in Industrial Equipment?

Self motor parts are integral to industrial equipment, particularly in conveyor systems where they drive the movement of goods. The use of efficient motors enhances production capabilities and reduces operational costs through improved reliability. Buyers from South America and Europe should consider the power ratings and durability of motors, ensuring they can withstand the demands of continuous operation in various industrial settings.

How Are Self Motor Parts Utilized in Agriculture?

In agriculture, electric motors are commonly used in irrigation systems to manage water distribution effectively. These motors facilitate efficient water management, crucial for crop yield and sustainability. Buyers in this sector must focus on voltage specifications and the motors’ resistance to environmental conditions, such as moisture and dust, to ensure optimal performance in diverse climates.

What Is the Importance of Self Motor Parts in Renewable Energy?

Self motor parts, particularly in wind turbine generators, play a vital role in renewable energy production. These motors convert wind energy into electrical energy, contributing to sustainable energy solutions. For international buyers, especially in Europe, sourcing motors with high efficiency ratings from certified manufacturers is critical to maximize energy output and ensure long-term operational success.

How Do Self Motor Parts Benefit the Marine Industry?

In the marine industry, self motor parts are essential for propulsion systems in boats and ships. High-performance motors enhance fuel efficiency and overall vessel performance, critical for commercial operations. Buyers should look for marine-grade materials and ensure compliance with safety standards to mitigate risks associated with marine environments.

3 Common User Pain Points for ‘self motor parts’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Sourcing Self Motor Parts

O problema: B2B buyers often face the daunting challenge of ensuring that the self motor parts they source meet stringent quality standards. This is particularly critical for industries such as automotive manufacturing, where subpar components can lead to performance failures, increased warranty claims, and damage to brand reputation. Buyers may struggle with inconsistencies in quality across suppliers, especially when sourcing from diverse regions like Africa and South America, where manufacturing practices can vary significantly.

A solução: To mitigate quality risks, buyers should implement a rigorous supplier evaluation process. This includes conducting audits to assess the manufacturing capabilities and quality control measures of potential suppliers. Establishing partnerships with reputable manufacturers who adhere to international quality standards, such as ISO certifications, can also enhance reliability. Additionally, integrating a sample testing phase before bulk orders can help verify that the parts meet required specifications. Investing in a quality assurance team that can continuously monitor supplier performance will ensure consistent quality over time.

Scenario 2: Managing Inventory Levels for Self Motor Parts

O problema: Another prevalent pain point is managing inventory levels effectively. B2B buyers often struggle to balance having enough stock to meet demand without overstocking, which ties up capital and increases storage costs. Fluctuations in demand can make it challenging to predict how many self motor parts to order, leading to potential stockouts or excess inventory.

A solução: Implementing an inventory management system that uses real-time data analytics can significantly streamline this process. By leveraging demand forecasting tools, buyers can analyze historical sales data to predict future needs accurately. Establishing relationships with suppliers that offer just-in-time delivery can also alleviate the pressure of holding large inventories. Furthermore, utilizing drop-shipping methods allows buyers to reduce inventory costs while still fulfilling customer orders promptly. Regularly reviewing and adjusting inventory policies based on market trends will help maintain optimal stock levels.

Scenario 3: Understanding Technical Specifications and Compatibility

O problema: Many B2B buyers encounter difficulties in understanding the technical specifications of self motor parts, which can lead to purchasing incompatible components. This is particularly true in international markets where different manufacturers may use varying standards and specifications. Misunderstanding the nuances of kW ratings, voltage requirements, or pinion teeth configurations can result in costly returns and delays.

A solução: To address this challenge, buyers should invest time in training their purchasing and technical teams on the key specifications and compatibility requirements of self motor parts. Creating a comprehensive reference guide that outlines common specifications, including a glossary of terms and compatibility charts, can serve as a valuable resource. Additionally, establishing a direct line of communication with manufacturers or suppliers for technical inquiries can provide clarity and ensure that the right parts are selected. Utilizing online tools that offer detailed product comparisons and specifications can also facilitate informed purchasing decisions, minimizing the risk of errors.

Strategic Material Selection Guide for self motor parts

What Are the Key Materials for Self Motor Parts?

When selecting materials for self motor parts, it is crucial for B2B buyers to consider the properties, advantages, and limitations of each material. This analysis focuses on four common materials: aluminum, steel, plastic composites, and copper, each with distinct characteristics that impact performance and suitability for various applications.

How Does Aluminum Perform in Self Motor Parts?

Aluminum is widely used in self motor parts due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating up to 150°C and can withstand moderate pressure levels, making it suitable for various automotive applications. The primary advantage of aluminum is its high strength-to-weight ratio, which enhances fuel efficiency in vehicles. However, it can be more expensive than other materials and may require specialized manufacturing processes, such as die-casting or extrusion. For international buyers, compliance with standards such as ASTM and ISO is critical, particularly in regions like Europe where stringent regulations apply.

What Are the Benefits of Using Steel in Self Motor Parts?

Steel is another prevalent material for self motor parts, known for its exceptional strength and durability. It can handle high temperatures (up to 300°C) and pressures, making it ideal for components that experience significant stress. The main advantage of steel is its cost-effectiveness and ease of manufacturing, as it can be easily welded and machined. However, steel is prone to corrosion, which necessitates protective coatings or treatments. For buyers in regions like the Middle East, where humidity can accelerate corrosion, selecting galvanized or stainless steel can mitigate this issue. Compliance with standards such as DIN is also essential for ensuring quality.

Why Are Plastic Composites Gaining Popularity in Self Motor Parts?

Plastic composites are increasingly being utilized in self motor parts due to their lightweight and corrosion-resistant properties. They can withstand temperatures up to 120°C and are often used in applications where weight reduction is critical. The advantages of plastic composites include lower manufacturing costs and the ability to mold complex shapes easily. However, they may not offer the same level of strength as metals and can be sensitive to high temperatures and UV exposure. For international buyers, understanding the specific grades of plastics and their compliance with industry standards, such as ASTM, is vital, especially in regions with diverse climate conditions.

How Does Copper Contribute to Self Motor Parts?

Copper is primarily used in electrical components of self motor parts, such as wiring and connectors, due to its excellent electrical conductivity. It can handle temperatures up to 200°C and is highly resistant to corrosion. The key advantage of copper is its superior conductivity, which enhances the efficiency of electrical systems. However, copper can be more expensive than aluminum and steel, and its weight can be a disadvantage in applications focused on weight reduction. For buyers in Europe and South America, ensuring compliance with electrical standards and regulations is essential for maintaining safety and performance.

Summary of Material Properties for Self Motor Parts

| Material | Typical Use Case for self motor parts | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Lightweight components, housings | Elevada relação resistência/peso | Custo mais elevado e fabrico complexo | Médio |

| Aço | Structural components, brackets | Económica e duradoura | Suscetível à corrosão | Baixo |

| Compósitos plásticos | Non-structural parts, casings | Lightweight and easy to mold | Limited strength and temperature sensitivity | Baixo |

| Cobre | Fiação elétrica e conectores | Excelente condutividade | Higher cost and heavier weight | Alto |

This guide provides a comprehensive overview of the strategic material selection for self motor parts, enabling international B2B buyers to make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for self motor parts

The manufacturing and quality assurance processes for self motor parts are crucial for ensuring reliability, performance, and compliance with international standards. This section provides a comprehensive overview of these processes, focusing on the stages of manufacturing, quality control checkpoints, relevant standards, and verification methods that international B2B buyers should consider, especially those from Africa, South America, the Middle East, and Europe.

What Are the Main Stages of Manufacturing Self Motor Parts?

Material Preparation: Selecting the Right Components

The manufacturing process begins with the careful selection of raw materials. For self motor parts, this typically includes high-quality metals, plastics, and electronic components. Suppliers often use advanced materials like high-strength alloys and thermoplastics to enhance durability and performance.

Material preparation also involves cutting, shaping, and treating the materials to meet specific engineering requirements. Techniques such as laser cutting or CNC machining are commonly employed to ensure precision. This stage is critical as the quality of the raw materials directly impacts the performance and longevity of the final product.

How Are Self Motor Parts Formed?

Once materials are prepared, the next stage is forming. This can involve various processes such as:

- Elenco: Pouring molten metal into molds to create complex shapes.

- Forjamento: Applying pressure to shape metal, enhancing its strength.

- Maquinação: Removing material using tools to achieve precise dimensions.

- Moldagem por injeção: Used primarily for plastic components, where heated material is injected into molds.

Each of these techniques has its advantages and is selected based on the part’s design requirements, material properties, and production volume.

What Does the Assembly Process Involve?

After forming, the next phase is assembly, where various components are put together to create the self motor part. This often includes:

- Mechanical Assembly: Joining parts using screws, bolts, or welding.

- Electrical Assembly: Integrating electronic components such as sensors and wiring.

Automation plays a significant role in this stage, with robotic systems increasingly used to enhance accuracy and reduce labor costs. The assembly process must be meticulously planned to ensure that all components fit correctly and function as intended.

What Are the Finishing Techniques Used in Manufacturing?

Finishing processes are essential for improving the aesthetics and functionality of self motor parts. Common techniques include:

- Tratamento de superfície: Methods such as anodizing, painting, or powder coating to enhance corrosion resistance and appearance.

- Quality Testing: Final inspections to ensure that the part meets design specifications and performance standards.

These finishing touches not only enhance the product’s visual appeal but also extend its lifespan and reliability.

How Is Quality Assurance Integrated into Manufacturing?

Quais são as normas internacionais a que os compradores devem estar atentos?

Quality assurance in the manufacturing of self motor parts often adheres to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards ensures that manufacturers consistently produce high-quality products and continuously improve their processes.

Illustrative image related to self motor parts

Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for automotive components may also apply. These certifications verify that products meet regulatory requirements and safety standards, which is crucial for gaining trust in international markets.

Quais são os principais pontos de verificação do controlo de qualidade?

Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

- Controlo de Qualidade de Entrada (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- Controlo de qualidade em processo (IPQC): Monitoring the production process to catch defects early and ensure adherence to specifications.

- Controlo de Qualidade Final (FQC): Conducting thorough inspections and testing on the finished products before they are shipped.

By implementing these checkpoints, manufacturers can identify and rectify issues at various stages, minimizing the risk of defective products reaching customers.

What Common Testing Methods Are Used for Self Motor Parts?

Testing methods vary based on the part’s application but commonly include:

- Testes funcionais: Ensuring the part operates correctly under load conditions.

- Teste de durabilidade: Assessing how well the part withstands wear and environmental factors.

- Testes elétricos: Verifying the integrity of electrical components and connections.

These tests help ensure that self motor parts can perform reliably in real-world conditions, thereby reducing the likelihood of failures.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

What Steps Should Buyers Take for Supplier Audits?

B2B buyers should conduct thorough audits of potential suppliers to assess their manufacturing capabilities and quality control processes. This can include:

- On-site Visits: Observing the manufacturing process, quality control checkpoints, and compliance with international standards.

- Revisão dos relatórios de qualidade: Requesting documentation that details the supplier’s quality management practices, including past audit results and corrective actions taken.

These audits provide valuable insights into the supplier’s operations and can help build a foundation of trust.

How Can Third-party Inspections Enhance Confidence?

Engaging third-party inspection services can further assure buyers of product quality. These organizations can conduct independent audits and testing to verify that the manufacturer adheres to the required standards. This is particularly beneficial for international buyers who may not have the capacity to conduct on-site inspections.

Quais são as nuances do controlo de qualidade para os compradores internacionais?

International B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, must consider regional variations in quality standards and regulations. Understanding local compliance requirements is essential for successful trade relationships.

Additionally, language barriers and cultural differences may impact communication regarding quality expectations. Establishing clear quality agreements and using certified translation services can mitigate these challenges.

In conclusion, the manufacturing processes and quality assurance for self motor parts are intricate and vital for producing reliable products. By understanding these processes and verifying supplier capabilities, B2B buyers can make informed decisions that ensure quality and compliance in their procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘self motor parts’

To effectively source self motor parts in today’s competitive B2B landscape, it’s vital to approach the procurement process methodically. This guide provides a practical checklist designed to streamline your sourcing efforts and ensure that you find reliable suppliers who meet your specific needs.

Passo 1: Defina as suas especificações técnicas

Understanding your technical requirements is foundational for sourcing self motor parts. Specify the type of parts needed (e.g., starters, alternators) and their operational parameters such as voltage, kW ratings, and rotation direction. This clarity will help you communicate effectively with suppliers and ensure compatibility with existing systems.

Passo 2: Pesquisar potenciais fornecedores

Conduct thorough research to identify potential suppliers. Use online platforms, industry trade shows, and local directories to gather a list of manufacturers and distributors. Focus on suppliers with a solid reputation in your target regions, such as Africa, South America, the Middle East, and Europe, as regional knowledge can significantly impact logistics and compliance.

Passo 3: Avaliar as credenciais do fornecedor

Before committing to any supplier, evaluate their credentials meticulously. Request certifications such as ISO standards, quality assurance processes, and any relevant industry-specific licenses. Ensure that the supplier has a history of compliance with international quality standards, which can mitigate risks associated with poor product quality.

Passo 4: Solicitar amostras de produtos

Always request product samples before placing a bulk order. This allows you to assess the quality and performance of the self motor parts firsthand. Pay attention to the materials used, durability, and overall craftsmanship to ensure that they meet your operational needs.

Passo 5: Compare preços e condições

Gather detailed quotations from multiple suppliers and compare them. Look beyond just the price; consider payment terms, shipping costs, and delivery timelines. A slightly higher price may be justified by better service levels or superior quality, which can save costs in the long run.

Passo 6: Check References and Reviews

Reach out to existing customers or request case studies to gauge the supplier’s reliability and service quality. Online reviews can also provide insights into the supplier’s reputation. This step is crucial for assessing whether the supplier can meet your expectations and adhere to delivery schedules.

Passo 7: Establish a Clear Communication Plan

Once you have selected a supplier, establish a clear communication plan to ensure smooth collaboration. Define points of contact, reporting structures, and timelines for updates. Effective communication can prevent misunderstandings and facilitate quicker resolution of any issues that may arise during the procurement process.

By following this checklist, B2B buyers can navigate the complexities of sourcing self motor parts more effectively, ensuring that they select the right suppliers and products for their specific operational needs.

Comprehensive Cost and Pricing Analysis for self motor parts Sourcing

Understanding the cost structure and pricing dynamics for self motor parts is crucial for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This analysis breaks down the essential components that contribute to the overall costs and pricing strategies for these parts.

What Are the Key Cost Components in Self Motor Parts Manufacturing?

-

Materiais: The primary cost driver in manufacturing self motor parts is the raw materials. Common materials include steel, copper, and various plastics. Fluctuations in global commodity prices can significantly impact costs, necessitating buyers to stay informed about market trends.

-

Trabalho: Labor costs vary widely depending on the region of production. Countries with lower labor costs may offer competitive pricing, but this can sometimes compromise quality. Understanding the local labor market and associated costs is essential for effective budgeting.

-

Custos indiretos de produção: This includes costs related to utilities, facility maintenance, and other indirect expenses necessary for production. Overhead can vary based on the supplier’s operational efficiency and geographical location.

-

Ferramentas: Tooling costs are associated with the creation of molds and dies used in the production of parts. Custom tooling can be a significant upfront investment, particularly for specialized components, and should be factored into overall costs.

-

Controlo de Qualidade (QC): Ensuring that products meet industry standards and specifications incurs additional costs. Implementing stringent QC processes is vital for maintaining product integrity, especially when sourcing for different markets with varying regulatory requirements.

-

Logística: Transportation and shipping costs can vary dramatically based on distance, mode of transport, and Incoterms. Buyers should consider these costs as part of the total cost of ownership (TCO) when evaluating suppliers.

-

Margem: The profit margin that suppliers build into their pricing can vary based on market demand and competition. Understanding the average margins in the industry can aid buyers in negotiating better pricing.

How Do Price Influencers Impact Self Motor Parts Sourcing?

-

Volume e quantidade mínima de encomenda (MOQ): Pricing often decreases with higher order volumes due to economies of scale. Buyers should assess their purchasing needs and negotiate MOQs that align with their inventory strategies.

-

Especificações e personalização: Custom parts or those with specific requirements can lead to higher costs. Clear communication about specifications can help avoid unexpected price increases.

-

Qualidade dos materiais e certificações: Higher quality materials and specific certifications (such as ISO standards) can raise costs but are often necessary for compliance and reliability in certain markets.

-

Fatores relacionados ao fornecedor: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium but offer greater assurance in terms of quality and delivery reliability.

-

Incoterms: Understanding the agreed Incoterms is essential, as they dictate the responsibilities of buyers and sellers regarding shipping, risk, and cost. This can significantly affect the final landed cost of parts.

What Are the Best Practices for Buyers in Sourcing Self Motor Parts?

-

Negociar eficazmente: Building strong relationships with suppliers can lead to better pricing and terms. Buyers should approach negotiations with a clear understanding of their needs and market conditions.

-

Foco na eficiência de custos: Evaluate the total cost of ownership rather than just the purchase price. This includes factoring in logistics, maintenance, and potential downtime costs associated with lower-quality parts.

-

Esteja ciente das nuances dos preços: International buyers should be mindful of regional pricing variations and the impact of local economic conditions on costs. Understanding these nuances can provide leverage during negotiations.

-

Maintain Flexibility: Be open to adjusting order volumes and timelines to accommodate suppliers’ capabilities, which can lead to cost savings.

-

Mantenha-se informado: Keeping abreast of market trends, material prices, and geopolitical factors can empower buyers to make informed decisions and strategically time their purchases.

Conclusão

While indicative prices may fluctuate, understanding the underlying cost components and influencers is essential for effective sourcing of self motor parts. By leveraging these insights, international B2B buyers can optimize their procurement strategies and enhance their competitive edge in the market.

Alternatives Analysis: Comparing self motor parts With Other Solutions

Understanding the Importance of Alternatives in Self Motor Parts

In the dynamic landscape of automotive components, particularly for self motor parts, it is crucial for businesses to evaluate alternatives that can meet their operational needs effectively. Alternative solutions may provide various advantages, including cost savings, enhanced performance, and improved maintenance. This section explores some viable alternatives to self motor parts, allowing international B2B buyers to make informed decisions based on their specific requirements.

Tabela comparativa

| Aspecto comparativo | Self Motor Parts | Arrancadores Remanufacturados | Electric Motor Systems |

|---|---|---|---|

| Desempenho | Reliable start-up and consistent operation. | Comparable performance to new parts but may vary by quality. | High efficiency and torque; can be optimized for specific applications. |

| Custo | Generally higher upfront costs for new parts. | Lower initial cost; savings on remanufactured options. | Can be expensive to install, but lower operating costs over time. |

| Facilidade de implementação | Standard installation procedures; requires skilled labor. | Similar installation to new parts; often requires minimal adjustments. | May require significant modifications to existing systems. |

| Manutenção | Regular checks needed; longer lifespan with quality parts. | Maintenance may be less frequent but can vary with quality. | Minimal maintenance; often self-monitoring systems. |

| Melhor caso de uso | Ideal for high-demand vehicles needing reliability. | Suitable for cost-conscious buyers looking for reliable alternatives. | Best for applications requiring high efficiency and reduced weight. |

Exploring the Alternatives in Detail

Arrancadores Remanufacturados

Remanufactured starters present a cost-effective alternative to new self motor parts. These components undergo a rigorous refurbishment process, ensuring they meet original equipment specifications. The primary advantage is the reduced cost, making them appealing for budget-conscious buyers. However, the performance may not always match that of new parts, and the longevity can depend on the quality of the remanufacturing process. Buyers should consider the warranty and reputation of the supplier to ensure reliability.

Electric Motor Systems

Electric motor systems represent a technological shift away from traditional self motor parts. These systems are designed for high efficiency and torque, making them suitable for various applications, especially in electric vehicles. While the initial investment can be significant, the long-term operational savings and lower maintenance requirements can offset the upfront costs. However, integrating electric motor systems may necessitate extensive modifications to existing setups, which can pose challenges for some businesses.

Conclusão: escolhendo a solução certa para as suas necessidades

When selecting between self motor parts and their alternatives, B2B buyers must assess their specific operational needs, budget constraints, and long-term goals. Self motor parts are ideal for those prioritizing reliability and performance, while remanufactured starters offer a balance of cost and efficiency. Electric motor systems, although initially costly, provide a forward-thinking solution that can enhance efficiency and reduce maintenance. By carefully analyzing these alternatives, businesses can make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for self motor parts

Understanding the essential technical properties and trade terminology for self motor parts is crucial for B2B buyers looking to make informed purchasing decisions. This section highlights key specifications and common jargon that will aid international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

What are the Key Technical Properties of Self Motor Parts?

1. kW Rating

The kilowatt (kW) rating indicates the power output of the motor. It is a critical specification as it affects the performance and efficiency of the motor parts. Buyers must consider this value to ensure compatibility with the vehicle or machinery, as selecting a part with an inadequate kW rating can lead to operational failures.

2. Tensão nominal

Voltage ratings, typically expressed in volts (e.g., 6V, 12V, 24V), denote the electrical potential required to operate the motor. Understanding voltage compatibility is essential for B2B buyers to prevent electrical mismatches that could cause damage or inefficiency in operations.

3. Direção de rotação

The rotation direction, which can be clockwise or counter-clockwise, is vital for ensuring that the motor part functions correctly within the system. This specification is particularly important when selecting starters or alternators, as an incorrect rotation can lead to mechanical failures.

4. Tipo de desenho

Motor parts may come in various design types, such as direct drive, gear reduction, or planetary gear reduction. Each design offers different advantages in terms of torque, efficiency, and size. B2B buyers should evaluate their specific application needs to select the most suitable design type.

Illustrative image related to self motor parts

5. Number of Pinion Teeth

This specification is crucial for starters, as it affects the engagement with the flywheel. The number of teeth must match the vehicle’s specifications to ensure a proper fit and function. An incorrect match can lead to wear and tear or complete failure of the starting system.

What Are Common Trade Terms in the Self Motor Parts Industry?

1. OEM (Fabricante de Equipamento Original)

OEM refers to parts made by the original manufacturer of the vehicle or equipment. These parts are often preferred for their guaranteed compatibility and quality. Understanding OEM specifications helps buyers ensure they are purchasing reliable components.

2. MOQ (Quantidade mínima de encomenda)

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. This term is crucial for B2B buyers as it affects inventory management and cost efficiency. Knowing the MOQ helps companies plan their purchases according to demand.

3. RFQ (Pedido de Orçamento)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. It is essential for B2B transactions as it allows buyers to compare offers and negotiate better deals, ensuring they receive the best value for their investment.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is crucial for international buyers to understand their obligations and rights during the shipping process.

5. Termos da garantia

Understanding warranty terms is vital for B2B buyers to assess the level of protection they have against defects or failures. Different parts may come with varying warranty durations and conditions, impacting the long-term cost of ownership and risk management.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing self motor parts, ultimately leading to more efficient operations and reduced costs.

Navigating Market Dynamics and Sourcing Trends in the self motor parts Sector

What Are the Current Market Dynamics and Key Trends in the Self Motor Parts Sector?

The global self motor parts market is experiencing a transformative phase driven by several key factors. The demand for automotive components, particularly in regions such as Africa, South America, the Middle East, and Europe, is being propelled by an increase in vehicle ownership and the need for aftermarket parts. Emerging markets are witnessing a rise in disposable income, leading to greater consumer expenditure on vehicle maintenance and upgrades. Additionally, advancements in technology are reshaping sourcing strategies. B2B buyers are increasingly leveraging digital platforms to streamline procurement processes, enabling them to access a broader range of suppliers and products efficiently.

Another significant trend is the shift towards electric and hybrid vehicles, which is influencing the types of self motor parts in demand. Components that cater to these newer technologies, such as high-efficiency starters and alternators, are becoming critical for suppliers. Moreover, the integration of smart technologies into vehicles is driving the need for more sophisticated motor parts, thus creating new opportunities for innovation in design and manufacturing.

Furthermore, the competitive landscape is evolving, with manufacturers focusing on enhancing quality and reducing lead times to meet the expectations of international buyers. Collaborative partnerships and strategic alliances are becoming common as companies seek to expand their market reach and optimize their supply chains.

How Can Sustainability and Ethical Sourcing Impact the Self Motor Parts Sector?

Sustainability and ethical sourcing are increasingly crucial in the self motor parts sector, reflecting a growing awareness of environmental impacts among international B2B buyers. The automotive industry is under pressure to reduce its carbon footprint, leading to a demand for sustainable practices throughout the supply chain. This includes sourcing materials that are environmentally friendly and adopting processes that minimize waste and energy consumption.

Ethical sourcing practices are also gaining traction, with buyers preferring suppliers that adhere to fair labor practices and transparent supply chains. This trend is particularly relevant in regions where labor standards may vary significantly. Certifications such as ISO 14001 for environmental management and Fair Trade for ethical labor practices are becoming vital for suppliers aiming to attract conscientious buyers.

In addition, the use of recycled materials in manufacturing self motor parts is on the rise. Buyers are increasingly seeking products that incorporate recycled components, aligning with their sustainability goals. This not only reduces the environmental impact of production but also helps in lowering costs, creating a win-win scenario for both suppliers and buyers.

What Is the Brief Evolution of the Self Motor Parts Industry and Its B2B Implications?

The self motor parts industry has evolved significantly over the past few decades. Initially dominated by traditional combustion engine components, the sector has progressively adapted to technological advancements and changing consumer preferences. The introduction of electronic systems in vehicles has led to the development of more complex motor parts, enhancing performance and efficiency.

As the industry moves towards electric and hybrid vehicles, suppliers are re-evaluating their product lines to meet new demands. This evolution necessitates a shift in sourcing strategies for B2B buyers, who must now consider not only the technical specifications of parts but also their compatibility with advanced vehicle technologies. Understanding these changes is crucial for international buyers, as it enables them to make informed decisions and capitalize on emerging opportunities within the market.

Frequently Asked Questions (FAQs) for B2B Buyers of self motor parts

-

How do I solve issues with sourcing self motor parts internationally?

To address sourcing challenges, first identify reliable suppliers with a solid track record in your target regions. Use platforms like Alibaba or trade shows to connect with manufacturers. Consider requesting samples to evaluate quality before placing large orders. Additionally, ensure that suppliers are familiar with international shipping regulations and can provide necessary documentation for customs clearance. Regular communication and building a relationship with your supplier can also mitigate potential issues. -

What is the best type of self motor part for my specific application?

The best self motor part depends on your application requirements, such as voltage, power rating, and design specifications. For instance, if you need a starter for heavy machinery, look for high kW ratings and durability features. Research manufacturers that specialize in your specific needs and consult with their technical support teams to ensure compatibility. Always consider the operational environment, as extreme conditions may necessitate specialized components. -

What are the minimum order quantities (MOQs) for self motor parts?

MOQs can vary significantly among suppliers. Many manufacturers set MOQs based on production costs and inventory turnover rates, often ranging from 50 to 500 units. When negotiating, clarify if MOQs can be adjusted based on your order size or if they offer trial orders. Some suppliers may allow lower MOQs for first-time customers or specific product lines, so it’s beneficial to discuss your needs openly. -

How can I effectively vet suppliers of self motor parts?

To vet suppliers, start by reviewing their business credentials, including certifications like ISO and industry-specific accreditations. Request references from previous clients and check online reviews. Conducting a factory visit, if feasible, can provide insight into their manufacturing processes and quality control systems. Additionally, consider their responsiveness to inquiries and willingness to provide technical support, as these factors often indicate reliability and commitment. -

What payment terms should I expect when sourcing self motor parts?

Payment terms can vary widely, but common practices include a deposit (typically 30%) upfront and the remainder upon delivery. Some suppliers may offer letters of credit or escrow services for larger orders, which can provide security for both parties. Always clarify payment methods accepted, such as bank transfers, PayPal, or credit terms, and ensure these align with your financial capabilities and risk management strategies. -

How do I ensure quality assurance for self motor parts?

Establishing quality assurance begins with choosing suppliers who have robust quality control processes in place. Request detailed documentation, including test reports and compliance certificates, for the parts you are sourcing. Implement a sample approval process before bulk orders, and consider third-party inspections during production or prior to shipping. Additionally, inquire about warranties and return policies to safeguard against defects. -

What logistics considerations should I keep in mind when importing self motor parts?

Logistics plays a crucial role in the timely delivery of self motor parts. Factor in shipping methods, costs, and estimated delivery times when placing orders. Understand the customs regulations for your destination country, including tariffs and import duties. Working with a freight forwarder can streamline the process, ensuring all documentation is in order and that you remain compliant with local laws. -

Can I customize self motor parts to meet specific requirements?

Yes, many manufacturers offer customization options for self motor parts, including specifications related to size, power ratings, and design features. When discussing customization, provide clear and detailed requirements, including any technical drawings if available. Be aware that custom orders may have higher MOQs and longer lead times, so plan accordingly. Discuss potential costs and timelines upfront to ensure your needs are met effectively.

Top 4 Self Motor Parts Manufacturers & Suppliers List

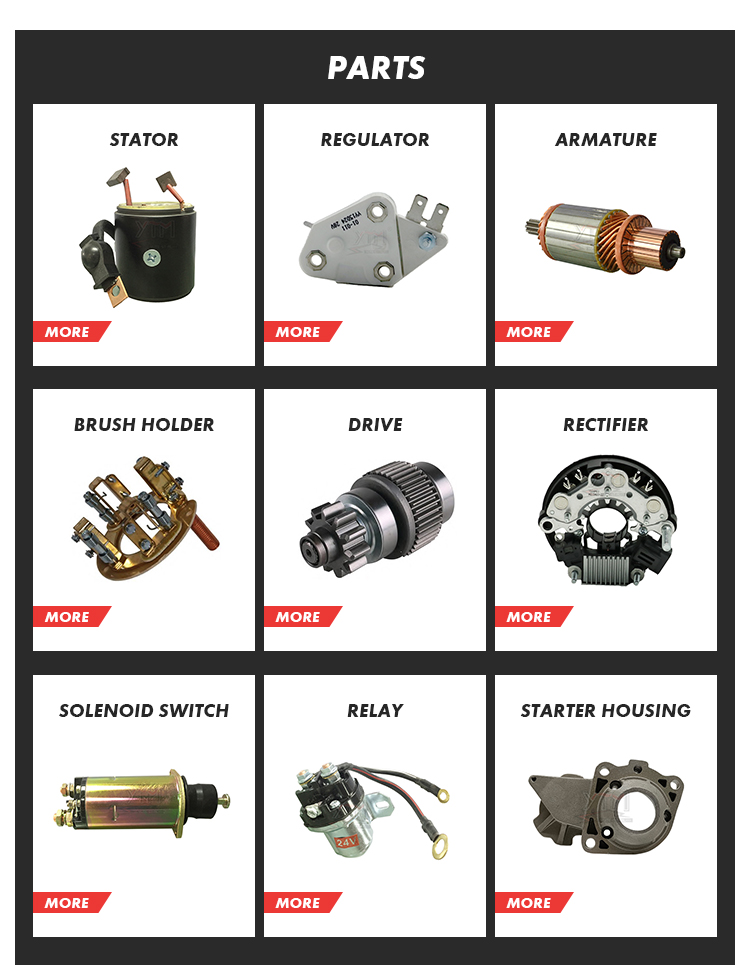

1. Scribd – Starter Motor Components

Domínio: scribd.com

Registada: 2006 (19 anos)

Introdução: O motor de arranque é composto por vários componentes principais que funcionam em conjunto para pôr o motor a trabalhar. Os principais componentes incluem: 1. Solenoide de arranque: Utiliza corrente eléctrica para engatar a engrenagem do pinhão de acionamento. 2. Bobinas de campo: Geram um campo magnético. 3. Bobinas da armadura: Reagem para induzir movimento. 4. Escovas: Transferem a corrente entre as partes estáticas e rotativas. 5. Embraiagem do pinhão de transmissão: liga e desliga o...

2. AutoElectro - Motores de arranque

Domínio: autoelectro.pt

Registado: 1999 (26 anos)

Introdução: Starter motors are responsible for turning the engine over during ignition, allowing air and fuel to enter for combustion. Key components include: Armature (an electromagnet on the drive shaft), Commutator (conducts electricity via brushes), Brushes (make contact with the commutator), Solenoid (acts as a switch connecting the starter motor to the battery), Plunger (engages the pinion), Lever Fork …

3. BuyAutoParts – Fast Shipping & Warranty

Domínio: buyautoparts.com

Registada: 2001 (24 anos)

Introdução: {“Envio rápido”: ”Envio gratuito para encomendas superiores a $99. Enviamos a partir de vários armazéns em todo o país, para que receba a sua peça o mais rapidamente possível.”, ”Garantia”: ”Garantia gratuita, de um ano (ou mais), sem limite de quilómetros. Cobre tudo; peças e custos de envio.”, ”Devoluções”: ”Devolução por qualquer motivo no prazo de 60 dias para um reembolso total.”, ”Especialização”: ”Especialistas em peças para automóveis desde 1989. Classificado como 4.9/5 por mais de 400.0...

4. Pinterest – Starter Motor Guide

Domínio: pinterest.com

Registado: 2009 (16 anos)

Introdução: Starter Motor: Diagram, Parts, Working, Types & Uses [PDF] – Discusses the function, parts, diagram, types, working principle, bad symptoms & solutions of starter motors.

Strategic Sourcing Conclusion and Outlook for self motor parts

Strategic sourcing for self motor parts is essential for international B2B buyers seeking to optimize their supply chains and enhance operational efficiency. By prioritizing quality, reliability, and cost-effectiveness, businesses can foster stronger relationships with suppliers, ensuring they receive the best products to meet their needs. Understanding the diverse range of options available—such as new versus remanufactured parts, various kW ratings, and voltage specifications—enables buyers to make informed decisions tailored to their specific requirements.

Illustrative image related to self motor parts

Furthermore, as the global market continues to evolve, buyers from Africa, South America, the Middle East, and Europe must remain agile and proactive in their sourcing strategies. Emphasizing local partnerships and leveraging technological advancements can yield significant competitive advantages.

Looking ahead, the demand for high-quality self motor parts is poised to grow, driven by advancements in automotive technology and increasing vehicle ownership across emerging markets. Now is the time for B2B buyers to assess their sourcing strategies and align them with future market trends. Engage with suppliers who can provide not only the products you need but also the expertise to navigate this dynamic landscape effectively.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.