Introduction: Navigating the Global Market for how do you tell if a starter is bad

In the dynamic landscape of global business, understanding how to tell if a starter is bad is crucial for companies relying on automotive components for their operations. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the stakes are high when it comes to sourcing reliable automotive parts. A faulty starter can lead to significant downtime and increased operational costs, making it essential for businesses to identify potential issues before they escalate.

This comprehensive guide delves into the various signs of a failing starter, including key symptoms such as unusual noises, dashboard alerts, and slow engine cranking. Additionally, we will explore the different types of starters available in the market, their applications across various vehicle models, and the importance of proper maintenance to extend their lifespan.

Furthermore, we provide actionable insights on supplier vetting processes, helping businesses make informed decisions when sourcing parts. By understanding the costs associated with starter replacements and the nuances of quality assurance, B2B buyers can mitigate risks and ensure operational efficiency. This guide serves as a valuable resource for international buyers, empowering them to navigate the complexities of the automotive parts market confidently and effectively.

Índice

- Top 2 How Do You Tell If A Starter Is Bad Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do you tell if a starter is bad

- Understanding how do you tell if a starter is bad Types and Variations

- Key Industrial Applications of how do you tell if a starter is bad

- 3 Common User Pain Points for ‘how do you tell if a starter is bad’ & Their Solutions

- Strategic Material Selection Guide for how do you tell if a starter is bad

- In-depth Look: Manufacturing Processes and Quality Assurance for how do you tell if a starter is bad

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you tell if a starter is bad’

- Comprehensive Cost and Pricing Analysis for how do you tell if a starter is bad Sourcing

- Alternatives Analysis: Comparing how do you tell if a starter is bad With Other Solutions

- Essential Technical Properties and Trade Terminology for how do you tell if a starter is bad

- Navigating Market Dynamics and Sourcing Trends in the how do you tell if a starter is bad Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do you tell if a starter is bad

- Strategic Sourcing Conclusion and Outlook for how do you tell if a starter is bad

- Aviso legal importante e termos de utilização

Understanding how do you tell if a starter is bad Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Testes elétricos | Uses voltmeters to measure voltage levels at the starter and battery. | Oficinas de reparação automóvel, manutenção de frotas | Prós: Accurate diagnosis, prevents misdiagnosis. Contras: Requires specialized equipment and knowledge. |

| Inspeção visual | Involves checking for physical damage, oil leaks, and corrosion. | Vehicle inspection services, maintenance providers | Prós: Rápido e económico. Contras: May miss internal issues not visible externally. |

| Sound Diagnosis | Listening for clicking, grinding, or no sound when starting. | Mechanic shops, automotive training programs | Prós: Simple and quick assessment. Contras: Subjective; may require experience to interpret correctly. |

| Jump-Start Method | Attempts to start the vehicle using another vehicle’s battery. | Automotive assistance services, roadside help | Prós: Immediate solution for battery issues. Contras: Not effective if the starter is faulty; risk of electrical damage. |

| Systematic Troubleshooting | Comprehensive testing of the entire starting system for faults. | Automotive diagnostics firms, fleet services | Prós: Thorough and accurate diagnosis. Contras: Time-consuming and may require advanced tools. |

What Are the Characteristics of Electrical Testing for Starters?

Electrical testing is a diagnostic method that uses voltmeters to check the voltage levels at the starter and battery. This technique is particularly useful in B2B settings such as automotive repair shops and fleet maintenance operations, where accurate diagnostics are essential for efficient vehicle management. Buyers should consider the cost of specialized equipment and the need for trained personnel to interpret the results correctly. This method helps in preventing misdiagnosis, saving time and resources.

How Does Visual Inspection Help in Identifying Starter Issues?

Visual inspection involves a straightforward examination of the starter and surrounding components for signs of damage, oil leaks, or corrosion. This method is commonly employed by vehicle inspection services and maintenance providers, offering a quick and cost-effective way to identify potential starter problems. While visual inspection can rapidly highlight external issues, it may not detect internal faults, making it crucial for buyers to combine this method with more in-depth diagnostics for comprehensive assessments.

Why Is Sound Diagnosis Important in Starter Evaluation?

Sound diagnosis relies on listening for specific noises when attempting to start the vehicle, such as clicking or grinding sounds. This approach is often used in mechanic shops and automotive training programs, as it provides a simple and quick way to assess starter functionality. While it is an accessible method, its subjective nature can lead to misinterpretation, especially for those without extensive experience. B2B buyers should ensure their technicians are trained in sound diagnosis to maximize its effectiveness.

What Are the Benefits and Limitations of the Jump-Start Method?

The jump-start method involves using another vehicle’s battery to start a non-functioning vehicle. It is often utilized by automotive assistance services and roadside help teams as a quick fix for battery issues. While this method can provide immediate relief, it is ineffective if the starter itself is faulty, and there is a risk of causing electrical damage if not performed correctly. B2B buyers should weigh the convenience of this method against its limitations and consider having a backup plan for persistent starting issues.

How Effective Is Systematic Troubleshooting for Starters?

Systematic troubleshooting is a comprehensive approach that tests the entire starting system for faults, ensuring accurate diagnosis. This method is valuable for automotive diagnostics firms and fleet services, as it addresses potential issues holistically. Although thorough, this approach can be time-consuming and may require advanced diagnostic tools. Buyers should factor in the time and resources needed for systematic troubleshooting, as it is often the most reliable way to ensure long-term vehicle performance and reliability.

Key Industrial Applications of how do you tell if a starter is bad

| Indústria/Setor | Specific Application of how do you tell if a starter is bad | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Oficinas de reparação automóvel | Diagnosticar problemas de arranque em veículos | Reduz o tempo de inatividade e melhora a satisfação do cliente | Access to quality diagnostic tools and starter replacement parts |

| Transporte e Logística | Ensuring fleet vehicle reliability | Minimiza as interrupções operacionais e os custos de manutenção | Bulk purchasing agreements for starters and diagnostic equipment |

| Equipamento de construção | Evaluating starter functionality in heavy machinery | Enhances equipment uptime and productivity | Compatibilidade com várias marcas e modelos de máquinas |

| Agricultural Sector | Assessing starter performance in farming equipment | Increases efficiency of operations and reduces repair costs | Availability of specialized starter parts for diverse equipment |

| Operações mineiras | Monitoring starter health in mining vehicles | Improves safety and reduces unplanned maintenance | Sourcing durable starters suitable for harsh environments |

How Do Automotive Repair Shops Utilize Starter Diagnostics?

Automotive repair shops are critical in diagnosing starter issues in vehicles. By recognizing the symptoms of a bad starter, such as clicking noises or dashboard light indicators, mechanics can quickly identify the problem, leading to efficient repairs. This not only enhances customer satisfaction but also reduces vehicle downtime. For international buyers, sourcing quality diagnostic tools and reliable starter replacement parts is essential to ensure that they can effectively service diverse vehicle makes and models.

What Role Does Starter Diagnosis Play in Transportation and Logistics?

In the transportation and logistics sector, ensuring the reliability of fleet vehicles is paramount. Regularly diagnosing starter issues helps fleet managers mitigate the risk of operational disruptions caused by vehicle failures. By investing in bulk purchasing agreements for starters and diagnostic equipment, companies can effectively manage maintenance costs and ensure that their fleet remains operational. This is especially important for buyers in regions with challenging terrains, where reliable vehicle performance is crucial.

How Is Starter Assessment Critical in Construction Equipment?

In the construction industry, evaluating starter functionality in heavy machinery is vital for maintaining operational efficiency. Equipment failures can lead to significant project delays and increased costs. By implementing regular starter diagnostics, construction firms can ensure that their machinery operates reliably, thereby enhancing productivity. Buyers need to consider compatibility with various brands and models of machinery when sourcing starter parts to avoid costly delays in repairs.

Why Is Starter Performance Important in Agriculture?

In the agricultural sector, assessing starter performance in farming equipment is essential for maximizing efficiency. Equipment failure can result in lost productivity during critical planting and harvesting seasons. By understanding how to diagnose starter issues, agricultural businesses can minimize repair costs and ensure that their equipment is always ready for use. Buyers should seek specialized starter parts that cater to the diverse range of equipment used in agriculture to maintain operational efficiency.

How Does Starter Monitoring Affect Mining Operations?

In mining operations, monitoring starter health in vehicles is crucial for ensuring safety and minimizing unplanned maintenance. A malfunctioning starter can halt operations, posing risks to both equipment and personnel. By implementing a systematic approach to diagnosing starter issues, mining companies can enhance their operational reliability. Sourcing durable starters that can withstand harsh mining conditions is a key consideration for international buyers looking to maintain safety and efficiency in their operations.

3 Common User Pain Points for ‘how do you tell if a starter is bad’ & Their Solutions

Scenario 1: Inconsistent Performance of Fleet Vehicles

O problema: For businesses relying on a fleet of vehicles, consistent performance is crucial. A bad starter can lead to unexpected vehicle failures, resulting in delayed deliveries and increased operational costs. Fleet managers often struggle to identify the early signs of a failing starter, leading to unplanned downtime and repair expenses. This inconsistency can damage customer relationships and impact overall productivity.

A solução: To mitigate this issue, fleet managers should implement a proactive maintenance schedule that includes regular inspections of the starting system. Train staff to recognize early signs of starter failure, such as dashboard warning lights, unusual clicking sounds, and slow cranking. Additionally, investing in diagnostic tools like a voltmeter can help determine battery health and whether the issue lies with the battery or the starter itself. Establish partnerships with reliable automotive service providers who can conduct thorough checks and timely repairs. By addressing potential starter issues early, fleet managers can maintain operational efficiency and reduce unexpected costs.

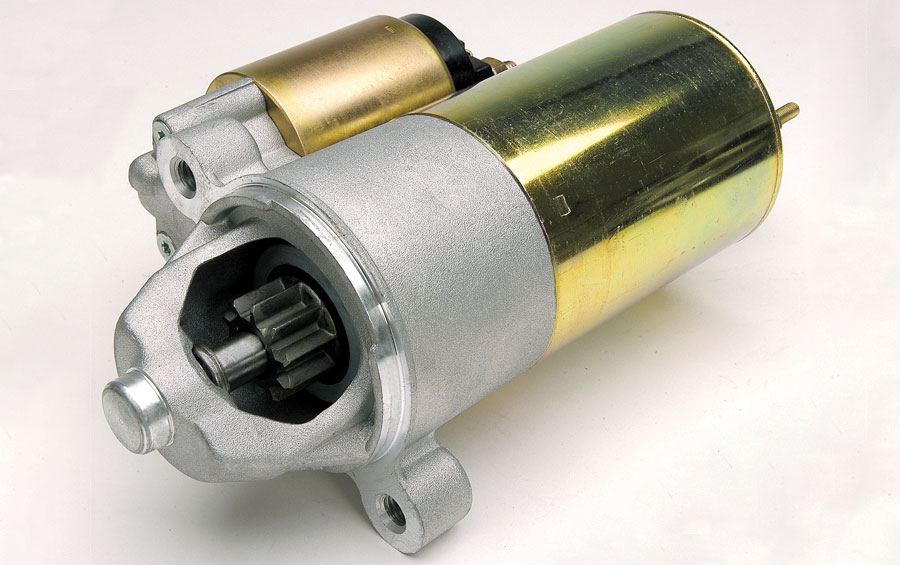

Illustrative image related to how do you tell if a starter is bad

Scenario 2: Difficulty in Diagnosing Starter Issues vs. Battery Problems

O problema: Many businesses face the challenge of distinguishing between battery issues and starter failures. When a vehicle fails to start, the confusion can lead to misdiagnosis, resulting in unnecessary repairs and costs. This scenario is particularly prevalent in regions where access to skilled automotive technicians is limited, and untrained staff may struggle to identify the root cause of the problem.

A solução: To overcome this challenge, companies should invest in training programs for their maintenance teams to enhance their diagnostic skills. Equip them with diagnostic tools, including voltmeters and multimeters, to accurately test battery voltage and starter functionality. A systematic approach to troubleshooting can be established: first, check the battery’s voltage; if it reads above 12.6 volts, the battery is likely fine. Next, listen for clicks or grinding noises when attempting to start the engine, which can indicate starter issues. By empowering staff with the right knowledge and tools, companies can reduce diagnostic errors and streamline their repair processes.

Scenario 3: High Repair Costs from Ignoring Starter Maintenance

O problema: Many businesses overlook the importance of regular starter maintenance, often focusing solely on more visible components like tires and brakes. This neglect can lead to catastrophic failures, resulting in high repair costs and extended vehicle downtime. For businesses operating in competitive markets, such delays can significantly impact profitability and service delivery.

A solução: Implementing a comprehensive maintenance program that includes routine inspections of the starter system can help mitigate these risks. This program should encompass regular checks for electrical connections, battery health, and oil leaks that may affect the starter. Additionally, businesses can benefit from documenting maintenance activities and repairs to identify patterns that may indicate recurring issues. Engaging with suppliers who offer high-quality starter components can also lead to longer-lasting performance, reducing the frequency of repairs. By prioritizing preventative maintenance, businesses can minimize unexpected breakdowns and associated costs, ultimately enhancing their operational reliability.

Strategic Material Selection Guide for how do you tell if a starter is bad

What Materials Are Best for Diagnosing Starter Issues?

When assessing the performance of a starter motor, the materials used in its components can significantly affect its reliability and diagnostic capabilities. Here, we analyze four common materials that are integral to understanding how to tell if a starter is bad.

Copper: The Standard for Electrical Conductivity

Principais propriedades: Copper is renowned for its excellent electrical conductivity, making it the preferred choice for starter motor wiring and connections. It can withstand high temperatures and has a melting point of about 1,984°F (1,085°C).

Prós e contras: The primary advantage of copper is its superior conductivity, which ensures minimal energy loss during operation. However, copper is prone to corrosion, especially in humid climates, which can lead to electrical failures. Additionally, its cost can be higher than alternatives like aluminum.

Impacto na aplicação: In regions with high humidity, such as parts of Africa and South America, copper’s susceptibility to corrosion may necessitate additional protective coatings or treatments. This can influence maintenance schedules and overall lifecycle costs.

Considerações para compradores internacionais: Compliance with standards like ASTM B187 is crucial when sourcing copper components. Buyers should also consider local environmental conditions that may affect copper’s longevity.

Alumínio: uma alternativa leve

Principais propriedades: Aluminum is lightweight and has good corrosion resistance, with a melting point around 1,221°F (660.3°C). It is often used in starter housings and components.

Prós e contras: The main advantage of aluminum is its low weight, which can contribute to overall vehicle efficiency. However, while it is corrosion-resistant, it does not conduct electricity as well as copper, which can lead to inefficiencies in electrical performance.

Impacto na aplicação: In regions where weight reduction is crucial for fuel efficiency, such as in Europe, aluminum’s properties can be beneficial. However, its lower conductivity might require thicker wires or larger connectors, which could complicate design.

Considerações para compradores internacionais: Buyers should ensure that aluminum components meet standards like DIN EN 573 for material quality. Additionally, the cost-effectiveness of aluminum in comparison to copper can be a deciding factor in budget-sensitive markets.

Steel: The Durable Choice for Structural Integrity

Principais propriedades: Steel, particularly high-carbon steel, offers remarkable strength and durability, with a melting point of approximately 2,500°F (1,370°C). It is often used in starter motor casings and gears.

Prós e contras: Steel’s primary advantage is its strength, which provides structural integrity to starter motors. However, it is heavier than both copper and aluminum and is prone to rusting if not properly coated.

Impacto na aplicação: In rugged environments, such as those found in parts of Nigeria or Brazil, the durability of steel can be a significant asset. However, its weight may affect vehicle dynamics and fuel efficiency.

Illustrative image related to how do you tell if a starter is bad

Considerações para compradores internacionais: Compliance with standards like ASTM A36 for structural steel is essential. Buyers should also consider the additional costs associated with protective coatings to prevent rust.

Plastic Composites: The Insulating Option

Principais propriedades: Plastic composites are used for insulation and housing components in starters. They are lightweight and can withstand moderate temperatures, typically up to 200°F (93°C).

Prós e contras: The primary advantage of plastic composites is their excellent insulation properties, which help prevent electrical shorts. However, they may not withstand extreme temperatures or mechanical stress as well as metals.

Impacto na aplicação: In regions with high humidity or temperature fluctuations, plastic composites can provide effective insulation. However, their limitations in extreme conditions may require careful selection based on local climate.

Considerações para compradores internacionais: Buyers should ensure that plastic composites meet relevant standards, such as JIS K 6920 for thermoplastics. Understanding local temperature ranges is crucial for selecting appropriate materials.

Tabela resumida

| Material | Typical Use Case for how do you tell if a starter is bad | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Fiação e ligações elétricas | Condutividade elétrica superior | Suscetível à corrosão | Alto |

| Alumínio | Componentes de alojamento e leves | Leve e resistente à corrosão | Condutividade inferior à do cobre | Médio |

| Aço | Componentes estruturais e invólucros | Alta resistência e durabilidade | Mais pesado e com tendência para a ferrugem | Médio |

| Compósitos plásticos | Isolamento e alojamento | Excelente isolamento elétrico | Resistência limitada à temperatura | Baixo |

This analysis provides a comprehensive overview for B2B buyers looking to understand the implications of material selection in starter motors, particularly in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for how do you tell if a starter is bad

Quais são as principais etapas do processo de fabrico de arrancadores?

Manufacturing a starter involves several critical stages, each requiring precision and adherence to quality standards to ensure the final product’s reliability and performance. The main stages include material preparation, forming, assembly, and finishing.

1. Material Preparation:

The manufacturing process begins with the careful selection of materials. Key components of a starter include copper for wiring, high-grade steel for the casing, and durable plastics for insulation. Suppliers must ensure that raw materials meet specific quality standards, such as ASTM or ISO certifications. Material inspection is a crucial step, where incoming materials undergo rigorous testing for quality and compliance.

2. Forming:

In this stage, raw materials are shaped into components using techniques such as stamping, casting, and machining. Stamping is commonly used for metal parts, while casting might be employed for the housing. Advanced CNC machining tools are often utilized to achieve precise dimensions and tolerances, which are critical for the starter’s overall functionality.

3. Assembly:

Assembly involves bringing together the various components of the starter. This stage often requires skilled labor and automated systems to ensure that each part is correctly fitted. The assembly line may incorporate robotics for repetitive tasks, enhancing efficiency and reducing human error. Each assembly step is documented to trace the process for future quality control assessments.

4. Finishing:

The final stage involves applying protective coatings, such as paint or galvanization, to prevent corrosion and enhance durability. This stage may also include electrical testing to ensure that the starter meets performance standards. Finishing touches can include labeling and packaging, preparing the product for shipment.

What International Standards Are Relevant to Starter Manufacturing Quality Control?

Quality assurance in starter manufacturing is governed by various international standards. For B2B buyers, understanding these standards is crucial for ensuring that the products meet safety, reliability, and performance expectations.

ISO 9001:

This standard outlines a framework for quality management systems (QMS). Manufacturers adhering to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Buyers should look for suppliers with ISO 9001 certification as it indicates a commitment to continuous improvement and customer satisfaction.

Marcação CE:

For products sold in Europe, CE marking signifies compliance with EU safety, health, and environmental protection standards. It is essential for B2B buyers in Europe to verify that their suppliers have obtained CE certification for starters to ensure they meet regulatory requirements.

Padrões API:

The American Petroleum Institute (API) sets standards for oil and gas industry equipment, including starters used in heavy machinery. Compliance with API standards indicates that the product is suitable for demanding industrial applications.

What Quality Control Checkpoints Should Be Considered in Starter Manufacturing?

Quality control (QC) is integral to the manufacturing process, ensuring that each starter meets the necessary performance criteria. Key QC checkpoints include:

1. Incoming Quality Control (IQC):

Before production begins, raw materials are subjected to IQC. This process involves inspecting and testing materials to ensure they meet predefined specifications. Any substandard materials are rejected, preventing defects in the final product.

2. In-Process Quality Control (IPQC):

During the manufacturing process, IPQC checkpoints are established to monitor production quality. This includes regular inspections of components at various stages of assembly and forming. Statistical process control (SPC) methods may be employed to analyze production data and identify any trends that could indicate potential quality issues.

3. Final Quality Control (FQC):

Once the assembly is complete, FQC is conducted to verify that the finished starters meet all performance specifications. This may include functional testing, electrical testing, and visual inspections. A comprehensive report is generated, documenting the results of these tests.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

For B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital. Here are some actionable strategies:

1. Supplier Audits:

Conducting on-site audits allows buyers to evaluate a supplier’s manufacturing processes and quality control measures directly. During an audit, buyers can assess the adherence to international standards and review documentation related to IQC, IPQC, and FQC.

Illustrative image related to how do you tell if a starter is bad

2. Quality Reports:

Requesting detailed quality reports from suppliers can provide insights into their QC processes. These reports should include information about testing methodologies, frequency of inspections, and any corrective actions taken in response to quality issues.

3. Third-Party Inspections:

Engaging third-party inspection services can provide an impartial assessment of a supplier’s quality control processes. These services can conduct random inspections during production and before shipment, offering additional assurance of quality compliance.

Quais são as nuances de controle de qualidade e certificação para compradores B2B internacionais?

B2B buyers in different regions must be aware of specific nuances in quality control and certification processes. For instance, regulatory requirements may vary significantly between regions, impacting the certification process.

Requisitos de conformidade regionais:

In Africa and South America, buyers should be familiar with local regulations and standards that apply to automotive components. Certifications that are recognized in Europe, such as CE marking, may not be as stringent in other regions. Understanding these differences is essential for risk management.

Considerações culturais:

Cultural attitudes toward quality can also vary. In some regions, there may be a greater emphasis on formal certifications, while in others, relationships and trust may play a more significant role. Buyers should consider these factors when evaluating potential suppliers.

Documentação e rastreabilidade:

Ensuring that suppliers maintain comprehensive documentation is critical for traceability. Buyers should request documentation related to the sourcing of materials, manufacturing processes, and quality control measures. This information is essential for compliance audits and for addressing any potential quality issues that arise post-purchase.

By understanding the manufacturing processes and quality assurance measures for starters, B2B buyers can make informed decisions that enhance product reliability and performance, ultimately leading to greater customer satisfaction and reduced operational risks.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you tell if a starter is bad’

In the automotive industry, accurately identifying a failing starter is crucial for efficient operations and customer satisfaction. This guide serves as a practical checklist for B2B buyers looking to understand how to tell if a starter is bad, ensuring that they can make informed decisions when sourcing starter components or services.

Passo 1: Recognize Common Symptoms of Starter Failure

Understanding the signs of a faulty starter is essential for timely intervention. Look for symptoms such as:

– Dashboard Lights: If the dashboard lights illuminate but the engine does not crank, this may indicate a bad starter.

– Clicking Noises: A clicking sound when turning the key often points to starter issues, while silence may also signify failure.

Passo 2: Conduct a Preliminary Electrical Check

Before assuming the starter is faulty, assess the vehicle’s electrical system. This step is vital because many starting issues stem from weak batteries or poor connections.

– Battery Voltage: Use a voltmeter to check the battery’s voltage. A reading below 12.3 volts usually means the battery needs charging or replacement.

– Connection Inspection: Examine battery cables and connections for corrosion or looseness, as these can impede power flow to the starter.

Illustrative image related to how do you tell if a starter is bad

Passo 3: Perform a Physical Inspection of the Starter

A visual check of the starter can reveal significant issues. Inspecting the starter can prevent unnecessary replacements and costs.

– Oil Soaking: Look for oil leaks around the starter. Oil can damage electrical components, leading to premature failure.

– Physical Condition: Check for signs of wear, burn marks, or physical damage, which can indicate a need for replacement.

Passo 4: Evaluate the Starter’s Response to Jump Starting

If initial checks are inconclusive, try jump-starting the vehicle. This method can help determine if the starter is the issue or if another component is at fault.

– Observing Behavior: If the engine turns over with a jump but fails to start afterward, the battery may be the culprit, not the starter.

– Temporary Fixes: If the starter engages but the engine still does not run, further diagnostics are necessary to confirm starter failure.

Passo 5: Consult with Trusted Suppliers or Mechanics

When a starter issue is confirmed, consulting with experienced suppliers or automotive professionals is critical. Their expertise can guide you in sourcing quality components or services.

– Credenciais de fornecedor: Verify the supplier’s reputation and certifications to ensure they provide reliable products.

– Suporte técnico: Seek suppliers that offer technical assistance or warranties, which can safeguard your investment.

Passo 6: Plan for Replacement or Repair

Deciding whether to replace or repair a starter involves evaluating costs and expertise. Understanding this step can help minimize downtime and maintain operational efficiency.

– Cost Comparison: Weigh the cost of parts and labor against potential repairs. Often, replacement is more cost-effective in the long run.

– DIY vs. Professional Service: Assess your team’s capabilities. If in-house expertise is lacking, hiring a professional may be more prudent.

Passo 7: Implement Preventive Maintenance Practices

To avoid future starter issues, establish a regular maintenance schedule. This proactive approach can extend the life of starters and related components.

– Regular Inspections: Schedule routine checks of electrical connections and battery health.

– Leak Monitoring: Keep an eye on potential oil leaks that could affect the starter’s performance.

Illustrative image related to how do you tell if a starter is bad

By following this checklist, B2B buyers can efficiently diagnose starter issues, ensuring the reliability of their automotive operations and enhancing customer service.

Comprehensive Cost and Pricing Analysis for how do you tell if a starter is bad Sourcing

Understanding the cost and pricing structure for identifying and sourcing solutions related to bad starters is crucial for international B2B buyers. This analysis breaks down the primary cost components, price influencers, and offers strategic tips for negotiation and cost efficiency.

Quais são os principais componentes de custo no fornecimento inicial?

-

Materiais: The cost of raw materials used in starter production, such as metals (copper, aluminum), plastics, and electronic components, significantly affects the overall price. Quality materials may incur higher initial costs but can lead to longer-lasting products, impacting the Total Cost of Ownership (TCO).

-

Trabalho: Labor costs vary by region and can affect the final pricing of starters. In regions with higher labor costs, such as parts of Europe, manufacturers may charge more. However, cheaper labor markets (e.g., parts of Africa and South America) can lead to lower production costs, influencing pricing strategies.

-

Custos indiretos de produção: This includes costs associated with factory operations, utilities, equipment maintenance, and administration. Efficient manufacturing processes can help minimize overhead, allowing suppliers to offer competitive pricing.

-

Ferramentas: Initial tooling costs for starter production can be substantial, especially for custom designs. Buyers should consider how these costs are amortized over production runs, as higher volume orders can lead to lower per-unit costs.

-

Controlo de Qualidade (QC): Implementing rigorous QC processes ensures product reliability. However, enhanced QC measures can increase costs. Buyers should assess whether the additional expense aligns with their quality standards and risk tolerance.

-

Logística: Transportation and shipping costs are vital components, particularly for international buyers. The choice of Incoterms can affect who bears the cost of shipping, insurance, and customs duties, impacting the final price.

-

Margem: Supplier profit margins can vary significantly based on market conditions, competition, and perceived product value. Understanding these factors can provide insight into pricing flexibility during negotiations.

How Do Price Influencers Impact Starter Sourcing?

-

Volume e quantidade mínima de encomenda (MOQ): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better prices and manage inventory effectively.

-

Especificações e personalização: Custom starters designed for specific vehicle models may incur higher costs. Buyers should weigh the benefits of customized solutions against standard options.

-

Qualidade dos materiais e certificações: Products with certifications (e.g., ISO, CE) may come at a premium but often offer assurances of quality and reliability. Buyers should assess the importance of these certifications in their purchasing decisions.

-

Fatores relacionados ao fornecedor: The supplier’s reputation, reliability, and historical performance can influence pricing. Established suppliers may charge more due to perceived reliability, while emerging suppliers might offer lower prices to gain market entry.

-

Incoterms: The choice of Incoterms can significantly affect the landed cost of products. Buyers should be familiar with terms like FOB, CIF, and EXW to negotiate effectively and understand their total costs, including shipping and handling.

What Are Some Effective Buyer Tips for Negotiating Starter Prices?

-

Negocie com sabedoria: Engage suppliers in discussions about pricing and be prepared to leverage volume commitments or long-term contracts for better rates.

-

Foco no custo total de propriedade (TCO): Evaluate not just the initial purchase price but also the expected lifespan, maintenance costs, and potential downtime related to starter failures. This holistic view can justify higher upfront costs for more durable products.

-

Compreender as nuances dos preços regionais: Be aware of regional differences in manufacturing costs and labor rates. For instance, sourcing from lower-cost regions may offer substantial savings, but consider the trade-offs in quality and logistics.

-

Criar relações com os fornecedores: Strong relationships can lead to better pricing, priority service, and favorable payment terms. Consider long-term partnerships rather than one-off transactions.

-

Mantenha-se informado sobre as tendências do mercado: Keep an eye on shifts in material costs, labor markets, and global supply chain dynamics. This knowledge can empower buyers to negotiate more effectively and anticipate price changes.

Conclusão

In navigating the complexities of sourcing starters, international B2B buyers must consider a multifaceted approach to cost and pricing analysis. By understanding the key components, influencers, and strategic negotiation tips, buyers can make informed decisions that optimize both cost efficiency and product reliability. Always remember to account for potential fluctuations in pricing and to negotiate terms that safeguard your interests in the ever-evolving global market.

Alternatives Analysis: Comparing how do you tell if a starter is bad With Other Solutions

Introduction: Exploring Alternatives for Diagnosing Starter Issues

When it comes to diagnosing a bad starter in a vehicle, traditional methods often rely on mechanical expertise and manual troubleshooting. However, with advancements in technology, several alternative solutions have emerged that can streamline this process. Understanding these alternatives can empower B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, to make informed decisions that optimize their operations and reduce downtime.

Tabela comparativa

| Aspecto comparativo | How Do You Tell If A Starter Is Bad | Ferramentas de diagnóstico (por exemplo, multímetro) | Professional Diagnostics (Mechanic Services) |

|---|---|---|---|

| Desempenho | Effective for basic diagnostics | High accuracy in electrical issues | Análise exaustiva dos sistemas do veículo |

| Custo | Low (DIY approach) | Moderate (cost of tools) | High (labor costs plus diagnostics) |

| Facilidade de implementação | Requer conhecimentos básicos de mecânica | Requires basic electrical knowledge | Minimal effort for the vehicle owner |

| Manutenção | Requires ongoing knowledge updates | Minimal (tools are durable) | No maintenance required by the vehicle owner |

| Melhor caso de uso | Quick, initial troubleshooting | Detailed electrical diagnostics | Full vehicle assessment, including starters |

Discriminação detalhada das alternativas

1. Diagnostic Tools (e.g., Multimeter)

Using diagnostic tools like a multimeter allows for an accurate assessment of the starter’s electrical performance. This method measures voltage, current, and resistance, helping to determine whether the starter or another component, such as the battery, is at fault. The advantage of using a multimeter is its precision and ability to diagnose a range of electrical issues beyond just the starter. However, this method requires some technical knowledge and familiarity with electrical systems, which may pose a challenge for less experienced users.

Illustrative image related to how do you tell if a starter is bad

2. Professional Diagnostics (Mechanic Services)

Engaging a professional mechanic for diagnostics provides a thorough evaluation of the entire vehicle’s starting system. Mechanics have access to advanced diagnostic equipment and extensive experience, allowing them to identify issues that may not be visible through simpler methods. While this approach offers the highest accuracy and reliability, it comes at a higher cost, which can be a significant factor for businesses operating on tight budgets. Additionally, relying on external services may lead to longer downtime, which can impact operational efficiency.

Conclusão: escolhendo a solução certa para as suas necessidades

For B2B buyers, the choice between traditional starter diagnostics and alternative methods boils down to a balance of cost, expertise, and urgency. If your organization has in-house mechanical knowledge, utilizing basic troubleshooting techniques may be sufficient for quick assessments. However, for those lacking technical expertise or facing complex issues, investing in diagnostic tools or professional services can provide greater accuracy and reliability. Ultimately, understanding the specific needs and capabilities of your team will guide you in selecting the most effective solution to maintain vehicle reliability and minimize downtime.

Essential Technical Properties and Trade Terminology for how do you tell if a starter is bad

What Are the Key Technical Properties to Identify a Bad Starter?

Understanding the technical specifications of a starter motor is essential for B2B buyers, especially when sourcing replacement parts or evaluating supplier offerings. Here are some critical specifications:

-

Grau do material

The material used in the construction of the starter motor significantly impacts its durability and performance. Common materials include high-grade steel for the housing and copper for the windings. A higher material grade typically indicates better corrosion resistance and longevity, which is crucial for automotive applications in diverse climates, especially in regions like Africa and South America where environmental conditions can vary widely. -

Classificação de binário

The torque rating refers to the amount of rotational force the starter can generate to crank the engine. This specification is vital because insufficient torque can lead to starting failures, particularly in larger engines or in colder climates. Buyers should ensure that the starter they select meets or exceeds the OEM specifications for torque to guarantee reliable performance. -

Tensão nominal

Most automotive starters operate on a 12V system, but variations exist. Understanding the voltage requirements is critical, as mismatched voltage can lead to starter failure or damage to the vehicle’s electrical system. B2B buyers must verify that the voltage rating aligns with the vehicle’s specifications to avoid costly repairs. -

Consumo de corrente

This specification indicates how much electrical current the starter consumes during operation, typically measured in amperes. A starter with a lower current draw can help reduce strain on the vehicle’s battery, enhancing overall efficiency. For businesses operating fleets, lower current draw starters can lead to reduced battery wear and maintenance costs. -

Gama de temperaturas

Starters are subjected to various temperatures during operation. Knowing the operational temperature range ensures that the starter can withstand extremes without failure. This is particularly relevant for buyers in regions with extreme weather conditions, as a starter that operates efficiently in high temperatures may not perform well in colder climates, and vice versa.

Quais são os termos comerciais comuns relacionados com motores de arranque?

Understanding industry jargon is essential for effective communication and negotiation in the automotive parts market. Here are some common terms:

-

OEM (Fabricante de Equipamento Original)

OEM parts are components made by the original manufacturer of the vehicle, ensuring compatibility and quality. B2B buyers often prefer OEM parts for their reliability, as they are designed to meet the exact specifications required by the vehicle manufacturer. -

MOQ (Quantidade mínima de encomenda)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to manage inventory effectively and avoid overstocking or understocking parts, particularly in regions where demand may fluctuate. -

RFQ (Pedido de Orçamento)

An RFQ is a document sent to suppliers requesting price quotes for specific products or services. This term is vital for B2B buyers as it initiates the procurement process and allows businesses to compare pricing and terms from multiple suppliers. -

Incoterms (Termos Comerciais Internacionais)

These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers navigate shipping, insurance, and logistics, reducing the risk of disputes. -

Prazo de entrega

Lead time is the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for B2B buyers to plan their inventory and ensure that they can meet customer demand without delays.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing starters, ensuring they select products that meet their operational needs and standards.

Navigating Market Dynamics and Sourcing Trends in the how do you tell if a starter is bad Sector

What Are the Current Market Dynamics Affecting the Starter Industry?

The global automotive starter market is witnessing significant transformations driven by advancements in technology and changing consumer preferences. One of the primary drivers is the increasing demand for electric vehicles (EVs) and hybrid models, which utilize more sophisticated starter systems. This trend is particularly evident in regions like Europe, where regulatory frameworks are pushing for greener alternatives. Additionally, the rise in automotive electronics and smart technologies is leading to more complex starter systems, requiring B2B buyers to source components that align with these innovations.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are also influencing sourcing strategies. Companies are increasingly utilizing data analytics to predict starter failures before they occur, enhancing the maintenance process and reducing downtime. In regions like Africa and South America, where infrastructure may be lacking, mobile diagnostics and remote monitoring solutions are becoming vital for fleet management, enabling businesses to maintain optimal performance.

Furthermore, international trade dynamics are shifting. Tariffs, trade agreements, and geopolitical factors are affecting sourcing strategies for buyers in different regions. For instance, companies in Brazil and Nigeria may face challenges in sourcing reliable starter components from international suppliers due to fluctuating import regulations. Therefore, establishing local partnerships and understanding regional market nuances is crucial for B2B buyers aiming to navigate these complexities effectively.

How Important Is Sustainability and Ethical Sourcing in the Starter Supply Chain?

Sustainability and ethical sourcing are increasingly critical considerations for B2B buyers in the automotive sector, particularly in the context of starter components. The environmental impact of manufacturing processes, including the extraction of raw materials and energy consumption, is under scrutiny. Buyers are now expected to prioritize suppliers that adhere to sustainable practices, such as reducing carbon footprints and minimizing waste.

Moreover, the importance of ethical supply chains cannot be overstated. Companies are being held accountable for their sourcing decisions, with consumers and regulators alike demanding transparency. For instance, B2B buyers should look for suppliers who can provide certifications that verify the environmental and ethical standards of their materials. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ labels are becoming essential for demonstrating commitment to sustainability.

In addition to environmental considerations, ethical sourcing practices enhance brand reputation and foster customer loyalty. By aligning with suppliers that prioritize social responsibility, B2B buyers can contribute to fair labor practices and community development, particularly in emerging markets. This holistic approach not only mitigates risks but also positions companies as leaders in responsible sourcing, appealing to a growing segment of eco-conscious consumers.

How Has the Starter Industry Evolved Over Time?

The evolution of the starter industry has been marked by technological advancements and changing automotive needs. Initially, starters were simple mechanical devices powered by direct battery connections. Over the decades, as vehicles became more complex, starters evolved into sophisticated electrical components integrated with various automotive systems.

The introduction of electronic ignition systems in the late 20th century marked a significant turning point, allowing starters to be controlled electronically rather than mechanically. This transition improved reliability and efficiency, paving the way for the development of starter systems that are now crucial for modern vehicles, including those with advanced fuel injection and hybrid technologies.

Today, the starter industry continues to adapt to the demands of electric and hybrid vehicles, necessitating innovations in design and materials. As manufacturers work towards producing lighter, more efficient starters, the focus has shifted towards ensuring compatibility with evolving automotive technologies. This evolution highlights the importance for B2B buyers to stay informed about the latest trends and advancements in starter technology to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of how do you tell if a starter is bad

-

How do I identify the symptoms of a bad starter?

A bad starter may present several symptoms, including a clicking sound when turning the ignition key, a slow cranking engine, or the engine failing to crank at all. Dashboard warning lights may illuminate without the engine starting, indicating potential electrical issues. Inspecting the starter for oil leaks or signs of overheating is crucial, as these factors can significantly affect its performance. If you notice any of these signs, it is advisable to consult a professional mechanic for a thorough diagnosis. -

What is the best approach to sourcing quality starters for my business?

To source quality starters, start by identifying reputable suppliers with a proven track record in the automotive industry. Conduct thorough research on their product offerings, customer reviews, and certifications. Establish communication to inquire about their quality assurance processes, warranty terms, and compliance with international standards. Request samples to evaluate the product’s reliability and performance before making bulk purchases, ensuring they align with your business requirements. -

How can I ensure the starters I buy meet international quality standards?

To ensure starters meet international quality standards, verify that your suppliers adhere to recognized certifications such as ISO 9001 or TS16949. Request documentation that demonstrates compliance with these standards. Additionally, consider conducting factory audits or inspections to assess their manufacturing processes. Collaborating with suppliers who have a strong commitment to quality control will help mitigate risks associated with subpar products. -

What factors should I consider when negotiating payment terms with suppliers?

When negotiating payment terms, consider factors such as your cash flow, supplier reliability, and order size. Common payment terms include net 30, 60, or 90 days, depending on the supplier’s policies and your negotiation leverage. Discuss options for partial payments upon order confirmation and the remaining balance upon delivery to balance risk. Ensure that payment methods are secure and convenient for both parties, potentially including options like letters of credit or escrow services for larger transactions. -

What is the typical minimum order quantity (MOQ) for starters?

The minimum order quantity (MOQ) for starters can vary significantly between suppliers, typically ranging from 50 to 500 units. Factors influencing MOQ include the supplier’s production capacity, inventory levels, and the specific type of starter being ordered. Always clarify MOQs during initial discussions and consider negotiating lower quantities for first-time orders or trial runs. This approach allows you to assess product quality and market demand without committing to large inventory investments. -

How do I vet suppliers for reliability in the starter parts market?

To vet suppliers, conduct comprehensive background checks, focusing on their business history, reputation, and customer feedback. Utilize platforms like Alibaba or Global Sources to read reviews and ratings. Request references from previous clients, and inquire about their experiences with product quality and customer service. Additionally, assess the supplier’s financial stability, manufacturing capabilities, and adherence to delivery schedules to ensure a reliable partnership. -

Que considerações logísticas devo ter em conta ao importar fermentos?

When importing starters, consider shipping methods, lead times, and customs regulations in your country. Evaluate freight options, such as sea or air freight, based on urgency and cost-effectiveness. Ensure your suppliers can provide the necessary shipping documents, including bills of lading and customs declarations. Additionally, familiarize yourself with import duties and taxes to avoid unexpected costs. Partnering with a logistics provider experienced in automotive parts can streamline the process and reduce complications. -

How can I customize starters to meet specific requirements for my market?

Customizing starters involves collaborating closely with your supplier to discuss specific requirements such as voltage, size, or performance specifications. Ensure the supplier has the capability to produce custom parts and inquire about their design and prototyping processes. Providing detailed specifications and possibly sketches can help convey your vision. Be prepared for potential minimum order increases and longer lead times for customized products. Regular communication during the development phase is key to achieving the desired outcome.

Top 2 How Do You Tell If A Starter Is Bad Manufacturers & Suppliers List

1. Reddit - Diagnóstico de mau arranque

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: Esta empresa, Reddit - Bad Starter Diagnosis, é uma entidade notável no mercado. Para obter informações específicas sobre o produto, recomenda-se que visite diretamente o seu sítio Web.

2. Ford – Trucks and Parts

Strategic Sourcing Conclusion and Outlook for how do you tell if a starter is bad

In conclusion, understanding how to identify a bad starter is crucial for minimizing downtime and ensuring the reliability of your operations. Key indicators such as dashboard warning lights, clicking sounds, and slow cranking can provide early warnings of starter issues. By proactively monitoring these symptoms and conducting regular maintenance on electrical connections and battery health, businesses can extend the lifespan of their starter systems and avoid costly repairs.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing is essential. Engaging with reliable suppliers who provide quality starter components can enhance your operational efficiency. Leveraging relationships with trusted manufacturers not only guarantees product quality but also fosters a more resilient supply chain.

As you navigate the complexities of sourcing automotive parts, consider investing in comprehensive training for your teams to improve diagnostics and maintenance practices. This forward-thinking approach not only mitigates risks associated with starter failures but also positions your business for long-term success. Stay vigilant, prioritize quality, and ensure your operations remain uninterrupted by potential starter issues.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.