Introduction: Navigating the Global Market for starter motor or battery

In the competitive landscape of the automotive industry, sourcing high-quality starter motors and batteries presents a significant challenge for international B2B buyers. Understanding the nuances of these essential components is crucial for ensuring reliable vehicle performance and longevity. This comprehensive guide delves into the various types of starter motors and batteries available in the global market, examining their applications across different vehicle types and conditions.

Navigating this complex marketplace requires an informed approach to supplier vetting, cost analysis, and performance evaluation. Buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia, will benefit from insights into the latest trends, technological advancements, and best practices for procurement.

The guide empowers decision-makers by providing actionable information on how to identify the right components for their specific needs, ultimately enhancing operational efficiency and reducing downtime. By understanding the interdependencies between starter motors and batteries, as well as recognizing the signs of potential failures, businesses can make strategic purchasing decisions that align with their operational goals. With this resource, B2B buyers can confidently navigate the global market, ensuring they secure the best products to support their automotive needs.

Índice

- Top 5 Starter Motor Or Battery Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter motor or battery

- Understanding starter motor or battery Types and Variations

- Key Industrial Applications of starter motor or battery

- 3 Common User Pain Points for ‘starter motor or battery’ & Their Solutions

- Strategic Material Selection Guide for starter motor or battery

- In-depth Look: Manufacturing Processes and Quality Assurance for starter motor or battery

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor or battery’

- Comprehensive Cost and Pricing Analysis for starter motor or battery Sourcing

- Alternatives Analysis: Comparing starter motor or battery With Other Solutions

- Essential Technical Properties and Trade Terminology for starter motor or battery

- Navigating Market Dynamics and Sourcing Trends in the starter motor or battery Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter motor or battery

- Strategic Sourcing Conclusion and Outlook for starter motor or battery

- Aviso legal importante e termos de utilização

Understanding starter motor or battery Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Bateria de chumbo-ácido | Traditional technology, reliable, cost-effective | Automóvel, máquinas industriais | Prós: Low cost, widely available; Contras: Heavier, shorter lifespan in extreme temperatures. |

| Bateria de iões de lítio | Lightweight, high energy density, longer life cycle | Electric vehicles, portable tools | Prós: Longer lifespan, fast charging; Contras: Higher cost, sensitive to temperature extremes. |

| Motor de arranque com redução de engrenagem | Higher torque output, compact design | Heavy-duty vehicles, racing cars | Prós: More efficient, smaller size; Contras: Can be more expensive, requires precise installation. |

| Arrancador de Íman Permanente | Uses permanent magnets for efficiency | Motorcycles, compact cars | Prós: Lightweight, simple design; Contras: Limited torque, may not suit all applications. |

| Arrancador de alto desempenho | Enhanced durability and performance for demanding uses | Performance vehicles, racing | Prós: High torque, reliable under stress; Contras: Higher price point, may require specialized installation. |

What are the Key Characteristics of Lead-Acid Batteries?

Lead-acid batteries are the most common type in automotive applications, known for their reliability and affordability. They consist of lead dioxide and sponge lead plates submerged in sulfuric acid. This type is particularly suitable for vehicles with high starting demands, such as trucks and buses. B2B buyers should consider the lifespan, typically 3-5 years, and the environmental impact of disposal when purchasing, as these batteries can be heavy and less efficient in extreme temperatures.

How Do Lithium-Ion Batteries Compare for B2B Applications?

Lithium-ion batteries are increasingly popular due to their lightweight nature and high energy density, making them ideal for electric vehicles and portable equipment. They offer a longer lifespan and faster charging capabilities compared to lead-acid batteries. B2B buyers should weigh the initial investment against long-term benefits, as these batteries can be more expensive but may provide significant savings on maintenance and replacements over time.

What Makes Gear Reduction Starters Ideal for Heavy-Duty Vehicles?

Gear reduction starters are designed to deliver higher torque in a compact form, making them perfect for heavy-duty vehicles and racing applications. By reducing the gear ratio, these starters can turn the engine more efficiently, especially in demanding conditions. Buyers in the automotive sector should consider installation requirements and the potential for improved performance when selecting this type of starter, as they may incur higher upfront costs.

Why Choose Permanent Magnet Starters for Lightweight Vehicles?

Permanent magnet starters are characterized by their use of permanent magnets, which enhance efficiency and reduce weight. This makes them particularly suitable for motorcycles and compact cars, where space and weight savings are critical. B2B buyers should evaluate the torque requirements of their applications, as these starters may not meet the needs of larger engines, but they excel in smaller, more efficient vehicles.

What are the Advantages of High-Performance Starters?

High-performance starters are engineered for durability and reliability under extreme conditions, catering to performance vehicles and racing applications. They provide high torque and are designed to withstand the rigors of competitive environments. When considering a high-performance starter, B2B buyers should account for the higher price point and potential installation complexities, but the investment can yield significant performance benefits in demanding applications.

Key Industrial Applications of starter motor or battery

| Indústria/Setor | Specific Application of starter motor or battery | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Fabricação Automotiva | Produção de veículos eléctricos e híbridos | Aumenta a fiabilidade e o desempenho do veículo | Quality certifications, compatibility with existing systems |

| Equipamento de construção | Heavy machinery ignition systems | Ensures operational efficiency on job sites | Durability under extreme conditions, local support services |

| Agricultura | Starting engines in tractors and harvesters | Increases uptime and productivity during harvest | Resistance to corrosion, ability to withstand temperature extremes |

| Transporte e Logística | Fleet vehicle starter systems | Reduces maintenance costs and downtime | Bulk purchasing options, warranty terms, and service availability |

| Marinha | Starter motors for boats and ships | Improves safety and reliability in marine operations | Compliance with marine standards, resistance to saltwater corrosion |

How Is the Starter Motor or Battery Used in Automotive Manufacturing?

In the automotive manufacturing sector, starter motors and batteries are critical for the production of electric and hybrid vehicles. These components ensure reliable engine ignition and optimal performance. Manufacturers require high-quality batteries that can withstand rigorous testing and provide consistent power. Additionally, sourcing partners must have relevant quality certifications and be able to provide components compatible with advanced vehicle systems. This is particularly important for international buyers from regions like Europe, where regulatory compliance is stringent.

What Role Do Starter Motors and Batteries Play in Construction Equipment?

In the construction industry, starter motors and batteries are vital for the ignition systems of heavy machinery, such as excavators and bulldozers. Reliable starting systems ensure that equipment can operate efficiently on job sites, minimizing downtime. Buyers in this sector must focus on sourcing components that are durable and capable of functioning in extreme conditions, including high temperatures and dust. Local support services are also crucial for quick replacements and repairs, especially in remote areas common in Africa and South America.

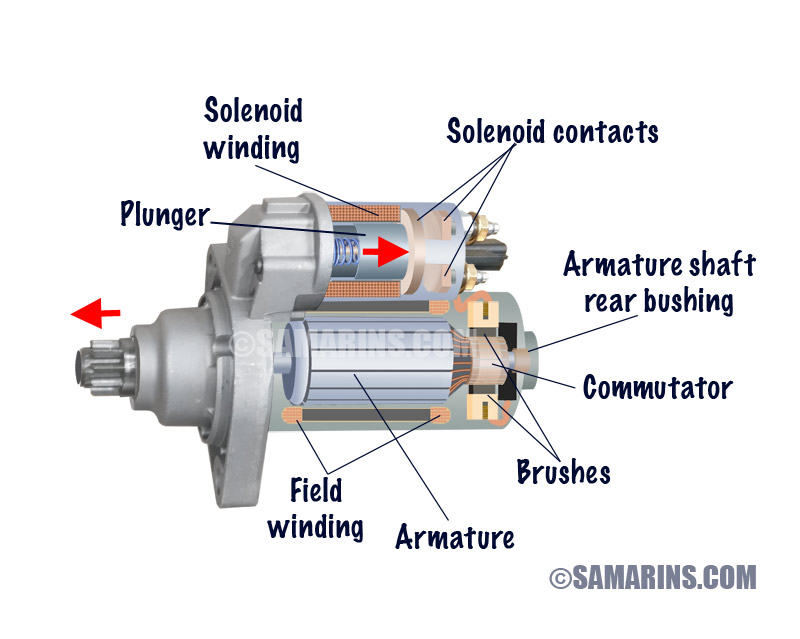

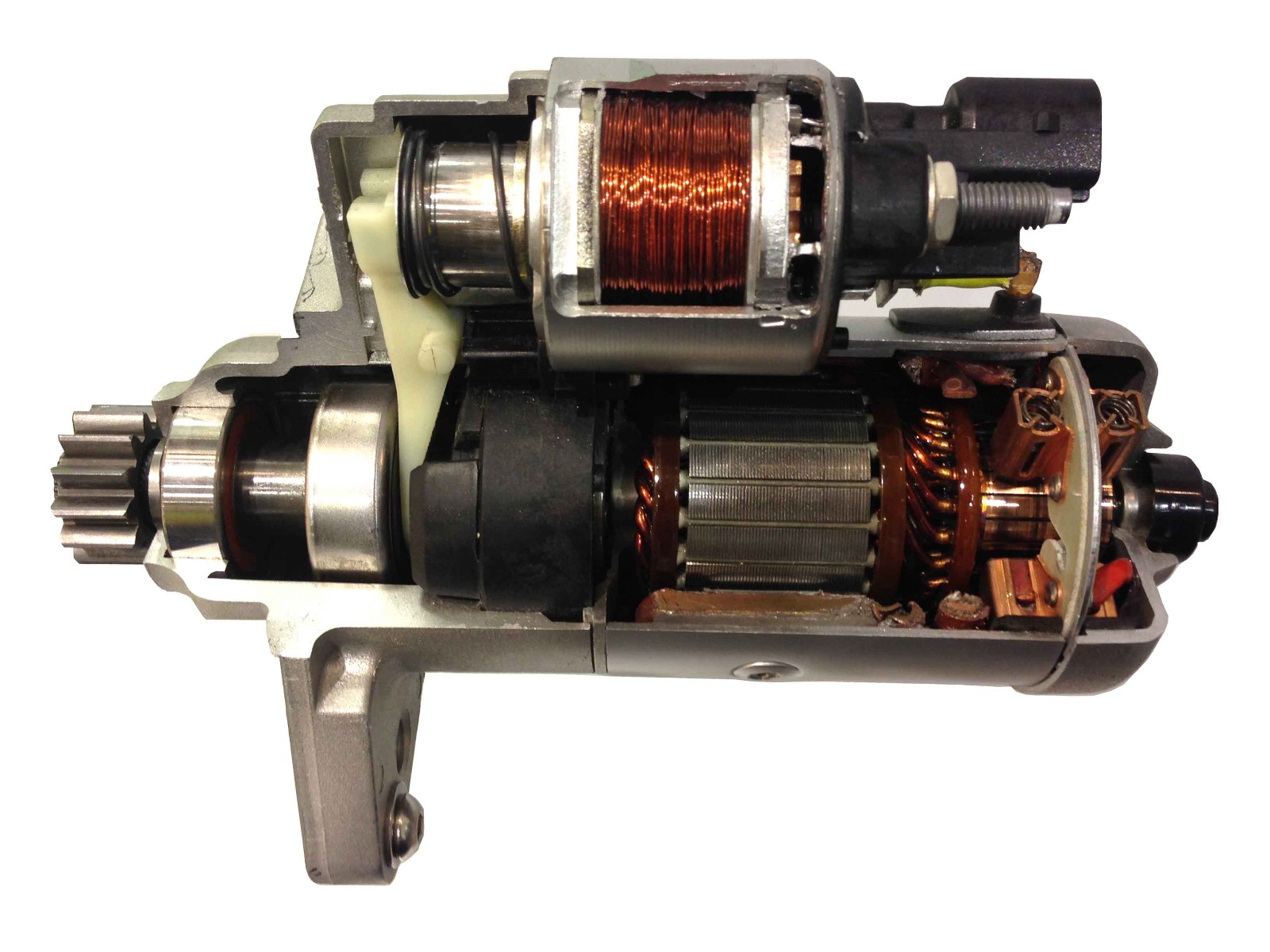

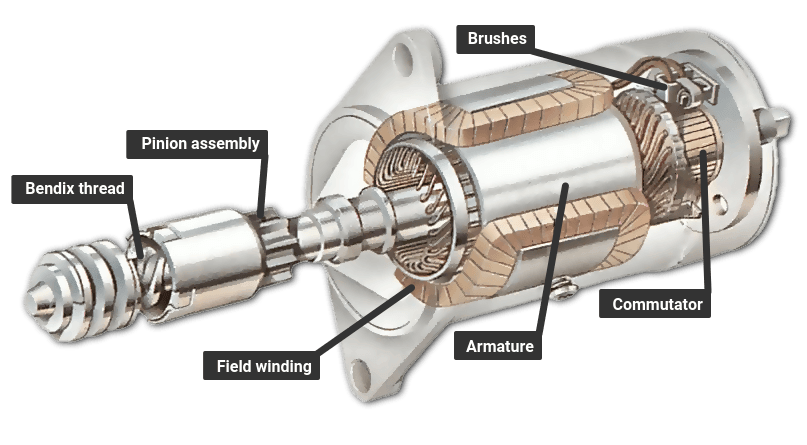

Illustrative image related to starter motor or battery

How Are Starter Motors and Batteries Utilized in Agriculture?

In agricultural applications, starter motors and batteries are essential for powering tractors and harvesters. These machines often operate in challenging environments, requiring batteries that can handle vibrations, temperature fluctuations, and moisture. A reliable starting system increases uptime during critical harvest periods, directly impacting productivity and profitability. Agricultural buyers should prioritize sourcing components that offer resistance to corrosion and can function effectively in varied climates, particularly in the Middle East and South America.

What Is the Importance of Starter Motors and Batteries in Transportation & Logistics?

In the transportation and logistics sector, starter motors and batteries are integral to fleet vehicle operations. A reliable starting system reduces maintenance costs and minimizes vehicle downtime, leading to enhanced operational efficiency. Companies should consider bulk purchasing options to ensure they have sufficient stock for quick replacements. Warranty terms and service availability are also key considerations for international buyers looking to maintain a well-functioning fleet, especially in regions with fluctuating supply chains.

How Do Starter Motors and Batteries Function in Marine Applications?

In the marine industry, starter motors and batteries are crucial for the reliable operation of boats and ships. These components must be able to withstand harsh marine environments, including exposure to saltwater and humidity. Ensuring safety and reliability in marine operations is paramount, making it essential for buyers to source starter motors that comply with marine standards. Additionally, sourcing partners should provide components that have a proven track record of performance in similar applications, especially for buyers from regions with significant maritime activities.

3 Common User Pain Points for ‘starter motor or battery’ & Their Solutions

Scenario 1: The Challenge of Identifying the Root Cause of Starting Failures

O problema: B2B buyers often face difficulties when vehicles fail to start, especially when dealing with multiple components like the starter motor, battery, and alternator. This challenge is exacerbated in regions with extreme weather conditions, where fluctuating temperatures can accelerate component wear. Buyers may find themselves in a situation where the vehicle’s electrical system displays symptoms that could indicate a failing battery, starter, or alternator, leading to confusion and potential downtime.

A solução: To effectively identify the root cause of starting failures, buyers should adopt a systematic troubleshooting approach. Start by checking the battery condition first, as it is the most common failure point. Look for signs such as corrosion on terminals or a bloated battery case. Utilizing a multimeter to check voltage levels can provide immediate insights—ideally, a healthy battery should read around 12.6 volts when fully charged. If the battery is functional, proceed to test the alternator by checking the voltage while the engine is running; it should read between 13.8 and 14.2 volts. Lastly, if the battery and alternator are operational, focus on the starter motor. A professional technician can perform a bench test on the starter to ensure it is functioning correctly. By utilizing these diagnostic methods, B2B buyers can minimize downtime and quickly address starting issues.

Scenario 2: The Impact of Environmental Conditions on Battery Life

O problema: Buyers in regions with extreme temperatures—whether hot or cold—often struggle with shortened battery life. High heat can lead to battery fluid evaporation, while cold can reduce a battery’s cranking power. This challenge can be particularly pronounced in sectors reliant on heavy machinery or fleets, where vehicle reliability is critical to operations.

A solução: To combat the effects of environmental conditions on battery life, buyers should consider investing in high-performance batteries specifically designed for extreme temperatures. Look for batteries that feature enhanced heat resistance or cold-cranking amps (CCA) ratings suited for colder climates. It is also advisable to implement regular maintenance checks, including cleaning terminals and ensuring secure connections to prevent corrosion. Additionally, utilizing battery blankets or insulated battery boxes can provide extra protection in extreme conditions. By proactively sourcing appropriate batteries and employing regular maintenance practices, businesses can significantly extend battery lifespan and enhance vehicle reliability.

Scenario 3: The Cost of Poor Installation Practices

O problema: Improper installation of starter motors and batteries can lead to expensive repairs and operational disruptions. B2B buyers may encounter issues such as misalignment, which can damage components, or incorrect wiring, which can lead to electrical failures. This scenario is often aggravated by a lack of skilled technicians, particularly in emerging markets.

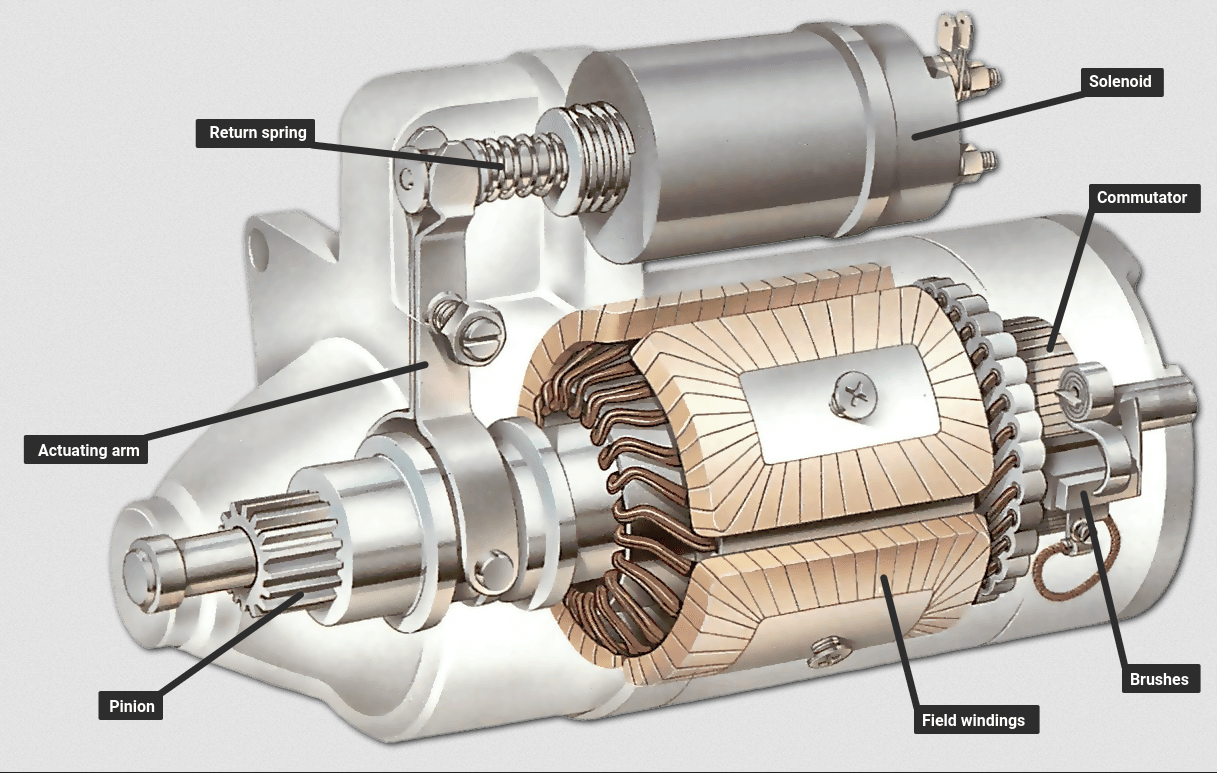

Illustrative image related to starter motor or battery

A solução: To mitigate the risks associated with poor installation practices, it is crucial for buyers to prioritize training and certification for technicians. Investing in training programs focused on the correct installation and troubleshooting of starter motors and batteries can yield long-term cost savings. Buyers should also consider partnering with reputable suppliers who provide detailed installation guidelines and support. Furthermore, implementing a quality assurance checklist before and after installation can help ensure that all components are correctly aligned and connected. By fostering a culture of quality and education within the workforce, businesses can avoid costly mistakes and enhance the reliability of their vehicle fleets.

Strategic Material Selection Guide for starter motor or battery

What Materials Are Commonly Used in Starter Motors and Batteries?

When selecting materials for starter motors and batteries, B2B buyers must consider various factors, including performance, durability, and cost. Here, we analyze four common materials used in these applications: copper, aluminum, lead, and plastic.

How Does Copper Benefit Starter Motors and Batteries?

Copper is a highly conductive metal, making it an ideal choice for electrical components in starter motors and batteries. Its excellent thermal and electrical conductivity ensures efficient power transfer, which is crucial for reliable performance. Copper also has good corrosion resistance, particularly when coated, extending its lifespan in various environments.

Prós: Copper’s high conductivity leads to minimal energy loss, enhancing the efficiency of starter motors and batteries. Its durability and resistance to corrosion make it suitable for long-term use, especially in challenging climates.

Contras: The primary drawback of copper is its cost, which can be significantly higher than alternatives like aluminum. Additionally, copper’s weight can be a concern in applications where reducing weight is critical.

Illustrative image related to starter motor or battery

Impacto na aplicação: Copper is compatible with a wide range of electrical systems and can withstand high temperatures, making it suitable for automotive applications. However, international buyers should be aware of the varying standards for copper quality and purity across regions.

Why Choose Aluminum for Starter Motors and Batteries?

Aluminum is another popular material, especially in the manufacturing of starter motor housings and battery casings. It is lightweight and has good corrosion resistance, making it suitable for automotive applications where weight reduction is essential.

Prós: The lightweight nature of aluminum allows for improved fuel efficiency in vehicles. It is also more cost-effective than copper, making it an attractive option for manufacturers looking to reduce production costs.

Contras: While aluminum is resistant to corrosion, it does not conduct electricity as efficiently as copper. This can lead to higher energy losses in electrical applications, which may affect performance in high-demand scenarios.

Impacto na aplicação: Aluminum’s compatibility with various media makes it suitable for starter motors and battery casings. However, international buyers should consider the differing standards for aluminum alloys, such as those set by ASTM and JIS.

What Role Does Lead Play in Battery Production?

Lead is primarily used in lead-acid batteries, which are widely used in automotive applications. It offers excellent electrochemical properties, making it a reliable choice for battery manufacturing.

Prós: Lead is highly durable and has a long service life, which is beneficial for automotive applications. Its ability to withstand high temperatures and pressures makes it suitable for various operating conditions.

Contras: The environmental impact of lead is significant, as it is toxic and requires careful handling and disposal. Additionally, lead-acid batteries are heavier than their lithium-ion counterparts, which may be a disadvantage in weight-sensitive applications.

Impacto na aplicação: Lead-acid batteries are compliant with many international standards, but buyers must ensure adherence to environmental regulations regarding lead usage and disposal, particularly in regions with strict compliance laws.

Illustrative image related to starter motor or battery

How Does Plastic Contribute to Starter Motor and Battery Design?

Plastic materials, such as polypropylene and polyethylene, are commonly used for battery casings and insulation in starter motors. They provide excellent electrical insulation and are resistant to corrosion and chemicals.

Prós: Plastic is lightweight and cost-effective, making it a popular choice for battery casings. Its versatility allows for various designs and configurations, enhancing manufacturability.

Contras: While plastic is resistant to corrosion, it may not withstand high temperatures as effectively as metals. Additionally, some plastics can degrade over time when exposed to UV light, which may limit their lifespan in outdoor applications.

Impacto na aplicação: The compatibility of plastics with various battery chemistries makes them suitable for a wide range of applications. International buyers should consider the specific plastic grades and their compliance with regional standards, such as those set by DIN and ASTM.

Summary Table of Material Selection for Starter Motors and Batteries

| Material | Typical Use Case for starter motor or battery | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Ligações eléctricas nos motores de arranque | Alta condutividade | Caro e pesado | Alto |

| Alumínio | Motor housings and battery casings | Leve e económico | Condutividade inferior à do cobre | Médio |

| Chumbo | Lead-acid batteries | Long service life and durability | Toxic and environmentally harmful | Médio |

| Plástico | Battery casings and insulation | Leve e versátil | Temperature sensitivity | Baixo |

This material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of materials used in starter motors and batteries, facilitating informed purchasing decisions tailored to their specific regional needs.

In-depth Look: Manufacturing Processes and Quality Assurance for starter motor or battery

What Are the Main Stages in the Manufacturing Process of Starter Motors and Batteries?

The manufacturing processes for starter motors and batteries are critical to ensuring reliability and performance. Each stage, from material preparation to finishing, plays a vital role in the final product’s quality.

Material Preparation: What Materials Are Used and How Are They Processed?

The first step in manufacturing starter motors and batteries is the selection and preparation of materials. For starter motors, this typically includes high-grade steel for the housing, copper for the windings, and various alloys for gears and other internal components. Batteries primarily consist of lead, sulfuric acid, and plastic casings.

Materials undergo rigorous testing for quality and specifications before being processed. This may involve chemical analysis for lead purity or tensile strength tests for steel. Proper material selection is crucial as it directly influences the durability and performance of the finished product.

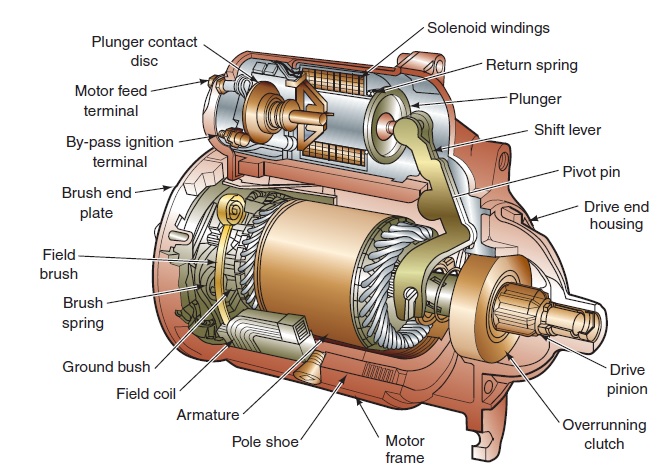

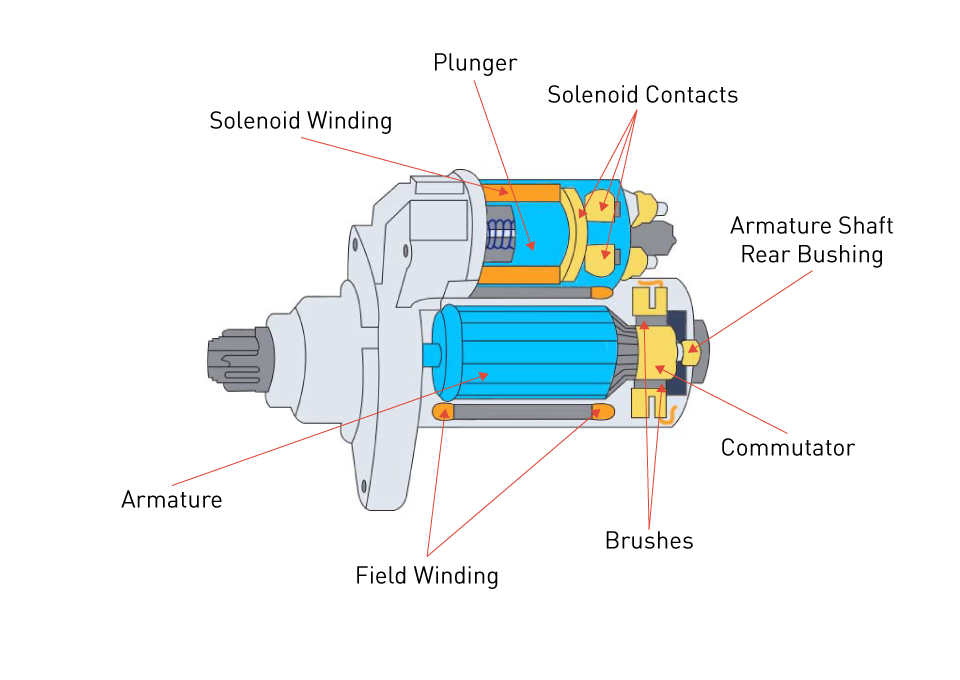

Como são fabricados e montados os motores de arranque?

Once materials are prepared, the forming process begins. For starter motors, this includes stamping metal components, winding copper wire into coils, and machining parts to precise specifications. Advanced techniques like CNC (Computer Numerical Control) machining are often employed to ensure accuracy and consistency.

The assembly stage follows, where components are meticulously combined. This involves placing the armature into the stator, connecting wiring, and securing the housing. Automation plays a significant role here, with robotic arms often used for tasks like soldering and fastening, which enhances efficiency and reduces human error.

What Finishing Processes Ensure Quality in Starter Motors and Batteries?

The finishing stage encompasses several treatments designed to enhance the product’s durability and performance. For starter motors, this may include surface coatings to prevent corrosion, while batteries often undergo sealing and labeling processes. Quality control checks are integrated throughout to ensure that every component meets specified standards.

What Quality Assurance Standards Are Relevant for Starter Motors and Batteries?

Quality assurance is integral to manufacturing, especially in sectors where reliability is paramount, such as automotive components. International standards like ISO 9001 provide a framework for quality management systems, ensuring that manufacturers maintain consistent quality throughout their processes.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for products intended for specific markets. These certifications indicate that products meet stringent safety and performance criteria, which can be particularly important for international B2B buyers.

Quais são os principais pontos de verificação do controlo de qualidade no processo de fabrico?

To ensure the highest quality, multiple checkpoints are established throughout the manufacturing process:

-

Controlo de Qualidade de Entrada (IQC): This is the first checkpoint, where raw materials are inspected upon arrival. Any substandard materials are rejected to prevent quality issues down the line.

-

Controlo de qualidade em processo (IPQC): During the manufacturing process, samples are taken at various stages to assess compliance with quality standards. This is critical for detecting defects early and minimizing waste.

-

Controlo de Qualidade Final (FQC): Once assembly is complete, finished products undergo thorough testing. This may include functional tests, durability assessments, and safety checks to ensure they meet or exceed specifications.

What Common Testing Methods Are Used for Starter Motors and Batteries?

Various testing methods are employed to validate the performance and safety of starter motors and batteries. These include:

-

Testes elétricos: For starter motors, this involves measuring voltage, current, and resistance to ensure proper operation. For batteries, capacity tests are performed to determine how much charge they can hold.

-

Ensaios ambientais: Products are subjected to extreme temperatures and humidity to simulate real-world conditions. This helps assess how well they will perform in different climates, particularly important for markets in Africa and the Middle East.

-

Testes mecânicos: This includes vibration and shock tests to evaluate durability. Starter motors must withstand the rigors of operation, while batteries are tested for physical robustness.

Como podem os compradores B2B verificar as medidas de controlo de qualidade dos fornecedores?

For B2B buyers, particularly those in international markets, verifying a supplier’s quality control measures is essential for ensuring product reliability. Here are actionable steps to take:

-

Realizar auditorias: Regular audits of manufacturing facilities can help assess compliance with quality standards. This can be done by the buyer or through third-party services.

-

Solicitar relatórios de qualidade: Suppliers should provide detailed quality reports, including data from IQC, IPQC, and FQC stages. These reports should outline any issues encountered and the corrective actions taken.

-

Contrate inspetores terceirizados: Utilizing independent inspection agencies can provide an unbiased assessment of the supplier’s quality processes. This is particularly useful for international buyers who may not have the resources for on-site inspections.

Quais são as nuances do controlo de qualidade para os compradores internacionais?

B2B buyers in Africa, South America, the Middle East, and Europe face unique challenges and considerations regarding quality control. Different regions may have varying regulations and standards, which necessitate a thorough understanding of local requirements.

-

Cultural and Regulatory Awareness: Buyers should familiarize themselves with the regulatory environment in their target markets. For example, CE marking is essential for products sold in Europe, while other regions may have different compliance requirements.

-

Barreiras linguísticas: Ensure that quality documentation is available in the buyer’s language to avoid miscommunication regarding specifications and standards.

-

Considerações logísticas: The transportation of starter motors and batteries may involve additional risks, such as exposure to extreme temperatures or vibrations. Buyers should ensure that suppliers have logistics strategies in place to mitigate these risks.

In conclusion, understanding the manufacturing processes and quality assurance practices for starter motors and batteries is crucial for international B2B buyers. By focusing on these areas, buyers can ensure they select reliable suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor or battery’

In the competitive landscape of automotive components, sourcing the right starter motor or battery is crucial for ensuring reliable vehicle performance. This guide aims to provide a practical checklist for B2B buyers, helping you navigate the procurement process effectively.

Passo 1: Defina as suas especificações técnicas

Understanding your technical requirements is the foundation of a successful sourcing process. Specify the voltage, capacity, and dimensions needed for your starter motor or battery. Consider the vehicle types and conditions they will operate in, as different environments (e.g., extreme heat or cold) can impact performance.

- Voltage and Capacity: Ensure compatibility with the vehicle’s electrical system.

- Dimensões físicas: Verify that the components fit within the designated space in the vehicle.

Passo 2: Pesquisar fornecedores de renome

Finding trustworthy suppliers is essential for quality assurance. Investigate potential suppliers by reviewing their industry reputation, customer reviews, and experience in manufacturing starter motors or batteries.

- Experiência no sector: Look for suppliers with a proven track record in the automotive sector.

- Certificações: Verify if they hold relevant certifications (e.g., ISO 9001) to ensure quality standards.

Passo 3: Avaliar as certificações dos fornecedores

Supplier certifications provide insights into their operational quality and compliance with industry standards. Request documentation for certifications relevant to automotive components, such as TS16949 for automotive quality management.

- Garantia de qualidade: Certifications can indicate adherence to international quality standards.

- Environmental Compliance: Check for certifications like ISO 14001 to ensure environmentally responsible practices.

Passo 4: Solicitar amostras de produtos

Before making a bulk purchase, request samples of starter motors or batteries. This allows you to assess the quality and suitability of the products firsthand.

- Teste de desempenho: Conduct tests to evaluate the product’s performance under expected operating conditions.

- Avaliação da durabilidade: Ensure that the samples can withstand environmental factors relevant to your market.

Passo 5: Negociar condições e preços

Engage in negotiations to secure favorable terms, including pricing, payment schedules, and delivery timelines. This step is critical for maintaining budget constraints while ensuring timely availability of products.

- Descontos para compras em massa: Inquire about price reductions for larger orders.

- Flexibilidade de pagamento: Discuss payment terms that align with your cash flow situation.

Passo 6: Estabelecer um processo de controlo de qualidade

Implement a quality control process to monitor the performance of the starter motors or batteries you receive. This ensures that the products meet your specifications and quality expectations consistently.

- Inspection Procedures: Define how incoming products will be inspected for quality.

- Mecanismo de feedback: Create a system for reporting and addressing any quality issues with the supplier.

Passo 7: Construir relações a longo prazo

Fostering long-term relationships with suppliers can lead to better pricing, priority service, and collaborative problem-solving. Regular communication and feedback can strengthen these relationships.

- Revisões regulares: Schedule periodic reviews to discuss performance and explore new product developments.

- Collaborative Innovation: Work together on developing solutions that meet emerging market needs.

By following this structured checklist, B2B buyers can make informed decisions when sourcing starter motors or batteries, ensuring reliability and performance in their vehicle fleets.

Comprehensive Cost and Pricing Analysis for starter motor or battery Sourcing

What Are the Key Cost Components in Sourcing Starter Motors and Batteries?

When sourcing starter motors and batteries, understanding the cost structure is essential for effective budgeting and negotiation. Key components include:

-

Materiais: The primary cost driver, materials such as lead, lithium, and copper are critical in battery production, while starter motors require high-grade metals and magnets. Fluctuations in raw material prices can significantly impact overall costs.

-

Trabalho: Labor costs vary by region and complexity of the manufacturing process. Skilled labor is needed for assembly, testing, and quality assurance, which can increase costs in regions with higher wage standards.

-

Despesas gerais de fabrico: This encompasses the indirect costs associated with production, including utilities, factory maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overhead costs.

-

Ferramentas: Initial tooling costs can be substantial, especially for custom or specialized components. Investing in high-quality tools can improve manufacturing efficiency and reduce long-term costs.

-

Controlo de qualidade (CQ): Ensuring product reliability is paramount. Implementing rigorous QC processes adds to the cost but can prevent costly failures and recalls, which are particularly important in automotive applications.

-

Logística: Transportation and warehousing are critical in the cost structure. International shipping can add significant costs, especially if dealing with bulky items like batteries. Understanding logistics and optimizing routes can lead to savings.

-

Margem: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can vary based on market conditions, demand, and supplier relationship dynamics.

How Do Price Influencers Affect the Cost of Starter Motors and Batteries?

Several factors can influence the pricing of starter motors and batteries:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating for bulk purchases can be advantageous for buyers looking to minimize costs.

-

Especificações e personalização: Custom designs or specific performance requirements can increase costs. Buyers should balance their need for customization with the potential price implications.

-

Materiais: The choice of materials directly affects pricing. Higher-quality materials often result in increased durability but also higher costs. Buyers should assess the trade-off between material quality and total cost of ownership.

-

Qualidade e certificações: Products with industry certifications (like ISO, CE, etc.) may come at a premium. However, these certifications often assure reliability and can reduce the risk of failure, which is crucial for automotive components.

-

Factores do fornecedor: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer premium products but with better service and reliability, while emerging suppliers might provide lower prices but with less assurance.

-

Incoterms: Understanding Incoterms is vital for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total cost of procurement.

What Are the Best Buyer Tips for Negotiating Starter Motor and Battery Prices?

Navigating the complexities of pricing and cost structures can be challenging for international B2B buyers. Here are some actionable tips:

-

Negotiate Wisely: Always enter negotiations with a clear understanding of your budget and the market rate for the products you seek. Leverage multiple supplier quotes to secure the best deal.

-

Focus on Cost-Efficiency: Consider the total cost of ownership, which includes initial purchase price, maintenance, and replacement costs. A lower upfront cost may lead to higher long-term expenses if the product is less reliable.

-

Understand Pricing Nuances in Different Regions: Pricing strategies can vary widely across Africa, South America, the Middle East, and Europe. Familiarize yourself with regional market conditions and cultural negotiation styles to enhance your purchasing strategy.

-

Be Aware of Economic Factors: Currency fluctuations, tariffs, and trade agreements can impact costs. Staying informed about these factors can help you make better purchasing decisions.

-

Request Transparency: Ask suppliers for a breakdown of costs, including materials, labor, and logistics. This transparency can aid in negotiations and help you understand where savings might be possible.

By understanding the cost components, price influencers, and effective negotiation strategies, B2B buyers can make informed sourcing decisions for starter motors and batteries that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing starter motor or battery With Other Solutions

Introduction to Alternatives for Starter Motor and Battery Solutions

In the automotive and machinery sectors, the reliability of starting mechanisms is paramount for efficient operations. While starter motors and batteries are the traditional solutions for ignition systems, there are alternative technologies available that can provide similar or enhanced functionalities. This analysis will compare starter motors and batteries against alternative solutions such as solid-state starters and supercapacitors, highlighting their performance, costs, and best use cases.

Tabela comparativa

| Aspecto comparativo | Starter Motor Or Battery | Solid-State Starter | Supercapacitor |

|---|---|---|---|

| Desempenho | High torque, reliable | Fast engagement, low maintenance | Rapid energy discharge, high cycle life |

| Custo | Custo inicial moderado | Custo inicial mais elevado | Custo inicial moderado |

| Facilidade de implementação | Instalação standard | Requer instalação especializada | Requires compatible systems |

| Manutenção | Necessidade de controlos regulares | Manutenção mínima necessária | Manutenção mínima necessária |

| Melhor caso de uso | Veículos convencionais | Aplicações de alto desempenho | Hybrid or electric vehicles |

Discriminação detalhada das alternativas

What are Solid-State Starters and Their Advantages?

Solid-state starters utilize electronic components to initiate engine operations. They offer a significant advantage in terms of speed and responsiveness, engaging almost instantaneously compared to traditional starter motors. Their low maintenance requirements stem from the absence of moving parts, resulting in increased durability. However, the initial investment is higher, making them a less attractive option for budget-conscious buyers. They are best suited for high-performance vehicles or specialized applications where reliability and speed are critical.

How Do Supercapacitors Function as an Alternative?

Supercapacitors are energy storage devices that deliver quick bursts of power, making them ideal for applications requiring rapid energy discharge. Their ability to charge and discharge quickly allows for efficient energy management, particularly in hybrid or electric vehicles. Unlike traditional batteries, supercapacitors have a much longer cycle life and can withstand extreme temperature variations. However, their lower energy density means they cannot store energy as efficiently as batteries, making them less suitable for applications requiring sustained power over longer periods.

Conclusão: escolhendo a solução certa para as suas necessidades

For B2B buyers, the choice between starter motors, batteries, and alternative solutions hinges on specific operational requirements, budget constraints, and maintenance considerations. Starter motors and batteries remain the go-to options for most conventional vehicles due to their established reliability. However, industries demanding rapid engagement and low maintenance may benefit from solid-state starters, while those focused on energy efficiency and performance in electric vehicles might consider supercapacitors. By analyzing these alternatives in relation to their operational environment, buyers can make informed decisions that best align with their strategic objectives.

Illustrative image related to starter motor or battery

Essential Technical Properties and Trade Terminology for starter motor or battery

What Are the Key Technical Properties of Starter Motors and Batteries?

Understanding the technical specifications of starter motors and batteries is vital for B2B buyers seeking to ensure quality and compatibility in their procurement processes. Here are some critical properties to consider:

-

Grau do material

– Definição: This refers to the type of materials used in the manufacturing of starter motors and batteries, such as lead-acid for batteries and various metals for starter components.

– Importância: Higher material grades typically correlate with enhanced durability and performance. For example, copper wiring in starters can improve conductivity and efficiency, leading to better engine cranking. -

Amperes de arranque a frio (CCA)

– Definição: CCA measures a battery’s ability to start an engine in cold temperatures, indicating how much current a battery can provide at 0°F (-18°C) for 30 seconds while maintaining at least 7.2 volts.

– Importância: This specification is crucial for buyers in regions with extreme weather conditions, as it directly impacts the reliability of starting systems in cold climates. -

Tensão nominal

– Definição: The standard voltage for most automotive batteries is 12 volts, while starter motors usually operate at this voltage to engage the engine.

– Importância: Ensuring compatibility with the vehicle’s electrical system is essential for performance and safety. A mismatch can lead to operational failures and potential damage. -

Classificação de binário

– Definição: This refers to the rotational force that a starter motor can exert, usually measured in Newton-meters (Nm).

– Importância: A higher torque rating means the starter can more effectively turn over larger engines, making this specification vital for buyers of heavy-duty vehicles or industrial applications. -

Ciclo de vida

– Definição: This denotes the number of charge and discharge cycles a battery can endure before its capacity significantly diminishes.

– Importância: A longer cycle life translates to lower replacement costs and reduced downtime, making it a critical factor for businesses that rely on continuous vehicle operation.

What Are Common Trade Terminology Terms Related to Starter Motors and Batteries?

Familiarity with industry jargon can enhance negotiations and ensure clarity in communications. Here are several essential terms:

-

OEM (Fabricante de Equipamento Original)

– Definição: Companies that manufacture products that are marketed by another company under its own brand.

– Importância: OEM parts are often preferred for their guaranteed compatibility and performance, making them a reliable choice for B2B buyers focused on quality. -

MOQ (Quantidade mínima de encomenda)

– Definição: A menor quantidade de um produto que um fornecedor está disposto a vender.

– Importância: Understanding MOQ is crucial for budgeting and inventory management. High MOQs can affect cash flow and storage capabilities. -

RFQ (Pedido de Orçamento)

– Definição: A document sent to suppliers requesting pricing and terms for specific products.

– Importância: Utilizing RFQs can streamline the procurement process, ensuring competitive pricing and fostering better supplier relationships. -

Incoterms (Termos Comerciais Internacionais)

– Definição: Um conjunto de regras internacionais pré-definidas que clarificam as responsabilidades dos compradores e vendedores nas transacções internacionais.

– Importância: Familiarity with Incoterms can prevent misunderstandings regarding shipping, insurance, and tariffs, which is critical for international buyers, especially in diverse markets. -

Período de garantia

– Definição: The duration during which a product is guaranteed against defects or failures.

– Importância: A longer warranty period can indicate a manufacturer’s confidence in their product’s quality and reliability, providing peace of mind for B2B buyers. -

Prazo de entrega

– Definição: The amount of time that passes from the initiation of a process until its completion, particularly regarding order fulfillment.

– Importância: Understanding lead times helps businesses plan their inventory and production schedules effectively, minimizing disruptions in operations.

By grasping these essential properties and terms, B2B buyers can make informed decisions, ensuring that they select the right starter motors and batteries for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the starter motor or battery Sector

What Are the Key Market Drivers Impacting the Starter Motor and Battery Sector?

The starter motor and battery sector is witnessing significant transformation driven by technological advancements, evolving consumer preferences, and environmental considerations. One of the primary global drivers is the increasing demand for electric vehicles (EVs). With governments worldwide pushing for sustainability and reducing carbon emissions, there is a noticeable shift toward batteries designed for electric and hybrid vehicles. This trend is especially prominent in regions like Europe and parts of the Middle East, where stringent regulations on emissions are being enforced.

Emerging technologies such as lithium-ion and solid-state batteries are gaining traction, offering higher energy densities and faster charging times. These advancements are crucial for international B2B buyers, especially in markets like South America and Africa, where the adoption of renewable energy solutions is on the rise. Additionally, the integration of smart technologies, such as IoT-enabled battery management systems, is becoming a standard expectation. Buyers are increasingly looking for suppliers who can provide these high-tech solutions alongside traditional products.

Moreover, supply chain dynamics are evolving. Disruptions caused by global events have led businesses to seek localized suppliers to ensure consistent product availability. This trend is particularly relevant for buyers in regions like Africa and South America, where infrastructure challenges can impact delivery timelines. As such, B2B buyers must consider suppliers who can navigate these complexities effectively while maintaining quality and reliability.

Illustrative image related to starter motor or battery

How Can Sustainability and Ethical Sourcing Influence B2B Purchases in the Starter Motor and Battery Sector?

Sustainability has become a cornerstone of purchasing decisions in the starter motor and battery sector. The environmental impact of battery production, particularly concerning lithium extraction and battery disposal, is a growing concern among consumers and businesses alike. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and environmental responsibility.

The importance of ethical supply chains cannot be overstated. Buyers are looking for manufacturers who not only comply with local and international regulations but also adhere to best practices in labor rights and environmental stewardship. Certifications such as ISO 14001 for environmental management and the Responsible Minerals Initiative (RMI) are becoming prerequisites for suppliers aiming to enter competitive markets.

Furthermore, the demand for ‘green’ materials is rising. For instance, manufacturers are exploring alternatives to conventional lead-acid batteries, such as lithium iron phosphate (LiFePO4), which have a lower environmental impact and longer lifecycle. By aligning with suppliers focused on sustainability, B2B buyers can enhance their brand reputation, meet regulatory requirements, and attract environmentally conscious customers.

How Has the Starter Motor and Battery Sector Evolved Over Time?

The evolution of the starter motor and battery sector reflects the broader trends in automotive technology and consumer needs. Initially, starter motors were simple electromechanical devices, but advancements in technology have led to the development of more sophisticated systems that integrate seamlessly with modern vehicle electronics.

The battery technology landscape has also undergone significant changes. From lead-acid batteries, which dominated the market for decades, there has been a marked shift toward lithium-ion batteries, particularly in the context of electric vehicles. This transition is not just about performance; it also addresses the growing demand for energy efficiency and longer-lasting power solutions.

Illustrative image related to starter motor or battery

As we move forward, the sector is expected to continue evolving, with innovations such as solid-state batteries and advanced energy management systems paving the way for the next generation of automotive power solutions. For B2B buyers, understanding this evolution is crucial in making informed purchasing decisions that align with future market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of starter motor or battery

-

How do I identify whether I need a new starter motor or battery?

To determine whether the issue lies with the starter motor or the battery, start by observing the symptoms. If you hear a clicking sound when turning the ignition but the engine doesn’t crank, the battery might be dead. If the engine cranks slowly or not at all, the starter could be the problem. Conduct a jump-start test: if the vehicle starts with a jump but dies when disconnected, the battery may be faulty. If it doesn’t start even after a jump, the starter is likely at fault. Regular maintenance and testing can help prevent unexpected failures. -

What is the best battery for high-temperature environments?

For regions with high temperatures, look for batteries designed with heat-resistant features, such as those using absorbed glass mat (AGM) technology. AGM batteries are less prone to overheating and can withstand extreme conditions, making them ideal for areas with high ambient temperatures. Ensure the battery has a high cold cranking amp (CCA) rating, which indicates its ability to start the engine in challenging conditions. Always consult with suppliers about specific product lines that cater to your regional climate and vehicle specifications. -

What customization options are available for starter motors and batteries?

Many manufacturers offer customization options for starter motors and batteries to meet specific requirements. Customizations may include modifications in size, voltage, and performance specifications tailored to unique vehicle models or operational conditions. Additionally, branding options such as logo printing or color specifications may also be available. When sourcing, communicate your specific needs to potential suppliers to ensure they can accommodate your requirements and provide samples if necessary. -

What is the minimum order quantity (MOQ) for starter motors and batteries?

Minimum order quantities can vary significantly depending on the supplier and the product. Generally, for starter motors and batteries, MOQs can range from 50 to several hundred units. It’s essential to discuss MOQ directly with potential suppliers, as many may offer flexibility based on your purchasing frequency and relationship. For first-time buyers, consider negotiating a smaller initial order to assess product quality and supplier reliability before committing to larger quantities. -

How can I vet suppliers for starter motors and batteries?

Vetting suppliers is critical to ensuring product quality and reliability. Start by researching potential suppliers’ reputations through online reviews and industry forums. Request references from other clients and verify their experience and satisfaction. Assess the supplier’s certifications and compliance with international quality standards, such as ISO certifications. Additionally, visiting the supplier’s facility, if feasible, can provide insight into their manufacturing processes and quality control measures. -

What payment terms should I expect when sourcing batteries and starter motors?

Payment terms can vary widely among suppliers, but common practices include advance payments, net 30, or net 60 terms. Some suppliers may offer discounts for early payments or bulk orders. It’s advisable to clarify payment terms upfront and ensure they align with your cash flow management. Consider using secure payment methods, such as letters of credit or escrow services, to mitigate risks in international transactions. Always review the terms in the context of the total cost, including shipping and customs duties. -

What quality assurance processes should be in place for batteries and starter motors?

Quality assurance processes should include rigorous testing of components before assembly, as well as final product testing for performance and safety. Suppliers should have a documented quality management system that outlines their testing protocols, including routine inspections and compliance with international standards. Request detailed reports on quality control procedures and any certifications that demonstrate adherence to industry standards. Additionally, consider implementing your own quality checks upon receipt of goods to ensure they meet your specifications. -

What logistics considerations should I keep in mind when importing batteries and starter motors?

Logistics plays a crucial role in the successful importation of batteries and starter motors. Ensure you are aware of shipping regulations specific to these products, especially concerning hazardous materials. Collaborate with experienced freight forwarders familiar with international shipping practices to handle customs clearance and transportation. It’s also important to consider lead times and shipping costs, which can significantly impact your overall budget. Planning for potential delays and ensuring proper insurance coverage for shipments can help mitigate risks during transportation.

Top 5 Starter Motor Or Battery Manufacturers & Suppliers List

1. AutoZone – Free Alternator and Battery Testing

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: This company, AutoZone – Free Alternator and Battery Testing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Global Automotive – Automotive Repair Services

Domínio: globalautomotiveva.com

Registada: 2013 (12 anos)

Introdução: Global Automotive offers a range of automotive repair services including: maintenance, oil change, state inspections, tire rotation, tune-ups, alignments, brake services, coolant flush, transmission flush, vehicle belt replacement, auto repair, check engine light diagnostics, tire repair, vehicle AC repair, starter and alternator repair, muffler and exhaust repair, transmission replacement, engine…

3. MGEXP – Starter Motor Solutions

Domínio: mgexp.com

Registado: 2011 (14 anos)

Introdução: 1. Weak starter motor when hot, similar to a dead battery. 2. Starter motor functions well when cold, starting the car within half a turn of the crankshaft. 3. After driving, the starter motor struggles to turn the engine when the engine bay is warm, only turning it a quarter turn at low speed before dying. 4. The coil becomes too hot to touch when the engine is warm, potentially indicating a fail…

4. Battery Tender Jr – Smart Charger

Domínio: mechanics.stackexchange.com

Registado: 2009 (16 anos)

Introdução: Battery Tender Jr, smart charger, multimeter, starter motor, starter motor solenoid.

5. Facebook – Camaro SS Convertible

Domínio: facebook.com

Registado: 1997 (28 anos)

Introdução: Camaro (convertibles only), 2016 SS Convertible, 20,000 miles, new battery just a month or so ago.

Strategic Sourcing Conclusion and Outlook for starter motor or battery

What Are the Key Takeaways for Strategic Sourcing of Starter Motors and Batteries?

In the realm of strategic sourcing for starter motors and batteries, understanding the interdependence of these components is crucial for efficient procurement. Suppliers should prioritize quality and reliability to minimize operational disruptions, particularly in regions with extreme weather conditions that can affect component lifespan. Additionally, fostering relationships with manufacturers that offer comprehensive warranties and support can enhance supply chain resilience.

How Can B2B Buyers Enhance Their Procurement Strategies?

International B2B buyers from Africa, South America, the Middle East, and Europe must leverage data-driven insights to inform their sourcing decisions. This includes analyzing the total cost of ownership rather than just upfront costs, as well as considering the long-term impact of product quality on maintenance and operational efficiency. Engaging with local suppliers can also facilitate quicker response times and reduce shipping costs, enhancing overall supply chain agility.

What’s Next for the Global Market in Starter Motors and Batteries?

As the market evolves, the push for sustainability and innovation will shape sourcing strategies. Buyers should stay informed about emerging technologies, such as electric vehicle components, which may redefine their needs. Embrace these changes and consider diversifying supplier bases to mitigate risks. By proactively adapting to market trends, you can ensure a competitive edge and drive business growth in an increasingly interconnected global landscape.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.