Introduction: Navigating the Global Market for how to tell if its the alternator or the battery

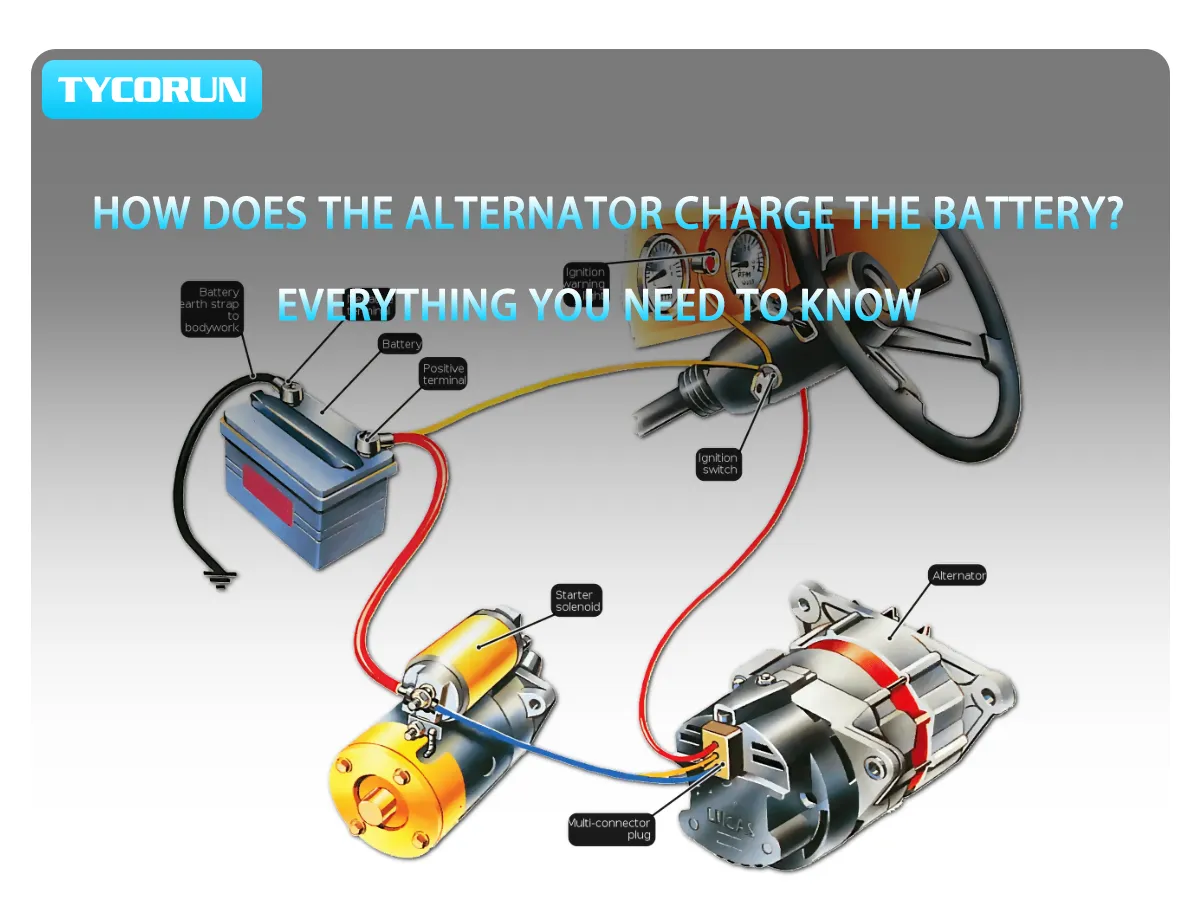

In today’s competitive automotive market, understanding how to determine whether a vehicle issue stems from the alternator or the battery is crucial for B2B buyers. This guide, “How to Tell If It’s the Alternator or the Battery,” serves as an essential resource for international suppliers, mechanics, and automotive businesses, particularly those operating in Africa, South America, the Middle East, and Europe, including regions like Nigeria and Vietnam. With the increasing complexity of automotive electrical systems, accurately diagnosing these common issues can save time and reduce costs associated with misdiagnoses.

This comprehensive guide delves into various types of batteries and alternators, their applications, and the symptoms indicative of potential failures. It also provides actionable insights on supplier vetting, ensuring that buyers can source high-quality components effectively. By understanding the operational characteristics of both batteries and alternators, as well as the typical symptoms of failure, businesses can make informed decisions that enhance their service offerings and customer satisfaction.

Furthermore, we will explore cost considerations, maintenance tips, and testing methodologies, empowering B2B buyers to confidently navigate the global market. By leveraging this guide, automotive businesses can enhance their diagnostic capabilities, ultimately leading to improved operational efficiency and profitability in a rapidly evolving industry.

Índice

- Top 3 How To Tell If Its The Alternator Or The Battery Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to tell if its the alternator or the battery

- Understanding how to tell if its the alternator or the battery Types and Variations

- Key Industrial Applications of how to tell if its the alternator or the battery

- 3 Common User Pain Points for ‘how to tell if its the alternator or the battery’ & Their Solutions

- Strategic Material Selection Guide for how to tell if its the alternator or the battery

- In-depth Look: Manufacturing Processes and Quality Assurance for how to tell if its the alternator or the battery

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to tell if its the alternator or the battery’

- Comprehensive Cost and Pricing Analysis for how to tell if its the alternator or the battery Sourcing

- Alternatives Analysis: Comparing how to tell if its the alternator or the battery With Other Solutions

- Essential Technical Properties and Trade Terminology for how to tell if its the alternator or the battery

- Navigating Market Dynamics and Sourcing Trends in the how to tell if its the alternator or the battery Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to tell if its the alternator or the battery

- Strategic Sourcing Conclusion and Outlook for how to tell if its the alternator or the battery

- Aviso legal importante e termos de utilização

Understanding how to tell if its the alternator or the battery Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Voltage Test with Multimeter | Measures battery voltage while the engine is running | Vehicle maintenance, fleet management | Prós: Accurate diagnosis; Contras: Requires tools and knowledge. |

| Battery Load Test | Assesses battery performance under load | Automotive repair shops, vehicle service centers | Prós: Reliable results; Contras: Equipment needed can be costly. |

| Inspeção visual | Verifica a existência de sinais físicos de desgaste ou danos | Automotive dealerships, repair workshops | Prós: Quick assessment; Contras: May overlook internal issues. |

| Teste de arranque | Tests if the vehicle starts after a jump | Fleet operations, roadside assistance services | Prós: Simple method; Contras: May not indicate underlying issues. |

| Teste de saída do alternador | Measures alternator voltage output directly | Diagnóstico automóvel, serviços de reparação | Prós: Directly identifies alternator issues; Contras: Requires access to engine components. |

What is the Voltage Test with Multimeter and Its B2B Applications?

The voltage test using a multimeter is a fundamental method for diagnosing battery and alternator issues. By measuring the voltage at the battery terminals while the engine runs, businesses can determine whether the alternator is charging the battery effectively. This method is particularly useful for vehicle maintenance providers and fleet management companies that need to ensure their vehicles remain operational. While it offers accurate diagnostics, it requires personnel to be trained in using the multimeter, which may incur additional training costs.

How Does a Battery Load Test Benefit Automotive Repair Shops?

A battery load test evaluates a battery’s performance under simulated starting conditions. This test helps automotive repair shops and vehicle service centers identify batteries that may appear functional but fail under load. The reliability of results makes this method crucial for businesses that prioritize customer safety and satisfaction. However, the equipment required for this test can be expensive, which may be a consideration for smaller shops.

Why is Visual Inspection a Quick Diagnostic Method?

Visual inspection involves examining the battery and alternator for obvious signs of wear, corrosion, or damage. This method is quick and can be performed by technicians during routine checks at automotive dealerships or repair workshops. While it provides immediate feedback, it may not catch internal failures, making it less reliable for comprehensive diagnostics. This approach is beneficial for businesses looking to streamline their initial assessment processes.

What is the Jump Start Test and Its Limitations for Fleet Operations?

The jump start test is a straightforward method to determine if a dead battery is the issue by attempting to start the vehicle with jumper cables. This method is often utilized by fleet operations and roadside assistance services due to its simplicity and speed. However, while it can indicate a battery issue, it does not provide insights into potential underlying problems, such as alternator failure, which could lead to repeated issues if not addressed.

How to Conduct an Alternator Output Test for Accurate Diagnostics?

An alternator output test measures the voltage output directly from the alternator while the engine is running. This test is essential for automotive diagnostics and repair services, allowing technicians to confirm whether the alternator is functioning correctly. It offers a direct assessment of alternator health, making it invaluable for businesses that rely on accurate and efficient vehicle repairs. However, conducting this test requires access to engine components, which may complicate the diagnostic process for some service providers.

Key Industrial Applications of how to tell if its the alternator or the battery

| Indústria/Setor | Specific Application of how to tell if its the alternator or the battery | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Serviços de diagnóstico para sistemas eléctricos de veículos | Reduces downtime by accurately diagnosing issues, enhancing customer satisfaction | Disponibilidade de ferramentas de diagnóstico e de técnicos formados |

| Transporte e Logística | Fleet maintenance and management for commercial vehicles | Assegura a eficiência operacional e minimiza as avarias inesperadas | Reliable sourcing of parts and quick repair services |

| Agricultura | Maintenance of agricultural machinery and vehicles | Prevents costly delays in operations and ensures equipment reliability | Access to specialized knowledge in agricultural machinery |

| Mineração | Equipment maintenance for heavy-duty vehicles and machinery | Increases safety and productivity by preventing equipment failure | Quality assurance of replacement parts and local repair services |

| Construção | Maintenance of construction vehicles and generators | Reduces project delays and enhances equipment lifespan | Fornecimento de peças duradouras adequadas a ambientes agressivos |

How is ‘how to tell if its the alternator or the battery’ utilized in Automotive Repair?

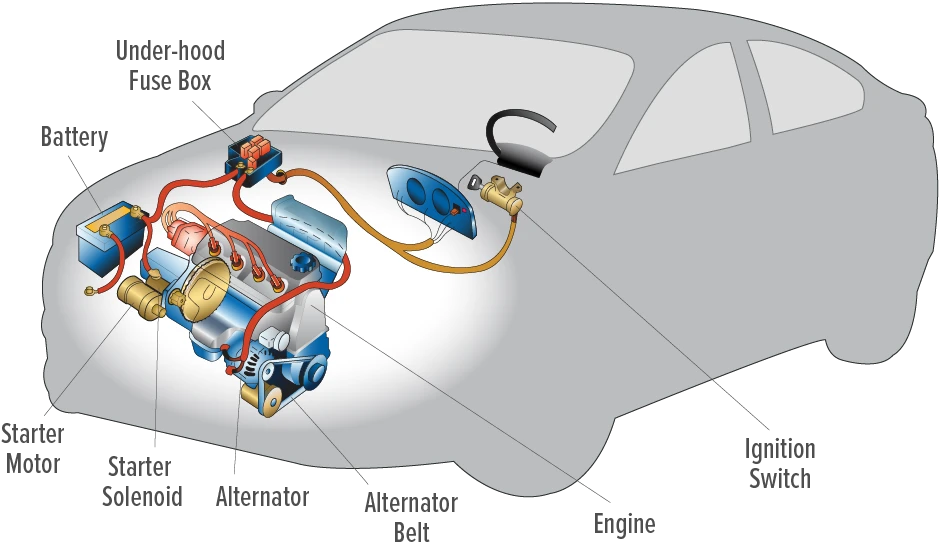

In the automotive repair industry, accurately diagnosing whether a vehicle’s issue stems from the alternator or the battery is crucial for effective service delivery. Repair shops use diagnostic tools to test the voltage and amperage outputs of both components, allowing technicians to identify the root cause of electrical failures. This capability not only enhances the repair process but also increases customer trust, as clients appreciate quick and reliable assessments. For international buyers, sourcing quality diagnostic equipment and training for technicians is essential, particularly in regions where advanced automotive technology may be less accessible.

What are the benefits of diagnosing battery or alternator issues in Transportation & Logistics?

In the transportation and logistics sector, maintaining a fleet of vehicles is vital for operational efficiency. Regularly diagnosing battery and alternator issues helps fleet managers prevent unexpected breakdowns that can disrupt service and lead to financial losses. By implementing systematic checks, businesses can ensure that vehicles are always ready for use, thus optimizing delivery schedules. For companies operating in emerging markets, partnering with reliable parts suppliers and service centers is essential to minimize downtime and maintain fleet productivity.

How does agricultural equipment benefit from understanding battery vs. alternator problems?

In agriculture, the reliability of machinery and vehicles is paramount for timely operations such as planting and harvesting. Understanding whether a malfunction is due to the battery or alternator allows farmers to quickly address issues, thereby reducing potential delays in critical tasks. Agricultural businesses benefit from sourcing durable and high-quality parts that can withstand harsh environments. Additionally, having access to local technicians who specialize in agricultural equipment can significantly reduce repair times, enhancing overall productivity during peak seasons.

Why is diagnosing electrical issues important in the mining industry?

The mining industry relies heavily on heavy-duty vehicles and machinery that require consistent power supply for safe and efficient operation. Diagnosing whether electrical issues are caused by the alternator or battery is essential for preventing equipment failure, which can pose safety risks and lead to costly downtime. Mining companies must ensure they have access to quality parts and skilled technicians familiar with the specific demands of mining equipment. This focus not only enhances safety but also contributes to the overall productivity of mining operations.

How does construction equipment maintenance benefit from proper electrical diagnostics?

In construction, the reliability of machinery such as excavators and generators is critical for keeping projects on schedule. Diagnosing whether issues stem from the alternator or battery allows construction managers to perform timely maintenance, thus preventing project delays. Companies benefit from sourcing high-quality replacement parts that can endure the rigors of construction environments. Additionally, having a network of local repair services ensures that any downtime is minimized, keeping projects on track and within budget.

3 Common User Pain Points for ‘how to tell if its the alternator or the battery’ & Their Solutions

Cenário 1: Dificuldade em diagnosticar problemas eléctricos nas frotas

O problema: Fleet managers often face significant challenges when diagnosing electrical issues in their vehicles, especially when a vehicle exhibits symptoms of both battery and alternator failure. The stakes are high; misdiagnosing the issue can lead to unnecessary repairs, increased downtime, and ultimately lost revenue. For instance, if a delivery truck fails to start, it may be unclear whether the problem lies with a dead battery or a failing alternator. This uncertainty can lead to wasted time and resources as technicians test and replace components that may not need servicing.

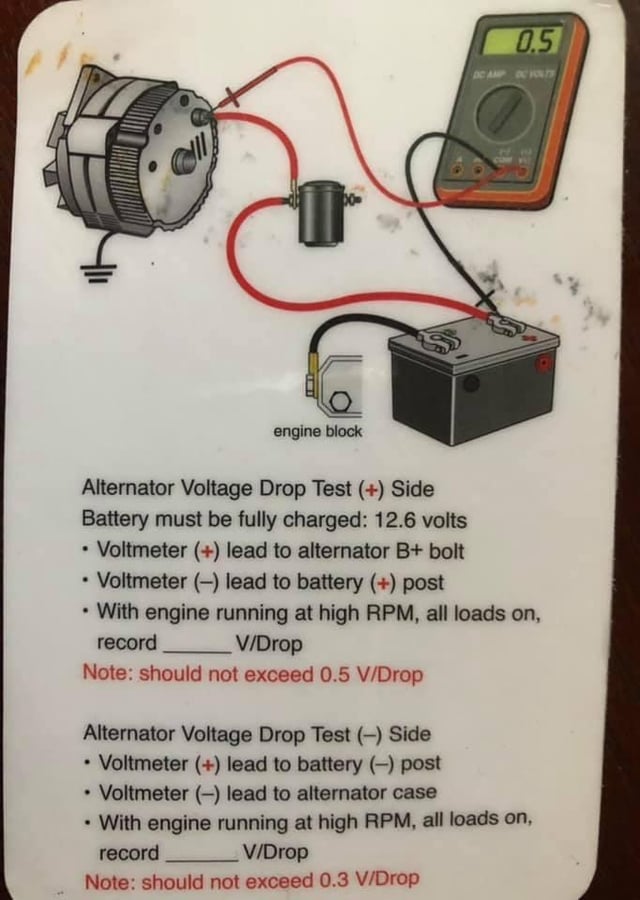

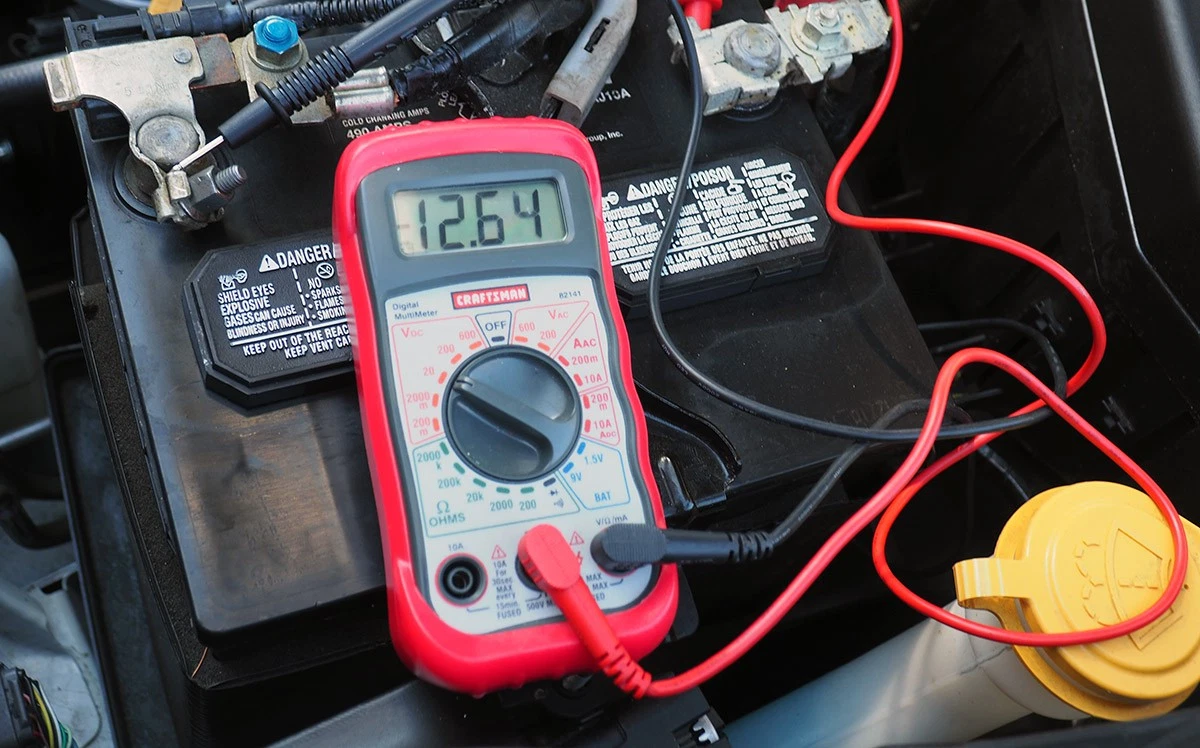

A solução: To effectively diagnose whether the issue is with the battery or the alternator, fleet managers should implement a systematic approach. First, invest in multimeters or battery testers that are easy to use and provide accurate readings. Teach technicians to check the battery voltage with the engine off; a healthy battery should read about 12.6 volts. If the voltage is significantly lower, it indicates a battery issue. Next, start the vehicle and measure the voltage across the battery terminals again; it should read between 13 and 14.5 volts if the alternator is functioning correctly. If the voltage drops below this range, it suggests a problem with the alternator. By equipping their teams with the right tools and training, fleet managers can streamline the diagnostic process, reducing downtime and improving operational efficiency.

Scenario 2: High Repair Costs Due to Inefficient Testing

O problema: B2B buyers, particularly those in the automotive repair sector, often encounter high repair costs stemming from inefficient testing methods when determining whether a battery or alternator is at fault. Some technicians may resort to trial-and-error approaches, replacing both components without accurate diagnostics. This can lead to inflated service bills and dissatisfied customers, damaging the reputation of the service provider.

A solução: To mitigate repair costs and enhance diagnostic accuracy, service centers should adopt a more methodical approach to testing. They can implement a standardized diagnostic protocol that includes clear steps for testing both the battery and alternator. For instance, before any replacement occurs, technicians should conduct a load test on the battery to assess its ability to hold charge. They should also perform an alternator output test under load conditions. Investing in diagnostic equipment that can perform these tests efficiently can save both time and money. Additionally, providing ongoing training for technicians on the latest diagnostic techniques can improve the overall quality of service and customer satisfaction, ultimately leading to repeat business.

Illustrative image related to how to tell if its the alternator or the battery

Scenario 3: Lack of Knowledge on Preventive Maintenance

O problema: Many B2B buyers, especially those managing small to medium-sized fleets, often lack the knowledge necessary for preventive maintenance of batteries and alternators. This oversight can lead to unexpected failures, resulting in costly roadside assistance or emergency repairs. For example, a company may find itself with a vehicle that won’t start due to a neglected battery or alternator, causing delays in service and increased operational costs.

A solução: To avoid such scenarios, businesses should prioritize preventive maintenance by developing a comprehensive maintenance schedule for their vehicles. This schedule should include regular inspections of the battery and alternator, focusing on key indicators such as corrosion on terminals, loose connections, and battery age. Establishing a routine where batteries are tested every six months can help catch potential issues before they escalate. Furthermore, B2B buyers can partner with local service providers for periodic check-ups, ensuring that all electrical components are functioning optimally. Providing training sessions for drivers and fleet managers on recognizing early signs of battery or alternator failure can also empower them to take proactive measures, reducing the likelihood of unexpected breakdowns and enhancing overall fleet reliability.

Strategic Material Selection Guide for how to tell if its the alternator or the battery

When diagnosing whether the issue lies with the alternator or the battery, the choice of materials used in diagnostic tools and components is crucial. This analysis focuses on four common materials that play a significant role in the functionality and reliability of these systems.

What Are the Key Properties of Copper in Diagnostic Tools?

Copper is widely used in electrical systems, including battery cables and alternator wiring, due to its excellent electrical conductivity. It has a high melting point (1,984°F or 1,085°C) and good corrosion resistance when properly coated. These properties ensure efficient power transfer and minimal energy loss.

Prós e contras do cobre:

Copper’s high conductivity makes it ideal for applications requiring efficient energy transfer. However, it is relatively expensive compared to alternatives like aluminum, which can increase the overall cost of manufacturing and installation. Additionally, copper can corrode if not adequately protected, especially in humid or saline environments.

Illustrative image related to how to tell if its the alternator or the battery

Impacto na aplicação:

Copper’s compatibility with various media, including automotive fluids, makes it suitable for automotive applications. However, international buyers must consider the potential for corrosion in specific climates, such as coastal regions in Africa or South America.

How Does Aluminum Compare for Use in Battery and Alternator Components?

Aluminum is often used as an alternative to copper due to its lower cost and lightweight properties. It has a melting point of approximately 1,221°F (660°C) and offers decent electrical conductivity, though not as high as copper.

Prós e contras do alumínio:

Aluminum is lightweight and cost-effective, making it a popular choice for automotive applications. However, its lower conductivity can lead to increased resistance and heat generation, which may affect performance over time. Additionally, aluminum is more susceptible to oxidation, which can impair electrical connections if not properly treated.

Impacto na aplicação:

Aluminum’s lightweight nature is beneficial for reducing vehicle weight, improving fuel efficiency. However, international buyers should be aware of standards for corrosion resistance, particularly in regions with high humidity or varying temperatures, such as Southeast Asia and parts of Europe.

What Role Does Plastic Play in Battery and Alternator Housing?

Plastics, particularly thermoplastics like polycarbonate and polypropylene, are commonly used in battery and alternator housings due to their lightweight and durable properties. They can withstand temperatures up to 300°F (149°C) and have good chemical resistance.

Prós e contras do plástico:

The primary advantage of plastic is its resistance to corrosion and lightweight nature, which can enhance overall vehicle efficiency. However, plastics may not provide the same level of structural integrity as metals, potentially leading to issues under high-stress conditions. Additionally, plastics can degrade over time when exposed to UV light.

Impacto na aplicação:

Plastic housings are suitable for various automotive applications, but international buyers should consider the specific environmental conditions, such as UV exposure in sunny regions or extreme temperatures in desert climates.

Why Is Rubber Essential for Electrical Connections?

Rubber is essential for insulation in battery and alternator applications. It can withstand temperatures ranging from -40°F to 212°F (-40°C to 100°C) and provides excellent electrical insulation properties.

Pros and Cons of Rubber:

Rubber’s flexibility and durability make it ideal for protecting electrical connections from moisture and mechanical stress. However, it can degrade over time, especially when exposed to oils and extreme temperatures, which may necessitate more frequent replacements.

Impacto na aplicação:

Rubber’s insulating properties are crucial for safety in automotive applications. International buyers should ensure compliance with local standards for materials used in electrical insulation, particularly in regions with varying climate conditions.

Summary Table of Material Selection for Diagnosing Alternator vs. Battery Issues

| Material | Typical Use Case for how to tell if its the alternator or the battery | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Battery cables, alternator wiring | Excelente condutividade elétrica | High cost, susceptible to corrosion | Alto |

| Alumínio | Lightweight wiring and connectors | Económica e leve | Lower conductivity, prone to oxidation | Médio |

| Plástico | Housings for batteries and alternators | Resistente à corrosão e leve | Less structural integrity than metals | Baixo |

| Rubber | Insulation for electrical connections | Flexible and durable for protection | Degrades over time, especially with oils | Médio |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions regarding the materials used in diagnosing alternator and battery issues, tailored to their specific regional conditions and compliance requirements.

Illustrative image related to how to tell if its the alternator or the battery

In-depth Look: Manufacturing Processes and Quality Assurance for how to tell if its the alternator or the battery

What Are the Key Manufacturing Processes for Alternators and Batteries?

Understanding the manufacturing processes of alternators and batteries is crucial for B2B buyers looking to source reliable automotive components. The production of these electrical devices typically involves several stages: material preparation, forming, assembly, and finishing.

How is Material Prepared for Alternators and Batteries?

The first stage in manufacturing involves sourcing high-quality raw materials. For batteries, this includes lead, sulfuric acid, and separators, while alternators require materials like copper, aluminum, and steel. Suppliers must ensure that these materials meet international quality standards to guarantee performance and longevity.

Once sourced, materials undergo rigorous testing for purity and quality. This initial quality control (QC) step is critical, as impurities can significantly impact the efficiency of both batteries and alternators. B2B buyers should inquire about the supplier’s material sourcing policies and the quality checks performed on incoming materials.

Illustrative image related to how to tell if its the alternator or the battery

What Techniques are Used in Forming Components?

After material preparation, the forming stage begins. For batteries, this includes casting lead plates and assembling the separators that will hold the electrolyte. In alternators, the forming process involves winding copper wire into coils and shaping the housing components.

Advanced techniques such as die-casting and stamping are often employed to create precise shapes and sizes. The use of automated machinery can increase efficiency and reduce errors. B2B buyers should assess whether suppliers utilize modern manufacturing technologies and techniques to maintain high standards in their products.

How are Alternators and Batteries Assembled?

Assembly is a critical phase that combines the various components into a finished product. For batteries, this involves carefully stacking the lead plates and filling them with electrolyte under controlled conditions to avoid contamination. In alternators, the assembly process includes mounting the rotor, stator, and voltage regulator.

Quality control during assembly is vital. Suppliers often implement in-process quality checks (IPQC) to ensure that every component is correctly installed and that the assembly meets specified tolerances. Buyers should ask about the assembly protocols and how these are documented.

What Finishing Techniques Are Applied to Ensure Quality?

Finishing processes such as coating, labeling, and packaging play a significant role in the final quality of alternators and batteries. For batteries, protective coatings prevent corrosion and ensure safety during operation. Alternators may undergo surface treatments to improve durability.

Final quality checks (FQC) are conducted at this stage to verify that the product meets all specifications. This may involve testing electrical output, physical dimensions, and overall functionality. B2B buyers should seek detailed reports on these final inspections to ensure that the products they are sourcing are reliable.

Que normas de garantia de qualidade devem os compradores B2B considerar?

Quality assurance in the manufacturing of alternators and batteries is governed by several international and industry-specific standards. ISO 9001 is a widely recognized standard that specifies requirements for a quality management system, ensuring that suppliers maintain consistent quality.

Illustrative image related to how to tell if its the alternator or the battery

In addition, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the end-use of the products. B2B buyers should verify that their suppliers hold these certifications and understand their implications.

Quais são os principais pontos de controlo de CQ no fabrico?

Quality control checkpoints are essential to maintaining high standards throughout the manufacturing process. These include:

- Controlo de Qualidade de Entrada (IQC): This involves inspecting raw materials upon arrival to ensure they meet required specifications.

- Controlo de qualidade em processo (IPQC): Continuous monitoring during the manufacturing process helps to identify defects early.

- Controlo de Qualidade Final (FQC): A thorough examination of the finished product before packaging ensures compliance with specifications.

B2B buyers should request information on how often these checks are performed and the criteria used for passing or failing components.

What Testing Methods Are Commonly Used for Alternators and Batteries?

Various testing methods are employed to ensure that both alternators and batteries meet performance standards. Common tests include:

- Voltage Testing: For batteries, this measures the voltage output to determine if they can hold a charge. Alternators are tested for voltage output while the engine is running.

- Teste de carga: This assesses how well a battery performs under load conditions, which is crucial for determining its reliability in real-world scenarios.

- Testes funcionais: For alternators, this involves checking the electrical output under various engine speeds to ensure consistent performance.

B2B buyers should ensure that their suppliers have robust testing protocols and can provide documentation of test results.

Como podem os compradores B2B verificar os processos de controlo de qualidade dos fornecedores?

To ensure that suppliers adhere to quality standards, B2B buyers should take proactive steps:

- Realizar auditorias: Regular supplier audits can help verify that manufacturing processes and quality control measures are being followed.

- Solicitar relatórios de qualidade: Suppliers should provide detailed reports on their quality control processes, including any deviations from standard practices.

- Utilizar serviços de inspeção de terceiros: Engaging third-party inspectors can provide an unbiased assessment of a supplier’s quality assurance practices.

Quais são as nuances de controle de qualidade e certificação para compradores B2B internacionais?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance. Different countries may have varying standards and certifications, which can complicate the sourcing process.

Buyers should be aware of local regulations regarding automotive components and ensure that their suppliers comply with both local and international standards. Additionally, understanding the implications of certifications like CE and ISO can help buyers make informed decisions when selecting suppliers.

In conclusion, the manufacturing processes and quality assurance measures for alternators and batteries are complex but essential for ensuring product reliability. B2B buyers must be diligent in evaluating suppliers, understanding manufacturing techniques, and verifying quality control practices to secure high-quality automotive components.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to tell if its the alternator or the battery’

Introdução

This guide serves as a practical checklist for B2B buyers in the automotive sector seeking to determine whether a vehicle’s electrical issue stems from the alternator or the battery. Understanding the symptoms and testing methods associated with both components is essential for efficient diagnostics and procurement of replacement parts. This checklist will help you streamline the sourcing process by ensuring you gather the right information and make informed decisions.

Passo 1: Identify Symptoms

Start by documenting the specific symptoms your vehicle is exhibiting. Recognizing whether the car struggles to start, shows dimming lights, or has electrical accessories malfunctioning can guide your diagnosis. Each symptom may point toward either the battery or the alternator, allowing you to narrow down your focus.

Passo 2: Conduct Initial Battery Tests

Perform basic tests to assess the battery’s health. Use a multimeter to measure the voltage; a healthy battery should read around 12.6 volts. If the voltage is significantly lower, the battery may be the culprit, necessitating further inspection or replacement.

- Dica: Charge the battery fully and test again after a day to check for any voltage drop.

Passo 3: Evaluate Alternator Performance

Once you have assessed the battery, turn your attention to the alternator. Start the vehicle and measure the voltage across the battery terminals while the engine is running. A reading between 13 and 14.5 volts indicates a functioning alternator. If the voltage is below this range, further investigation is required.

- Warning: Avoid disconnecting the battery while the engine is running, as this can damage the alternator and vehicle electronics.

Passo 4: Check for Warning Lights

Look for any warning lights on the vehicle’s dashboard. A battery warning light could indicate issues with either the battery or alternator. Understanding the meaning behind these warning indicators can provide further clues about the source of the problem.

Passo 5: Review Maintenance History

Gather information on the vehicle’s maintenance history, particularly concerning the battery and alternator. Check if either component has been replaced recently or if there have been recurring issues. This context can inform your sourcing decisions and highlight potential areas of concern.

Passo 6: Consult with Experts

Engage with automotive professionals or mechanics for their insights on common issues related to the battery and alternator in your specific vehicle model. Their expertise can shed light on potential pitfalls and help you identify the right components for replacement.

Passo 7: Sourcing Quality Components

When ready to procure parts, prioritize suppliers who offer warranties, detailed specifications, and quality certifications. Ensure that the components meet industry standards and are compatible with your vehicle’s make and model. This diligence helps to avoid future issues and ensures reliable performance.

By following these steps, B2B buyers can effectively diagnose whether an electrical issue is related to the battery or alternator, leading to informed procurement decisions and enhanced operational efficiency.

Comprehensive Cost and Pricing Analysis for how to tell if its the alternator or the battery Sourcing

When assessing the costs associated with diagnosing whether a vehicle issue stems from the battery or the alternator, it’s essential to consider various components that contribute to the overall expense. Understanding these elements will help international B2B buyers make informed decisions, especially in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Diagnosing Battery vs. Alternator Issues?

-

Materiais: The primary materials involved include batteries and alternators, along with diagnostic tools like multimeters. The cost of these components can vary significantly based on the brand, specifications, and quality. For instance, premium batteries may cost 20-30% more but offer better longevity and performance.

-

Trabalho: Labor costs can vary based on geographical location and the complexity of the diagnosis. In regions with high labor costs, such as parts of Europe, you may find that diagnostic services can add a significant markup to the overall pricing. Conversely, in regions with lower labor costs, such as some parts of Africa or South America, you may benefit from lower service fees.

-

Custos indiretos de produção: This includes the costs associated with the production of batteries and alternators, such as factory maintenance, utilities, and administrative expenses. Manufacturers often factor these costs into their pricing strategies, which can affect the final price for buyers.

-

Ferramentas e controlo de qualidade (QC): The costs associated with the tools used for manufacturing and the quality control processes are significant. Products that undergo rigorous testing and quality assurance may command higher prices but tend to offer more reliability, which is crucial in automotive applications.

-

Logística: Transportation costs can also influence pricing, especially for international buyers. Incoterms will dictate who bears the cost of shipping, insurance, and duties. For instance, utilizing DDP (Delivered Duty Paid) can simplify logistics for buyers by ensuring all costs are included in the quoted price.

-

Margem: Suppliers will apply a margin that reflects their operational costs and desired profit. This can vary widely based on market demand, competition, and supplier relationships.

What Influences Pricing for International B2B Buyers?

-

Volume e quantidade mínima de encomenda (MOQ): Larger orders often lead to reduced per-unit costs. Buyers should negotiate MOQs that align with their operational needs to maximize cost efficiency.

-

Especificações e personalização: Custom specifications can lead to higher costs. Buyers should assess whether standard products will meet their needs, as customization often includes additional fees.

-

Certificações de qualidade: Products with recognized quality certifications may be priced higher. However, these certifications can provide peace of mind regarding product reliability, which is particularly important in regions where automotive failures can have severe consequences.

-

Fatores relacionados ao fornecedor: The reputation and reliability of suppliers can greatly influence pricing. Established suppliers with a proven track record may charge more but often provide better customer support and warranty options.

-

Incoterms: Understanding the implications of various Incoterms can help buyers control costs. For example, opting for EXW (Ex Works) might lower the price but could lead to higher logistical expenses.

What Buyer Tips Can Enhance Cost-Efficiency?

-

Negociar: Always engage in negotiations regarding pricing, especially for bulk orders. Suppliers may offer discounts for larger volumes or long-term partnerships.

-

Custo total de propriedade (TCO): Consider not only the initial purchase price but also the long-term costs associated with maintenance, reliability, and warranty services. A slightly higher upfront cost can lead to significant savings over time.

-

Pesquisar as condições do mercado local: Buyers in regions like Nigeria or Vietnam should be aware of local market dynamics, as pricing can vary based on demand, availability, and currency fluctuations.

-

Leverage Technology: Utilize diagnostic tools to assess battery and alternator health accurately. This can help avoid unnecessary replacements and reduce overall costs.

In summary, understanding the comprehensive cost and pricing analysis when diagnosing whether an issue lies with the battery or alternator is crucial for B2B buyers. By considering the outlined cost components, pricing influencers, and strategic buyer tips, businesses can make informed purchasing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing how to tell if its the alternator or the battery With Other Solutions

Understanding Alternatives for Diagnosing Vehicle Electrical Issues

In the realm of automotive maintenance, diagnosing whether an issue lies with the alternator or the battery is critical for ensuring vehicle reliability. While traditional methods exist for this diagnosis, alternative solutions have emerged that can offer varying degrees of efficiency and effectiveness. This analysis explores different approaches to identifying electrical system failures, focusing on how they compare to the conventional method of diagnosing alternator versus battery issues.

Illustrative image related to how to tell if its the alternator or the battery

| Aspecto comparativo | How To Tell If Its The Alternator Or The Battery | Alternative 1: Multimeter Testing | Alternative 2: Diagnostic Tools |

|---|---|---|---|

| Desempenho | Reliable for basic diagnosis; requires some knowledge of electrical systems. | Highly accurate; can test voltage and current effectively. | Comprehensive diagnostics; provides detailed insights into multiple vehicle systems. |

| Custo | Low-cost method; typically requires minimal tools (e.g., multimeter). | Moderate cost; multimeters vary in price but are generally affordable. | Higher initial investment; diagnostic tools can be expensive but offer extensive features. |

| Facilidade de implementação | Requires basic understanding of vehicle electrical systems; moderate complexity. | Simple for those familiar with electrical testing; can be challenging for novices. | User-friendly; designed for mechanics and DIY enthusiasts, often with guided interfaces. |

| Manutenção | Minimal maintenance required; involves occasional tool upkeep. | Low maintenance; multimeters are durable and long-lasting. | Regular software updates may be needed; hardware maintenance is essential for longevity. |

| Melhor caso de uso | Ideal for quick checks and basic troubleshooting. | Best for precise electrical measurements and troubleshooting. | Suitable for comprehensive diagnostics across multiple vehicle systems. |

Discriminação detalhada das alternativas

1. Multimeter Testing

Using a multimeter is a straightforward and effective method for diagnosing battery and alternator issues. This tool can measure voltage, resistance, and current, allowing users to identify whether the battery is holding a charge or if the alternator is functioning properly. The pros of this method include its affordability and accessibility. However, it requires a basic understanding of electrical systems, which may be a barrier for some users. Additionally, while it provides accurate measurements, it does not offer insights into other vehicle systems that could be affecting performance.

2. Diagnostic Tools

Diagnostic tools represent a more advanced alternative for assessing vehicle electrical systems. These tools connect directly to the vehicle’s onboard diagnostics (OBD) system and can provide comprehensive insights into various components, including the battery and alternator. Their primary advantage is the ability to diagnose multiple issues simultaneously and display error codes, which can guide mechanics in their troubleshooting process. However, the cost of these tools can be prohibitive for smaller operations or individual users. Moreover, they may require training to operate effectively, which can add to the overall expense.

Conclusão: escolhendo a solução certa para as suas necessidades

When determining the best method to diagnose whether an issue lies with the alternator or battery, B2B buyers should consider their specific operational needs, technical expertise, and budget constraints. For those seeking a quick and cost-effective solution, traditional methods or multimeter testing may suffice. However, businesses that require comprehensive diagnostics for multiple vehicle systems may benefit more from investing in advanced diagnostic tools. Ultimately, the right choice will depend on the scale of operations and the desired level of diagnostic accuracy.

Essential Technical Properties and Trade Terminology for how to tell if its the alternator or the battery

Quais são as principais propriedades técnicas a ter em conta no diagnóstico de problemas da bateria ou do alternador?

When determining whether a vehicle’s problem stems from the battery or the alternator, understanding certain technical properties is crucial for B2B buyers, particularly in automotive parts distribution. Here are several critical specifications to consider:

-

Voltage Output (V)

The voltage output of both the battery and alternator is a fundamental parameter. A healthy battery should register around 12.6 volts when fully charged. Meanwhile, an alternator should produce between 13 to 14.5 volts while the engine is running. Knowing these voltage benchmarks helps in quickly diagnosing the component in question. -

Amperage Rating (A)

The amperage rating indicates how much current a battery or alternator can supply. For instance, typical passenger vehicle alternators have a maximum amperage between 130 to 200 amps, while larger commercial vehicles can require up to 400 amps. Buyers should consider these ratings when selecting replacement parts, ensuring compatibility with vehicle specifications. -

Cycle Life (Cycles)

Cycle life refers to the number of charge and discharge cycles a battery can endure before its capacity diminishes significantly. This is especially important for B2B buyers in regions with fluctuating power demands, as batteries with higher cycle lives provide better reliability and lower replacement costs over time. -

Temperature Tolerance (°C)

Temperature tolerance is vital for both batteries and alternators. Batteries can lose efficiency in extreme temperatures, both hot and cold. For instance, a battery may struggle in sub-zero conditions, affecting starting performance. Understanding the temperature tolerances of these components can guide buyers in selecting products suited for specific climates. -

Physical Dimensions (mm/inches)

The physical size of the battery and alternator is essential for fitting them into specific vehicle models. B2B buyers must ensure that the parts they procure match the OEM specifications for seamless installation and operation. -

Composição do material

The materials used in batteries (e.g., lead-acid, lithium-ion) and alternators (e.g., copper windings, aluminum housing) significantly affect their performance and longevity. For example, lithium-ion batteries often provide better performance in terms of weight and efficiency compared to traditional lead-acid batteries. Understanding material properties can help buyers make informed choices about durability and performance.

What Are the Common Trade Terms Relevant to Battery and Alternator Diagnostics?

Familiarity with industry terminology is vital for effective communication and decision-making in the B2B sector. Here are some key terms that buyers should understand:

-

OEM (Fabricante de Equipamento Original)

OEM refers to components made by the original manufacturer of a vehicle. OEM parts are generally preferred for replacements due to their guaranteed compatibility and quality, which is critical for maintaining vehicle performance. -

MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps businesses plan their inventory and procurement strategies effectively, especially when dealing with automotive parts. -

RFQ (Pedido de Orçamento)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. It is essential for B2B transactions as it allows buyers to compare pricing and terms from multiple vendors before making purchasing decisions. -

Incoterms (Termos Comerciais Internacionais)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. Familiarity with these terms helps B2B buyers understand shipping responsibilities, risk management, and cost implications when sourcing automotive components. -

Período de garantia

The warranty period refers to the duration for which a manufacturer guarantees the product’s performance. Understanding warranty terms is crucial for B2B buyers to assess risk and ensure long-term support for their purchases. -

Mercado pós-venda

Aftermarket refers to parts and accessories that are not sourced from the OEM but are available for replacement or enhancement. Recognizing the aftermarket landscape helps buyers explore a broader range of options, often at competitive prices.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed purchasing decisions when addressing battery or alternator issues, ultimately enhancing operational efficiency and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the how to tell if its the alternator or the battery Sector

In the competitive landscape of automotive parts, understanding the nuances of diagnosing issues related to the alternator and battery is crucial for international B2B buyers. The demand for efficient and reliable vehicle maintenance solutions is driven by several global factors, including the growing automotive market in developing regions, rising vehicle ownership rates, and increasing consumer awareness about vehicle upkeep. Notably, markets in Africa, South America, the Middle East, and Europe are experiencing a surge in vehicle maintenance services, with a corresponding need for high-quality components. This trend emphasizes the importance of sourcing reliable products that can withstand varying climatic conditions and driving habits prevalent in these regions.

Illustrative image related to how to tell if its the alternator or the battery

Emerging technologies are reshaping the sourcing landscape. The use of advanced diagnostic tools, such as multimeters and specialized battery testers, is becoming standard practice for mechanics and service providers. These tools not only facilitate accurate assessments of whether a battery or alternator is at fault but also enhance the efficiency of service operations. Furthermore, e-commerce platforms are increasingly being utilized for sourcing automotive parts, allowing buyers to access a wider range of products, compare prices, and streamline procurement processes. Additionally, the integration of supply chain management software is helping businesses optimize inventory levels and reduce lead times, which is particularly beneficial for international buyers operating in diverse markets.

What Role Does Sustainability Play in Sourcing Automotive Parts?

Sustainability is becoming a significant factor in the sourcing of automotive components, including batteries and alternators. The environmental impact of automotive manufacturing and disposal is under scrutiny, prompting buyers to prioritize suppliers that adopt sustainable practices. Ethical sourcing entails not only reducing carbon footprints but also ensuring that materials used in production are responsibly obtained. This is particularly relevant in the context of battery manufacturing, where the extraction of raw materials like lithium and cobalt can have detrimental effects on local ecosystems.

Buyers are increasingly looking for suppliers who offer ‘green’ certifications and materials, indicating adherence to environmental standards. Companies that utilize recycled materials or implement energy-efficient manufacturing processes are likely to gain a competitive edge in the marketplace. Additionally, fostering transparent supply chains enhances brand reputation and builds consumer trust, especially in regions where environmental awareness is rapidly growing.

How Has the Automotive Parts Sector Evolved Over Time?

The evolution of the automotive parts sector, particularly regarding battery and alternator diagnostics, has been marked by significant technological advancements. In the early days of automotive engineering, diagnosing electrical issues was primarily based on manual checks and rudimentary tests. However, the introduction of digital multimeters and advanced diagnostic equipment has revolutionized the industry, allowing for more accurate and efficient troubleshooting.

Illustrative image related to how to tell if its the alternator or the battery

Over the years, the complexity of vehicles has increased, necessitating more sophisticated understanding and expertise in automotive electronics. The shift towards electric and hybrid vehicles is further driving innovation in battery technology, emphasizing the need for robust sourcing strategies that can adapt to these changes. For B2B buyers, staying informed about these trends and advancements is essential for making strategic purchasing decisions and maintaining competitive advantages in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of how to tell if its the alternator or the battery

-

How do I determine if my vehicle issue is related to the alternator or the battery?

To distinguish between a battery and alternator problem, start by checking the battery voltage with a multimeter. A healthy battery should read around 12.6 volts. If the vehicle starts but dies shortly after, it may indicate a failing alternator. Observe the headlights; if they dim or fluctuate with engine speed, the alternator could be at fault. For thorough diagnostics, consider consulting a local automotive professional or supplier who can provide additional testing tools or services tailored to your needs. -

What signs indicate a failing battery versus a failing alternator?

Common symptoms of a failing battery include slow engine cranking, clicking sounds when starting, or a complete failure to start. Conversely, a failing alternator often manifests as dimming headlights, erratic electrical accessory behavior, or a battery warning light on the dashboard. Understanding these signs can help you source the right replacement parts efficiently. Ensure your suppliers provide high-quality batteries and alternators to minimize future issues. -

What is the best way to source high-quality batteries and alternators for my fleet?

When sourcing batteries and alternators, look for suppliers with established reputations in your region. Verify their certifications and quality assurance processes. Consider partnering with manufacturers that offer warranty coverage and reliable customer support. Additionally, review customer testimonials and industry ratings to ensure you choose suppliers that meet your specific needs in terms of performance, durability, and compliance with local regulations. -

What are the typical minimum order quantities (MOQ) for batteries and alternators?

MOQs for batteries and alternators can vary significantly between suppliers, often ranging from 10 to 100 units. It’s essential to communicate your needs clearly and negotiate terms that suit your business model. Some suppliers may offer flexibility on MOQs for new clients or bulk orders, so be sure to inquire about potential discounts for larger quantities or long-term agreements to optimize your procurement strategy. -

How can I ensure the quality of alternators and batteries I purchase?

To ensure quality, work with suppliers who provide detailed product specifications, testing certifications, and compliance with international standards. Request samples to evaluate performance before placing a bulk order. Additionally, consider establishing a quality assurance protocol that includes regular inspections and testing of incoming inventory. This proactive approach will help mitigate risks associated with defective components and maintain operational efficiency. -

What payment terms should I expect when sourcing automotive parts internationally?

Payment terms can vary widely depending on the supplier’s policies and your relationship with them. Common arrangements include advance payment, letters of credit, or net payment terms (e.g., 30 or 60 days). It’s advisable to discuss terms upfront and consider using secure payment methods to protect your transactions. Establishing a good rapport with suppliers may also lead to more favorable terms as your partnership develops. -

How do logistics and shipping impact my procurement of automotive components?

Logistics play a crucial role in the timely delivery of automotive components. Consider factors such as shipping routes, customs regulations, and import duties that may affect your costs and timelines. Collaborate with suppliers who have reliable logistics partners to ensure efficient shipping and handling. Additionally, having a contingency plan for potential delays can help maintain your supply chain’s resilience and keep your operations running smoothly. -

Que opções de personalização estão disponíveis para baterias e alternadores?

Many suppliers offer customization options, including specific voltage ratings, capacity, and physical dimensions for batteries, as well as tailored alternator outputs to meet unique vehicle requirements. Discuss your specifications with potential suppliers to explore available options. Custom solutions can enhance performance and compatibility, particularly for specialized vehicles or equipment. Be sure to confirm lead times and potential cost implications of custom orders during your discussions.

Top 3 How To Tell If Its The Alternator Or The Battery Manufacturers & Suppliers List

1. Reddit - Informações sobre baterias para automóveis

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: The battery provides power to all electronics, including the starter. The alternator charges the battery when the engine is running. The starter uses battery power to turn over the engine. Symptoms of a dead battery include no power at all, while a failing alternator may show a battery light on the dashboard when the engine is running.

2. Em todo o país - Informações sobre alternadores e baterias

Domínio: blog.nationwide.com

Registada: 1994 (31 anos)

Introdução: Alternator: Powers the car when the engine is running, charges the battery, lasts the lifetime of the car but can wear out. Signs of a bad alternator include dim interior lights, dim or overly bright headlights, growling noises, and burning smells. Battery: Stores power, starts the engine, powers electronics, regulates voltage, typically lasts 3-5 years. Signs of a bad battery include dim dashboar…

3. Mechanics – Alternator Testing Technique

Domínio: mechanics.stackexchange.com

Registado: 2009 (16 anos)

Introdução: The text discusses a technique to test an alternator by removing a 12V battery lead while the vehicle is running. It explains that this method is not recommended as it can damage the vehicle’s electronics and the alternator itself. The alternator is internally regulated, and disconnecting the battery can lead to voltage spikes that may harm the car’s semiconductor circuits. It suggests using a mul…

Strategic Sourcing Conclusion and Outlook for how to tell if its the alternator or the battery

In conclusion, understanding whether the issue lies with the battery or the alternator is crucial for maintaining vehicle reliability and reducing downtime. For B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, strategic sourcing of high-quality automotive parts and diagnostic tools can significantly enhance operational efficiency. Key indicators, such as the vehicle’s starting behavior, the condition of electrical accessories, and voltage readings, can guide you in diagnosing problems accurately.

Investing in reliable components and testing equipment not only minimizes repair costs but also extends the lifespan of your vehicles. By prioritizing quality and efficiency in your sourcing strategies, you can ensure that your fleet remains operational and responsive to market demands.

As you navigate the complexities of automotive maintenance, consider forming partnerships with trusted suppliers who can provide timely access to parts and expertise. Embrace the opportunity to enhance your procurement practices and position your business for success in an increasingly competitive landscape. Your proactive approach to strategic sourcing will pay dividends in performance and reliability.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.