Introdução: Navegando no mercado global de substituição de motores de arranque

No atual cenário automóvel competitivo, o fornecimento de peças de substituição fiáveis para motores de arranque pode representar desafios significativos para os compradores B2B internacionais. Quer esteja a operar na Nigéria, na Arábia Saudita ou em toda a Europa, compreender os meandros dos sistemas de arranque do motor é crucial para manter a eficiência operacional. Este guia abrangente mergulha no mundo multifacetado da substituição do motor de arranque, abrangendo vários tipos de motores de arranque, as suas aplicações em diferentes modelos de veículos e processos essenciais de verificação de fornecedores.

Ao explorar os factores que influenciam os custos, incluindo a mão de obra, a disponibilidade de peças e a dinâmica do mercado regional, este guia fornece aos compradores as informações necessárias para tomarem decisões de compra informadas. Além disso, abordamos problemas comuns que podem levar a falhas no arrancador, fornecendo dicas práticas de resolução de problemas para minimizar o tempo de inatividade. O guia foi concebido para capacitar as empresas em África, na América do Sul, no Médio Oriente e na Europa, oferecendo estratégias acionáveis para selecionar os melhores fornecedores, compreender as considerações relativas à garantia e maximizar o valor dos seus investimentos.

Navegar no mercado global de substituição de motores de arranque pode ser assustador, mas com os conhecimentos e recursos certos, pode melhorar o seu processo de aquisição e garantir a fiabilidade da sua frota.

Índice

- Lista dos 2 principais fabricantes e fornecedores de substituição do motor de arranque

- Introdução: Navegando no mercado global de substituição de motores de arranque

- Compreender a substituição do motor de arranque Tipos e variações

- Principais aplicações industriais da substituição do motor de arranque

- 3 pontos de dor comuns dos utilizadores para ‘substituição do motor de arranque’ e as suas soluções

- Guia estratégico de seleção de materiais para substituição do motor de arranque

- Análise aprofundada: Processos de fabrico e garantia de qualidade para a substituição do motor de arranque

- Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘substituição do motor de arranque’

- Análise exaustiva dos custos e dos preços para a substituição do motor de arranque Sourcing

- Análise de alternativas: Comparação da substituição do motor de arranque com outras soluções

- Propriedades técnicas essenciais e terminologia comercial para a substituição do motor de arranque

- Navegar na dinâmica do mercado e nas tendências de fornecimento no sector da substituição do motor de arranque

- Perguntas mais frequentes (FAQs) para compradores B2B de substituição do motor de arranque

- Conclusão sobre o aprovisionamento estratégico e perspectivas para a substituição do motor de arranque

- Aviso legal importante e termos de utilização

Compreender a substituição do motor de arranque Tipos e variações

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Arrancador elétrico standard | Comumente utilizado na maioria dos veículos, alimentado por bateria | Oficinas de reparação automóvel, gestão de frotas | Prós: Amplamente disponível, económico. Contras: Vida útil limitada, pode exigir substituições frequentes. |

| Motor de arranque de alto binário | Potência melhorada para motores maiores, concebidos para utilização em trabalhos pesados | Veículos comerciais, corridas de desempenho | Prós: Maior fiabilidade, melhor desempenho. Contras: Custo mais elevado, pode exigir uma instalação especializada. |

| Motor de arranque com redução de engrenagem | Possui um sistema de engrenagens que aumenta o binário e reduz o tamanho | Máquinas pesadas, veículos de alto desempenho | Prós: Design compacto, transferência de energia eficiente. Contras: Mais complexo, manutenção potencialmente mais elevada. |

| Mini arrancador | Design mais pequeno e mais leve, frequentemente utilizado em aplicações de competição | Carros desportivos, equipas de corrida | Vantagens: Poupança de peso, melhor folga. Contras: Preço mais elevado, pode não se adaptar a todos os tipos de veículos. |

| Motor de arranque remanufaturado | Unidades recondicionadas que cumprem as especificações OEM | Compradores preocupados com o orçamento, operadores de frotas | Vantagens: Económica, amiga do ambiente. Contras: Qualidade variável, períodos de garantia mais curtos. |

Quais são as caraterísticas dos arrancadores eléctricos standard?

Os motores de arranque eléctricos standard são o tipo de motor de arranque mais utilizado em vários modelos de veículos. São alimentados diretamente pela bateria do veículo e foram concebidos para uma instalação e substituição simples. Estes motores de arranque são adequados para aplicações automóveis gerais, o que os torna ideais para oficinas de reparação automóvel e serviços de gestão de frotas. Aquando da compra, os compradores B2B devem considerar a disponibilidade de peças de substituição e o tempo de vida útil típico, uma vez que estes motores de arranque podem exigir substituições frequentes.

Como é que os arrancadores de binário elevado diferem dos modelos padrão?

Os motores de arranque de binário elevado são concebidos para motores maiores, fornecendo potência melhorada para garantir uma rotação fiável do motor em condições exigentes. Estes motores de arranque são particularmente benéficos para veículos comerciais e aplicações de corrida de alto desempenho onde o desempenho do motor é crítico. Os compradores B2B devem avaliar os seus requisitos de potência específicos e considerar o investimento inicial mais elevado em relação aos benefícios de fiabilidade e desempenho a longo prazo que estes motores de arranque oferecem.

O que torna os arrancadores de redução de engrenagens únicos?

Os arrancadores de redução de engrenagem utilizam um mecanismo de engrenagem para melhorar a saída de binário, mantendo um tamanho compacto. Este design é vantajoso em maquinaria pesada e veículos de alto desempenho, onde o espaço é limitado mas as necessidades de energia são elevadas. Os compradores B2B devem avaliar a complexidade da instalação e os potenciais requisitos de manutenção, uma vez que a conceção complexa pode exigir conhecimentos ou ferramentas especializados.

Porquê escolher Mini Starters para veículos de alto desempenho?

Os mini motores de arranque foram concebidos para veículos de competição e de desempenho, oferecendo uma alternativa mais leve e mais pequena aos motores de arranque tradicionais. O seu peso reduzido pode levar a um melhor desempenho do veículo, particularmente em ambientes competitivos. No entanto, os compradores B2B devem estar cientes do preço mais elevado e garantir a compatibilidade com o modelo específico do veículo, uma vez que nem todos os veículos podem acomodar este tipo de arrancador.

Quais são as vantagens dos motores de arranque remanufaturados?

Os motores de arranque remanufacturados são unidades recondicionadas que cumprem as especificações do fabricante do equipamento original (OEM), proporcionando uma solução económica para compradores preocupados com o orçamento. Estes motores de arranque são particularmente apelativos para os operadores de frotas que procuram manter o desempenho do veículo sem incorrer em elevados custos de substituição. Ao considerar as opções remanufaturadas, os compradores B2B devem investigar os termos da garantia e a reputação do fornecedor para assegurar a qualidade e a fiabilidade.

Principais aplicações industriais da substituição do motor de arranque

| Indústria/Setor | Aplicação específica da substituição do motor de arranque | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Substituição de veículos da frota comercial | Reduz o tempo de inatividade, garantindo a eficiência operacional | Garantia de qualidade, compatibilidade com vários modelos de veículos |

| Equipamento de construção | Substituição do motor de arranque para máquinas pesadas | Aumenta a fiabilidade e reduz os custos de manutenção | Disponibilidade de peças duradouras, opções de entrega rápida |

| Agricultura | Substituição de tractores e ceifeiras | Minimiza o tempo de inatividade durante as épocas agrícolas críticas | Componentes resistentes às intempéries, fiabilidade do fornecedor local |

| Mineração | Substituição do motor de arranque para camiões mineiros | Garante operações contínuas em ambientes agressivos | Especificações para trabalhos pesados, aquisição a fabricantes de renome |

| Transporte e Logística | Substituição de veículos de entrega e logística | Aumenta a fiabilidade da frota e a satisfação do cliente | Relação custo-eficácia, opções de garantia e assistência técnica |

Como é que a substituição do motor de arranque é crítica para a reparação automóvel?

No sector da reparação automóvel, a substituição de motores de arranque para veículos de frotas comerciais é essencial para manter a eficiência operacional. Um motor de arranque avariado pode levar a um tempo de inatividade significativo, afectando os calendários de entrega e a disponibilidade do serviço. Os gestores de frotas têm de garantir que os motores de arranque de substituição são compatíveis com vários modelos de veículos e cumprem as normas de garantia de qualidade para evitar problemas recorrentes. O acesso rápido a peças fiáveis pode reduzir os atrasos e aumentar a produtividade global da frota.

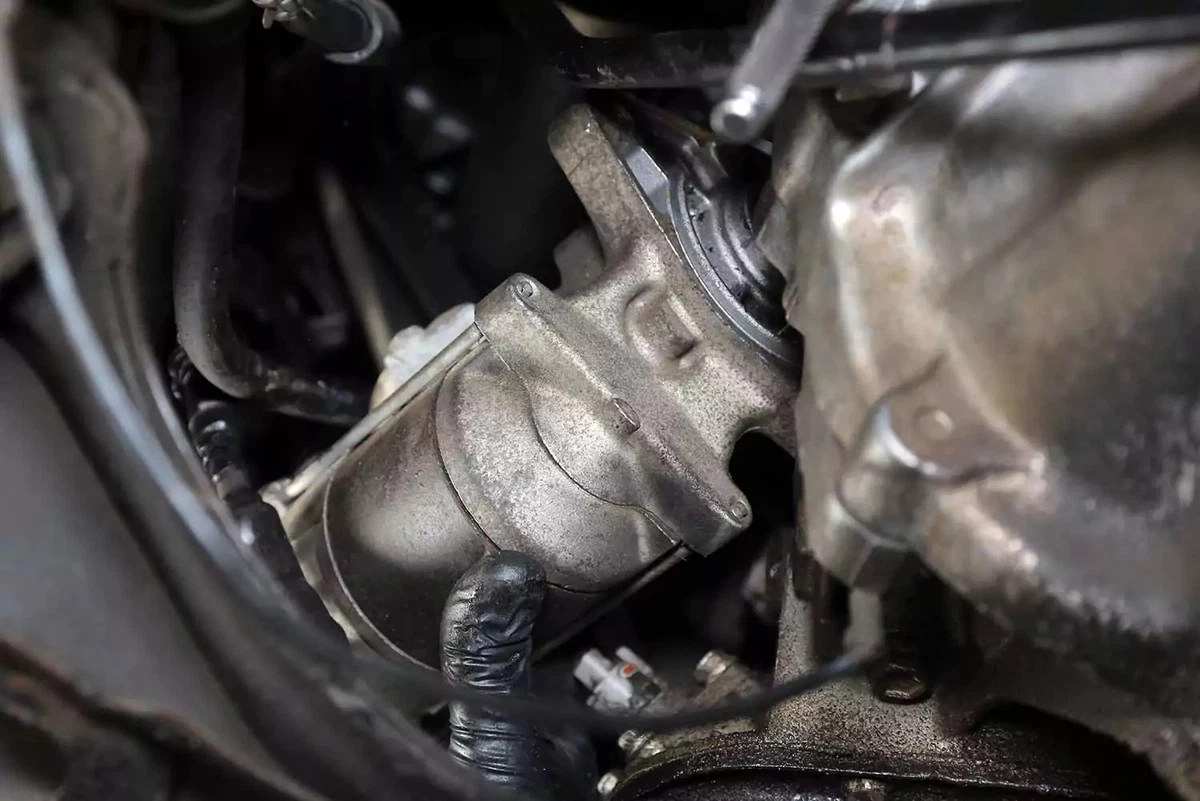

Imagem ilustrativa relacionada com a substituição do motor de arranque

Qual o papel da substituição do motor de arranque no equipamento de construção?

Na indústria da construção, a maquinaria pesada, como escavadoras e bulldozers, requer frequentemente a substituição do motor de arranque para garantir um funcionamento fiável. Estas máquinas são críticas para os prazos e eficiência dos projectos, e qualquer falha no motor de arranque pode levar a atrasos dispendiosos. As empresas devem dar prioridade ao fornecimento de componentes de arranque duradouros e resistentes às condições climatéricas, capazes de suportar os rigores dos ambientes de construção. As opções de entrega rápida também são vitais, permitindo que as empresas de construção minimizem o tempo de inatividade e mantenham a produtividade.

Porque é que a substituição do motor de arranque é importante na agricultura?

Para o equipamento agrícola, particularmente tractores e ceifeiras, a substituição do motor de arranque é crucial durante as épocas de pico da agricultura. Um motor de arranque avariado pode interromper as operações em alturas críticas, afectando o rendimento e a rentabilidade das colheitas. Os compradores deste sector têm de considerar componentes que possam resistir a condições climatéricas adversas e às exigências físicas do trabalho agrícola. A fiabilidade do fornecedor local é essencial, uma vez que o acesso atempado a peças de substituição pode fazer uma diferença significativa na eficiência operacional.

Qual o impacto da substituição do motor de arranque nas operações mineiras?

Na indústria mineira, onde os camiões e a maquinaria pesada operam em condições extremas, as substituições do motor de arranque são vitais para garantir operações ininterruptas. É necessário um motor de arranque fiável para minimizar o tempo de inatividade, especialmente em locais remotos onde as capacidades de manutenção podem ser limitadas. As empresas têm de obter motores de arranque para trabalhos pesados que cumpram especificações de desempenho rigorosas. Além disso, a parceria com fabricantes de renome pode oferecer garantia de qualidade e durabilidade em ambientes de mineração adversos.

Que vantagens oferece a substituição do motor de arranque nos transportes e na logística?

No sector dos transportes e da logística, as substituições de motores de arranque para veículos de entrega aumentam a fiabilidade da frota e a satisfação do cliente. Um motor de arranque funcional assegura que os veículos podem arrancar prontamente, evitando atrasos nos prazos de entrega. Ao adquirir motores de arranque, as empresas devem considerar a relação custo-eficácia, as opções de garantia e a disponibilidade de assistência técnica para assegurar a eficiência operacional a longo prazo. Os motores de arranque fiáveis podem contribuir significativamente para manter uma vantagem competitiva nesta indústria de ritmo acelerado.

3 pontos de dor comuns dos utilizadores para ‘substituição do motor de arranque’ e as suas soluções

Cenário 1: Dificuldade em identificar a causa raiz dos problemas de arranque

O problema: Os compradores B2B enfrentam frequentemente o desafio de diagnosticar a causa exacta dos problemas de arranque do motor. Um motor de arranque avariado pode apresentar sintomas semelhantes aos de uma bateria descarregada ou de um sistema de ignição defeituoso, o que leva a confusão e a potenciais erros de diagnóstico. Isto não só faz perder tempo como também pode levar a gastos desnecessários em peças que podem não resolver o problema. Para as empresas que dependem de frotas de veículos, isto pode resultar em tempo de inatividade e perda de receitas.

A solução: Para resolver este problema, é crucial implementar uma abordagem sistemática de resolução de problemas. Comece por efetuar uma inspeção minuciosa do sistema elétrico do veículo. Utilize um multímetro para verificar a tensão da bateria e garantir que cumpre as especificações necessárias (pelo menos 12,4 volts). Em seguida, inspeccione as ligações da bateria para verificar se há corrosão ou folga, o que pode levar a problemas de arranque. Além disso, verifique os fusíveis relacionados com o sistema de arranque e de ignição. Este processo de diagnóstico inicial pode ajudar a isolar o problema no próprio motor de arranque ou noutros componentes, permitindo uma estratégia de substituição mais direcionada e económica. A parceria com um fornecedor fiável que ofereça especificações e orientações detalhadas sobre os componentes do motor de arranque pode simplificar ainda mais o processo.

Cenário 2: Custos de substituição elevados e problemas de disponibilidade

O problema: A obtenção de um motor de arranque de substituição de qualidade pode ser uma preocupação significativa para os compradores B2B, especialmente quando operam em regiões com acesso limitado a peças automóveis. Os custos associados às peças de substituição podem variar muito em função da marca e do modelo do veículo, bem como das condições do mercado local. Esta disparidade pode afetar os orçamentos, especialmente para as empresas que gerem grandes frotas, onde vários motores de arranque podem ter de ser substituídos simultaneamente.

A solução: Para atenuar os elevados custos de substituição e os problemas de disponibilidade, as empresas devem estabelecer relações com vários fornecedores em diferentes regiões. Esta abordagem permite preços competitivos e garante o acesso a uma variedade de peças. Além disso, considere investir em motores de arranque do mercado pós-venda que cumpram as especificações OEM, mas que tenham um preço mais baixo. Ao adquirir peças, solicite opções de compra a granel ou descontos para encomendas regulares, o que pode levar a poupanças significativas ao longo do tempo. A implementação de um sistema de gestão de inventário padronizado também pode ajudar a controlar e antecipar as necessidades de peças, reduzindo as compras de emergência que, muitas vezes, são mais caras.

Cenário 3: Complexidade da instalação e custos de mão de obra

O problema: O processo de instalação de motores de arranque pode ser complexo, particularmente para certos tipos de veículos em que o motor de arranque não é facilmente acessível. Esta complexidade conduz frequentemente a custos de mão de obra mais elevados quando se contratam mecânicos profissionais, o que pode representar uma despesa substancial para as empresas. Além disso, se a instalação não for efectuada corretamente, pode levar a mais problemas no futuro, agravando os custos e o tempo de inatividade.

A solução: Para gerir eficazmente os desafios de instalação, considere investir em programas de formação para mecânicos ou técnicos internos. Fornecer-lhes as competências e conhecimentos necessários para efetuar substituições de motores de arranque pode reduzir a dependência de mão de obra externa e os custos associados. Além disso, desenvolva um conjunto de procedimentos de instalação padronizados, adaptados aos veículos específicos da sua frota. Isto pode simplificar o processo e garantir a consistência na qualidade da instalação. Ao comprar os motores de arranque, opte por produtos que venham com guias de instalação abrangentes ou tutoriais em vídeo. Estes recursos podem ajudar a sua equipa a executar a substituição de forma eficiente e correta, minimizando o risco de complicações futuras.

Imagem ilustrativa relacionada com a substituição do motor de arranque

Guia estratégico de seleção de materiais para substituição do motor de arranque

Quais são os principais materiais utilizados na substituição do motor de arranque?

Ao selecionar materiais para substituição de motores de arranque, é crucial considerar as suas propriedades, vantagens e limitações. Esta análise centra-se em quatro materiais comuns: alumínio, aço, cobre e materiais compósitos. Cada material tem caraterísticas únicas que podem influenciar o desempenho, a durabilidade e a relação custo-benefício.

Alumínio: Leve e resistente à corrosão

O alumínio é frequentemente utilizado em componentes de arranque do motor devido à sua natureza leve e excelente resistência à corrosão. Pode suportar temperaturas elevadas, o que o torna adequado para aplicações automóveis. A principal vantagem do alumínio é o seu baixo peso, que contribui para a eficiência global do veículo. No entanto, o alumínio pode ser menos durável do que o aço em condições de alta tensão, tornando-o propenso a deformações. Para os compradores internacionais, especialmente em regiões com elevada humidade, como partes de África e da América do Sul, a resistência à corrosão do alumínio é uma vantagem significativa, mas devem garantir a conformidade com as normas locais, como a ASTM, para a qualidade do material.

Aço: Resistência e durabilidade

O aço é um material amplamente utilizado em motores de arranque, particularmente para componentes que requerem elevada resistência e durabilidade. Oferece uma excelente resistência ao desgaste e pode suportar pressões e temperaturas elevadas, o que o torna ideal para aplicações pesadas. A principal desvantagem do aço é o seu peso, que pode afetar negativamente o desempenho do veículo e a eficiência do combustível. Além disso, os componentes de aço podem ser susceptíveis à ferrugem se não forem devidamente tratados, especialmente em climas húmidos. Os compradores no Médio Oriente e na Europa devem procurar opções de aço galvanizado ou inoxidável para garantir a longevidade e a conformidade com os regulamentos ambientais locais.

Imagem ilustrativa relacionada com a substituição do motor de arranque

Cobre: Condutividade superior

O cobre é frequentemente utilizado em motores de arranque devido à sua condutividade eléctrica superior, que melhora o desempenho ao assegurar uma transferência de energia eficiente. A principal vantagem do cobre é a sua capacidade de suportar cargas eléctricas elevadas, tornando-o ideal para solenóides e cablagem de arranque. No entanto, o cobre é mais caro do que o alumínio e o aço, o que pode aumentar o custo global do conjunto do motor de arranque. Para os compradores B2B em regiões como a Nigéria, onde a eficiência eléctrica é crucial, as vantagens do cobre podem compensar o seu custo. A conformidade com as normas internacionais para componentes eléctricos é também essencial, garantindo que os materiais cumprem os padrões de segurança e desempenho.

Materiais compósitos: Soluções inovadoras

Os materiais compósitos estão a emergir como uma opção viável para os motores de arranque, particularmente em aplicações que requerem componentes leves e resistentes à corrosão. Os materiais compósitos podem ser concebidos para oferecer propriedades específicas, tais como rácios elevados de resistência/peso e resistência à expansão térmica. Embora os compósitos possam reduzir o peso e melhorar a eficiência do combustível, podem não ser tão duráveis como os metais em condições extremas. Para os compradores internacionais, especialmente na Europa, compreender as complexidades de fabrico e garantir a conformidade com normas como a DIN pode ser fundamental na seleção de materiais compósitos para os motores de arranque.

Tabela de resumo da seleção de materiais para a substituição do motor de arranque

| Material | Caso de utilização típico para substituição do motor de arranque | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Caixas e suportes de arranque | Leve e resistente à corrosão | Menos durável sob alta tensão | Médio |

| Aço | Conjuntos de engrenagens e componentes estruturais | Alta resistência e durabilidade | Mais pesado e suscetível à ferrugem | Baixo |

| Cobre | Ligações eléctricas e solenóides | Condutividade elétrica superior | Custo mais elevado em comparação com os metais | Alto |

| Materiais compósitos | Componentes leves em motores de arranque avançados | Propriedades personalizáveis | Potencialmente menos durável | Médio |

Este guia estratégico de seleção de materiais fornece aos compradores B2B informações essenciais sobre os vários materiais utilizados nas substituições de motores de arranque, destacando as suas propriedades, vantagens e limitações. A compreensão destes factores pode ajudar a tomar decisões de compra informadas que se alinham com os requisitos regionais e as normas de conformidade.

Análise aprofundada: Processos de fabrico e garantia de qualidade para a substituição do motor de arranque

Quais são as principais etapas do processo de fabrico de arrancadores de motores?

O fabrico de motores de arranque envolve várias fases críticas que garantem que o produto final cumpre as normas de desempenho e durabilidade. Estas fases incluem a preparação do material, a moldagem, a montagem e o acabamento. Cada fase é essencial para produzir um motor de arranque fiável que possa suportar as exigências de vários tipos de motores.

Como é que o material é preparado para a produção de motores de arranque?

O processo de fabrico começa com a seleção do material, concentrando-se principalmente em metais de alta qualidade, como o aço e o alumínio, para a caixa e os componentes. O cobre é frequentemente utilizado para os enrolamentos devido à sua excelente condutividade. Os materiais são obtidos primeiramente junto de fornecedores conceituados que cumprem as normas de qualidade internacionais. Antes da utilização, os materiais são submetidos a inspecções rigorosas para verificar a existência de defeitos, garantindo que apenas os melhores materiais são utilizados na produção.

Uma vez confirmados os materiais, estes são cortados, moldados e tratados para atingirem as especificações desejadas. Por exemplo, os componentes de aço podem ser tratados termicamente para aumentar a resistência e a durabilidade, o que é crucial para os componentes que sofrem grandes tensões durante o funcionamento.

Que técnicas de conformação são normalmente utilizadas no fabrico de motores de arranque?

As técnicas de conformação desempenham um papel crucial na modelação dos componentes de arranque. Os métodos mais comuns incluem:

- Estampagem: Utilizada para criar caixas e suportes metálicos, a estampagem consiste em prensar folhas de metal nas formas pretendidas, utilizando matrizes. Este método é eficaz e garante uma elevada precisão.

- Usinagem: Esta técnica é utilizada para peças que exigem tolerâncias apertadas, como o induzido e o comutador. As máquinas CNC (Controlo Numérico Computadorizado) são frequentemente utilizadas para obter dimensões e acabamentos de superfície precisos.

- Moldagem por injeção: Para componentes de plástico como as tampas de solenóides, o método preferido é a moldagem por injeção. Este processo permite formas complexas e é eficaz para a produção em massa.

Estas técnicas de conformação são selecionadas com base nas propriedades dos materiais e nos requisitos específicos do projeto de arranque, assegurando que cada componente cumpre os critérios de desempenho necessários.

Como é efectuado o processo de montagem dos arrancadores de motores?

A fase de montagem é fundamental para garantir que todos os componentes se encaixam corretamente e funcionam como pretendido. Este processo inclui normalmente os seguintes passos:

- Inspeção de componentes: Antes da montagem, cada componente é submetido a uma inspeção visual e funcional para detetar eventuais defeitos de fabrico.

- Operações da linha de montagem: Técnicos especializados ou sistemas automatizados montam os componentes numa sequência pré-determinada. Isto inclui a instalação da armadura, do solenoide e da engrenagem de acionamento na caixa.

- Especificações de binário: Os montadores respeitam as especificações específicas de binário para os parafusos e os elementos de fixação, a fim de garantir que todas as peças são montadas de forma segura sem causar danos.

- Ligações elétricas: A cablagem e as ligações eléctricas corretas são cruciais para o funcionamento do motor de arranque. Estas ligações são testadas quanto à continuidade e à resistência do isolamento.

O processo de montagem foi concebido para minimizar os erros e garantir que o produto final cumpre as normas operacionais.

Que técnicas de acabamento são aplicadas aos arrancadores de motores?

As técnicas de acabamento melhoram a durabilidade e a estética dos motores de arranque. Os processos mais comuns incluem:

- Revestimento: Os motores de arranque recebem frequentemente revestimentos protectores, tais como revestimento em pó ou galvanoplastia, para evitar a corrosão e melhorar a longevidade. Isto é particularmente importante para os motores de arranque que funcionam em ambientes agressivos.

- Testes de qualidade: Depois de terminados, os motores de arranque são submetidos a vários testes, incluindo testes funcionais e testes de carga, para garantir que funcionam corretamente em diferentes condições.

Estes passos de acabamento não só melhoram o aspeto do arrancador, como também prolongam a sua vida útil, o que é uma consideração vital para os compradores B2B.

Que normas internacionais e medidas de controlo de qualidade são relevantes para os arrancadores de motores?

A garantia de qualidade é fundamental no fabrico de motores de arranque. Muitos fabricantes aderem a normas internacionais, como a ISO 9001, que define os requisitos para um sistema de gestão da qualidade. A conformidade com estas normas indica um compromisso com a qualidade consistente e a satisfação do cliente.

Como são implementados os pontos de controlo de qualidade?

O controlo de qualidade (CQ) está integrado em todo o processo de fabrico, envolvendo vários pontos de verificação fundamentais:

- Controlo de Qualidade de Entrada (IQC): Este ponto de controlo inicial garante que as matérias-primas cumprem as normas de qualidade especificadas antes de entrarem na linha de produção.

- Controlo de qualidade em processo (IPQC): Durante o fabrico, são realizadas várias inspecções para controlar a qualidade dos componentes e conjuntos em diferentes fases. Esta abordagem proactiva ajuda a identificar e a retificar os problemas antes que estes se agravem.

- Controlo de Qualidade Final (FQC): Uma vez que o motor de arranque esteja completamente montado, o FQC envolve testes abrangentes de cada unidade. Isto inclui testes funcionais, testes de carga e avaliações de desempenho para confirmar que o arrancador funciona dentro dos parâmetros especificados.

Que métodos de teste são normalmente utilizados para garantir a qualidade do motor de arranque?

Os métodos de ensaio comuns para motores de arranque incluem:

- Testes elétricos: Trata-se de verificar o desempenho elétrico do motor de arranque, incluindo a resistência e o consumo de corrente, para garantir um funcionamento eficaz.

- Testes mecânicos: O teste de carga simula as condições do mundo real para verificar se o motor de arranque pode lidar com as exigências de vários tipos de motores.

- Teste de durabilidade: Os arrancadores podem ser submetidos a ensaios de vibração e de ciclos térmicos para avaliar a sua fiabilidade em condições extremas.

Estes métodos de teste fornecem a garantia de que os arrancadores terão um desempenho fiável no terreno, o que é fundamental para os compradores B2B que procuram manter elevados padrões operacionais.

Como podem os compradores B2B verificar as medidas de controlo de qualidade dos fornecedores?

Para os compradores B2B internacionais, especialmente de regiões como África, América do Sul, Médio Oriente e Europa, é essencial verificar as medidas de controlo de qualidade de um fornecedor. Aqui estão algumas estratégias:

- Auditorias a fornecedores: A realização de auditorias regulares aos fornecedores pode ajudar a avaliar a sua adesão às normas de qualidade e aos processos de fabrico. Isto pode incluir a revisão do seu sistema de gestão da qualidade e dos protocolos de controlo de qualidade.

- Relatórios de qualidade: Solicitar relatórios de qualidade detalhados, incluindo resultados de testes e certificações de conformidade, pode fornecer informações sobre as práticas de fabrico do fornecedor e a fiabilidade do produto.

- Inspeções por terceiros: A contratação de serviços de inspeção por terceiros pode oferecer uma avaliação imparcial das instalações de produção e dos processos de controlo de qualidade do fornecedor. Isto é particularmente valioso para os compradores que podem não ter os recursos para realizar inspecções no local.

Quais são as nuances do controlo de qualidade para compradores B2B internacionais?

Os compradores internacionais têm de navegar por várias nuances de controlo de qualidade quando adquirem motores de arranque. É crucial compreender as normas regionais, os regulamentos de importação e os requisitos de certificação. Por exemplo, os produtos podem ter de cumprir marcações CE (Conformité Européenne) específicas para entrar nos mercados europeus ou cumprir as normas automóveis locais em África e no Médio Oriente.

Além disso, os compradores devem considerar as implicações da logística da cadeia de abastecimento na qualidade. Os atrasos ou o mau manuseamento durante o transporte podem afetar a integridade dos produtos. Assim, estabelecer uma comunicação forte com os fornecedores e parceiros logísticos é vital para manter a qualidade ao longo da cadeia de abastecimento.

Ao dar ênfase a processos de fabrico rigorosos e a medidas abrangentes de garantia de qualidade, os compradores B2B podem garantir que obtêm motores de arranque de alta qualidade que satisfazem as suas necessidades operacionais e melhoram a eficiência global da sua cadeia de fornecimento.

Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘substituição do motor de arranque’

Para facilitar a aquisição eficaz de peças de substituição para motores de arranque, este guia fornece uma abordagem estruturada para compradores B2B. Seguir estes passos ajudará a garantir a aquisição de produtos de alta qualidade que satisfaçam as suas necessidades operacionais, optimizando os custos.

Passo 1: Defina as suas especificações técnicas

Antes de contactar os fornecedores, esclareça os seus requisitos técnicos. Isto inclui o tipo de motor de arranque necessário, a compatibilidade com modelos de veículos específicos e quaisquer especificações de desempenho. Especificações claramente definidas ajudam os fornecedores a fornecer orçamentos exactos e a garantir que os produtos satisfazem as suas exigências operacionais.

- Considerar as marcas e modelos de veículos: Veículos diferentes podem exigir designs de arranque únicos.

- Avaliar os indicadores de desempenho: Avaliar a velocidade de arranque e o binário necessários para um desempenho ótimo do motor.

Passo 2: Pesquisar potenciais fornecedores

Realize uma pesquisa exaustiva para identificar fornecedores fiáveis. Procure empresas com um historial comprovado no sector das peças para automóveis, especialmente as especializadas em motores de arranque.

- Utilizar plataformas em linha: Sites como o Alibaba, ThomasNet e fóruns específicos do sector podem fornecer informações sobre fornecedores de renome.

- Verificar críticas e classificações: O feedback de outros compradores pode revelar a fiabilidade do fornecedor e a qualidade do produto.

Passo 3: Avaliar as certificações dos fornecedores

Certifique-se de que os potenciais fornecedores possuem as certificações necessárias e cumprem as normas internacionais. Certificações como a ISO 9001 para a gestão da qualidade podem indicar o empenhamento de um fornecedor na qualidade.

- Solicitar documentação: Peça cópias dos certificados e de quaisquer documentos de conformidade relevantes.

- Verificar a autenticidade: Contactar os organismos de certificação, se necessário, para confirmar que as certificações são válidas.

Passo 4: Pedir amostras

Antes de efetuar encomendas em massa, solicite amostras dos motores de arranque. Isto permite-lhe avaliar a qualidade, o ajuste e o desempenho em primeira mão.

- Efetuar controlos de qualidade: Inspecionar amostras para verificar a qualidade do material, a precisão do fabrico e o desempenho geral.

- Compatibilidade do teste: Assegurar que o motor de arranque se adapta aos modelos de veículos previstos sem qualquer modificação.

Passo 5: Analisar preços e condições de pagamento

Compare os preços de diferentes fornecedores, tendo em conta que o preço mais baixo nem sempre equivale ao melhor valor. Avalie as condições de pagamento, incluindo depósitos, opções de crédito e custos de envio.

- Considerar o custo total de propriedade: Tenha em conta o transporte, as tarifas potenciais e os termos da garantia ao avaliar o custo global.

- Negociar as condições: Não hesite em negociar preços ou calendários de pagamento que se adaptem às suas restrições orçamentais.

Passo 6: Rever as opções de garantia e suporte

Investigue as condições de garantia oferecidas pelos fornecedores. Uma garantia sólida pode proteger o seu investimento e indicar a confiança do fornecedor no seu produto.

- Compreender os pormenores da cobertura: Esclarecer o que a garantia inclui e a duração da cobertura.

- Avaliar o apoio ao cliente: Assegurar que o fornecedor fornece apoio adequado para a instalação e resolução de problemas.

Passo 7: Estabeleça uma relação de longo prazo

Depois de identificar um fornecedor fiável, considere estabelecer uma relação a longo prazo. Isto pode levar a melhores preços, serviço prioritário e soluções à medida das necessidades da sua empresa.

- Comunicar regularmente: Manter linhas de comunicação abertas para discutir necessidades futuras e feedback.

- Considerar acordos de compra a granel: Os contratos a longo prazo podem ajudar a garantir preços e disponibilidade favoráveis.

Ao seguir esta lista de verificação, pode simplificar o seu processo de aquisição de peças de substituição para motores de arranque, garantindo que seleciona produtos de qualidade de fornecedores fiáveis e que gere os custos de forma eficaz.

Análise exaustiva dos custos e dos preços para a substituição do motor de arranque Sourcing

Compreender a intrincada estrutura de custos e preços para o fornecimento de substituição do motor de arranque é essencial para os compradores B2B internacionais, especialmente os de regiões como África, América do Sul, Médio Oriente e Europa. Uma análise abrangente dos componentes de custo e dos influenciadores de preço pode ajudar a tomar decisões de compra informadas.

Quais são os principais componentes de custo na substituição do motor de arranque?

-

Materiais: Os principais custos de material envolvem os componentes do motor de arranque, tais como as bobinas do campo eletromagnético, a armadura, o solenoide e a caixa. Os preços podem variar significativamente com base na qualidade do material e nas práticas de aprovisionamento. Por exemplo, a utilização de materiais de alta qualidade pode aumentar a durabilidade, mas também aumentar os custos.

-

Trabalho: Os custos de mão de obra incluem o fabrico e a instalação. A mão de obra especializada é necessária para uma montagem precisa e um controlo de qualidade, contribuindo para as despesas globais. A mão de obra mecânica para a instalação pode variar muito em função da localização e da complexidade do veículo.

-

Custos indiretos de produção: Inclui os custos relacionados com as operações da fábrica, incluindo serviços públicos, rendas e despesas administrativas. Uma operação eficiente pode reduzir as despesas gerais e, consequentemente, o preço final do produto.

-

Ferramentas: O investimento inicial em ferramentas e maquinaria para a produção pode ser substancial, particularmente para os arrancadores personalizados. O custo das ferramentas é frequentemente amortizado ao longo das séries de produção, afectando os preços unitários.

-

Controlo de Qualidade (QC): Testes rigorosos e procedimentos de garantia de qualidade asseguram que os motores de arranque cumprem as normas de desempenho. Embora isto aumente os custos, é vital para manter a reputação da marca e a satisfação do cliente.

-

Logística: O transporte e o manuseamento das unidades de arranque podem influenciar significativamente os preços, especialmente no caso de envios internacionais. Devem ser considerados factores como a distância de transporte, os direitos aduaneiros e os impostos de importação.

-

Margem: Os fornecedores aplicam uma margem de lucro sobre o preço final do produto, que varia em função das condições de mercado, da concorrência e do valor percebido do produto.

O que influencia o preço da substituição do motor de arranque?

-

Volume e quantidade mínima de encomenda (MOQ): As compras em massa podem conduzir a custos unitários mais baixos. Os fornecedores oferecem frequentemente descontos para encomendas maiores, pelo que é essencial avaliar as necessidades de volume antes de negociar os preços.

-

Especificações e personalização: Os motores de arranque personalizados para modelos de veículos específicos ou requisitos de desempenho podem afetar significativamente os preços. Os compradores devem considerar se os produtos normalizados satisfazem as suas necessidades para evitar despesas desnecessárias.

-

Materiais e certificações de qualidade: A escolha de materiais e a adesão a normas de qualidade internacionais (por exemplo, certificações ISO) podem ter impacto nos custos. Uma qualidade mais elevada está frequentemente associada a um aumento dos preços, mas pode resultar em taxas de avaria mais baixas e numa vida útil mais longa.

-

Fatores relacionados ao fornecedor: A reputação e a fiabilidade do fornecedor desempenham um papel crucial na fixação dos preços. Os fornecedores estabelecidos podem cobrar um prémio devido ao seu historial comprovado, enquanto os fornecedores emergentes podem oferecer preços competitivos para ganhar quota de mercado.

-

Incoterms: A compreensão das condições de comércio pode afetar os custos totais. Por exemplo, escolher ‘Delivered Duty Paid’ (DDP) pode simplificar a logística para o comprador, mas pode aumentar os custos iniciais devido às responsabilidades adicionais assumidas pelo fornecedor.

Como é que os compradores podem negociar para obter melhores preços?

-

Alavancar o custo total de propriedade (TCO): Ao negociar, considere o TCO, que inclui o preço de compra inicial, os custos de instalação, a manutenção e o potencial tempo de inatividade. A apresentação de uma análise do TCO pode ser uma vantagem nas negociações.

-

Construir relações a longo prazo: O estabelecimento de uma parceria fiável com os fornecedores pode conduzir a condições de preços favoráveis. Os contratos a longo prazo podem garantir melhores preços e um serviço prioritário.

-

Estar informado sobre os preços de mercado: O conhecimento das taxas actuais do mercado para motores de arranque pode dar poder aos compradores durante as negociações. A pesquisa regular das tendências de preços e das ofertas da concorrência pode fornecer informações para uma negociação eficaz.

-

Considere fornecedores locais: Para os compradores em regiões como a África e a América do Sul, o abastecimento de fabricantes locais pode reduzir os custos logísticos e os prazos de entrega, resultando potencialmente em preços mais competitivos.

Conclusão

Navegar pelo cenário de custos e preços para o fornecimento de peças de reposição para motores de arranque envolve uma compreensão completa dos vários componentes de custo e da dinâmica do mercado. Ao concentrar-se em factores como o volume, as especificações e a fiabilidade do fornecedor, os compradores podem otimizar as suas estratégias de compra e garantir uma boa relação custo-eficácia. Lembre-se sempre de que os preços podem flutuar com base nas condições do mercado, portanto, manter a flexibilidade nas negociações é fundamental.

Análise de alternativas: Comparação da substituição do motor de arranque com outras soluções

Introdução: Explorando alternativas à substituição do motor de arranque

Na indústria automóvel, especialmente no sector B2B, a tomada de decisões eficazes depende frequentemente da avaliação de várias soluções para problemas comuns. Quando confrontadas com problemas de arranque do motor, as empresas podem dar por si a considerar a substituição do motor de arranque ou a explorar soluções alternativas. Compreender os prós e os contras de cada opção pode ajudar os compradores a fazer escolhas informadas que se alinham com as suas necessidades operacionais e restrições orçamentais.

Tabela comparativa

| Aspecto comparativo | Substituição do motor de arranque | Alternativa 1: Substituição da bateria | Alternativa 2: Reparação do arranque |

|---|---|---|---|

| Desempenho | Restaura a funcionalidade total, arranque fiável | Pode resolver problemas de arranque se o problema for a bateria | Pode restaurar a função, mas pode não resolver todos os problemas |

| Custo | $150 - $1.100 (mão de obra + peças) | $50 - $200 (dependendo do tipo de bateria) | $100 - $500 (peças + mão de obra) |

| Facilidade de implementação | Requer instalação profissional ou conhecimentos avançados de bricolage | Geralmente simples, pode ser feito em menos de uma hora | Requer competências e ferramentas de diagnóstico, pode ser complexo |

| Manutenção | Baixo após a substituição; recomenda-se a realização de controlos periódicos | Moderado; é necessária a manutenção da bateria | Varia; depende da extensão das reparações |

| Melhor caso de uso | Quando se confirma que o motor de arranque está avariado | Quando os problemas de arranque se devem a uma bateria descarregada ou fraca | Quando os problemas menores podem ser resolvidos sem uma substituição completa |

Discriminação detalhada das alternativas

Alternativa 1: Substituição da bateria

A substituição da bateria do veículo pode muitas vezes resolver problemas de arranque, especialmente se a bateria for antiga ou tiver um desempenho insuficiente. Esta solução é geralmente mais económica, com preços que variam entre $50 e $200. A implementação é simples, o que a torna uma opção viável para empresas com conhecimentos básicos de mecânica. No entanto, é importante notar que, se o motor de arranque for de facto a causa principal do problema, uma bateria nova não resolverá a questão, levando a um potencial tempo de inatividade. A manutenção regular é essencial para prolongar a vida útil da bateria, o que pode aumentar os custos operacionais globais.

Alternativa 2: Reparação do arranque

A reparação do motor de arranque é outra alternativa que pode ser adequada para determinadas empresas, especialmente se o motor de arranque apresentar sinais de desgaste, mas não estiver completamente avariado. Os custos de reparação podem variar entre $100 e $500, dependendo da extensão dos danos e da mão de obra envolvida. Esta opção permite às empresas prolongar a vida útil do motor de arranque existente, poupando custos em comparação com uma substituição completa. No entanto, este método requer competências de diagnóstico para garantir que a reparação resolverá efetivamente os problemas. Além disso, pode não proporcionar o mesmo nível de fiabilidade que um motor de arranque novo, levando a potenciais falhas repetidas no futuro.

Conclusão: escolhendo a solução certa para as suas necessidades

Ao avaliar as opções para resolver os problemas de arranque do motor, os compradores B2B devem considerar os seus requisitos operacionais específicos, as restrições orçamentais e a fiabilidade de cada solução. A substituição do motor de arranque é frequentemente a opção mais fiável para garantir um desempenho ótimo, mas tem um custo mais elevado. Em contrapartida, a substituição da bateria oferece uma solução rápida e económica se a bateria for a culpada, enquanto a reparação do motor de arranque pode ser uma opção económica quando é possível resolver problemas menores. Em última análise, a escolha dependerá de uma avaliação exaustiva do sistema de arranque do veículo, dos recursos disponíveis e dos objectivos operacionais a longo prazo.

Propriedades técnicas essenciais e terminologia comercial para a substituição do motor de arranque

Quais são as principais caraterísticas técnicas para a substituição do motor de arranque?

Ao considerar a substituição do motor de arranque, é essencial compreender as propriedades técnicas dos motores de arranque para tomar decisões de compra informadas. Eis as especificações essenciais a ter em conta:

1. Classe do material

O material utilizado na construção de um motor de arranque afecta significativamente a sua durabilidade e desempenho. Os materiais comuns incluem aço de alta qualidade para a caixa e cobre para os componentes eléctricos. Os compradores B2B devem dar prioridade a motores de arranque fabricados com materiais que ofereçam elevada resistência ao desgaste, especialmente em regiões com temperaturas extremas ou condições de condução difíceis.

2. Especificações de binário

As especificações de binário indicam a quantidade de força de rotação necessária para instalar corretamente o motor de arranque. Isto é vital para garantir que o motor de arranque funciona eficientemente sem risco de danos. A compreensão dos requisitos de binário pode ajudar os compradores a especificar as ferramentas e técnicas de instalação corretas, reduzindo a probabilidade de falha prematura.

3. Amperagem de arranque

A amperagem de arranque refere-se à quantidade de corrente que o motor de arranque consome durante o arranque do motor. Os motores de arranque funcionam normalmente entre 200-400 amperes. Os compradores devem fazer corresponder esta especificação ao sistema elétrico do veículo para evitar um desempenho inferior ou danos. Isto é especialmente importante para os veículos pesados normalmente utilizados em aplicações industriais em regiões como África e América do Sul.

4. Dimensões e montagem

Os motores de arranque variam em tamanho e forma, pelo que é crucial assegurar a montagem correta para a instalação. Os compradores devem verificar as dimensões e as configurações de montagem do motor de arranque para garantir a compatibilidade com o modelo específico do seu veículo. Isto minimiza os desafios de instalação e potenciais problemas de devolução.

5. Resistência eléctrica

A resistência eléctrica nos motores de arranque é um indicador-chave da eficiência. Uma menor resistência traduz-se normalmente num melhor desempenho e numa menor produção de calor. Os compradores B2B devem procurar motores de arranque com especificações que demonstrem uma baixa resistência eléctrica para aumentar a fiabilidade e a longevidade.

Quais são os termos comerciais comuns relacionados com a substituição do motor de arranque?

A familiaridade com o jargão do sector é essencial para uma comunicação e negociação eficazes no mercado B2B. Aqui estão alguns termos comuns relacionados com a substituição do motor de arranque:

1. OEM (Fabricante de Equipamento Original)

OEM refere-se a peças que são fabricadas pelo mesmo fabricante que produziu os componentes originais para um veículo. Estas peças são geralmente consideradas de maior qualidade e adaptam-se melhor do que as alternativas pós-venda. Os compradores B2B preferem frequentemente peças OEM para garantir a compatibilidade e a fiabilidade.

2. MOQ (Quantidade mínima de encomenda)

O MOQ é a quantidade mais pequena de um produto que um fornecedor está disposto a vender. Compreender o MOQ é crucial para os compradores B2B, especialmente em regiões com uma procura flutuante, uma vez que pode afetar a gestão do inventário e o fluxo de caixa.

3. RFQ (Pedido de Cotação)

Um pedido de cotação é um documento enviado aos fornecedores para solicitar preços para quantidades específicas de produtos. Este processo permite que os compradores comparem as ofertas e negoceiem os termos de forma eficaz, garantindo que obtêm o melhor valor para o seu investimento.

Imagem ilustrativa relacionada com a substituição do motor de arranque

4. Incoterms

Os Incoterms são termos comerciais internacionais que definem as responsabilidades dos compradores e vendedores no comércio internacional. A familiaridade com estes termos ajuda os compradores B2B a compreender os custos de envio, as responsabilidades de entrega e a gestão de riscos durante o transporte, o que é particularmente importante para as transacções transfronteiriças.

5. Período de garantia

O período de garantia é o período de tempo durante o qual um fabricante repara ou substitui uma peça defeituosa. A compreensão dos termos da garantia pode dar aos compradores a garantia da qualidade e do suporte do produto, crucial para manter a eficiência operacional.

Ao compreender estas propriedades técnicas e termos comerciais, os compradores B2B podem tomar decisões mais informadas relativamente às substituições de motores de arranque, garantindo que selecionam os produtos certos para as suas necessidades enquanto navegam nas complexidades do comércio internacional.

Navegar na dinâmica do mercado e nas tendências de fornecimento no sector da substituição do motor de arranque

Quais são as actuais dinâmicas de mercado no sector da substituição do motor de arranque?

O sector da substituição de motores de arranque está a assistir a mudanças dinâmicas impulsionadas por vários factores globais, que afectam particularmente os compradores B2B internacionais de regiões como África, América do Sul, Médio Oriente e Europa. Os principais impulsionadores incluem o aumento das taxas de propriedade de veículos, especialmente nos mercados emergentes, o que leva a uma maior demanda por peças de reposição. Além disso, o aumento dos veículos eléctricos (EVs) está a alterar o panorama, uma vez que os motores de arranque tradicionais estão a ser substituídos por sistemas mais avançados, criando oportunidades para os fornecedores que se adaptam a estas mudanças tecnológicas.

As tendências de aprovisionamento são cada vez mais influenciadas por plataformas digitais que facilitam processos de aquisição simplificados. Os compradores B2B estão a tirar partido do comércio eletrónico e dos mercados online para obter peças de forma mais eficiente, comparando preços e qualidade numa gama mais vasta de fornecedores. Além disso, a integração de análises avançadas está a ajudar as empresas a prever a procura e a gerir o inventário de forma mais eficaz, o que leva à redução dos prazos de entrega e dos custos.

Imagem ilustrativa relacionada com a substituição do motor de arranque

Em regiões como a Nigéria e a Arábia Saudita, as capacidades de fabrico local estão a crescer, impulsionadas por iniciativas governamentais para impulsionar as economias locais e reduzir a dependência das importações. Esta tendência incentiva os compradores internacionais a considerarem os fornecedores regionais para obterem prazos de entrega mais rápidos e custos potencialmente mais baixos. No entanto, desafios como a flutuação das taxas de câmbio e a variação das normas regulamentares podem complicar as estratégias de aprovisionamento, exigindo uma pesquisa de mercado e uma avaliação de riscos exaustivas.

Como é que a sustentabilidade está a moldar a indústria de substituição de motores de arranque?

À medida que a sustentabilidade se torna uma prioridade em todas as indústrias, o sector da substituição do motor de arranque não é exceção. O impacto ambiental dos processos de fabrico e o ciclo de vida das peças automóveis estão a ser cada vez mais analisados. Os compradores B2B estão cada vez mais concentrados na aquisição de produtos de fornecedores que demonstram um compromisso com práticas sustentáveis. Isto inclui a utilização de materiais reciclados nos componentes do motor de arranque e processos de fabrico eficientes em termos energéticos.

O fornecimento ético está a tornar-se uma consideração importante para os compradores internacionais. Espera-se que as empresas mantenham a transparência nas suas cadeias de fornecimento, assegurando que os materiais são obtidos de forma responsável e que as práticas laborais cumprem normas éticas. Certificações como a ISO 14001 para a gestão ambiental e a ISO 9001 para a gestão da qualidade estão a tornar-se pré-requisitos para os fornecedores que pretendem atrair compradores conscientes.

Imagem ilustrativa relacionada com a substituição do motor de arranque

Além disso, as inovações em tecnologias de arranque “verdes”, como as que utilizam materiais mais leves ou designs mais eficientes, estão a tornar-se mais prevalecentes. Os compradores são encorajados a dar prioridade aos fornecedores que investem em investigação e desenvolvimento com o objetivo de reduzir a pegada ambiental, alinhando-se assim com objectivos de sustentabilidade empresarial mais amplos e melhorando a reputação da sua marca no mercado.

Qual é a evolução histórica do sector da substituição de motores de arranque?

O sector da substituição do motor de arranque evoluiu significativamente desde a introdução do motor de arranque elétrico no início do século XX. Inicialmente, a norma era o acionamento manual da manivela, que era trabalhoso e muitas vezes inseguro. O advento do motor de arranque elétrico revolucionou o funcionamento do veículo, tornando-o mais acessível e conveniente.

Ao longo das décadas, os avanços tecnológicos levaram ao desenvolvimento de sistemas de arranque mais sofisticados, incluindo arrancadores com redução de velocidade e modelos de binário elevado concebidos para veículos maiores. O aumento da eletrónica e das tecnologias digitais transformou ainda mais o design dos motores de arranque, com sistemas integrados que melhoram o desempenho e a fiabilidade.

Atualmente, à medida que a indústria automóvel abraça os veículos eléctricos e híbridos, o sector enfrenta novos desafios e oportunidades. Os sistemas de arranque tradicionais estão a ser redefinidos e os fornecedores têm de se adaptar a estas mudanças para satisfazer as exigências dos veículos modernos. Esta evolução sublinha a importância da inovação contínua e da capacidade de resposta às tendências do mercado, que são fundamentais para os compradores B2B que procuram soluções fiáveis e actualizadas no mercado de substituição de motores de arranque.

Perguntas mais frequentes (FAQs) para compradores B2B de substituição do motor de arranque

-

Como é que posso determinar se preciso de um novo motor de arranque?

Para avaliar se precisa de um novo motor de arranque, observe o comportamento de arranque do seu veículo. Os sinais comuns incluem arranque irregular, um som de clique ao rodar a chave ou nenhuma resposta. Além disso, verifique a bateria e as ligações eléctricas, uma vez que os problemas nestas áreas podem imitar os problemas do motor de arranque. Se a resolução de problemas confirmar a falha do motor de arranque, considere a possibilidade de obter um substituto junto de um fornecedor fiável para garantir a qualidade e a compatibilidade com o seu veículo. -

Que factores influenciam o custo da substituição do motor de arranque?

O custo da substituição do motor de arranque varia com base em vários factores, incluindo a marca, o modelo e o ano do veículo, bem como a complexidade da instalação. Em média, os custos de substituição podem variar entre $150 e mais de $1.100, dependendo da mão de obra e das peças. As compras em massa podem muitas vezes levar a descontos, pelo que é aconselhável avaliar os potenciais fornecedores para obter preços competitivos, especialmente para encomendas maiores. -

Como posso verificar os fornecedores de peças de substituição do motor de arranque?

Para avaliar eficazmente os fornecedores, comece por investigar a sua reputação através de análises de clientes e comentários do sector. Avalie as suas certificações e a conformidade com as normas de qualidade internacionais. Solicite amostras para avaliar a qualidade do produto e garantir que cumpre as suas especificações. Além disso, informe-se sobre a fiabilidade da cadeia de fornecimento, os prazos de entrega e o apoio pós-venda para garantir uma parceria de confiança. -

Qual é a quantidade mínima de encomenda (MOQ) para motores de arranque?

As quantidades mínimas de encomenda (MOQ) para motores de arranque podem variar muito entre fornecedores, normalmente entre 50 e 500 unidades. Os factores que influenciam as MOQ incluem as capacidades de produção do fornecedor, as estratégias de preços e os níveis de inventário. Quando estiver a fazer a aquisição, comunique claramente as suas necessidades aos fornecedores, uma vez que estes podem oferecer flexibilidade nas MOQ para contratos maiores ou encomendas repetidas. -

Que condições de pagamento devo esperar quando adquiro motores de arranque a nível internacional?

As condições de pagamento podem variar significativamente consoante o fornecedor e o país de origem. As práticas comuns incluem um depósito de 30% com o saldo devido aquando da entrega, ou líquido 30-60 dias após a receção das mercadorias. Esclareça sempre os métodos de pagamento aceites (como transferência bancária ou carta de crédito) e considere a possibilidade de negociar condições que protejam os seus interesses, especialmente no caso de encomendas maiores. -

Como é que posso garantir a qualidade dos motores de arranque que adquiro?

Para garantir a qualidade, estabeleça especificações e normas claras com o seu fornecedor antes de efetuar uma encomenda. Solicite certificações que demonstrem a conformidade com normas de qualidade internacionais, como a ISO. Implemente um processo de garantia de qualidade (QA) que inclua a inspeção de amostras antes da expedição completa e considere a possibilidade de efetuar inspecções por terceiros para encomendas maiores, de modo a reduzir os riscos. -

Que considerações logísticas devo ter em conta para a importação de motores de arranque?

Ao importar motores de arranque, tenha em consideração factores logísticos, tais como métodos de envio, prazos de entrega e regulamentos aduaneiros específicos do seu país. Escolha um transitário fiável, familiarizado com peças automóveis, para simplificar o processo de expedição. Tenha em conta possíveis tarifas e impostos e certifique-se de que toda a documentação está em ordem para evitar atrasos na alfândega. -

Posso personalizar os motores de arranque para satisfazer requisitos específicos?

Sim, muitos fornecedores oferecem opções de personalização para motores de arranque para satisfazer requisitos específicos do veículo ou necessidades de marca. A personalização pode incluir alterações de design, especificações eléctricas específicas ou embalagens exclusivas. Comunique claramente os seus requisitos aos potenciais fornecedores e solicite orçamentos para projectos personalizados, uma vez que estes podem envolver custos adicionais e prazos de entrega mais longos.

Lista dos 2 principais fabricantes e fornecedores de substituição do motor de arranque

1. Toyota – Guia de substituição do motor de arranque

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: Substituição do motor de arranque do Toyota Corolla 2007; processo relativamente simples; normalmente envolve dois parafusos e ligações eléctricas; o tempo estimado para a substituição é de cerca de 30 minutos, se acessível; as peças necessárias incluem um motor de arranque novo (aproximadamente $150) e possivelmente ferramentas para remoção.

2. Facebook - Dicas de reparação automóvel

Domínio: facebook.com

Registado: 1997 (28 anos)

Introdução: Esta empresa, Facebook - Car Repair Tips, é uma entidade notável no mercado. Para obter informações específicas sobre o produto, recomenda-se a visita direta ao seu sítio Web.

Conclusão sobre o aprovisionamento estratégico e perspectivas para a substituição do motor de arranque

No domínio da substituição de motores de arranque, o aprovisionamento estratégico surge como uma prática vital para os compradores internacionais B2B, particularmente em regiões como África, América do Sul, Médio Oriente e Europa. Compreender as complexidades dos sistemas de arranque, desde os seus componentes mecânicos até aos custos associados, permite às empresas tomar decisões de compra informadas que optimizam tanto o desempenho como as despesas. Ao tirar partido dos fornecedores e fabricantes locais, os compradores podem aumentar a eficiência da cadeia de fornecimento, assegurando simultaneamente a disponibilidade de peças de alta qualidade adaptadas a modelos de veículos específicos.

Imagem ilustrativa relacionada com a substituição do motor de arranque

Além disso, reconhecer os sinais de falha do motor de arranque e a importância de substituições atempadas pode evitar tempos de paragem dispendiosos e manter a eficiência operacional. À medida que o panorama automóvel evolui, será crucial adotar uma abordagem proactiva ao aprovisionamento e à manutenção.

No futuro, encorajamos os compradores B2B a dar prioridade a parcerias com fornecedores fiáveis que ofereçam não só preços competitivos, mas também conhecimentos técnicos e apoio. Ao fazê-lo, as empresas podem posicionar-se favoravelmente no mercado competitivo, assegurando que satisfazem as exigências dos seus clientes e promovendo simultaneamente o crescimento e a sustentabilidade a longo prazo.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.