Introduction: Navigating the Global Market for how long should an alternator last in a car

In the dynamic landscape of the automotive industry, understanding how long an alternator should last in a car is crucial for B2B buyers navigating global supply chains. Alternators play a vital role in vehicle performance, supplying electrical power and ensuring battery longevity. However, sourcing high-quality alternators that meet diverse regional standards can be challenging, particularly in markets across Africa, South America, the Middle East, and Europe, including Germany and Brazil.

This comprehensive guide delves into the intricacies of alternator longevity, exploring various types, their applications, and the factors influencing their lifespan. Buyers will find valuable insights on how to vet suppliers effectively, ensuring that they procure reliable components that align with their operational needs. Additionally, the guide addresses cost considerations, helping businesses make informed budgetary decisions without compromising quality.

By equipping B2B buyers with actionable knowledge on alternator durability, maintenance tips, and signs of failure, this guide empowers stakeholders to enhance their procurement strategies. Understanding these elements not only aids in reducing unexpected downtimes but also fosters more resilient vehicle fleets. As the automotive market continues to evolve, leveraging the insights presented here will be instrumental in securing dependable alternators that drive business success.

Índice

- Top 1 How Long Should An Alternator Last In A Car Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how long should an alternator last in a car

- Understanding how long should an alternator last in a car Types and Variations

- Key Industrial Applications of how long should an alternator last in a car

- 3 Common User Pain Points for ‘how long should an alternator last in a car’ & Their Solutions

- Strategic Material Selection Guide for how long should an alternator last in a car

- In-depth Look: Manufacturing Processes and Quality Assurance for how long should an alternator last in a car

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long should an alternator last in a car’

- Comprehensive Cost and Pricing Analysis for how long should an alternator last in a car Sourcing

- Alternatives Analysis: Comparing how long should an alternator last in a car With Other Solutions

- Essential Technical Properties and Trade Terminology for how long should an alternator last in a car

- Navigating Market Dynamics and Sourcing Trends in the how long should an alternator last in a car Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how long should an alternator last in a car

- Strategic Sourcing Conclusion and Outlook for how long should an alternator last in a car

- Aviso legal importante e termos de utilização

Understanding how long should an alternator last in a car Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Alternador padrão | Average lifespan of 7 years or 150,000 miles | General automotive repair and maintenance | Prós: Económico, amplamente disponível. Contras: Limited warranty, may lack advanced features. |

| High-Performance Alternator | Concebido para sistemas eléctricos de elevada exigência | Performance vehicles, racing applications | Prós: Enhanced durability, higher output. Contras: Custo mais elevado, pode exigir instalação especializada. |

| Alternador Remanufacturado | Rebuilt to original specifications | Cost-sensitive buyers, fleet vehicles | Prós: Cheaper than new, environmentally friendly. Contras: Potential for shorter lifespan, quality varies. |

| OEM (Original Equipment Manufacturer) Alternator | Made by the original manufacturer | New vehicle replacements, warranty work | Prós: Ajuste e desempenho garantidos. Contras: Higher price, limited availability for older models. |

| Alternador inteligente | Integrated with vehicle’s smart systems | Veículos eléctricos e híbridos | Prós: Optimizes energy use, prolongs battery life. Contras: More complex, higher initial investment. |

What are the Key Characteristics of Standard Alternators?

Standard alternators typically have a lifespan of approximately seven years or 150,000 miles under normal driving conditions. They are designed for conventional vehicles and are suitable for general automotive repair and maintenance. B2B buyers should consider the cost-effectiveness and availability of these alternators, although they may not come with extensive warranties or advanced features. Businesses looking for reliable yet economical options for fleet maintenance often opt for standard alternators.

Why Choose High-Performance Alternators for Demanding Applications?

High-performance alternators cater to vehicles with significant electrical demands, such as those used in racing or off-road conditions. These alternators offer enhanced durability and higher output to support advanced electronics. For B2B buyers in the automotive performance sector, investing in high-performance alternators can lead to improved vehicle reliability and customer satisfaction. However, the higher initial cost and potential need for specialized installation should be factored into purchasing decisions.

What are the Benefits of Remanufactured Alternators?

Remanufactured alternators are rebuilt to meet original specifications and serve as a cost-effective alternative to new parts. They are particularly appealing to cost-sensitive buyers and fleet operators looking to balance quality with budget constraints. While they are generally cheaper and environmentally friendly, buyers should be aware that the lifespan may be shorter than that of new units, and quality can vary significantly between manufacturers.

Why Consider OEM Alternators for Vehicle Replacements?

OEM alternators are produced by the original manufacturer and are designed to fit and perform exactly as intended in specific vehicle models. They are ideal for new vehicle replacements and warranty work, ensuring reliability and compliance with manufacturer standards. B2B buyers may find that while OEM alternators guarantee quality and performance, they often come at a higher price and may be harder to source for older vehicles.

Como é que os alternadores inteligentes melhoram o desempenho do veículo?

Smart alternators are integrated with a vehicle’s smart systems, optimizing energy usage and prolonging battery life, particularly in electric and hybrid vehicles. This technology is increasingly relevant for B2B buyers in the electric vehicle market, where efficiency is paramount. While the initial investment for smart alternators is higher, the long-term benefits, including reduced battery replacements and enhanced vehicle performance, can justify the cost for businesses focused on sustainability and innovation.

Key Industrial Applications of how long should an alternator last in a car

| Indústria/Setor | Specific Application of how long should an alternator last in a car | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Fabricação Automotiva | Quality control in alternator production | Ensures longevity and reliability of vehicles, reducing warranty claims. | Sourcing high-quality materials and components for durability. |

| Gestão de frotas | Regular maintenance scheduling based on alternator lifespan | Reduces downtime and enhances operational efficiency across fleets. | Understanding regional climate effects on alternator performance. |

| Serviços de reparação automóvel | Diagnostic tools for assessing alternator lifespan | Informs customers about necessary repairs, improving service satisfaction. | Investing in advanced diagnostic equipment for accurate assessments. |

| Empresas de exportação/importação | Assessing alternator specifications for international standards | Ensures compliance and reduces returns from non-compliant products. | Familiarity with local regulations and standards in target markets. |

| Electric Vehicle Sector | Research and development of advanced alternators | Enhances vehicle performance and energy efficiency in EVs. | Collaboration with technology partners for innovative solutions. |

How Does Automotive Manufacturing Utilize Alternator Lifespan Knowledge?

In the automotive manufacturing sector, understanding the lifespan of alternators is crucial for quality control processes. By ensuring that alternators are designed to last around seven years or 150,000 miles, manufacturers can significantly reduce warranty claims and enhance the reputation of their vehicles. For international buyers, sourcing high-quality materials and components that meet these longevity standards is essential to ensure reliability and customer satisfaction.

How Does Fleet Management Benefit from Alternator Lifespan Insights?

Fleet management companies can optimize their operations by scheduling regular maintenance based on the expected lifespan of alternators. This proactive approach minimizes vehicle downtime and enhances overall operational efficiency. For businesses operating in regions with extreme weather conditions, understanding how these factors affect alternator performance is vital for maintaining fleet reliability and reducing unexpected repairs.

How Do Automotive Repair Services Leverage Alternator Lifespan Information?

Automotive repair services can enhance their customer service by using knowledge of alternator lifespan to inform clients about necessary repairs. By diagnosing issues related to alternators early, repair shops can prevent more significant problems and foster customer loyalty. Investing in advanced diagnostic tools that accurately assess alternator health will empower these businesses to provide reliable service and build trust with their clientele.

What Role Does Export/Import Play in Alternator Specification Compliance?

For export and import businesses, understanding the lifespan and specifications of alternators is crucial to ensure compliance with international standards. This knowledge helps mitigate the risk of returns due to non-compliance issues, ultimately protecting the business’s bottom line. Familiarity with local regulations in target markets, such as those in Africa, South America, and Europe, is essential for successful operations and customer satisfaction.

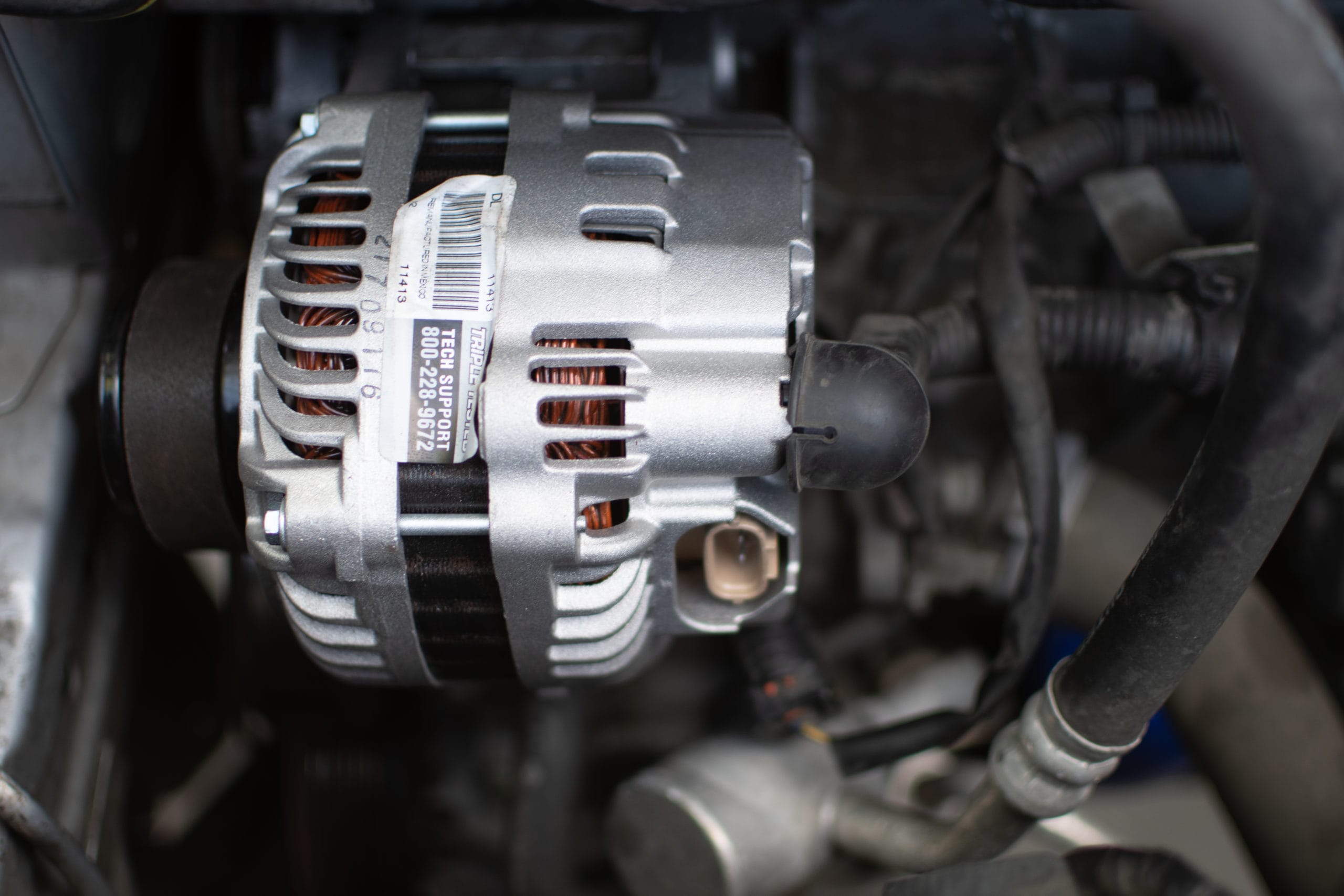

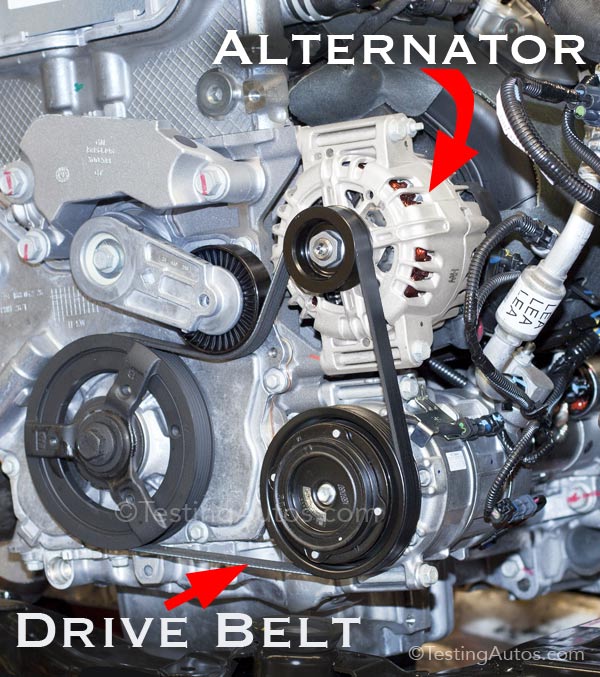

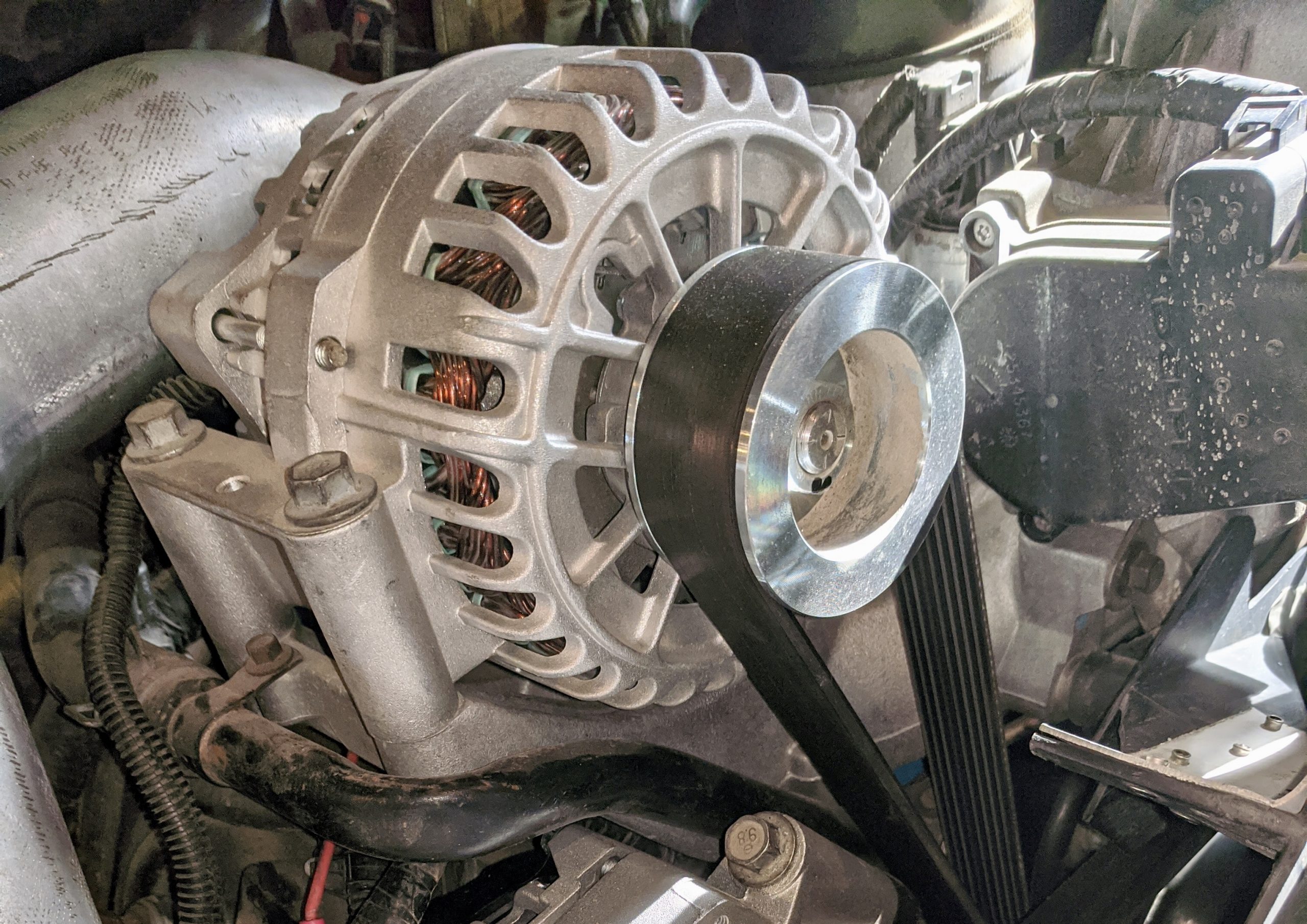

Illustrative image related to how long should an alternator last in a car

How Is the Electric Vehicle Sector Innovating with Alternator Technology?

In the electric vehicle sector, research and development teams are leveraging insights about traditional alternator lifespans to innovate new solutions that enhance vehicle performance and energy efficiency. As the market shifts towards more sustainable options, collaboration with technology partners to develop advanced alternators tailored for electric vehicles will be key to staying competitive. Understanding the unique requirements of international buyers will also facilitate the successful introduction of these innovations in diverse markets.

3 Common User Pain Points for ‘how long should an alternator last in a car’ & Their Solutions

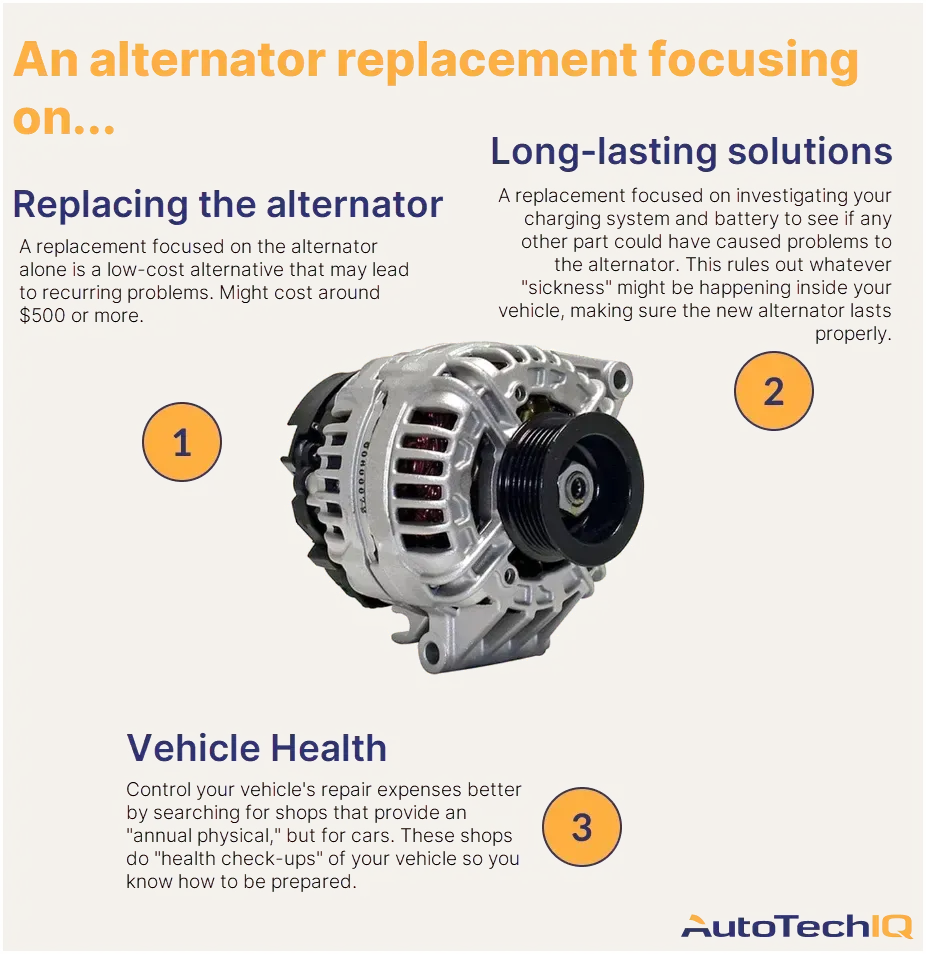

Scenario 1: Unexpected Vehicle Downtime Due to Alternator Failure

O problema: A fleet manager in Brazil experiences frequent unexpected vehicle breakdowns, leading to significant downtime and operational disruptions. The vehicles, essential for transportation and logistics, often have alternators that fail unexpectedly, leaving drivers stranded. This not only impacts delivery schedules but also raises concerns about safety and reliability, ultimately affecting client trust and satisfaction.

A solução: To mitigate this issue, the fleet manager should implement a proactive maintenance program focused on the alternators’ lifespan. Start by establishing a routine inspection schedule, ideally every six months, to check the alternator’s performance alongside the vehicle’s battery and electrical systems. Educate drivers about the signs of alternator failure, such as dimming headlights or unusual noises, to encourage early reporting of potential issues. Furthermore, sourcing high-quality, OEM (Original Equipment Manufacturer) alternators can ensure longer lifespan and reliability. Develop partnerships with reliable suppliers who can provide warranty-backed products. This approach not only minimizes unexpected failures but also enhances fleet efficiency and customer satisfaction.

Illustrative image related to how long should an alternator last in a car

Scenario 2: Misleading Lifespan Information Leading to Poor Purchasing Decisions

O problema: An auto parts retailer in Germany faces a common dilemma: customers frequently inquire about the average lifespan of alternators, leading to confusion and mistrust. The retailer often encounters customers returning alternators after short use, citing discrepancies between their expectations and the actual performance. This situation strains the retailer’s relationship with suppliers and customers alike, resulting in lost sales and a damaged reputation.

A solução: To address this challenge, the retailer should create comprehensive educational materials that clarify the factors influencing alternator lifespan, such as vehicle type, driving conditions, and maintenance practices. This can include infographics, blog posts, and in-store brochures that explain that, on average, alternators last around seven years or 150,000 miles, but various factors can shorten this lifespan. Additionally, offering a selection of premium alternators with extended warranties can provide customers with peace of mind. Training staff to communicate effectively about these details can also enhance customer confidence in their purchasing decisions, leading to increased sales and customer loyalty.

Scenario 3: Integration of Aftermarket Electronics Overloading Alternators

O problema: A vehicle modification company in South Africa specializes in custom builds but faces challenges when clients install aftermarket electronics. Many clients report issues with their alternators failing prematurely due to increased electrical demands, leading to costly repairs and dissatisfied customers. This situation not only affects the company’s reputation but also results in warranty claims and loss of repeat business.

A solução: The company should develop a clear guideline for clients on how to assess their vehicle’s electrical capacity before adding aftermarket components. This guideline should include recommendations for alternator upgrades that match the increased electrical load. Collaborating with alternator manufacturers to provide custom solutions tailored to specific vehicle models and aftermarket setups can also be beneficial. Additionally, offering installation services that ensure proper wiring and load management will enhance overall customer satisfaction. By taking these steps, the company can position itself as a trusted expert in vehicle modifications, reducing the risk of alternator failures and fostering long-term customer relationships.

Strategic Material Selection Guide for how long should an alternator last in a car

When selecting materials for alternators, it is crucial to consider their properties, advantages, and limitations. This analysis will focus on four common materials used in alternator components: aluminum, copper, steel, and plastic. Each material has distinct characteristics that impact performance, manufacturing, and suitability for various applications.

Quais são as principais propriedades do alumínio nos alternadores?

Aluminum is widely used in alternator housings and components due to its lightweight nature and excellent corrosion resistance. It typically withstands temperatures up to 150°C and has a low density, making it ideal for automotive applications where weight reduction is essential. The material’s thermal conductivity also aids in heat dissipation, which is vital for maintaining performance during operation.

Prós e contras do alumínio:

Aluminum’s primary advantage is its lightweight and corrosion-resistant properties, which enhance fuel efficiency and longevity. However, it can be more expensive than steel and may require specialized manufacturing techniques, which can increase production costs. Additionally, aluminum may not provide the same structural strength as steel in high-stress applications.

How Does Copper Enhance Performance in Alternators?

Copper is predominantly used for windings and electrical connections in alternators due to its excellent electrical conductivity, which is crucial for efficient power generation. It can handle high temperatures and has a melting point of approximately 1,085°C, making it suitable for high-performance applications. Copper also exhibits good resistance to corrosion, particularly when coated.

Prós e contras do cobre:

The key advantage of copper is its superior conductivity, which results in better energy efficiency and performance. However, copper is relatively expensive compared to aluminum and steel, which can be a significant consideration for manufacturers aiming to keep costs down. Additionally, the weight of copper can be a drawback in applications where weight savings are critical.

Illustrative image related to how long should an alternator last in a car

Qual é o papel do aço na fabricação de alternadores?

Steel is often used in alternator frames and brackets due to its high strength and durability. It can withstand significant mechanical stress and is generally less expensive than aluminum and copper. Steel components can also be treated to improve corrosion resistance, extending their lifespan in harsh environments.

Prós e contras do aço:

The main advantage of steel is its strength and cost-effectiveness, making it a popular choice for structural components. However, steel is heavier than aluminum, which can negatively impact vehicle performance. Additionally, if not properly treated, steel can corrode over time, leading to premature failure.

Why Is Plastic Considered for Certain Alternator Components?

Plastic is increasingly used in non-structural components of alternators, such as covers and insulation. It is lightweight, resistant to corrosion, and can be molded into complex shapes, allowing for design flexibility. Plastics can typically withstand temperatures up to 100°C, depending on the type used.

Prós e contras do plástico:

The primary advantage of plastic is its low weight and versatility in design, which can lead to reduced manufacturing costs. However, plastics may not be suitable for high-temperature applications and can degrade over time when exposed to UV light and heat. This limitation can impact the long-term reliability of alternator components.

What Should International B2B Buyers Consider?

When sourcing materials for alternators, international buyers must consider compliance with local standards such as ASTM, DIN, or JIS, which can vary significantly by region. For example, European buyers may prioritize materials that meet stringent environmental regulations, while buyers in Africa and South America may focus on cost-effectiveness and availability. Understanding regional preferences and material performance is essential for successful procurement.

| Material | Typical Use Case for how long should an alternator last in a car | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Caixas e componentes estruturais | Leve e resistente à corrosão | Higher cost and lower strength compared to steel | Médio |

| Cobre | Enrolamentos e ligações elétricas | Excelente condutividade elétrica | Custo e peso elevados | Alto |

| Aço | Frames and brackets | Elevada resistência e rentável | Mais pesado e propenso à corrosão | Baixo |

| Plástico | Coberturas e isolamento | Leve e versátil | Limited temperature resistance and potential degradation | Baixo |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize alternator performance while considering regional requirements and cost factors.

In-depth Look: Manufacturing Processes and Quality Assurance for how long should an alternator last in a car

Quais são as principais fases do processo de fabrico de um alternador?

Manufacturing an alternator involves several critical stages that ensure the final product meets performance expectations and quality standards. These stages include material preparation, forming, assembly, and finishing.

-

Preparação do material: This initial phase involves selecting high-grade materials that can withstand the demanding conditions of automotive use. Common materials include aluminum for the housing and copper for the windings. Suppliers often conduct material inspections to verify compliance with industry standards before usage.

-

Formando: The forming process shapes the raw materials into components of the alternator. Techniques like die-casting for the housing and stamping for internal parts are commonly employed. This stage may also involve machining processes to achieve precise dimensions, critical for the alternator’s performance and longevity.

-

Montagem: After forming, components are assembled into a complete alternator. This stage typically utilizes automated assembly lines to enhance efficiency and consistency. Key components, such as the rotor, stator, and voltage regulator, are carefully assembled to ensure proper electrical and mechanical functionality.

-

Acabamento: The finishing stage includes processes like painting, coating, and testing. Protective coatings are applied to prevent corrosion, while aesthetic finishes may also be considered, particularly for aftermarket applications. This stage also involves initial performance testing to ensure that the alternator meets specified voltage and current output.

How Do Quality Control Procedures Ensure Alternator Longevity?

Quality control (QC) is vital in the manufacturing process of alternators, ensuring that each unit produced is reliable and meets the expected lifespan. International standards such as ISO 9001 guide manufacturers in establishing effective QC protocols.

-

Pontos de controlo chave do CQ:

– Controlo de Qualidade de Entrada (IQC): This checkpoint assesses raw materials for quality and specifications before they are used in production. Ensuring the integrity of materials directly impacts the durability of the final product.

– Controlo de qualidade em processo (IPQC): During the manufacturing process, IPQC involves regular inspections and tests to monitor the assembly and functionality of components. This includes checks for dimensional accuracy and electrical performance.

– Controlo de Qualidade Final (FQC): Before products are shipped, FQC verifies that the completed alternators meet all specifications and performance standards. This may involve functional testing under simulated operating conditions to confirm reliability. -

Métodos de teste comuns: Various testing methods are employed throughout the manufacturing process. These include electrical testing to measure output voltage and current, thermal testing to ensure the unit can operate under high temperatures, and vibration testing to simulate real-world driving conditions.

What International Standards Apply to Alternator Manufacturing Quality Assurance?

B2B buyers must be aware of the international standards that govern the manufacturing and quality assurance of alternators. Compliance with these standards not only assures product quality but also facilitates smoother trade across borders.

Illustrative image related to how long should an alternator last in a car

-

ISO 9001: This widely recognized standard outlines criteria for a quality management system, emphasizing consistent quality and customer satisfaction. Manufacturers adhering to ISO 9001 demonstrate a commitment to quality processes throughout their operations.

-

Marcação CE: For products sold in the European Economic Area (EEA), CE marking indicates conformity with health, safety, and environmental protection standards. This is particularly relevant for buyers in Europe, as compliance is mandatory for market entry.

-

Padrões API: The American Petroleum Institute (API) sets standards that may apply to alternators used in specific industrial applications. Familiarity with these standards can be beneficial for buyers in sectors where oil and gas equipment is involved.

Como podem os compradores B2B verificar os processos de controlo de qualidade dos fornecedores?

To ensure that the alternators purchased meet the required quality standards, B2B buyers should implement thorough verification processes of their suppliers’ QC protocols.

-

Auditorias a fornecedores: Conducting regular audits of suppliers allows buyers to assess compliance with quality standards and manufacturing practices. Audits can include reviewing documentation, inspecting manufacturing facilities, and interviewing quality control personnel.

-

Relatórios de qualidade: Requesting detailed quality reports from suppliers can provide insights into their QC processes and performance metrics. These reports should include data on defect rates, testing results, and compliance with international standards.

-

Inspeções por terceiros: Engaging independent third-party inspection services can offer an unbiased evaluation of the manufacturing process. These inspections can occur at various stages, from raw material sourcing to final product testing, ensuring that all QC checkpoints are met.

Quais são as nuances do controlo de qualidade para compradores B2B internacionais?

B2B buyers from regions like Africa, South America, the Middle East, and Europe must navigate specific quality control nuances when sourcing alternators. Understanding these nuances can lead to better procurement decisions.

-

Normas regionais: Each region may have unique regulations and standards that affect product quality. For instance, buyers in Europe must ensure compliance with CE marking, while those in Africa might prioritize local certifications that reflect regional market requirements.

-

Considerações culturais: Different regions may have varied approaches to quality assurance. Understanding local practices can help buyers communicate effectively with suppliers and ensure that quality expectations are aligned.

-

Logística e cadeia de abastecimento: The logistics of transporting alternators can introduce risks. Buyers should ensure that their suppliers have robust supply chain management practices that account for potential delays or damage during transit, which can affect product quality upon delivery.

By understanding the manufacturing processes and quality assurance measures that govern alternators, B2B buyers can make informed decisions that enhance the reliability and longevity of their automotive components. This knowledge not only aids in selecting reputable suppliers but also helps in establishing long-term relationships that are mutually beneficial.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long should an alternator last in a car’

Introdução

Understanding the lifespan of an alternator is crucial for B2B buyers in the automotive industry. This guide provides a structured checklist for sourcing and evaluating alternators, ensuring that you make informed purchasing decisions that align with your operational needs. By following these steps, you can optimize performance, reduce downtime, and enhance customer satisfaction.

Passo 1: Defina as suas especificações técnicas

Before starting your search, clearly outline the technical specifications needed for your vehicles. Consider factors such as voltage output, amperage requirements, and compatibility with existing vehicle systems. This step is essential to ensure that the alternators you procure meet the operational demands of your fleet.

Passo 2: Research Market Standards and Lifespan

Investigate industry standards regarding alternator lifespan. On average, alternators last around seven years or 150,000 miles; however, this can vary based on vehicle use and environmental conditions. Understanding these benchmarks helps in setting realistic expectations for maintenance and replacement cycles.

Passo 3: Avalie potenciais fornecedores

Thoroughly vet suppliers to ensure they can meet your quality and reliability standards. Request detailed company profiles, product specifications, and case studies from similar businesses. Look for suppliers with a proven track record in your target regions, such as Africa, South America, and Europe, as local expertise can be invaluable.

- Verificar as certificações: Ensure that suppliers hold relevant industry certifications, which signify adherence to quality standards.

- Review Customer Feedback: Analyze testimonials and reviews from previous clients to gauge supplier reliability.

Passo 4: Assess Quality Control Processes

Inquire about the quality control measures employed by your potential suppliers. A robust quality assurance process can significantly impact the longevity and performance of the alternators. Look for suppliers who conduct rigorous testing and inspections throughout the manufacturing process.

Passo 5: Negotiate Terms and Warranty Options

Discuss terms of sale, including pricing, payment options, and delivery schedules. Additionally, ensure you clarify warranty conditions for the alternators. A strong warranty can protect your investment and provide peace of mind, especially if issues arise shortly after purchase.

- Understand Return Policies: Familiarize yourself with the supplier’s return and replacement policies, which can mitigate risks associated with defective products.

Passo 6: Solicitar amostras para teste

Before finalizing your order, request samples of the alternators for testing. This step allows you to verify the quality and compatibility of the products with your vehicles. Conduct thorough performance tests to ensure they meet your operational requirements.

Illustrative image related to how long should an alternator last in a car

Passo 7: Estabeleça uma relação de longo prazo

Once you’ve made your purchase, focus on building a long-term partnership with your suppliers. Regular communication can help address any issues promptly and foster collaboration for future needs. A solid relationship can lead to better pricing, priority service, and more tailored solutions over time.

By following this checklist, B2B buyers can confidently navigate the procurement process for alternators, ensuring they select high-quality components that enhance vehicle performance and reliability.

Comprehensive Cost and Pricing Analysis for how long should an alternator last in a car Sourcing

Quais são os principais componentes de custo no fabrico de alternadores?

Understanding the cost structure for alternators is crucial for B2B buyers looking to source these components effectively. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materiais: The choice of materials significantly influences the cost. High-quality metals, copper wiring, and durable plastics are essential for longevity and performance. Buyers should consider sourcing alternators made from premium materials to ensure reliability, especially in regions with challenging driving conditions.

-

Trabalho: Labor costs vary significantly by region. In developed markets like Germany, labor rates are typically higher compared to regions in Africa or South America. Understanding local labor costs can help buyers negotiate better prices based on where the alternators are manufactured.

-

Custos indiretos de produção: This includes costs related to factory operations such as utilities, rent, and administrative expenses. Companies with lean manufacturing practices can offer more competitive pricing, so investigating a supplier’s operational efficiency can provide insights into potential cost savings.

-

Ferramentas: The initial investment in tooling can be substantial, particularly for custom or specialized alternators. Buyers should inquire about tooling costs, especially if they require unique specifications that may lead to higher initial prices.

-

Controlo de Qualidade (QC): Ensuring that alternators meet quality standards incurs costs that can vary by supplier. Certifications such as ISO or specific automotive standards may add to the price but can also enhance reliability and longevity.

-

Logística: Transportation costs should not be overlooked, especially for international shipments. Factors such as shipping methods, distance, and import duties can significantly affect the overall cost.

-

Margem: Suppliers will typically add a margin to cover their costs and profit. Understanding the market dynamics can help buyers negotiate this margin effectively.

Como os influenciadores de preço afetam os custos do alternador?

Several factors influence the pricing of alternators that B2B buyers should consider:

-

Volume/MOQ: Purchasing in larger quantities often results in lower per-unit costs. Buyers should evaluate their needs and consider bulk purchases to achieve better pricing.

-

Especificações e personalização: Custom alternators tailored to specific vehicle models or applications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materiais e certificações de qualidade: Alternators made from high-grade materials or those that meet specific quality certifications generally command higher prices. Buyers should assess whether the added cost aligns with their performance expectations.

-

Fatores relacionados ao fornecedor: Supplier reputation, production capacity, and reliability can influence pricing. Established suppliers with a track record of quality may charge more but can also reduce the risk of product failure.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is essential for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the overall cost.

What Tips Can Help Buyers Optimize Costs When Sourcing Alternators?

B2B buyers can adopt several strategies to enhance cost-efficiency in sourcing alternators:

-

Negociação: Leverage volume purchases and long-term contracts to negotiate better terms with suppliers. Highlighting competitive quotes from other suppliers can also strengthen your bargaining position.

-

Custo total de propriedade (TCO): Consider the TCO, which includes purchase price, installation costs, maintenance, and potential downtime. Investing in a higher-quality alternator may yield savings over time due to reduced failures and maintenance.

-

Nuances de preços para compradores internacionais: When sourcing from different regions, be aware of currency fluctuations, import tariffs, and regional market conditions. These factors can significantly affect the final price.

-

Avaliação de fornecedores: Conduct thorough research on potential suppliers. Evaluate their production capabilities, quality assurance processes, and customer service. This diligence can lead to better long-term partnerships and cost savings.

Isenção de responsabilidade

The prices and strategies discussed herein are indicative and can vary based on specific circumstances, including market conditions and supplier negotiations. Buyers should conduct due diligence and seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing how long should an alternator last in a car With Other Solutions

Exploring Alternatives to ‘How Long Should an Alternator Last in a Car’

When considering the longevity of an alternator in vehicles, it’s beneficial to explore alternative solutions or technologies that can fulfill similar roles. This analysis provides a comparative overview of the expected lifespan of an alternator against other viable options, helping B2B buyers make informed decisions based on their unique operational needs and financial considerations.

| Aspecto comparativo | How Long Should An Alternator Last In A Car | Lithium-Ion Battery Systems | Regenerative Braking Systems |

|---|---|---|---|

| Desempenho | Average lifespan: 7 years or 150,000 miles | High efficiency, long cycle life | Improves fuel efficiency, reduces wear on brakes |

| Custo | Replacement cost: $300 – $1,000 | Initial cost: $500 – $1,500; lower lifetime costs | Installation cost: $1,000 – $3,000 |

| Facilidade de implementação | Moderate; requires skilled labor for replacement | Complex; requires specialized training for installation | Moderate; can be integrated with existing systems |

| Manutenção | Regular checks recommended; low maintenance | Minimal; regular monitoring needed | Low; routine checks on brake systems required |

| Melhor caso de uso | Standard vehicles needing reliable power generation | Electric vehicles or hybrid systems | Vehicles where fuel efficiency is critical |

Understanding Lithium-Ion Battery Systems

Lithium-ion battery systems have become increasingly popular in electric and hybrid vehicles. They offer a high energy density and longer cycle life compared to traditional lead-acid batteries and alternators. However, their initial costs can be significantly higher, ranging from $500 to $1,500, depending on capacity and technology. While maintenance is minimal, these systems require careful monitoring to avoid performance degradation over time. For B2B buyers in industries focused on eco-friendliness or high-efficiency vehicles, lithium-ion systems may be the most suitable option.

Evaluating Regenerative Braking Systems

Regenerative braking systems are an innovative alternative that captures energy during braking and converts it into electrical energy, which can be reused to power vehicle systems. This technology can enhance fuel efficiency and extend the life of traditional braking components, making it ideal for vehicles operating in stop-and-go environments. The installation costs range from $1,000 to $3,000, and while the integration is moderately complex, the long-term savings in fuel and maintenance can be substantial. B2B buyers in logistics or fleet management may find regenerative braking systems particularly advantageous, as they can lead to significant operational cost reductions.

Conclusion: Selecting the Right Solution for Your Needs

When evaluating the longevity of an alternator against alternative solutions, it’s essential for B2B buyers to consider performance, cost, ease of implementation, maintenance, and the specific use case of their vehicles. Each alternative presents unique advantages and challenges, influencing the overall operational efficiency and cost-effectiveness. By aligning the choice of technology with organizational goals—whether that be sustainability, performance, or cost savings—buyers can make informed decisions that best fit their operational requirements.

Essential Technical Properties and Trade Terminology for how long should an alternator last in a car

Quais são as principais caraterísticas técnicas de um alternador?

When considering the longevity and performance of an alternator, several technical specifications are crucial for B2B buyers to understand. Here are the key properties:

Illustrative image related to how long should an alternator last in a car

-

Grau do material

The materials used in alternator construction significantly affect durability and performance. High-grade aluminum and copper are commonly used due to their excellent conductivity and resistance to corrosion. Choosing an alternator made from quality materials ensures reliability, especially in harsh operating conditions typical in regions like Africa and South America. -

Tensão nominal

Alternators typically operate at a voltage range of 12-14.5 volts for standard automotive applications. Understanding the voltage rating is essential for ensuring compatibility with vehicle electrical systems. An alternator with the correct voltage rating prevents potential overloading or underperformance, which can lead to electrical failures. -

Amperagem de saída

The amperage output, often ranging from 60 to 200 amps, determines how much electrical power the alternator can supply. Businesses need to assess the total electrical load of the vehicle, including aftermarket accessories, to select an alternator that can meet these demands without strain. Insufficient amperage can lead to battery drain and reduced vehicle performance. -

Tipo de rolamento

Alternators may use either ball bearings or sleeve bearings, affecting their lifespan and noise levels. Ball bearings tend to provide a longer service life and less friction, making them preferable in high-performance applications. Understanding bearing types helps buyers select alternators that will endure rigorous usage and minimize maintenance costs. -

Resistência ao calor

The ability of an alternator to withstand high temperatures is critical, especially in environments with extreme heat. Alternators designed with heat-resistant materials and better cooling mechanisms can last longer and operate efficiently. This property is particularly relevant in regions with high ambient temperatures, as it reduces the risk of overheating and subsequent failure. -

Níveis de tolerância

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing of alternators. High tolerance levels ensure that components fit perfectly, reducing the risk of mechanical failure. This aspect is vital for maintaining operational efficiency and prolonging the service life of the alternator.

Quais são os termos comerciais comuns relacionados com alternadores?

Understanding industry jargon can enhance communication and facilitate smoother transactions for B2B buyers. Here are some key terms:

-

OEM (Fabricante de Equipamento Original)

OEM refers to parts made by the vehicle’s manufacturer or an authorized supplier. OEM alternators are designed to meet the exact specifications of the original component, ensuring compatibility and performance. Buyers often prefer OEM parts for their reliability and warranty coverage. -

MOQ (Quantidade mínima de encomenda)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and pricing strategies. Understanding MOQ helps businesses negotiate better deals and manage stock levels effectively. -

RFQ (Pedido de Orçamento)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. B2B buyers use RFQs to compare offers and make informed purchasing decisions. A well-structured RFQ can lead to better pricing and service conditions. -

Incoterms (Termos Comerciais Internacionais)

Incoterms are standardized trade terms used in international contracts to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B transactions, as they clarify costs and risk allocation, especially in cross-border transactions. -

Período de garantia

The warranty period is the duration during which the manufacturer guarantees the alternator’s performance against defects. Understanding warranty terms is essential for B2B buyers to assess long-term value and potential replacement costs. -

Custo do ciclo de vida

Lifecycle cost encompasses the total cost of ownership of an alternator, including purchase price, maintenance, and replacement. This concept is critical for B2B buyers looking to optimize their investments and ensure long-term operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting alternators for their vehicles, ensuring reliability and cost-effectiveness in their operations.

Navigating Market Dynamics and Sourcing Trends in the how long should an alternator last in a car Sector

What Are the Current Market Dynamics and Key Trends Affecting Alternator Lifespan in the Automotive Sector?

The global automotive sector is witnessing significant shifts in market dynamics, particularly regarding the lifespan and maintenance of critical components like alternators. On average, an alternator is expected to last around seven years or approximately 150,000 miles, but this lifespan can vary based on several factors. Increasingly, consumers are opting for vehicles equipped with advanced electronic systems, which place additional demands on alternators. As a result, international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, must consider sourcing high-quality alternators that can withstand the rigors of modern vehicle requirements.

Emerging B2B technology trends, such as predictive maintenance and IoT (Internet of Things) applications, are reshaping how companies approach alternator sourcing. These technologies enable real-time monitoring of vehicle performance, allowing businesses to anticipate alternator failures before they occur, thus minimizing downtime and repair costs. Furthermore, the rise of e-commerce platforms and digital supply chains is facilitating easier access to a diverse range of alternators from global suppliers, streamlining the procurement process for international buyers.

Additionally, the demand for remanufactured alternators is growing, driven by cost-saving measures and sustainability considerations. B2B buyers are increasingly looking for suppliers that can provide remanufactured parts that meet stringent quality standards, offering a more sustainable alternative to new components.

How Are Sustainability and Ethical Sourcing Impacting Alternator Procurement in the Automotive Sector?

Sustainability and ethical sourcing are becoming paramount in the automotive industry, particularly in the context of alternator procurement. The environmental impact of manufacturing processes and the materials used in alternators are critical considerations for B2B buyers. As regulations around emissions and waste management tighten globally, companies are seeking suppliers that prioritize eco-friendly practices, such as using recycled materials and reducing waste during production.

Moreover, ethical supply chains are gaining traction, with buyers demanding transparency regarding the sourcing of materials and labor practices involved in the production of alternators. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming essential for suppliers aiming to demonstrate their commitment to sustainable practices. Buyers from regions like Europe, which often have stricter environmental regulations, are particularly inclined to partner with suppliers that can provide verified green credentials.

The growing focus on sustainability is also influencing product innovation. Manufacturers are exploring new technologies to enhance the efficiency and longevity of alternators, thereby reducing their overall environmental footprint. By investing in sustainable sourcing strategies, B2B buyers can not only meet compliance requirements but also enhance their brand reputation among environmentally-conscious consumers.

Illustrative image related to how long should an alternator last in a car

What Historical Developments Have Shaped Alternator Lifespan Expectations?

The evolution of the alternator can be traced back to its invention in the early 20th century, with significant advancements occurring over the decades. Initially, vehicles utilized generators that required more maintenance and were less efficient than modern alternators. The introduction of the alternator in the 1960s revolutionized automotive electrical systems, providing a more reliable and efficient means of charging batteries and powering vehicle electronics.

In recent years, advancements in materials and technology have further enhanced alternator performance. Innovations such as improved magnetic materials and electronic voltage regulation have contributed to longer lifespans and better efficiency. As automotive technology continues to evolve, particularly with the rise of electric and hybrid vehicles, the expectations surrounding alternator longevity are also shifting, prompting B2B buyers to adapt their sourcing strategies accordingly.

Understanding these historical developments is crucial for international buyers as they navigate the current market landscape. By recognizing the advancements in alternator technology and their implications for lifespan and maintenance, businesses can make informed decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of how long should an alternator last in a car

-

How long should an alternator last in a car?

On average, an alternator is expected to last around 7 years or approximately 150,000 miles. However, several factors can influence this lifespan, including the quality of the alternator, driving conditions, and the electrical demands of the vehicle. In regions with extreme temperatures or heavy usage of electronic accessories, the lifespan may be shorter. Regular maintenance and inspections can help identify potential issues before they lead to failure. -

What are the signs of a failing alternator?

Common signs of a failing alternator include dimming headlights, difficulty starting the car, a burning smell, and dashboard warning lights. Additionally, intermittent electrical issues, such as malfunctioning power windows or audio systems, may indicate alternator problems. If these symptoms are observed, it is crucial to have the alternator inspected promptly to avoid further damage to the vehicle’s electrical system. -

What factors should I consider when sourcing alternators from international suppliers?

When sourcing alternators internationally, consider factors such as the supplier’s reputation, compliance with international quality standards, and the availability of warranties. It’s also essential to assess the supplier’s production capacity, lead times, and ability to provide customization options. Conducting thorough due diligence, including visiting manufacturing facilities if possible, can help ensure a reliable partnership. -

What is the minimum order quantity (MOQ) for alternators when dealing with suppliers?

The minimum order quantity (MOQ) for alternators can vary significantly based on the supplier and the type of alternator required. Some suppliers may have a low MOQ for standard models, while specialized or custom alternators may require larger orders. It’s advisable to negotiate terms that align with your business needs and ensure that you have sufficient demand to justify the order size. -

How can I ensure the quality of alternators purchased from international suppliers?

To ensure quality, request certifications and compliance documents from suppliers that demonstrate adherence to international standards, such as ISO or TS certifications. Additionally, consider conducting third-party inspections before shipment and requesting samples for quality testing. Establishing a clear quality assurance protocol and maintaining open communication with suppliers can also mitigate risks associated with product quality. -

What payment terms are typical when sourcing alternators internationally?

Payment terms can vary but commonly include options such as letter of credit, upfront deposits, or net payment terms after delivery. It is essential to negotiate terms that protect your interests, especially regarding large orders. Utilizing escrow services can also provide additional security during the transaction, ensuring that funds are only released when the goods meet specified criteria. -

How do logistics and shipping impact the sourcing of alternators?

Logistics and shipping play a crucial role in the sourcing process, as they can affect lead times, costs, and product integrity. Consider factors such as shipping methods, customs regulations, and potential delays when planning your orders. Collaborating with experienced logistics partners can help streamline the process and mitigate risks associated with international shipping. -

What should I include in my supplier vetting process for alternators?

Your supplier vetting process should include an assessment of the supplier’s production capacity, quality control measures, financial stability, and customer references. Additionally, evaluating their compliance with international standards and understanding their supply chain transparency can provide insight into their reliability. Conducting site visits and requesting detailed product information can further enhance your evaluation process, ensuring that you partner with trustworthy suppliers.

Top 1 How Long Should An Alternator Last In A Car Manufacturers & Suppliers List

1. Savannah Toyota – Alternator Services

Domínio: savannahtoyota.com

Registado: 1996 (29 anos)

Introdução: The alternator powers all electronics in the vehicle while the engine is running, functioning as a generator using the gas engine as its energy source. Signs of a failing alternator include a battery warning light, dim headlights, burning rubber smell, devices not charging, whining sounds, and inability to start the vehicle. Most alternators last between 80,000 and 150,000 miles (about seven years…

Strategic Sourcing Conclusion and Outlook for how long should an alternator last in a car

In summary, understanding the lifespan of an alternator—typically averaging around seven years or 150,000 miles—is crucial for B2B buyers in the automotive sector. Recognizing the signs of alternator failure can prevent unexpected vehicle downtime and costly repairs, thereby enhancing operational efficiency. Strategic sourcing of high-quality alternators can significantly impact the longevity and reliability of vehicle fleets, especially in regions like Africa, South America, the Middle East, and Europe, where diverse driving conditions can affect component performance.

Investing in quality parts not only ensures better performance but also strengthens supplier relationships and supports sustainable practices in the automotive industry. As you consider your sourcing strategies, prioritize suppliers who offer reliable warranties and robust support services.

Illustrative image related to how long should an alternator last in a car

Looking ahead, the demand for reliable automotive components will only grow. By leveraging strategic sourcing practices, you can position your business to meet these challenges head-on. Engage with trusted manufacturers and suppliers to secure alternators that meet the rigorous demands of your market. Make informed decisions today to drive your business forward tomorrow.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.