Introduction: Navigating the Global Market for what does it mean when your headlights flicker

In the complex landscape of automotive maintenance, understanding the implications of flickering headlights can be a critical concern for international B2B buyers. Headlight flickering is not merely a nuisance; it can indicate underlying issues that compromise safety and vehicle performance. This comprehensive guide delves into the various causes of headlight flickering, equipping you with the knowledge to make informed purchasing decisions regarding automotive parts and services. From identifying the types of flickering issues—such as problems with the battery, alternator, or wiring—to exploring potential applications and solutions, this resource covers all essential aspects.

We also address the importance of supplier vetting, helping you discern which vendors provide reliable components and services that meet global standards. Understanding the cost implications of these repairs can further empower you to negotiate better deals, ensuring your fleet remains safe and efficient. This guide is specifically tailored for B2B buyers across Africa, South America, the Middle East, and Europe, including markets like Germany and Saudi Arabia. By leveraging the insights within this guide, you will not only enhance your vehicle maintenance strategies but also foster stronger partnerships with suppliers who prioritize quality and reliability. Prepare to navigate the complexities of automotive electrical systems with confidence, ensuring that your operations run smoothly and safely on the road.

Índice

- Top 3 What Does It Mean When Your Headlights Flicker Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what does it mean when your headlights flicker

- Understanding what does it mean when your headlights flicker Types and Variations

- Key Industrial Applications of what does it mean when your headlights flicker

- 3 Common User Pain Points for ‘what does it mean when your headlights flicker’ & Their Solutions

- Strategic Material Selection Guide for what does it mean when your headlights flicker

- In-depth Look: Manufacturing Processes and Quality Assurance for what does it mean when your headlights flicker

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what does it mean when your headlights flicker’

- Comprehensive Cost and Pricing Analysis for what does it mean when your headlights flicker Sourcing

- Alternatives Analysis: Comparing what does it mean when your headlights flicker With Other Solutions

- Essential Technical Properties and Trade Terminology for what does it mean when your headlights flicker

- Navigating Market Dynamics and Sourcing Trends in the what does it mean when your headlights flicker Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what does it mean when your headlights flicker

- Strategic Sourcing Conclusion and Outlook for what does it mean when your headlights flicker

- Aviso legal importante e termos de utilização

Understanding what does it mean when your headlights flicker Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Dying Battery | Flickering occurs when the battery is low on charge. | Oficinas de reparação automóvel, gestão de frotas | Pros: Easy to diagnose and replace; Cons: Short lifespan if not monitored. |

| Failing Alternator | Inconsistent electrical output; may accompany battery warning light. | Vehicle maintenance services, dealerships | Pros: Critical for overall vehicle function; Cons: Can lead to further electrical failures if ignored. |

| Worn-Out Bulbs | Flickering due to age or damage; easy visual inspection. | Automotive retail, repair shops | Pros: Quick fix; Cons: May require frequent replacements if quality is low. |

| Loose Connections | Flickering during rough driving; often linked to physical damage. | Diagnóstico automóvel, serviços de reparação | Pros: Inexpensive repairs; Cons: Difficult to locate without expertise. |

| Faulty Headlamp Switch | Inconsistent function linked to switch malfunction. | Electrical system specialists, repair shops | Pros: Relatively easy replacement; Cons: May indicate larger electrical issues. |

What Are the Key Characteristics of a Dying Battery and Its B2B Relevance?

A dying battery is often the most straightforward cause of flickering headlights. This issue is characterized by a gradual decline in the battery’s ability to hold a charge, often exacerbated by extreme temperatures or frequent short trips. For B2B buyers in automotive repair or fleet management, understanding battery life cycles is essential. Regular battery inspections and timely replacements can significantly enhance vehicle reliability and safety, ultimately reducing downtime.

How Does a Failing Alternator Impact Headlight Performance in Business Fleets?

A failing alternator affects the vehicle’s overall electrical output, leading to flickering headlights as the battery struggles to maintain power. This issue is critical for businesses operating fleets, as it can impact vehicle performance and safety. B2B buyers should prioritize regular alternator checks during routine maintenance to prevent unexpected failures, which can disrupt operations and incur additional costs.

Why Should B2B Buyers Be Aware of Worn-Out Bulbs?

Worn-out bulbs are a common cause of headlight flickering, easily identifiable through visual inspection. For automotive retailers and repair shops, keeping a stock of high-quality replacement bulbs is crucial for customer satisfaction. Regularly replacing old bulbs not only enhances vehicle safety but also helps maintain the shop’s reputation for quality service.

What Are the Implications of Loose Connections for Automotive Diagnostics?

Loose connections often lead to flickering headlights, particularly noticeable during rough driving conditions. This issue can be challenging to diagnose without proper expertise, making it essential for automotive diagnostics businesses to offer thorough electrical system inspections. Addressing loose connections promptly can prevent more significant electrical problems and improve overall vehicle reliability.

How Does a Faulty Headlamp Switch Affect Vehicle Electrical Systems?

A faulty headlamp switch can lead to inconsistent headlight function, which may not only affect visibility but also indicate underlying electrical issues. For B2B buyers in the automotive repair sector, understanding the implications of headlamp switch failures is vital. Regular training on electrical systems can equip technicians to handle these issues efficiently, ensuring customer vehicles remain safe and operational.

Key Industrial Applications of what does it mean when your headlights flicker

| Indústria/Setor | Specific Application of what does it mean when your headlights flicker | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Diagnosing electrical issues in vehicles | Enhanced safety and reliability of vehicles, reducing liability | Need for quality diagnostic tools and trained technicians |

| Transporte e Logística | Fleet vehicle maintenance and safety checks | Improved fleet reliability and reduced downtime | Sourcing durable parts and establishing regular maintenance schedules |

| Equipamento de construção | Ensuring safety in heavy machinery operations | Minimizing accidents and ensuring compliance with safety regulations | Access to specialized parts and expertise in machinery repair |

| Serviços de emergência | Vehicle readiness for first responders | Ensured operational reliability during critical missions | High-quality components and rapid sourcing capabilities |

| Transportes públicos | Maintenance of buses and public vehicles | Increased passenger safety and satisfaction | Long-term supplier relationships for consistent part availability |

How is ‘what does it mean when your headlights flicker’ applied in the automotive repair industry?

In the automotive repair sector, understanding why headlights flicker is crucial for diagnosing broader electrical issues within vehicles. Repair shops often utilize this knowledge to provide thorough inspections and repairs, ensuring that vehicles are safe for operation. Addressing flickering headlights can prevent more severe electrical problems, ultimately enhancing vehicle reliability and reducing liability for repair businesses. When sourcing parts, repair shops should prioritize high-quality components and ensure technicians are well-trained in diagnosing electrical issues.

What role does headlight flickering diagnosis play in transportation and logistics?

In the transportation and logistics industry, maintaining a fleet of vehicles is vital for operational efficiency. Diagnosing headlight flickering can lead to early detection of electrical system failures, which can cause significant downtime if not addressed. By ensuring that headlights function correctly, companies can enhance road safety and minimize disruptions in service. B2B buyers in this sector should focus on sourcing durable electrical components and establishing routine maintenance checks to keep fleets operational.

How does understanding headlight flickering impact construction equipment safety?

For construction equipment, where visibility can be critical, understanding the implications of flickering headlights is essential for maintaining safe operations. This knowledge allows operators to identify potential electrical issues before they escalate into more dangerous situations. Construction firms benefit from minimizing accidents and ensuring compliance with safety regulations. Buyers in this industry should prioritize sourcing specialized parts and working with suppliers who can provide expertise in machinery repairs.

Why is headlight flickering diagnosis critical for emergency services?

Emergency services depend on the reliability of their vehicles, where flickering headlights can signal potential electrical failures that compromise mission readiness. Understanding and addressing these issues ensures that first responders can operate without hindrance during critical situations. For B2B buyers in this sector, sourcing high-quality components and establishing rapid sourcing capabilities are paramount to maintaining vehicle readiness and operational reliability.

How does the public transportation sector benefit from addressing headlight flickering?

In public transportation, ensuring that buses and other vehicles are safe and functional is crucial for passenger safety and satisfaction. Diagnosing and resolving headlight flickering can prevent accidents and enhance the overall travel experience for users. B2B buyers in this sector should focus on developing long-term supplier relationships to ensure consistent availability of quality parts, allowing for timely maintenance and service continuity.

3 Common User Pain Points for ‘what does it mean when your headlights flicker’ & Their Solutions

Scenario 1: Frequent Flickering Leads to Safety Concerns on the Road

O problema: For fleet managers overseeing a large number of vehicles, ensuring the safety of drivers is paramount. Flickering headlights can pose serious risks, making vehicles less visible to other road users and potentially leading to accidents. When multiple vehicles exhibit this issue, it creates an operational headache, as it not only disrupts daily operations but also raises concerns about compliance with safety regulations. The stress of managing these safety issues, coupled with the urgency to maintain fleet functionality, can overwhelm any manager.

A solução: To address this challenge effectively, fleet managers should implement a proactive maintenance program that includes regular inspections of the electrical systems of all vehicles. This entails scheduling routine checks specifically focused on the battery, alternator, wiring, and headlight components. Partnering with reliable automotive service providers who specialize in fleet maintenance can ensure that any flickering headlight issues are diagnosed and resolved promptly. Additionally, investing in diagnostic tools that monitor electrical systems can provide real-time data on potential problems, allowing for timely interventions before they escalate into safety hazards.

Scenario 2: Lost Productivity Due to Unexpected Breakdowns

O problema: B2B buyers in logistics and transportation industries face significant losses when vehicles experience unexpected breakdowns due to flickering headlights. Such issues can lead to delays in deliveries, increased repair costs, and, ultimately, dissatisfied customers. For businesses operating under tight schedules, the unpredictability of vehicle performance can severely impact productivity and profitability, straining relationships with clients and partners.

A solução: To mitigate the risk of breakdowns caused by flickering headlights, companies should establish a comprehensive vehicle maintenance schedule that includes regular inspections and timely replacement of worn-out components. Additionally, creating a checklist that drivers can use for daily vehicle inspections can help identify early signs of electrical issues, such as dimming or flickering lights. By investing in quality replacement parts and ensuring that all repairs are performed by qualified technicians, businesses can enhance vehicle reliability and minimize downtime. Utilizing fleet management software to track vehicle health and maintenance history can also provide insights into patterns that may indicate a recurring issue, allowing for strategic planning of repairs and replacements.

Scenario 3: High Repair Costs from Neglected Electrical Systems

O problema: Companies that overlook the importance of vehicle electrical systems often find themselves facing escalating repair costs. Flickering headlights can be a symptom of underlying issues such as a failing alternator or damaged wiring. When these problems go unaddressed, they can lead to more severe electrical failures, resulting in costly repairs and extended downtime. For B2B buyers who need to manage tight budgets, these unexpected expenses can disrupt financial planning and resource allocation.

A solução: To avoid the financial burden associated with neglected electrical systems, businesses should prioritize staff training on the importance of vehicle maintenance, particularly concerning electrical components. This could involve workshops or seminars led by automotive experts who can educate employees about the signs of electrical issues, including flickering headlights. Implementing a regular audit system to review vehicle performance and maintenance records can also help identify trends that may require attention. Furthermore, negotiating service contracts with automotive specialists can provide a predictable cost structure for repairs and maintenance, reducing the likelihood of unexpected expenses while ensuring that vehicles remain in optimal condition.

Strategic Material Selection Guide for what does it mean when your headlights flicker

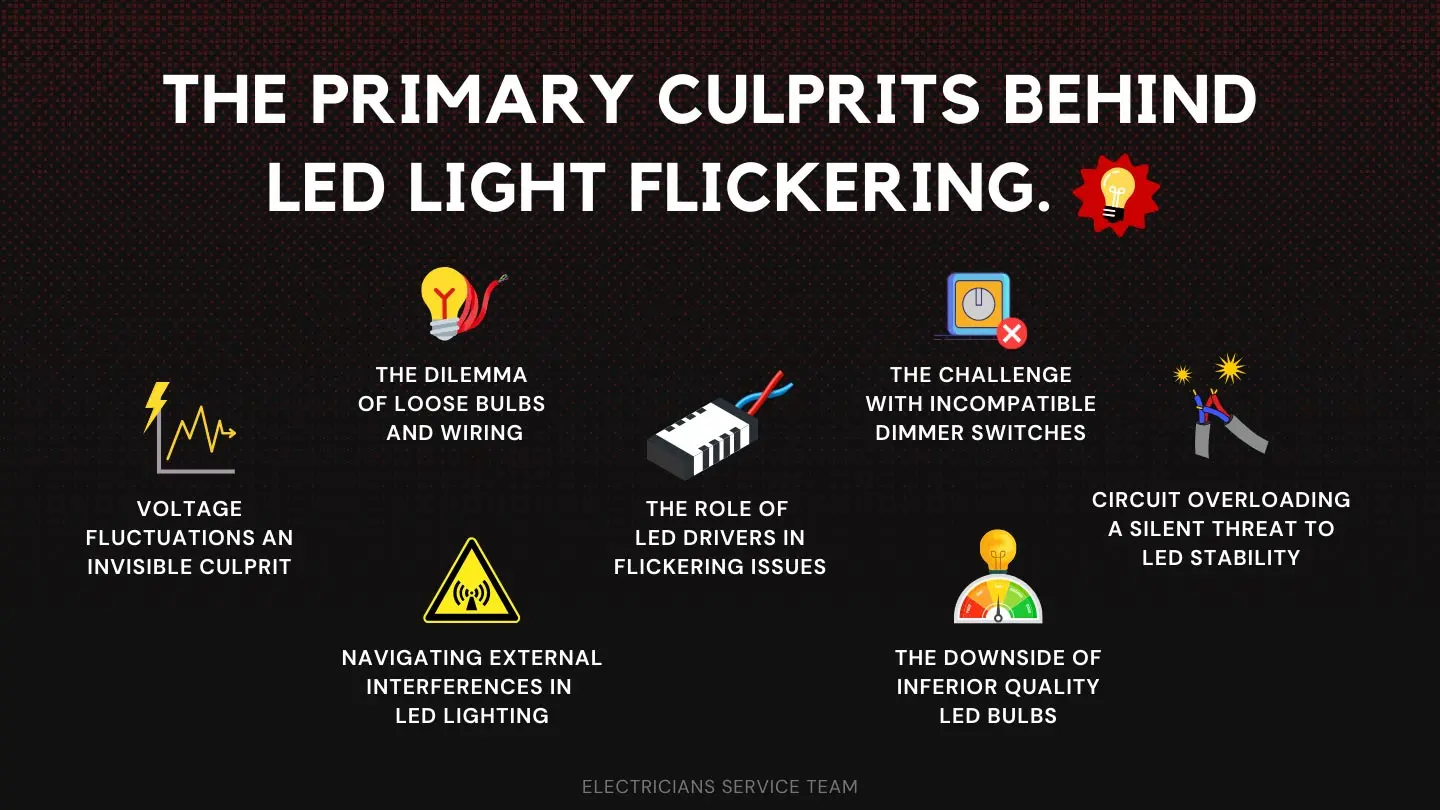

What Materials Are Commonly Used in Electrical Components Related to Headlight Flickering?

When addressing the issue of headlight flickering, understanding the materials used in the electrical components is crucial. The materials selected for wiring, connectors, and switches can significantly affect performance, durability, and overall vehicle safety. Here, we analyze four common materials used in these applications: copper, aluminum, plastic, and rubber.

How Does Copper Influence Headlight Performance?

Copper is widely used in automotive wiring due to its excellent electrical conductivity. It can efficiently carry the electrical current necessary for headlight operation, ensuring consistent performance.

Propriedades principais: Copper has a high conductivity rating, typically around 59.6 x 10^6 S/m, and is resistant to corrosion when properly insulated.

Prós e contras: The advantages of copper include its durability and resistance to corrosion, which make it suitable for long-term use in vehicles. However, copper is relatively expensive compared to other materials, and its weight can contribute to overall vehicle mass.

Illustrative image related to what does it mean when your headlights flicker

Impacto na aplicação: Copper wiring is compatible with various electrical systems and can handle the temperature fluctuations experienced in automotive environments.

Considerações para compradores internacionais: Buyers from regions like Europe and the Middle East may need to ensure compliance with standards such as DIN or ASTM for electrical components. Additionally, the availability of copper may vary based on local market conditions.

What Role Does Aluminum Play in Automotive Electrical Systems?

Aluminum is another common material used in automotive wiring and connectors. It is lighter than copper, which can help reduce the overall weight of the vehicle.

Propriedades principais: Aluminum has a conductivity rating of approximately 37.7 x 10^6 S/m, which is lower than copper but still sufficient for many applications.

Prós e contras: The primary advantage of aluminum is its lightweight nature, which can improve fuel efficiency. However, aluminum is more prone to corrosion and may require additional protective coatings, increasing manufacturing complexity.

Impacto na aplicação: While aluminum can be used in various electrical applications, its lower conductivity means longer runs may require larger gauge wiring to avoid voltage drop.

Considerações para compradores internacionais: In regions like South America and Africa, where cost may be a significant factor, aluminum may be favored for its lower price point. Compliance with local standards is essential to ensure safety and reliability.

How Do Plastic Components Affect Headlight Systems?

Plastics are often used in the manufacturing of headlight housings, switches, and connectors due to their versatility and insulating properties.

Propriedades principais: Plastics can withstand a wide range of temperatures and are generally resistant to moisture and chemicals.

Illustrative image related to what does it mean when your headlights flicker

Prós e contras: The advantages of using plastic include its lightweight nature and lower cost. However, plastics can be less durable over time, especially when exposed to UV light or extreme temperatures.

Impacto na aplicação: Plastic components are essential for insulation in electrical systems, preventing short circuits and enhancing safety.

Considerações para compradores internacionais: Buyers should be aware of the specific grades of plastic used, as compliance with standards such as JIS in Japan or ASTM in the U.S. can affect performance and safety.

What Is the Importance of Rubber in Electrical Connections?

Rubber is primarily used for insulation and sealing in electrical connections, protecting against moisture and environmental factors.

Propriedades principais: Rubber has excellent elasticity and can withstand a range of temperatures, making it ideal for automotive applications.

Prós e contras: The key advantage of rubber is its ability to provide a tight seal, preventing moisture ingress. However, rubber can degrade over time, especially when exposed to ozone or UV light.

Impacto na aplicação: Rubber components are vital for ensuring the longevity of electrical connections in headlight systems, preventing flickering caused by moisture-related issues.

Illustrative image related to what does it mean when your headlights flicker

Considerações para compradores internacionais: Buyers should ensure that rubber materials meet local environmental standards, particularly in regions with stringent regulations regarding chemical composition.

Quadro recapitulativo da análise de materiais

| Material | Typical Use Case for what does it mean when your headlights flicker | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Wiring and connectors for electrical systems | Excellent conductivity and durability | Custo e peso mais elevados | Alto |

| Alumínio | Lightweight wiring and connectors | Reduced weight for better fuel efficiency | More prone to corrosion | Médio |

| Plástico | Housings, switches, and insulation | Versátil e rentável | Less durable over time | Baixo |

| Rubber | Insulation and sealing for electrical connections | Provides moisture protection | Can degrade with exposure | Médio |

This analysis provides a comprehensive overview of the materials used in automotive electrical systems related to headlight flickering. By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for what does it mean when your headlights flicker

What Are the Key Stages in Manufacturing Headlight Components?

The manufacturing process for headlight components is intricate, involving several critical stages to ensure high-quality performance and reliability. Understanding these stages is vital for B2B buyers, especially those in regions with diverse automotive needs like Africa, South America, the Middle East, and Europe.

How is Material Prepared for Headlight Production?

The first stage in manufacturing headlight components involves material preparation. This includes selecting high-quality materials such as polycarbonate for lenses and aluminum or plastic for housing. The chosen materials must meet specific durability and optical clarity standards. Suppliers often perform material testing to ensure they comply with international specifications, which can vary based on regional regulations.

What Forming Techniques Are Used in Headlight Manufacturing?

Once materials are prepared, the next stage is forming. This involves processes such as injection molding for plastic components and stamping for metal parts. Injection molding allows for intricate designs and precise dimensions, which are crucial for proper light dispersion and safety. Quality assurance during this stage includes monitoring temperature and pressure settings to prevent defects such as warping or bubbles in the plastic.

How is Assembly Conducted for Headlight Units?

The assembly stage involves bringing together the various components—such as lenses, bulbs, wiring, and housings—into a complete headlight unit. This step often employs automated assembly lines to enhance efficiency and precision. Each connection must be secure to prevent flickering, which is often a result of loose wiring or poor connections. Quality control checks at this stage may include visual inspections and functional tests to ensure that all components operate as intended.

What Finishing Techniques Are Essential for Headlight Quality?

Finishing touches are vital for enhancing both aesthetics and functionality. This stage may include applying coatings to improve UV resistance and scratch protection. Additionally, headlight units are often subjected to rigorous testing for water and dust resistance. Quality assurance in this phase ensures that the final product meets both performance and safety standards.

Que medidas de controlo de qualidade são essenciais no fabrico de faróis?

Quality control (QC) is crucial in the production of headlight units to ensure they meet safety and performance standards. For B2B buyers, understanding these QC measures can help in evaluating potential suppliers.

Que normas internacionais devem os compradores B2B considerar?

International standards, such as ISO 9001, focus on quality management systems, ensuring that manufacturers maintain consistent quality in their processes. Additionally, industry-specific certifications, like CE marking in Europe and SAE standards in the United States, indicate compliance with safety and performance regulations. B2B buyers should prioritize suppliers who adhere to these standards to mitigate risks associated with product failures.

Quais são os principais pontos de verificação do controlo de qualidade?

Quality control involves several critical checkpoints throughout the manufacturing process:

-

Controlo de Qualidade de Entrada (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. Suppliers should provide documentation confirming the quality of materials, including test reports.

-

Controlo de qualidade em processo (IPQC): During manufacturing, IPQC ensures that processes are followed correctly. Techniques such as statistical process control (SPC) can be used to monitor production metrics and detect anomalies in real-time.

-

Controlo de Qualidade Final (FQC): The final inspection ensures that the completed headlight units meet all specifications. This may involve functional tests, including checking for proper light output, flickering, and electrical integrity.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

Verifying a supplier’s quality control processes is essential for B2B buyers to ensure reliability and safety in headlight products.

What Auditing Procedures Should Be Followed?

One effective way to verify a supplier’s quality control is through audits. These can be conducted internally or by third-party organizations specializing in quality assurance. Audits should review compliance with ISO standards and other industry-specific regulations, providing a comprehensive overview of the supplier’s practices.

Illustrative image related to what does it mean when your headlights flicker

How Can Buyers Access Quality Reports?

Buyers should request quality reports from suppliers that detail their QC processes and results. These reports should include documentation of any issues encountered and how they were resolved, which is crucial for understanding the supplier’s reliability and responsiveness to quality concerns.

Qual o papel das inspecções por terceiros?

Engaging a third-party inspection service can provide an unbiased assessment of a supplier’s quality control measures. These services often conduct on-site inspections, offering insights into production practices and adherence to safety standards. This step can be particularly beneficial for international buyers dealing with suppliers in regions with varying quality assurance practices.

Quais são as nuances do controlo de qualidade para compradores B2B internacionais?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding regional nuances in quality control is essential.

How Do Regional Regulations Affect Quality Standards?

Different regions may have specific regulatory requirements that affect quality standards for automotive components. For instance, European markets may demand stricter compliance with CE marking, while Middle Eastern markets might prioritize different safety certifications. B2B buyers should familiarize themselves with these regional requirements to ensure compliance and avoid potential legal issues.

What Challenges Do International Buyers Face in Quality Assurance?

International buyers may encounter challenges such as language barriers, varying interpretations of quality standards, and differences in manufacturing practices. To overcome these challenges, buyers should establish clear communication channels with suppliers and consider employing local representatives familiar with regional standards and practices.

Conclusão

Understanding the manufacturing processes and quality assurance measures for headlight components is crucial for B2B buyers in various international markets. By focusing on material preparation, forming techniques, assembly, and finishing, alongside rigorous quality control practices, buyers can ensure they source reliable and safe headlight products. Verifying supplier quality through audits, quality reports, and third-party inspections further strengthens buyer confidence, paving the way for successful international transactions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what does it mean when your headlights flicker’

Introdução

Understanding the causes of headlight flickering is essential for ensuring vehicle safety and performance. This guide provides a structured approach for B2B buyers in the automotive sector to source reliable solutions and components related to this common issue. By following this checklist, you can make informed purchasing decisions that enhance vehicle safety and reliability.

Passo 1: Identify Common Causes of Headlight Flickering

Before sourcing solutions, understand the primary causes of flickering headlights. The most prevalent issues include dying batteries, failing alternators, and worn-out bulbs. Recognizing these factors is critical as it will guide your procurement of appropriate parts or services.

Passo 2: Defina as suas especificações técnicas

Establish clear technical specifications for the components you need. This may include the type of bulbs, battery capacity, or alternator output. Accurate specifications ensure compatibility and performance, ultimately leading to better customer satisfaction.

Passo 3: Pesquisar potenciais fornecedores

Conduct thorough research on suppliers who specialize in automotive electrical systems. Look for companies with a proven track record in supplying high-quality components. Review customer testimonials and industry ratings to gauge their reliability.

Passo 4: Avaliar as certificações dos fornecedores

Ensure that your potential suppliers hold relevant industry certifications. Certifications such as ISO 9001 or specific automotive quality standards indicate that the supplier adheres to quality management practices. This step is crucial to mitigate risks associated with defective components.

Passo 5: Solicitar amostras para teste

Before making bulk purchases, request samples of the components you intend to buy. Testing samples in real-world conditions can help identify any issues related to performance or compatibility. This step is vital for ensuring that the components meet your technical specifications and quality expectations.

Passo 6: Avaliar a garantia e o apoio pós-venda

Review the warranty terms and after-sales support provided by suppliers. A robust warranty can protect your investment, while effective after-sales support ensures that you receive assistance in case of product failures or issues. This consideration is essential for maintaining long-term partnerships.

Passo 7: Finalizar a sua estratégia de aprovisionamento

Based on your research and testing, develop a procurement strategy that outlines your purchasing process. This should include budgeting, timelines, and order quantities. A well-defined strategy helps streamline your sourcing efforts and ensures that you can respond promptly to customer needs.

By following this structured checklist, B2B buyers can confidently navigate the complexities of sourcing solutions for headlight flickering issues, ensuring enhanced vehicle safety and performance.

Comprehensive Cost and Pricing Analysis for what does it mean when your headlights flicker Sourcing

What Are the Key Cost Components Involved in Sourcing Solutions for Flickering Headlights?

When analyzing the costs associated with addressing the issue of flickering headlights, several key components contribute to the overall expenditure. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materiais: The cost of components such as batteries, alternators, wiring, headlamp switches, and other electrical parts is a significant factor. The prices can vary based on the quality and specifications of the materials used. For instance, premium materials designed for durability may incur higher costs but can lead to longer-lasting solutions.

-

Trabalho: Skilled labor is essential for diagnosing and repairing electrical systems. Labor costs can fluctuate based on geographical location, expertise level, and the complexity of the repair. In regions with a higher cost of living, labor rates may be more substantial, impacting the total service cost.

-

Custos indiretos de produção: This includes costs associated with utilities, rent, and administrative expenses necessary for producing components. Efficient operations can help in minimizing these overheads, thereby reducing the final cost to buyers.

-

Ferramentas: Specialized tools are often required for repairs and diagnostics. Investing in advanced diagnostic equipment can ensure accuracy but may increase initial costs. However, this investment can also lead to better quality service, thus enhancing customer satisfaction.

-

Controlo de Qualidade (QC): Ensuring high-quality components through rigorous testing processes can add to costs. However, the long-term benefits of reduced failure rates and customer trust make QC a vital investment.

-

Logística: Transportation and warehousing costs are critical, especially for international shipments. Factors such as shipping method, destination, and customs regulations can influence logistics costs significantly.

-

Margem: Suppliers typically add a profit margin to cover their operational costs and risks. Understanding the margin expectations of different suppliers can aid in negotiations and sourcing decisions.

How Do Price Influencers Affect the Cost of Headlight Solutions?

Several factors can influence pricing in this sector, particularly for B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Bulk purchasing often leads to discounts. Suppliers may offer better pricing for larger orders, allowing businesses to optimize their procurement strategy.

-

Specs/Customization: Custom solutions tailored to specific vehicle models or regional requirements can incur higher costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Materiais: The choice of materials can significantly impact price. Using more advanced or durable materials will generally increase costs but can enhance product longevity.

-

Qualidade/Certificações: Products that meet international quality standards or certifications may come at a premium. However, they often provide better reliability and performance, which can justify the higher initial investment.

-

Fatores relacionados ao fornecedor: Established suppliers with a solid reputation may charge more due to perceived quality and reliability. Conversely, emerging suppliers may offer competitive pricing but may lack proven track records.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers, impacting shipping costs and risk management.

What Negotiation and Cost-Efficiency Tips Can Help International B2B Buyers?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant cost savings. Here are some practical tips:

-

Pesquisar e comparar: Conduct thorough market research to understand pricing trends and supplier reputations. Comparing multiple quotes can provide leverage during negotiations.

-

Custo total de propriedade (TCO): Consider not just the purchase price but the total cost of ownership, including maintenance and replacement costs. This perspective can help justify higher initial costs for better-quality products.

-

Aproveite os relacionamentos: Building long-term relationships with suppliers can lead to better pricing, priority service, and improved product availability.

-

Considere fornecedores locais: Sourcing from local suppliers may reduce logistics costs and lead times. Additionally, they may have better insights into regional market needs and conditions.

-

Negociar termos: Be open to negotiating payment terms, delivery schedules, and warranties. Flexible terms can enhance cash flow and reduce financial pressure.

By understanding these components and strategically navigating the sourcing landscape, B2B buyers can make informed decisions that balance cost, quality, and reliability when addressing flickering headlights in their fleets.

Alternatives Analysis: Comparing what does it mean when your headlights flicker With Other Solutions

Understanding Alternatives for Addressing Headlight Flickering Issues

When vehicle headlights flicker, it signifies underlying electrical system issues that can pose safety risks. For B2B buyers, particularly those managing fleets or automotive services, understanding the causes and implications of flickering headlights is crucial. However, it’s also essential to consider alternative solutions and technologies that can enhance vehicle safety and performance.

Tabela comparativa

| Aspecto comparativo | What Does It Mean When Your Headlights Flicker | Substituição da bateria | Upgraded Headlight System |

|---|---|---|---|

| Desempenho | Indicates potential battery, alternator, or wiring issues | Restores power to headlights, resolves flickering | Provides brighter, more reliable lighting |

| Custo | Generally low (diagnostic fees) | Moderate (battery costs vary) | Higher initial investment (premium bulbs/LEDs) |

| Facilidade de implementação | Requires diagnostic skills to identify root cause | Simple for DIY or quick service | More complex installation, may require professional help |

| Manutenção | Ongoing monitoring of electrical components | Minimal (battery replacement every 3-5 years) | Regular checks needed for bulb integrity |

| Melhor caso de uso | Identifying and resolving electrical issues | Ideal for existing vehicles with failing batteries | Recommended for safety-focused fleets or high-use vehicles |

Discriminação detalhada das alternativas

Substituição da bateria

Replacing a failing battery is one of the most straightforward solutions to address flickering headlights. It directly resolves power supply issues that can cause inconsistent headlight performance. The advantages include a relatively low cost and ease of implementation, as many vehicle owners can handle battery replacements themselves. However, this solution does not address potential underlying problems in the vehicle’s electrical system, which could lead to repeat issues if not diagnosed properly.

Illustrative image related to what does it mean when your headlights flicker

Upgraded Headlight System

Investing in an upgraded headlight system, such as LED or HID (High-Intensity Discharge) lights, offers several benefits. These systems provide superior illumination, improving visibility and safety while driving. Although the initial investment is higher and installation may require professional assistance, the long-term benefits, including reduced energy consumption and longer lifespan, can justify the cost. However, this solution may not directly address flickering issues caused by other electrical faults unless those faults are resolved first.

Conclusão: escolhendo a solução certa para as suas necessidades

For B2B buyers, selecting the appropriate solution for headlight flickering requires careful consideration of the specific circumstances surrounding each vehicle or fleet. While diagnosing the cause of flickering headlights is crucial, integrating solutions such as battery replacements or upgraded headlight systems can significantly enhance vehicle safety and operational efficiency. Assessing the performance, cost, ease of implementation, maintenance requirements, and best use cases will help make informed decisions that align with organizational goals and ensure reliable vehicle operation on the road.

Essential Technical Properties and Trade Terminology for what does it mean when your headlights flicker

What Are the Key Technical Properties Related to Headlight Flickering?

Understanding the technical properties associated with headlight flickering is crucial for B2B buyers in the automotive sector. These properties help in identifying the root causes and ensuring the quality and reliability of automotive components.

1. Tensão nominal

The voltage rating indicates the maximum voltage that electrical components, including headlights, can handle without failure. For automotive applications, this is typically around 12 volts for standard vehicles. Understanding this specification is vital for ensuring compatibility and preventing electrical overloads that could lead to flickering.

2. Wiring Gauge

The wiring gauge refers to the thickness of the wires used in the electrical system. Thicker wires (lower gauge numbers) can carry more current without overheating. Choosing the correct wire gauge is essential for maintaining a stable electrical flow to headlights, thus reducing the risk of flickering caused by insufficient current.

3. Bulb Lumens Output

Lumens measure the brightness of headlights. A higher lumen output indicates a brighter light, which improves visibility. When selecting bulbs for replacement, understanding the lumen output ensures that the new bulbs meet or exceed the original specifications, preventing issues like flickering due to inadequate light output.

4. Connector Quality

The quality of connectors used in the headlight system affects the integrity of electrical connections. High-quality connectors reduce the risk of corrosion and ensure secure connections, which are crucial for consistent electrical flow. Poor connectors can lead to intermittent connections, causing flickering headlights.

Illustrative image related to what does it mean when your headlights flicker

5. Resistência elétrica

Electrical resistance within the wiring and connectors can lead to voltage drops, affecting the performance of headlights. Low-resistance components are essential for minimizing energy loss and ensuring that headlights operate efficiently. High resistance can result in flickering or dimming lights, indicating potential failures in the electrical system.

What Are Common Trade Terms Related to Headlight Flickering?

Familiarity with industry terminology can enhance communication and decision-making for B2B buyers in automotive sectors, particularly regarding headlight issues.

1. OEM (Fabricante de Equipamento Original)

OEM refers to companies that produce parts that are used in the manufacturing of vehicles. When sourcing replacement parts for headlights, buyers often prefer OEM parts to ensure compatibility and reliability, reducing the risk of flickering caused by substandard components.

Illustrative image related to what does it mean when your headlights flicker

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory management and purchasing decisions. For components like headlight bulbs, knowing the MOQ can help in planning stock levels to avoid shortages that may lead to flickering issues.

3. RFQ (Pedido de Orçamento)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. When dealing with headlight components, issuing an RFQ can help buyers obtain competitive pricing and terms, ensuring they invest in quality parts that prevent flickering.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms define the responsibilities of buyers and sellers in international trade. Understanding these terms is vital for B2B transactions involving headlight components, as they clarify shipping, liability, and delivery responsibilities, which can impact the timely availability of parts necessary to resolve flickering issues.

5. Mercado pós-venda

The aftermarket refers to parts and accessories sold after the initial sale of the vehicle. While aftermarket products can be more affordable, they may not always meet OEM specifications. Buyers should evaluate the quality of aftermarket headlights and components to avoid flickering and ensure vehicle safety.

Understanding these technical properties and trade terminology can empower B2B buyers to make informed decisions in the automotive sector, particularly regarding headlight performance and reliability.

Navigating Market Dynamics and Sourcing Trends in the what does it mean when your headlights flicker Sector

What Are the Key Market Dynamics Influencing Headlight Flickering Solutions for B2B Buyers?

The automotive lighting sector, particularly regarding headlight flickering, is driven by several global trends. One significant factor is the increasing consumer demand for safety features in vehicles, which has led manufacturers to innovate more reliable lighting systems. Additionally, as electric vehicles (EVs) gain traction, suppliers are adapting their offerings to meet the unique electrical requirements of these vehicles. This shift creates opportunities for B2B buyers to invest in advanced lighting solutions that enhance vehicle safety and efficiency.

Emerging technologies, such as adaptive lighting systems and LED technology, are also shaping the market. These advancements not only improve visibility but also reduce energy consumption, aligning with the growing emphasis on sustainability in the automotive sector. For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of these technologies is crucial for making informed sourcing decisions. Collaborating with suppliers who prioritize innovation and reliability can enhance product offerings and customer satisfaction.

Furthermore, the market is witnessing a consolidation of suppliers focusing on ethical sourcing and transparency in their supply chains. This trend is particularly relevant for B2B buyers seeking to mitigate risks associated with supply chain disruptions, such as those experienced during the COVID-19 pandemic. By partnering with suppliers who uphold high standards of quality and sustainability, buyers can not only ensure a steady supply of components but also align their business practices with the growing consumer preference for environmentally responsible products.

How Do Sustainability and Ethical Sourcing Impact the Headlight Flickering Sector?

Sustainability is becoming a critical focus in the automotive industry, impacting how B2B buyers approach sourcing headlight components. The environmental impact of manufacturing processes, particularly concerning the extraction of raw materials and energy consumption, has prompted companies to seek greener alternatives. For instance, adopting LED technologies can significantly reduce energy consumption compared to traditional halogen bulbs, contributing to lower carbon footprints.

Moreover, ethical sourcing practices are gaining traction as consumers increasingly demand transparency regarding the origins of the products they purchase. B2B buyers need to ensure that their suppliers adhere to ethical standards, such as fair labor practices and responsible material sourcing. This can involve looking for certifications that indicate compliance with environmental and social governance (ESG) criteria. For example, suppliers with ‘green’ certifications demonstrate a commitment to sustainable practices, which can enhance a company’s reputation and appeal to environmentally conscious consumers.

As the automotive sector evolves, buyers should prioritize partnerships with suppliers who not only offer high-quality products but also align with sustainability goals. This approach not only mitigates risks associated with regulatory compliance but also positions businesses favorably in a competitive market increasingly driven by consumer preferences for sustainability.

What Is the Historical Context of Headlight Technology and Its Relevance Today?

The evolution of headlight technology has significantly influenced the current landscape of automotive lighting solutions. Initially, vehicles were equipped with simple incandescent bulbs, which offered limited visibility and efficiency. As safety regulations tightened and consumer expectations grew, advancements in lighting technology emerged, including halogen and, more recently, LED systems.

These developments have transformed headlight functionality, making them more energy-efficient while enhancing road safety. The transition to LED lighting, in particular, has revolutionized the market, providing longer lifespans and reduced energy consumption compared to traditional options. This historical context underscores the importance of continuous innovation in the industry, particularly as new vehicle models increasingly incorporate advanced lighting systems.

For B2B buyers, understanding this evolution is crucial for making informed decisions about sourcing headlight components. By selecting suppliers that embrace cutting-edge technologies and prioritize safety and sustainability, businesses can ensure they remain competitive and responsive to the needs of a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of what does it mean when your headlights flicker

-

How do I solve headlight flickering issues in vehicles?

To address headlight flickering, begin by inspecting the battery and alternator, as these are common culprits. A failing battery may not supply sufficient power, while a malfunctioning alternator can fail to recharge it. Check for loose wiring or corroded connections that may disrupt electrical flow. If the bulbs are old or damaged, replace them promptly. Lastly, consider consulting a qualified technician for a comprehensive diagnosis to ensure all electrical components are functioning correctly. -

What is the best solution for flickering headlights in commercial fleets?

For commercial fleets, the best solution is a proactive maintenance program that includes regular inspections of the electrical system, battery, alternator, and headlight components. Implementing a scheduled maintenance routine can help identify issues before they escalate. Additionally, sourcing high-quality replacement parts and establishing relationships with reliable suppliers can ensure that your fleet remains operational and safe on the road. -

What are the common causes of headlight flickering in vehicles?

Headlight flickering can result from several issues, including a dying battery, failing alternator, worn-out bulbs, loose connections, bad wiring, or a faulty headlamp switch. Each of these causes can disrupt the electrical flow to the headlights, leading to inconsistent performance. Understanding these causes allows fleet managers to implement targeted solutions and reduce downtime. -

How can I vet suppliers for automotive electrical components?

When vetting suppliers for automotive electrical components, assess their reputation and experience in the industry. Look for certifications that demonstrate compliance with international quality standards. Request samples or references from existing clients to evaluate product quality. It’s also beneficial to inquire about their supply chain reliability and logistics capabilities, especially if you’re sourcing from international markets. -

What are the minimum order quantities (MOQ) for headlight replacement parts?

Minimum order quantities (MOQ) for headlight replacement parts can vary significantly among suppliers. Typically, MOQs may range from a few units to several hundred, depending on the type of part and supplier policies. To optimize costs and inventory, negotiate MOQs with suppliers, particularly for bulk orders, and consider the implications of storage and distribution in your region. -

What payment terms should I consider when sourcing automotive parts internationally?

When sourcing automotive parts internationally, consider payment terms that balance risk and cash flow. Common options include letters of credit, advance payments, or net terms (e.g., 30, 60, or 90 days). Evaluate the supplier’s payment flexibility and ensure that terms are clearly outlined in the contract to prevent disputes. Additionally, consider using escrow services for large transactions to ensure security. -

How do I ensure quality assurance (QA) for automotive parts?

To ensure quality assurance (QA) for automotive parts, establish clear specifications and standards before placing orders. Request certifications or test reports from suppliers to verify product compliance with international quality standards. Implement a QA process that includes receiving inspections, regular audits, and feedback loops with suppliers to address quality issues promptly and maintain high standards in your fleet. -

What logistics considerations should I keep in mind when importing automotive components?

When importing automotive components, consider logistics factors such as shipping costs, lead times, and customs regulations. Ensure that you have a reliable logistics partner who can navigate international shipping complexities and provide timely delivery. Additionally, familiarize yourself with import duties and taxes that may impact overall costs. Proper planning can help mitigate delays and ensure that your supply chain remains efficient.

Top 3 What Does It Mean When Your Headlights Flicker Manufacturers & Suppliers List

1. Underground Lighting – LED Headlight Kits

Domínio: undergroundlighting.com

Registada: 2015 (10 anos)

Introdução: Black Friday Sale 20% OFF at Checkout; Product types include Accessories, Back Up LED, Brake Light & Turn Signal LEDs, Fog Light LEDs, HID Accessories, HID Ballast, HID Bulbs, HIDs, HIDs Canbus, LED Headlight, LED Interior Bulbs, LED Load Resistors, Off Road Strobes, Trucks; HID Conversion Kits, various bulb part numbers (H1, H3, H4, H7, H8, H9, H11, H10, H13, H15, 9004, 9005, 9006, 9007, 9012, 52…

2. Supercar – LED Headlight PWM Control

Domínio: mechanics.stackexchange.com

Registado: 2009 (16 anos)

Introdução: Supercar headlights use pulse-width modulation (PWM) to adjust brightness. Instead of using a large resistor to vary current, the LEDs are flashed on and off faster than the human eye can detect. This method allows for brightness control without generating excessive heat, as the LED cools while off. The flashing effect is visible in videos because cameras capture the frames at a speed that reveals…

3. Kia – Soul Owners

Strategic Sourcing Conclusion and Outlook for what does it mean when your headlights flicker

In summary, understanding the causes of headlight flickering is crucial for maintaining vehicle safety and reliability. Key issues such as a dying battery, failing alternator, worn-out bulbs, and loose connections can compromise not only the performance of the headlights but also the overall safety of the vehicle. For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, it is essential to strategically source high-quality automotive components and services to mitigate these risks.

Investing in reliable suppliers who provide timely maintenance and parts can enhance the longevity of vehicles and reduce unexpected breakdowns. As the global automotive market evolves, embracing innovative solutions in vehicle maintenance and repair will be critical.

We encourage international buyers to prioritize partnerships with trusted vendors that offer comprehensive diagnostics and quality components to ensure safety on the roads. By addressing headlight flickering proactively, businesses can enhance operational efficiency and safeguard their assets. Let’s drive towards a future where vehicle safety and performance are paramount—take the next step in optimizing your fleet’s health today.

Illustrative image related to what does it mean when your headlights flicker

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.