Introduction: Navigating the Global Market for automotive alternator parts

Navigating the global market for automotive alternator parts can be a daunting task for B2B buyers, especially when it comes to sourcing high-quality components that meet diverse regional demands. With the automotive industry experiencing rapid growth across Africa, South America, the Middle East, and Europe, the need for reliable alternator parts is more critical than ever. Whether you are servicing light trucks, commercial vehicles, or industrial machinery, understanding the intricacies of alternator components—from repair kits to remanufactured units—can significantly impact your operational efficiency and profitability.

This comprehensive guide is designed to equip international B2B buyers with essential insights into the automotive alternator parts market. We delve into various types of parts available, their applications across different vehicle categories, and the importance of selecting trustworthy suppliers. Furthermore, we will discuss strategies for vetting suppliers to ensure quality and compliance, as well as provide a breakdown of cost considerations to help you make informed purchasing decisions.

By leveraging the information contained in this guide, buyers from Nigeria to Germany will be empowered to navigate the complexities of the automotive alternator parts landscape confidently. This resource not only addresses the challenges faced in sourcing quality parts but also highlights opportunities for strategic partnerships and long-term success in the global market.

Índice

- Top 4 Automotive Alternator Parts Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automotive alternator parts

- Understanding automotive alternator parts Types and Variations

- Key Industrial Applications of automotive alternator parts

- 3 Common User Pain Points for ‘automotive alternator parts’ & Their Solutions

- Strategic Material Selection Guide for automotive alternator parts

- In-depth Look: Manufacturing Processes and Quality Assurance for automotive alternator parts

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive alternator parts’

- Comprehensive Cost and Pricing Analysis for automotive alternator parts Sourcing

- Alternatives Analysis: Comparing automotive alternator parts With Other Solutions

- Essential Technical Properties and Trade Terminology for automotive alternator parts

- Navigating Market Dynamics and Sourcing Trends in the automotive alternator parts Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automotive alternator parts

- Strategic Sourcing Conclusion and Outlook for automotive alternator parts

- Aviso legal importante e termos de utilização

Understanding automotive alternator parts Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Alternadores padrão | OEM specifications, various amperage ratings | Veículos de passageiros, camiões ligeiros | Prós: Económica e fiável. Contras: Limited customization options. |

| Alternadores de alta potência | Enhanced amperage (up to 240A), designed for performance | Racing, heavy electrical load applications | Prós: Increased performance, supports high-demand electronics. Contras: Higher cost, may require additional modifications. |

| Alternadores remanufaturados | Rebuilt from original parts, tested for quality | Budget-conscious buyers, fleet maintenance | Prós: Económico e amigo do ambiente. Contras: Potential variability in quality, shorter lifespan than new units. |

| Alternator Repair Kits | Comprehensive kits with essential components for rebuilding | Entusiastas da bricolage, pequenas oficinas de reparação | Prós: Cost savings on repairs, customizable. Contras: Requires technical knowledge for assembly. |

| Alternadores para trabalhos pesados | Built to withstand harsh conditions, typically used in commercial vehicles | Heavy trucks, agricultural machinery | Prós: Durability, reliability under extreme conditions. Contras: Higher initial investment, heavier weight. |

Quais são as características dos alternadores padrão?

Standard alternators are designed to meet OEM specifications and come in a variety of amperage ratings suitable for a wide range of vehicles, including passenger cars and light trucks. They are typically more cost-effective, making them a popular choice for B2B buyers looking for reliable replacements without extensive customization. When purchasing, consider the specific amperage required for the vehicle’s electrical system to ensure optimal performance.

How Do High-Output Alternators Differ from Standard Options?

High-output alternators are engineered to deliver significantly more amperage, often exceeding 240A. This makes them ideal for applications requiring additional electrical power, such as racing or vehicles with heavy electronic loads. Buyers should assess the vehicle’s electrical demands and compatibility, as these alternators may necessitate modifications to the installation setup. While they offer enhanced performance, their higher cost and potential need for additional modifications are key considerations.

O que devem os compradores saber sobre os alternadores remanufacturados?

Remanufactured alternators are refurbished units made from original parts, tested to ensure they meet performance standards. They offer a budget-friendly option for businesses focused on cost savings, especially in fleet maintenance. However, variability in quality can be a concern, and they may not last as long as new units. Buyers should check warranty terms and consider the specific performance needs of their vehicles.

Why Choose Alternator Repair Kits for DIY Projects?

Alternator repair kits provide all the essential components needed for rebuilding an alternator, making them ideal for DIY enthusiasts and small repair shops. These kits can lead to significant cost savings compared to purchasing new or remanufactured units. However, buyers should possess the technical skills required for assembly, as improper installation can lead to performance issues. Assessing the complexity of the repair and the availability of tools is crucial before purchasing.

What Are the Benefits of Heavy-Duty Alternators?

Heavy-duty alternators are designed to endure extreme conditions and are commonly used in commercial vehicles and agricultural machinery. Their robust construction ensures reliability and performance in demanding environments. While they offer exceptional durability, the initial investment is higher than standard models, and their weight can be a factor in vehicle design. Businesses should weigh the long-term benefits of reliability against the upfront costs when considering heavy-duty options.

Key Industrial Applications of automotive alternator parts

| Indústria/Setor | Specific Application of Automotive Alternator Parts | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Fabricação Automotiva | Production of OEM alternators for vehicles | Ensures reliability and performance in new vehicles | Certificação de qualidade, compatibilidade com vários modelos |

| Heavy Machinery & Construction | Powering hydraulic systems and electrical tools | Aumenta a eficiência operacional e reduz o tempo de inatividade | Heavy-duty specifications, rugged design, warranty terms |

| Agricultura | Alternators for farming equipment | Supports continuous operation in remote areas | Availability of specific voltage ratings, reliability under harsh conditions |

| Marine & Power Sports | Alternators for boats and recreational vehicles | Improves energy management for onboard systems | Water-resistance, compatibility with marine standards |

| Energia renovável | Alternators in wind and solar energy systems | Enables efficient energy conversion and storage | Performance under variable conditions, durability, and serviceability |

How Are Automotive Alternator Parts Used in Automotive Manufacturing?

In the automotive manufacturing sector, automotive alternator parts are crucial for producing original equipment manufacturer (OEM) alternators. These alternators convert mechanical energy into electrical energy, powering various vehicle systems. Manufacturers prioritize high-quality components to ensure reliability and performance in new vehicles, which is vital for brand reputation and customer satisfaction. For international buyers, particularly in regions like Germany or Nigeria, sourcing OEM-quality alternators requires attention to compatibility with diverse vehicle models and adherence to global quality standards.

What Role Do Automotive Alternator Parts Play in Heavy Machinery & Construction?

In heavy machinery and construction, automotive alternator parts are employed to power hydraulic systems and electrical tools essential for operations. These alternators enhance operational efficiency by providing reliable power, minimizing downtime during critical projects. Buyers in this sector must consider heavy-duty specifications and rugged designs to withstand harsh working conditions. Additionally, warranty terms and service support are key factors, especially for international buyers who may face logistical challenges in sourcing replacement parts.

How Do Automotive Alternator Parts Support Agriculture?

Agricultural machinery relies heavily on automotive alternator parts to ensure continuous operation, particularly in remote areas where access to power sources is limited. These alternators power essential equipment like irrigation systems and harvesters, directly impacting productivity and yield. For international buyers, particularly from regions like South America, it’s essential to source alternators with specific voltage ratings and robust designs that can endure harsh environmental conditions, ensuring longevity and reliability in the field.

Why Are Automotive Alternator Parts Important in Marine & Power Sports?

In the marine and power sports industry, automotive alternator parts are vital for managing energy on boats and recreational vehicles. These alternators improve energy management for onboard systems such as navigation, lighting, and communication devices. Buyers must ensure that the sourced parts are water-resistant and comply with marine standards to prevent corrosion and failure. The importance of reliability is heightened in this sector, as equipment failure can lead to significant safety risks and operational disruptions.

How Are Automotive Alternator Parts Utilized in Renewable Energy Systems?

Automotive alternator parts are increasingly integrated into renewable energy systems, such as wind and solar energy setups. They play a critical role in converting mechanical energy into electrical energy, facilitating efficient energy storage and management. For international buyers, particularly in regions focusing on sustainable energy solutions, it’s crucial to source alternators that perform well under variable environmental conditions and offer durability. The capacity for serviceability and maintenance support is also a key consideration, ensuring long-term operational efficiency.

3 Common User Pain Points for ‘automotive alternator parts’ & Their Solutions

Scenario 1: Sourcing Quality Alternator Parts in Emerging Markets

O problema: B2B buyers in regions such as Africa and South America often struggle to find high-quality automotive alternator parts due to limited local suppliers and the prevalence of counterfeit products. This can lead to purchasing components that fail prematurely, resulting in costly repairs and diminished trust from their customers. For many businesses, the risk of downtime or vehicle breakdowns caused by subpar parts can severely impact their operations and bottom line.

A solução: To mitigate this risk, buyers should establish relationships with reputable suppliers who specialize in OEM (Original Equipment Manufacturer) quality parts. Conducting thorough research to identify suppliers with a strong track record and positive reviews in the industry is crucial. Additionally, leveraging international trade platforms can help connect buyers with established manufacturers who offer warranties and guarantees on their products. It is also beneficial to request detailed documentation and testing certifications for the alternator parts to ensure they meet quality standards before making a purchase.

Scenario 2: Understanding Compatibility Issues with Alternators

O problema: Another common challenge for B2B buyers is the compatibility of alternator parts with various vehicle models. Buyers often face difficulties in identifying which parts are suitable for specific makes and models, leading to incorrect orders and wasted resources. This issue is exacerbated when dealing with multiple vehicle lines or older models that may have less readily available information on part specifications.

A solução: To address compatibility concerns, buyers should utilize detailed catalogs and digital databases that provide comprehensive information on vehicle specifications and part compatibility. Many suppliers offer online tools that allow users to input vehicle identification numbers (VINs) to ensure they are ordering the correct parts. Additionally, engaging with knowledgeable technical support teams from suppliers can provide valuable insights and assistance in selecting the right alternator parts. Keeping an updated inventory management system that tracks part numbers and vehicle applications can further streamline the ordering process and reduce errors.

Scenario 3: Navigating Repair and Rebuild Options for Alternators

O problema: B2B buyers often grapple with the decision of whether to repair or replace alternators, particularly in situations where the cost of new parts is high. This dilemma is especially pronounced for businesses in regions with tight budgets or fluctuating economic conditions. Buyers may be unsure about the most cost-effective and reliable options for prolonging the life of alternators while maintaining performance standards.

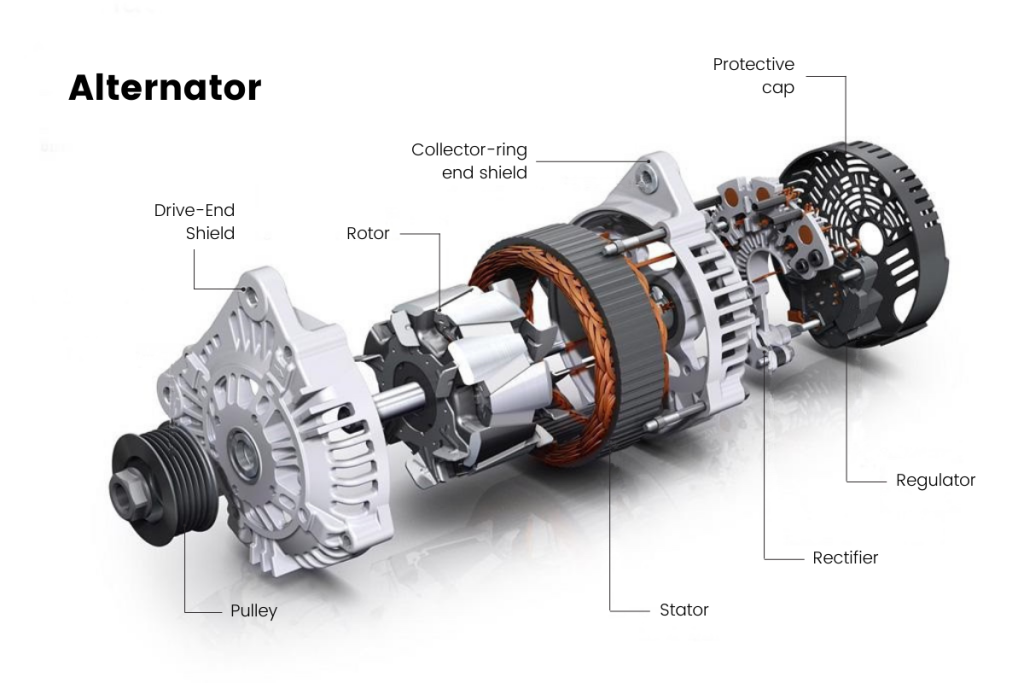

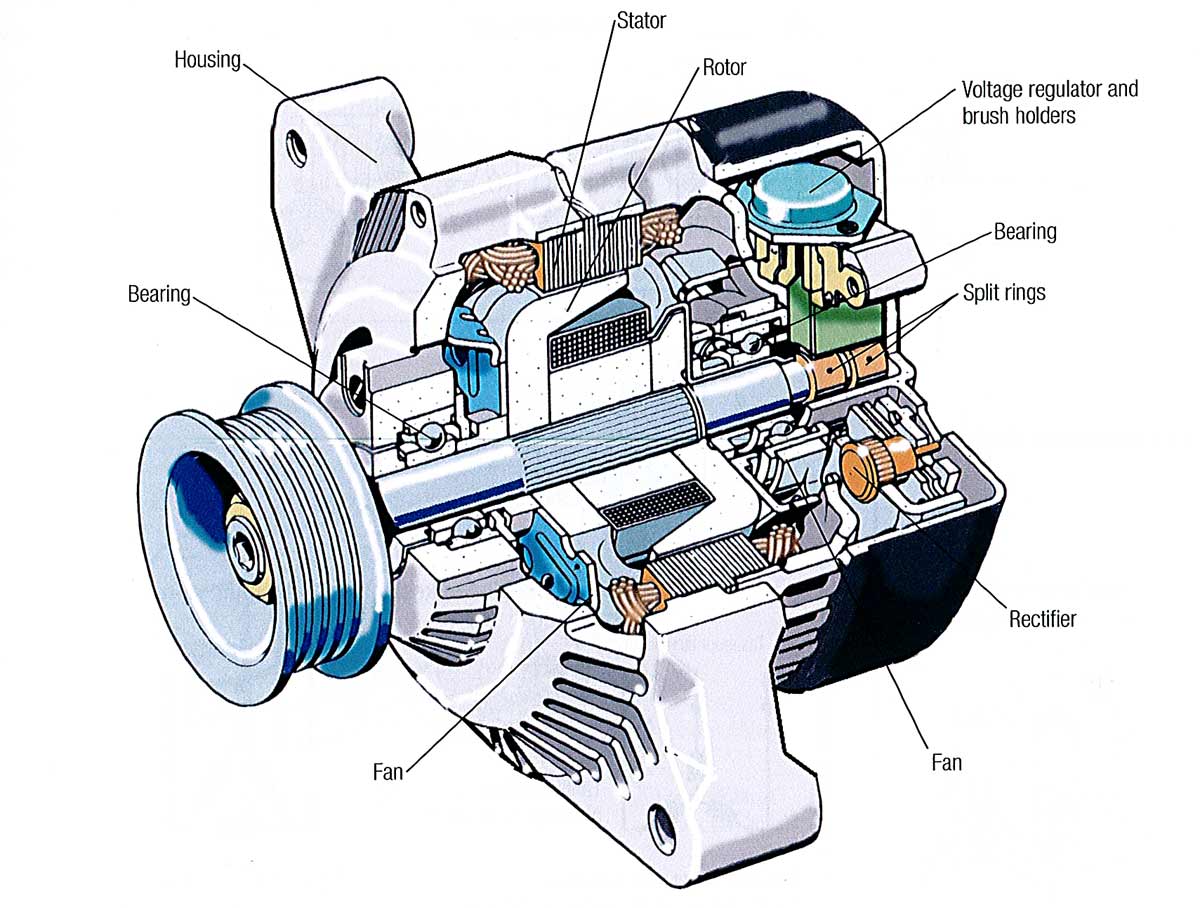

A solução: Buyers should assess the total cost of ownership (TCO) when considering repair versus replacement options. Investing in high-quality repair kits that include essential components such as heavy-duty regulators, rectifiers, and bearings can often provide a more economical solution compared to purchasing entirely new units. Furthermore, establishing relationships with specialized rebuilders who can provide expert service and warranties on their work can enhance confidence in the longevity of repaired alternators. Documenting the performance of repaired units through testing before reinstallation can also ensure reliability and assist in making informed decisions for future repairs.

Strategic Material Selection Guide for automotive alternator parts

What Are the Key Materials Used in Automotive Alternator Parts?

When selecting materials for automotive alternator parts, it’s essential to consider the properties that directly impact performance, durability, and cost. Here, we analyze four common materials used in alternator components: aluminum, copper, steel, and plastic.

How Does Aluminum Benefit Automotive Alternator Parts?

Aluminum is frequently used in the housings and brackets of alternators due to its lightweight and excellent thermal conductivity. It typically has a temperature rating of around 150°C, making it suitable for high-performance applications.

Prós: Aluminum is resistant to corrosion, which is crucial for vehicles operating in diverse climates, particularly in regions with high humidity or saline environments like coastal areas in Africa and South America. Its lightweight nature contributes to overall vehicle efficiency.

Contras: While aluminum is durable, it can be more expensive than some alternatives and may require specialized manufacturing processes, which can increase production costs.

Impacto na aplicação: Aluminum’s compatibility with various media makes it suitable for automotive applications, but care must be taken to avoid galvanic corrosion when paired with dissimilar metals.

Considerações para compradores internacionais: Compliance with standards such as ASTM and DIN is vital. Buyers from Europe, for instance, may prioritize materials that meet stringent environmental regulations.

Que papel desempenha o cobre no desempenho do alternador?

Copper is predominantly used in windings and connectors due to its superior electrical conductivity, which is essential for efficient energy transfer. It can withstand high temperatures, typically rated up to 200°C.

Prós: Copper’s excellent conductivity ensures minimal energy loss, enhancing alternator efficiency. Additionally, its durability and resistance to fatigue make it ideal for high-load applications.

Contras: The primary drawback is its cost, as copper is significantly more expensive than alternatives like aluminum. Furthermore, it is prone to corrosion if not adequately protected.

Impacto na aplicação: Copper’s compatibility with high electrical loads makes it ideal for performance-oriented alternators, but it requires careful handling in humid environments to prevent oxidation.

Considerações para compradores internacionais: Buyers should verify compliance with electrical standards and consider the availability of copper in their local markets, particularly in regions where sourcing might be challenging.

Porque é que o aço é utilizado nos componentes do alternador?

Steel is often utilized in structural components such as the rotor and stator frames due to its strength and rigidity. It typically has a temperature resistance of around 300°C, making it suitable for high-stress applications.

Prós: Steel’s high tensile strength and durability make it ideal for heavy-duty applications. It is also generally more cost-effective than aluminum and copper.

Illustrative image related to automotive alternator parts

Contras: Steel is heavier than aluminum and can be susceptible to corrosion if not properly treated. This can be a significant drawback in applications where weight savings are critical.

Impacto na aplicação: Steel’s robustness is beneficial for alternators in commercial vehicles, but its weight can negatively impact fuel efficiency in passenger vehicles.

Considerações para compradores internacionais: Compliance with international standards such as ASTM and JIS is crucial, especially for buyers in Europe and the Middle East, where quality assurance is paramount.

How Does Plastic Fit into the Design of Alternators?

Plastic is commonly used in non-load-bearing components such as covers and insulators due to its lightweight and insulating properties. It can withstand temperatures up to 120°C.

Illustrative image related to automotive alternator parts

Prós: Plastic is cost-effective and can be molded into complex shapes, allowing for design flexibility. Its insulating properties are beneficial for electrical safety.

Contras: Plastic is less durable compared to metals and can degrade over time, especially under high-temperature conditions.

Impacto na aplicação: While plastic is suitable for covers and non-structural components, it may not be appropriate for high-stress areas of the alternator.

Considerações para compradores internacionais: Buyers should ensure that the plastics used comply with environmental regulations, particularly in Europe, where there is a strong emphasis on sustainability.

Summary Table of Material Selection for Automotive Alternator Parts

| Material | Typical Use Case for automotive alternator parts | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Caixas, suportes | Leve, resistente à corrosão | Higher cost, complex manufacturing | Médio |

| Cobre | Windings, connectors | Excelente condutividade | Expensive, prone to corrosion | Alto |

| Aço | Rotor, stator frames | Alta resistência, rentável | Heavy, corrosion risk | Baixo |

| Plástico | Coberturas, isoladores | Cost-effective, design flexibility | Less durable, temperature limitations | Baixo |

This guide provides a comprehensive overview of material selection for automotive alternator parts, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for automotive alternator parts

Manufacturing automotive alternator parts involves a series of well-defined processes that ensure high performance and reliability. For B2B buyers, understanding these processes is crucial for making informed decisions when selecting suppliers. This section outlines the key stages of manufacturing, quality assurance measures, and how buyers can verify the quality of alternator parts.

What Are the Main Stages of Manufacturing Automotive Alternator Parts?

The manufacturing process for automotive alternator parts typically comprises four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Automotive Alternator Parts?

Material preparation is the foundation of any manufacturing process. For alternators, high-grade materials such as aluminum, copper, and various alloys are commonly used. These materials are selected for their electrical conductivity, mechanical strength, and resistance to corrosion.

Illustrative image related to automotive alternator parts

- Material Sourcing: Suppliers often procure raw materials from certified vendors to ensure quality. B2B buyers should inquire about the origin of materials and any certifications they hold.

- Testes: Before use, materials undergo rigorous testing to verify their properties. Common tests include tensile strength, conductivity, and corrosion resistance.

What Techniques Are Used in Forming Automotive Alternator Parts?

The forming stage involves shaping the raw materials into components that will be assembled into the final product.

- Elenco: Components such as the alternator housing are often produced through die casting, which allows for complex shapes and high precision.

- Maquinação: Parts like rotors and stators are machined to achieve the required dimensions and tolerances. CNC (Computer Numerical Control) machining is commonly used for its accuracy and efficiency.

- Estampagem: Metal stamping is frequently used for producing flat parts, such as end plates and brackets, ensuring uniformity and reducing waste.

How Are Automotive Alternator Parts Assembled?

Assembly is a critical stage where individual components come together to form the complete alternator.

- Manual and Automated Assembly: Depending on the manufacturer, assembly may be a manual, automated, or hybrid process. Automated assembly lines enhance efficiency and reduce labor costs.

- Subconjunto: Components like voltage regulators and rectifiers may be pre-assembled before final assembly, ensuring that each part is tested for functionality prior to incorporation into the alternator.

What Are the Key Finishing Techniques for Automotive Alternator Parts?

Finishing involves applying surface treatments and coatings to enhance durability and aesthetics.

- Coatings: Processes such as anodizing or powder coating are often used to improve corrosion resistance and surface finish. These treatments are especially important for alternator parts exposed to harsh environments.

- Testing for Electrical Performance: Before packaging, alternators undergo electrical testing to ensure they meet performance specifications. This includes checking output voltage, current capacity, and overall functionality.

What Quality Assurance Measures Are Common in Automotive Alternator Manufacturing?

Quality assurance is integral to the manufacturing process, ensuring that all alternator parts meet international standards and customer expectations.

What Are the Relevant International Standards for Automotive Alternator Parts?

For B2B buyers, understanding quality standards is essential for supplier evaluation. Key international standards include:

- ISO 9001: This standard focuses on quality management systems and is widely adopted across industries, including automotive manufacturing. Compliance indicates that a manufacturer has established processes for consistent quality.

- Marcação CE: In Europe, CE marking signifies that products meet safety, health, and environmental protection standards. B2B buyers in Europe should prioritize suppliers with CE-certified products.

What Industry-Specific Quality Checks Are Conducted?

In addition to international standards, several industry-specific checks are important.

- Certificação API: In certain markets, API (American Petroleum Institute) certification is required for components used in automotive electrical systems, ensuring that they meet specific performance criteria.

- ISO/TS 16949: This standard is specific to the automotive industry, emphasizing defect prevention and the reduction of variation and waste in the supply chain.

Como são estabelecidos os pontos de controlo de qualidade no processo de fabrico?

Quality control checkpoints are critical throughout the manufacturing process to ensure compliance with standards.

- Controlo de Qualidade de Entrada (IQC): This checkpoint occurs at the start of the manufacturing process, where raw materials are inspected for quality before they are used.

- Controlo de qualidade em processo (IPQC): During manufacturing, various checkpoints are established to monitor the process, ensuring that each component meets specifications before moving to the next stage.

- Controlo de Qualidade Final (FQC): The final stage involves comprehensive testing of the assembled alternator. This includes performance testing and visual inspections to identify any defects.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is vital.

What Audit Processes Should Buyers Consider?

- Auditorias a fornecedores: Conducting on-site audits can provide insights into a supplier’s quality assurance processes. Buyers should look for evidence of compliance with relevant standards and effective quality control systems.

- Relatórios de qualidade: Requesting detailed quality reports can help assess the reliability of the supplier. These reports should include data on defect rates, testing methodologies, and compliance with international standards.

Qual o papel das inspecções por terceiros?

Engaging third-party inspection services can add an additional layer of assurance. These independent entities can verify that manufacturing processes and products meet specified standards, providing unbiased evaluations.

Quais são as nuances do QC/CERT para os compradores B2B internacionais?

Navigating quality certification requirements can be complex, especially for international transactions. B2B buyers should be aware of:

- Normas regionais: Different regions may have specific requirements that affect certification. For instance, buyers in Europe must be familiar with CE marking, while those in North America might focus on ANSI or SAE standards.

- Documentação: Ensuring that suppliers provide proper documentation for certifications can streamline the import process and mitigate risks associated with compliance failures.

By understanding the manufacturing processes and quality assurance measures for automotive alternator parts, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet international standards and deliver high-quality products.

Illustrative image related to automotive alternator parts

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive alternator parts’

To assist B2B buyers in sourcing automotive alternator parts effectively, this guide provides a step-by-step checklist designed to streamline the procurement process. By following these actionable steps, buyers can ensure they obtain high-quality parts that meet their technical requirements while fostering strong supplier relationships.

Passo 1: Defina as suas especificações técnicas

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements. This includes understanding the types of vehicles you are sourcing for, the specific alternator models needed, and any performance standards that must be met.

– Considerações:

– Voltage and amperage specifications.

– Compatibility with existing vehicle systems.

Passo 2: Pesquisar fornecedores de renome

Identifying reliable suppliers is critical to ensuring quality and consistency. Conduct thorough research to compile a list of potential suppliers known for their quality automotive parts.

– Acções-chave:

– Look for suppliers with a robust online presence and positive reviews.

– Utilize industry trade shows or online platforms to find reputable manufacturers.

Passo 3: Avaliar as certificações dos fornecedores

To ensure you are dealing with a professional and compliant supplier, verify their certifications and quality standards. This step is crucial in minimizing risks associated with substandard parts.

– O que verificar:

– ISO certifications or other relevant quality management systems.

– Compliance with regional regulations, especially in your target markets.

Passo 4: Solicitar amostras para teste

Once you have shortlisted potential suppliers, request samples of the alternator parts. Testing samples is vital to ensure they meet your quality standards and technical specifications before making a larger commitment.

– Testing Focus:

– Assess durability and performance under operational conditions.

– Confirm compatibility with the intended vehicle models.

Passo 5: Negociar condições e preços

Engaging in negotiations is a critical step in establishing a beneficial relationship with your supplier. Discuss pricing, payment terms, and delivery timelines to ensure they align with your business needs.

– Negotiation Points:

– Volume discounts for larger orders.

– Warranty terms and after-sales support.

Passo 6: Estabelecer um protocolo de comunicação

Effective communication is key to a successful sourcing relationship. Establish a clear protocol for regular updates and issue resolution to avoid misunderstandings.

– Communication Best Practices:

– Determine preferred channels (e.g., email, phone).

– Set expectations for response times and regular check-ins.

Passo 7: Monitorizar o desempenho dos fornecedores

After placing orders, monitor the supplier’s performance to ensure they continue to meet your expectations. This step is crucial for long-term success and building a reliable supply chain.

– Métricas de desempenho:

– Timeliness of deliveries.

– Quality consistency of the parts received.

By following this checklist, B2B buyers can navigate the complexities of sourcing automotive alternator parts with confidence, ensuring they select the right suppliers and receive quality products that meet their operational needs.

Illustrative image related to automotive alternator parts

Comprehensive Cost and Pricing Analysis for automotive alternator parts Sourcing

Analyzing the cost structure and pricing of automotive alternator parts is crucial for international B2B buyers, particularly those sourcing from regions such as Africa, South America, the Middle East, and Europe. Understanding the key components that contribute to the overall pricing can empower buyers to make informed purchasing decisions.

What Are the Key Cost Components in Automotive Alternator Parts?

The cost structure for automotive alternator parts typically encompasses several components:

-

Materiais: The choice of raw materials significantly impacts the cost. High-quality copper, aluminum, and specialized alloys are often used in manufacturing alternators. Premium materials enhance durability and performance but come at a higher cost.

-

Trabalho: Labor costs vary by region and can be influenced by local wage standards. Skilled labor is required for assembly and quality control, which adds to the overall labor expense.

-

Custos indiretos de produção: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Ferramentas: The initial investment in tooling and machinery is substantial. Custom tooling for specific alternator models can increase upfront costs but may lead to cost savings in mass production.

-

Controlo de Qualidade (QC): Implementing rigorous QC processes ensures that each alternator meets industry standards, which can increase costs but ultimately saves money by reducing returns and warranty claims.

-

Logística: Transportation costs are critical, especially for international shipments. These costs can fluctuate based on distance, mode of transport, and regional regulations.

-

Margem: Suppliers typically add a margin on top of their total costs to ensure profitability. This margin can vary widely depending on the supplier’s business model and market conditions.

How Do Price Influencers Affect Automotive Alternator Pricing?

Several factors can influence the pricing of automotive alternator parts:

-

Volume/MOQ: Purchasing in bulk often results in lower per-unit costs. Suppliers are more willing to negotiate prices for large orders, which can significantly reduce expenses for buyers.

-

Especificações/Personalização: Custom alternators or those with specific features may incur additional costs. Buyers should evaluate whether the added features justify the price increase.

-

Materiais e certificações de qualidade: Higher-quality materials and certifications (like ISO standards) can increase costs but also enhance reliability and performance, which is particularly important in demanding markets.

-

Fatores relacionados ao fornecedor: The reputation and reliability of suppliers can impact pricing. Established suppliers with a proven track record may command higher prices due to their reliability and service.

-

Incoterms: Understanding Incoterms is vital for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, affecting the overall cost structure.

What Are the Best Negotiation Tips for B2B Buyers in Automotive Alternator Sourcing?

When negotiating prices, consider the following strategies to ensure cost-efficiency:

-

Pesquisar preços de mercado: Conduct thorough market research to understand the going rates for alternator parts. Having this information can empower you during negotiations.

-

Potenciar as relações a longo prazo: Building strong relationships with suppliers can lead to better pricing and terms over time. Trust can often result in favorable negotiations.

-

Foco no custo total de propriedade (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, warranties, and potential downtimes. A higher upfront cost may be justified if the product offers better durability and performance.

-

Esteja ciente das nuances dos preços: Pricing can vary significantly across different regions. Factors like tariffs, import taxes, and local market conditions can affect final costs. For example, sourcing from Germany may involve different costs than sourcing from Nigeria.

Conclusão

Understanding the cost components and pricing influencers in automotive alternator sourcing is essential for making informed purchasing decisions. By leveraging negotiation strategies and focusing on the total cost of ownership, B2B buyers can achieve significant cost savings and ensure they receive quality products that meet their needs.

Isenção de responsabilidade: Prices mentioned in the analysis are indicative and may vary based on market conditions and specific supplier agreements. Always consult with suppliers for precise pricing tailored to your requirements.

Alternatives Analysis: Comparing automotive alternator parts With Other Solutions

Understanding Alternatives to Automotive Alternator Parts

In the automotive industry, sourcing the right components is crucial for performance and reliability. While automotive alternator parts serve as the backbone of a vehicle’s electrical charging system, buyers must consider alternative solutions that may offer similar functionalities or benefits. This analysis compares automotive alternator parts with two viable alternatives: high-output alternators e battery management systems. Each option presents unique advantages and challenges that can influence purchasing decisions.

Tabela comparativa

| Aspecto comparativo | Automotive Alternator Parts | Alternadores de alta potência | Sistemas de gestão de baterias |

|---|---|---|---|

| Desempenho | Essential for standard operation and electrical load management | Increased output, ideal for high-demand applications | Optimizes battery use and extends lifespan |

| Custo | Varies widely; generally lower than high-output options | Higher initial cost due to advanced technology | Moderate cost, but can lead to long-term savings |

| Facilidade de implementação | Generally straightforward; direct replacement | May require modifications to fit and function | Installation can be complex; professional help often needed |

| Manutenção | Regular inspections; wear parts may need replacement | Lower frequency of maintenance but may need upgrades | Minimal; mostly software updates and monitoring |

| Melhor caso de uso | Standard vehicles with average electrical demands | Performance vehicles, off-road, or heavy-duty applications | Vehicles with advanced electronics or frequent battery drain issues |

Analyzing High-Output Alternators

High-output alternators are designed to provide greater power than standard models, making them suitable for vehicles with additional electrical accessories, such as sound systems or off-road lights. The primary advantage of these alternators is their ability to handle increased electrical loads without straining the battery. However, they often come with a higher price tag and may require specific fittings or modifications to the vehicle, complicating installation. For B2B buyers, this option is ideal when performance and reliability under high demand are critical.

Illustrative image related to automotive alternator parts

Exploring Battery Management Systems

Battery management systems (BMS) represent a modern approach to managing vehicle electrical systems. They optimize battery use by ensuring that the battery is charged correctly and that its lifespan is maximized. While the initial investment in a BMS may be moderate, it can lead to significant savings by extending battery life and reducing the frequency of replacements. However, the installation process can be complex, often necessitating professional assistance. This solution is particularly beneficial for vehicles with advanced electronics or those that experience frequent battery drain, making it a good choice for fleet management or high-tech vehicles.

Conclusion: Making Informed Decisions for Automotive Solutions

When choosing between automotive alternator parts and alternative solutions, B2B buyers must assess their specific needs, including the vehicle’s electrical demands, budget constraints, and installation capabilities. Automotive alternator parts are a reliable choice for standard applications, while high-output alternators and battery management systems provide enhanced performance and efficiency for specialized needs. By understanding the strengths and limitations of each option, buyers can make informed decisions that align with their operational requirements and long-term goals.

Essential Technical Properties and Trade Terminology for automotive alternator parts

What Are the Essential Technical Properties of Automotive Alternator Parts?

Understanding the critical specifications of automotive alternator parts is crucial for B2B buyers seeking quality and reliability. Here are some key properties to consider:

-

Grau do material

– The material used in alternator parts significantly impacts durability and performance. Common materials include aluminum and high-grade steel for casings and copper for windings. High-grade materials ensure resistance to heat and corrosion, extending the lifespan of the alternator. For international buyers, knowing the material grade helps in assessing the suitability for various environmental conditions. -

Amperagem de saída

– This specification indicates the maximum electrical current the alternator can produce, typically measured in amps. Alternators can range from 60 to over 240 amps. Understanding the required output amperage is essential for matching the alternator to specific vehicle requirements, especially for heavy-duty applications in commercial or agricultural vehicles. -

Regulação da tensão

– Voltage regulators maintain the output voltage of the alternator within safe limits, preventing overcharging or undercharging of the battery. The efficiency of voltage regulation is crucial for the longevity of the vehicle’s electrical system. Buyers should ensure that the alternator includes a robust voltage regulator to enhance performance and reliability. -

Níveis de tolerância

– Tolerance levels refer to the permissible limits of variation in dimensions and performance specifications. High tolerance levels are essential for ensuring proper fit and function within the vehicle’s electrical system. For manufacturers and rebuilders, understanding tolerance levels aids in maintaining quality control and meeting OEM standards. -

Bearing Quality

– The quality of bearings used in alternators directly affects noise levels and operational smoothness. High-quality, sealed bearings can reduce friction and prolong the life of the alternator. For buyers, selecting alternators with premium bearings is vital to ensure quiet operation and reliability, especially in markets where noise regulations may apply. -

Cooling Features

– Many modern alternators include built-in cooling features such as vents or heat sinks to dissipate heat generated during operation. Proper cooling enhances performance and prevents overheating, which can lead to premature failure. Buyers should consider these features, especially in regions with high ambient temperatures.

What Are Common Trade Terms in the Automotive Alternator Parts Industry?

Familiarity with industry jargon can streamline communications and negotiations. Here are several essential trade terms:

-

OEM (Fabricante de Equipamento Original)

– OEM parts are manufactured by the same company that produced the original components for the vehicle. These parts are typically preferred for their guaranteed compatibility and quality. Buyers should consider OEM parts when seeking reliability and assurance of fit. -

MOQ (Quantidade mínima de encomenda)

– This term refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it can affect inventory management and cash flow. Buyers should negotiate MOQs to align with their purchasing capabilities and storage capacities. -

RFQ (Pedido de Orçamento)

– An RFQ is a formal process where buyers request pricing and terms from suppliers. It serves as a critical step in procurement, enabling buyers to compare offers and make informed decisions. Crafting a clear RFQ can help streamline the purchasing process and ensure all necessary specifications are covered. -

Incoterms

– Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international shipping. Understanding these terms helps in clarifying shipping costs, risk transfer, and delivery responsibilities, which is vital for international transactions. -

Prazo de entrega

– This refers to the time taken from placing an order to its delivery. Knowing the lead time is essential for planning and inventory management. Buyers should inquire about lead times to ensure they can meet customer demands without delays. -

Peças de reposição

– Aftermarket parts are made by third-party manufacturers and are designed to replace OEM parts. These can vary in quality and price. Understanding the difference between OEM and aftermarket parts helps buyers make informed decisions based on their needs for quality, cost, and availability.

By grasping these technical properties and trade terms, international B2B buyers can navigate the automotive alternator parts market more effectively, ensuring they make informed decisions that align with their operational requirements and regional demands.

Navigating Market Dynamics and Sourcing Trends in the automotive alternator parts Sector

What Are the Current Market Dynamics and Key Trends in the Automotive Alternator Parts Sector?

The global automotive alternator parts market is witnessing robust growth, driven by several key factors. The increasing demand for electric and hybrid vehicles is a primary driver, as these vehicles require advanced alternator systems to manage their complex electrical needs. Furthermore, the rise in vehicle production in emerging markets such as Nigeria and Brazil is contributing to increased demand for alternator parts. International B2B buyers should note that the market is also influenced by technological advancements, including the integration of smart technology in alternators, which enhances vehicle efficiency and performance.

Another significant trend is the move towards remanufactured and aftermarket parts, which offer cost-effective solutions without compromising quality. This shift is particularly relevant in regions where budget constraints are prevalent, allowing buyers to access premium parts at competitive prices. Additionally, the rise of digital platforms for sourcing parts is reshaping how international buyers procure automotive alternator components. Online marketplaces provide a broader selection and facilitate price comparisons, making it easier for B2B buyers to find the best deals.

How Is Sustainability and Ethical Sourcing Impacting the Automotive Alternator Parts Market?

Sustainability is becoming increasingly critical in the automotive alternator parts sector. The environmental impact of manufacturing processes, particularly regarding waste and emissions, is prompting buyers to seek suppliers who adhere to sustainable practices. Ethical sourcing is essential for maintaining corporate responsibility and ensuring compliance with international regulations.

B2B buyers should prioritize suppliers that utilize ‘green’ materials and offer certifications such as ISO 14001, which indicates a commitment to environmental management. By sourcing from companies that focus on sustainable practices, buyers can enhance their brand reputation and appeal to environmentally-conscious consumers. Moreover, the push for sustainability is influencing the design of alternator parts, with manufacturers exploring the use of recyclable materials and energy-efficient production processes.

What Is the Brief Evolution of the Automotive Alternator Parts Industry?

The automotive alternator parts industry has evolved significantly since the introduction of the alternator in the early 1960s. Initially, alternators replaced generators due to their ability to produce more electricity at lower RPMs, which was crucial for powering the growing number of electrical components in vehicles. Over the decades, advancements in technology have led to the development of more compact and efficient alternators, including those designed for electric and hybrid vehicles.

Illustrative image related to automotive alternator parts

The aftermarket sector has also expanded, driven by the increasing popularity of remanufactured parts that provide a cost-effective alternative to new components. The rise of e-commerce has further transformed the landscape, enabling international buyers to access a wider range of products and suppliers than ever before. As the automotive industry continues to innovate, the alternator parts market is poised for further growth, driven by both technological advancements and changing consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of automotive alternator parts

1. How do I identify a reliable supplier for automotive alternator parts?

To identify a reliable supplier, start by researching their reputation in the market. Look for reviews, testimonials, and case studies from other B2B clients. Verify their certifications and compliance with international quality standards. Engage in direct communication to assess their responsiveness and willingness to provide detailed product information. Additionally, consider their experience in your specific market region, as local knowledge can enhance supply chain efficiency.

2. What are the key factors to consider when sourcing alternator parts internationally?

When sourcing alternator parts internationally, consider factors such as product quality, supplier reliability, shipping costs, and delivery timelines. Evaluate the supplier’s ability to meet your minimum order quantities (MOQ) and customization needs. It’s also essential to understand the import regulations in your country, including tariffs and taxes. Ensure clear communication regarding payment terms and conditions to avoid any misunderstandings.

3. How can I ensure the quality of the automotive alternator parts I purchase?

To ensure quality, request samples from potential suppliers before placing a bulk order. Look for products that meet industry standards and certifications, such as ISO 9001. Establish a quality assurance process, including inspections during production and before shipment. Consider partnering with suppliers that offer warranties or guarantees on their products, as this indicates confidence in their quality.

4. What customization options are available for automotive alternator parts?

Customization options may include specific voltage outputs, sizes, or special features such as enhanced durability for extreme conditions. Many suppliers offer bespoke solutions tailored to your business needs. Discuss your requirements during the initial negotiations, and ensure that the supplier has the capability and flexibility to accommodate these customizations without significantly extending lead times.

5. What is the typical minimum order quantity (MOQ) for automotive alternator parts?

MOQs can vary widely among suppliers based on their production capabilities and the specific parts you are ordering. Generally, it can range from a few dozen to several hundred units. It’s important to communicate your requirements clearly and negotiate terms that suit your business model, especially if you are just starting out or testing a new product line.

6. What payment terms should I expect when sourcing automotive alternator parts?

Payment terms can vary by supplier and region. Common options include upfront payments, net 30/60/90 days, or a mix of deposit and final payment upon delivery. Some suppliers may also offer trade credit or financing options. Always clarify payment terms before finalizing any agreement to ensure they align with your financial planning and cash flow.

7. How do logistics impact the sourcing of automotive alternator parts?

Logistics play a crucial role in the timely delivery of automotive alternator parts. Consider factors such as shipping methods, lead times, and the reliability of freight forwarders. Evaluate the supplier’s ability to handle customs clearance efficiently to avoid delays. Building a relationship with logistics partners can also enhance supply chain transparency and efficiency.

8. What are the common challenges faced when sourcing automotive alternator parts globally?

Common challenges include language barriers, differing regulations, fluctuating shipping costs, and potential delays in delivery. It’s vital to establish clear communication channels with suppliers and logistics partners. Additionally, staying informed about geopolitical issues and trade agreements can help mitigate risks associated with international sourcing. Developing a contingency plan for supply chain disruptions can also be beneficial.

Top 4 Automotive Alternator Parts Manufacturers & Suppliers List

1. Alternators – OEM-Quality Options

Domínio: loja.advanceautoparts.com

Registado: 1997 (28 anos)

Introdução: Alternator – Advance Auto Parts offers OEM-quality alternators from brands like Carquest, ACDelco, and Bosch. The alternator is a key component of a vehicle’s electrical charging system, converting mechanical energy into electricity to power the vehicle’s electrical system and maintain battery charge. A failing alternator can lead to battery depletion and engine failure. The product includes vario…

2. HowStuffWorks – Alternadores

Domínio: auto.howstuffworks.com

Registado: 1998 (27 anos)

Introdução: Os alternadores são pequenos e leves, aproximadamente do tamanho de um coco, construídos com uma carcaça externa de alumínio para dissipação de calor e não magnetização. Os componentes principais incluem:

– Polia de transmissão fixada ao eixo do rotor, convertendo energia mecânica em energia elétrica.

– S terminal: senses battery voltage.

– IG terminal: ignition switch for voltage regulator.

– L terminal: closes circuit …

3. DB Electrical – High Quality Alternators

Domínio: dbelectrical.com

Registada: 2000 (25 anos)

Introdução: High quality alternators at low prices; Free same day shipping over $50 (USA/48 only); Meets OEM standards for quality and fitment; Features include high-temperature epoxy, heavy duty rectifiers, high quality regulators, well-engineered bearings, and high-temperature grease; Rigorous multipoint testing program for each model; Typically saves up to 30% off retail OEM prices; Available for various v…

4. Alternator Parts – High Output Alternators

Domínio: alternatorparts.com

Registado: 1999 (26 anos)

Introdução: USA Built High Output Alternators, Stock Amperage, Starters, and more. Over 40 years of auto electric experience in the USA. Products include: High Output Alternators, Conversion Kits, Voltage Regulators, Bridge Rectifiers, Bearings, Pulleys, Starters, and more. Featured products include Dodge/Chrysler/Jeep External Regulator Kit, GM Dual Rectifier CS144 Alternators, Ford Large Case 6G Power Strok…

Strategic Sourcing Conclusion and Outlook for automotive alternator parts

In conclusion, the strategic sourcing of automotive alternator parts is crucial for businesses aiming to enhance their supply chain efficiency and maintain a competitive edge in the market. By prioritizing quality, leveraging premium-grade components, and partnering with reputable manufacturers, international B2B buyers can ensure that they receive reliable products that meet the diverse needs of their clientele. The emphasis on comprehensive repair and rebuild kits allows for cost-effective solutions, catering to both professional rebuilders and DIY enthusiasts alike.

As the automotive industry continues to evolve, staying informed about market trends and technological advancements is essential. The demand for high-performance and durable alternator parts will likely increase, driven by the growing complexity of vehicle electrical systems. Thus, establishing strong relationships with suppliers across regions—particularly in Africa, South America, the Middle East, and Europe—will be key to fostering long-term success.

We encourage B2B buyers to proactively engage with suppliers, explore innovative sourcing strategies, and invest in high-quality parts that align with their operational goals. The future of the automotive alternator parts market is promising, and those who adapt will thrive in this dynamic landscape.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.