Introdução: Navegando no mercado global de quanto custa um motor de arranque para um carro

In today’s competitive automotive industry, understanding the cost of a car starter is crucial for international B2B buyers seeking to optimize their procurement strategies. As businesses from Africa, South America, the Middle East, and Europe look to source reliable automotive parts, navigating the complexities of starter pricing can pose significant challenges. This comprehensive guide will break down the various factors influencing starter costs, including type, quality, and labor expenses, enabling you to make informed purchasing decisions.

The guide covers a wide array of topics, such as the differences between economy and OEM starters, the implications of choosing new versus remanufactured parts, and the importance of assessing additional repair needs that may arise during installation. Furthermore, it highlights the significance of vetting suppliers to ensure you are partnering with reputable manufacturers who can deliver high-quality products consistently.

By equipping yourself with the insights and information contained within this guide, you will be better prepared to navigate the global market for car starters. This knowledge empowers you to negotiate effectively, manage costs, and ultimately enhance your supply chain efficiency, ensuring that your business remains competitive in an ever-evolving automotive landscape. Whether you’re operating in Germany, Brazil, or beyond, understanding how to evaluate and source car starters can lead to significant operational advantages.

Índice

- Top 3 How Much Does A Starter Cost For A Car Manufacturers & Suppliers List

- Introdução: Navegando no mercado global de quanto custa um motor de arranque para um carro

- Compreender quanto custa um motor de arranque para um automóvel Tipos e variações

- Principais aplicações industriais de quanto custa um motor de arranque para um automóvel

- 3 Pontos de dor comuns dos utilizadores para ‘quanto custa um motor de arranque para um carro’ e as suas soluções

- Guia de seleção de materiais estratégicos para quanto custa um motor de arranque para um automóvel

- Análise aprofundada: Processos de fabrico e garantia de qualidade para quanto custa um motor de arranque para um automóvel

- Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘quanto custa um motor de arranque para um carro’

- Análise exaustiva dos custos e dos preços de quanto custa um motor de arranque para um automóvel Sourcing

- Análise de alternativas: Comparação do custo de um motor de arranque para um automóvel com outras soluções

- Propriedades técnicas essenciais e terminologia comercial para quanto custa um motor de arranque para um automóvel

- Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector de quanto custa um motor de arranque para um automóvel

- Perguntas frequentes (FAQs) para compradores B2B de quanto custa um motor de arranque para um automóvel

- Strategic Sourcing Conclusion and Outlook for quanto custa um motor de arranque para um automóvel

- Aviso legal importante e termos de utilização

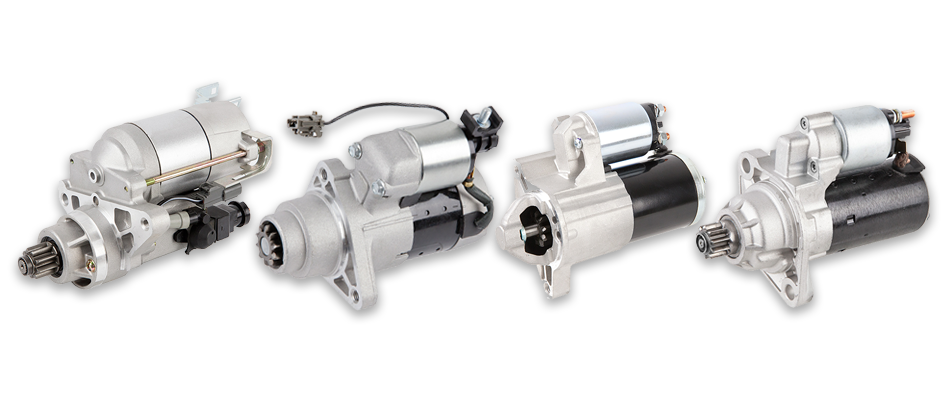

Compreender quanto custa um motor de arranque para um automóvel Tipos e variações

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Iniciadores económicos | Budget-friendly, aftermarket options, lower lifespan | Small repair shops, budget-conscious fleets | Prós: Cost-effective, easy to source. Contras: Tempo de vida mais curto, pode não ser fiável. |

| Arrancadores OEM | Original equipment quality, designed for specific vehicle models | Authorized dealerships, fleet management | Prós: High reliability, perfect fit. Contras: Higher cost, limited availability for older models. |

| Arrancadores de alto desempenho | Enhanced durability, designed for performance vehicles | Racing teams, high-performance garages | Prós: Superior performance, longer lifespan. Contras: Caro, pode exigir uma instalação especializada. |

| Arrancadores Remanufacturados | Reconstruído com peças usadas, mais barato do que novo | Independent mechanics, cost-sensitive businesses | Prós: Affordable, environmentally friendly. Contras: Variable quality, may not last as long as new. |

| Entradas de especialidade | Custom-designed for unique applications, often rare | Specialty vehicle manufacturers, custom car shops | Prós: Tailored solutions, unique offerings. Contras: High cost, limited supply. |

What Are Economy Starters and When Should B2B Buyers Consider Them?

Economy starters are aftermarket parts designed for budget-conscious buyers. They typically range from $75 to $200, making them attractive for small repair shops or businesses that operate on tight margins. However, their lower lifespan may lead to more frequent replacements, which can increase long-term costs. B2B buyers should weigh the immediate savings against potential future expenses when choosing this option.

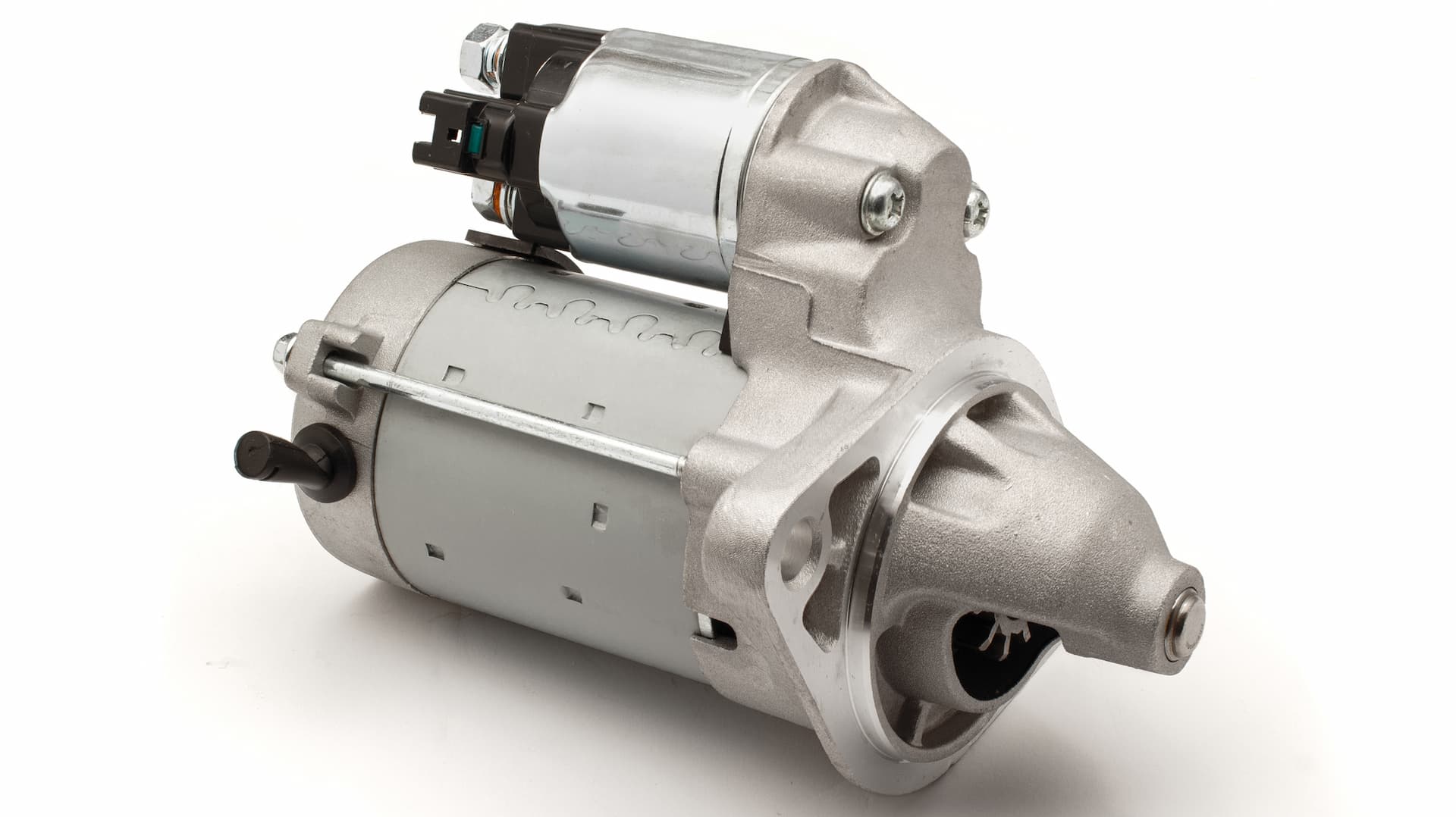

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

Why Choose OEM Starters for Your Fleet or Dealership?

Original Equipment Manufacturer (OEM) starters are specifically designed for each vehicle model, ensuring a perfect fit and optimal performance. Priced between $150 and $400, they are ideal for authorized dealerships and fleet management companies that prioritize reliability and customer satisfaction. While they come at a higher price point, the investment can lead to fewer returns and higher customer trust in the long run.

What Makes High-Performance Starters Suitable for Specialized Markets?

High-performance starters, often ranging from $300 to $1,000, are engineered for performance vehicles and racing applications. These starters provide enhanced durability and faster cranking speeds, making them essential for racing teams and high-performance garages. B2B buyers in these sectors must consider the specialized installation requirements and higher costs but can benefit from superior performance and longevity.

How Do Remanufactured Starters Offer Value to Cost-Sensitive Businesses?

Remanufactured starters are rebuilt using used parts, offering a more affordable alternative to new starters, typically costing between $50 and $300. This option is popular among independent mechanics and businesses looking to save on repairs. While they are budget-friendly and environmentally sustainable, buyers should be cautious of variable quality and potentially shorter lifespans compared to new components.

What Are Specialty Starters and Their Applications in Niche Markets?

Specialty starters are custom-designed for unique vehicles or applications, often found in specialized manufacturing or custom car shops. While they can be significantly more expensive, their tailored solutions cater to specific needs. B2B buyers must assess the rarity and potential supply issues, as these starters may not be readily available, making them suitable for businesses focused on niche markets or custom builds.

Principais aplicações industriais de quanto custa um motor de arranque para um automóvel

| Indústria/Setor | Aplicação específica de Quanto custa um motor de arranque para um automóvel | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Oficinas de reparação automóvel | Estimating costs for starter replacements in service quotes | Accurate pricing enhances customer trust and satisfaction | Availability of OEM vs aftermarket parts, local labor rates |

| Gestão de frotas | Budgeting for vehicle maintenance and repair costs | Optimizes fleet operational costs and minimizes downtime | Volume discounts on parts, reliability of suppliers |

| Car Dealerships | Offering starter replacement as part of service packages | Increases service department revenue and customer loyalty | Quality of parts, warranty options, turnaround time for repairs |

| Empresas de exportação/importação | Sourcing starters for resale in international markets | Expands product offerings and meets diverse market demands | Compliance with local regulations, shipping costs, supplier reliability |

| Retalhistas de peças para automóveis | Retail pricing strategies for starters based on market demand | Maximizes profit margins and inventory turnover | Competitor pricing, regional demand variations, supplier terms |

How Do Automotive Repair Shops Utilize Starter Cost Information?

Automotive repair shops leverage knowledge of starter replacement costs to provide transparent service quotes to customers. By accurately estimating costs based on vehicle type and labor requirements, shops can build trust and foster customer satisfaction. For international B2B buyers, understanding local labor rates and availability of OEM versus aftermarket parts is crucial for maintaining competitive pricing and service quality.

How Is Starter Cost Information Important for Fleet Management?

Fleet management companies must budget for regular vehicle maintenance, including starter replacements. By accurately forecasting these costs, they can optimize operational budgets and minimize vehicle downtime. For buyers in regions like Africa and South America, sourcing reliable parts at competitive prices is essential to ensure fleet efficiency and reduce long-term maintenance costs.

Why Do Car Dealerships Focus on Starter Replacement Pricing?

Car dealerships often include starter replacement in their service packages to enhance customer loyalty and increase revenue from their service departments. By understanding the cost implications of starter replacements, dealerships can offer competitive pricing and promote value-added services. International buyers should consider the quality of parts and warranty options to ensure customer satisfaction and repeat business.

What Role Do Export/Import Businesses Play in Sourcing Starters?

Export and import businesses can capitalize on the demand for car starters by sourcing them for resale in various international markets. Understanding the cost of starters helps these businesses set competitive pricing and expand their product offerings. Compliance with local regulations and shipping costs are vital considerations for international buyers in ensuring profitability and market access.

How Do Automotive Parts Retailers Determine Pricing Strategies?

Automotive parts retailers utilize starter cost information to develop effective pricing strategies that reflect market demand. By analyzing competitor pricing and regional variations, retailers can maximize profit margins and improve inventory turnover. For B2B buyers, understanding sourcing terms and supplier reliability is essential to ensure a steady supply of quality parts that meet customer needs.

3 Pontos de dor comuns dos utilizadores para ‘quanto custa um motor de arranque para um carro’ e as suas soluções

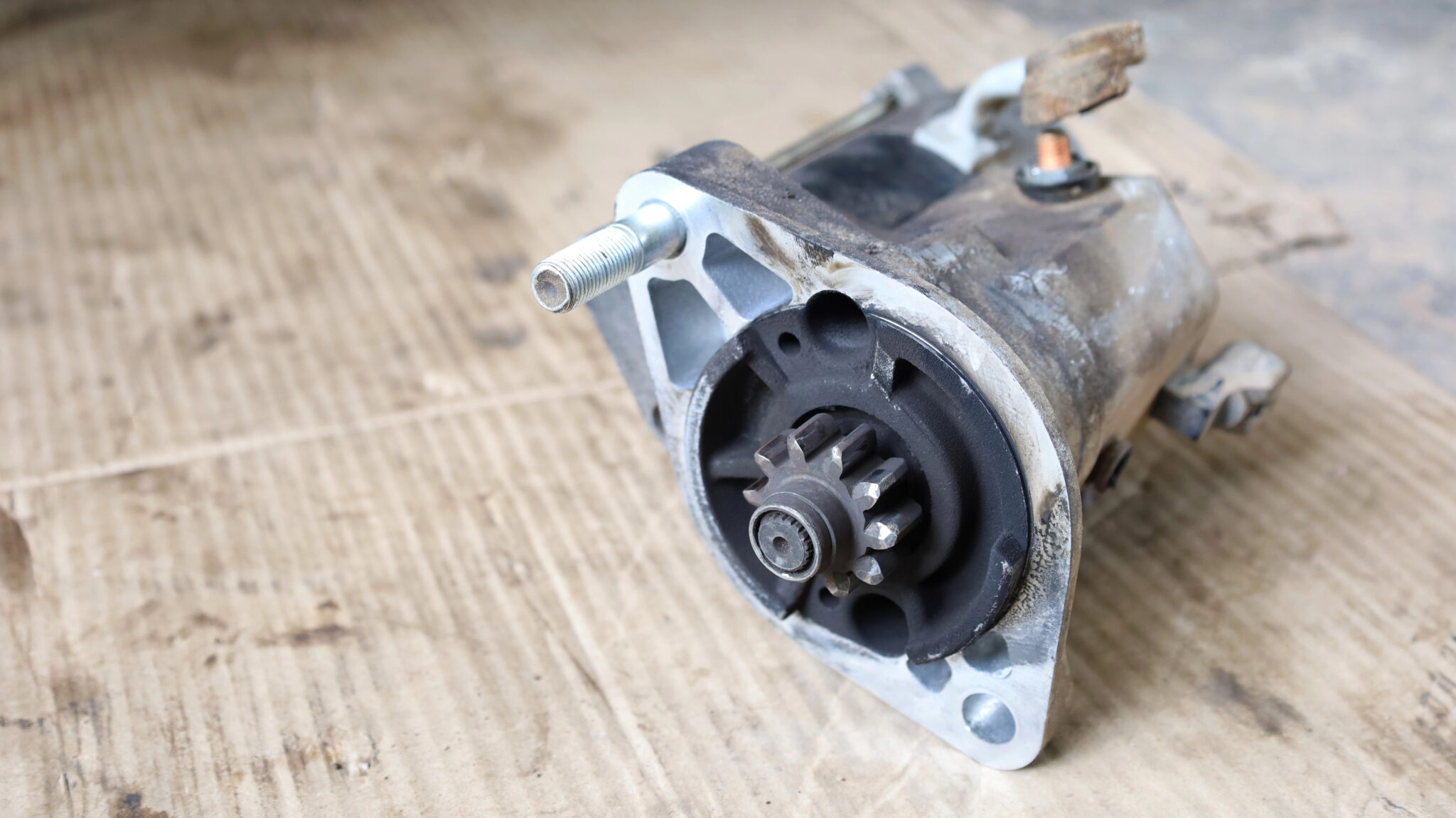

Scenario 1: Understanding the Hidden Costs of Starter Replacement

O problema: B2B buyers often underestimate the total cost associated with starter replacement. While they may have a budget for the starter motor itself, they frequently overlook additional expenses such as labor, potential additional repairs, and the sourcing of high-quality parts. This oversight can lead to budget overruns and delays in vehicle repairs, which is particularly problematic for businesses relying on a fleet of vehicles.

A solução: To effectively manage costs, B2B buyers should conduct a thorough cost analysis before proceeding with a starter replacement. This includes obtaining detailed quotes that break down the costs of both parts and labor. Buyers should engage with suppliers to understand the range of starter prices—ranging from economy options to OEM parts—and factor in the potential for additional repairs, such as battery replacements or wiring repairs, that might be necessary if the starter has been malfunctioning for some time. Building relationships with reliable automotive service providers can also yield insights into the typical repair costs for specific vehicle types, allowing for better budgeting and planning.

Scenario 2: Navigating Quality vs. Cost in Starter Options

O problema: International B2B buyers often grapple with the dilemma of choosing between economy and high-quality starter motors. While the initial cost savings of an economy starter can be attractive, these parts may not provide the longevity or reliability needed for business operations, especially in regions with challenging driving conditions. This can lead to frequent replacements and increased long-term costs, affecting operational efficiency.

A solução: Buyers should prioritize quality by investing in OEM or high-performance starters, especially for vehicles used in demanding conditions. To make informed decisions, they can consult with automotive experts who can provide insights into the expected lifespan and performance of different starter types. Additionally, conducting a cost-benefit analysis that considers the total cost of ownership—factoring in repair frequency and vehicle downtime—will help buyers understand the long-term value of investing in higher-quality starters. Establishing a supplier relationship that offers warranties on parts can also provide peace of mind and protect against premature failure.

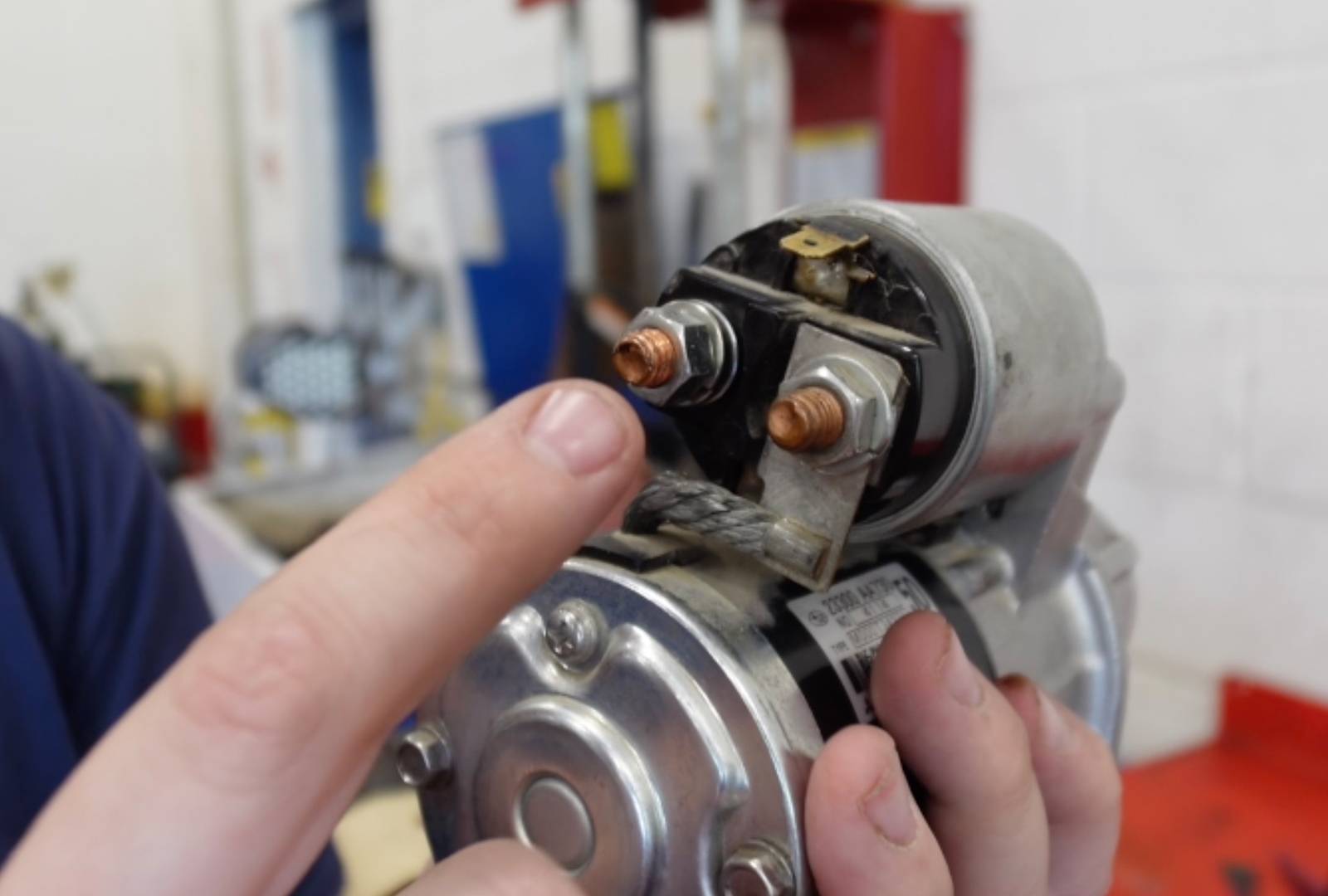

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

Scenario 3: Dealing with Complex Installations in Luxury or Specialty Vehicles

O problema: For B2B buyers managing fleets that include luxury or specialty vehicles, the complexity of starter installations can lead to significant frustrations. These vehicles often require specialized knowledge and tools for replacement, resulting in higher labor costs and extended downtime. This scenario is particularly challenging for businesses with tight schedules and high reliance on their vehicles for operations.

A solução: B2B buyers should partner with automotive repair shops that specialize in luxury and specialty vehicles. These shops often have the expertise and equipment necessary to perform quick and efficient replacements, minimizing downtime. Buyers can also prepare by identifying the specific starter requirements for each vehicle make and model in their fleet, which can help facilitate smoother communications with service providers. Additionally, scheduling routine maintenance checks can help identify starter issues early, allowing for proactive replacements rather than reactive fixes, ultimately saving time and money in the long run. Engaging with fleet management software can also provide insights into vehicle health, helping buyers anticipate repairs and budget effectively.

Guia de seleção de materiais estratégicos para quanto custa um motor de arranque para um automóvel

When selecting materials for automotive starters, particularly in a B2B context, it’s essential to consider various factors such as performance properties, cost implications, and regional compliance standards. Below is an analysis of four common materials used in starter construction: aluminum, steel, copper, and plastic composites.

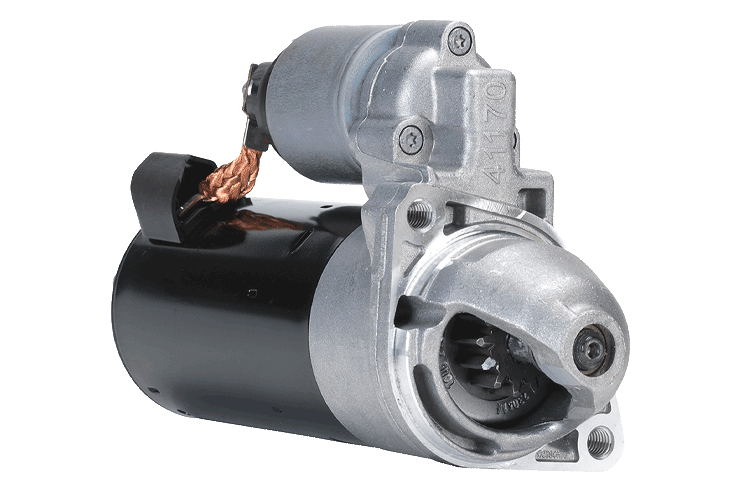

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

What Are the Key Properties of Aluminum for Starters?

Aluminum is widely used in automotive applications due to its lightweight nature and excellent corrosion resistance. It typically withstands temperatures up to 150°C and has a good strength-to-weight ratio, making it ideal for components that require both durability and reduced weight.

Prós: Aluminum’s lightweight properties contribute to improved fuel efficiency in vehicles. It is also relatively easy to machine and can be cast into complex shapes, which enhances design flexibility.

Contras: While aluminum is resistant to corrosion, it can be less durable under high-stress conditions compared to steel. It also tends to be more expensive than some other materials, which can impact the overall cost of the starter.

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

Impacto na aplicação: Aluminum is particularly suited for starters in compact cars where weight savings are critical. However, it may not be the best choice for heavy-duty applications, such as trucks or SUVs, where higher durability is required.

Considerações para compradores internacionais: Buyers in regions like Europe may prefer aluminum starters due to stringent fuel efficiency regulations. Compliance with EU standards for lightweight materials is also a consideration.

Qual é a comparação do aço como material para arrancadores?

Steel is another common material used in starter construction, known for its high strength and durability. It can withstand higher temperatures and pressures, making it suitable for demanding automotive environments.

Prós: Steel is highly durable and can resist mechanical wear and tear effectively. It is also more cost-effective than aluminum, making it a popular choice for manufacturers looking to keep production costs low.

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

Contras: The main drawback of steel is its weight, which can negatively impact vehicle performance and fuel efficiency. Additionally, steel is prone to corrosion unless properly treated or coated.

Impacto na aplicação: Steel starters are often used in larger vehicles, such as trucks and SUVs, where strength and durability are prioritized over weight.

Considerações para compradores internacionais: In regions like South America and Africa, where road conditions can be challenging, the durability of steel starters is particularly appealing. Compliance with local standards for automotive components is also crucial.

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

What Role Does Copper Play in Starter Performance?

Copper is primarily used in electrical components of starters, such as windings and connections, due to its excellent electrical conductivity.

Prós: Copper’s high conductivity ensures efficient power transfer, which is critical for starter performance. It also has good corrosion resistance, especially when coated.

Contras: Copper is more expensive than aluminum and steel, which can increase the overall cost of the starter. Additionally, it is heavier than aluminum, which could be a disadvantage in weight-sensitive applications.

Impacto na aplicação: Copper is essential in starters for high-performance vehicles where optimal electrical performance is required.

Considerações para compradores internacionais: Buyers in Europe, particularly in Germany, may prioritize copper components due to their compliance with high-performance automotive standards.

How Do Plastic Composites Fit into Starter Design?

Plastic composites are increasingly being used in automotive applications for their lightweight and versatile properties. They can be molded into complex shapes, allowing for innovative designs.

Prós: Plastic composites are lightweight, which can help improve fuel efficiency. They also resist corrosion and can be produced at a lower cost compared to metals.

Contras: The main limitation is that plastic composites may not withstand high temperatures or mechanical stress as well as metals, potentially leading to failure in demanding environments.

Impacto na aplicação: Plastic composites are suitable for non-load-bearing components in starters, such as housings and covers, where weight reduction is beneficial.

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

Considerações para compradores internacionais: In regions with varying climate conditions, such as the Middle East, the thermal stability of plastic composites must be assessed to ensure they meet local performance expectations.

Quadro resumo da seleção de materiais para arrancadores

| Material | Caso de utilização típico de quanto custa um motor de arranque para um automóvel | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Starters in compact cars | Leve e resistente à corrosão | Menos durável sob tensão | Médio |

| Aço | Starters in trucks and SUVs | Alta resistência e durabilidade | Mais pesado e propenso à corrosão | Baixo |

| Cobre | Electrical components in high-performance starters | Excelente condutividade elétrica | Caro e mais pesado | Alto |

| Compósitos plásticos | Non-load-bearing components in starters | Leve e económico | Resistência térmica e mecânica limitada | Baixo |

This analysis provides a comprehensive overview of material options for automotive starters, enabling B2B buyers to make informed decisions based on performance, cost, and compliance with regional standards.

Análise aprofundada: Processos de fabrico e garantia de qualidade para quanto custa um motor de arranque para um automóvel

Quais são as principais fases do processo de fabrico dos motores de arranque para automóveis?

The manufacturing of car starters involves several critical stages that ensure the final product meets the necessary performance and reliability standards. Understanding these stages can help B2B buyers assess the quality and suitability of suppliers.

1. Material Preparation: What Materials Are Used in Starter Manufacturing?

The first step in the manufacturing process is the preparation of raw materials. Car starters are typically made from a combination of metals, plastics, and electrical components. Key materials include:

- Cobre for wiring and electrical connections, due to its excellent conductivity.

- Steel or Aluminum for the casing and structural components, providing strength and durability.

- Plastic Resins for insulation and non-conductive parts, ensuring safety and efficiency.

Proper material selection is crucial as it directly affects the starter’s performance and longevity. B2B buyers should inquire about the sourcing and quality of materials used by suppliers to ensure compliance with international standards.

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

2. Forming: How Are Starter Components Shaped and Sized?

Once materials are prepared, the next stage is forming. This involves various techniques, including:

- Estampagem: Used for creating metal parts by pressing sheets of metal into desired shapes.

- Moldagem por injeção: A process employed for producing plastic components, ensuring precise dimensions and complex geometries.

- Usinagem: Involves cutting and shaping metal parts to achieve the required specifications.

Each forming technique plays a role in determining the quality and performance of the starter. Suppliers should provide details on the machinery and technology used, as advanced equipment often correlates with higher quality products.

3. Assembly: How Are Starters Assembled?

Assembly is where all the components come together. This stage typically includes:

- Integração de componentes: Inserting electrical components into the casing and securing them.

- Cablagem: Connecting electrical wires and ensuring proper insulation to prevent short circuits.

- Montagem final: Attaching all parts, including the solenoid and drive gear, to form a complete starter unit.

Automation is increasingly used in assembly lines to improve efficiency and consistency. B2B buyers should assess whether the supplier employs automated processes, as this can enhance product quality and reduce labor costs.

4. Finishing: What Processes Enhance the Durability of Starters?

The finishing stage involves applying protective coatings and performing quality checks. Common processes include:

- Pintura ou revestimento: To prevent corrosion and enhance appearance.

- Tratamento de superfície: Such as anodizing or galvanizing, which can improve durability and resistance to wear.

These finishing techniques not only improve aesthetics but also extend the lifespan of the starter. Buyers should verify that suppliers adhere to recognized finishing standards to ensure long-lasting products.

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

What Quality Control Measures Are Implemented in Starter Manufacturing?

Quality assurance is a critical aspect of starter manufacturing that ensures reliability and performance. International and industry-specific standards guide these processes.

1. What Are the Relevant International Standards for Quality Assurance?

Many manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that a manufacturer has established processes to ensure consistent product quality.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for products used in automotive applications can also be relevant. Buyers should request proof of certification from suppliers to confirm compliance.

2. What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to maintaining product integrity throughout the manufacturing process. Key checkpoints include:

- Controlo de Qualidade de Entrada (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- Controlo de qualidade em processo (IPQC): Ongoing checks during manufacturing to identify defects early.

- Controlo de Qualidade Final (FQC): Comprehensive testing of finished products before they are shipped to customers.

Implementing these checkpoints helps to minimize defects and enhance product reliability. B2B buyers should inquire about the specific quality control measures employed by their suppliers.

3. What Common Testing Methods Are Used to Ensure Product Quality?

Testing methods for car starters typically include:

- Testes elétricos: To verify that the starter meets voltage and current specifications.

- Teste de durabilidade: Assessing the starter’s performance under extreme conditions, such as high temperatures and vibrations.

- Testes funcionais: Ensuring the starter operates correctly when installed in a vehicle.

These tests are vital for confirming that the product will perform reliably in real-world conditions. Buyers should request test reports and certifications from suppliers to validate their claims.

Como podem os compradores B2B verificar os processos de controlo de qualidade dos fornecedores?

Ensuring that suppliers maintain rigorous quality control processes is essential for B2B buyers. Here are some strategies to verify this:

1. What Role Do Audits Play in Supplier Quality Verification?

Conducting audits is a proactive approach to assess a supplier’s adherence to quality standards. Buyers can perform:

- On-site Audits: Visiting the manufacturing facility to evaluate processes, equipment, and quality control measures in action.

- Supplier Self-Audits: Requesting suppliers to provide self-assessment reports demonstrating compliance with standards.

These audits help buyers gain confidence in the supplier’s capabilities and quality assurance practices.

2. How Can Buyers Utilize Reports and Third-Party Inspections?

Buyers can request detailed reports from suppliers, including:

- Relatórios de controlo de qualidade: Summarizing testing results and quality metrics.

- Certification Documents: Proof of compliance with international and industry-specific standards.

Additionally, utilizing third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes and quality assurance measures. This can be particularly valuable for international buyers seeking to mitigate risks associated with overseas sourcing.

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

Que nuances devem os compradores internacionais B2B ter em conta relativamente ao controlo de qualidade?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several nuances when evaluating quality control:

- Conformidade regulamentar: Different regions may have specific regulations affecting product safety and performance. Understanding these requirements is essential to avoid compliance issues.

- Diferenças culturais: Variations in manufacturing practices and quality expectations can influence product quality. Engaging in open communication with suppliers can help bridge these gaps.

- Logística e cadeia de abastecimento: International shipping can impact product integrity. Buyers should ensure that suppliers have robust logistics processes to protect products during transit.

By taking these factors into account, B2B buyers can make informed decisions and establish strong partnerships with reliable suppliers in the automotive industry.

Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘quanto custa um motor de arranque para um carro’

Introdução

Navigating the procurement of automotive starters requires a strategic approach, especially for B2B buyers operating in diverse markets like Africa, South America, the Middle East, and Europe. This guide serves as a practical checklist to help you understand the factors influencing starter costs and to ensure you make informed purchasing decisions. By following these steps, you can optimize your sourcing process and secure the best value for your investment.

Passo 1: Defina as suas especificações técnicas

Before initiating your search for starters, it’s vital to clearly outline your technical requirements. Specify the vehicle types, models, and any performance criteria that the starters must meet.

– Considerations: Note the make, model, and year of the vehicles, as these details significantly affect starter compatibility and pricing.

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

Passo 2: Pesquisar tendências de preços de mercado

Understanding current market pricing trends for automotive starters can help you gauge a fair price range. Prices can vary widely based on the type of starter (economy, OEM, or high-performance).

– Market Analysis: Look for industry reports or online automotive parts databases that provide insights into average costs in your target regions.

Passo 3: Avaliar as certificações dos fornecedores

Supplier certifications can indicate the quality and reliability of the starters you intend to purchase. Ensure potential suppliers hold relevant industry certifications that guarantee adherence to quality standards.

– Key Certifications: Look for ISO certifications or industry-specific quality assurance endorsements that validate the supplier’s manufacturing processes.

Passo 4: Solicite amostras e especificações do produto

Before placing a bulk order, request samples or detailed product specifications from shortlisted suppliers. This step allows you to assess the quality and compatibility of the starters with your vehicles.

– Testes: Conduct quality assurance tests on samples to confirm that they meet your operational requirements and performance expectations.

Passo 5: Compare Warranty and Service Options

A robust warranty and reliable service options can significantly affect your long-term satisfaction with the starters. Compare the warranty terms offered by different suppliers to ensure adequate coverage.

– Service Support: Assess the availability of after-sales support, including installation assistance and technical support, which can be crucial for maintenance and troubleshooting.

Passo 6: Negociar termos e condições

Once you have narrowed down your supplier options, it’s time to negotiate terms and conditions. This includes pricing, payment terms, delivery schedules, and return policies.

– Focus Areas: Aim for favorable terms that align with your budget and operational timelines, while ensuring flexibility for future orders.

Passo 7: Finalize Your Order and Monitor Supply Chain

After reaching an agreement, finalize your order and establish a monitoring system to oversee the supply chain process. Regularly track order status, delivery timelines, and inventory levels to prevent disruptions in your operations.

– Supply Chain Visibility: Utilize software tools or dashboards that provide real-time insights into your supply chain, ensuring you can respond promptly to any issues that may arise.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing automotive starters, ensuring they obtain quality products at competitive prices while maintaining strong supplier relationships.

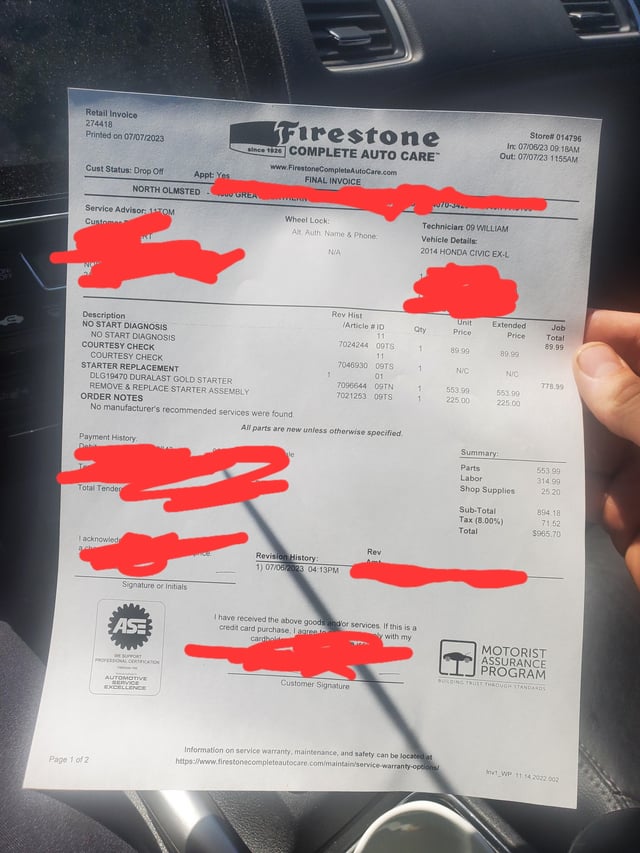

Análise exaustiva dos custos e dos preços de quanto custa um motor de arranque para um automóvel Sourcing

Understanding the cost structure and pricing dynamics for sourcing car starters is essential for international B2B buyers. This analysis outlines the various cost components, pricing influencers, and offers strategic tips for negotiation and sourcing.

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

What Are the Key Cost Components for Car Starters?

-

Materiais: The primary cost driver for car starters is the raw materials used in manufacturing. This includes metals like copper and aluminum, electrical components, and plastics. The quality of these materials can significantly influence the price, with higher-grade materials typically resulting in better performance and longevity.

-

Trabalho: Labor costs encompass both direct production labor and the workforce involved in assembly and quality control. Labor rates vary widely based on geographic location and the complexity of the starter design. For example, manufacturing in regions with lower labor costs can lead to more competitive pricing.

-

Custos indiretos de produção: Overhead costs include utilities, rent, and equipment depreciation related to the production facility. Efficient production processes and lean manufacturing techniques can help reduce these overheads, ultimately lowering the price for buyers.

-

Ferramentas: Initial tooling costs can be significant, particularly for custom or high-performance starters. These costs must be amortized over the production volume, affecting the pricing structure. For low-volume orders, tooling costs can dramatically increase the unit price.

-

Controlo de Qualidade (QC): Implementing rigorous QC processes ensures that each starter meets safety and performance standards. While this adds to the cost, it can be a worthwhile investment, reducing the risk of defects and warranty claims.

-

Logística: Shipping and handling costs, influenced by distance, mode of transport, and import tariffs, can add to the total cost of ownership. For international buyers, understanding these logistics costs is crucial for accurate budgeting.

-

Margem: Suppliers typically include a profit margin in their pricing. This margin can vary based on market conditions, competition, and the supplier’s overall business strategy.

O que influencia o preço dos motores de arranque para automóveis?

-

Volume e quantidade mínima de encomenda (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. However, suppliers may impose MOQs, especially for custom parts, which can affect pricing for smaller buyers.

-

Especificações e personalização: Custom starters designed for specific vehicle models or performance requirements generally come at a premium. Buyers should weigh the necessity of customization against potential cost increases.

-

Qualidade dos materiais e certificações: Starters made with premium materials or those that meet specific industry certifications (like ISO) typically command higher prices. Buyers should consider the long-term benefits of investing in higher-quality products.

-

Fatores relacionados ao fornecedor: The reputation and reliability of the supplier can impact pricing. Established suppliers with proven track records may charge more but offer better quality assurance and service.

-

Incoterms: Understanding the Incoterms agreed upon in the contract can significantly affect the total landed cost. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can shift the financial responsibility for shipping and insurance between the buyer and seller.

What Tips Can Help Buyers Negotiate Effectively?

-

Realizar um estudo de mercado exaustivo: Understanding the market landscape helps buyers identify competitive pricing and potential suppliers. This knowledge can empower negotiation strategies.

-

Aproveitar os descontos por volume: Buyers planning larger orders should negotiate for volume discounts. Presenting a clear forecast of future orders can incentivize suppliers to offer better pricing.

-

Avalie o custo total de propriedade (TCO): Consider not just the upfront cost but also the long-term implications of maintenance, warranty, and replacement costs. A slightly higher initial investment in quality starters can lead to savings over time.

-

Be Aware of Regional Pricing Nuances: Buyers from regions like Africa and South America may face additional challenges such as tariffs and import duties that affect the total cost. Understanding these factors can help buyers make more informed decisions.

-

Establish Clear Communication: Maintain open lines of communication with suppliers to clarify expectations around pricing, delivery timelines, and quality standards. Building strong relationships can lead to more favorable terms over time.

Isenção de responsabilidade sobre preços indicativos

Prices for car starters can vary widely based on the aforementioned factors. The indicative price ranges typically fall between $75 and $1,000, depending on the specifications and quality. Buyers should obtain detailed quotes tailored to their specific needs and circumstances to ensure accurate budgeting.

Análise de alternativas: Comparação do custo de um motor de arranque para um automóvel com outras soluções

Introduction to Alternative Solutions for Car Starters

When it comes to maintaining vehicle performance, the starter is a pivotal component in the ignition system. While understanding how much a starter costs is essential for budgeting repairs or replacements, it is equally important to explore alternative solutions that can either complement or substitute the traditional starter mechanism. This analysis will delve into various options available for automotive ignition systems, providing B2B buyers with a comprehensive understanding of their choices.

Comparison of Alternatives

| Aspecto comparativo | Quanto custa um motor de arranque para um automóvel | High-Performance Battery Systems | Push-to-Start Technology |

|---|---|---|---|

| Desempenho | Essential for engine cranking; varies by vehicle | Improved cranking power; often lighter | Instant ignition; requires no key |

| Custo | $250 – $1,000 (including parts and labor) | $200 – $600 (battery only) | $300 – $700 (system upgrade) |

| Facilidade de implementação | Moderado; requer competências mecânicas | Easy to install for professionals; may need adjustments | Complex; often requires professional installation |

| Manutenção | Regular checks; replace every 5-10 years | Minimal; depends on usage and quality | Low; mainly software updates |

| Melhor caso de uso | Standard vehicles needing reliable starting | Performance cars or frequent users | Luxury vehicles and modern fleets |

Discriminação detalhada das alternativas

High-Performance Battery Systems

High-performance battery systems offer an alternative to traditional starters, especially for vehicles requiring enhanced cranking power. These batteries are designed to deliver a higher discharge rate, which can significantly improve engine start-up times and overall vehicle performance. While the upfront cost is comparable to that of a standard starter, the longevity and reliability can offset this initial investment. However, these systems may require professional installation and adjustments, which can add to the overall expenditure.

Push-to-Start Technology

Push-to-start technology represents a modern shift in vehicle ignition systems, eliminating the need for traditional keys and starters. Instead, this system allows the driver to start the engine with a simple push of a button, integrating advanced security features and convenience. The costs associated with this technology can be higher due to installation complexities and the need for compatible components. While it offers a sleek, modern solution, it is best suited for luxury vehicles or fleets that prioritize cutting-edge technology and user experience.

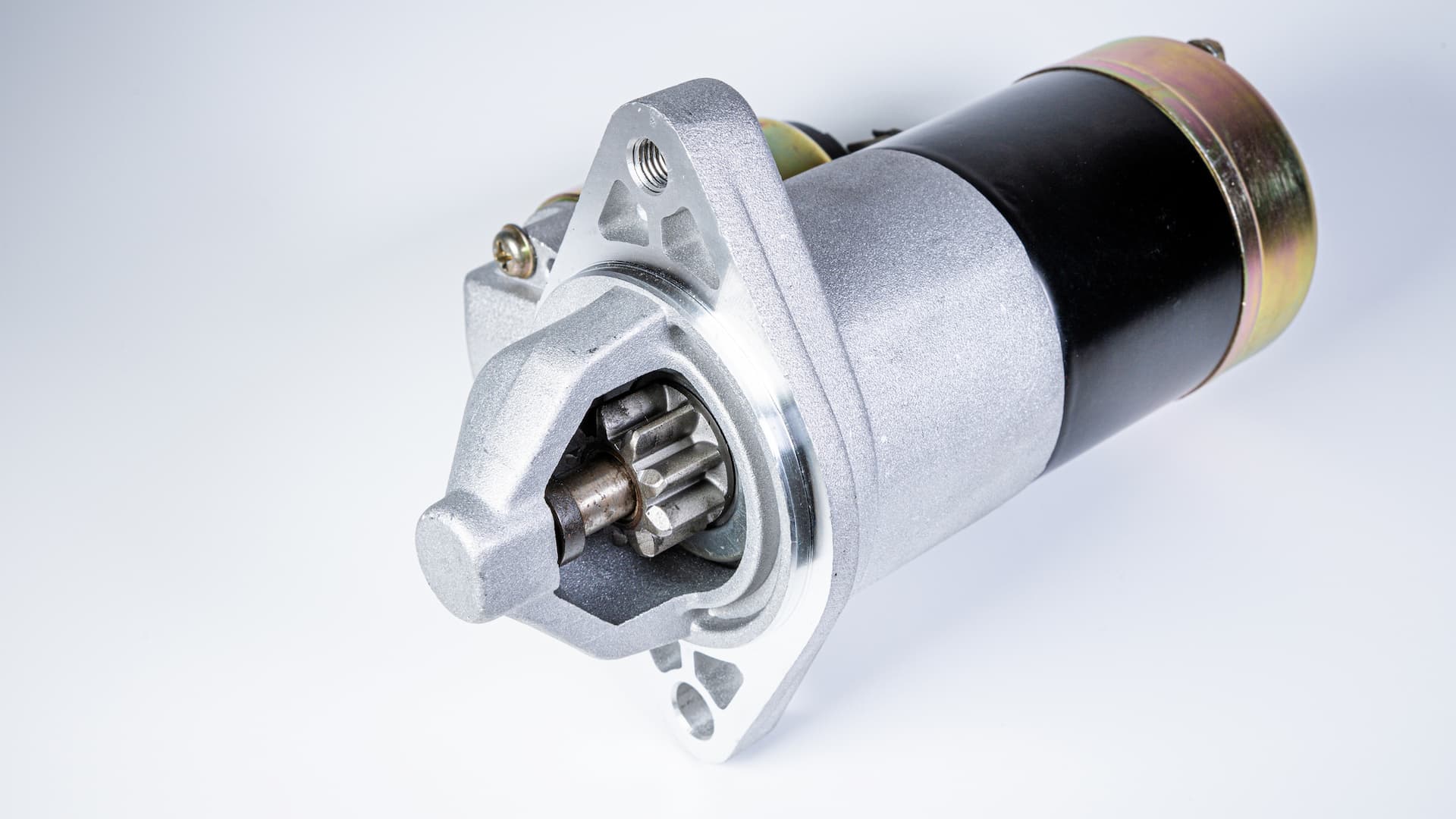

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

Conclusão: escolhendo a solução certa para as suas necessidades

For B2B buyers evaluating their options, understanding the costs and functionalities of a traditional starter versus alternative solutions is crucial. The decision should be guided by factors such as vehicle type, performance requirements, and budget constraints. While a traditional starter remains a reliable choice for most vehicles, alternatives like high-performance batteries and push-to-start systems may be more suitable for specific applications. Ultimately, assessing the unique needs of your fleet or automotive service will enable you to make a well-informed choice that balances cost, performance, and maintenance considerations.

Propriedades técnicas essenciais e terminologia comercial para quanto custa um motor de arranque para um automóvel

What Are the Key Technical Properties of a Car Starter That Affect Cost?

Understanding the technical properties of a car starter is crucial for B2B buyers, as these specifications directly influence the pricing, performance, and compatibility of the starter with various vehicle models. Here are several essential specifications to consider:

1. Grau do material

The materials used in starter construction can vary widely, impacting durability and performance. Common materials include high-grade steel for the casing and copper for the windings. Higher-grade materials typically result in better conductivity and longer lifespan, thus affecting the cost. For B2B buyers, investing in starters made with superior materials can reduce maintenance costs and improve vehicle reliability.

2. Classificação de binário

Torque rating refers to the amount of rotational force the starter can produce to crank the engine. This specification is critical, especially for vehicles with larger engines that require more power to start. A starter with a higher torque rating may come at a premium but can provide better performance in demanding conditions. Buyers should assess the torque requirements of their vehicle fleet to ensure optimal starter selection.

3. Especificações elétricas

Electrical specifications, including voltage and current draw, are vital in determining compatibility with a vehicle’s electrical system. Most starters operate on 12V systems, but understanding the amperage draw during start-up can help in selecting a starter that minimizes strain on the battery. B2B buyers should prioritize starters that match the electrical needs of their vehicles to prevent electrical failures and battery drain.

4. Resistência ao calor

Starters are subjected to high temperatures during operation, particularly in performance vehicles or in regions with extreme climates. A starter’s ability to withstand heat without failure is a key property that affects its longevity. Materials with higher heat resistance can prevent overheating and failure, making them a wise investment for businesses operating in harsh environments.

5. Período de garantia

The warranty period offered by manufacturers serves as a measure of the product’s reliability and quality. A longer warranty often indicates greater manufacturer confidence in the starter’s performance and durability. B2B buyers should consider warranty terms when evaluating cost versus long-term value, as a starter with a robust warranty can reduce replacement costs over time.

Quais são os termos comerciais comuns relacionados com os motores de arranque para automóveis?

Familiarity with industry terminology is essential for B2B buyers to navigate procurement and contract negotiations effectively. Here are several common trade terms relevant to the purchase of car starters:

1. OEM (Fabricante de Equipamento Original)

OEM refers to parts made by the vehicle’s manufacturer, ensuring compatibility and quality. OEM starters are typically more expensive than aftermarket options but offer assurance of performance. Buyers should weigh the benefits of OEM parts against their budget constraints and the specific needs of their fleet.

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and cash flow. Buyers should negotiate terms that align with their purchasing needs to avoid overcommitting to stock they may not use.

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

3. RFQ (Pedido de Orçamento)

An RFQ is a formal document sent to suppliers requesting pricing and terms for a specific quantity of goods. This process helps buyers compare offers and negotiate better deals. Utilizing RFQs can streamline procurement and ensure competitive pricing for starters.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping and delivery. Understanding these terms is vital for international transactions, as they clarify who bears the cost and risk at various points in the shipping process. This knowledge can significantly impact the overall cost of acquiring starters.

5. Prazo de entrega

Lead time refers to the time taken from placing an order to receiving the product. For businesses that rely on timely repairs and maintenance, understanding lead times is critical for planning and inventory management. Buyers should communicate clearly with suppliers about expected lead times to ensure operational efficiency.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when purchasing car starters, ensuring they select the right products that meet their operational needs and budget constraints.

Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector de quanto custa um motor de arranque para um automóvel

What Are the Current Market Trends Influencing the Cost of Car Starters?

The global automotive industry is witnessing dynamic shifts driven by various factors that significantly impact the cost and sourcing of car starters. One of the primary drivers is the rising demand for electric and hybrid vehicles, particularly in regions like Europe and North America. This shift necessitates more sophisticated starter technologies, influencing pricing structures. Moreover, supply chain disruptions due to geopolitical tensions and the COVID-19 pandemic have led to increased material costs, particularly for rare earth metals used in advanced starter motors.

International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should note the ongoing trends towards digitalization in sourcing processes. This includes the adoption of e-commerce platforms and digital marketplaces, which facilitate easier access to various suppliers and parts. Additionally, there is an increasing trend toward just-in-time inventory management, allowing businesses to reduce overhead costs while ensuring they have the necessary parts on hand.

Another emerging trend is the emphasis on quality over price. Buyers are increasingly looking for OEM (Original Equipment Manufacturer) parts, which, while more expensive, guarantee reliability and longevity. This trend is particularly pronounced in markets with stringent vehicle regulations, such as Germany, where compliance with environmental standards is crucial.

Como é que a sustentabilidade está a moldar o fornecimento de motores de arranque para automóveis?

Sustainability is becoming a central concern for B2B buyers in the automotive sector, particularly in sourcing components like starters. The environmental impact of manufacturing processes and material sourcing is under scrutiny, leading companies to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes using recyclable materials and minimizing waste during production.

Ethical sourcing is also gaining traction. Buyers are increasingly demanding transparency in supply chains, ensuring that materials are sourced responsibly and that workers are treated fairly. This trend is particularly relevant in regions like Africa and South America, where mining and material extraction can have significant socio-economic impacts.

Imagem ilustrativa relacionada com quanto custa um motor de arranque para um automóvel

To align with these sustainability goals, businesses are seeking out ‘green’ certifications for their suppliers. These certifications indicate adherence to environmental standards and responsible sourcing practices. By partnering with suppliers who prioritize sustainability, companies can enhance their brand reputation and appeal to environmentally conscious consumers.

What Historical Developments Have Influenced the Starter Market?

The evolution of car starters has been marked by significant technological advancements. Initially, starters were simple mechanical devices, but the advent of electric starters in the early 20th century revolutionized vehicle ignition systems. Over the decades, improvements in materials and engineering have led to the development of more efficient and reliable starters.

The 21st century has seen a shift towards more sophisticated starter systems, particularly with the rise of hybrid and electric vehicles. This evolution has made starters not only a critical component for traditional combustion engines but also an integral part of modern electric and hybrid systems. As a result, the cost of starters has become increasingly variable, influenced by technological complexity and the demand for high-performance components.

For B2B buyers, understanding these historical developments is crucial. It provides context for current pricing trends and helps inform sourcing strategies that align with technological advancements and market demands.

Perguntas frequentes (FAQs) para compradores B2B de quanto custa um motor de arranque para um automóvel

-

Como é que determino o custo de um motor de arranque para o meu veículo?

To determine the cost of a starter, consider the vehicle’s make, model, and year, as these factors significantly influence pricing. Generally, starters range from $75 for economy models to over $1,000 for high-performance or specialty starters. Additionally, account for labor costs, which vary based on the complexity of the installation and local rates. It’s advisable to obtain quotes from multiple suppliers to ensure competitive pricing and quality. -

Qual é o melhor tipo de motor de arranque para o meu veículo?

The best type of starter depends on your vehicle’s specifications and your budget. Original Equipment Manufacturer (OEM) starters offer reliability and performance but come at a higher price. Aftermarket options can be budget-friendly, with prices ranging from $75 to $400. For high-performance vehicles, investing in specialty starters may be necessary. Always consult with your supplier to match the starter to your vehicle’s requirements. -

Como posso avaliar os fornecedores de motores de arranque para automóveis?

When vetting suppliers for automotive starters, consider their industry reputation, customer reviews, and certifications. Request samples and check the quality of their products, including warranty terms. It’s also beneficial to assess their manufacturing capabilities and lead times, especially for international shipments. Building a relationship with reliable suppliers can lead to better pricing and terms over time. -

Quais são as quantidades mínimas de encomenda (MOQ) para as entradas?

Minimum order quantities can vary widely among suppliers. Typically, MOQs for automotive parts like starters range from 10 to 100 units, depending on the supplier’s policies and production capabilities. For international buyers, negotiating MOQs is often possible, especially if you are establishing a long-term partnership. Always clarify MOQs before placing an order to avoid unexpected costs. -

Que condições de pagamento devo esperar quando forneço entradas a nível internacional?

Payment terms for international transactions can vary, but common options include upfront payments, letters of credit, or payment upon delivery. Many suppliers offer net 30 or net 60 terms for established customers. It’s essential to negotiate favorable terms that align with your cash flow and to ensure that all agreements are documented to protect both parties. -

Como é que trato da logística na importação de entradas?

When importing starters, consider the shipping method (air or sea), as it will affect delivery times and costs. Engage a reliable freight forwarder to manage customs clearance, documentation, and delivery logistics. Ensure that you understand the import regulations in your country, including tariffs and taxes, to avoid delays or additional costs. Clear communication with your supplier about shipping timelines is also crucial. -

What quality assurance measures should I look for in starter components?

Quality assurance measures for starters include adherence to industry standards and certifications, such as ISO 9001. Request detailed product specifications and test reports from suppliers to ensure reliability and performance. Many reputable manufacturers also offer warranties on their products, which can serve as a quality guarantee. Conducting random quality checks during production can further mitigate risks. -

Can I customize starters for specific applications?

Yes, many suppliers offer customization options for starters to fit specific applications or performance requirements. This may include adjustments in size, power ratings, or additional features like solenoid types. When seeking custom solutions, provide detailed specifications and discuss your needs with the supplier early in the process. Custom orders may require longer lead times and higher costs, so plan accordingly.

Top 3 How Much Does A Starter Cost For A Car Manufacturers & Suppliers List

1. Last Chance Auto Repairs - Custos de substituição do motor de arranque

Domínio: últimareparosautomóveis.com

Registado: 2009 (16 anos)

Introdução: Starter Replacement Cost: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. Labor costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Average total cost: $250 – $1,000+. Factors affecting cost: Vehicle type & model, New vs Re-Manufactured starters, Additional repairs (battery, wiring, flywheel). DIY costs: Par…

2. CarParts.com – High-Quality Car Starters

Domínio: carparts.com

Registado: 1999 (26 anos)

Introdução: Car Starters – Standard, Reverse Rotation from $75 | CarParts.com offers a wide selection of high-quality replacement starters, both new and remanufactured. Key features include guaranteed fit, fast shipping, and hassle-free returns. The product is suitable for vehicles showing signs of a bad starter, such as oil leakage or smoke. The company emphasizes the selection and testing of starters by ind…

3. CarTalk – Starter Replacement Costs

Domínio: cartalk.com

Registrado: 1995 (30 anos)

Introdução: The cost to replace a starter in a car typically ranges from $600 to $900 for common vehicles, and from $900 to $1,400 for luxury models. The price varies based on the vehicle’s design and accessibility of the starter. Symptoms of a failing starter include a clicking sound when attempting to start, a screeching noise, or intermittent functionality. Starters can be new, remanufactured, or rebuilt, …

Strategic Sourcing Conclusion and Outlook for quanto custa um motor de arranque para um automóvel

As the automotive industry continues to evolve, understanding the cost dynamics associated with starter replacements is crucial for international B2B buyers. The average replacement cost typically ranges from $250 to $1,000, influenced by factors such as vehicle type, starter quality, and labor costs. Strategic sourcing can help businesses optimize these expenses by identifying reliable suppliers and negotiating favorable terms, ensuring both quality and cost-effectiveness.

For buyers in regions like Africa, South America, the Middle East, and Europe, it is essential to consider not just the immediate costs, but also the long-term implications of purchasing decisions. Emphasizing the value of new versus remanufactured starters can lead to significant savings and enhanced vehicle performance. Moreover, engaging with reputable suppliers can provide access to warranties and additional services, further mitigating risks associated with starter replacements.

Looking ahead, as the global automotive market expands, staying informed about sourcing strategies and cost factors will be paramount. We encourage B2B buyers to leverage this knowledge and seek partnerships that foster growth, efficiency, and innovation in their operations.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.