Introdução: Navegando no mercado global de custo de um alternador

No atual panorama automóvel em rápida evolução, compreender as custo de um alternador é essencial para os compradores B2B que procuram manter uma vantagem competitiva nos seus respectivos mercados. A aquisição dos alternadores certos para veículos pode ser uma tarefa complexa, especialmente porque o mercado global está repleto de variações de tipos, especificações e preços. Este guia visa desmistificar os meandros envolvidos na aquisição de alternadores, abrangendo aspectos cruciais como os diferentes tipos de alternadores, as suas aplicações e os factores que influenciam os seus custos.

Os compradores internacionais de regiões como a África, a América do Sul, o Médio Oriente e a Europa - países como o Brasil e a Nigéria - enfrentam desafios únicos no fornecimento de componentes automóveis fiáveis. Com condições económicas e dinâmicas da cadeia de fornecimento variáveis, é fundamental compreender como examinar eficazmente os fornecedores e navegar pelas estruturas de preços. Este recurso abrangente não só delineia os elementos-chave que determinam o custo dos alternadores, como também fornece informações práticas sobre a seleção de fornecedores, assegurando que os compradores podem tomar decisões de compra informadas.

Ao tirar partido da informação apresentada neste guia, os compradores B2B estarão mais bem equipados para identificar os alternadores mais adequados às suas necessidades, otimizar as suas estratégias de aquisição e, em última análise, melhorar a sua eficiência operacional. Quer seja um distribuidor, uma oficina de reparação ou um gestor de frotas, compreender a dinâmica dos custos dos alternadores permitir-lhe-á tomar decisões estratégicas que geram valor no seu negócio.

Índice

- Lista dos 3 principais fabricantes e fornecedores de custo de um alternador

- Introdução: Navegando no mercado global de custo de um alternador

- Compreender o custo de um alternador Tipos e variações

- Principais aplicações industriais do custo de um alternador

- 3 Pontos de dor comuns dos utilizadores para ‘custo de um alternador’ e respectivas soluções

- Guia de seleção estratégica de materiais para o custo de um alternador

- Análise aprofundada: Processos de fabrico e garantia de qualidade para o custo de um alternador

- Guia prático de aprovisionamento: Uma lista de verificação passo-a-passo para ‘custo de um alternador’

- Análise abrangente de custos e preços para o custo de um alternador Sourcing

- Análise de alternativas: Comparação do custo de um alternador com outras soluções

- Caraterísticas técnicas essenciais e terminologia comercial para o custo de um alternador

- Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector do custo de um alternador

- Perguntas frequentes (FAQs) para compradores B2B sobre o custo de um alternador

- Conclusão sobre o aprovisionamento estratégico e perspectivas para o custo de um alternador

- Aviso legal importante e termos de utilização

Compreender o custo de um alternador Tipos e variações

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Novos alternadores | Componentes novos, máxima fiabilidade | Veículos de frota, camiões comerciais | Prós: Desempenho ótimo, garantia incluída. Contras: Custo inicial mais elevado. |

| Remanufacturado | Reconstruído a partir de peças usadas, com uma boa relação custo-benefício | Oficinas de reparação, oficinas independentes | Prós: Custo mais baixo, amigo do ambiente. Contras: Tempo de vida potencialmente mais curto do que o de um novo. |

| Alto rendimento | Concebido para sistemas eléctricos de elevada exigência | Veículos de alto desempenho, maquinaria pesada | Prós: Maior potência de saída, adequada para eletrónica avançada. Contras: Mais caro, pode exigir modificações. |

| OEM (Fabricante de Equipamento Original) | Diretamente dos fabricantes de veículos, especificações exactas | Concessionários, centros de serviços especializados | Prós: Ajuste perfeito, garantia de fiabilidade. Contras: Preço de prémio, disponibilidade limitada. |

| Alternadores universais | Design versátil, pode adaptar-se a vários tipos de veículos | Fornecedores do mercado pós-venda, mecânicos de bricolage | Prós: Económica e de ampla aplicabilidade. Contras: Pode não oferecer um desempenho ótimo para modelos específicos. |

Quais são as principais caraterísticas dos novos alternadores para os compradores B2B?

Os alternadores novos são fabricados de raiz, garantindo a máxima qualidade e fiabilidade. Estes componentes são ideais para empresas que operam frotas ou veículos comerciais, onde a fiabilidade é fundamental. Os compradores devem ter em conta a garantia oferecida, uma vez que muitos alternadores novos vêm com uma cobertura alargada, proporcionando tranquilidade. No entanto, o custo inicial é normalmente mais elevado do que outras opções, o que pode ser um fator significativo para empresas preocupadas com o orçamento.

Como é que os Alternadores Remanufacturados servem o mercado B2B?

Os alternadores remanufaturados são uma solução económica para muitas empresas, particularmente as do sector da reparação automóvel. Estas unidades são recondicionadas a partir de alternadores usados anteriormente e podem oferecer poupanças substanciais sem sacrificar demasiada qualidade. Os compradores B2B devem avaliar a garantia e a reputação do fabricante, uma vez que estes factores podem influenciar a fiabilidade. Embora sejam geralmente menos dispendiosos, o tempo de vida pode ser mais curto em comparação com as unidades novas, pelo que as empresas devem ponderar a possibilidade de substituições mais frequentes.

Quais são as vantagens dos alternadores de alto rendimento em sectores específicos?

Os alternadores de alto rendimento são concebidos para satisfazer as exigências dos veículos com sistemas eléctricos extensos, tais como automóveis de alto desempenho e maquinaria pesada. Proporcionam uma maior potência, essencial para suportar eletrónica avançada e modificações pós-venda. Os compradores B2B em sectores como os desportos motorizados ou a construção devem considerar estas unidades devido às suas capacidades de desempenho melhoradas. No entanto, estes alternadores têm muitas vezes um preço superior e podem necessitar de modificações adicionais no veículo, o que pode aumentar os custos globais.

Porquê escolher alternadores OEM para precisão e fiabilidade?

Os alternadores OEM são fabricados pelas mesmas empresas que produzem as peças originais do veículo, garantindo um ajuste perfeito e compatibilidade. São particularmente preferidos por concessionários e centros de assistência especializados que dão prioridade à qualidade e fiabilidade. Embora ofereçam garantia relativamente ao desempenho, o custo pode ser significativamente mais elevado do que as opções pós-venda, o que pode dissuadir alguns compradores sensíveis ao orçamento. No entanto, para as empresas que dão prioridade à qualidade e à longevidade, o investimento pode valer a pena.

Como é que os alternadores universais satisfazem as diversas necessidades B2B?

Os alternadores universais são concebidos para se adaptarem a uma vasta gama de tipos de veículos, o que os torna uma escolha flexível para fornecedores do mercado pós-venda e mecânicos de bricolage. A sua versatilidade permite às empresas armazenar menos peças e, ao mesmo tempo, satisfazer as várias necessidades dos clientes. Embora sejam muitas vezes mais económicos, os compradores devem ser cautelosos, uma vez que estas unidades podem não oferecer o mesmo nível de desempenho que os alternadores de modelos específicos. As empresas devem avaliar os compromissos entre custo e desempenho para garantir que satisfazem eficazmente os seus requisitos operacionais.

Principais aplicações industriais do custo de um alternador

| Indústria/Setor | Aplicação específica do custo de um alternador | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Automotivo | Substituição e reparação de alternadores de veículos | Garante a fiabilidade e a segurança do veículo, reduzindo os custos de inatividade | Compatibilidade com modelos de veículos, opções de garantia e fiabilidade do fornecedor |

| Construção | Alimentação de máquinas e equipamentos pesados | Aumenta a eficiência operacional, minimizando os riscos de falha do equipamento | Especificações que correspondem aos requisitos das máquinas, disponibilidade local e prazos de entrega |

| Energia renovável | Integração em sistemas de energia eólica e solar | Facilita a conversão de energia, optimizando a produção de energia | Requisitos de tensão, durabilidade ambiental e relação custo-eficácia |

| Marinha | Alternadores em barcos e navios para sistemas eléctricos | Apoia a navegação e os sistemas operacionais, garantindo a segurança | Materiais de qualidade marítima, estabilidade de tensão e conformidade com os regulamentos marítimos |

| Agricultura | Utilização em tractores e máquinas agrícolas | Aumenta a produtividade, garantindo a fiabilidade do equipamento durante a colheita | Compatibilidade com várias máquinas agrícolas, com recurso a fornecedores locais para uma boa relação custo-eficácia |

Qual a importância do custo de um alternador na indústria automóvel?

No sector automóvel, o custo de um alternador é fundamental para manter a fiabilidade do veículo. Ao substituir ou reparar alternadores, as empresas devem garantir a compatibilidade com modelos de veículos específicos para evitar custos adicionais e tempo de inatividade. Um alternador avariado pode levar a interrupções operacionais significativas, tornando essencial que as empresas do sector automóvel adquiram peças de alta qualidade que cumpram as normas da garantia. Os compradores internacionais, particularmente de regiões como África e América do Sul, devem considerar as redes de fornecedores locais para um acesso mais rápido às peças e custos de envio reduzidos.

Porque é que o custo de um alternador é importante na construção?

Na construção, a maquinaria e o equipamento pesados dependem dos alternadores para obter energia. O custo destes componentes afecta diretamente a eficiência operacional e os prazos dos projectos. Uma falha do alternador pode interromper as operações, levando a um aumento dos custos de mão de obra e a atrasos nos projectos. Os compradores deste sector devem concentrar-se no fornecimento de alternadores que cumpram requisitos específicos de potência e normas de durabilidade adequadas a ambientes de trabalho difíceis. Além disso, a consideração de fornecedores locais pode reduzir os prazos de entrega e melhorar os serviços de apoio.

Que papel desempenha o custo de um alternador nas aplicações de energias renováveis?

Nos sistemas de energias renováveis, como a energia eólica e solar, os alternadores são vitais para a conversão de energia mecânica em energia eléctrica. O custo destes componentes tem impacto no orçamento global do projeto e no retorno do investimento. Os compradores devem avaliar a saída de tensão e a eficiência dos alternadores para maximizar a produção de energia. Para além disso, é crucial adquirir componentes duradouros que possam resistir às condições ambientais. Os compradores internacionais também devem considerar fornecedores especializados em tecnologias de energia renovável para garantir a conformidade com os regulamentos e normas locais.

Como é que o custo de um alternador afecta as aplicações marítimas?

Para aplicações marítimas, os alternadores são essenciais para alimentar os sistemas de navegação e operacionais em barcos e navios. O custo destes alternadores pode influenciar a segurança e a funcionalidade globais das embarcações marítimas. Os compradores devem dar prioridade ao fornecimento de alternadores de qualidade marítima que ofereçam estabilidade de tensão e conformidade com os regulamentos marítimos. Compreender as necessidades eléctricas específicas das diferentes embarcações é também crucial. Os compradores internacionais devem procurar fornecedores com um forte historial em aplicações marítimas para garantir fiabilidade e desempenho.

Porque é que o custo de um alternador é crítico na agricultura?

Na agricultura, os tractores e as máquinas agrícolas dependem dos alternadores para os seus sistemas eléctricos. O custo de um alternador afecta a fiabilidade e a eficiência das operações agrícolas, especialmente durante as épocas de pico, como as colheitas. Os compradores precisam de garantir que os alternadores adquiridos são compatíveis com vários tipos de maquinaria agrícola e podem suportar condições difíceis. Trabalhar com fornecedores locais pode ajudar a reduzir os custos e melhorar os prazos de entrega, garantindo que os agricultores possam manter o seu equipamento a funcionar sem problemas.

3 Pontos de dor comuns dos utilizadores para ‘custo de um alternador’ e respectivas soluções

Cenário 1: Compreender a variabilidade dos custos dos alternadores

O problema: Para os compradores B2B, particularmente aqueles em regiões com mercados de veículos diversos como a Nigéria ou o Brasil, compreender a variabilidade de custos dos alternadores pode ser assustador. Factores como a marca, o modelo e o ano do veículo têm um impacto significativo nos preços, causando confusão no planeamento do orçamento para reparações ou substituições. Os compradores podem não ter a certeza se estão a ser cobrados em excesso ou se os preços indicados reflectem o verdadeiro valor de mercado. Esta incerteza pode dificultar a tomada de decisões e conduzir a potenciais perdas financeiras.

A solução: Para navegar na complexidade dos custos do alternador, os compradores B2B devem investir tempo numa pesquisa de mercado exaustiva. A criação de uma base de dados abrangente de preços de alternadores de diferentes fornecedores pode proporcionar clareza. Utilize ferramentas de preços padrão da indústria ou contacte associações automóveis locais para recolher dados de preços relevantes. Além disso, considere a possibilidade de estabelecer relações com vários fornecedores para comparar cotações de forma eficaz. Esta estratégia não só permite que os compradores tomem decisões informadas, como também aumenta a capacidade de negociação, garantindo que obtêm preços justos que reflectem os requisitos específicos dos seus veículos.

Cenário 2: Identificar a qualidade versus o custo na seleção do alternador

O problema: Um ponto de dor comum para os compradores B2B é o desafio de distinguir entre alternadores de alta qualidade e opções mais baratas e de qualidade inferior. Em regiões como o Médio Oriente, onde as temperaturas extremas podem afetar o desempenho do veículo, a seleção de um alternador inferior pode levar a falhas frequentes e a um aumento dos custos de manutenção. Os compradores são frequentemente pressionados a manter os custos baixos, o que leva ao risco de comprometer a qualidade, o que pode ter implicações a longo prazo na gestão da sua frota.

A solução: Para resolver este problema, os compradores B2B devem dar prioridade às avaliações de qualidade em detrimento da poupança imediata de custos. Implementar um processo de avaliação robusto que inclua a verificação das credenciais do fabricante, ofertas de garantia e análises de clientes. Efetuar a devida diligência solicitando amostras ou unidades de teste aos fornecedores para avaliar o desempenho em condições locais. Além disso, considere a possibilidade de adquirir alternadores de fabricantes reputados que cumpram as normas de qualidade internacionais, mesmo que tenham um custo inicial mais elevado. Esta abordagem pode, em última análise, reduzir o custo total de propriedade, minimizando a frequência de substituições e reparações.

Cenário 3: Os custos ocultos associados à substituição do alternador

O problema: Os compradores B2B ignoram frequentemente os custos ocultos associados à substituição do alternador, tais como encargos de mão de obra, taxas de diagnóstico e peças adicionais necessárias para a instalação. Na Europa, onde os custos de mão de obra podem ser elevados, estas despesas adicionais podem aumentar significativamente a despesa total. Os compradores podem concentrar-se apenas no preço do alternador em si, para se surpreenderem com a fatura final depois de contabilizados todos os custos associados.

A solução: Para atenuar o impacto dos custos ocultos, os compradores B2B devem adotar uma abordagem holística ao elaborar o orçamento para a substituição do alternador. Comece por obter orçamentos detalhados que discriminem todos os custos potenciais, incluindo mão de obra e diagnósticos, de vários fornecedores de serviços. Implemente uma lista de verificação que descreva todos os componentes necessários para a instalação e manutenção, garantindo que não são necessárias peças adicionais inesperadamente. Além disso, considere a possibilidade de negociar custos de mão de obra fixos ou de procurar oficinas que ofereçam pacotes de peças e mão de obra. Esta estratégia proactiva permitirá uma orçamentação mais precisa e evitará pressões financeiras inesperadas durante o processo de reparação.

Guia de seleção estratégica de materiais para o custo de um alternador

Quais são os principais materiais utilizados no fabrico de alternadores?

Ao selecionar materiais para a produção de alternadores, vários factores influenciam o desempenho, o custo e a adequação a várias aplicações. A compreensão das propriedades, vantagens e limitações destes materiais é crucial para os compradores internacionais B2B, especialmente em regiões como África, América do Sul, Médio Oriente e Europa.

Como o cobre influencia o desempenho e o custo do alternador?

O cobre é um material primário nos enrolamentos do alternador devido à sua excelente condutividade eléctrica e propriedades térmicas. Suporta temperaturas elevadas e é resistente à corrosão, o que o torna ideal para aplicações automóveis onde o calor e a humidade são predominantes.

Prós: A elevada condutividade do cobre assegura uma produção eficiente de energia e uma perda mínima de energia. Também oferece durabilidade, contribuindo para a longevidade do alternador.

Contras: A principal desvantagem é o custo; o cobre é relativamente caro em comparação com alternativas como o alumínio. Além disso, os processos de fabrico que envolvem o cobre podem ser complexos, exigindo técnicas especializadas para garantir a qualidade.

Impacto na aplicação: A compatibilidade do cobre com cargas eléctricas elevadas torna-o adequado para veículos modernos que exigem uma potência significativa para vários sistemas eléctricos.

Considerações para compradores internacionais: Os compradores devem garantir a conformidade com as normas internacionais, como a ASTM B170 para o cobre, e estar cientes da flutuação dos preços do cobre, que pode afetar os custos globais.

Qual é o papel do alumínio na construção do alternador?

O alumínio é frequentemente utilizado como uma alternativa leve ao cobre no fabrico de alternadores, particularmente nos componentes do rotor e da carcaça. Tem uma densidade mais baixa, o que pode contribuir para a redução global do peso do veículo.

Prós: O alumínio é menos dispendioso do que o cobre e mais fácil de trabalhar, o que pode simplificar os processos de fabrico. A sua resistência à corrosão também o torna adequado para vários ambientes.

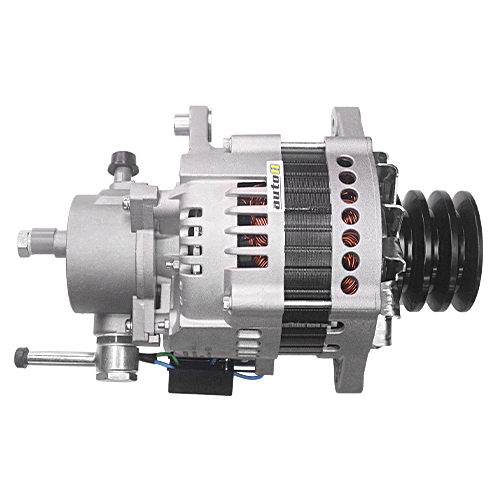

Imagem ilustrativa relacionada com o custo de um alternador

Contras: Embora o alumínio tenha uma condutividade decente, não é tão eficiente como o cobre, o que pode levar a uma maior perda de energia. Além disso, os componentes de alumínio podem ter uma condutividade térmica inferior, afectando o desempenho em condições de carga elevada.

Impacto na aplicação: O alumínio é adequado para aplicações em que a redução de peso é fundamental, mas pode não ser ideal para veículos de elevado desempenho que exijam a máxima eficiência eléctrica.

Considerações para compradores internacionais: Os compradores devem verificar a conformidade com normas como a ASTM B221 para o alumínio e considerar o impacto ambiental da extração e transformação do alumínio.

Como é que o aço contribui para a durabilidade do alternador?

O aço é normalmente utilizado nos componentes estruturais dos alternadores, como os núcleos do estator e do rotor. A sua resistência e durabilidade tornam-no uma escolha fiável para garantir que o alternador pode suportar tensões mecânicas.

Prós: O aço proporciona uma excelente integridade estrutural e tem um custo relativamente baixo em comparação com outros materiais. Está também facilmente disponível, o que o torna uma escolha prática para os fabricantes.

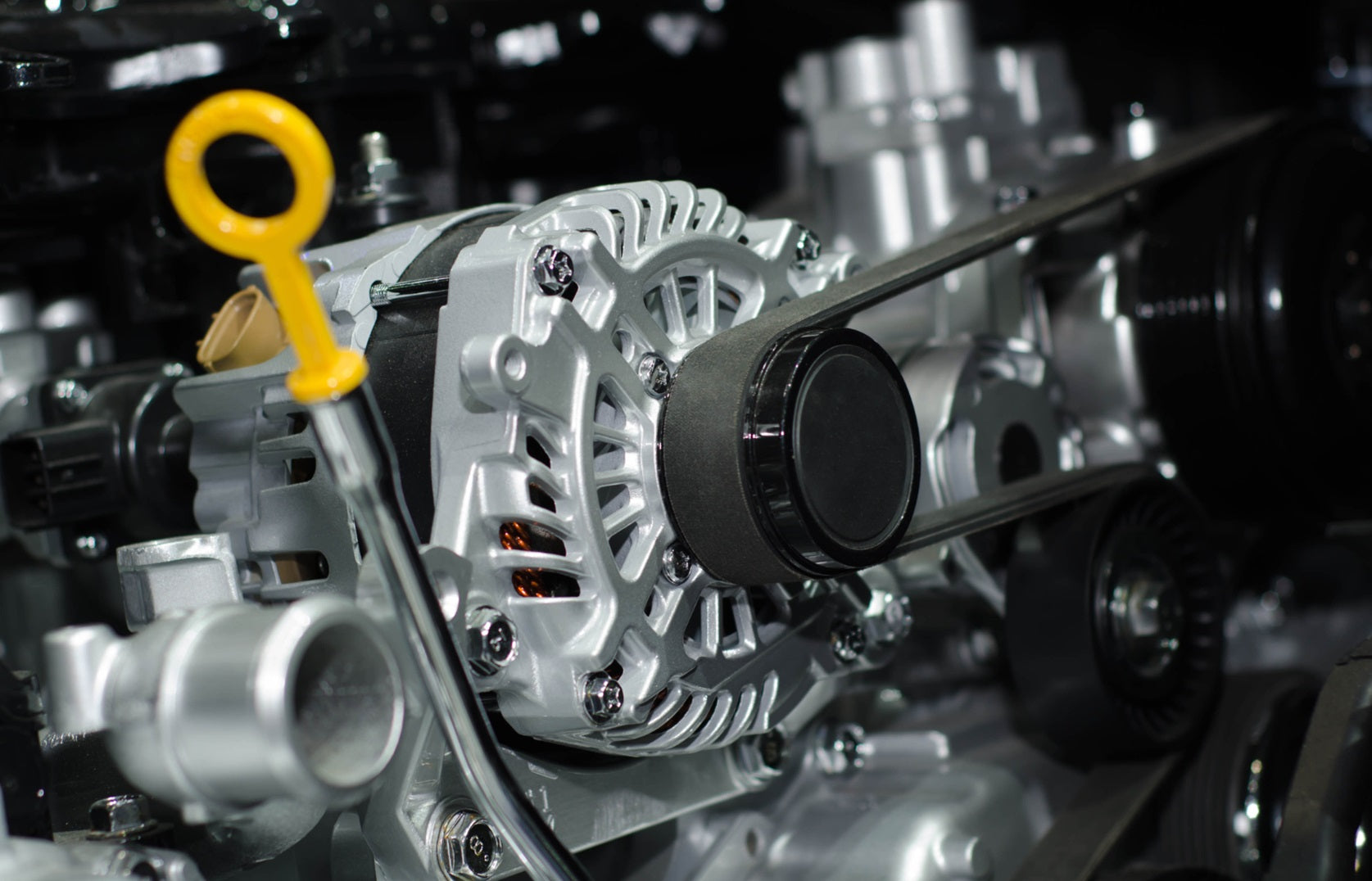

Imagem ilustrativa relacionada com o custo de um alternador

Contras: O aço é mais pesado do que alternativas como o alumínio, o que pode acrescentar peso desnecessário ao veículo. Além disso, é propenso à corrosão se não for corretamente tratado.

Impacto na aplicação: A resistência do aço é benéfica para aplicações que requerem componentes robustos, mas o seu peso pode ser uma desvantagem em veículos orientados para o desempenho.

Considerações para compradores internacionais: Os compradores devem certificar-se de que os componentes de aço cumprem as normas relevantes, como a ASTM A36, e considerar a necessidade de revestimentos protectores para aumentar a resistência à corrosão.

Que vantagens oferece o plástico na conceção do alternador?

Os materiais plásticos, nomeadamente os polímeros de alto rendimento, são cada vez mais utilizados nos componentes dos alternadores, como as carcaças e os isoladores. Estes materiais podem proporcionar um isolamento eficaz e reduzir o peso.

Prós: Plastics are lightweight and resistant to corrosion, which can improve the overall efficiency and lifespan of the alternator. They can also be molded into complex shapes, allowing for innovative designs.

Imagem ilustrativa relacionada com o custo de um alternador

Contras: Plastics may not withstand high temperatures as well as metals, potentially limiting their use in high-performance applications. Additionally, they can be less durable under mechanical stress compared to metals.

Impacto na aplicação: Plastics are suitable for non-load-bearing components where weight savings and corrosion resistance are priorities.

Considerações para compradores internacionais: Buyers should verify that plastic components comply with relevant standards, such as ISO 9001 for quality management, and consider the implications of plastic waste in their supply chain.

Imagem ilustrativa relacionada com o custo de um alternador

Tabela resumida da seleção de materiais para alternadores

| Material | Typical Use Case for cost of an alternator | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Enrolamentos e ligações elétricas | Elevada condutividade elétrica | Custo elevado e fabrico complexo | Alto |

| Alumínio | Rotor and housing components | Leve e económico | Condutividade inferior à do cobre | Médio |

| Aço | Núcleos do estator e do rotor | Excelente resistência e durabilidade | Mais pesado e propenso à corrosão | Baixo |

| Plástico | Caixas e isoladores | Leve e resistente à corrosão | Desempenho limitado em altas temperaturas | Médio |

Understanding these materials and their implications can help B2B buyers make informed decisions that align with their operational needs and market demands.

Análise aprofundada: Processos de fabrico e garantia de qualidade para o custo de um alternador

Quais são as principais fases de fabrico de um alternador?

The manufacturing process of an alternator involves several critical stages that ensure the final product meets performance and reliability standards. These stages include material preparation, forming, assembly, and finishing, each requiring specific techniques and quality checks.

Como é que os materiais são preparados para a produção de alternadores?

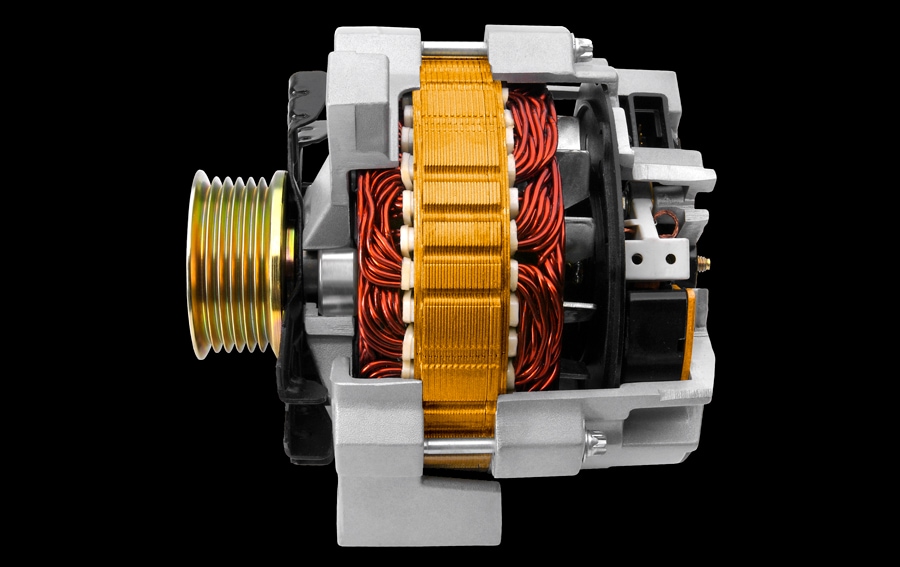

The first step in manufacturing alternators is the preparation of raw materials, primarily high-quality metals like copper, aluminum, and steel. Copper is essential for the windings, while aluminum is often used for the housing due to its lightweight properties. Steel is used for components like the rotor and stator.

Materials undergo rigorous inspection to ensure they meet industry standards. This includes checking for purity levels and any defects that could compromise performance. Suppliers should provide certifications verifying the quality of these materials, which can be crucial for B2B buyers who need to ensure that the components will perform reliably in various operating environments.

Que técnicas são utilizadas na formação de componentes do alternador?

Once the materials are prepared, the next stage is forming. This typically involves several techniques, including:

- Estampagem: Used to create the casing and other flat components of the alternator. Precision stamping ensures that parts fit together correctly, reducing assembly errors.

- Enrolamento: Copper wire is wound around the stator to create electromagnetic fields. The winding process is critical, as the number of turns affects the alternator’s output.

- Maquinação: Parts are often machined to achieve the necessary tolerances and smooth finishes. This step may include drilling, milling, and turning operations.

These forming techniques must adhere to strict tolerances to ensure the alternator operates efficiently. B2B buyers should inquire about the machinery and technology used in these processes, as advanced techniques can lead to better performance and lower failure rates.

Como são montados os componentes do alternador?

The assembly of an alternator is where all the prepared and formed components come together. This process typically includes:

- Integração de componentes: Stator and rotor assemblies are combined, and electrical connections are made. Proper alignment is essential to ensure the alternator operates smoothly.

- Testing During Assembly: Quality control checkpoints are established throughout the assembly process. This includes in-process quality control (IPQC), where components are tested for functionality before moving on to the next stage.

- Montagem final: Once all components are integrated, the alternator undergoes a final assembly check to ensure all screws, bolts, and electrical connections are secure.

B2B buyers should understand that the assembly process can significantly impact the overall performance of the alternator. They should consider suppliers that implement robust assembly protocols and conduct thorough checks at each stage.

What Finishing Processes Are Essential for Alternators?

Finishing processes enhance the durability and aesthetic appeal of the alternator. These may include:

Imagem ilustrativa relacionada com o custo de um alternador

- Painting or Coating: A protective coating is often applied to prevent corrosion and enhance the appearance. This is crucial, particularly for alternators used in harsh environments.

- Testing for Electrical Performance: After finishing, alternators undergo electrical testing to ensure they meet voltage and current specifications. This testing is critical for verifying that the alternator will perform effectively under load.

These finishing processes not only contribute to the product’s longevity but also to its reliability. Buyers should ask for documentation that details the finishing techniques used by suppliers to ensure compliance with international standards.

Que medidas de garantia de qualidade são implementadas no fabrico de alternadores?

Quality assurance (QA) is an integral part of the alternator manufacturing process. It ensures that the final product meets all necessary safety and performance standards.

What International Standards Should B2B Buyers Look for?

International standards such as ISO 9001 play a crucial role in the manufacturing and quality assurance of alternators. ISO 9001 focuses on establishing a quality management system that enhances customer satisfaction and ensures consistent quality. Additionally, industry-specific certifications like CE marking and API standards may also be relevant, depending on the application of the alternator.

B2B buyers should prioritize suppliers who can demonstrate compliance with these standards, as this indicates a commitment to quality and reliability.

How Are Quality Checkpoints Structured During Production?

Quality checkpoints are strategically placed throughout the manufacturing process to catch potential issues early. Common checkpoints include:

Imagem ilustrativa relacionada com o custo de um alternador

- Controlo de Qualidade de Entrada (IQC): As matérias-primas são inspecionadas à chegada para garantir que cumprem as especificações.

- Controlo de qualidade em processo (IPQC): Components are tested during the assembly process to catch defects early.

- Controlo de Qualidade Final (FQC): The finished alternator undergoes thorough testing to verify performance metrics before shipping.

Implementing these checkpoints helps prevent defects from reaching the customer, ensuring that B2B buyers receive high-quality products.

Que métodos de ensaio são normalmente utilizados para os alternadores?

Several testing methods are employed to ensure the alternator meets performance standards:

- Teste de carga: Measures the alternator’s output under various load conditions to ensure it can handle the required electrical demand.

- Voltage Testing: Verifies that the alternator produces the correct voltage output, typically between 13.5 and 14.5 volts.

- Testes térmicos: Assesses the alternator’s performance under high-temperature conditions to ensure it can operate effectively in extreme environments.

B2B buyers should request detailed testing reports from suppliers to verify that all necessary testing has been conducted.

Como os compradores B2B podem verificar a garantia de qualidade dos fornecedores?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider several verification methods:

- Auditorias a fornecedores: Conducting regular audits of suppliers can provide insights into their manufacturing and quality assurance processes.

- Relatórios de qualidade: Requesting quality assurance reports can help buyers understand the testing methods and results.

- Inspeções por terceiros: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices.

Particularly for international buyers from regions such as Africa, South America, the Middle East, and Europe, understanding local compliance and certification nuances is essential. Suppliers should be able to navigate and fulfill both international and local standards, ensuring that products are suitable for their intended markets.

Conclusão

The manufacturing processes and quality assurance measures for alternators are critical factors that directly impact performance, reliability, and cost. By understanding these processes and the associated quality standards, B2B buyers can make informed decisions when sourcing alternators for their operations. Ensuring that suppliers adhere to rigorous manufacturing and quality assurance protocols will lead to better product outcomes and customer satisfaction.

Guia prático de aprovisionamento: Uma lista de verificação passo-a-passo para ‘custo de um alternador’

To assist B2B buyers in effectively sourcing alternators, this guide provides a structured checklist that outlines critical steps to ensure informed and successful procurement. By following this checklist, buyers can navigate the complexities of alternator costs and specifications, ultimately leading to better purchasing decisions.

Passo 1: Defina as suas especificações técnicas

Understanding the exact requirements for the alternators you need is fundamental. This includes knowing the make, model, and year of the vehicles they will service, as well as the amperage and mounting styles required. Accurate specifications help avoid compatibility issues and ensure the alternators will perform effectively in your applications.

Passo 2: Pesquisar preços de mercado

Conducting thorough market research on the cost of alternators will provide insight into average pricing and help identify competitive offers. Prices can vary widely based on brand, type (new vs. remanufactured), and regional factors. Establishing a budget based on this research will guide your procurement strategy and negotiations.

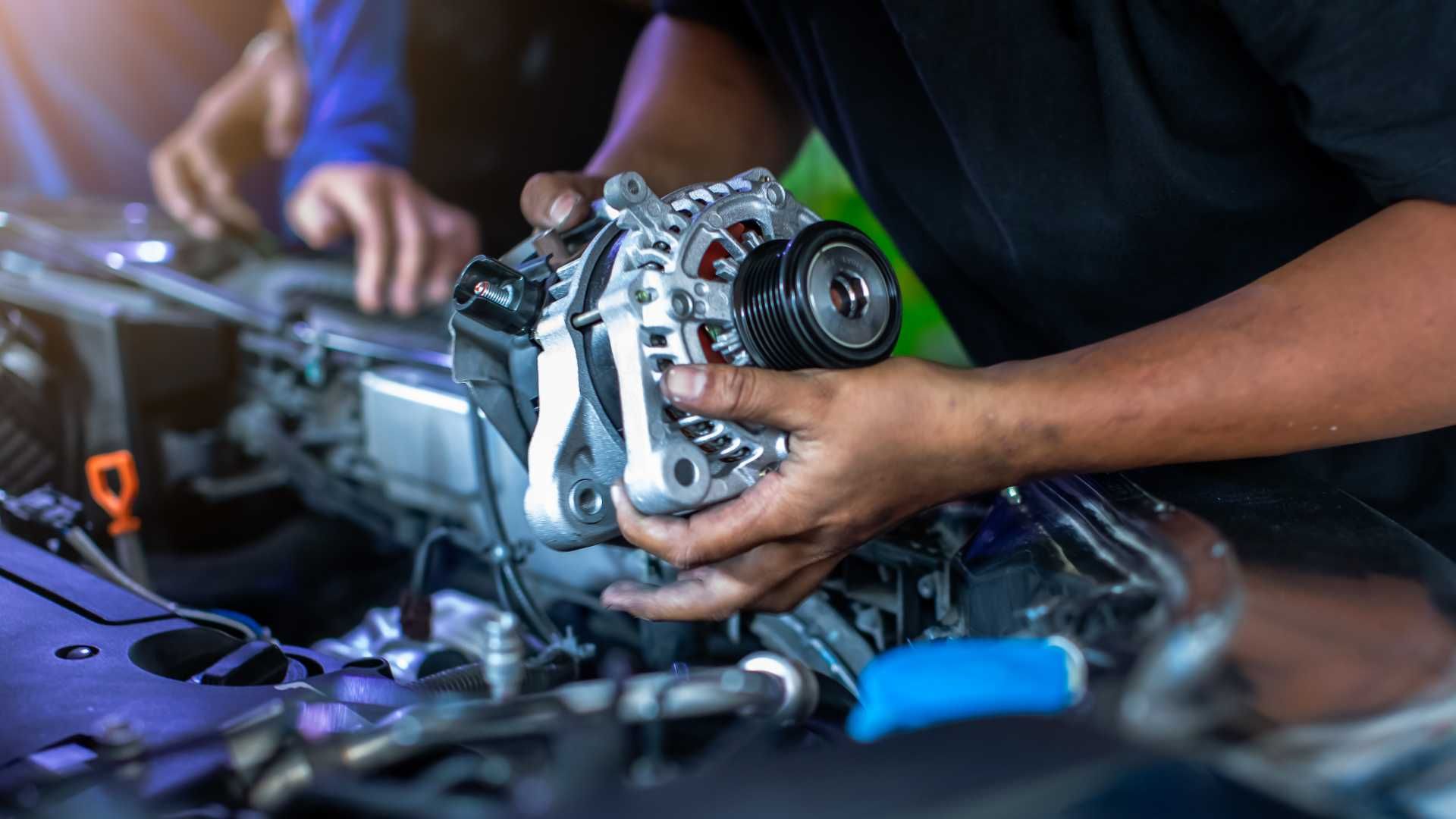

Imagem ilustrativa relacionada com o custo de um alternador

Passo 3: Avalie potenciais fornecedores

Before committing to a supplier, it is crucial to assess their credibility and reliability. Request company profiles, product catalogs, and references from other clients in similar industries. Look for suppliers with a proven track record of quality and service, as this can significantly impact your purchasing experience.

- Considerações:

- Check for customer testimonials and case studies.

- Evaluate their experience in your specific region, such as Africa or South America, to understand any logistical challenges they may face.

Passo 4: Verificar as certificações dos fornecedores

Ensuring that your chosen suppliers meet industry standards and certifications is vital for maintaining quality control. Look for certifications such as ISO 9001 or specific automotive industry standards. These certifications indicate that the supplier adheres to rigorous quality management practices.

Passo 5: Avaliar as políticas de garantia e devolução

A robust warranty and clear return policy can safeguard your investment. When sourcing alternators, inquire about the warranty duration and coverage, as well as the process for returning faulty parts. This is particularly important in B2B transactions where the cost of defective parts can lead to significant operational disruptions.

Imagem ilustrativa relacionada com o custo de um alternador

Passo 6: Negociar termos e condições

Once you have identified potential suppliers, engage in negotiations to secure favorable terms. This includes pricing, payment terms, delivery timelines, and any bulk purchase discounts. Effective negotiation can lead to cost savings and enhanced supply chain efficiency.

Passo 7: Plan for Logistics and Shipping

Consider the logistics of transporting the alternators from the supplier to your location. Evaluate shipping costs, delivery times, and any customs regulations that may apply, especially for international purchases. Proper logistics planning can prevent delays and ensure that you receive the alternators when needed.

By following this checklist, B2B buyers can make informed decisions when procuring alternators, ultimately ensuring they secure high-quality products at competitive prices while mitigating risks associated with sourcing.

Análise abrangente de custos e preços para o custo de um alternador Sourcing

Understanding the cost structure and pricing dynamics associated with alternator sourcing is crucial for B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. This section provides a comprehensive breakdown of cost components, price influencers, and actionable buyer tips to optimize purchasing strategies.

What Are the Key Cost Components of an Alternator?

The total cost of an alternator encompasses several critical components:

-

Materiais: The primary materials include copper for windings, steel for the rotor and stator, and plastics for housing. The quality and sourcing of these materials significantly influence the overall cost. Copper prices, for instance, can fluctuate based on global market conditions.

-

Trabalho: Labor costs vary depending on the manufacturing location. In regions with higher labor costs, such as parts of Europe, the overall price of the alternator may be elevated compared to lower-cost regions like parts of Asia.

-

Custos indiretos de produção: This includes expenses related to utilities, facility maintenance, and administrative costs. Efficient manufacturing processes can help reduce overhead, thus lowering the final price.

-

Ferramentas: Custom tooling for specific alternator designs can be a substantial upfront investment. The amortization of these costs over production volumes can influence unit pricing, making it essential for buyers to consider order sizes.

-

Controlo de Qualidade (QC): Implementing stringent QC measures ensures product reliability, but it also adds to the overall cost. Certifications such as ISO can further enhance credibility but may come with additional costs.

-

Logística: Transportation and warehousing costs are critical, especially for international shipments. Incoterms play a pivotal role in determining who bears these costs, impacting the total landed price.

-

Margem: Suppliers typically add a profit margin to cover their operational costs and risks. This margin can vary widely based on market competition and the supplier’s positioning strategy.

Como os influenciadores de preço afetam os custos do alternador?

Several factors can significantly influence the pricing of alternators:

-

Volume/MOQ (Quantidade mínima de encomenda): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should evaluate their purchasing needs to leverage bulk pricing effectively.

-

Especificações e personalização: Custom specifications, such as increased amperage or special mounting styles, can increase costs. Buyers should assess whether these specifications are necessary or if standard options will suffice.

-

Materiais e qualidade: Higher-quality materials and components will elevate costs but can lead to longer-lasting products. Buyers should balance the initial cost against potential long-term savings.

-

Fatores relacionados ao fornecedor: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their brand and reliability, while newer entrants might offer lower prices to capture market share.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Different Incoterms (like FOB, CIF, DDP) affect who pays for shipping, insurance, and duties, impacting the total cost.

What Negotiation Strategies Can Buyers Employ?

When sourcing alternators, buyers can adopt several strategies to enhance cost-efficiency:

-

Explorar vários fornecedores: Solicit quotes from various suppliers to compare prices and terms. This not only helps in identifying the best price but also provides leverage during negotiations.

-

Avaliar o custo total de propriedade (TCO): Look beyond the purchase price. Consider maintenance costs, warranty terms, and the expected lifespan of the alternator. A slightly higher upfront cost may yield better long-term value.

-

Negociar condições de pagamento: Flexible payment terms can aid cash flow management. Discuss options like extended payment periods or installment payments to ease financial pressure.

-

Leverage Market Insights: Stay informed about market trends and material costs. Knowledge of fluctuations can aid in timing purchases and negotiating better deals.

Conclusão

Understanding the comprehensive cost and pricing analysis for alternators is essential for B2B buyers aiming to make informed purchasing decisions. By recognizing cost components, price influencers, and employing strategic negotiation techniques, buyers can optimize their sourcing processes. As market conditions continue to evolve, staying informed will remain a critical factor in achieving cost-efficiency and ensuring product reliability.

Isenção de responsabilidade: Prices may vary based on market conditions, supplier pricing strategies, and specific buyer requirements. Always verify current pricing with suppliers before making purchasing decisions.

Análise de alternativas: Comparação do custo de um alternador com outras soluções

Exploring Alternatives to Alternators: Cost and Performance Insights

In the automotive and industrial sectors, the reliability of electrical systems is paramount. While alternators are widely used to convert mechanical energy into electrical power, several alternatives exist that can serve similar functions. This section compares the cost and performance of alternators against other viable solutions, such as battery storage systems and generator systems. Understanding these options can help B2B buyers make informed decisions based on their specific operational needs.

| Aspecto comparativo | Cost Of An Alternator | Battery Storage System | Generator System |

|---|---|---|---|

| Desempenho | Provides consistent voltage output (13.5-14.5 volts) for vehicle systems. | Offers energy storage for off-grid applications or during peak demand. | Generates power on demand but may require refueling. |

| Custo | $100 – $1,000 (installation included). | $200 – $2,500 (depends on capacity and type). | $300 – $5,000 (varies by size and fuel type). |

| Facilidade de implementação | Typically straightforward installation; requires matching to vehicle specs. | Installation may require additional infrastructure for integration. | Can be complex; may need professional setup for larger systems. |

| Manutenção | Moderate; periodic checks and replacements needed every 7-10 years. | Low to moderate; regular monitoring of battery health is essential. | High; requires fuel management and regular maintenance. |

| Melhor caso de uso | Ideal for standard vehicles needing reliable electrical supply. | Best for renewable energy applications and backup power solutions. | Suitable for remote locations or as a primary power source in emergencies. |

Análise aprofundada das alternativas

Sistemas de armazenamento de baterias

Battery storage systems, such as lithium-ion or lead-acid batteries, provide an effective alternative to alternators, especially in applications where energy storage is crucial. These systems can store excess energy generated from renewable sources, making them ideal for off-grid scenarios. While the initial investment can be higher, especially for advanced battery types, they offer the advantage of reduced long-term energy costs and can serve multiple applications beyond just vehicle power. However, the complexity of installation and the need for regular maintenance to ensure battery health can be drawbacks for some businesses.

Generator Systems

Generator systems are another alternative that can provide power when needed, particularly in industrial or construction settings. These units can operate on various fuels, including diesel, gasoline, or natural gas, making them versatile. While they can generate power on demand, the operational costs can escalate due to fuel requirements and maintenance needs. Generators are best suited for situations where a consistent power supply is critical, but the higher initial cost and ongoing fuel expenses can deter some buyers.

Imagem ilustrativa relacionada com o custo de um alternador

Conclusão: escolhendo a solução certa para as suas necessidades

When evaluating the cost of an alternator versus alternative solutions like battery storage systems and generators, B2B buyers must consider their specific operational requirements, budget constraints, and maintenance capabilities. Each option has its unique advantages and potential drawbacks, and the best choice will depend on factors such as the intended application, power needs, and long-term cost-effectiveness. By thoroughly assessing these aspects, businesses can make informed decisions that align with their strategic goals and operational demands.

Caraterísticas técnicas essenciais e terminologia comercial para o custo de um alternador

What Are the Key Technical Properties of an Alternator That Impact Cost?

Understanding the technical specifications of an alternator is crucial for B2B buyers, especially when evaluating costs and making purchasing decisions. Here are several essential properties to consider:

1. Amperagem de saída

Amperage indicates the electrical current the alternator can produce, typically ranging from 40 to over 200 amps. This specification is vital because it determines whether the alternator can meet the electrical demands of the vehicle, especially for those with numerous electronic components. A higher amperage alternator often comes at a premium due to the increased amount of copper winding and materials used.

2. Tensão nominal

The standard voltage output for modern alternators is between 13.8 and 14.6 volts. A consistent voltage is necessary to charge the battery effectively and power all electrical systems. If the alternator cannot maintain this voltage range, it may lead to battery failure or malfunctioning electrical components, resulting in costly repairs or replacements.

3. Estilo de montagem

The alternator’s mounting style (e.g., side-mounted or front-mounted) is crucial for compatibility with specific vehicle models. Each vehicle requires a precise fit to ensure optimal performance. Therefore, understanding the correct mounting style can prevent costly mistakes in purchasing the wrong alternator, which may necessitate further modifications or returns.

Imagem ilustrativa relacionada com o custo de um alternador

4. Type of Electrical Connections

Alternators can feature different wiring configurations, such as 1-wire or 3-wire setups. The complexity of these connections can influence the installation cost and the alternator’s price. A 3-wire alternator typically costs more due to its enhanced functionality and reliability, making it important to align the choice with the vehicle’s electrical system requirements.

5. Composição do material

The materials used in the construction of the alternator—primarily copper and steel—affect both its performance and price. Copper, used in windings, is a key conductor of electricity. The quality and grade of materials can influence the longevity and efficiency of the alternator, impacting overall costs and maintenance expenses.

What Trade Terminology Should B2B Buyers Understand When Purchasing Alternators?

Familiarizing yourself with industry terminology can streamline the purchasing process and enhance negotiations. Here are several common terms:

1. OEM (Fabricante de Equipamento Original)

This term refers to parts made by the original manufacturer of the vehicle. OEM alternators are typically more expensive but offer guaranteed compatibility and quality assurance, making them a preferred choice for many buyers who prioritize reliability.

2. MOQ (Quantidade mínima de encomenda)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to ensure they meet supplier requirements while managing inventory effectively. Buying below the MOQ may lead to higher per-unit costs or inability to procure the alternator.

3. RFQ (Pedido de Orçamento)

An RFQ is a formal document requesting pricing and terms from suppliers. It is a crucial step in the procurement process, allowing buyers to compare options, negotiate terms, and ensure they receive competitive pricing for alternators.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand shipping costs and risks, which can significantly affect the total cost of purchasing an alternator.

5. Mercado pós-venda

This term refers to parts not made by the original manufacturer but by third-party companies. Aftermarket alternators may offer cost savings but can vary in quality. Buyers should assess the reputation of aftermarket brands to ensure reliability and performance.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding alternator purchases, ultimately leading to better cost management and operational efficiency.

Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector do custo de um alternador

What Are the Current Market Dynamics Influencing the Cost of an Alternator?

The global alternator market is experiencing a dynamic shift influenced by several key factors. Demand for automotive electrical systems is rising due to increased vehicle electrification and the adoption of advanced driver-assistance systems (ADAS). This trend is particularly pronounced in regions like Africa and South America, where the automotive sector is rapidly evolving. The growth of electric vehicles (EVs) is driving innovation in alternator design, pushing manufacturers to focus on higher efficiency and compact models to meet the power demands of modern vehicles.

Emerging B2B sourcing trends include a growing preference for remanufactured alternators, which are more cost-effective and environmentally friendly. This trend is especially relevant in regions facing economic constraints, such as Nigeria and Brazil, where buyers seek affordable yet reliable alternatives. Additionally, international buyers are increasingly leveraging digital platforms for procurement, allowing for better price comparisons and access to a wider range of suppliers.

Key market dynamics also include fluctuating raw material prices, particularly copper, which is essential for alternator manufacturing. As countries focus on resource sustainability, the cost of sourcing these materials is becoming a significant factor in pricing strategies. Furthermore, regulatory changes aimed at reducing carbon footprints are influencing manufacturers to adopt greener production practices, ultimately impacting the overall cost structure.

How Does Sustainability and Ethical Sourcing Impact the Cost of an Alternator?

Sustainability and ethical sourcing are becoming paramount concerns for B2B buyers in the alternator sector. The environmental impact of alternator production, particularly in terms of resource extraction and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as using recycled materials and minimizing carbon emissions during manufacturing.

Ethical supply chains are essential for maintaining brand reputation and customer loyalty. Companies that demonstrate a commitment to sustainability are often seen as more trustworthy, which can enhance their competitive edge in the market. B2B buyers should look for suppliers that hold certifications such as ISO 14001, which indicates a commitment to effective environmental management systems.

Moreover, the use of ‘green’ materials—such as bio-based plastics or sustainably sourced metals—can not only reduce environmental impact but also appeal to consumers who prioritize eco-friendly products. As the demand for sustainable products grows, suppliers who adopt these materials may find themselves with a cost advantage, as they can often command higher prices due to perceived value.

What Is the Historical Context of the Alternator Market?

The alternator has evolved significantly since its inception in the early 20th century. Initially used primarily in larger vehicles, it became standard in passenger cars by the 1960s, replacing the less efficient generator systems. This transition was driven by the increasing electrical demands of vehicles, including lighting and ignition systems.

Over the decades, advancements in technology have led to the development of more compact and efficient alternators, such as those utilizing advanced materials and designs that enhance performance. The rise of electronic components in vehicles has further solidified the alternator’s role as a critical component of automotive electrical systems.

In recent years, the focus has shifted towards enhancing the efficiency and reliability of alternators in response to growing environmental concerns and the push for electric vehicles. This historical context is crucial for B2B buyers, as understanding these trends can inform purchasing decisions and strategic sourcing approaches.

Perguntas frequentes (FAQs) para compradores B2B sobre o custo de um alternador

-

How do I determine the cost of an alternator for my specific vehicle model?

To determine the cost of an alternator for your vehicle, you must consider the year, make, and model, as these factors significantly influence pricing. Additionally, the alternator’s amperage and type—whether it’s a new or remanufactured part—will also affect costs. It’s advisable to consult with multiple suppliers to get quotes based on your specific vehicle’s requirements, ensuring you account for any additional shipping or import duties if sourcing internationally. -

What factors influence the pricing of alternators in international markets?

Several factors influence alternator pricing in international markets, including local demand and supply dynamics, shipping costs, tariffs, and exchange rates. Additionally, the quality of the alternator, warranty options, and whether it’s a remanufactured or new part can also affect pricing. For B2B buyers, understanding these factors can help in negotiating better deals and ensuring cost-effectiveness. -

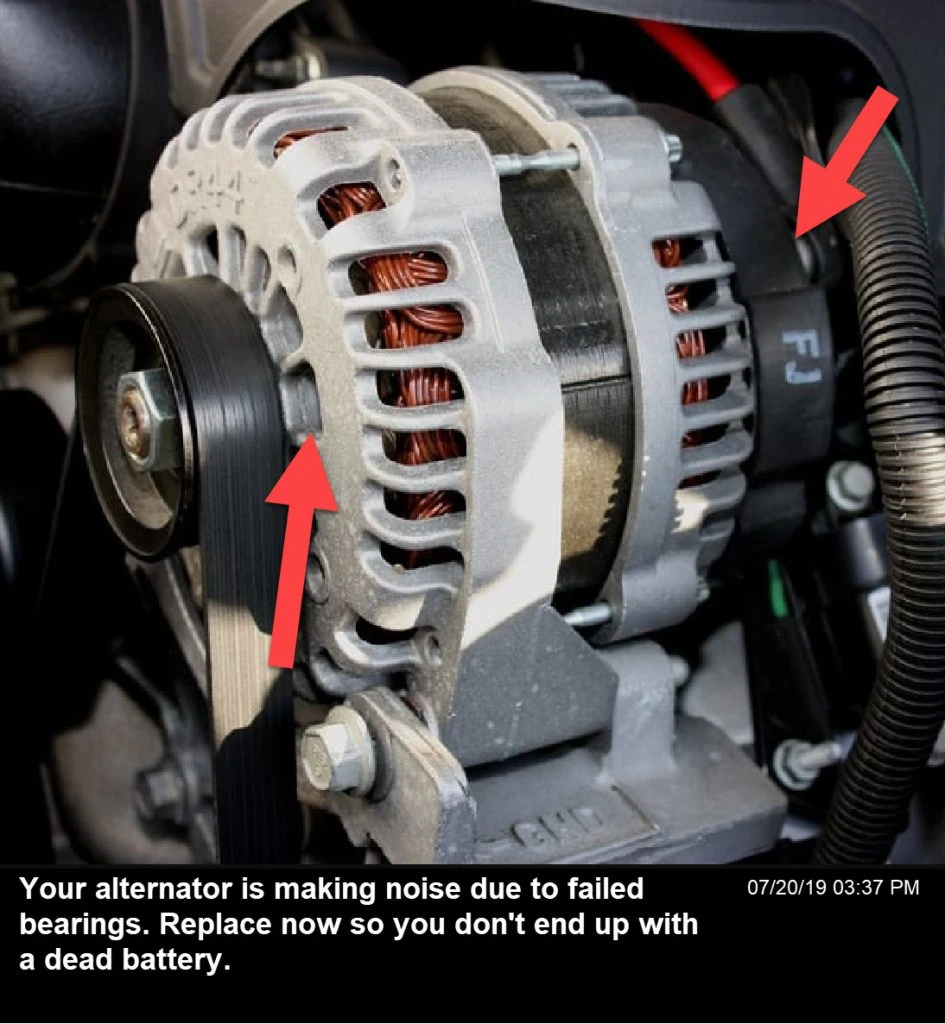

What are the common signs that an alternator needs to be replaced?

Common signs of a failing alternator include dimming headlights, electrical system failures, unusual noises from the engine, and the battery warning light illuminating on the dashboard. If these symptoms are present, timely replacement is crucial to avoid further damage to the vehicle’s electrical system. As a B2B buyer, ensuring that your suppliers can provide high-quality alternators that address these issues is essential. -

What are the typical payment terms for sourcing alternators from international suppliers?

Payment terms can vary widely among international suppliers, but common practices include upfront payments, net 30, or net 60 terms. Some suppliers may also offer letter of credit (LC) options for larger orders. It’s essential to clarify payment terms before finalizing any deals to avoid misunderstandings and ensure smooth transactions. -

How can I vet suppliers for purchasing alternators internationally?

Vetting suppliers involves assessing their reputation, production capabilities, and compliance with industry standards. Check for certifications, read customer reviews, and request references from previous clients. Additionally, consider visiting their facilities if possible, or using third-party audit services to ensure they meet your quality and ethical standards. -

What is the minimum order quantity (MOQ) for alternators when sourcing from suppliers?

The MOQ for alternators can vary based on the supplier and the specific product. Typically, suppliers may require a MOQ of anywhere from 10 to 50 units. It’s important to negotiate these terms upfront, especially if you are a smaller business, to ensure you can meet your inventory needs without overcommitting. -

Are there customization options available for alternators, and how do they affect cost?

Many suppliers offer customization options such as specific amperage ratings, mounting styles, or electrical connections. Customizations can increase costs due to the need for specialized production processes and materials. Discuss your requirements in detail with suppliers to understand how these changes will affect pricing and lead times. -

Que considerações logísticas devo ter em mente ao importar alternadores?

When importing alternators, consider shipping methods, delivery times, and customs clearance processes. It’s vital to work with reliable logistics partners who can handle the complexities of international shipping. Additionally, ensure that you understand the import regulations and tariffs in your country to avoid unexpected costs and delays.

Lista dos 3 principais fabricantes e fornecedores de custo de um alternador

1. J.D. Power – Custos de substituição do alternador

Domínio: jdpower.com

Registrado: 1995 (30 anos)

Introdução: Alternator replacement costs range from $350 to $900, with average parts costing $100 to $350, and luxury models costing $500 to $700. Labor costs can add $350 to $500 if done at a dealership. Rebuilt alternators are available and should match or exceed the original amp rating. DIY installation is possible for skilled individuals, potentially saving on labor costs.

2. Toyota – RAV4 Alternator Replacement

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: 2006 Toyota RAV4, substituição do alternador, $450 custo total incluindo mão de obra.

3. Car Talk - Custos de substituição do alternador

Domínio: cartalk.com

Registrado: 1995 (30 anos)

Introdução: The cost to replace an alternator ranges from $600 to $1,500. An alternator is a critical component that maintains the charge of the battery and powers various electrical systems in the vehicle. It converts mechanical energy into electrical energy and is driven by an accessory belt in the engine. Signs of a failing alternator include a check engine light, dimming headlights, and the need for jump-…

Conclusão sobre o aprovisionamento estratégico e perspectivas para o custo de um alternador

In conclusion, understanding the cost dynamics of alternators is essential for international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. Key factors influencing alternator prices include vehicle specifications, amperage requirements, and availability of remanufactured units. Strategic sourcing not only helps in identifying reliable suppliers but also in negotiating favorable terms that can significantly reduce overall costs.

For businesses, leveraging insights on alternator functionality and maintenance can lead to improved operational efficiency and reduced downtime. As technology continues to evolve, the demand for high-quality, cost-effective alternators is expected to rise, presenting both challenges and opportunities for sourcing professionals.

Looking ahead, it is crucial for B2B buyers to stay informed about market trends and advancements in alternator technology. Engaging with reputable suppliers and utilizing comprehensive sourcing strategies will empower businesses to make informed decisions that enhance their supply chain resilience. Take proactive steps today to optimize your sourcing strategy and ensure your operations remain competitive in an ever-evolving market landscape.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.