Introduction: Navigating the Global Market for how much do new headlights cost

In today’s competitive automotive industry, understanding the cost of new headlights is crucial for international B2B buyers. Whether you are sourcing headlights for vehicle fleets in Nigeria or selecting premium lighting solutions for luxury cars in Saudi Arabia, the price range can vary significantly. This guide delves into the multifaceted world of headlight costs, offering insights into various types, including halogen, HID, and LED options. It also explores the factors influencing pricing, such as vehicle make and model, and the complexities involved in sourcing these components.

Navigating the global market for automotive headlights presents unique challenges. From determining the appropriate bulb type to understanding labor costs associated with installation, buyers must be well-informed to make strategic purchasing decisions. This comprehensive resource equips B2B buyers with the knowledge needed to evaluate suppliers, assess product quality, and understand the implications of different headlight technologies on overall vehicle safety and performance.

With a specific focus on buyers from Africa, South America, the Middle East, and Europe, this guide aims to empower decision-makers by providing actionable insights into sourcing and cost management. By leveraging this information, you can optimize your procurement processes, ensuring that your organization not only meets safety standards but also enhances operational efficiency and profitability.

Índice

- Top 3 How Much Do New Headlights Cost Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much do new headlights cost

- Understanding how much do new headlights cost Types and Variations

- Key Industrial Applications of how much do new headlights cost

- 3 Common User Pain Points for ‘how much do new headlights cost’ & Their Solutions

- Strategic Material Selection Guide for how much do new headlights cost

- In-depth Look: Manufacturing Processes and Quality Assurance for how much do new headlights cost

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much do new headlights cost’

- Comprehensive Cost and Pricing Analysis for how much do new headlights cost Sourcing

- Alternatives Analysis: Comparing how much do new headlights cost With Other Solutions

- Essential Technical Properties and Trade Terminology for how much do new headlights cost

- Navigating Market Dynamics and Sourcing Trends in the how much do new headlights cost Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much do new headlights cost

- Strategic Sourcing Conclusion and Outlook for how much do new headlights cost

- Aviso legal importante e termos de utilização

Understanding how much do new headlights cost Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Lâmpadas halógenas | Cost-effective, easy to replace, available in various brightness levels | General vehicle maintenance and repair shops | Prós: Acessível, amplamente disponível; Contras: Short lifespan, dimmer compared to other types. |

| Descarga de Alta Intensidade (HID) | Brighter than halogen, requires a ballast for operation | Automotive lighting specialists, luxury vehicle services | Prós: Longer lifespan, significantly brighter; Contras: More expensive, complicated installation. |

| Díodo emissor de luz (LED) | Energy-efficient, long-lasting, often integrated into modern vehicles | Electric vehicle manufacturers, high-end automotive repair | Prós: Extremely long lifespan, low power consumption; Contras: High initial cost, potential need for complete assembly replacement. |

| Faróis a laser | Exceptional range and visibility, often found in luxury models | Premium automotive markets, specialized vehicle manufacturers | Prós: Outstanding visibility, innovative technology; Contras: Very high cost, limited availability. |

| Unidades de feixe selado | Uniform design, typically easy to replace, regulated standards | Older vehicle repairs, fleet maintenance | Prós: Simple replacement, standardized size; Contras: Limited to older vehicles, less energy-efficient. |

What Are Halogen Bulbs and Their B2B Relevance?

Halogen bulbs are the most common type of headlight used in vehicles today, favored for their affordability and ease of replacement. Typically costing between $10 and $40, these bulbs are suitable for general vehicle maintenance and repair shops. B2B buyers should consider their short lifespan and dimmer output compared to more advanced options, which may lead to more frequent replacements, impacting overall cost-effectiveness.

How Do High-Intensity Discharge (HID) Bulbs Benefit Businesses?

HID bulbs are renowned for their brightness and longevity, providing three to five times more light than halogen bulbs. Priced around $150 per unit, they are ideal for automotive lighting specialists and luxury vehicle services. While they offer superior illumination and a lifespan of 2,000-3,000 hours, their installation complexity and higher costs necessitate professional handling, making them a strategic investment for businesses focusing on high-performance vehicles.

Why Are LED Headlights Gaining Popularity in B2B Markets?

LED headlights represent the latest technology in automotive lighting, known for their energy efficiency and longevity, lasting up to 30,000 hours. Their costs range from $50 to $200 per pair, making them a viable option for electric vehicle manufacturers and high-end automotive repair facilities. Businesses should evaluate the potential need for complete assembly replacements, as failures often arise from electronic components rather than the diodes themselves, which could affect warranty considerations.

What Makes Laser Headlights Unique for Premium Automotive Applications?

Laser headlights are a cutting-edge technology offering exceptional visibility, suitable for high-end vehicles and premium automotive markets. While they provide outstanding range, their high replacement costs, which can reach several thousand dollars, limit their accessibility. B2B buyers should weigh the benefits of superior visibility against the investment required, especially in markets where luxury vehicles dominate.

How Do Sealed Beam Units Serve Older Vehicle Maintenance?

Sealed beam units are a legacy technology characterized by their standardized design, making them easy to replace and suitable for older vehicles. Commonly used in fleet maintenance and repairs for classic cars, these units are cost-effective but lack the energy efficiency and brightness of modern options. B2B buyers should consider the limited applicability in contemporary markets as vehicles increasingly move towards more advanced lighting solutions.

Illustrative image related to how much do new headlights cost

Key Industrial Applications of how much do new headlights cost

| Indústria/Setor | Specific Application of how much do new headlights cost | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Fabricação Automotiva | Fornecimento de componentes de faróis para linhas de montagem | Cost-effective procurement of quality headlight systems | Supplier reliability, compliance with international standards |

| Gestão de frotas | Budgeting for headlight replacements in vehicle fleets | Ensures safety compliance and reduces downtime for fleet vehicles | Bulk purchasing agreements, warranty terms, and service options |

| Serviços de reparação automóvel | Offering headlight replacement services | Increased service offerings and customer satisfaction | Availability of parts, pricing models, and labor costs |

| Plataformas de comércio eletrónico | Selling headlight replacement kits | Expanding product range to meet consumer demand | Supplier partnerships, shipping logistics, and competitive pricing |

| Retalhistas de peças para automóveis | Retailing various headlight types and assemblies | Capturing diverse customer segments with different needs | Stock variety, supplier relationships, and pricing strategies |

How Do Automotive Manufacturers Utilize Headlight Cost Information?

Automotive manufacturers must consider the costs associated with sourcing headlight components for their assembly lines. This includes evaluating various types of headlights—halogen, HID, and LED—and their respective price points. Understanding the cost implications allows manufacturers to optimize their production budgets while ensuring compliance with safety standards. For international buyers, especially in regions like Africa and South America, it is crucial to partner with reliable suppliers who can deliver quality components that meet local regulations.

What Role Does Headlight Cost Play in Fleet Management?

Fleet management companies must budget for headlight replacements as part of their vehicle maintenance programs. Knowing the replacement costs helps in forecasting expenses and ensures that all vehicles remain compliant with safety regulations. This is particularly important in regions like the Middle East, where harsh weather conditions can lead to quicker deterioration of headlight systems. Fleet managers should consider bulk purchasing agreements to lower costs and ensure timely availability of parts, reducing vehicle downtime.

How Can Automotive Repair Services Benefit from Headlight Replacement Costs?

Automotive repair services can enhance their offerings by including headlight replacement services, capitalizing on the growing demand for vehicle safety maintenance. By understanding the cost of various headlight types, repair shops can provide transparent pricing to customers, boosting trust and satisfaction. For buyers in Europe, where regulations on vehicle safety are stringent, having access to quality parts and competitive pricing is essential for maintaining a loyal customer base.

Why Are E-commerce Platforms Focused on Headlight Replacement Kits?

E-commerce platforms can capitalize on the rising demand for headlight replacement kits by offering a variety of products at competitive prices. By understanding the cost of various headlight types, these platforms can tailor their marketing strategies to attract a broader customer base. For international buyers, especially in emerging markets, establishing strong supplier partnerships and efficient shipping logistics is vital to ensure timely delivery and customer satisfaction.

What Should Automotive Parts Retailers Consider When Selling Headlights?

Automotive parts retailers must be aware of the diverse needs of their customers when retailing headlight components and assemblies. Understanding the cost of different headlight types allows retailers to stock a variety of options, catering to both budget-conscious consumers and those seeking premium products. In regions like Nigeria, where vehicle maintenance can vary widely, having a robust stock variety and strong supplier relationships can provide a competitive edge in the market.

Illustrative image related to how much do new headlights cost

3 Common User Pain Points for ‘how much do new headlights cost’ & Their Solutions

Scenario 1: Navigating the Complex Pricing Structure of Headlight Replacement

O problema: B2B buyers often face challenges when trying to estimate the costs associated with headlight replacements for their fleet vehicles. With a wide range of bulb types and assembly options available—ranging from inexpensive halogen bulbs to high-end LED modules—the price can vary dramatically. Buyers may find themselves overwhelmed by the complexities of pricing, which can lead to budget overruns and unexpected expenses. Additionally, the lack of transparent pricing from suppliers can create confusion, making it difficult to make informed purchasing decisions.

A solução: To effectively manage headlight replacement costs, B2B buyers should first conduct a thorough analysis of their fleet’s headlight requirements. This involves identifying the specific make, model, and year of each vehicle to determine the type of headlight needed. Buyers can create a comprehensive inventory that categorizes vehicles by headlight type—halogen, HID, or LED—and then research the average costs associated with each option. It’s advisable to establish relationships with reputable suppliers who provide transparent pricing and bulk purchasing discounts. By consolidating purchases and negotiating contracts, buyers can secure more favorable pricing and reduce overall costs. Leveraging data analytics tools to track and forecast headlight replacement needs can also assist in budgeting and ensure that expenditures remain within planned limits.

Scenario 2: Dealing with Labor Costs for Headlight Installation

O problema: Another significant pain point for B2B buyers is the labor costs associated with headlight installation. Depending on the vehicle type and the complexity of the headlight system, installation can require extensive labor, especially for modern vehicles where the entire assembly must be replaced rather than just the bulb. This can lead to labor costs that are as high as the parts themselves, significantly impacting the total expense of headlight replacement.

A solução: To mitigate labor costs, buyers should consider investing in training for their maintenance staff. By equipping in-house technicians with the necessary skills to perform headlight replacements, companies can reduce their reliance on external service providers. Additionally, buyers should explore the option of purchasing headlight assemblies that are designed for easier installation, thereby minimizing labor time. It’s also beneficial to create a standardized maintenance schedule that allows for bulk replacements during routine service, which can streamline operations and reduce labor costs. By implementing these strategies, buyers can effectively control installation costs and enhance the overall efficiency of their fleet maintenance operations.

Scenario 3: Ensuring Compliance with Safety Standards and Regulations

O problema: B2B buyers are often concerned about ensuring compliance with safety standards and regulations related to vehicle lighting. Non-compliance can lead to legal liabilities, increased insurance costs, and safety hazards for drivers. The variety of headlight options available can further complicate the selection process, as not all products meet the required standards. This can result in costly recalls or replacements if substandard parts are used.

A solução: To ensure compliance, B2B buyers should prioritize sourcing headlight products from reputable manufacturers that provide clear certification and compliance documentation. It is crucial to verify that all replacement bulbs and assemblies meet local and international safety standards, such as the Department of Transportation (DOT) regulations. Buyers can establish a checklist of compliance criteria to assess potential suppliers, focusing on quality assurances, warranty offerings, and product specifications. Additionally, implementing a regular inspection and maintenance schedule can help identify any non-compliant parts before they pose a safety risk. By being proactive in compliance management, buyers not only enhance safety but also protect their business from potential legal repercussions and associated costs.

Strategic Material Selection Guide for how much do new headlights cost

What Materials Are Commonly Used in Headlight Manufacturing?

When considering the cost of new headlights, the materials used in their construction play a crucial role in determining both performance and pricing. Here, we analyze four common materials: polycarbonate, glass, aluminum, and composite materials, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Polycarbonate Affect Headlight Cost and Performance?

Propriedades principais: Polycarbonate is a thermoplastic known for its high impact resistance and lightweight nature. It can withstand a range of temperatures and pressures, making it suitable for automotive applications.

Illustrative image related to how much do new headlights cost

Prós e contras: The primary advantage of polycarbonate is its durability; it is shatter-resistant and can endure harsh weather conditions. However, it is prone to scratching and UV degradation unless treated with protective coatings. Additionally, while polycarbonate is less expensive than glass, the cost can increase significantly with added treatments.

Impacto na aplicação: Polycarbonate is compatible with various automotive lighting technologies, including halogen and LED systems. However, its susceptibility to yellowing and clouding over time can affect visibility and safety.

Considerações para compradores internacionais: Buyers from regions like Africa and the Middle East should ensure that polycarbonate headlights meet local UV resistance standards. Compliance with international standards like ASTM is essential to guarantee product reliability.

What Role Does Glass Play in Headlight Construction?

Propriedades principais: Glass is a traditional material known for its clarity and resistance to scratching. It can handle high temperatures and has excellent optical properties.

Prós e contras: Glass headlights provide superior light transmission and are less prone to yellowing compared to polycarbonate. However, they are heavier and more fragile, making them susceptible to breakage. The manufacturing complexity also increases costs, as glass requires precise molding and treatment.

Impacto na aplicação: Glass is often used in high-end vehicles where optical clarity is paramount. Its durability against UV light makes it suitable for long-term use, but its weight can affect vehicle efficiency.

Considerações para compradores internacionais: Buyers should be aware of the fragility of glass headlights, especially in regions with rough road conditions. Compliance with standards such as DIN in Europe is crucial for ensuring quality and safety.

How Does Aluminum Contribute to Headlight Assembly?

Propriedades principais: Aluminum is a lightweight metal known for its corrosion resistance and strength-to-weight ratio. It can withstand high temperatures and is often used in headlight housings.

Prós e contras: The main advantage of aluminum is its durability and resistance to environmental factors. However, it can be more expensive than plastic alternatives, and the manufacturing process can be complex due to the need for precise machining.

Impacto na aplicação: Aluminum is commonly used in high-performance vehicles where weight savings are critical. Its robustness ensures that the headlight assembly can endure vibrations and impacts.

Illustrative image related to how much do new headlights cost

Considerações para compradores internacionais: In regions with high humidity, such as parts of South America, aluminum’s corrosion resistance is a significant advantage. Buyers should verify that aluminum components comply with local and international standards.

What Are the Benefits of Composite Materials in Headlights?

Propriedades principais: Composite materials combine various substances to enhance performance characteristics, such as strength, weight, and resistance to environmental factors.

Prós e contras: Composites can be engineered for specific applications, offering a balance of cost and performance. However, they can be more expensive to produce and may require specialized manufacturing techniques.

Illustrative image related to how much do new headlights cost

Impacto na aplicação: Composites are increasingly used in modern vehicles for their lightweight properties and design flexibility. They can be tailored to meet specific performance criteria, such as thermal resistance.

Considerações para compradores internacionais: Buyers should consider the availability of composite materials in their region and ensure compliance with relevant standards. In markets with stringent regulations, such as Europe, adherence to safety and performance standards is vital.

Summary Table of Material Selection for Headlight Costs

| Material | Typical Use Case for how much do new headlights cost | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Policarbonato | Standard headlights in mid-range vehicles | High impact resistance and lightweight | Prone to scratching and UV degradation | Baixo |

| Vidro | High-end vehicles requiring clarity | Superior light transmission and durability | Heavier and more fragile | Alto |

| Alumínio | High-performance vehicles needing lightweight design | Resistente à corrosão e durável | More expensive with complex manufacturing | Médio |

| Compósito | Modern vehicles for optimized performance | Customizable for specific applications | Potentially higher production costs | Medium to High |

This guide provides a comprehensive analysis of materials used in headlight manufacturing, helping international B2B buyers make informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for how much do new headlights cost

What Are the Key Manufacturing Processes for Headlights?

The manufacturing of headlights is a complex process that requires precision engineering and high-quality materials. Understanding these processes can help B2B buyers assess the value and reliability of the headlights they intend to procure.

Quais são as principais fases do fabrico de faróis?

-

Preparação do material

The first step involves sourcing high-grade materials, such as polycarbonate for the lens and aluminum or plastic for the housing. Suppliers must ensure these materials meet international standards for durability and optical clarity. Quality materials are essential not only for aesthetics but also for safety and performance. -

Formando

The forming process includes shaping the lens and housing components. This is typically done through injection molding for plastic parts and die-casting for metal components. The precision of this step is crucial, as any defects can lead to poor fit or functionality. Advanced techniques such as 3D printing are also emerging to create intricate designs or prototypes. -

Montagem

In the assembly phase, various components, including bulbs (halogen, HID, or LED), reflectors, and lenses, are brought together. Automated assembly lines are often employed to ensure uniformity and efficiency. Quality assurance measures are implemented at this stage to check for proper alignment and sealing, which are critical for water and dust resistance. -

Acabamento

The finishing stage involves applying coatings to enhance durability and aesthetics. For instance, anti-fog and UV-resistant coatings are applied to the lens to prolong its lifespan. This step may also include polishing and final inspections to ensure that the headlights meet design specifications.

How Is Quality Assurance Managed in Headlight Manufacturing?

Quality assurance (QA) is a cornerstone of the manufacturing process, particularly in the automotive industry where safety is paramount. A comprehensive QA strategy encompasses several international and industry-specific standards.

Illustrative image related to how much do new headlights cost

Which International Standards Are Relevant for Headlight Manufacturing?

-

ISO 9001

This standard outlines the requirements for a quality management system (QMS) and is widely recognized across various industries. Compliance with ISO 9001 indicates that the manufacturer has established a systematic approach to managing quality, which can reassure B2B buyers regarding product reliability. -

Marcação CE

For products sold in Europe, CE marking demonstrates conformity with health, safety, and environmental protection standards. Manufacturers must ensure that their headlights comply with directives like the Low Voltage Directive (LVD) and the Electromagnetic Compatibility (EMC) Directive. -

Padrões API

While more commonly associated with petroleum products, API standards can also influence the quality of automotive lighting systems, especially in terms of materials used in manufacturing.

What Are the Key QC Checkpoints in Headlight Production?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify defects early and ensure compliance with standards.

-

Controlo de Qualidade de Entrada (IQC)

This phase involves inspecting raw materials upon arrival at the manufacturing facility. Tests may include checking for material integrity, optical clarity, and compliance with specifications. -

Controlo de qualidade em processo (IPQC)

During the manufacturing stages, regular inspections are conducted to monitor adherence to quality standards. This includes verifying the accuracy of molds, the consistency of assembly, and the effectiveness of coatings. -

Controlo de Qualidade Final (FQC)

Before packaging, the finished headlights undergo a comprehensive inspection. Tests might include functionality checks, water resistance testing, and light output evaluations to ensure they meet performance criteria.

What Common Testing Methods Are Used in Headlight Quality Assurance?

B2B buyers should be aware of the various testing methods employed to ensure that headlights meet safety and performance standards.

-

Ensaios fotométricos

This involves measuring the light output and distribution pattern of the headlights to ensure they meet regulatory requirements. This testing is critical for safety and compliance with traffic regulations. -

Ensaios ambientais

Headlights must withstand various environmental conditions, such as temperature fluctuations, humidity, and exposure to UV light. Environmental testing simulates these conditions to assess durability and performance. -

Teste de durabilidade

Manufacturers often conduct impact tests to evaluate how well headlights can withstand physical shocks, ensuring they remain functional even under adverse conditions.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

When sourcing headlights, B2B buyers should take proactive steps to ensure that suppliers adhere to rigorous quality control measures.

-

Auditorias a fornecedores

Conducting on-site audits can provide insights into a supplier’s manufacturing processes and QA protocols. This enables buyers to assess the reliability and credibility of the supplier. -

Solicitação de relatórios de qualidade

Suppliers should provide documentation of their quality control processes, including test results and compliance certificates. This information is crucial for verifying adherence to international standards. -

Inspeções por terceiros

Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These inspections can be particularly valuable for international buyers who may not have direct oversight.

Quais são as nuances de controle de qualidade e certificação para compradores B2B internacionais?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should consider the following nuances when it comes to QC and certification:

-

Conformidade regulamentar

Different regions may have specific regulations regarding automotive lighting. Buyers should ensure that products comply with local standards to avoid legal issues. -

Cultural and Economic Factors

Understanding the local market dynamics can help buyers negotiate better terms and ensure that they are sourcing products that meet local preferences and standards. -

Logística e cadeia de abastecimento

International shipping may complicate quality assurance. Buyers should establish clear communication channels with suppliers to address any issues that arise during transit.

By understanding the manufacturing processes and quality assurance protocols involved in headlight production, B2B buyers can make informed decisions that prioritize safety, performance, and compliance in their procurement strategies.

Illustrative image related to how much do new headlights cost

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much do new headlights cost’

Introdução

When considering the procurement of new headlights for vehicles, it’s essential for B2B buyers to navigate the complex landscape of options, costs, and suppliers effectively. This practical sourcing guide outlines a step-by-step checklist to ensure informed decision-making, optimizing both performance and budget.

Passo 1: Assess Your Vehicle Requirements

Understanding the specific requirements for headlights based on vehicle make, model, and trim is crucial. Each vehicle may require different types of bulbs—halogen, HID, or LED—each with varying performance characteristics and costs. Ensure that you have accurate specifications to avoid costly errors in procurement.

Passo 2: Determine Your Budget Range

Establishing a clear budget helps in filtering options effectively. Headlight costs can range from $10 for basic halogen bulbs to over $1,000 for advanced LED assemblies. Consider not only the initial purchase price but also long-term maintenance and replacement costs, particularly for vehicles with sealed headlight units.

Passo 3: Pesquisar opções de fornecedores

Conduct thorough research on potential suppliers. Look for established companies with a strong reputation in the automotive lighting market. Consider factors such as:

– Certificações de fornecedores: Ensure they meet industry standards.

– Product range: Suppliers should offer various headlight types to suit different vehicles.

Illustrative image related to how much do new headlights cost

Passo 4: Verificar a qualidade e conformidade do produto

Quality assurance is critical in headlight procurement. Verify that the products meet relevant safety standards, such as DOT certification in the U.S. or equivalent standards in your region. This ensures that the headlights will perform reliably and safely, minimizing the risk of failure.

Passo 5: Pedir amostras ou demonstrações

Before finalizing a supplier, request samples or demonstrations of the headlights. This allows you to evaluate the quality of light output, durability, and overall performance. Testing products firsthand can reveal important insights about their suitability for your specific applications.

Passo 6: Evaluate Warranty and Support Terms

Review the warranty terms and after-sales support offered by suppliers. A robust warranty indicates confidence in product quality, while good customer support can facilitate easier returns or exchanges if issues arise. Consider the length of coverage and what it includes, as this can impact long-term satisfaction.

Passo 7: Negociar as condições e finalizar a compra

Once you have identified a suitable supplier, engage in negotiations to secure the best pricing and terms. Discuss bulk purchasing discounts, payment terms, and delivery schedules. Clear communication at this stage can lead to a mutually beneficial partnership and potentially lower costs.

By following this checklist, B2B buyers can navigate the complexities of sourcing new headlights with confidence, ensuring optimal choices that align with their operational needs and budget constraints.

Illustrative image related to how much do new headlights cost

Comprehensive Cost and Pricing Analysis for how much do new headlights cost Sourcing

What Are the Key Cost Components for New Headlights in B2B Sourcing?

When sourcing new headlights, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

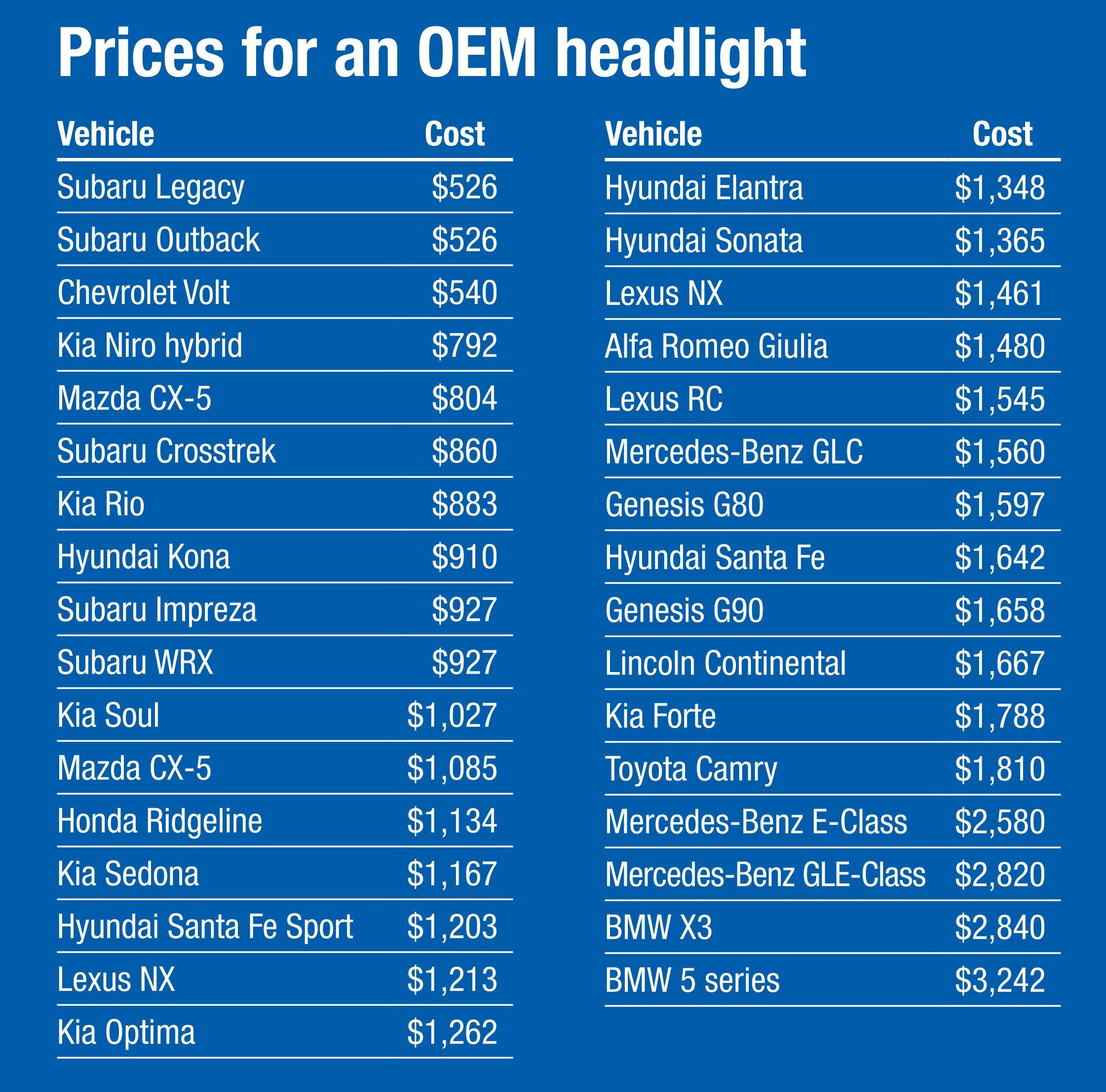

Materiais: The type of headlight significantly influences material costs. Halogen bulbs are typically the least expensive, ranging from $10 to $40, while high-intensity discharge (HID) and LED options can escalate costs to $150 and $200, respectively. For complete headlight assemblies, especially in modern vehicles with advanced features, prices can soar to $1,000 or more.

-

Trabalho: Labor costs are essential to consider, particularly when installation is complex. Replacing a simple bulb may incur minimal labor costs, but replacing complete assemblies or performing intricate installations can add hundreds of dollars to the final price.

-

Despesas gerais de fabrico: This includes costs related to production facilities, equipment maintenance, and utilities. Higher overhead can result in increased prices for the end buyer, particularly for premium products with advanced technology.

-

Tooling and QC: Tooling costs are associated with the manufacturing process, especially for custom or specialized headlight designs. Quality control ensures that products meet safety and performance standards, adding to the overall cost but also preventing future liabilities related to product failures.

-

Logística: Shipping costs can vary significantly depending on the origin of the headlights and the destination. Factors such as distance, transportation mode, and customs duties should be accounted for, especially for international transactions.

-

Margem: Supplier margins can vary based on brand reputation, market demand, and exclusivity of the product. Established brands may command higher prices due to perceived quality and reliability.

What Factors Influence Headlight Pricing in the B2B Market?

Several price influencers impact the sourcing of headlights, including volume or minimum order quantity (MOQ), specifications or customization, material quality, certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Bulk purchases often lead to significant discounts. Suppliers may offer better pricing for larger orders, enabling B2B buyers to optimize their procurement budgets.

-

Specifications/Customization: Custom headlights designed to meet specific vehicle requirements can drive up costs. Buyers should weigh the need for customization against the potential for higher prices.

-

Materials and Quality/Certifications: The choice of materials directly affects durability and performance. Higher-quality products may carry certifications that can justify their higher price point, enhancing safety and compliance.

-

Factores do fornecedor: Supplier reliability, reputation, and negotiation flexibility can significantly impact pricing. Building strong relationships with suppliers can lead to better terms and conditions.

-

Incoterms: Understanding shipping terms can help buyers manage costs effectively. Incoterms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, influencing the overall cost structure.

What Are the Best Practices for Negotiating Headlight Prices in International Markets?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, negotiating effectively is key to achieving cost-efficiency.

-

Research and Benchmarking: Understanding market prices and competitor offerings can empower buyers during negotiations. This knowledge helps in assessing whether quotes are competitive.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the TCO, which includes installation, maintenance, and potential future replacement costs. A higher initial investment in quality headlights may yield long-term savings.

-

Negotiation Leverage: Leverage factors like volume commitments or long-term partnerships to negotiate better pricing or terms.

-

Pricing Nuances: Be aware of regional pricing variations due to local market conditions, import tariffs, and currency fluctuations. This knowledge can aid in negotiating favorable terms.

Isenção de responsabilidade sobre preços indicativos

The prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and specific vehicle requirements. Buyers are encouraged to conduct thorough market research and engage with suppliers for accurate quotations tailored to their needs.

Alternatives Analysis: Comparing how much do new headlights cost With Other Solutions

When considering the costs associated with new headlights, it’s essential to explore alternative solutions that may fulfill the same needs while potentially offering different advantages. B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, should analyze these alternatives to make informed purchasing decisions. This section compares the traditional headlight replacement with other solutions like headlight restoration and advanced lighting technologies.

| Aspecto comparativo | How Much Do New Headlights Cost | Restauração de faróis | LED Conversion Kits |

|---|---|---|---|

| Desempenho | Varies by type; LED offers best visibility | Restores clarity, but may not match new performance | Significantly improves brightness and longevity |

| Custo | $10 to $300 for bulbs; $600 to $2,800 for assemblies | $25 to $150 for DIY or professional service | $50 to $200 for bulbs; installation may vary |

| Facilidade de implementação | Moderate; may require professional installation for assemblies | Generally easy for DIY; professional help available | Moderate; may require technical skills for installation |

| Manutenção | Low; replace as needed | Periodic restoration every few years | Minimal; long-lasting with basic checks |

| Melhor caso de uso | Necessary for damaged units; safety-critical | Cost-effective for cloudy lenses | Ideal for upgrading older systems for better performance |

What are the Pros and Cons of Headlight Restoration?

Headlight restoration is a cost-effective method to improve the clarity and functionality of existing headlight lenses. It typically involves cleaning and polishing the lens surface to remove oxidation and scratches, which can significantly enhance visibility at night. The restoration process can be done with kits available at local auto parts stores, costing between $25 and $150. However, while this method can restore brightness, it does not replace the actual bulb or assembly, meaning it may not resolve deeper issues like electrical faults or severely degraded bulbs.

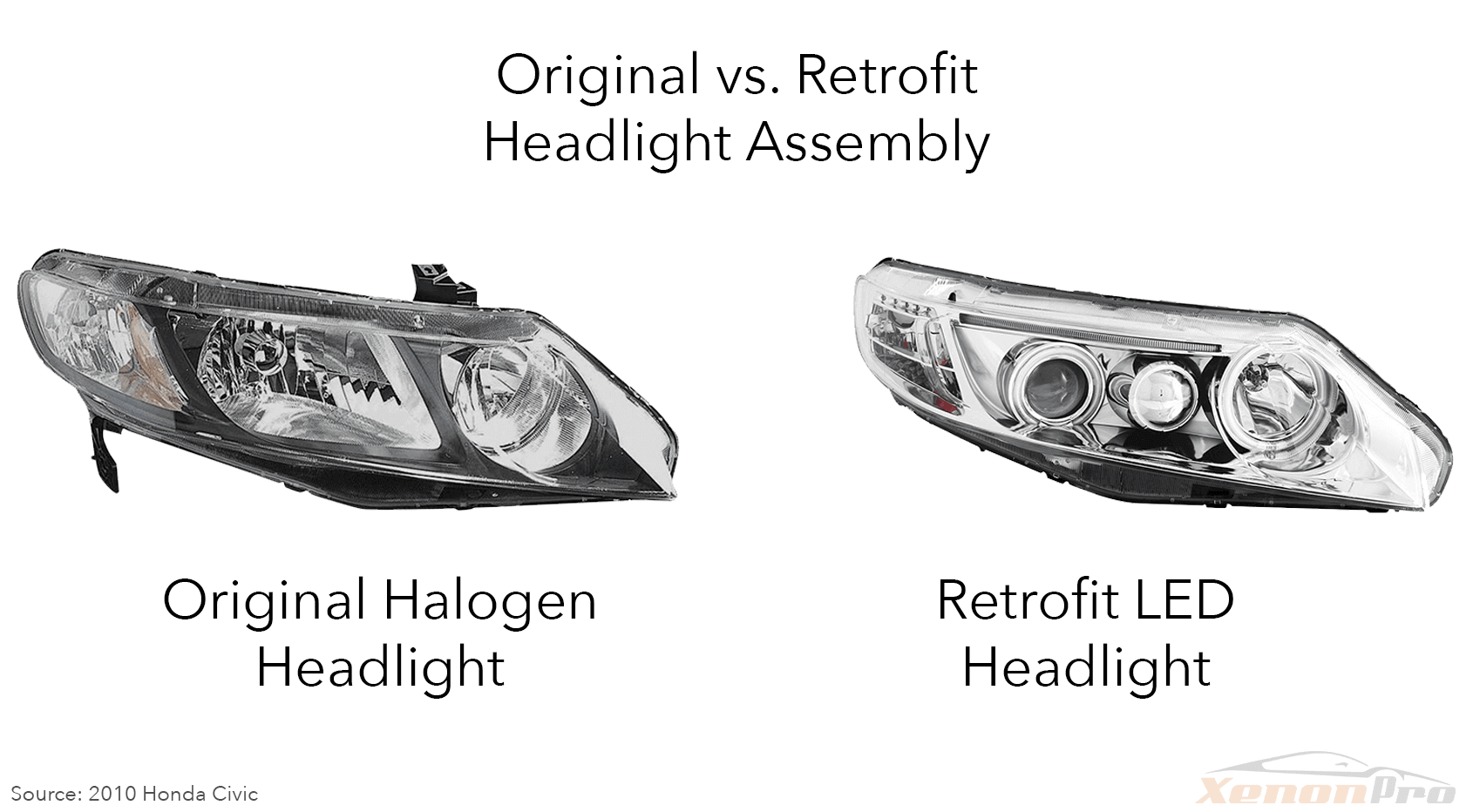

How Do LED Conversion Kits Compare?

LED conversion kits provide an opportunity to upgrade existing headlights to modern LED technology. These kits can greatly enhance visibility and longevity, with replacement costs ranging from $50 to $200. Installation may require some technical skills, as users often need to modify existing fixtures. While LEDs have a higher initial cost, their long lifespan (up to 30,000 hours) and low maintenance make them an attractive option. However, users should consider potential warranty implications when using aftermarket kits.

Conclusão: como os compradores B2B devem escolher a solução certa?

B2B buyers must assess their specific needs when deciding between new headlights and alternative solutions. If safety and performance are paramount, investing in new headlights or LED conversion kits may be the best route. However, for those looking to enhance visibility without the costs associated with complete replacements, headlight restoration can be a viable, budget-friendly option. Ultimately, evaluating the performance, cost, and ease of implementation will guide buyers toward the most suitable choice for their fleet or vehicle requirements.

Essential Technical Properties and Trade Terminology for how much do new headlights cost

What Are the Key Technical Properties Influencing Headlight Costs?

When considering the costs associated with new headlights, several critical technical properties come into play. Understanding these specifications can help B2B buyers make informed purchasing decisions.

1. Grau do material

The material used in headlight manufacturing significantly affects durability and performance. Common materials include polycarbonate, which is lightweight and resistant to impact, and glass, known for its clarity and resistance to scratching. Higher-grade materials often come with a premium price but provide better longevity and performance, reducing replacement frequency.

Illustrative image related to how much do new headlights cost

2. Tipo de lâmpada

Headlights can utilize various bulb types, each with distinct characteristics. Halogen bulbs are the most affordable but have a shorter lifespan. High-Intensity Discharge (HID) bulbs offer superior brightness and longevity but are more expensive. Light Emitting Diodes (LEDs) are becoming standard due to their energy efficiency and long life, although they often require an entire assembly replacement when they fail, significantly impacting costs.

3. Wattage and Lumens Output

Wattage indicates the energy consumption of the headlight, while lumens measure brightness. Higher wattage typically translates to more lumens, leading to better visibility. However, increased wattage can lead to higher energy costs and potential compatibility issues with older vehicle models. Understanding these metrics is crucial for buyers to ensure compliance with regional regulations and to meet safety standards.

4. Water and Dust Resistance Rating (IP Rating)

The Ingress Protection (IP) rating indicates how well a headlight can resist dust and moisture. For instance, an IP67 rating means the unit is completely dust-tight and can withstand immersion in water up to 1 meter. This is vital for ensuring longevity, particularly in regions with harsh weather conditions. Buyers should seek headlights with higher IP ratings to reduce the likelihood of premature failure.

5. Electrical Compatibility

Headlights must be compatible with a vehicle’s electrical system. This includes voltage requirements and connector types. Mismatches can lead to flickering lights or complete failures. Ensuring compatibility minimizes installation costs and enhances safety.

What Are Common Trade Terms Related to Headlight Costs?

Understanding industry jargon is essential for B2B buyers in navigating the complexities of headlight procurement.

Illustrative image related to how much do new headlights cost

1. OEM (Fabricante de Equipamento Original)

OEM refers to parts made by the vehicle’s original manufacturer. These parts often come with a guarantee of quality and compatibility but are typically more expensive than aftermarket alternatives. Buyers should weigh the benefits of reliability against budget constraints.

2. MOQ (Quantidade mínima de encomenda)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory levels and overall purchasing costs. Understanding the MOQ helps buyers plan their procurement strategies effectively.

3. RFQ (Pedido de Orçamento)

An RFQ is a formal process where buyers request price quotes from suppliers. It allows businesses to compare costs and terms from multiple vendors. Crafting a detailed RFQ can lead to better pricing and terms, benefiting overall procurement strategies.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Knowing these terms helps buyers understand shipping costs, risk management, and delivery responsibilities, essential for budgeting and logistics planning.

5. Peças de reposição

Aftermarket parts are produced by companies other than the vehicle manufacturer. They can be cheaper but may vary in quality and compatibility. Buyers should assess the trade-offs between cost and reliability when considering aftermarket options.

By understanding these technical properties and trade terminology, B2B buyers can navigate the complexities of headlight procurement more effectively, ensuring they make informed decisions that align with their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the how much do new headlights cost Sector

What Are the Key Trends Influencing Headlight Replacement Costs?

The global market for automotive headlights is experiencing significant transformation driven by technological advancements and evolving consumer preferences. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate a landscape where the cost of headlight replacements can vary dramatically. A notable trend is the increasing adoption of LED and HID technologies, which, while offering superior performance and longevity, also come with higher upfront costs. For instance, while halogen bulbs may cost between $10 and $40, LED assemblies can reach upwards of $1,000, particularly for luxury models. This shift towards advanced lighting solutions is partly fueled by stricter safety regulations and consumer demand for enhanced vehicle aesthetics and functionality.

Moreover, as the automotive industry transitions towards electric and hybrid vehicles, the sourcing of headlight components is also evolving. B2B buyers must consider not only the cost but also the compatibility of these components with new vehicle models. The complexity of modern headlight systems, often requiring entire module replacements instead of simple bulb changes, adds another layer of cost that buyers need to account for in their sourcing strategies. Additionally, the emergence of smart lighting systems that adapt to driving conditions is becoming a key differentiator in the market, impacting both the pricing structure and the sourcing dynamics.

How Does Sustainability Impact the Sourcing of Headlights?

Sustainability is increasingly shaping the automotive lighting market, compelling B2B buyers to consider the environmental impact of their sourcing decisions. The production of headlights, particularly those utilizing traditional materials and processes, can contribute significantly to carbon emissions and waste. Therefore, sourcing headlights from suppliers that prioritize sustainable practices is becoming essential. This includes using eco-friendly materials, such as recycled plastics and sustainable manufacturing processes that minimize energy consumption.

Illustrative image related to how much do new headlights cost

Moreover, buyers are encouraged to seek partnerships with manufacturers that hold ‘green’ certifications, ensuring that their products adhere to stringent environmental standards. The push for sustainability is not just a regulatory requirement but also a market differentiator, as consumers and businesses increasingly favor products that contribute to reduced environmental footprints. By aligning sourcing strategies with sustainability goals, B2B buyers can enhance their brand reputation while also complying with regional regulations that may govern automotive parts production and disposal.

How Have Headlight Technologies Evolved Over Time?

The evolution of headlight technologies has been marked by a shift from simple incandescent bulbs to sophisticated lighting solutions that enhance vehicle safety and aesthetics. Historically, headlights were predominantly sealed-beam units, making replacements straightforward and affordable. However, as vehicle designs became more complex, the introduction of halogen, HID, and LED technologies transformed the landscape.

Halogen bulbs, once the standard, offered better brightness and efficiency but required more frequent replacements. The advent of HID technology brought about significant improvements in luminosity and longevity, albeit at a higher cost and complexity of installation. Today, LEDs represent the cutting edge of headlight technology, providing exceptional lifespan and energy efficiency but often necessitating the replacement of entire headlight assemblies when they fail. This evolution reflects broader trends in the automotive industry towards energy efficiency, safety, and advanced technological integration, influencing how B2B buyers approach sourcing and cost management in the headlight replacement market.

Illustrative image related to how much do new headlights cost

Frequently Asked Questions (FAQs) for B2B Buyers of how much do new headlights cost

-

How do I determine the cost of replacing headlights for my vehicle?

To estimate the cost of replacing headlights, first identify the type of bulbs your vehicle requires, as prices vary significantly. Basic halogen bulbs can cost between $10 and $40 each, while high-intensity discharge (HID) bulbs range from $150 to $300. For modern vehicles with LED systems, costs can soar to $1,000 or more for complete headlight assemblies. Check your vehicle’s manual or consult with a trusted auto parts supplier to obtain the correct specifications and pricing. -

What factors influence the price of headlight replacements?

Several factors influence headlight replacement costs, including the vehicle’s make and model, the type of bulbs (halogen, HID, or LED), and whether you need to replace just the bulb or the entire assembly. Labor costs also contribute, especially for complex installations that may require removing parts of the vehicle. Additionally, sourcing from reputable suppliers can affect prices due to quality and warranty considerations. -

Where can I find reliable suppliers for headlight components?

To find reliable suppliers for headlight components, consider attending automotive trade shows or industry expos, where manufacturers showcase their products. Online platforms such as Alibaba or global trade directories can also help you connect with verified suppliers. Always check for reviews, certifications, and references to ensure the supplier meets quality standards and can accommodate your specific needs. -

What is the minimum order quantity (MOQ) for headlight purchases?

Minimum order quantities (MOQs) for headlights can vary widely based on the supplier and the type of product. Some manufacturers may have an MOQ as low as 10 units, while others, especially for custom or high-end products, may require orders of 100 units or more. Always inquire about MOQs before finalizing your supplier agreement to ensure it aligns with your inventory needs. -

How can I ensure the quality of the headlights I source?

To ensure quality in sourced headlights, request samples before placing a bulk order. Verify that the products meet international safety standards, such as DOT or ECE certifications, and ask for documentation of testing results. Additionally, establish a quality assurance process that includes inspections upon receipt of goods to catch any defects early and maintain compliance with your market regulations. -

What payment terms should I expect when sourcing headlights internationally?

Payment terms for international headlight sourcing typically range from upfront payments, such as 30% deposit and 70% upon delivery, to net 30 or net 60 terms. Always clarify payment methods accepted (e.g., bank transfer, PayPal) and any associated fees. It’s advisable to use secure payment methods and consider escrow services for larger transactions to protect your investment. -

How do logistics impact the cost of sourcing headlights?

Logistics can significantly affect the total cost of sourcing headlights due to shipping fees, customs duties, and handling charges. Consider factors such as the shipping method (air freight vs. sea freight), delivery timeframes, and the reliability of the logistics provider. Establishing a good relationship with logistics partners can lead to better rates and smoother customs processes, ultimately lowering costs. -

Can I customize headlights for specific markets or vehicles?

Yes, many suppliers offer customization options for headlights, allowing you to tailor designs, colors, or functionalities to meet market demands. When discussing customization, provide detailed specifications and any regulatory requirements for your target market. Keep in mind that customized products may come with higher MOQs and longer lead times, so plan accordingly to avoid delays in your supply chain.

Top 3 How Much Do New Headlights Cost Manufacturers & Suppliers List

1. CarParts – Headlights Assembly

Domínio: carparts.com

Registado: 1999 (26 anos)

Introdução: Car Headlights – Halogen, HID, Xenon, LED Assembly from $70. Available for driver and passenger sides. Wide selection of replacement headlights from respected manufacturers. Different lighting technologies offered: Halogen, HID/Xenon, LED. Fast shipping and hassle-free returns. 5% OFF first order in app only.

2. Ford – Fusion Headlight Replacement

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: 2014 Ford Fusion; front left headlight bulb replacement; quoted labor cost: $300 (plus cost of the part); oil change place refused to do the replacement; extensive labor required (lifting the vehicle and removing several body panels).

3. Xenon Pro – Headlight Replacement Cost Guide

Domínio: xenonpro.com

Registada: 2013 (12 anos)

Introdução: Headlight Replacement Cost – Complete Guide

1. **Factory Headlight Bulb Replacement Cost**

– **Halogen (factory)**: $30 – $50 per pair, Lifespan: 1,000+ hours

– **Xenon (factory)**: $50 – $150 per pair, Lifespan: 10,000+ hours

– **LED (factory)**: N/A, Lifespan: 30,000+ hours (entire assembly must be replaced)

2. **Headlight Conversion Kit Cost**

– **LED Conversion Kit**: $60 – $200,…

Strategic Sourcing Conclusion and Outlook for how much do new headlights cost

What Key Insights Should B2B Buyers Consider Regarding Headlight Costs?

In summary, the cost of new headlights can vary significantly based on the type of bulb and vehicle model, ranging from $10 for basic halogen replacements to thousands for advanced LED assemblies. This variance underscores the importance of strategic sourcing for B2B buyers, particularly those in emerging markets like Africa, South America, and the Middle East, where understanding local vehicle preferences and pricing dynamics is crucial.

Investing in quality headlight replacements not only ensures compliance with safety standards but also reduces long-term costs associated with frequent replacements and potential accidents due to inadequate lighting. Furthermore, as automotive technologies evolve, staying informed about the latest advancements in headlight technology—such as adaptive lighting and energy-efficient LEDs—will be vital for making informed purchasing decisions.

As you navigate the complexities of headlight sourcing, consider leveraging partnerships with reputable suppliers who can provide insights into the best options for your fleet. By prioritizing quality and safety in your sourcing strategy, you can enhance operational efficiency and ultimately drive better business outcomes. Embrace the opportunity to optimize your procurement processes—make informed choices today to ensure a brighter tomorrow for your operations.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Illustrative image related to how much do new headlights cost

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.