Introduction: Navigating the Global Market for how to fix a headlight

In the ever-evolving landscape of the automotive industry, sourcing reliable solutions for how to fix a headlight remains a critical challenge for international B2B buyers. Headlights are not just vital for vehicle safety; they are also essential for compliance with regional regulations across markets in Africa, South America, the Middle East, and Europe, including Germany and Brazil. This comprehensive guide is designed to equip decision-makers with the knowledge needed to navigate the complexities of headlight repair and replacement, ensuring optimal visibility and safety on the roads.

Throughout this guide, we will delve into various types of headlight bulbs—incandescent, halogen, HID, and LED—highlighting their specific applications and advantages. We will also cover essential considerations for supplier vetting, ensuring that buyers can identify reputable manufacturers and distributors. Additionally, we will provide insights into cost factors associated with headlight replacement, enabling buyers to make informed decisions that align with their budgetary constraints.

By empowering B2B buyers with actionable insights and practical information, this guide aims to streamline the procurement process and enhance operational efficiency. Whether you are in the automotive aftermarket or managing a fleet, understanding how to effectively fix a headlight will not only improve safety but also enhance customer satisfaction and compliance with local regulations.

Índice

- Top 1 How To Fix A Headlight Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to fix a headlight

- Understanding how to fix a headlight Types and Variations

- Key Industrial Applications of how to fix a headlight

- 3 Common User Pain Points for ‘how to fix a headlight’ & Their Solutions

- Strategic Material Selection Guide for how to fix a headlight

- In-depth Look: Manufacturing Processes and Quality Assurance for how to fix a headlight

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to fix a headlight’

- Comprehensive Cost and Pricing Analysis for how to fix a headlight Sourcing

- Alternatives Analysis: Comparing how to fix a headlight With Other Solutions

- Essential Technical Properties and Trade Terminology for how to fix a headlight

- Navigating Market Dynamics and Sourcing Trends in the how to fix a headlight Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to fix a headlight

- Strategic Sourcing Conclusion and Outlook for how to fix a headlight

- Aviso legal importante e termos de utilização

Understanding how to fix a headlight Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Incandescent Headlights | Traditional bulbs, typically low-cost, short lifespan | Oficinas de reparação automóvel, serviços de frotas | Prós: Acessível; Contras: Short lifespan, less energy-efficient. |

| Halogen Headlights | Improved brightness and lifespan over incandescent bulbs | Car manufacturers, auto parts retailers | Prós: Better visibility; Contras: Generates more heat, can be fragile. |

| HID (Descarga de Alta Intensidade) | Bright, energy-efficient, longer lifespan | Luxury vehicle manufacturers, aftermarket suppliers | Prós: Excellent visibility, energy-efficient; Contras: More expensive, requires special fixtures. |

| LED (Diodo emissor de luz) | Longa vida útil, baixo consumo de energia, funcionamento mais frio | Electric vehicle manufacturers, tech-focused auto shops | Prós: Very long lifespan, low heat; Contras: Higher upfront cost, may require retrofitting. |

| Composite Headlight Units | Integrated housing for bulb and lens, varying technologies | OEM suppliers, automotive assemblers | Prós: Simplifies installation; Contras: Higher replacement costs, may require full assembly change. |

What Are the Key Characteristics of Incandescent Headlights?

Incandescent headlights are the most traditional type of automotive lighting, known for their simplicity and low cost. They produce light by heating a filament until it glows, making them easy to replace. However, their lifespan is relatively short, often requiring frequent replacements. For B2B buyers, these bulbs are suitable for budget-conscious operations, such as local repair shops or fleets that prioritize low initial costs over longevity.

How Do Halogen Headlights Enhance Visibility?

Halogen headlights are an evolution of incandescent technology, offering brighter light and a longer lifespan. They utilize a halogen gas to increase efficiency and light output. B2B applications include automotive repair facilities and parts retailers, where enhanced visibility is crucial for customer satisfaction. While they are more durable than incandescent bulbs, they do generate more heat and can be prone to damage during installation.

What Advantages Do HID Headlights Provide for Luxury Vehicles?

HID headlights are known for their high brightness and energy efficiency, making them popular in luxury vehicles. They produce light through an electrical arc between two electrodes in a gas-filled chamber, offering a significantly longer lifespan compared to traditional bulbs. B2B buyers in the luxury car segment or aftermarket suppliers should consider HID systems for their superior visibility. However, they come with higher costs and may require specific fixtures, which can complicate installation.

Why Are LED Headlights Becoming the Preferred Choice?

LED headlights are rapidly gaining popularity due to their long lifespan and low energy consumption. They emit light through a semiconductor, resulting in minimal heat production. This technology is ideal for electric vehicle manufacturers and tech-focused auto shops looking to provide cutting-edge solutions. While the initial investment is higher, the long-term savings on replacements and energy make them an attractive option for B2B buyers aiming for sustainability.

What Are the Benefits of Composite Headlight Units?

Composite headlight units combine the bulb and lens into a single assembly, streamlining the replacement process. This design can accommodate various technologies, including halogen, HID, and LED. B2B applications include OEM suppliers and automotive assemblers who benefit from the ease of installation and reduced labor costs. However, the full assembly replacement can be pricier than simply changing a bulb, which is a key consideration for cost-sensitive buyers.

Key Industrial Applications of how to fix a headlight

| Indústria/Setor | Specific Application of how to fix a headlight | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Routine headlight maintenance and replacement services | Enhances customer safety and satisfaction, leading to repeat business | Reliable suppliers for quality bulbs and tools; compliance with local regulations |

| Gestão de frotas | Regular inspections and replacements for company vehicles | Reduz o tempo de inatividade e assegura a eficiência operacional | Bulk purchasing options; compatibility with various vehicle models |

| Transportes públicos | Maintenance of headlights on buses and commercial vehicles | Ensures compliance with safety regulations, improving public trust | Durable and high-performance bulbs; quick replacement solutions |

| Construction & Logistics | Headlight servicing for heavy machinery and transport vehicles | Increases visibility and safety on job sites, reducing accidents | Specialized bulbs for heavy-duty applications; local sourcing for quick access |

| Fabricação Automotiva | Quality control in headlight assembly for new vehicles | Improves product reliability and customer satisfaction | Consistent quality standards; partnerships with certified suppliers |

How is ‘How to Fix a Headlight’ Applied in Automotive Repair?

In the automotive repair sector, fixing headlights is a common service provided to enhance vehicle safety. Mechanics routinely replace dim or burnt-out bulbs to ensure optimal illumination for drivers. This not only improves visibility at night but also ensures compliance with local vehicle regulations. For international B2B buyers, sourcing high-quality, vehicle-specific bulbs and tools from reliable suppliers is essential to maintain service standards and customer satisfaction.

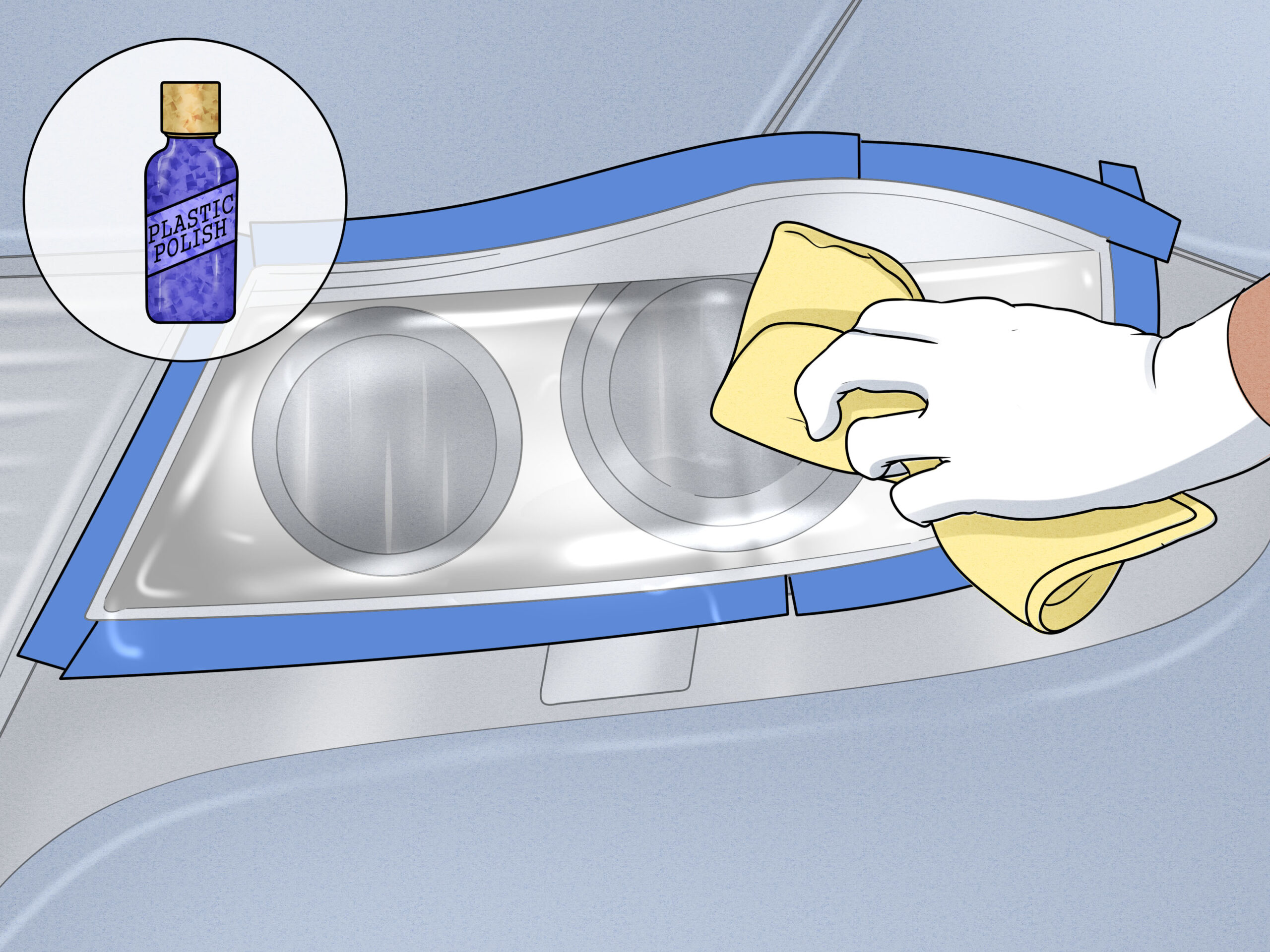

Illustrative image related to how to fix a headlight

What is the Role of Headlight Maintenance in Fleet Management?

Fleet management companies prioritize regular headlight inspections and replacements to minimize vehicle downtime. By ensuring that all vehicles have functioning headlights, businesses can maintain operational efficiency and reduce the risk of accidents. For B2B buyers in this sector, sourcing bulk headlight products that fit a variety of vehicle models is crucial. Additionally, establishing relationships with suppliers who offer quick delivery and support can streamline maintenance processes.

How Do Public Transportation Services Benefit from Headlight Fixes?

Public transportation systems must adhere to strict safety regulations, making headlight maintenance vital. Regular servicing of headlights on buses and commercial vehicles ensures that they operate safely and efficiently, fostering public trust. B2B buyers in this sector should consider sourcing durable, high-performance bulbs that can withstand frequent use and harsh conditions. Quick replacement solutions can also minimize service disruptions.

Why is Headlight Servicing Important in Construction & Logistics?

In the construction and logistics industry, ensuring that heavy machinery and transport vehicles have functioning headlights is critical for safety on job sites. Properly illuminated work areas help reduce accidents and improve overall visibility for operators. B2B buyers in this sector should seek specialized bulbs designed for heavy-duty applications. Additionally, sourcing locally can facilitate quick access to replacement parts when needed.

How Does Quality Control in Automotive Manufacturing Relate to Headlight Assembly?

In automotive manufacturing, maintaining quality control in headlight assembly is essential for producing reliable vehicles. Headlight performance directly impacts customer satisfaction and safety ratings. B2B buyers in this industry should prioritize partnerships with certified suppliers who can consistently meet quality standards. Ensuring that headlight components are sourced from reputable manufacturers is vital for minimizing warranty claims and enhancing brand reputation.

3 Common User Pain Points for ‘how to fix a headlight’ & Their Solutions

Scenario 1: Difficulty Identifying the Correct Bulb Replacement

O problema: Many B2B buyers face the challenge of selecting the appropriate headlight bulb for various vehicle models. This can be particularly frustrating when dealing with a diverse fleet where vehicles may have different specifications. Misidentifying the bulb type not only leads to wasted time but can also delay operations and increase costs due to the need for additional purchases and installations.

A solução: To effectively address this issue, it’s crucial to implement a systematic approach to bulb identification. B2B buyers should invest in comprehensive cataloging systems that include detailed specifications for each vehicle model in their fleet. Utilizing digital tools or apps that allow for scanning vehicle VINs can also help in accurately identifying the correct bulb types. Furthermore, establishing partnerships with reliable suppliers that offer a wide range of vehicle-specific bulbs can streamline the procurement process. This proactive approach will minimize errors and ensure that buyers can quickly source the right products, thus maintaining operational efficiency.

Scenario 2: Complications During Headlight Installation

O problema: Installing headlight bulbs can often turn into a complicated process, especially for those unfamiliar with the intricacies of various vehicle models. B2B buyers may encounter issues such as inadequate access to the headlight assembly, which can require specialized tools or even the removal of other components. These complications can lead to increased labor costs and extended downtime for vehicles, impacting overall productivity.

Illustrative image related to how to fix a headlight

A solução: To mitigate these challenges, it is essential for B2B buyers to invest in training for their maintenance teams. Providing hands-on workshops or access to detailed installation guides tailored to specific vehicle models can enhance the skill set of technicians. Additionally, investing in a versatile toolkit that includes all necessary tools for headlight replacement can save time during installations. Suppliers can also offer installation services or detailed instructional videos that guide technicians through the process, ensuring that they can handle any installation challenges with confidence and efficiency.

Scenario 3: Navigating Electrical Issues Beyond Bulb Replacement

O problema: After replacing a headlight bulb, some users find that the new bulb still does not illuminate. This can often indicate underlying electrical issues, such as a blown fuse or faulty wiring, which can be perplexing for maintenance teams. B2B buyers may struggle to diagnose these problems without a clear understanding of the vehicle’s electrical system, leading to further delays and potential additional costs.

A solução: To effectively tackle this issue, B2B buyers should consider investing in diagnostic tools that can quickly identify electrical faults in vehicles. These tools can help technicians pinpoint whether the issue lies with the bulb, the fuse, or other electrical components. Additionally, establishing a clear protocol for troubleshooting headlight issues can streamline the process. This should include checking the fuse condition first, followed by inspecting wiring and connections. Creating a comprehensive database of common electrical issues related to headlights can also serve as a valuable resource for maintenance teams, enabling them to resolve issues efficiently and minimize vehicle downtime.

Illustrative image related to how to fix a headlight

Strategic Material Selection Guide for how to fix a headlight

When selecting materials for fixing headlights, it’s essential to consider the various components involved, such as bulbs, connectors, and housings. Each material has unique properties that can influence performance, durability, and cost. Below is an analysis of four common materials used in headlight repair, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Glass in Headlight Applications?

Glass is often used for headlight lenses due to its excellent optical clarity and resistance to UV radiation. It typically has a high-temperature rating, making it suitable for the heat generated by bulbs. However, glass can be brittle and prone to shattering upon impact.

Pros and Cons of Glass:

– Prós: High transparency, good heat resistance, UV stability.

– Contras: Fragility, heavier than alternatives, potential for breakage during installation.

Impacto na aplicação: Glass is compatible with various bulb types, including halogen and HID, and can withstand the heat generated during operation. However, its weight and fragility may pose challenges in certain vehicle designs.

Considerações para compradores internacionais: Compliance with automotive safety standards is crucial. In Europe, for instance, glass must meet ECE regulations, while in the U.S., it must comply with DOT standards. Buyers should also consider shipping logistics due to the fragility of glass.

How Does Plastic Compare as a Material for Headlight Components?

Plastic, particularly polycarbonate, is increasingly used for headlight lenses and housings. It offers excellent impact resistance and is lightweight, which can improve fuel efficiency in vehicles.

Prós e contras do plástico:

– Prós: Lightweight, shatter-resistant, easier to mold into complex shapes.

– Contras: Susceptible to scratching, may yellow over time when exposed to UV light, lower heat resistance compared to glass.

Impacto na aplicação: Plastic is suitable for modern vehicle designs that require lightweight components. However, its longevity can be affected by environmental factors, which may necessitate regular replacement.

Considerações para compradores internacionais: Buyers should ensure that the plastic materials comply with local regulations regarding automotive components. In regions with high UV exposure, selecting UV-stabilized plastics is advisable.

What Role Do Metal Connectors Play in Headlight Systems?

Metal connectors are crucial for ensuring a reliable electrical connection in headlight systems. Common materials include copper and aluminum, known for their excellent conductivity.

Pros and Cons of Metal:

– Prós: High conductivity, durability, and resistance to thermal expansion.

– Contras: Prone to corrosion if not properly treated, heavier than plastic alternatives.

Impacto na aplicação: Metal connectors are essential for maintaining consistent electrical flow, which is critical for headlight performance. Corrosion can lead to connectivity issues, impacting functionality.

Considerações para compradores internacionais: Compliance with standards such as ASTM or DIN for electrical components is vital. Buyers should also consider the local environment, as regions with high humidity may require corrosion-resistant coatings.

Why are Rubber Seals Important in Headlight Assemblies?

Rubber seals are used to protect headlight components from moisture and dust. They play a crucial role in maintaining the integrity of the headlight system.

Pros and Cons of Rubber:

– Prós: Excellent sealing properties, flexibility, and resistance to environmental factors.

– Contras: Can degrade over time due to exposure to heat and UV light, may require periodic replacement.

Impacto na aplicação: Rubber seals ensure the longevity of headlight assemblies by preventing moisture ingress, which can lead to electrical failures or lens fogging.

Considerações para compradores internacionais: Buyers should ensure that rubber materials meet local automotive standards for durability and performance. In regions with extreme temperatures, selecting high-quality rubber compounds is essential to avoid premature degradation.

Illustrative image related to how to fix a headlight

Summary Table of Material Selection for Headlight Repair

| Material | Typical Use Case for how to fix a headlight | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Vidro | Lentes dos faróis | Elevada nitidez ótica | Brittle and heavy | Médio |

| Plástico | Lenses and housings | Lightweight and shatter-resistant | Susceptible to scratching and UV damage | Baixo |

| Metal | Connectors for electrical connections | Excelente condutividade | Suscetível à corrosão | Médio |

| Rubber | Seals for moisture protection | Great sealing properties | Degrada-se com o tempo | Baixo |

This strategic material selection guide provides valuable insights for international B2B buyers looking to enhance their headlight repair offerings, ensuring they choose the right materials for performance, durability, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how to fix a headlight

What Are the Key Stages in the Manufacturing Process for Headlight Components?

Manufacturing headlight components involves several crucial stages that ensure the final product meets performance and safety standards.

Preparação do material

The process begins with material selection, where manufacturers choose high-quality plastics, glass, and metal components. These materials are critical for durability and effectiveness in various environmental conditions. For instance, polycarbonate is often used for lens production due to its lightweight and impact-resistant properties.

Illustrative image related to how to fix a headlight

Once selected, materials undergo preparation, which includes cutting, molding, and shaping to meet specific design requirements. Advanced techniques like injection molding are commonly employed to create precise lens shapes that optimize light distribution.

Técnicas de conformação

Following material preparation, the forming stage shapes the components into their final forms. This can include processes such as blow molding for creating bulb housings and vacuum forming for lens production. The choice of technique depends on the complexity and specifications of the headlight design.

For example, LED headlights may utilize more sophisticated forming techniques to accommodate the intricate circuitry required for their operation. The precision in this stage directly impacts the efficiency and performance of the headlight.

Montagem de componentes

The assembly process involves integrating various components, including bulbs, lenses, and housing. This stage requires meticulous attention to detail, as the alignment and fitting of parts are critical for optimal performance. Automated assembly lines often facilitate this process, but manual checks are essential to ensure quality control.

During assembly, manufacturers must also consider the ease of installation for end-users. This includes designing headlight assemblies that allow for straightforward bulb replacements, which is particularly important for B2B buyers in sectors like automotive repair and maintenance.

Illustrative image related to how to fix a headlight

Finishing Touches

Finishing processes such as polishing, coating, and quality inspections ensure that the headlight components meet aesthetic and functional standards. For instance, a UV-resistant coating may be applied to lenses to prevent yellowing and maintain clarity over time.

Finishing touches also include labeling and packaging, which must comply with international regulations and standards. Proper labeling is crucial for B2B buyers to ensure they receive products that meet their specific needs and local regulations.

How Is Quality Assurance Implemented in Headlight Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each headlight meets the required safety and performance standards.

What Are the Relevant International Standards for Headlight Manufacturing?

Manufacturers typically adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE marking for European markets and API standards for automotive products are also important. These certifications indicate compliance with safety and performance regulations, which are critical for B2B buyers in various regions.

Illustrative image related to how to fix a headlight

What Are the Quality Control Checkpoints During Production?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to ensure product integrity. Common checkpoints include:

-

Controlo de Qualidade de Entrada (IQC): This stage involves inspecting raw materials and components before production begins. Suppliers must provide certificates of compliance to confirm that materials meet specified standards.

-

Controlo de qualidade em processo (IPQC): During manufacturing, regular inspections are conducted to monitor the production process and detect any deviations from quality standards. This may involve checking the alignment of components during assembly.

-

Controlo de Qualidade Final (FQC): After assembly, the finished headlight units undergo rigorous testing, including light output tests, durability assessments, and electrical safety evaluations. This stage ensures that all products meet performance specifications before they are shipped.

Como os compradores B2B podem verificar as práticas de controlo de qualidade dos fornecedores?

B2B buyers must be proactive in verifying the quality control practices of their suppliers. Here are several methods to ensure compliance:

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control processes. Buyers should establish a checklist based on their specific requirements and industry standards, ensuring that audits cover all relevant QC checkpoints.

Audits can be done either through on-site visits or remote evaluations, particularly for international suppliers. Buyers should also consider the frequency of audits, as regular assessments can help maintain high-quality standards.

How Important Are Quality Reports and Third-Party Inspections?

Requesting quality reports from suppliers can provide insights into their QC practices. These reports should detail the results of IQC, IPQC, and FQC assessments, along with any corrective actions taken in response to identified issues.

Illustrative image related to how to fix a headlight

Third-party inspections can also add an extra layer of assurance. Independent inspectors can evaluate the manufacturing processes and product quality, providing unbiased feedback that can help B2B buyers make informed decisions.

Quais são as nuances do controlo de qualidade para compradores B2B internacionais?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, must navigate specific quality control nuances when sourcing headlight products.

How Do Regional Regulations Impact Quality Control?

Different regions have varying regulations concerning automotive components. For instance, European markets have strict compliance requirements, including CE marking, while other regions may have less stringent standards. B2B buyers should familiarize themselves with local regulations to ensure that products meet legal requirements.

What Should Buyers Consider Regarding Product Traceability?

Product traceability is another crucial aspect of quality control. B2B buyers should ensure that suppliers maintain detailed records of the manufacturing process, including material sources and production batches. This traceability is vital for addressing any quality issues that may arise post-purchase.

Conclusão

Understanding the manufacturing processes and quality assurance protocols for headlight components is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, buyers can ensure they are sourcing high-quality products. Furthermore, implementing rigorous quality control measures aligned with international standards and best practices will help mitigate risks and enhance product reliability. As the automotive industry continues to evolve, maintaining a robust quality assurance framework will be pivotal for successful procurement strategies across global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to fix a headlight’

Introdução

This practical sourcing guide is designed to assist B2B buyers in efficiently procuring the necessary tools and components for fixing vehicle headlights. Whether you’re sourcing for a repair shop, dealership, or automotive parts distributor, following this checklist will ensure you acquire quality products and services that meet industry standards.

Passo 1: Identify Your Specific Requirements

Understanding the specific needs of your operation is the first step in sourcing headlight repair components. This includes determining the types of vehicles you service and the common issues faced, such as bulb types (halogen, LED, HID) and fixture compatibility. Clearly defining these requirements will streamline the sourcing process and help you avoid costly errors.

Passo 2: Pesquise fornecedores confiáveis

Conduct thorough research to find suppliers with a strong reputation in the automotive parts industry. Look for suppliers who specialize in lighting and electrical components, and verify their track record by checking reviews and ratings from other businesses. A reliable supplier will not only provide quality products but also offer customer support and after-sales services.

Passo 3: Evaluate Product Quality and Compliance

Before making a purchase, assess the quality of the headlight components. Request product samples or specifications that detail the materials and manufacturing processes used. Ensure that the products comply with international safety and quality standards, as this will impact the reliability and performance of the headlights in various driving conditions.

Illustrative image related to how to fix a headlight

Passo 4: Compare preços e condições de pagamento

Gather quotes from multiple suppliers to compare pricing effectively. Look beyond the base price; consider the total cost of ownership, which includes shipping, taxes, and potential import duties. Additionally, negotiate favorable payment terms that align with your cash flow needs, such as extended payment periods or bulk purchase discounts.

Passo 5: Verify Warranty and Return Policies

A solid warranty and clear return policy are essential when sourcing automotive parts. Ensure that the supplier offers a warranty that covers defects and performance issues for a reasonable period. Familiarize yourself with the return process in case the products do not meet your expectations or specifications, as this will safeguard your investment.

Passo 6: Check Technical Support and Training Availability

Inquire whether the supplier provides technical support or training for their products. This is particularly important for complex headlight systems, such as LED or adaptive headlights, where proper installation and maintenance are critical for performance. Suppliers that offer training can enhance your team’s skills, leading to better service delivery.

Passo 7: Estabeleça uma relação de longo prazo

Building a long-term relationship with your suppliers can provide significant advantages, including access to exclusive products and pricing. Engage in regular communication to stay updated on new products and industry trends. A strong partnership can also lead to collaborative opportunities, such as joint marketing initiatives or product development.

By following this checklist, B2B buyers can ensure a streamlined and effective procurement process for headlight repair components, ultimately enhancing service quality and customer satisfaction in their automotive operations.

Comprehensive Cost and Pricing Analysis for how to fix a headlight Sourcing

What Are the Key Cost Components for Fixing a Headlight?

When analyzing the cost structure associated with fixing a headlight, several components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materiais: The most significant cost is often the headlight bulb itself. Prices can vary widely based on type (e.g., halogen, HID, LED), brand, and specifications. High-performance bulbs typically command a premium, which should be factored into pricing.

-

Trabalho: Labor costs can vary depending on the complexity of the installation process. Simple bulb replacements may require minimal labor, while more intricate assemblies could necessitate skilled technicians. This is particularly relevant for B2B buyers looking to outsource installation.

-

Custos indiretos de produção: This includes costs associated with running production facilities, including utilities, rent, and salaries. These overheads can influence the final price of headlight components, particularly if sourced from regions with higher operational costs.

-

Ferramentas: If specialized tools or fixtures are required for manufacturing or installation, these costs will also need to be included in the overall pricing structure.

-

Controlo de qualidade: Ensuring that headlight components meet safety and performance standards incurs additional costs. Certifications and compliance with international standards can add to the price, making this an important factor for buyers focused on quality.

-

Logística: Transportation costs can significantly affect pricing, especially for international shipments. Factors such as distance, shipping method, and freight rates must be accounted for.

-

Margem: Finally, suppliers typically include a margin to ensure profitability. This margin can vary based on competition, market demand, and the supplier’s strategic positioning.

How Do Price Influencers Impact Headlight Sourcing?

Several factors can influence pricing for headlight components in the B2B market.

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, which can significantly affect overall pricing.

-

Especificações e personalização: Custom-designed headlights or specialized bulbs can lead to increased costs. The more specific the requirements, the higher the price, particularly if unique materials or technologies are needed.

-

Materiais: The choice of materials directly impacts cost. For instance, LED bulbs typically cost more than standard halogen options, but they offer longevity and efficiency that may justify the initial expense.

-

Qualidade e certificações: Products with higher quality or additional certifications (like ISO or CE) often come at a premium. Buyers should weigh the benefits of these certifications against the price.

-

Fatores relacionados ao fornecedor: The reputation and reliability of a supplier can also influence pricing. Established suppliers with a proven track record may command higher prices due to their perceived value.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms dictate who bears responsibility for shipping costs, insurance, and risk, which can affect the total landed cost.

What Buyer Tips Can Enhance Cost Efficiency in Headlight Sourcing?

International B2B buyers should consider several strategies to enhance cost efficiency when sourcing headlight components:

-

Negociar: Always negotiate terms and prices. Many suppliers are willing to discuss pricing, especially for large orders or long-term contracts.

-

Foco no custo total de propriedade (TCO): Evaluate not just the purchase price but the overall cost associated with the headlight, including installation, maintenance, and replacement frequency. Investing in higher-quality bulbs can reduce TCO in the long run.

-

Compreender as nuances dos preços: International buyers should be aware of regional pricing differences. Factors such as local demand, currency fluctuations, and economic conditions can significantly affect costs.

-

Leverage Technology: Utilize digital platforms and tools for price comparison, supplier evaluation, and procurement management to ensure competitive pricing.

-

Considere fornecedores locais: For buyers in Africa or South America, sourcing from local manufacturers may reduce logistics costs and improve supply chain efficiency.

Isenção de responsabilidade para preços indicativos

Pricing for headlight components can vary widely based on several factors, including market conditions, supplier relationships, and specific customer requirements. Therefore, the figures mentioned herein should be regarded as indicative, and buyers are encouraged to conduct their own market research to obtain accurate pricing aligned with their specific needs.

Alternatives Analysis: Comparing how to fix a headlight With Other Solutions

Introduction: Exploring Alternative Solutions for Headlight Repair

When it comes to maintaining vehicle safety and compliance, a functioning headlight is crucial. While the traditional method of replacing a headlight bulb is widely known and practiced, there are alternative solutions that can also address headlight issues. This analysis explores various methods, enabling B2B buyers to evaluate options based on performance, cost, ease of implementation, and maintenance.

Comparison Table of Headlight Repair Solutions

| Aspecto comparativo | How To Fix A Headlight | Alternative 1: Headlight Restoration Kit | Alternative 2: LED Headlight Conversion |

|---|---|---|---|

| Desempenho | Restaura a luminosidade original | Improves clarity and brightness | Provides superior illumination and longevity |

| Custo | Moderate (bulb price) | Low to moderate (kit price) | Higher initial cost (conversion kit) |

| Facilidade de implementação | Processo simples de bricolage | Requires some skill and patience | Instalação mais complexa |

| Manutenção | Minimal, depending on bulb type | Periodic reapplication needed | Long-lasting, minimal maintenance |

| Melhor caso de uso | Direct replacement of burnt-out bulbs | Restoring faded or cloudy lenses | Upgrading to modern lighting technology |

Discriminação detalhada das alternativas

What Are the Benefits and Drawbacks of Using a Headlight Restoration Kit?

Headlight restoration kits offer a practical solution for vehicles with oxidized or cloudy lenses, which can significantly diminish headlight performance. These kits typically include polishing compounds and protective sealants that restore clarity and enhance brightness. The primary advantage is the cost-effectiveness compared to full headlight replacement. However, the process requires a certain level of skill and patience, as it involves multiple steps like sanding and polishing. Additionally, the effects may not be permanent; periodic reapplication is necessary to maintain clarity.

How Does Upgrading to LED Headlights Compare to Traditional Methods?

Switching to LED headlights represents a significant technological advancement over traditional halogen bulbs. LEDs provide superior illumination, a longer lifespan, and energy efficiency, making them an attractive option for both consumers and businesses. The installation of an LED conversion kit can be more complex than simply changing a bulb, often requiring additional wiring and compatibility checks. While the upfront costs are higher, the long-term savings on replacement and energy consumption can justify the investment. Nevertheless, businesses must consider local regulations regarding headlight modifications, as some regions have strict guidelines for vehicle lighting.

Illustrative image related to how to fix a headlight

Conclusion: Choosing the Right Headlight Solution for Your Business

Selecting the appropriate headlight repair solution involves evaluating specific operational needs and vehicle conditions. For straightforward bulb replacements, the traditional method remains effective and easy to implement. However, for vehicles with aging lenses, restoration kits can rejuvenate headlight clarity at a lower cost. On the other hand, upgrading to LED technology offers long-term benefits in performance and efficiency, albeit at a higher initial investment. Ultimately, B2B buyers should assess their priorities—whether it’s cost, performance, or maintenance ease—to determine the best approach for their fleet or individual vehicle needs.

Essential Technical Properties and Trade Terminology for how to fix a headlight

When addressing the complexities of fixing headlights in vehicles, understanding essential technical properties and industry terminology is crucial for B2B buyers. This knowledge not only facilitates informed decision-making but also enhances communication with suppliers and manufacturers.

What Are the Critical Technical Specifications for Headlight Replacement?

-

Tipo de lâmpada e compatibilidade

– Definição: Headlights come in various types, including halogen, HID (High-Intensity Discharge), and LED. Each type has unique compatibility requirements for specific vehicle makes and models.

– Importância do B2B: Knowing the bulb type ensures that buyers procure the correct parts for their inventory or service offerings, minimizing return rates and enhancing customer satisfaction. -

Saída de lúmen

– Definição: This measures the brightness of the headlight bulb. Higher lumen output translates to better visibility on the road.

– Importância do B2B: For businesses focusing on automotive lighting solutions, offering products with varying lumen outputs allows them to cater to different customer needs, from basic replacements to high-performance options. -

Temperatura da cor

– Definição: Measured in Kelvin (K), this indicates the color of the light emitted by the bulb. Common ranges include warm white (around 3000K) and cool white (5000K to 6000K).

– Importância do B2B: Understanding color temperature can help buyers select bulbs that enhance safety and aesthetics, particularly for clients seeking to improve vehicle visibility in challenging conditions. -

Vida útil da lâmpada

– Definição: This refers to the average duration a bulb will operate before it fails, typically measured in hours.

– Importância do B2B: Businesses can market longer-lasting bulbs as cost-effective solutions, appealing to customers who prioritize durability and reduced maintenance costs. -

Intervalo de temperatura de funcionamento

– Definição: The range of temperatures in which a headlight bulb can function effectively. Extreme temperatures can affect performance and lifespan.

– Importância do B2B: Buyers must consider local climate conditions when sourcing products to ensure reliability and performance in their target markets.

Quais são os termos comerciais comuns relacionados com a substituição de faróis?

-

OEM (Fabricante de Equipamento Original)

– Definição: Refers to parts made by the vehicle’s original manufacturer. OEM headlights are designed to fit and function exactly like the original parts.

– Importância do B2B: Sourcing OEM parts can enhance product credibility and customer trust, particularly among clients seeking quality assurance. -

MOQ (Quantidade mínima de encomenda)

– Definição: The smallest number of units that a supplier is willing to sell in one order.

– Importância do B2B: Understanding MOQ is essential for inventory planning and cost management, helping businesses optimize their purchasing strategies. -

RFQ (Pedido de Orçamento)

– Definição: A document sent to suppliers requesting pricing and terms for specific products.

– Importância do B2B: Utilizing RFQs allows buyers to compare prices and terms across multiple suppliers, ensuring competitive procurement. -

Incoterms (Termos Comerciais Internacionais)

– Definição: A set of predefined international rules that clarify the responsibilities of buyers and sellers in international trade.

– Importância do B2B: Familiarity with Incoterms is vital for global transactions, as it defines costs, risks, and delivery responsibilities, helping prevent disputes. -

Mercado pós-venda

– Definição: Refers to parts and accessories that are not sourced from the original manufacturer but are designed to fit and function with the vehicle.

– Importância do B2B: The aftermarket can provide cost-effective alternatives for customers, expanding the product range and potential revenue streams for businesses. -

Installation Kits

– Definição: Packages that include all necessary components for headlight installation, such as bulbs, connectors, and tools.

– Importância do B2B: Offering complete installation kits can enhance customer convenience and satisfaction, making it easier for businesses to sell lighting solutions.

By grasping these essential technical properties and industry terms, B2B buyers can navigate the complexities of headlight replacement more effectively, ensuring they meet customer needs while optimizing their procurement processes.

Illustrative image related to how to fix a headlight

Navigating Market Dynamics and Sourcing Trends in the how to fix a headlight Sector

What Are the Key Market Trends Influencing the Headlight Replacement Sector?

The global headlight replacement market is experiencing significant growth, driven by factors such as increasing vehicle ownership and advancements in lighting technology. Internationally, the shift towards LED and HID lighting systems is reshaping consumer preferences, as these options offer greater energy efficiency and longer lifespans compared to traditional halogen bulbs. As B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate these dynamics, they must consider the implications of these technologies on inventory management and sourcing strategies.

Emerging trends include the rise of e-commerce platforms that facilitate the procurement of headlight components, enabling buyers to access a wider range of products with ease. This trend is particularly pronounced in Europe, where digital marketplaces are rapidly gaining traction. Additionally, sustainability is becoming a central theme, as buyers increasingly seek suppliers who prioritize eco-friendly materials and practices. Understanding these trends allows B2B buyers to align their purchasing decisions with market demands, enhancing their competitive edge in an evolving landscape.

How Is Sustainability and Ethical Sourcing Impacting the Headlight Replacement Market?

Sustainability and ethical sourcing are crucial considerations in the headlight replacement sector. The environmental impact of automotive lighting products, particularly in terms of energy consumption and waste generation, is garnering attention from both consumers and regulatory bodies. B2B buyers must prioritize suppliers who offer ‘green’ certifications and utilize recyclable materials in their products. This not only reduces the carbon footprint but also aligns with global efforts to promote environmental responsibility.

Furthermore, the importance of transparency in supply chains cannot be overstated. Buyers should inquire about the sourcing practices of their suppliers to ensure that materials are obtained ethically, minimizing the risk of exploitation in developing regions. By adopting sustainable procurement practices, B2B buyers can enhance their brand reputation and meet the growing consumer demand for environmentally friendly products. This commitment to sustainability can also lead to cost savings over time, as energy-efficient lighting options often result in lower operational expenses.

What Is the Evolution of Headlight Technology and Its Relevance for B2B Buyers?

The evolution of headlight technology has been marked by significant advancements that have transformed the automotive industry. From the early days of incandescent bulbs to the contemporary adoption of LED and HID systems, each innovation has enhanced visibility, safety, and energy efficiency. This progression is particularly relevant for B2B buyers, as understanding historical trends can inform future procurement strategies.

Illustrative image related to how to fix a headlight

Initially, headlights were primarily functional, serving to illuminate roadways at night. However, as vehicle safety regulations became more stringent and consumer expectations evolved, manufacturers began to focus on performance, design, and energy efficiency. Today, buyers must consider not only the technical specifications of headlight products but also their compliance with international standards and regulations. Staying informed about these developments enables B2B buyers to make educated purchasing decisions that align with current industry standards and consumer preferences, ultimately enhancing their market positioning.

Frequently Asked Questions (FAQs) for B2B Buyers of how to fix a headlight

-

How do I know when to replace a headlight bulb?

Replacing a headlight bulb is essential when you notice a significant decrease in brightness, flickering, or if the bulb has completely burned out. Regular inspections, especially before long journeys, can help identify dimming lights. Factors like age, temperature extremes, and physical damage can accelerate wear. For B2B buyers, consider sourcing bulbs that offer longer lifespans and superior performance to minimize frequent replacements and enhance vehicle safety. -

What is the best type of headlight bulb for improved visibility?

When sourcing headlight bulbs, consider options like LED or HID bulbs, which generally provide brighter and more efficient lighting compared to traditional halogen bulbs. These modern alternatives offer better visibility and longer life, making them ideal for commercial vehicles that operate in diverse conditions. Ensure that the bulbs comply with local regulations and standards in the regions you serve, such as Europe or South America, to avoid legal issues. -

Can I replace just one headlight bulb, or should I change both?

While it is technically possible to replace just one headlight bulb, it is recommended to change both simultaneously. This practice ensures uniformity in light output and color, enhancing safety during night driving. For B2B buyers, stocking both bulbs can streamline inventory management and improve customer satisfaction, as they can offer a complete solution for headlight maintenance. -

What factors should I consider when sourcing headlight bulbs from suppliers?

When sourcing headlight bulbs, consider factors such as compatibility with various vehicle models, quality certifications, and the supplier’s reputation. Look for suppliers that provide comprehensive product specifications, including lumens, color temperature, and lifespan. Additionally, assess their logistics capabilities and responsiveness to ensure timely deliveries, especially if your business operates in regions with diverse vehicle types and lighting requirements. -

What are the common challenges in importing headlight bulbs for my business?

Importing headlight bulbs can involve challenges such as customs regulations, varying standards across countries, and potential tariffs. It’s crucial to understand the specific compliance requirements in your target markets, such as CE marking in Europe or ANATEL certification in Brazil. Partnering with knowledgeable logistics providers can help navigate these complexities and ensure smooth import processes. -

How can I vet suppliers for quality headlight bulbs?

To vet suppliers, request samples of their headlight bulbs to evaluate performance and quality. Check for certifications that indicate compliance with international standards, such as ISO 9001 or ECE regulations. Additionally, consider customer reviews, references, and the supplier’s track record in the industry. Engaging in direct communication can also help assess their willingness to provide support and address your specific needs. -

What are the typical payment terms when sourcing headlight bulbs internationally?

Payment terms can vary significantly among suppliers. Common practices include advance payment, letter of credit, or payment upon delivery. It’s advisable to negotiate terms that align with your cash flow and risk tolerance. Additionally, consider using secure payment methods that offer buyer protection, especially when dealing with new suppliers in regions like Africa or the Middle East. -

How can I ensure the quality of headlight bulbs during shipping?

To ensure quality during shipping, select suppliers that use robust packaging to protect the bulbs from damage. Request information about their quality assurance processes, including testing for performance and durability. Implementing a thorough inspection upon receipt can help identify any issues early on. Collaborating with reputable logistics partners can also minimize the risk of damage during transit, ensuring that you receive products in optimal condition.

Top 1 How To Fix A Headlight Manufacturers & Suppliers List

1. Donut Media – Video Creator

Domínio: facebook.com

Registado: 1997 (28 anos)

Introdução: Esta empresa, Donut Media – Video Creator, é uma entidade notável no mercado. Para obter detalhes específicos sobre os produtos, recomenda-se visitar diretamente o seu site.

Strategic Sourcing Conclusion and Outlook for how to fix a headlight

In conclusion, effectively addressing headlight issues is crucial for ensuring vehicle safety and compliance in international markets. Strategic sourcing plays a pivotal role in this process, allowing businesses to procure high-quality headlight bulbs and related components that meet local regulations and customer preferences. By understanding the factors that influence bulb longevity, visibility, and installation ease, B2B buyers can make informed purchasing decisions that enhance their service offerings and customer satisfaction.

Furthermore, the importance of maintaining a consistent inventory of both standard and specialized headlight products cannot be overstated. This approach not only streamlines repair processes but also positions businesses to respond swiftly to market demands, especially in regions such as Africa, South America, the Middle East, and Europe.

As we look ahead, it is essential for B2B buyers to leverage strategic partnerships with reliable suppliers to ensure access to the latest technologies and innovations in automotive lighting. By prioritizing quality and efficiency in sourcing, businesses can enhance their competitive edge and meet the evolving needs of their customers. Engage with trusted distributors and suppliers today to optimize your headlight solutions and drive your business forward.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Illustrative image related to how to fix a headlight

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.