Introdução: Navegando no mercado global de quanto custa instalar um alternador

No mundo acelerado da manutenção automóvel, compreender o custo de instalação de um alternador é crucial para os compradores internacionais B2B. Com os veículos a dependerem cada vez mais dos sistemas eléctricos, o alternador desempenha um papel vital na garantia da eficiência e segurança operacionais. No entanto, o fornecimento do alternador certo e a sua instalação podem apresentar desafios, particularmente quando se navega em diversos mercados em África, na América do Sul, no Médio Oriente e na Europa, incluindo países como o Vietname e o Brasil.

Este guia abrangente irá aprofundar os aspectos multifacetados dos custos de instalação do alternador, explorando vários tipos de alternadores, as suas aplicações em diferentes modelos de veículos e os factores que influenciam os preços. Além disso, fornecerá informações sobre como examinar eficazmente os fornecedores e selecionar componentes de alta qualidade que satisfaçam as necessidades específicas da sua frota ou serviços automóveis.

Ao equipar os compradores B2B com conhecimentos práticos e referências claras de custos, este guia permite tomar decisões de compra informadas, ajudando as empresas a otimizar os seus orçamentos operacionais, assegurando simultaneamente a fiabilidade dos seus veículos. Quer pretenda melhorar as suas ofertas de serviços ou otimizar a sua cadeia de fornecimento, compreender os meandros dos custos de instalação de alternadores é essencial para manter uma vantagem competitiva no mercado global.

Índice

- Lista dos 3 principais fabricantes e fornecedores de Quanto custa para instalar um alternador

- Introdução: Navegando no mercado global de quanto custa instalar um alternador

- Compreender quanto custa a instalação de um alternador Tipos e variações

- Principais aplicações industriais de quanto custa instalar um alternador

- 3 Pontos de dor comuns dos utilizadores para ‘quanto custa instalar um alternador’ e respectivas soluções

- Guia de seleção de material estratégico para quanto custa instalar um alternador

- Análise aprofundada: Processos de fabrico e garantia de qualidade para quanto custa a instalação de um alternador

- Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘quanto custa instalar um alternador’

- Análise exaustiva dos custos e dos preços de quanto custa instalar um alternador Sourcing

- Análise de alternativas: Comparação de quanto custa instalar um alternador com outras soluções

- Propriedades técnicas essenciais e terminologia comercial para quanto custa a instalação de um alternador

- Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector do quanto custa instalar um alternador

- Perguntas mais frequentes (FAQs) para compradores B2B de quanto custa instalar um alternador

- Conclusão e perspectivas do aprovisionamento estratégico para quanto custa a instalação de um alternador

- Aviso legal importante e termos de utilização

Compreender quanto custa a instalação de um alternador Tipos e variações

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Alternador padrão | Normalmente utilizado na maioria dos veículos; saída de 12V | Oficinas de reparação automóvel em geral | Prós: Amplamente disponível, com uma boa relação custo-benefício. Contras: Potência limitada para veículos com grande procura. |

| Alternador de alta potência | Concebido para veículos com maiores necessidades eléctricas; maior amperagem de saída | Veículos de alto desempenho, construções personalizadas | Prós: Suporta acessórios eléctricos adicionais. Contras: Custo mais elevado, pode exigir modificações. |

| Alternador Remanufacturado | Reconstruído a partir de peças usadas; inspeccionado e testado | Oficinas preocupadas com o orçamento | Prós: Custo mais baixo, amigo do ambiente. Contras: Garantia mais curta, potenciais problemas de fiabilidade. |

| Alternador a diesel | Especificamente concebido para motores diesel; construção robusta | Camiões comerciais, máquinas pesadas | Prós: Elevada durabilidade, adequada para cargas pesadas. Contras: Investimento inicial mais elevado. |

| Alternador inteligente | Incorpora tecnologia avançada para regulação da tensão | Veículos eléctricos e híbridos | Prós: Eficiência melhorada, maior duração da bateria. Contras: Mais complexo, custos de reparação potencialmente mais elevados. |

Quais são as principais caraterísticas dos alternadores standard?

Os alternadores normais são o tipo mais comum encontrado nos veículos, funcionando normalmente com uma saída de 12 volts. São concebidos para satisfazer as necessidades eléctricas básicas da maioria dos veículos de passageiros. Para os compradores B2B, são ideais para as oficinas de reparação automóvel em geral que procuram soluções fiáveis e económicas. Embora estejam prontamente disponíveis e sejam acessíveis, podem não ser suficientes para veículos com elevadas exigências eléctricas, limitando a sua aplicação em veículos de desempenho ou especializados.

Como é que os alternadores de alto rendimento respondem a necessidades específicas?

Os alternadores de alto rendimento são concebidos para veículos que requerem maior potência eléctrica, frequentemente encontrados em automóveis de alto desempenho ou em construções personalizadas. Fornecem uma saída de amperagem mais elevada, acomodando acessórios eléctricos adicionais, tais como sistemas áudio melhorados ou iluminação todo-o-terreno. Os compradores B2B no sector automóvel de alto desempenho consideram estes alternadores essenciais para a satisfação do cliente. No entanto, têm um preço mais elevado e podem necessitar de modificações para se adaptarem a determinados modelos de veículos.

Quais são as vantagens e desvantagens dos alternadores remanufaturados?

Os alternadores remanufacturados são construídos a partir de componentes usados que foram cuidadosamente inspeccionados e testados. Esta opção atrai as oficinas de reparação preocupadas com o orçamento que procuram minimizar os custos e, ao mesmo tempo, fornecer peças de qualidade. São geralmente mais económicos do que as alternativas novas e promovem a sustentabilidade. No entanto, os compradores devem ter em conta os períodos de garantia mais curtos e os potenciais problemas de fiabilidade associados às peças remanufacturadas, que podem ter impacto na satisfação do cliente a longo prazo.

Por que escolher alternadores a diesel para aplicações pesadas?

Os alternadores a gasóleo são concebidos para motores a gasóleo, caracterizados pela sua construção robusta para suportar cargas pesadas e ambientes exigentes. Estes alternadores são normalmente utilizados em camiões comerciais e maquinaria pesada, o que os torna vitais para os compradores B2B nos sectores dos transportes e da construção. Embora ofereçam uma durabilidade e um desempenho excepcionais, o investimento inicial é normalmente mais elevado, o que pode afetar as considerações orçamentais.

O que faz dos alternadores inteligentes uma escolha inovadora?

Os alternadores inteligentes utilizam tecnologia avançada para uma regulação precisa da tensão, o que os torna adequados para veículos eléctricos e híbridos. Melhoram a eficiência e prolongam a vida útil da bateria, apelando aos compradores B2B centrados na sustentabilidade e nas tecnologias automóveis modernas. No entanto, a sua complexidade pode levar a um aumento dos custos de reparação e a desafios no fornecimento de peças compatíveis, que os compradores devem ponderar em relação aos benefícios de um melhor desempenho do veículo.

Principais aplicações industriais de quanto custa instalar um alternador

| Indústria/Setor | Aplicação específica de Quanto custa a instalação de um alternador | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Análise de custos da instalação de alternadores em oficinas de manutenção de veículos | Aumenta a eficiência operacional e a satisfação do cliente | Qualidade das peças, disponibilidade de mão de obra especializada, opções de garantia |

| Gestão de frotas | Elaboração de orçamentos para substituição de alternadores em vários veículos | Reduz o tempo de inatividade e os custos de manutenção | Opções de compra a granel, fiabilidade do fornecedor, disponibilidade regional |

| Equipamento de construção | Avaliação dos custos de instalação de alternadores em máquinas pesadas | Assegura a fiabilidade e a produtividade do equipamento | Compatibilidade com as máquinas, assistência técnica, longevidade das peças |

| Fabrico de veículos eléctricos | Compreender os custos dos sistemas do tipo alternador nos veículos eléctricos | Apoia a inovação em tecnologias sustentáveis | Investigação sobre sistemas de energia alternativos, aquisição de componentes ecológicos |

| Máquinas agrícolas | Avaliação dos custos de instalação de alternadores em equipamento agrícola | Melhora a eficiência e reduz as interrupções operacionais | Flutuações sazonais da procura, compatibilidade do equipamento, opções de abastecimento local |

Qual é a relevância da pergunta ‘quanto custa instalar um alternador’ no sector da reparação automóvel?

Na indústria da reparação automóvel, compreender o custo de instalação de um alternador é crucial para as oficinas de manutenção que pretendem oferecer preços transparentes aos seus clientes. Esta análise de custos permite às oficinas orçamentar eficazmente, assegurando que podem oferecer preços competitivos, mantendo a rentabilidade. Além disso, ter uma noção clara dos custos de instalação ajuda os mecânicos a dar prioridade às reparações e a gerir as expectativas dos clientes relativamente aos prazos de entrega. Para os compradores internacionais, é vital obter alternadores de alta qualidade que cumpram os regulamentos e normas locais.

Que vantagens tem para a gestão de frotas o conhecimento dos custos de instalação dos alternadores?

Para as empresas de gestão de frotas, a avaliação do custo das instalações de alternadores é essencial para manter a eficiência operacional de uma frota. Ao orçamentar estas substituições, as empresas podem minimizar o tempo de inatividade dos veículos e evitar custos de reparação inesperados, que podem ter um impacto significativo na rentabilidade global. Os gestores de frotas devem considerar acordos de compra a granel com fornecedores para negociar melhores preços e garantir que as peças são compatíveis com os vários modelos de veículos da sua frota. Além disso, compreender as condições do mercado local pode ajudar a encontrar fornecedores fiáveis.

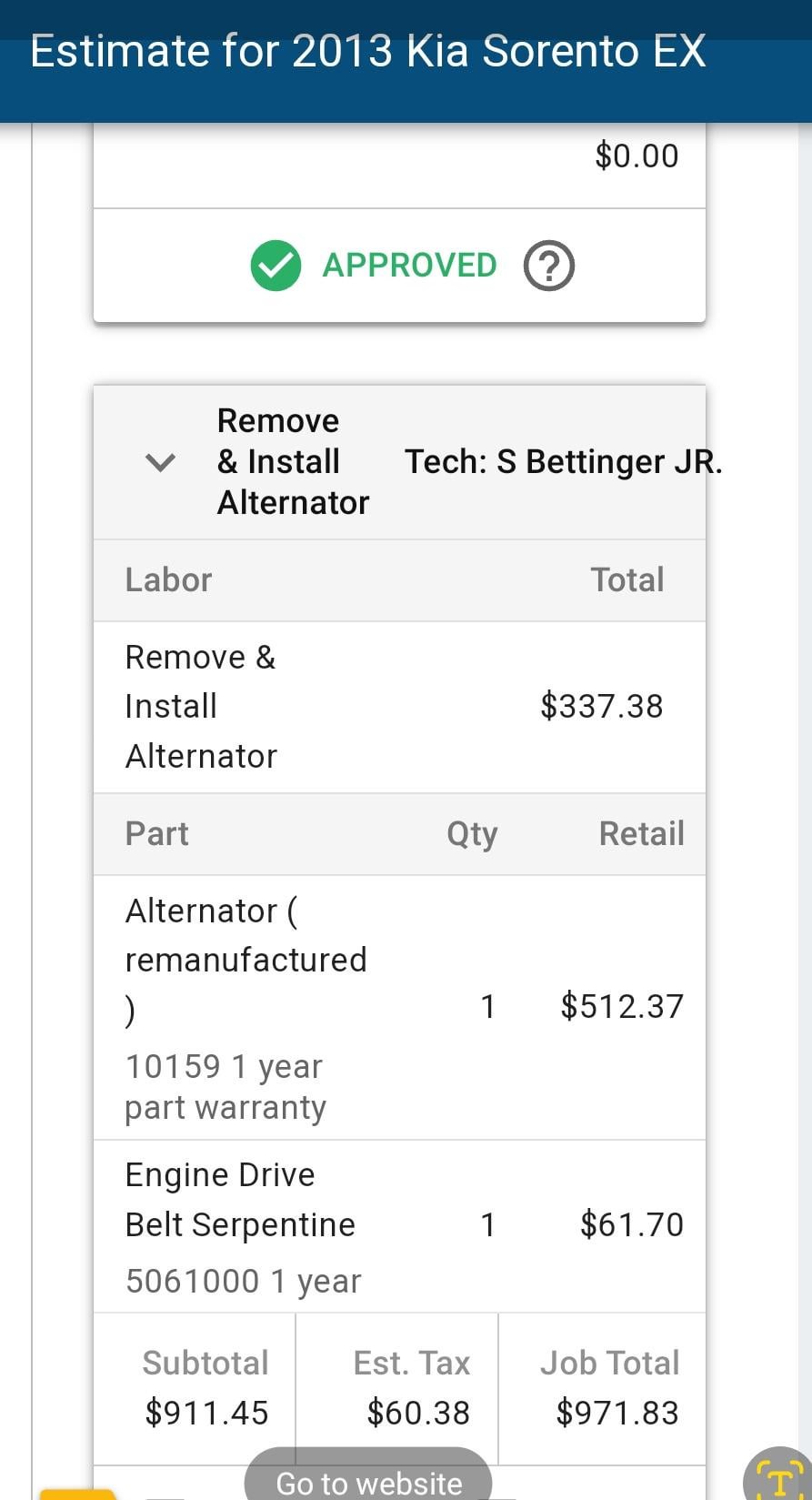

Imagem ilustrativa relacionada com quanto custa instalar um alternador

Como é que o custo da instalação de um alternador afecta as operações do equipamento de construção?

Na indústria da construção, as máquinas pesadas dependem de sistemas eléctricos eficientes, tornando o custo de instalação dos alternadores um fator crítico. Avaliações de custos precisas permitem que as empresas de construção tenham em conta as despesas de manutenção quando orçamentam os projectos. Um alternador fiável garante o bom funcionamento do equipamento, reduzindo a probabilidade de avarias dispendiosas. Os compradores neste sector devem dar prioridade ao fornecimento de peças compatíveis com modelos específicos de máquinas e considerar a disponibilidade de apoio técnico para resolver quaisquer desafios de instalação.

Por que razão é importante compreender os custos do alternador para o fabrico de veículos eléctricos?

À medida que o mercado dos veículos eléctricos (VE) se expande, torna-se cada vez mais importante compreender os custos associados à instalação de sistemas do tipo alternador. Os fabricantes de veículos eléctricos devem avaliar a forma como estes componentes podem melhorar o desempenho do veículo, gerindo simultaneamente os custos. A instalação de sistemas eficientes de produção de energia é crucial para garantir a fiabilidade do veículo e a satisfação do consumidor. Os compradores deste sector devem concentrar-se na aquisição de componentes inovadores e sustentáveis que estejam em conformidade com o seu compromisso de reduzir o impacto ambiental, bem como na avaliação dos fornecedores locais para uma melhor eficiência logística.

Como é que o conhecimento dos custos de instalação do alternador beneficia a maquinaria agrícola?

No sector agrícola, máquinas como tractores e ceifeiras necessitam frequentemente de sistemas eléctricos fiáveis alimentados por alternadores. A compreensão dos custos de instalação ajuda os agricultores e as empresas agrícolas a orçamentar as reparações e substituições essenciais, melhorando, em última análise, a eficiência do equipamento. Isto é particularmente importante durante as épocas altas, quando as interrupções operacionais podem levar a perdas significativas. Os compradores devem considerar as opções de fornecimento local para garantir um acesso rápido às peças e avaliar a compatibilidade com vários tipos de equipamento para evitar tempos de inatividade durante os períodos críticos da agricultura.

3 Pontos de dor comuns dos utilizadores para ‘quanto custa instalar um alternador’ e respectivas soluções

Cenário 1: Custos imprevistos durante a substituição do alternador

O problema: Os compradores B2B deparam-se frequentemente com despesas inesperadas aquando da substituição de um alternador, especialmente se não tiverem em conta a variabilidade dos custos associados aos diferentes modelos e tipos de veículos. Por exemplo, um gestor de frotas de uma empresa pode inicialmente orçamentar a substituição de um alternador padrão, apenas para descobrir que modelos específicos requerem peças especializadas que podem duplicar os custos previstos. Isto pode levar a frustração e tensão financeira, particularmente quando se trabalha com margens apertadas ou orçamentos de projectos.

Imagem ilustrativa relacionada com quanto custa instalar um alternador

A solução: Para atenuar este problema, os compradores B2B devem efetuar uma pesquisa exaustiva sobre os veículos específicos da sua frota antes de iniciarem o processo de substituição. Isto inclui a recolha de especificações detalhadas, tais como a marca, o modelo e o tamanho do motor, que influenciam diretamente o preço do alternador. Os compradores podem utilizar recursos como catálogos de fabricantes, fornecedores de peças automóveis e fóruns online para obter informações sobre os custos médios dos seus veículos específicos. Além disso, o estabelecimento de relações com fornecedores de confiança do sector automóvel pode fornecer informações sobre potenciais custos ocultos, tais como taxas de instalação ou a necessidade de componentes adicionais. Ao preparar um orçamento abrangente que inclua potenciais variações, os compradores podem garantir que estão financeiramente equipados para lidar com quaisquer despesas imprevistas.

Cenário 2: Atrasos na instalação do alternador

O problema: O tempo é essencial em muitas operações B2B, e os atrasos na instalação do alternador podem perturbar significativamente as actividades comerciais. Por exemplo, uma empresa de logística que dependa de uma frota de camiões de entrega pode enfrentar um tempo de inatividade considerável se um alternador falhar, levando a prazos não cumpridos e clientes insatisfeitos. O desafio é agravado se as peças de substituição não estiverem prontamente disponíveis ou se o processo de instalação for mais complexo do que o previsto.

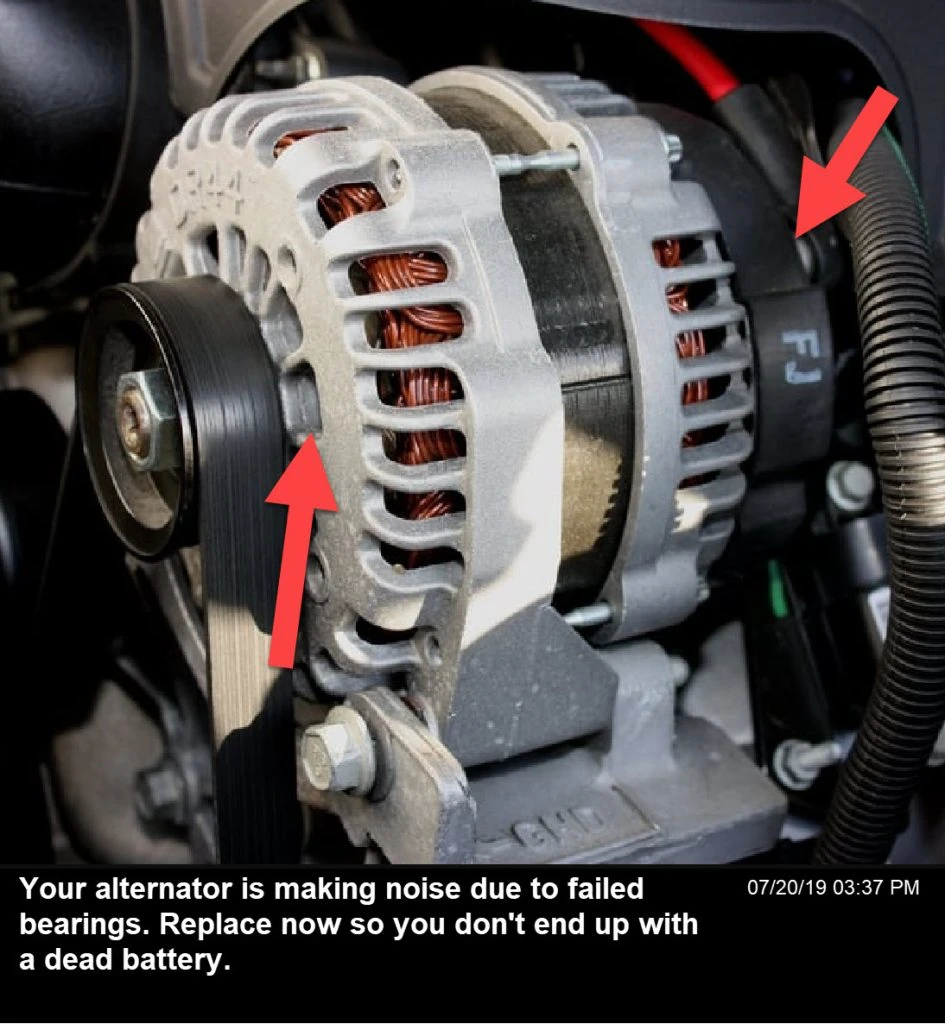

A solução: Para contrariar potenciais atrasos, os compradores B2B devem implementar um programa proactivo de manutenção e inspeção dos seus veículos, concentrando-se especificamente na saúde do alternador. As verificações regulares podem identificar sinais precoces de problemas no alternador, permitindo substituições preventivas antes de ocorrer uma falha completa. Além disso, o estabelecimento de parcerias com vários fornecedores locais de serviços automóveis pode aumentar a flexibilidade, assegurando a existência de alternativas em caso de atrasos com um fornecedor de serviços. A utilização de sistemas de gestão de inventário para controlar a disponibilidade de peças e encomendá-las com antecedência também pode simplificar o processo, reduzindo a probabilidade de um tempo de inatividade prolongado.

Cenário 3: Qualidade inconsistente dos alternadores de substituição

O problema: A qualidade dos alternadores de substituição pode variar significativamente entre fabricantes, o que representa um risco para os compradores B2B. Uma empresa pode optar por um alternador de baixo custo para poupar dinheiro, mas acabar por descobrir que este falha prematuramente, levando a custos de reparação adicionais e a interrupções operacionais. Esta inconsistência pode ser particularmente problemática em regiões onde o acesso a peças de alta qualidade é limitado.

A solução: Para garantir a qualidade dos alternadores que estão a ser comprados, os compradores B2B devem dar prioridade ao abastecimento de fabricantes reputados, conhecidos pela sua durabilidade e fiabilidade. Para tal, é necessário efetuar a devida diligência junto dos fornecedores, incluindo a verificação de críticas e classificações de outras empresas em sectores semelhantes. Investir em alternadores de maior qualidade pode implicar um custo inicial mais elevado, mas pode resultar em poupanças a longo prazo, reduzindo a frequência das substituições e os custos de mão de obra associados. Além disso, pedir garantias sobre as peças pode proporcionar uma camada extra de segurança, assegurando que os compradores estão protegidos contra falhas prematuras. O contacto com especialistas ou consultores do sector também pode fornecer informações valiosas sobre as melhores marcas e produtos adaptados às necessidades específicas da empresa.

Guia de seleção de material estratégico para quanto custa instalar um alternador

Que materiais são habitualmente utilizados na instalação do alternador e respectivos custos?

Quando se considera a instalação de um alternador, a seleção de materiais desempenha um papel crucial na determinação do custo global e do desempenho do componente. Abaixo, analisamos quatro materiais comuns utilizados no fabrico e instalação de alternadores, focando as suas propriedades, vantagens, desvantagens e considerações específicas para compradores B2B internacionais.

Quais são as principais propriedades do cobre em aplicações de alternadores?

O cobre é amplamente utilizado em enrolamentos de alternadores devido à sua excelente condutividade eléctrica. Suporta temperaturas elevadas, o que o torna adequado para aplicações automóveis onde a produção de calor é comum. Além disso, o cobre apresenta uma boa resistência à corrosão, o que é essencial para a longevidade em várias condições ambientais.

Prós e contras: A elevada condutividade do cobre garante uma produção de energia eficiente, mas é relativamente cara em comparação com alternativas como o alumínio. O processo de fabrico dos componentes de cobre pode ser complexo, o que leva a custos mais elevados. No entanto, as suas vantagens em termos de desempenho justificam frequentemente o investimento.

Impacto na aplicação: A compatibilidade do cobre com sistemas eléctricos de alto desempenho torna-o ideal para veículos modernos que requerem um fornecimento de energia fiável. No entanto, os compradores devem considerar as implicações da flutuação dos preços do cobre, que podem afetar os custos globais de instalação.

Imagem ilustrativa relacionada com quanto custa instalar um alternador

Considerações para compradores internacionais: A conformidade com as normas internacionais, tais como ASTM e JIS, é crucial, especialmente em regiões como a Europa e o Médio Oriente, onde as certificações de qualidade são obrigatórias. Os compradores em África e na América do Sul também devem estar cientes das opções de fornecimento local para reduzir os custos.

Como é que o alumínio se compara como material alternativo?

O alumínio é cada vez mais utilizado no fabrico de alternadores devido às suas propriedades de leveza e custo inferior ao do cobre. Tem uma condutividade eléctrica adequada, embora não tão elevada como a do cobre. O alumínio também oferece uma boa resistência à corrosão, especialmente quando anodizado.

Prós e contras: A principal vantagem do alumínio é a sua relação custo-eficácia e a redução do peso, o que pode melhorar a eficiência do combustível do veículo. No entanto, a sua menor condutividade significa que podem ser necessários fios de maior calibre, aumentando potencialmente a complexidade da instalação.

Impacto na aplicação: O alumínio é adequado para aplicações normais em que o peso e o custo são factores críticos. No entanto, para veículos de alto desempenho que requerem uma potência eléctrica óptima, o alumínio pode não ser a melhor escolha.

Considerações para compradores internacionais: Os compradores devem certificar-se de que os componentes de alumínio cumprem as normas e regulamentos relevantes na sua região. Em países como o Brasil e o Vietname, as capacidades locais de fabrico podem influenciar a seleção do material e o preço.

Imagem ilustrativa relacionada com quanto custa instalar um alternador

Qual é o papel do aço na montagem do alternador?

O aço é frequentemente utilizado nos suportes de montagem e nas caixas dos alternadores devido à sua resistência e durabilidade. Suporta grandes esforços mecânicos e proporciona uma base estável para o funcionamento do alternador.

Prós e contras: A principal vantagem do aço é a sua robustez, que garante que o alternador permanece firmemente montado em várias condições de condução. No entanto, o aço é suscetível de sofrer corrosão se não for tratado adequadamente, o que pode levar a uma falha prematura.

Impacto na aplicação: O aço é adequado para aplicações pesadas em que a integridade estrutural é fundamental. No entanto, os compradores devem ter em conta o potencial de ferrugem e corrosão, especialmente em ambientes húmidos ou costeiros.

Considerações para compradores internacionais: Os compradores devem procurar componentes de aço que cumpram as normas locais de resistência à corrosão, especialmente em regiões com elevada humidade, como partes de África e da América do Sul.

Qual é a importância do papel dos plásticos nos componentes do alternador?

Os plásticos são normalmente utilizados em componentes de alternadores, tais como coberturas e isoladores. São leves, resistentes à corrosão e podem ser fabricados em várias formas e tamanhos.

Imagem ilustrativa relacionada com quanto custa instalar um alternador

Prós e contras: A natureza leve dos plásticos pode contribuir para a redução do peso total do veículo, aumentando a eficiência do combustível. No entanto, podem não resistir a temperaturas elevadas tão bem como os metais, o que pode limitar a sua aplicação em cenários de elevado desempenho.

Impacto na aplicação: Os plásticos são adequados para componentes que não suportam carga, mas devem ser cuidadosamente selecionados para garantir que podem suportar as exigências térmicas e mecânicas específicas do alternador.

Considerações para compradores internacionais: Os compradores devem certificar-se de que os componentes de plástico cumprem as normas internacionais de segurança e desempenho, especialmente no sector automóvel, para evitar problemas de conformidade.

Tabela de resumo da seleção de materiais para a instalação do alternador

| Material | Caso de utilização típico para quanto custa a instalação de um alternador | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Enrolamentos e ligações elétricas | Elevada condutividade elétrica | Custo elevado e complexidade de fabrico | Alto |

| Alumínio | Fios e alguns componentes estruturais | Leve e económico | Condutividade inferior à do cobre | Médio |

| Aço | Suportes de montagem e caixas | Resistente e duradouro | Sujeito a corrosão sem tratamento | Médio |

| Plásticos | Coberturas e isoladores | Leve e resistente à corrosão | Resistência térmica limitada | Baixo |

Este guia estratégico de seleção de materiais fornece informações sobre os materiais utilizados nas instalações de alternadores, ajudando os compradores B2B internacionais a tomar decisões informadas que se alinham com as suas necessidades operacionais e requisitos de conformidade regionais.

Análise aprofundada: Processos de fabrico e garantia de qualidade para quanto custa a instalação de um alternador

Quais são as principais fases do processo de fabrico dos alternadores?

O fabrico de alternadores envolve várias fases-chave que garantem que o produto final cumpre as normas de qualidade e a eficiência operacional. A compreensão destas etapas é crucial para os compradores B2B, especialmente quando se trata de adquirir alternadores para aplicações automóveis.

Como é que o material é preparado para o fabrico de alternadores?

A preparação do material é o primeiro passo no processo de fabrico. Esta fase envolve normalmente a aquisição de matérias-primas de alta qualidade, tais como fio de cobre, aço para o estator e rotor e materiais de isolamento. A seleção destes materiais é fundamental, uma vez que têm um impacto direto no desempenho e na durabilidade do alternador.

O fio de cobre é frequentemente estirado em calibres específicos para garantir uma condutividade óptima, enquanto o aço é tratado para resistir à corrosão e ao desgaste. A qualidade do material pode ser verificada através de certificados de conformidade com as normas internacionais, garantindo que os compradores recebem produtos que satisfazem os seus requisitos operacionais.

Imagem ilustrativa relacionada com quanto custa instalar um alternador

Que técnicas são utilizadas para formar componentes de alternadores?

Uma vez preparados os materiais, o passo seguinte é a formação dos componentes do alternador. Isto inclui a estampagem do aço nas formas desejadas para o estator e o rotor, e o enrolamento do fio de cobre à volta destes componentes.

As técnicas mais comuns incluem:

- Estampagem e maquinagem: As chapas de aço são estampadas em várias formas necessárias para o rotor e o estator. A maquinagem de precisão garante que todos os componentes se encaixam perfeitamente.

- Enrolamento: O fio de cobre é enrolado à volta do estator num padrão específico para criar campos magnéticos. Este processo pode envolver máquinas de enrolamento automatizadas que garantem a consistência do número de voltas e da tensão do fio.

Estes processos são cruciais para garantir que o alternador possa gerar a potência eléctrica necessária de forma eficiente.

Como são montados os componentes do alternador?

A fase de montagem consiste em reunir todos os componentes formados num alternador completo. Este processo segue normalmente uma abordagem sistemática:

- Subconjunto: Os componentes individuais, como o rotor, o estator e o regulador de tensão, são montados primeiro.

- Montagem final: Os subconjuntos são então integrados, assegurando que todas as ligações eléctricas estão seguras e que o alternador funciona como previsto.

Durante a montagem, os fabricantes implementam frequentemente controlos para confirmar que cada componente cumpre as especificações do projeto. Isto pode envolver inspecções visuais e testes funcionais para garantir que o processo de montagem cumpre as normas de qualidade.

Que técnicas de acabamento são utilizadas na produção de alternadores?

Após a montagem, os alternadores são submetidos a processos de acabamento que melhoram o seu desempenho e o seu aspeto estético. As técnicas de acabamento podem incluir:

- Tratamento de superfície: Os componentes são frequentemente revestidos ou tratados para melhorar a resistência à corrosão. Isto pode envolver pintura ou galvanoplastia.

- Testes de qualidade: Cada alternador é submetido a testes rigorosos para garantir que cumpre as especificações de desempenho. Os testes podem incluir testes de carga, verificação da tensão de saída e avaliações de ruído.

Estes processos de acabamento são vitais para garantir que os alternadores possam suportar várias condições ambientais, mantendo a eficiência operacional.

Que normas de garantia de qualidade são relevantes para o fabrico de alternadores?

A garantia de qualidade (GQ) é primordial no fabrico de alternadores, particularmente para transacções B2B internacionais. Garantir a conformidade com normas reconhecidas não só aumenta a fiabilidade do produto, como também cria confiança junto dos compradores.

Que normas internacionais devem os compradores B2B considerar?

Uma das normas internacionais mais reconhecidas é ISO 9001, que define os critérios para um sistema de gestão da qualidade. A conformidade com esta norma indica que um fabricante estabeleceu uma abordagem sistemática para gerir os seus processos e garantir a qualidade do produto.

Além disso, certificações como CE (Conformité Européenne) para os mercados europeus e API (American Petroleum Institute) para aplicações específicas também podem ser importantes. Estas certificações indicam que os produtos cumprem normas específicas de segurança e desempenho.

Quais são os principais pontos de verificação do controlo de qualidade na produção de alternadores?

O controlo de qualidade (CQ) está integrado em várias fases do processo de fabrico:

- Controlo de Qualidade de Entrada (IQC): Esta etapa envolve a inspeção das matérias-primas à chegada para garantir que cumprem as normas especificadas.

- Controlo de qualidade em processo (IPQC): Ao longo do processo de fabrico, são estabelecidos vários pontos de controlo para monitorizar a qualidade dos componentes e das montagens. Isto pode incluir a medição das dimensões dos componentes e o teste das saídas eléctricas durante a montagem.

- Controlo de Qualidade Final (FQC): Após a montagem, cada alternador é submetido a testes finais para verificar se cumpre as especificações de desempenho. Isto pode incluir testes de carga e testes funcionais para garantir a fiabilidade.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

Para os compradores B2B, a verificação dos processos de controlo de qualidade de um fornecedor é essencial para mitigar os riscos. Aqui estão algumas estratégias eficazes:

- Auditorias: A realização de auditorias regulares aos fornecedores pode fornecer informações sobre os seus processos de fabrico e práticas de garantia de qualidade.

- Solicitação de relatórios de qualidade: Os compradores podem solicitar relatórios de qualidade detalhados que descrevem os resultados dos testes, a conformidade com as normas e quaisquer acções corretivas tomadas.

- Inspeções por terceiros: A contratação de serviços de inspeção por terceiros pode proporcionar uma avaliação imparcial dos processos de fabrico e de garantia de qualidade de um fornecedor.

Quais são as nuances do CQ e da certificação para os compradores internacionais B2B?

Para os compradores de regiões como África, América do Sul, Médio Oriente e Europa, é vital compreender as nuances do CQ e da certificação. As diferentes regiões podem ter normas e práticas diferentes, o que pode afetar a compatibilidade do produto e a conformidade regulamentar.

O que é que os compradores devem saber sobre as normas regionais?

Os compradores devem familiarizar-se com as normas específicas aplicáveis nas suas regiões. Por exemplo, a SANS (Normas Nacionais da África do Sul) podem ser relevantes para os compradores em África, enquanto INMETRO A certificação é essencial para os produtos comercializados no Brasil.

Além disso, compreender as implicações da regulamentação local sobre as importações e a documentação necessária pode facilitar as transacções e reduzir os atrasos na cadeia de abastecimento.

Em conclusão, um conhecimento profundo dos processos de fabrico e das práticas de garantia de qualidade envolvidas na produção de alternadores é essencial para os compradores B2B. Ao concentrarem-se na preparação do material, na moldagem, na montagem, no acabamento e no cumprimento das normas de qualidade, os compradores podem tomar decisões informadas que garantam a fiabilidade e o desempenho dos seus componentes automóveis.

Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘quanto custa instalar um alternador’

Neste guia, pretendemos fornecer aos compradores B2B uma lista de verificação clara e acionável para compreender os custos associados à instalação de um alternador. Quer esteja na indústria automóvel ou num sector relacionado, saber como obter e avaliar os custos de instalação de um alternador pode ter um impacto significativo na sua eficiência operacional e na gestão do orçamento.

Passo 1: Defina as suas especificações técnicas

Antes de iniciar o processo de aquisição, é essencial delinear os requisitos específicos para o alternador. Isto inclui conhecer a marca, o modelo e o tamanho do motor dos veículos da sua frota. Especificações exactas garantem a compatibilidade e ajudam a evitar erros dispendiosos durante a instalação.

- Considerar as necessidades de amperagem: Veículos diferentes requerem amperagens diferentes, o que pode afetar o preço e o desempenho do alternador.

- Identificar os estilos de montagem: Certifique-se de que o alternador cabe no espaço designado no veículo para evitar problemas futuros.

Passo 2: Pesquisar tendências de preços de mercado

Compreender os preços de mercado actuais para instalações de alternadores é crucial para o planeamento do orçamento. Os preços podem variar significativamente consoante a localização geográfica, o fornecedor e o tipo de alternador necessário.

- Comparar fornecedores locais e internacionais: Os preços podem variar consoante a disponibilidade regional e os custos de envio.

- Acompanhar as tendências sazonais: Alguns fornecedores podem oferecer descontos durante certas épocas do ano, o que pode levar a poupanças.

Passo 3: Avaliar as credenciais do fornecedor

Examine minuciosamente os potenciais fornecedores para garantir que cumprem as normas da indústria. Procure certificações, avaliações de clientes e o seu historial no mercado.

Imagem ilustrativa relacionada com quanto custa instalar um alternador

- Solicitar documentação: Peça certificações que demonstrem a conformidade com as normas de qualidade internacionais.

- Procurar referências: Contacte outras empresas que tenham trabalhado com o fornecedor para avaliar a sua fiabilidade e qualidade de serviço.

Passo 4: Avaliar as opções de garantia

As garantias podem afetar significativamente os custos a longo prazo associados às instalações de alternadores. Uma garantia robusta pode proporcionar paz de espírito e proteger o seu investimento.

- Comparar as durações das garantias: Garantias mais longas podem indicar uma maior qualidade ou confiança por parte do fabricante.

- Compreender a cobertura da garantia: Certifique-se de que esclarece o que está incluído na garantia, como peças e mão de obra.

Passo 5: Obter orçamentos pormenorizados

Depois de ter selecionado os potenciais fornecedores, peça orçamentos detalhados que discriminem todos os custos associados. Isto deve incluir peças, mão de obra e quaisquer taxas adicionais.

- Procura a transparência: Um fornecedor fiável fornecerá uma repartição clara dos custos, ajudando-o a compreender o que está a pagar.

- Considerar os custos ocultos: Pergunte sobre possíveis custos adicionais de envio, instalação ou outros serviços que possam não estar incluídos no orçamento inicial.

Passo 6: Planear a logística da instalação

O planeamento eficaz do processo de instalação pode poupar tempo e dinheiro. Considere o impacto que a instalação terá nas suas operações e quais os recursos necessários.

- Programar os horários de instalação: Coordene com o seu fornecedor para minimizar o tempo de inatividade da sua frota.

- Prepare a sua equipa: Certifique-se de que os seus técnicos são formados e estão equipados para efetuar o processo de instalação de forma eficiente.

Passo 7: Monitorizar o desempenho pós-instalação

Após a instalação, acompanhe o desempenho do alternador para identificar quaisquer problemas numa fase inicial. A monitorização regular pode evitar problemas mais significativos no futuro.

Imagem ilustrativa relacionada com quanto custa instalar um alternador

- Efetuar controlos regulares: Programar inspecções de rotina para garantir que o alternador funciona dentro do intervalo de tensão esperado.

- Desempenho do documento: Mantenha registos de quaisquer problemas ou irregularidades, que podem ser úteis para pedidos de garantia ou compras futuras.

Seguindo esta lista de verificação, os compradores B2B podem tomar decisões informadas relativamente aos custos e à logística da instalação de alternadores, assegurando que maximizam o seu investimento e mantêm a eficiência operacional.

Análise exaustiva dos custos e dos preços de quanto custa instalar um alternador Sourcing

Para compreender o custo de instalação de um alternador, é essencial analisar os vários componentes e factores de influência que contribuem para o preço global. Esta análise fornece informações valiosas para os compradores B2B internacionais, especialmente os que operam em África, na América do Sul, no Médio Oriente e na Europa.

Quais são os principais componentes de custo para a instalação de um alternador?

Materiais: O principal fator de custo na instalação do alternador são os materiais utilizados, incluindo o próprio alternador e componentes adicionais como correias e conectores. Os alternadores novos podem variar entre $100 e $1.000, dependendo de especificações como a marca, o modelo e a amperagem. As opções do mercado de substituição, incluindo unidades remanufacturadas, podem oferecer poupanças de custos, mas podem variar em termos de qualidade.

Trabalho: Os custos da mão de obra de instalação podem variar consoante a localização geográfica e a complexidade da instalação. Os custos de mão de obra típicos podem variar entre $50 e $150 por hora. É crucial considerar que a mão de obra especializada pode ser mais cara em regiões com custos de vida mais elevados, enquanto que os custos de mão de obra mais baixos podem ser encontrados em mercados emergentes.

Custos indiretos de produção: Inclui as despesas incorridas na produção do alternador, como o aluguer da fábrica, os serviços públicos e a manutenção do equipamento. Os custos gerais podem variar significativamente entre fabricantes, afectando o preço final.

Ferramentas e controlo de qualidade (QC): Os custos das ferramentas são essenciais para criar alternadores de alta qualidade. Processos rigorosos de controlo de qualidade garantem que os produtos cumprem as normas da indústria, o que pode ter um custo adicional. Os compradores devem avaliar as certificações e as práticas de garantia de qualidade dos seus fornecedores para evitar problemas futuros.

Logística: A logística do transporte de alternadores pode aumentar o custo total. As taxas de transporte internacional, os direitos aduaneiros e as tarifas podem afetar significativamente os preços, especialmente para os compradores em regiões com regulamentos de importação complexos.

Imagem ilustrativa relacionada com quanto custa instalar um alternador

Margem: Os fornecedores incluem normalmente uma margem de lucro nos seus preços. Esta margem varia em função da procura no mercado, da concorrência e da eficiência operacional do fornecedor.

Como os influenciadores de preço afetam os custos do alternador?

Volume e quantidade mínima de encomenda (MOQ): Os volumes de encomendas mais elevados conduzem frequentemente a custos unitários mais baixos. Negociar condições favoráveis com os fornecedores pode levar a descontos, particularmente para compras em grandes quantidades.

Especificações e personalização: Os alternadores personalizados para aplicações específicas podem implicar custos adicionais. Os compradores devem esclarecer antecipadamente as suas especificações para evitar aumentos de preços inesperados.

Materiais e certificações de qualidade: A escolha dos materiais tem um impacto significativo no custo. Os materiais de alta qualidade, como os enrolamentos de cobre, aumentam a durabilidade mas também o preço. As certificações (por exemplo, ISO, TS) podem garantir aos compradores a qualidade, mas podem implicar custos mais elevados.

Fatores relacionados ao fornecedor: A fiabilidade e a reputação dos fornecedores podem influenciar os preços. Os fornecedores estabelecidos com um historial de qualidade podem cobrar mais, mas também reduzem o risco de falha do produto, o que conduz a poupanças a longo prazo.

Incoterms: Compreender os Incoterms é crucial para as transacções internacionais. Estes definem as responsabilidades dos compradores e dos vendedores em termos de custos de transporte, seguros e gestão de riscos, o que pode afetar o preço global.

Que sugestões do comprador podem ajudar a otimizar os custos?

Negociação: Iniciar negociações com os fornecedores para garantir melhores preços, especialmente para encomendas maiores. A criação de relações a longo prazo também pode proporcionar condições favoráveis.

Relação custo-benefício: Avaliar o custo total de propriedade (TCO) em vez de apenas o preço de compra inicial. Considere factores como a garantia, a manutenção e o tempo de vida útil previsto ao avaliar os fornecedores.

Nuances de preços para compradores internacionais: Os compradores de diferentes regiões devem ter em conta as flutuações cambiais, os direitos aduaneiros e as condições do mercado regional que podem afetar os preços. A pesquisa de fornecedores locais pode também proporcionar vantagens em termos de custos.

Isenção de responsabilidade sobre preços indicativos

Os preços mencionados são indicativos e podem variar em função das condições de mercado, dos requisitos específicos do veículo e de factores regionais. Consulte sempre vários fornecedores e efectue uma diligência prévia completa para garantir o melhor preço e qualidade para as suas necessidades.

Análise de alternativas: Comparação de quanto custa instalar um alternador com outras soluções

Ao considerar o custo e a eficiência dos sistemas eléctricos dos veículos, particularmente no contexto da instalação do alternador, é essencial explorar várias alternativas. Esta análise compara o método tradicional de instalação de um alternador com duas soluções alternativas: a utilização de uma bateria de alta capacidade e a integração de um sistema de carregamento solar. Cada opção tem as suas caraterísticas únicas que podem influenciar significativamente a tomada de decisão dos compradores B2B.

| Aspecto comparativo | Quanto custa a instalação de um alternador | Bateria de alta capacidade | Sistema de carregamento solar |

|---|---|---|---|

| Desempenho | Fonte de alimentação fiável; normalmente produz 13,8-14,6 volts | Bom desempenho, mas limitado pela capacidade da bateria | Sustentável, mas dependente da disponibilidade de luz solar |

| Custo | $100 - $1,000 para peças e mão de obra | $200 - $500 para bateria, mais instalação | $300 - $1.500 para painéis e instalação |

| Facilidade de implementação | Moderado; requer competências mecânicas | Instalação fácil e direta | Complexo; requer uma instalação adequada e eventuais autorizações |

| Manutenção | Baixa; dura normalmente 7-10 anos | Moderado; pode exigir controlos e substituições regulares | Baixo; manutenção mínima, mas é necessário limpar o painel |

| Melhor caso de uso | Veículos de série com necessidades eléctricas convencionais | Veículos com elevadas exigências de potência ou paragens frequentes | Aplicações fora da rede ou empresas com preocupações ambientais |

Quais são os prós e os contras de utilizar uma bateria de elevada capacidade?

As baterias de alta capacidade podem ser uma alternativa viável à instalação de um novo alternador, especialmente para veículos com maiores exigências eléctricas. Estas baterias fornecem uma fonte de alimentação robusta e podem suportar vários componentes eléctricos sem a necessidade de recarga constante de um alternador. No entanto, o custo inicial pode ser significativo e o seu desempenho está diretamente ligado ao nível de carga da bateria. São necessárias verificações de manutenção regulares para garantir um desempenho ótimo, o que torna esta opção moderadamente exigente em termos de manutenção.

Como é que um sistema de carregamento solar se compara?

A integração de um sistema de carregamento solar oferece uma abordagem sustentável para alimentar os sistemas eléctricos dos veículos. Os painéis solares podem aproveitar a energia do sol, reduzindo a dependência das fontes de combustível tradicionais e diminuindo os custos operacionais globais. No entanto, este método implica um investimento inicial mais elevado e um processo de instalação complexo que pode exigir licenças e ajuda profissional. Além disso, o desempenho pode variar com base na localização geográfica e nas condições climatéricas, o que pode limitar a eficácia em regiões menos soalheiras.

Conclusão: como os compradores B2B devem escolher a solução certa?

Ao selecionar a solução mais adequada para as necessidades de energia eléctrica dos veículos, os compradores B2B devem ponderar os custos, o desempenho e os requisitos de manutenção de cada opção em relação ao seu contexto operacional específico. A instalação de um alternador é muitas vezes a escolha mais simples e fiável para veículos convencionais, enquanto as baterias de alta capacidade e os sistemas de carregamento solar oferecem alternativas adequadas a necessidades especializadas ou objectivos de sustentabilidade. Em última análise, a decisão deve estar alinhada com as exigências operacionais da empresa, as restrições orçamentais e os objectivos estratégicos a longo prazo, assegurando que a solução escolhida proporciona o valor e a eficiência ideais.

Imagem ilustrativa relacionada com quanto custa instalar um alternador

Propriedades técnicas essenciais e terminologia comercial para quanto custa a instalação de um alternador

Compreender as especificações técnicas e a terminologia associadas aos custos de instalação do alternador pode influenciar significativamente as decisões de aquisição dos compradores B2B. Aqui, exploramos as propriedades e termos essenciais que são cruciais para fazer escolhas informadas.

Quais são as principais propriedades técnicas dos alternadores?

1. Classificação de amperagem

A amperagem refere-se à corrente eléctrica máxima que o alternador pode produzir, normalmente medida em amperes. Esta especificação é fundamental, uma vez que determina a capacidade do alternador para alimentar vários componentes eléctricos de um veículo. Para os compradores B2B, a compreensão da amperagem necessária garante a compatibilidade com o sistema elétrico do veículo, ajudando a evitar incompatibilidades dispendiosas.

2. Saída de tensão

A tensão de saída padrão da maioria dos alternadores para automóveis varia entre 13,5 e 14,5 volts. Esta propriedade é vital para carregar a bateria e alimentar dispositivos eléctricos de forma eficiente. Um conhecimento profundo das especificações de tensão permite aos compradores selecionar alternadores que mantêm um desempenho ótimo, reduzindo assim o risco de falhas eléctricas.

3. Estilo de montagem

Os alternadores são fornecidos em vários estilos de montagem, que devem ser compatíveis com modelos de veículos específicos. Esta especificação inclui a posição e o tipo de suportes utilizados para a instalação. Para os compradores B2B, conhecer o estilo de montagem correto é essencial para evitar atrasos na instalação e custos adicionais relacionados com modificações ou devoluções.

4. Cobertura da garantia

A duração e os termos da cobertura da garantia podem variar significativamente entre alternadores. Uma garantia mais longa indica frequentemente uma maior qualidade de fabrico e fiabilidade. Para os compradores B2B, a seleção de alternadores com termos de garantia robustos pode minimizar os custos de manutenção futuros e aumentar o valor global.

5. Composição do material

Os materiais utilizados na construção de um alternador, particularmente o rotor e o estator, podem afetar a durabilidade e o desempenho. Os materiais comuns incluem o cobre para os enrolamentos e o alumínio para a caixa. A compreensão dos tipos de materiais ajuda os compradores a avaliar a qualidade e a longevidade do alternador, o que é crucial para a eficiência operacional a longo prazo.

Quais são os termos comerciais comuns relacionados com os custos de instalação do alternador?

1. OEM (Fabricante de Equipamento Original)

OEM refere-se a peças fabricadas pelo fabricante original do veículo. A utilização de alternadores OEM garante compatibilidade e fiabilidade, o que é essencial para manter o desempenho do veículo. Os compradores B2B preferem frequentemente peças OEM para garantir a qualidade e minimizar o risco de falhas.

2. MOQ (Quantidade mínima de encomenda)

O MOQ indica o número mais pequeno de unidades que um fornecedor está disposto a vender. Compreender o MOQ é vital para os compradores B2B, uma vez que afecta a gestão do inventário e os cálculos de custos. Os compradores devem considerar as suas necessidades operacionais para negociar termos favoráveis que se alinhem com a sua estratégia de compras.

Imagem ilustrativa relacionada com quanto custa instalar um alternador

3. RFQ (Pedido de Orçamento)

Um pedido de cotação é um documento utilizado pelos compradores para solicitar preços e condições aos fornecedores para produtos específicos. No contexto dos alternadores, a apresentação de um pedido de cotação pode ajudar os compradores a obter preços competitivos e a compreender as capacidades do fornecedor, facilitando assim uma melhor tomada de decisões.

4. Incoterms

Os Incoterms são termos comerciais internacionais que definem as responsabilidades dos compradores e vendedores no processo de expedição. A familiaridade com estes termos ajuda os compradores B2B a compreender os custos de envio, os prazos de entrega e a gestão de riscos associados à aquisição de alternadores de diferentes regiões.

5. Peças de reposição

As peças do mercado de substituição referem-se a componentes fabricados por outros fabricantes que não o fabricante original do veículo. Embora muitas vezes mais económicos, a qualidade e a compatibilidade dos alternadores do mercado de substituição podem variar. Os compradores B2B devem avaliar a fiabilidade das opções do mercado de substituição para garantir que cumprem as normas de desempenho.

Ao compreender estas propriedades técnicas essenciais e a terminologia comercial, os compradores B2B podem tomar decisões informadas relativamente aos custos e especificações das instalações de alternadores, conduzindo, em última análise, a processos de aquisição mais eficientes e a uma maior fiabilidade operacional.

Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector do quanto custa instalar um alternador

Quais são as actuais dinâmicas de mercado que influenciam o custo da instalação do alternador?

Na indústria automóvel global, o custo de instalação de um alternador é moldado por várias dinâmicas de mercado e tendências de fornecimento. Os principais factores incluem a procura crescente de veículos eléctricos (VE) e modelos híbridos, que exigem tecnologias avançadas de alternadores. À medida que os fabricantes se orientam para soluções mais ecológicas, esta mudança está a provocar um aumento da complexidade e do custo dos sistemas de alternadores. Em regiões como a África e a América do Sul, onde a eletrificação dos veículos está a ganhar força, os compradores B2B internacionais devem manter-se vigilantes quanto ao fornecimento de alternadores de alta qualidade que cumpram as normas regulamentares e de desempenho.

Além disso, o panorama da cadeia de abastecimento global está a evoluir devido às tensões geopolíticas, às políticas comerciais e às consequências da pandemia de COVID-19. Estes factores conduziram a um aumento dos custos de transporte e a prazos de entrega mais longos, afectando a estrutura geral de preços dos alternadores e da sua instalação. Na Europa e no Médio Oriente, os fabricantes estão também a concentrar-se na integração de tecnologias inteligentes nos alternadores para melhorar o desempenho dos veículos e a eficiência energética, influenciando ainda mais os custos de instalação.

As tecnologias emergentes, como as plataformas de fornecimento digital e a análise avançada de dados, estão a tornar-se ferramentas essenciais para os compradores B2B. Estas tecnologias facilitam relações mais transparentes com os fornecedores e permitem o acompanhamento em tempo real da qualidade dos componentes, conduzindo, em última análise, a uma melhor tomada de decisões relativamente à aquisição de alternadores. Como resultado, as empresas que utilizam estas ferramentas estão melhor posicionadas para negociar os custos de forma eficaz e garantir instalações atempadas.

Como é que a sustentabilidade e o fornecimento ético estão a afetar os custos de instalação do alternador?

A sustentabilidade é cada vez mais crítica para os compradores B2B no sector dos alternadores. O impacto ambiental dos processos de fabrico, particularmente no que diz respeito à extração de matérias-primas como o cobre e o alumínio, é uma preocupação crescente. As práticas de aprovisionamento ético estão a tornar-se uma prioridade à medida que as empresas se esforçam por minimizar as suas pegadas de carbono e aderir aos regulamentos ambientais internacionais. Esta tendência é particularmente acentuada em regiões onde a legislação ambiental é mais rigorosa, como a Europa.

Os compradores B2B devem dar prioridade aos fornecedores que oferecem certificações “verdes”, garantindo que os materiais utilizados nos alternadores são obtidos de forma responsável. Além disso, os alternadores remanufacturados constituem uma alternativa sustentável às unidades novas, muitas vezes a um custo reduzido. Ao escolherem componentes remanufacturados, as empresas podem reduzir significativamente o seu impacto ambiental, ao mesmo tempo que beneficiam da poupança de custos associada à instalação.

Além disso, a transparência na cadeia de abastecimento está a tornar-se essencial. Os compradores procuram cada vez mais fornecedores que possam demonstrar práticas laborais éticas e o cumprimento de normas ambientais. Este enfoque não só ajuda a mitigar os riscos associados a danos à reputação, mas também se alinha com os valores de uma base de consumidores mais ecologicamente conscientes. Ao integrar a sustentabilidade nas suas estratégias de aprovisionamento, os compradores internacionais podem promover parcerias a longo prazo com fornecedores empenhados na gestão ambiental, conduzindo, em última análise, a uma cadeia de fornecimento mais resistente.

Que tendências históricas moldaram o mercado de alternadores?

O alternador evoluiu significativamente desde a sua criação no início do século XX. Inicialmente, os veículos dependiam de geradores simples, que forneciam uma potência eléctrica limitada. A introdução do alternador nos anos 60 marcou um ponto de viragem, oferecendo maior eficiência e fiabilidade. Esta mudança foi essencial, uma vez que a procura de energia eléctrica nos veículos aumentou, impulsionada pela introdução de caraterísticas como o ar condicionado e sistemas áudio avançados.

Nas décadas que se seguiram, os avanços nos materiais e processos de fabrico melhoraram ainda mais o desempenho dos alternadores, tornando-os mais duradouros e económicos. À medida que o panorama automóvel se deslocou para a eletrificação, o papel do alternador tornou-se ainda mais crítico. Os alternadores modernos são agora parte integrante da gestão dos complexos sistemas eléctricos dos veículos, adaptando-se às crescentes exigências de potência, ao mesmo tempo que asseguram uma eficiência de combustível óptima.

Atualmente, o mercado dos alternadores assiste a uma nova vaga de inovação, sobretudo com o aparecimento dos veículos eléctricos e híbridos. Esta evolução sublinha a importância de se manter a par dos avanços tecnológicos e das tendências do mercado para os compradores B2B que procuram navegar eficazmente pelas complexidades do fornecimento de alternadores e dos custos de instalação. Ao compreender o contexto histórico, os compradores podem antecipar melhor os desenvolvimentos futuros e tomar decisões informadas que se alinham com as suas estratégias empresariais.

Perguntas mais frequentes (FAQs) para compradores B2B de quanto custa instalar um alternador

-

Quanto devo esperar pagar pela instalação do alternador?

O custo da instalação de um alternador pode variar significativamente com base em vários factores, incluindo a marca, o modelo e o ano do veículo, bem como o tipo de alternador necessário (novo, remanufacturado ou de substituição). Geralmente, o custo total das peças e da mão de obra varia entre $100 e $1.000. Em algumas regiões, os custos de mão de obra podem ser mais elevados devido às condições económicas locais ou à escassez de mão de obra especializada, pelo que é aconselhável obter vários orçamentos de fornecedores de serviços locais para garantir preços competitivos. -

Que factores influenciam o custo da instalação do alternador?

Vários factores podem afetar o custo de instalação de um alternador. Estes incluem as especificações do alternador (como a amperagem e o tipo), as taxas de mão de obra na sua região e se são necessárias reparações adicionais. Além disso, a disponibilidade de peças e a complexidade da instalação também podem contribuir para o custo global. Os compradores devem ter em conta estas variáveis quando orçamentam a substituição de um alternador. -

Existem alternativas mais baratas aos alternadores novos?

Sim, os compradores podem considerar os alternadores remanufacturados ou pós-venda como alternativas económicas aos novos. As unidades remanufacturadas são frequentemente renovadas a partir de peças usadas e podem proporcionar poupanças significativas, ao mesmo tempo que oferecem fiabilidade. No entanto, é essencial assegurar que estas alternativas cumprem as especificações exigidas para o veículo e vêm com uma garantia para proteção contra defeitos. -

Como posso encontrar fornecedores fiáveis de alternadores?

Para encontrar fornecedores fiáveis de alternadores, comece por pesquisar fabricantes e distribuidores com uma sólida reputação na indústria automóvel. Verifique as certificações e as opiniões dos clientes e considere a possibilidade de contactar os contactos da indústria para obter recomendações. Além disso, participar em feiras comerciais ou conferências do sector pode ajudá-lo a estabelecer contacto com potenciais fornecedores e a avaliar as suas ofertas em primeira mão. -

Que condições de pagamento devo esperar quando forneço alternadores a nível internacional?

As condições de pagamento podem variar muito entre fornecedores internacionais, pelo que é crucial discutir estes pormenores antecipadamente. As condições mais comuns incluem o pagamento no ato da encomenda, o pagamento antecipado parcial com o saldo a pagar no ato da entrega ou o pagamento após a receção dos bens. Também é aconselhável considerar a utilização de métodos de pagamento seguros, como cartas de crédito ou serviços de caução, que podem proporcionar proteção adicional a ambas as partes na transação. -

Quais são as quantidades mínimas de encomenda (MOQs) para os alternadores?

As quantidades mínimas de encomenda (MOQs) para alternadores podem variar consoante o fornecedor e as suas capacidades de produção. Alguns fornecedores podem ter MOQs baixos para modelos comuns, enquanto outros podem exigir quantidades maiores para unidades personalizadas ou especializadas. É aconselhável comunicar claramente as suas necessidades e negociar MOQs que se alinhem com os seus requisitos comerciais para evitar custos de inventário em excesso. -

Como posso assegurar a garantia de qualidade ao adquirir alternadores?

Para assegurar a garantia de qualidade ao adquirir alternadores, é importante trabalhar com fornecedores que cumpram as normas e certificações da indústria. Solicite especificações detalhadas do produto e processos de controlo de qualidade e considere a realização de auditorias ou inspecções à fábrica, se possível. Além disso, o estabelecimento de uma política de devolução de produtos defeituosos pode salvaguardar o seu investimento e manter a satisfação do cliente. -

Que considerações logísticas devo ter em mente ao importar alternadores?

Ao importar alternadores, tenha em consideração factores logísticos, tais como métodos de envio, regulamentos aduaneiros e prazos de entrega. Escolha um transitário fiável, familiarizado com peças automóveis, para tratar da logística de forma eficiente. Além disso, tenha em atenção os direitos de importação e os impostos, uma vez que estes podem ter um impacto significativo no custo global. O planeamento de potenciais atrasos no envio e no desalfandegamento é também essencial para manter a eficiência da cadeia de abastecimento.

Lista dos 3 principais fabricantes e fornecedores de Quanto custa para instalar um alternador

1. Toyota - RAV4 Substituição do Alternador

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: 2006 Toyota RAV4, substituição do alternador, $450 custo total incluindo mão de obra.

2. Facebook - Custos de substituição do alternador

Domínio: facebook.com

Registado: 1997 (28 anos)

Introdução: Esta empresa, Facebook - Alternator Replacement Costs, é uma entidade notável no mercado. Para obter detalhes específicos do produto, recomenda-se visitar diretamente o seu sítio Web.

3. CarTalk - Custos de substituição do alternador

Domínio: cartalk.com

Registrado: 1995 (30 anos)

Introdução: O custo de substituição de um alternador varia entre aproximadamente $600 e $1.500. Um alternador é um componente crítico que mantém a carga da bateria e alimenta vários sistemas eléctricos de um veículo. Os sintomas de uma avaria do alternador incluem uma luz de verificação do motor, faróis a escurecer e a necessidade de arranques rápidos. Os alternadores podem falhar devido a desgaste mecânico ou falha de componentes eléctricos. Novo...

Conclusão e perspectivas do aprovisionamento estratégico para quanto custa a instalação de um alternador

Em conclusão, compreender os custos associados à instalação de um alternador é essencial para os compradores B2B que navegam no mercado de peças automóveis. As despesas de instalação podem variar significativamente com base em factores como a marca e o modelo do veículo, o tipo de alternador e os custos de mão de obra. Uma abordagem de aprovisionamento estratégico não só ajudará a identificar soluções rentáveis, como também garantirá a seleção de componentes de alta qualidade que aumentam a fiabilidade operacional.

Investir tempo na pesquisa de fornecedores e compreender a dinâmica do mercado regional pode levar a poupanças substanciais e a uma melhor prestação de serviços. Para os compradores internacionais, especialmente os de África, América do Sul, Médio Oriente e Europa, a criação de parcerias fortes com fornecedores de renome pode facilitar melhores estratégias de aquisição e reduzir os prazos de entrega.

Olhando para o futuro, à medida que a indústria automóvel continua a evoluir com os avanços nos veículos eléctricos e híbridos, a importância do fornecimento de alternadores de elevado desempenho só irá aumentar. Contacte hoje mesmo os seus fornecedores para garantir que está equipado para as futuras exigências do mercado automóvel e explore soluções inovadoras que podem aumentar a eficiência e a rentabilidade das suas operações.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.