Introduction: Navigating the Global Market for how long does a toyota alternator last

In the competitive landscape of automotive parts, understanding how long a Toyota alternator lasts is essential for B2B buyers seeking reliable components for their fleets or resale. The longevity of an alternator can significantly impact vehicle performance and maintenance costs, making it crucial for businesses to make informed purchasing decisions. This comprehensive guide delves into the factors influencing alternator lifespan, including usage patterns, environmental conditions, and potential wear and tear from other vehicle components.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Nigeria—will benefit from insights into various types of Toyota alternators, their applications across different models, and strategies for vetting suppliers. The guide also addresses cost considerations, allowing businesses to balance quality and affordability when sourcing these critical components.

By empowering buyers with knowledge about the expected lifespan of Toyota alternators and the nuances of their maintenance, this guide serves as a vital resource for making strategic purchasing decisions. Whether you’re managing a fleet or operating in the automotive aftermarket, understanding the intricacies of alternator longevity will enhance your operational efficiency and reduce unexpected downtime.

Índice

- Top 4 How Long Does A Toyota Alternator Last Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how long does a toyota alternator last

- Understanding how long does a toyota alternator last Types and Variations

- Key Industrial Applications of how long does a toyota alternator last

- 3 Common User Pain Points for ‘how long does a toyota alternator last’ & Their Solutions

- Strategic Material Selection Guide for how long does a toyota alternator last

- In-depth Look: Manufacturing Processes and Quality Assurance for how long does a toyota alternator last

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does a toyota alternator last’

- Comprehensive Cost and Pricing Analysis for how long does a toyota alternator last Sourcing

- Alternatives Analysis: Comparing how long does a toyota alternator last With Other Solutions

- Essential Technical Properties and Trade Terminology for how long does a toyota alternator last

- Navigating Market Dynamics and Sourcing Trends in the how long does a toyota alternator last Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how long does a toyota alternator last

- Strategic Sourcing Conclusion and Outlook for how long does a toyota alternator last

- Aviso legal importante e termos de utilização

Understanding how long does a toyota alternator last Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Alternadores padrão | Typically last 7-10 years; designed for regular use | General automotive repairs | Prós: Reliable and widely available. Contras: May not withstand heavy loads. |

| Alternadores para trabalhos pesados | Built for high-demand applications; longer lifespan of 10-15 years | Commercial vehicles, towing, and fleets | Prós: Enhanced durability for demanding conditions. Contras: Investimento inicial mais elevado. |

| Alternadores de alto desempenho | Optimized for high output; often used in modified vehicles | Racing and performance vehicles | Prós: Increased power output. Contras: Shorter lifespan under normal conditions. |

| Alternadores OEM | Original equipment manufacturer parts; designed specifically for Toyota models | Authorized dealerships and repairs | Prós: Compatibilidade e qualidade garantidas. Contras: Often more expensive than aftermarket options. |

| Alternadores para o mercado de reposição | Generic replacements; may vary in quality | Independent repair shops | Prós: Económica e amplamente disponível. Contras: Quality can be inconsistent; shorter lifespan. |

Quais são as características dos alternadores padrão?

Standard alternators are the most common type found in Toyota vehicles, typically lasting between 7 to 10 years. They are designed for everyday use, making them suitable for personal vehicles and general automotive repairs. For B2B buyers, these alternators offer reliability and widespread availability, making them a go-to choice for fleet maintenance or independent repair shops. However, they may not be ideal for vehicles that frequently carry heavy loads or operate in extreme conditions, as their lifespan can be significantly reduced under such stresses.

How Do Heavy-Duty Alternators Differ in Lifespan and Application?

Heavy-duty alternators are engineered to withstand the rigors of commercial applications, boasting a lifespan of 10 to 15 years. They are particularly useful for commercial vehicles, towing applications, and fleet operations where high electrical loads are common. B2B buyers in these sectors should consider heavy-duty options for their durability and reliability, even though they come with a higher upfront cost. The investment pays off in reduced downtime and maintenance costs over time, making them a practical choice for businesses reliant on their vehicles.

What Benefits Do Performance Alternators Offer?

Performance alternators are specialized components designed for high-output applications, such as racing or modified vehicles. While they can provide increased power output, their lifespan may be shorter than that of standard alternators, particularly under normal driving conditions. B2B buyers in the automotive performance sector should weigh the benefits of enhanced power against the potential for more frequent replacements. This type of alternator is ideal for performance shops and racing teams that prioritize power over longevity.

Why Choose OEM Alternators for Toyota Vehicles?

OEM (Original Equipment Manufacturer) alternators are specifically designed for Toyota vehicles, ensuring compatibility and quality. They typically offer a reliable lifespan of 8 to 10 years, making them an excellent choice for authorized dealerships and repair centers. For B2B buyers, the assurance of quality and the guarantee of fit can justify the higher price point compared to aftermarket options. However, businesses should consider their budget and whether the premium for OEM parts aligns with their operational needs.

What Should Buyers Know About Aftermarket Alternators?

Aftermarket alternators are generic replacements that vary in quality and lifespan. They are often more affordable and readily available, making them a popular choice for independent repair shops. However, B2B buyers should be cautious as the quality of aftermarket parts can be inconsistent, potentially leading to shorter lifespans. For businesses focused on cost savings and willing to manage the risks associated with varying quality, aftermarket alternators can provide a viable solution for vehicle repairs and maintenance.

Key Industrial Applications of how long does a toyota alternator last

| Indústria/Setor | Specific Application of how long does a toyota alternator last | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Maintenance and replacement services for Toyota vehicles | Reduces downtime and enhances customer satisfaction through reliable service | Ensure access to quality parts and skilled technicians for installation |

| Gestão de frotas | Monitoring alternator lifespan in commercial vehicles | Increases operational efficiency by preventing unexpected failures | Implement regular maintenance schedules and invest in quality components |

| Transporte e Logística | Assessing vehicle performance for long-haul operations | Enhances reliability and safety of transport vehicles | Source durable alternators suitable for high-load applications |

| Equipamento agrícola | Evaluating alternator performance in farming machinery | Ensures uninterrupted operation of essential agricultural equipment | Consider environmental conditions and power demands of equipment |

| Energia renovável | Utilizing Toyota vehicles for energy transport and logistics | Supports sustainability initiatives while ensuring vehicle reliability | Prioritize sourcing alternators that can withstand variable climates |

How is ‘how long does a Toyota alternator last’ relevant for the automotive repair industry?

In the automotive repair sector, understanding the lifespan of a Toyota alternator is crucial for providing effective maintenance and replacement services. Technicians can better educate customers about the expected lifespan, typically around eight years, and the signs of impending failure. This proactive approach not only enhances customer satisfaction but also builds trust, as clients appreciate transparency regarding their vehicle’s health. For international buyers, sourcing high-quality replacement parts is essential to ensure longevity and reliability, particularly in regions with varying climate conditions that may affect alternator performance.

What role does alternator lifespan play in fleet management?

For fleet management, knowing how long a Toyota alternator lasts is vital for optimizing vehicle performance and minimizing downtime. Fleet operators can implement regular monitoring of alternator health to prevent unexpected failures, which can disrupt operations and incur additional costs. By understanding the specific demands placed on their vehicles, such as load and operating conditions, fleet managers can better schedule maintenance and replacements. This is particularly important in regions like Africa and South America, where road conditions and environmental factors can significantly impact vehicle reliability.

How does alternator performance impact transportation and logistics?

In the transportation and logistics industry, the longevity of Toyota alternators directly influences the safety and reliability of vehicles used for long-haul operations. A well-functioning alternator ensures that all electrical systems operate smoothly, which is critical for navigation and communication equipment. By regularly assessing alternator performance, logistics companies can enhance operational efficiency and reduce the risk of breakdowns. For international buyers, sourcing robust alternators designed for high-load applications is essential to maintain vehicle performance under demanding conditions.

Why is alternator evaluation important for agricultural equipment?

In the agricultural sector, the performance of alternators in farming machinery can determine the efficiency of operations. Understanding how long a Toyota alternator lasts helps farmers plan for maintenance and replacements, ensuring that essential equipment remains operational during critical planting and harvesting seasons. This is particularly significant in areas where agricultural machinery is subjected to harsh environmental conditions. Buyers should consider sourcing alternators that are not only durable but also compatible with various farming equipment to maximize their investment.

How does alternator reliability support renewable energy initiatives?

For businesses involved in renewable energy, utilizing Toyota vehicles for energy transport and logistics requires a reliable alternator to ensure seamless operations. Understanding the lifespan of these components allows companies to implement preventative maintenance strategies that align with their sustainability goals. By sourcing alternators that can withstand variable climates and heavy loads, businesses can ensure their logistics operations remain efficient and environmentally friendly. This proactive approach is especially beneficial for international buyers looking to support sustainable practices in their regions.

3 Common User Pain Points for ‘how long does a toyota alternator last’ & Their Solutions

Scenario 1: Unpredictable Alternator Lifespan and Its Impact on Fleet Operations

O problema: For businesses operating fleets of Toyota vehicles, managing maintenance schedules is critical to avoid downtime. However, many fleet managers struggle with the unpredictable lifespan of alternators, which can typically last around eight years but often fail prematurely due to various factors such as excessive electrical load or environmental conditions. This unpredictability can lead to unexpected breakdowns, which not only disrupt operations but also incur additional repair and towing costs.

A solução: To mitigate the risks associated with alternator failures, fleet managers should implement a proactive maintenance program that includes regular inspections and testing of alternators, especially for vehicles over five years old. Utilizing diagnostic tools to assess the alternator’s output voltage and overall health can provide early warning signs of potential failure. Additionally, it is beneficial to establish a relationship with a reliable parts supplier who can provide high-quality alternators that meet or exceed OEM specifications. By having a supply of alternators on hand, fleet operators can reduce downtime by facilitating quick replacements when necessary.

Scenario 2: The Challenge of Sourcing Quality Replacement Parts

O problema: B2B buyers often face challenges when sourcing replacement parts for Toyota vehicles, particularly alternators. With varying quality among aftermarket options and the risk of counterfeit products, buyers may find themselves in a dilemma over which parts to procure. This challenge is compounded by the critical role that a reliable alternator plays in vehicle performance, making it imperative to select the right component.

A solução: To ensure the procurement of high-quality alternators, B2B buyers should prioritize sourcing from reputable manufacturers known for their reliability and performance, such as Denso or Bosch. Conducting thorough market research and reading reviews from other buyers can help in identifying trustworthy suppliers. Additionally, buyers should consider establishing contracts with manufacturers that provide warranties and guarantees, ensuring that if a replacement part fails prematurely, they can easily secure a replacement without incurring additional costs. Educating the procurement team on the technical specifications required for Toyota alternators can also help in making informed purchasing decisions.

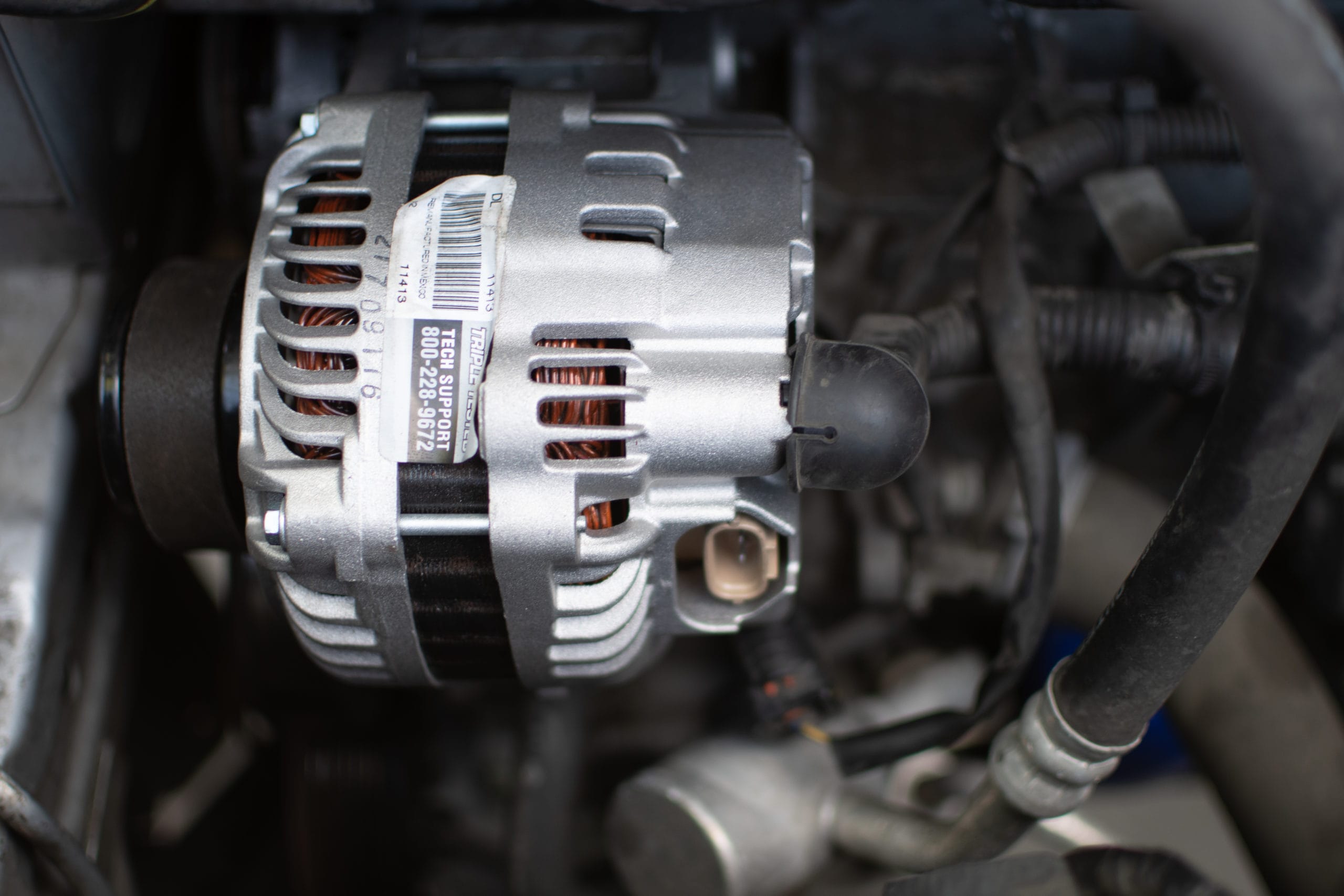

Illustrative image related to how long does a toyota alternator last

Scenario 3: Managing Customer Expectations Regarding Alternator Lifespan

O problema: Automotive repair shops often encounter customer inquiries about the lifespan of alternators, leading to potential dissatisfaction if customers experience early failures. Customers may have unrealistic expectations based on limited information, which can affect their trust in the repair shop. Managing these expectations while providing sound advice on vehicle maintenance is crucial for customer retention.

A solução: Repair shops should develop a comprehensive communication strategy that educates customers about the average lifespan of alternators and the factors that can influence their longevity, such as driving habits and environmental conditions. Providing customers with clear maintenance guidelines, such as regular battery checks and avoiding excessive electrical loads, can empower them to take proactive steps in extending the life of their alternators. Additionally, offering a vehicle health check service that includes alternator testing can build trust and demonstrate the shop’s commitment to quality service. By setting realistic expectations and providing valuable insights, repair shops can enhance customer satisfaction and loyalty.

Strategic Material Selection Guide for how long does a toyota alternator last

What Are the Common Materials Used in Toyota Alternators and Their Lifespan?

When considering the lifespan of a Toyota alternator, the materials used in its construction play a crucial role in determining durability, performance, and overall longevity. Here, we analyze four common materials utilized in the manufacturing of alternators, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Alumínio

Propriedades principais: Aluminum is lightweight, has excellent thermal conductivity, and is resistant to corrosion, making it ideal for automotive applications. It typically withstands temperatures up to 150°C (302°F) and offers good mechanical strength.

Prós e contras: The primary advantage of aluminum is its weight, which contributes to improved fuel efficiency in vehicles. However, it can be more expensive than other metals and may require specialized manufacturing processes, increasing production complexity. While aluminum provides good durability, it may not be as robust under extreme conditions compared to heavier metals.

Impacto na aplicação: Aluminum’s corrosion resistance makes it suitable for environments with high humidity or exposure to road salts, which is common in many regions, including Europe and parts of South America.

Considerações para compradores internacionais: Buyers should ensure compliance with international standards such as ASTM and ISO for aluminum quality. In regions like Africa and the Middle East, where temperatures can soar, selecting high-grade aluminum is essential for longevity.

2. Cobre

Propriedades principais: Copper is known for its excellent electrical conductivity, which is crucial for the efficient functioning of alternators. It can handle high temperatures (up to 200°C or 392°F) and has good corrosion resistance when treated.

Prós e contras: The primary advantage of copper is its superior conductivity, which enhances the alternator’s efficiency. However, copper is heavier and more expensive than alternatives like aluminum. Additionally, its susceptibility to corrosion in certain environments can be a drawback unless adequately coated.

Impacto na aplicação: Copper’s conductivity makes it ideal for wiring and components within the alternator, ensuring efficient power generation and distribution.

Considerações para compradores internacionais: Buyers in regions with high humidity or corrosive environments, such as coastal areas in Brazil or Nigeria, should prioritize copper components that are treated for corrosion resistance to ensure longevity.

3. Aço

Propriedades principais: Steel is known for its strength and durability, with a high resistance to wear and tear. It can withstand high temperatures (up to 300°C or 572°F) and is generally resistant to deformation.

Prós e contras: The strength of steel provides excellent structural integrity, making it suitable for heavy-duty applications. However, it is heavier than aluminum and can be prone to rust if not properly coated or treated. The manufacturing process for steel components can also be more complex, impacting overall production costs.

Illustrative image related to how long does a toyota alternator last

Impacto na aplicação: Steel is often used in the frame and housing of the alternator, providing protection against physical damage and environmental factors.

Considerações para compradores internacionais: Compliance with standards like DIN and JIS is crucial for steel components, especially in regions like Europe where quality assurance is prioritized. Buyers should also consider the potential for rust in humid climates, necessitating protective coatings.

4. Compósitos plásticos

Propriedades principais: Plastic composites are lightweight, resistant to corrosion, and can withstand moderate temperatures (up to 120°C or 248°F). They are often used for insulation and housing components.

Illustrative image related to how long does a toyota alternator last

Prós e contras: The main advantage of plastic composites is their lightweight nature, which can contribute to overall vehicle efficiency. However, they may not be as durable as metals under extreme conditions and can degrade over time with exposure to UV light and heat.

Impacto na aplicação: Plastic composites are suitable for non-load-bearing components, providing insulation and protection for electrical parts within the alternator.

Considerações para compradores internacionais: Buyers should ensure that the plastic composites used meet international safety and quality standards, particularly in regions with high UV exposure, such as Africa and the Middle East.

Tabela resumida

| Material | Typical Use Case for how long does a toyota alternator last | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Componentes estruturais e de alojamento | Leve e resistente à corrosão | Custo mais elevado e complexidade de fabrico | Médio |

| Cobre | Wiring and electrical components | Excelente condutividade elétrica | Mais pesado e propenso à corrosão | Alto |

| Aço | Frame and housing components | Alta resistência e durabilidade | Heavier and potential rust issues | Médio |

| Compósitos plásticos | Isolamento e partes não portadoras de carga | Leve e resistente à corrosão | Menos durável em condições extremas | Baixo |

This analysis provides actionable insights for international B2B buyers regarding the materials used in Toyota alternators, helping them make informed decisions based on performance, cost, and regional considerations.

Illustrative image related to how long does a toyota alternator last

In-depth Look: Manufacturing Processes and Quality Assurance for how long does a toyota alternator last

What Are the Main Stages of Manufacturing a Toyota Alternator?

The manufacturing process of a Toyota alternator involves several critical stages, each designed to ensure high-quality production and durability. Understanding these stages can help B2B buyers assess the reliability of potential suppliers.

Preparação de materiais: Que materiais são utilizados na produção de alternadores?

The first step in the manufacturing process is the selection and preparation of materials. High-quality aluminum alloys and copper are commonly used for the alternator’s housing and windings. These materials are chosen for their excellent conductivity and durability. Manufacturers often source materials from verified suppliers who comply with international standards, ensuring consistent quality. Proper material preparation also includes testing for impurities and defects, which can compromise the alternator’s performance.

How Are Alternator Components Formed?

Once materials are prepared, they undergo various forming processes. Techniques such as die casting, stamping, and machining are employed to create the alternator’s housing, rotor, and stator components. Advanced technologies like CNC (Computer Numerical Control) machining ensure precision in dimensions, which is crucial for performance. Additionally, automated processes are increasingly used to enhance consistency and reduce human error, further contributing to the longevity of the alternator.

What Is the Assembly Process for a Toyota Alternator?

After forming, the components move to the assembly stage. This phase is critical, as it combines all individual parts into a functional unit. Skilled technicians typically oversee this process, ensuring that each component is installed correctly and meets stringent specifications.

Are There Quality Control Checkpoints During Assembly?

Quality control (QC) is integrated throughout the assembly process. Manufacturers often implement in-process quality checks (IPQC) to monitor tolerances and functionality at various stages. This continuous oversight helps identify potential issues before they escalate, ensuring that the final product meets quality standards.

What Finishing Techniques Are Employed to Enhance Durability?

Once assembled, the alternators undergo finishing processes. These may include surface treatments such as anodizing or painting, which protect against corrosion and wear. Additionally, electrical testing is performed to ensure the alternator meets performance specifications, including voltage output and current capacity. This stage is crucial, as it directly impacts the alternator’s longevity and reliability.

Como é implementada a garantia de qualidade no fabrico de alternadores?

Quality assurance (QA) is vital for ensuring that every alternator produced meets both internal and external quality standards. Manufacturers often adhere to international standards such as ISO 9001, which provides a framework for consistent quality management systems. Compliance with these standards assures B2B buyers that the products are manufactured under rigorous quality guidelines.

Que normas internacionais devem ser conhecidas pelos compradores B2B?

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also be relevant, depending on the alternator’s application. These certifications indicate that the alternator meets specific safety and performance criteria, which can be particularly important for buyers in regulated markets.

What Are Common Testing Methods for Alternators?

Testing methods play a crucial role in the quality assurance process. Common tests include:

- Testes elétricos: Verifying voltage output and current handling capabilities.

- Ensaios de ciclo térmico: Assessing the alternator’s performance under extreme temperature variations.

- Ensaios de vibração: Ensuring that the alternator can withstand the vibrations encountered during operation.

These tests help identify potential weaknesses and ensure the alternator can perform reliably over its expected lifespan.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. This can be achieved through several methods:

Are Audits and Reports Effective for Ensuring Quality?

Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance measures. Buyers should request quality control reports, which detail testing results and compliance with international standards.

Illustrative image related to how long does a toyota alternator last

What Role Does Third-Party Inspection Play?

Engaging third-party inspection services can further validate a supplier’s claims regarding quality. These independent assessments can help identify discrepancies and ensure that the alternators meet the specified quality criteria before shipment.

Que nuances devem os compradores B2B internacionais ter em conta?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and manufacturing practices. Variations in local regulations, material availability, and supply chain reliability can affect the quality of alternators. Buyers should ensure that their suppliers are equipped to handle these challenges and can provide documentation that meets both local and international standards.

Conclusion: Why Understanding Manufacturing and QC Is Crucial for B2B Buyers

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for Toyota alternators is essential for B2B buyers. By focusing on key manufacturing stages, quality control standards, and testing methods, buyers can make informed decisions when sourcing alternators. This knowledge not only helps in selecting reliable suppliers but also ensures that the products meet the performance and longevity expectations critical for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does a toyota alternator last’

Introdução

Understanding the lifespan of a Toyota alternator is crucial for B2B buyers in the automotive sector, particularly when procuring components for maintenance or resale. This guide provides a step-by-step checklist to help you navigate the factors influencing alternator longevity, ensuring you make informed purchasing decisions that align with operational needs and customer expectations.

Illustrative image related to how long does a toyota alternator last

Passo 1: Avaliar os requisitos do seu veículo

Before sourcing alternators, evaluate the specific needs of the vehicles you service or sell. Consider the make, model, and year of the Toyota vehicles in your fleet or inventory. Understanding these specifications will help you identify compatible alternators that meet the electrical demands of each vehicle.

- Sub-bullet: Review manufacturer guidelines to understand power output requirements, typically around 14.5 volts for optimal performance.

- Sub-bullet: Factor in any modifications or additional electrical loads that may impact alternator performance.

Passo 2: Research Average Lifespan Data

Gather data on the average lifespan of Toyota alternators, which typically ranges from 8 to 12 years or 100,000 to 150,000 miles under normal conditions. This information is essential for setting realistic expectations with your customers regarding maintenance and replacement cycles.

- Sub-bullet: Analyze regional data, as environmental factors such as temperature extremes can affect alternator durability.

- Sub-bullet: Consult forums and industry reports to understand real-world performance across various Toyota models.

Passo 3: Avaliar a fiabilidade do fornecedor

Identifying reputable suppliers is key to ensuring the quality of the alternators you procure. Look for suppliers with a strong track record in the automotive industry and positive customer reviews.

- Sub-bullet: Request references from other businesses that have purchased alternators from the supplier.

- Sub-bullet: Check for certifications that indicate adherence to industry standards, such as ISO or TS certifications.

Passo 4: Considere as opções de garantia e suporte

A robust warranty and support structure can significantly impact your purchasing decision. Ensure that the alternators come with a warranty that covers defects and performance issues, providing peace of mind for you and your customers.

- Sub-bullet: Evaluate the warranty length and terms; a longer warranty often reflects manufacturer confidence in their product.

- Sub-bullet: Assess the supplier’s customer service responsiveness, as timely support can be crucial in resolving issues.

Passo 5: Analisar as estruturas de preços

Pricing can vary significantly based on the supplier, alternator specifications, and geographic location. Conduct a thorough market analysis to ensure you are getting competitive rates.

Illustrative image related to how long does a toyota alternator last

- Sub-bullet: Compare prices across multiple suppliers, but also consider the total cost of ownership, including shipping and handling.

- Sub-bullet: Look for bulk purchasing discounts or loyalty programs that can enhance your profit margins.

Passo 6: Test for Quality Assurance

Before finalizing a large order, consider obtaining samples for quality testing. This step allows you to assess the alternators’ performance and durability firsthand.

- Sub-bullet: Conduct load tests to ensure the alternators meet voltage and amperage specifications.

- Sub-bullet: Evaluate the build quality and materials used, as these factors can influence longevity.

Conclusão

By following this checklist, B2B buyers can make informed decisions when sourcing Toyota alternators, ensuring they meet operational needs and customer expectations. Understanding the intricacies of alternator lifespan and performance will contribute to better service delivery and enhanced customer satisfaction.

Comprehensive Cost and Pricing Analysis for how long does a toyota alternator last Sourcing

What Are the Key Cost Components for Sourcing a Toyota Alternator?

When considering the sourcing of a Toyota alternator, several cost components must be analyzed to understand the overall pricing structure. Key components include:

-

Materiais: The primary material for alternators is typically aluminum and copper, which are essential for effective electrical conductivity and durability. The choice of materials can significantly impact the cost, especially if premium-grade components are used.

-

Trabalho: Labor costs encompass the workforce required for assembly, quality control, and testing. Skilled labor is crucial in ensuring that the alternators meet performance standards, which can affect the overall price.

-

Custos indiretos de produção: This includes costs related to the production facility, machinery maintenance, utilities, and indirect labor. Efficient manufacturing processes can help reduce these overhead costs, thereby influencing the final price.

-

Ferramentas: The investment in specialized tools and equipment necessary for producing alternators can be substantial. Tooling costs are often amortized over the production volume, affecting pricing strategies.

-

Controlo de Qualidade (QC): QC processes ensure that each alternator meets stringent performance and safety standards. Enhanced QC measures may raise the cost but are essential for maintaining product reliability.

-

Logística: Transportation, warehousing, and distribution costs can vary significantly based on geographical location and the chosen Incoterms. These factors are particularly important for international buyers.

-

Margem: Suppliers typically apply a margin to cover their operational costs and profit. Understanding the margin expectations can aid in negotiating better pricing.

What Factors Influence the Price of Toyota Alternators?

Several price influencers should be considered when sourcing Toyota alternators:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate volume discounts to maximize cost efficiency.

-

Especificações e personalização: Customizations based on specific vehicle models or performance requirements can lead to increased costs. Clear communication of specifications helps in obtaining accurate quotes.

-

Materiais: The choice of materials impacts durability and performance. Higher-quality materials may incur higher costs but provide better longevity, ultimately affecting the Total Cost of Ownership (TCO).

-

Certificações de qualidade: Compliance with international quality standards (such as ISO or TS certifications) can influence the price. Certified products often command a premium but provide assurance of quality.

-

Fatores relacionados ao fornecedor: Supplier reliability, reputation, and location can affect pricing. Long-term relationships with reputable suppliers can lead to better pricing and terms.

-

Incoterms: The choice of Incoterms dictates who bears the cost and responsibility during shipping. Understanding these terms is crucial for calculating the total landed cost.

How Can Buyers Optimize Costs and Pricing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several tips can help optimize sourcing costs:

-

Negociar termos: Always negotiate payment terms, delivery schedules, and pricing. Building a strong relationship with suppliers can lead to better deals.

-

Considere o custo total de propriedade (TCO): While initial purchase price is important, evaluating the TCO—including maintenance, potential failures, and longevity—will provide a clearer picture of value.

-

Esteja ciente das nuances dos preços: Different regions may have varying pricing due to local economic conditions, tariffs, and import taxes. Buyers should conduct thorough market research to understand these factors.

-

Leverage Technology: Utilizing e-sourcing platforms can streamline the procurement process and allow for better price comparisons across suppliers.

-

Mantenha-se informado sobre as tendências do mercado: Keeping abreast of material costs and automotive market trends can provide leverage in negotiations and sourcing strategies.

Declaração de exoneração de responsabilidade sobre estimativas de preços

Pricing can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. The insights provided should be used as a guideline, and buyers are encouraged to conduct detailed market analysis and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing how long does a toyota alternator last With Other Solutions

Introduction: Understanding Alternatives in Automotive Power Solutions

When considering the longevity and reliability of automotive components, particularly alternators, it’s crucial to evaluate alternatives that serve similar functions. The Toyota alternator is known for its durability, typically lasting around eight years or 135,000 miles under normal conditions. However, various other solutions in the market can also fulfill the electrical power generation needs of vehicles. This analysis will compare the lifespan and effectiveness of the Toyota alternator against two alternative power solutions: high-performance aftermarket alternators and electric vehicle (EV) power management systems.

Tabela comparativa

| Aspecto comparativo | How Long Does A Toyota Alternator Last | High-Performance Aftermarket Alternator | Electric Vehicle Power Management System |

|---|---|---|---|

| Desempenho | Reliable; approx. 8 years/135,000 miles | Enhanced output; can exceed factory specs | Continuous power; optimized for efficiency |

| Custo | Moderate; OEM pricing varies by model | Higher initial investment; varies widely | Generally higher; includes EV technology |

| Facilidade de implementação | Straightforward; designed for specific models | Requires compatibility checks; may need modifications | Complex; requires integration with vehicle systems |

| Manutenção | Low; routine checks recommended | Moderate; may require more frequent monitoring | Minimal; mostly software updates needed |

| Melhor caso de uso | Standard vehicles with typical loads | Performance vehicles, high-demand applications | Electric and hybrid vehicles, efficiency-focused fleets |

Discriminação detalhada das alternativas

High-Performance Aftermarket Alternator

High-performance aftermarket alternators are designed to provide increased power output compared to standard OEM units. They are particularly beneficial for vehicles that require enhanced electrical performance, such as those with additional aftermarket accessories or heavy loads. The primary advantage is the ability to support higher demands without failure. However, they often come at a higher cost and may require additional installation considerations to ensure compatibility with the vehicle’s electrical system.

Electric Vehicle Power Management System

Electric vehicles (EVs) utilize sophisticated power management systems that control the distribution of electrical power throughout the vehicle. These systems are designed to optimize battery use, ensuring that energy is used efficiently and extends the overall range of the vehicle. The main benefit of EV power management is its ability to provide continuous power without the reliance on traditional mechanical components. However, this system tends to be more expensive and complex to implement, requiring specialized knowledge and equipment. It is ideal for fleets or businesses looking to transition to greener technologies.

Conclusão: escolhendo a solução certa para as suas necessidades

Selecting the right power generation solution for a vehicle depends on various factors, including the intended use, budget constraints, and the specific electrical demands of the vehicle. For businesses operating in traditional markets, the Toyota alternator remains a reliable choice with proven longevity. In contrast, companies looking to enhance performance or transition to electric vehicles may find aftermarket options or EV power management systems more suitable. Understanding the unique advantages and limitations of each solution will empower B2B buyers to make informed decisions that align with their operational requirements and strategic goals.

Illustrative image related to how long does a toyota alternator last

Essential Technical Properties and Trade Terminology for how long does a toyota alternator last

What Are the Key Technical Properties of a Toyota Alternator?

Understanding the technical specifications of a Toyota alternator is crucial for B2B buyers, especially when sourcing replacement parts for fleet vehicles or automotive repairs. Here are some essential properties to consider:

1. Tensão de saída

The output voltage of a Toyota alternator typically hovers around 14.5V when fully functional. This voltage is vital for recharging the vehicle’s battery and powering the electrical systems. Buyers should ensure that the alternator they purchase meets this specification to avoid electrical failures that could lead to operational downtime.

2. Lifespan Expectancy

On average, a Toyota alternator can last approximately eight years or around 100,000 to 150,000 miles, depending on usage conditions. High temperatures, excessive load, or frequent short trips can reduce this lifespan. Understanding expected longevity helps businesses plan for maintenance schedules and budget for replacements.

3. Composição do material

Most Toyota alternators are made from high-grade aluminum and copper, materials known for their durability and efficiency in electrical conductivity. The choice of materials impacts the alternator’s performance and lifespan. B2B buyers should prioritize suppliers that use OEM-standard materials to ensure reliability and optimal performance.

4. Especificações de peso e tamanho

Alternators vary in size and weight based on their design and intended application. Typically, a Toyota alternator weighs between 6 to 10 pounds. Knowledge of these specifications is essential for ensuring compatibility with various vehicle models and for logistics management in shipping and storage.

5. Mecanismo de arrefecimento

Many Toyota alternators are equipped with built-in cooling fans or are designed to dissipate heat effectively. This feature is critical for maintaining performance under heavy loads or in high-temperature environments. Buyers should consider this property when assessing the longevity and reliability of alternators in different climatic conditions.

What Are Common Trade Terms Related to Toyota Alternators?

Understanding industry terminology is crucial for successful B2B transactions. Here are some common terms you should know:

1. OEM (Fabricante de Equipamento Original)

OEM parts are manufactured by the vehicle’s original manufacturer. Sourcing OEM alternators ensures compatibility and reliability, making them preferable for businesses that prioritize quality and performance.

2. MOQ (Quantidade mínima de encomenda)

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and ensure they are not overcommitting financially.

3. RFQ (Pedido de Orçamento)

An RFQ is a formal document issued by a buyer to suppliers, requesting pricing and terms for specific products. Utilizing RFQs can streamline the procurement process and ensure that buyers receive competitive pricing on alternators.

Illustrative image related to how long does a toyota alternator last

4. Incoterms (Termos Comerciais Internacionais)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations and manage logistics more effectively.

5. Prazo de entrega

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time for alternators can help businesses plan their vehicle maintenance schedules and avoid unexpected downtimes.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing Toyota alternators, ensuring they select the right parts for their operational needs.

Illustrative image related to how long does a toyota alternator last

Navigating Market Dynamics and Sourcing Trends in the how long does a toyota alternator last Sector

What Are the Key Market Drivers for Toyota Alternators?

The global automotive market is experiencing significant shifts driven by technological advancements and changing consumer preferences. For B2B buyers, especially in emerging markets like Africa and South America, understanding these dynamics is crucial. The average lifespan of a Toyota alternator ranges from 8 to 12 years, depending on various factors such as usage patterns, environmental conditions, and maintenance practices. This variability creates opportunities for suppliers to offer tailored solutions, including high-performance alternators designed to withstand harsh climates, particularly in regions with extreme temperatures or heavy electrical loads.

Moreover, the rise of electric vehicles (EVs) is reshaping the landscape for traditional alternators. As more manufacturers pivot towards hybrid and fully electric models, the demand for conventional alternators may decline. However, there is a corresponding increase in the need for advanced power management systems and regenerative braking technologies that can optimize energy use in both conventional and electric vehicles. B2B buyers should stay informed about these trends to align their sourcing strategies with manufacturers that are innovating in these areas.

How Important Is Sustainability in the Sourcing of Toyota Alternators?

Sustainability has emerged as a critical factor in the sourcing of automotive components, including alternators. Environmental concerns are prompting businesses to seek suppliers who prioritize eco-friendly practices. This includes the use of recyclable materials and adherence to stringent environmental regulations. Buyers should look for manufacturers with certifications such as ISO 14001, which demonstrates commitment to effective environmental management systems.

Furthermore, ethical sourcing practices are gaining traction in the automotive sector. Suppliers that can prove their commitment to fair labor practices and transparency in their supply chains are more likely to gain trust and loyalty from B2B buyers. As global consumers increasingly favor brands that demonstrate corporate social responsibility, businesses that prioritize sustainability in their sourcing decisions may find themselves better positioned in the market.

What Has Driven the Evolution of Toyota Alternators Over Time?

The evolution of Toyota alternators reflects broader trends in automotive technology and consumer demands. Initially designed as simple generators to supply power to the vehicle’s electrical system, modern alternators are now equipped with advanced features that enhance their efficiency and reliability. For instance, the integration of smart technology allows for real-time monitoring of the alternator’s performance, providing drivers with alerts on potential failures before they occur.

The historical context of alternator development shows a shift from purely mechanical systems to more complex electronic controls, which improve energy efficiency and extend the lifespan of the component. This evolution presents an opportunity for B2B buyers to invest in high-quality, technologically advanced alternators that not only meet current performance standards but also anticipate future demands. Understanding this trajectory can help buyers make informed decisions about sourcing and investing in alternator technologies that align with their operational needs and sustainability goals.

In summary, navigating the market dynamics surrounding Toyota alternators requires a keen understanding of both current trends and future innovations. By prioritizing sustainability and ethical sourcing, B2B buyers can position themselves advantageously in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of how long does a toyota alternator last

-

How long does a Toyota alternator typically last?

The lifespan of a Toyota alternator generally ranges between 8 to 10 years, or approximately 100,000 to 150,000 miles, depending on driving conditions and usage. Factors such as extreme temperatures, load demands, and maintenance practices can influence this duration. Regular inspections can help identify early signs of wear, allowing for timely replacements and minimizing operational disruptions. -

What are the signs that a Toyota alternator needs to be replaced?

Common indicators of a failing alternator include dimming headlights, electrical malfunctions, unusual noises, and warning lights on the dashboard. If the vehicle has difficulty starting or frequently requires a jump start, it may signal an alternator issue. Monitoring these signs is crucial for B2B buyers managing fleets, as early detection can prevent unexpected downtime. -

Can I source Toyota alternators in bulk for my business?

Yes, many suppliers offer bulk purchasing options for Toyota alternators, which can be advantageous for businesses looking to maintain a fleet or provide parts for resale. Ensure to discuss minimum order quantities (MOQs) with your supplier and explore potential discounts for larger orders. This strategy can enhance your inventory management and reduce per-unit costs. -

What should I consider when vetting alternator suppliers?

When evaluating suppliers for Toyota alternators, consider their reputation, certification, and experience in the automotive parts industry. Request product samples to assess quality and compatibility, and inquire about their warranty policies and return processes. Additionally, check their ability to provide consistent supply and meet your specific requirements, including lead times and shipping options. -

Are there customization options available for Toyota alternators?

Some manufacturers offer customization options for Toyota alternators, such as varying power outputs or specific mounting configurations. Discuss your unique needs with potential suppliers to determine if they can accommodate modifications. Custom solutions can be particularly beneficial for businesses that operate vehicles with specialized electrical demands. -

What payment terms are typically offered for bulk alternator purchases?

Payment terms can vary by supplier but often include options like net 30, net 60, or upfront payment discounts. It is essential to negotiate favorable terms that align with your cash flow needs while ensuring that the supplier’s payment policies are transparent and reliable. Clarifying these terms upfront can prevent misunderstandings later. -

Como posso garantir a qualidade dos alternadores que compro?

To ensure quality assurance, request certifications and testing reports from your supplier. Establish a quality control process that includes inspecting incoming parts for defects and verifying compliance with industry standards. Building a close relationship with your supplier can also facilitate better communication regarding quality expectations and potential issues. -

What logistics considerations should I be aware of when sourcing alternators internationally?

When sourcing Toyota alternators internationally, consider shipping costs, customs regulations, and potential tariffs. Work with suppliers who can provide clear logistics information and support throughout the shipping process. Additionally, ensure that they have experience in international trade and can navigate the complexities of cross-border transactions to avoid delays and unexpected fees.

Top 4 How Long Does A Toyota Alternator Last Manufacturers & Suppliers List

1. Toyota – Original Alternator Lifespan

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: 2005 Toyota Camry, original alternator lifespan of 328,129 miles.

2. Toyota – Alternator Insights

Domínio: toyotaofeasley.com

Registado: 1996 (29 anos)

Introdução: The alternator is an electrical generator in a vehicle’s engine that converts mechanical energy into electrical energy, powering the battery, onboard computer, and other electrical components. Its lifespan varies based on wear, aftermarket components, and climate. Signs of a broken alternator include fluctuating headlights, burning electronics smell, illuminated warning lights, and malfunctioning …

3. OEM Alternators – Lifespan & Recommendations

Domínio: tacomaworld.com

Registada: 2006 (19 anos)

Introdução: OEM alternator lifespan varies; typically lasts between 135K to 300K miles. Recommended replacement brands include Denso and rebuilt units from local alternator shops. Avoid Auto Zone products due to reliability concerns. Spare brushes can be a cost-effective solution for emergencies. Rebuilding OEM alternators is often cheaper and can maintain quality.

4. 4Runners – 5th Gen Toyota 4Runner Alternators

Domínio: 4runners.com

Registada: 2006 (19 anos)

Introdução: 5th Gen Toyota 4Runner alternators are reported to last well beyond 100,000 miles, with some users noting their alternators functioning well at 161,000 miles and suggesting a replacement around 175,000 miles as a precaution. The discussion indicates that modern alternators tend to have a longer lifespan compared to those from earlier decades, which typically needed replacement around 60,000 miles….

Strategic Sourcing Conclusion and Outlook for how long does a toyota alternator last

The longevity of a Toyota alternator typically ranges from 8 to 12 years, or about 100,000 to 150,000 miles, depending on various factors such as driving conditions and vehicle load. Strategic sourcing of high-quality alternators can significantly enhance vehicle reliability, especially in regions with diverse climates and driving conditions, like Africa and South America. B2B buyers should prioritize sourcing from reputable manufacturers known for producing durable components, as this can mitigate the risks of premature alternator failure.

Furthermore, understanding the warning signs of alternator wear—such as electrical glitches or battery issues—can enable timely interventions, reducing overall maintenance costs. By leveraging partnerships with trusted suppliers, businesses can ensure access to reliable parts that enhance operational efficiency.

As the automotive landscape continues to evolve, investing in quality alternators and establishing strong supplier relationships will be crucial for maintaining vehicle performance and customer satisfaction. International B2B buyers are encouraged to explore strategic sourcing opportunities that align with their operational goals, ensuring they stay ahead in a competitive market.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Illustrative image related to how long does a toyota alternator last

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.