Introdução: Navegar no mercado global de quanto custa substituir um alternador

No atual mercado automóvel global, compreender quanto custa substituir um alternador é crucial para as empresas que operam em diversas regiões, como África, América do Sul, Médio Oriente e Europa. O fornecimento do alternador correto a um preço competitivo pode ter um impacto significativo na eficiência operacional e na rentabilidade. Este guia tem como objetivo fornecer aos compradores B2B internacionais uma visão aprofundada dos factores que influenciam os custos de substituição do alternador, incluindo os tipos de alternadores disponíveis, as suas aplicações em diferentes modelos de veículos e as melhores práticas para a verificação do fornecedor.

Navegar nesta paisagem intrincada requer uma compreensão abrangente dos vários elementos que afectam o preço, tais como o ano, a marca e o modelo do veículo, bem como a amperagem e o estilo de montagem do alternador. Além disso, este guia aborda a importância da garantia de qualidade ao selecionar fornecedores, assegurando que as empresas investem em componentes fiáveis que satisfazem as suas exigências operacionais.

Ao dotar os compradores B2B de conhecimentos práticos sobre os factores determinantes dos custos e as estratégias de aprovisionamento, este guia permite-lhes tomar decisões de compra informadas. Quer seja um gestor de frotas na Arábia Saudita ou um distribuidor de peças automóveis no Brasil, compreender as nuances dos custos de substituição do alternador permitir-lhe-á otimizar os seus processos de aquisição e melhorar os seus resultados.

Índice

- Lista dos 2 principais fabricantes e fornecedores de Quanto custa a substituição de um alternador

- Introdução: Navegar no mercado global de quanto custa substituir um alternador

- Para saber quanto custa substituir um alternador Tipos e variações

- Principais aplicações industriais de quanto custa a substituição de um alternador

- 3 Pontos de dor comuns dos utilizadores para ‘quanto custa substituir um alternador’ e respectivas soluções

- Guia de seleção de materiais estratégicos para a substituição de um alternador

- Análise aprofundada: Processos de fabrico e garantia de qualidade para quanto custa substituir um alternador

- Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘quanto custa substituir um alternador’

- Análise exaustiva dos custos e dos preços para a substituição de um alternador Sourcing

- Análise de alternativas: Comparação de quanto custa substituir um alternador com outras soluções

- Propriedades técnicas essenciais e terminologia comercial para quanto custa a substituição de um alternador

- Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector do quanto custa substituir um alternador

- Perguntas mais frequentes (FAQs) para compradores B2B de quanto custa substituir um alternador

- Conclusão e perspectivas do aprovisionamento estratégico para quanto custa substituir um alternador

- Aviso legal importante e termos de utilização

Para saber quanto custa substituir um alternador Tipos e variações

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Alternadores OEM | Fabricado pelo fabricante original do veículo. | Concessionários automóveis, manutenção de frotas | Prós: Alta qualidade, ajuste garantido; Contras: Caro, prazos de entrega mais longos. |

| Alternadores para o mercado de reposição | Produzido por fabricantes terceiros. | Oficinas de reparação independentes, retalhistas de peças para automóveis | Prós: Económica, variedade de opções; Contras: A qualidade pode variar, potenciais problemas de compatibilidade. |

| Alternadores remanufaturados | Reconstruído a partir de peças usadas com componentes novos. | Oficinas de reparação automóvel, consumidores preocupados com o orçamento | Prós: Custo inferior ao de um novo, amigo do ambiente; Contras: Pode não ter garantia, qualidade variável. |

| Alternadores de alta potência | Concebida para fornecer mais potência do que os modelos standard. | Veículos de alto desempenho, construções personalizadas | Prós: Aumento da capacidade eléctrica; Contras: Preço mais elevado, pode exigir modificações adicionais. |

| Alternadores de um fio | Sistema de cablagem simplificado, frequentemente utilizado em modelos mais antigos. | Automóveis clássicos, restauros antigos | Prós: Instalação fácil, menos componentes; Contras: Saída de amperagem limitada, não adequada para a eletrónica moderna. |

Quais são as caraterísticas dos alternadores OEM?

Os alternadores OEM são concebidos especificamente pelo fabricante do veículo, garantindo um ajuste perfeito e um desempenho ótimo. Estas peças são normalmente recomendadas para garantias de veículos novos e reparações topo de gama. Os compradores B2B, em particular os concessionários de automóveis e os serviços de manutenção de frotas, preferem frequentemente peças OEM pela sua fiabilidade e conformidade com as especificações do fabricante. No entanto, o custo mais elevado e os tempos de aquisição mais longos podem ser uma desvantagem para operações sensíveis ao orçamento.

Como é que os alternadores do mercado de substituição diferem?

Os alternadores do mercado de substituição são produzidos por fabricantes terceiros e podem variar significativamente em termos de qualidade e preço. São amplamente utilizados por oficinas de reparação independentes e retalhistas de peças automóveis devido à sua relação custo-eficácia. Os compradores B2B devem ter em conta a reputação do fabricante e as opções de garantia quando compram peças do mercado de substituição, uma vez que os alternadores de qualidade inferior podem levar a reparações e custos adicionais a longo prazo.

Quais são as vantagens dos alternadores remanufaturados?

Os alternadores remanufacturados são reconstruídos a partir de peças usadas e incluem frequentemente novos componentes para restaurar a funcionalidade. Apelam às oficinas de reparação automóvel e aos consumidores preocupados com o orçamento que procuram uma opção mais económica. Embora sejam amigos do ambiente e geralmente mais baratos do que as unidades novas, a variabilidade da qualidade e a potencial falta de cobertura da garantia são considerações importantes para os compradores B2B.

Quando é que os alternadores de alto rendimento devem ser considerados?

Os alternadores de alto rendimento são concebidos para fornecer uma maior potência eléctrica, o que os torna ideais para veículos de desempenho e construções personalizadas que requerem potência adicional para eletrónica avançada. As aplicações B2B incluem lojas especializadas em automóveis e centros de afinação de desempenho. Embora ofereçam maior capacidade, o preço mais elevado e a possível necessidade de modificações no veículo devem ser avaliados antes da compra.

Quais são as vantagens dos alternadores de um só fio?

Os alternadores de um só fio simplificam o processo de instalação, tornando-os adequados para carros clássicos e restauros antigos. Apresentam um sistema de cablagem simples que reduz a complexidade, apelando aos especialistas em restauro e aos amadores. No entanto, estes alternadores fornecem normalmente uma potência de amperagem inferior, o que os torna menos adequados para veículos modernos com grandes exigências eléctricas. Os compradores B2B devem avaliar os requisitos do veículo antes de optarem por este tipo.

Principais aplicações industriais de quanto custa a substituição de um alternador

| Indústria/Setor | Aplicação específica de Quanto custa a substituição de um alternador | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Gestão de frotas para veículos comerciais | Reduz o tempo de inatividade e os custos de manutenção, assegurando a eficiência operacional. | Disponibilidade de peças OEM vs. peças de substituição, opções de garantia e fiabilidade do fornecedor local. |

| Transporte e Logística | Operações de transporte de longa distância | Aumenta a fiabilidade do veículo, reduzindo o risco de avarias na estrada. | Compatibilidade com vários modelos e especificações de veículos, prazos de entrega de peças. |

| Construção | Manutenção de equipamento pesado | Minimiza os atrasos nos projectos devido a falhas no equipamento, melhorando a produtividade. | Fornecimento de alternadores de alta qualidade para marcas e modelos específicos de máquinas, assistência técnica. |

| Agricultura | Operações de máquinas agrícolas | Assegura o funcionamento contínuo durante os períodos críticos da agricultura, evitando perdas de rendimento. | Compreender as condições do mercado local e adquirir alternadores que cumpram as normas ambientais. |

| Mineração | Fiabilidade do equipamento mineiro | Aumenta a segurança e a eficiência operacional, reduzindo o tempo de inatividade do equipamento. | Disponibilidade local de peças, cumprimento das normas de segurança e relação custo-eficácia do aprovisionamento. |

Qual é a relevância da pergunta ‘quanto custa substituir um alternador’ para a reparação automóvel na gestão de frotas?

Na indústria de reparação automóvel, em particular na gestão de frotas, é crucial compreender os custos associados à substituição do alternador. As frotas são frequentemente compostas por vários veículos que requerem manutenção regular para garantir a eficiência e minimizar o tempo de inatividade. Ao gerir proactivamente as substituições de alternadores, as empresas podem reduzir a frequência de avarias inesperadas, diminuindo assim os custos de manutenção e mantendo o fluxo operacional. Para os compradores internacionais, especialmente em regiões como África e América do Sul, o fornecimento de alternadores fiáveis que se adaptem a vários modelos de veículos é essencial para garantir a compatibilidade e a qualidade.

Qual o papel da substituição do alternador nos transportes e na logística?

No sector dos transportes e da logística, a fiabilidade dos veículos é fundamental. As operações de transporte de longa distância dependem fortemente da funcionalidade dos sistemas eléctricos alimentados por alternadores. Uma falha pode levar a atrasos significativos e perdas financeiras. Compreender as implicações de custo da substituição do alternador permite às empresas de logística orçamentar eficazmente e planear os calendários de manutenção. Os compradores devem considerar o fornecimento de peças que estejam prontamente disponíveis na sua região, o que pode ajudar a evitar longos prazos de entrega e garantir reparações rápidas.

Qual o impacto da substituição do alternador nas operações de construção?

As empresas de construção dependem de equipamento pesado que funciona frequentemente em condições extenuantes. O papel do alternador na alimentação de sistemas eléctricos essenciais torna a sua fiabilidade vital para minimizar os atrasos nos projectos. A compreensão dos custos de substituição permite aos gestores de construção afetar recursos de forma eficaz e planear a manutenção do equipamento. Para os compradores internacionais, é importante adquirir alternadores compatíveis com marcas de maquinaria específicas, bem como garantir que os fornecedores podem prestar assistência e apoio atempados para evitar tempos de inatividade dispendiosos.

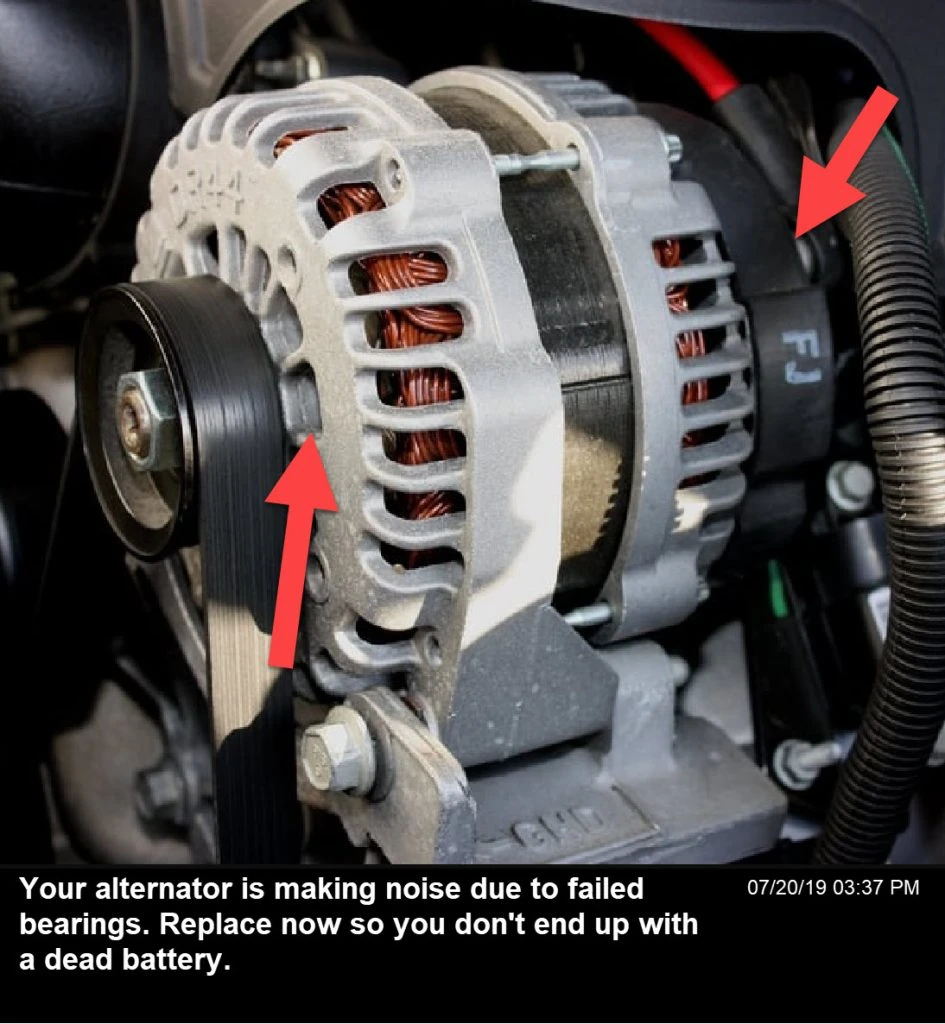

Imagem ilustrativa relacionada com quanto custa substituir um alternador

Porque é que a substituição do alternador é crítica para as máquinas agrícolas?

Na agricultura, a eficiência das máquinas está diretamente ligada à produtividade, especialmente durante as épocas de colheita. Os alternadores são cruciais para alimentar vários sistemas no equipamento agrícola. Uma falha pode levar a paragens operacionais, afectando o rendimento. Saber quanto custa substituir um alternador permite aos agricultores e às empresas agrícolas planear melhor a manutenção e evitar perdas. Os compradores em regiões como o Médio Oriente devem concentrar-se no fornecimento de peças que cumpram as normas ambientais locais, assegurando simultaneamente a sua compatibilidade com os diversos tipos de máquinas utilizadas na agricultura.

Como é que a substituição do alternador influencia as operações mineiras?

As operações mineiras requerem uma elevada fiabilidade de todo o equipamento, incluindo veículos e maquinaria que dependem de alternadores para energia eléctrica. Compreender os custos associados à substituição do alternador é essencial para manter a segurança e a eficiência no local. Uma falha no sistema elétrico pode levar a interrupções operacionais significativas. Os compradores devem dar prioridade ao fornecimento de alternadores de alta qualidade que cumpram os regulamentos de segurança e considerar fornecedores locais que possam fornecer entrega e apoio atempados, especialmente em locais remotos de exploração mineira.

3 Pontos de dor comuns dos utilizadores para ‘quanto custa substituir um alternador’ e respectivas soluções

Cenário 1: Orçamento para reparações inesperadas

O problema: Os compradores B2B enfrentam frequentemente o desafio de reparações inesperadas de veículos, incluindo substituições de alternadores, que podem perturbar o fluxo de caixa e os orçamentos operacionais. Para as empresas que dependem de uma frota de veículos, uma avaria do alternador pode levar a períodos de inatividade, afectando as entregas e os compromissos de serviço. A imprevisibilidade dos custos de reparação acrescenta uma outra camada de complexidade ao planeamento financeiro, especialmente em regiões onde as peças podem ser escassas ou significativamente aumentadas devido a desafios logísticos.

A solução: Para mitigar estes riscos financeiros, as empresas devem estabelecer um orçamento de manutenção proactivo que inclua uma rubrica para a substituição do alternador. As inspecções programadas regularmente podem ajudar a identificar potenciais problemas antes que estes se transformem em reparações dispendiosas. Os compradores devem também pesquisar fornecedores locais de peças de alternador para compreender a gama de preços e a disponibilidade na sua região. Por exemplo, o aprovisionamento junto de distribuidores regionais especializados em peças para automóveis pode, muitas vezes, produzir melhores preços do que confiar apenas nas cotações dos concessionários. Considere a possibilidade de estabelecer relações com mecânicos ou oficinas de confiança que possam oferecer taxas de mão de obra competitivas para as instalações. Além disso, a implementação de um sistema de controlo do desempenho do veículo pode fornecer dados valiosos sobre quando é necessária a manutenção, permitindo uma melhor previsão e orçamentação.

Cenário 2: Fornecimento de peças de qualidade no meio da variabilidade do mercado

O problema: Nos mercados internacionais, os compradores B2B lutam frequentemente para encontrar alternadores de alta qualidade a um preço justo. A tentação de optar por peças mais baratas e de qualidade inferior pode levar a um aumento das taxas de avaria, resultando em custos mais elevados a longo prazo devido a substituições e reparações repetidas. Este problema é particularmente acentuado em regiões onde prevalecem as peças contrafeitas ou de qualidade inferior, pondo em risco a fiabilidade e a segurança dos veículos.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

A solução: Para garantir a aquisição de alternadores de qualidade, os compradores B2B devem dar prioridade ao fornecimento de fabricantes de renome ou revendedores autorizados conhecidos pelos seus processos de garantia de qualidade. Investir tempo na pesquisa e verificação de fornecedores pode evitar futuras dores de cabeça. O estabelecimento de uma rede de fornecedores de confiança em diferentes regiões pode também proporcionar uma vantagem competitiva, permitindo às empresas comparar preços e disponibilidade. Além disso, considere a possibilidade de procurar garantias para as peças adquiridas; os fornecedores de renome oferecem frequentemente garantias alargadas que podem cobrir falhas ou defeitos. Isto não só protege o investimento inicial, como também assegura que as empresas estão equipadas para lidar com quaisquer problemas inesperados sem incorrer em custos excessivos.

Cenário 3: Compreender os custos de mão de obra e os desafios da instalação

O problema: Outro ponto problemático comum para os compradores B2B é a incerteza em torno dos custos de mão de obra associados às substituições de alternadores. Diferentes prestadores de serviços podem cobrar taxas variáveis com base na localização, experiência e custos gerais. Além disso, em regiões com escassez de técnicos especializados em automóveis, encontrar pessoal qualificado para efetuar a instalação pode ser um desafio, levando a atrasos e a custos potencialmente mais elevados.

A solução: Para enfrentar este desafio de forma eficaz, as empresas devem efetuar uma pesquisa exaustiva sobre as taxas de mão de obra na sua área e avaliar as credenciais de potenciais prestadores de serviços. Pedir orçamentos a vários mecânicos pode ajudar os compradores a avaliar um intervalo razoável para os custos de mão de obra. Também é benéfico perguntar sobre o tempo médio necessário para uma substituição de alternador, que normalmente varia de duas a três horas, para entender melhor os custos totais. Além disso, a formação de pessoal interno ou a utilização de serviços de mecânica móvel pode proporcionar flexibilidade e custos potencialmente mais baixos. Ao fomentar relações com escolas profissionais ou programas de formação locais, as empresas podem aproveitar um conjunto de talentos emergentes, assegurando que têm acesso a técnicos qualificados tanto para necessidades imediatas como para manutenção futura.

Guia de seleção de materiais estratégicos para a substituição de um alternador

Que materiais são habitualmente utilizados nos alternadores e o seu impacto nos custos de substituição?

Ao considerar a substituição de um alternador, os materiais utilizados na sua construção desempenham um papel crucial na determinação do desempenho, durabilidade e custo global. A compreensão destes materiais pode ajudar os compradores B2B a tomar decisões informadas que se alinham com as suas necessidades operacionais e requisitos de conformidade.

Quais são as principais propriedades do cobre nos alternadores?

O cobre é um material primário utilizado nos enrolamentos dos alternadores devido à sua excelente condutividade eléctrica. Pode suportar temperaturas elevadas, normalmente até 200°C, e oferece uma boa resistência à corrosão, o que é vital para a longevidade. A elevada condutividade assegura uma transferência de energia eficiente, o que é essencial para o desempenho do alternador.

Prós: A elevada condutividade do cobre resulta numa melhor eficiência e em menores perdas de energia. É durável e pode suportar as exigências eléctricas dos veículos modernos.

Contras: A principal desvantagem é o seu custo, uma vez que o cobre pode ser mais caro do que alternativas como o alumínio. Além disso, os processos de fabrico que envolvem o cobre podem ser complexos, aumentando o tempo de produção.

Impacto na aplicação: O cobre é compatível com todos os tipos de sistemas eléctricos, o que o torna uma escolha versátil para vários modelos de veículos.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

Considerações para compradores internacionais: Os compradores em regiões como África e América do Sul devem ter em conta as flutuações nos preços e na disponibilidade do cobre. O cumprimento de normas internacionais como a ASTM para a qualidade do material também pode afetar as decisões de aquisição.

Como é que o alumínio se compara como material de alternador?

O alumínio é frequentemente utilizado nas caixas dos alternadores e, por vezes, nos enrolamentos. Tem uma densidade inferior à do cobre, o que pode reduzir o peso total do alternador. O alumínio é também resistente à corrosão, particularmente quando anodizado, o que aumenta a sua durabilidade.

Prós: A natureza leve do alumínio pode melhorar a eficiência do veículo. É geralmente menos dispendioso do que o cobre, o que o torna uma opção económica.

Contras: Embora o alumínio tenha uma condutividade decente, não é tão eficiente como o cobre, o que pode levar a maiores perdas de energia. Os processos de fabrico do alumínio podem também ser mais complexos devido às suas propriedades.

Impacto na aplicação: O alumínio é adequado para várias aplicações automóveis, mas pode não ter um desempenho tão bom em sistemas eléctricos de elevada exigência em comparação com o cobre.

Considerações para compradores internacionais: Os compradores devem estar conscientes da necessidade de cumprir os regulamentos locais relativos ao fornecimento e reciclagem de alumínio, especialmente na Europa e no Médio Oriente, onde as normas ambientais são rigorosas.

Qual o papel do aço na construção de alternadores?

O aço é utilizado principalmente nos componentes estruturais dos alternadores, como a estrutura e os suportes de montagem. Proporciona resistência e durabilidade, essenciais para a integridade mecânica do alternador.

Prós: O aço é robusto e pode suportar tensões mecânicas significativas, o que o torna ideal para aplicações estruturais. É também relativamente barato em comparação com outros materiais.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

Contras: O aço é mais pesado do que o alumínio e pode ser propenso à corrosão se não for corretamente tratado. Isto pode afetar a longevidade do alternador em ambientes agressivos.

Impacto na aplicação: A resistência do aço torna-o adequado para aplicações pesadas, mas o seu peso pode afetar o desempenho geral do veículo.

Considerações para compradores internacionais: Os compradores devem certificar-se de que o aço utilizado está em conformidade com as normas locais, como a DIN na Europa, e considerar as implicações da resistência à corrosão em regiões húmidas ou costeiras.

Como é que o plástico é considerado no design do alternador?

Os componentes de plástico são frequentemente utilizados em alternadores para isolamento e peças de alojamento. Os plásticos de alta qualidade podem suportar temperaturas moderadas e proporcionar um bom isolamento elétrico.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

Prós: O plástico é leve, reduzindo o peso total do alternador. É também económico e pode ser moldado em formas complexas.

Contras: O plástico é menos durável do que os metais e pode não resistir a temperaturas elevadas com a mesma eficácia, o que conduz a potenciais falhas em condições extremas.

Impacto na aplicação: Embora o plástico possa ser adequado para o isolamento, as suas limitações em ambientes de elevada tensão tornam-no menos ideal para componentes estruturais.

Considerações para compradores internacionais: Os compradores devem verificar se os plásticos utilizados cumprem as normas de segurança e desempenho relevantes, especialmente em regiões onde são comuns temperaturas extremas.

Tabela resumida da seleção de materiais para alternadores

| Material | Caso de utilização típico para saber quanto custa substituir um alternador | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Enrolamentos para condutividade eléctrica | Elevada eficiência e durabilidade | Custo mais elevado e fabrico complexo | Alto |

| Alumínio | Caixas e alguns enrolamentos | Leve e económico | Condutividade inferior à do cobre | Médio |

| Aço | Componentes estruturais como caixilhos | Resistente e duradouro | Mais pesado e propenso à corrosão | Baixo |

| Plástico | Isolamento e peças da caixa | Leve e moldável | Menos durável sob alta tensão | Baixo |

Esta análise fornece aos compradores B2B uma compreensão abrangente dos materiais utilizados nos alternadores, permitindo decisões informadas que consideram o desempenho, o custo e a conformidade com as normas internacionais.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

Análise aprofundada: Processos de fabrico e garantia de qualidade para quanto custa substituir um alternador

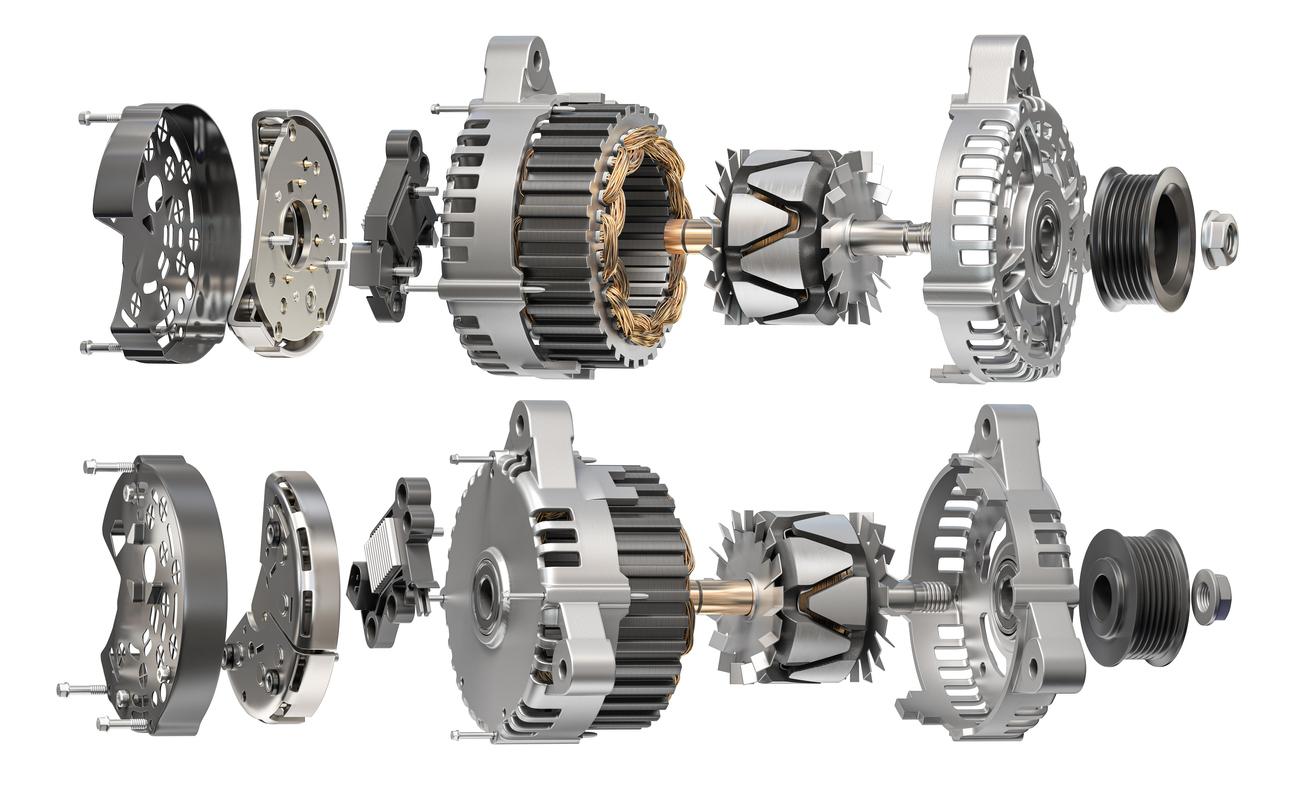

Quais são as principais fases de fabrico de um alternador?

O processo de fabrico de um alternador envolve várias fases críticas que garantem que o produto final cumpre as normas de desempenho e qualidade. A compreensão destas fases é essencial para os compradores B2B que procuram adquirir alternadores fiáveis para as suas operações.

-

Preparação do material:

O primeiro passo no fabrico de alternadores é a obtenção de matérias-primas de alta qualidade. Os principais componentes incluem o cobre para os enrolamentos, o aço para a estrutura e vários plásticos para o isolamento. Os fornecedores realizam frequentemente avaliações rigorosas para garantir que os materiais cumprem normas específicas, como a condutividade eléctrica e a resistência térmica. -

Formando:

Esta fase envolve a transformação das matérias-primas em componentes utilizáveis. Técnicas como a estampagem, a fundição e a maquinagem são utilizadas para criar peças como o rotor, o estator e a caixa. Cada componente é formado com precisão, uma vez que mesmo pequenos defeitos podem levar a falhas no desempenho. -

Montagem:

O processo de montagem combina os componentes formados num alternador completo. Normalmente, isto envolve várias etapas, incluindo a instalação de rolamentos, enrolamentos e rectificadores. As linhas de montagem automatizadas são comuns, mas os técnicos especializados supervisionam frequentemente as fases críticas da montagem para garantir a exatidão e o cumprimento das especificações do projeto. -

Acabamento:

Após a montagem, os alternadores são submetidos a processos de acabamento que podem incluir pintura ou revestimento para aumentar a resistência à corrosão. Esta fase envolve também controlos de qualidade para garantir que cada unidade cumpre as normas da indústria.

Que medidas de controlo de qualidade são essenciais para o fabrico de alternadores?

A garantia de qualidade é crucial no fabrico de alternadores, especialmente devido ao seu papel no desempenho dos veículos. Os compradores B2B devem estar familiarizados com as principais medidas de controlo de qualidade que os fabricantes implementam.

-

Normas internacionais:

A conformidade com normas internacionais como a ISO 9001 é fundamental para os fabricantes. Esta certificação indica que uma empresa estabeleceu um sistema de gestão da qualidade que cumpre as melhores práticas globais. Além disso, certificações como a CE e a API podem indicar a conformidade com normas específicas do sector. -

Pontos de controlo de qualidade:

– Controlo de Qualidade de Entrada (IQC): Esta fase envolve a inspeção das matérias-primas à chegada para garantir que cumprem as especificações exigidas. Os materiais que não passam na inspeção são rejeitados ou enviados de volta para o fornecedor.

– Controlo de qualidade em processo (IPQC): Durante o fabrico, são estabelecidos pontos de controlo em várias fases para monitorizar a qualidade dos componentes. Isto inclui controlos de precisão dimensional e de funcionalidade.

– Controlo de Qualidade Final (FQC): Uma vez concluída a montagem, são efectuadas as inspecções finais para testar a funcionalidade do alternador. Isto pode incluir testes eléctricos para garantir uma saída de tensão e uma capacidade de carga adequadas. -

Métodos de teste comuns:

Os fabricantes utilizam vários métodos de ensaio, incluindo:

– Testes elétricos: Assegura que o alternador satisfaz os valores de tensão e de corrente especificados.

– Testes térmicos: Avalia o desempenho do alternador em diferentes condições de temperatura.

– Teste de durabilidade: Simula a utilização a longo prazo para identificar potenciais pontos de falha.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

Para os compradores B2B, a verificação dos processos de controlo de qualidade dos fornecedores é fundamental para garantir que estão a adquirir produtos fiáveis. Eis várias estratégias que os compradores podem utilizar:

-

Auditorias a fornecedores:

A realização de auditorias no local permite que os compradores avaliem os processos de fabrico e as medidas de controlo de qualidade em primeira mão. Isto pode incluir a revisão da documentação, a observação dos processos de produção e a avaliação dos protocolos de ensaio. -

Solicitação de relatórios de qualidade:

Os compradores devem solicitar relatórios de garantia de qualidade que detalhem os resultados dos testes e inspecções. Estes relatórios fornecem informações sobre o empenhamento do fornecedor na qualidade e sobre quaisquer problemas que possam ter surgido durante a produção. -

Inspeções por terceiros:

A contratação de serviços de inspeção por terceiros pode oferecer uma avaliação imparcial dos processos de controlo de qualidade do fabricante. Estes serviços podem realizar controlos aleatórios e fornecer relatórios pormenorizados sobre a conformidade com as normas internacionais.

Quais são as nuances de controle de qualidade e certificação para compradores B2B internacionais?

Os compradores internacionais, particularmente de regiões como a África, a América do Sul, o Médio Oriente e a Europa, têm de estar cientes das nuances específicas relacionadas com o controlo de qualidade e a certificação.

-

Compreender as normas regionais:

As diferentes regiões podem ter normas e regulamentos diferentes. Por exemplo, a marcação CE é essencial para produtos vendidos no mercado europeu, enquanto outras regiões podem ter requisitos de certificação únicos. Os compradores devem familiarizar-se com estas normas para garantir a conformidade. -

Barreiras linguísticas e de documentação:

Quando se lida com fornecedores internacionais, as barreiras linguísticas podem complicar a compreensão da documentação de controlo de qualidade. Os compradores devem certificar-se de que todos os documentos críticos são fornecidos numa língua que compreendam ou procurar serviços de tradução, se necessário. -

Considerações culturais:

As diferenças culturais podem afetar a comunicação e as expectativas. Compreender as práticas comerciais e os estilos de negociação prevalecentes na região de um fornecedor pode melhorar a construção de relações e conduzir a melhores resultados de garantia de qualidade.

Conclusão

Os processos de fabrico e as medidas de garantia de qualidade dos alternadores são complexos e essenciais para garantir a fiabilidade e o desempenho. Para os compradores B2B, particularmente em diversos mercados internacionais, compreender estes processos é vital para tomar decisões de aquisição informadas. Concentrando-se nas fases de fabrico, implementando medidas de controlo de qualidade minuciosas e verificando as práticas dos fornecedores, as empresas podem garantir alternadores de alta qualidade que satisfaçam as suas necessidades operacionais.

Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘quanto custa substituir um alternador’

Introdução

Este guia serve como uma lista de verificação prática para compradores B2B que procuram navegar pelas complexidades da aquisição de alternadores e compreender os custos associados à sua substituição. Com variações de preços influenciadas por múltiplos factores, como o tipo de veículo, os custos de mão de obra e a localização geográfica, esta lista de verificação ajudará a garantir uma decisão de compra bem informada.

Passo 1: Defina as suas especificações técnicas

Compreender os requisitos específicos dos seus veículos é crucial antes de adquirir alternadores. Considere o ano, a marca, o modelo e o tamanho do motor dos veículos da sua frota. Isto assegura a compatibilidade e o desempenho, evitando erros dispendiosos associados a peças incompatíveis.

- Principais especificações a ter em conta:

- Amperagem requerida pelo alternador

- Estilo de montagem específico para o veículo

Passo 2: Investigação dos custos médios de substituição

Antes de iniciar o processo de aquisição, familiarize-se com os custos médios associados à substituição do alternador na sua região. Este conhecimento permite-lhe definir um orçamento realista e ajuda a identificar preços competitivos dos fornecedores.

- Repartição dos custos:

- Peças: Alternadores novos vs. remanufacturados

- Trabalho: Taxas típicas baseadas nas condições do mercado local

Passo 3: Avalie potenciais fornecedores

Examine minuciosamente os potenciais fornecedores antes de assumir um compromisso. Solicite perfis detalhados da empresa, catálogos de produtos e estudos de caso que demonstrem as suas capacidades. Assegurar que os fornecedores têm experiência com os tipos específicos de alternadores de que necessita pode poupar-lhe tempo e dinheiro.

- O que procurar:

- Certificações e garantias oferecidas

- Comentários ou testemunhos de clientes anteriores em sectores de atividade semelhantes

Passo 4: Avaliar a qualidade dos alternadores

A qualidade deve ser uma prioridade máxima na seleção de alternadores. As opções mais baratas podem poupar dinheiro inicialmente, mas podem levar a taxas de avaria e custos mais elevados no futuro. Procure peças OEM (Fabricante de Equipamento Original) ou alternativas pós-venda de boa reputação que garantam fiabilidade.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

- Indicadores de qualidade:

- Duração da garantia (as garantias mais longas indicam normalmente uma melhor qualidade)

- Reputação da marca no mercado

Passo 5: Compreender as políticas de garantia e devolução

Antes de finalizar a sua compra, reveja a garantia e as políticas de devolução dos alternadores. Uma garantia sólida não só protege o seu investimento como também reflecte a confiança do fabricante no seu produto.

- Considerações importantes:

- Duração da garantia e o que ela cobre

- Facilidade de devolução ou troca em caso de problemas

Passo 6: Planear a instalação e os custos de mão de obra

Tenha em conta o processo de instalação e os custos de mão de obra associados ao orçamentar a substituição do alternador. Saber se os seus mecânicos internos podem tratar da instalação ou se é necessário contratar profissionais externos pode afetar significativamente as despesas gerais.

- Factores de instalação:

- Preços médios de mão de obra na sua região

- Tempo necessário para a instalação com base na complexidade do veículo

Passo 7: Monitorizar a cadeia de abastecimento e a logística

Por fim, assegure-se de que a logística da sua cadeia de abastecimento é eficiente. Os atrasos na aquisição de alternadores podem levar a períodos de inatividade dos seus veículos, afectando as operações comerciais gerais. Estabeleça um calendário fiável para a entrega e considere vários fornecedores para peças críticas.

- Dicas de logística:

- Acompanhar os prazos de expedição e eventuais atrasos

- Avaliar a capacidade de resposta dos fornecedores para garantir uma comunicação atempada

Seguindo esta lista de verificação, os compradores B2B podem tomar decisões informadas ao adquirirem alternadores, assegurando tanto a rentabilidade como a fiabilidade nas operações dos seus veículos.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

Análise exaustiva dos custos e dos preços para a substituição de um alternador Sourcing

Quais são os principais componentes de custo para a substituição de um alternador?

Quando se considera a substituição de um alternador, entram em jogo vários componentes de custo. Os principais custos incluem materiais, mão de obra, despesas gerais de fabrico, ferramentas, controlo de qualidade (CQ), logística e margens de lucro.

-

Materiais: O custo do alternador pode variar muito em função das suas especificações, tais como a marca e o modelo do veículo, a amperagem necessária e o facto de se tratar de uma peça nova ou remanufacturada. Por exemplo, um alternador standard pode variar entre $50 e $500, enquanto os modelos de alto desempenho ou especializados podem exceder $1.000.

-

Trabalho: Os custos de mão de obra para a substituição de um alternador variam normalmente entre $120 e $200, dependendo da complexidade da instalação e da taxa horária do técnico. Em algumas regiões, os preços da mão de obra podem ser influenciados pelas condições económicas locais e pela disponibilidade de técnicos qualificados.

-

Despesas gerais de fabrico e ferramentas: Estes custos estão frequentemente incluídos no preço do alternador. Os custos gerais podem incluir os custos operacionais da fábrica, enquanto as ferramentas se referem à maquinaria e ao equipamento utilizados no processo de produção. Estes factores podem contribuir para as variações de preço, especialmente se forem necessárias ferramentas personalizadas para projectos específicos de alternadores.

-

Controlo de qualidade: Assegurar que cada alternador cumpre normas de qualidade rigorosas implica custos adicionais. Os fabricantes podem implementar protocolos de teste rigorosos, o que pode afetar o preço final. Os alternadores com certificações de qualidade têm geralmente preços mais elevados, mas oferecem maior fiabilidade e desempenho.

-

Logística: O custo de transporte dos alternadores dos fabricantes para os distribuidores ou utilizadores finais pode aumentar o preço global. Factores como a distância, o modo de transporte e as condições de expedição (Incoterms) podem influenciar significativamente os custos logísticos.

-

Margem: Os fornecedores acrescentam normalmente uma margem de lucro para cobrir os seus custos e assegurar a rentabilidade. Esta margem pode variar em função da concorrência no mercado, da procura e do poder de negociação do comprador.

O que influencia o preço da substituição do alternador?

Vários factores influenciam o preço das substituições de alternadores, particularmente para os compradores internacionais B2B.

-

Volume e quantidade mínima de encomenda (MOQ): Os compradores que efectuam encomendas a granel podem beneficiar de preços mais baixos por unidade. Negociar o MOQ pode levar a poupanças de custos, especialmente para distribuidores ou empresas com grande volume de negócios.

-

Especificações e personalização: Os alternadores personalizados, adaptados a modelos de veículos específicos ou a necessidades de desempenho, podem ter custos mais elevados. Os compradores devem avaliar se necessitam de soluções padrão ou personalizadas para otimizar o seu orçamento.

-

Materiais e certificações de qualidade: A escolha dos materiais tem um impacto direto na durabilidade e no desempenho do alternador. Os compradores devem considerar investir em componentes de qualidade superior que podem ter um custo inicial mais elevado, mas um custo total de propriedade mais baixo ao longo do tempo.

-

Fatores relacionados ao fornecedor: A reputação e a fiabilidade do fornecedor podem afetar significativamente os preços. Os fornecedores estabelecidos podem cobrar mais pelos seus produtos, mas muitas vezes oferecem melhores garantias, serviço ao cliente e qualidade do produto.

-

Incoterms: Compreender as condições de envio é crucial para as compras internacionais. Os Incoterms definem as responsabilidades dos compradores e dos vendedores em matéria de transporte, seguro e tarifas, com impacto no custo global e no prazo de entrega.

Que dicas podem ajudar os compradores a otimizar os custos de substituição do alternador?

Para maximizar a eficiência de custos ao adquirir alternadores, os compradores devem considerar as seguintes estratégias:

-

Negociar eficazmente: Criar relações com os fornecedores pode levar a melhores preços. Discuta possíveis descontos em massa, programas de fidelidade ou contratos de longo prazo que possam reduzir os custos.

-

Avalie o custo total de propriedade: Em vez de se concentrar apenas no preço de compra, considere factores como a durabilidade, a garantia e os custos de manutenção. Um alternador ligeiramente mais caro pode poupar dinheiro a longo prazo devido a taxas de avaria reduzidas e a uma vida útil mais longa.

-

Compreender as nuances dos preços regionais: Os preços das substituições de alternadores podem variar consoante a localização geográfica. Os compradores em regiões como África, América do Sul, Médio Oriente e Europa devem pesquisar as condições do mercado local e os desafios da cadeia de fornecimento para tomarem decisões informadas.

-

Mantenha-se informado sobre as tendências do mercado: Acompanhar a evolução do sector pode fornecer informações sobre flutuações de preços, disponibilidade de novas tecnologias e fornecedores emergentes.

Isenção de responsabilidade

Os preços mencionados são indicativos e podem variar com base em inúmeros factores, incluindo flutuações do mercado, requisitos específicos dos veículos e estratégias individuais de preços dos fornecedores. Consulte sempre vários fornecedores para obter os preços mais exactos e competitivos para as suas necessidades específicas.

Análise de alternativas: Comparação de quanto custa substituir um alternador com outras soluções

Na indústria automóvel, o alternador é um componente crucial responsável pela alimentação dos sistemas eléctricos e pela recarga da bateria do veículo. No entanto, quando surgem problemas, as empresas procuram frequentemente alternativas à substituição total do alternador. A compreensão destas alternativas pode fornecer aos compradores B2B soluções económicas adaptadas às suas necessidades operacionais.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

| Aspecto comparativo | Quanto custa a substituição de um alternador | Alternador Remanufacturado | Substituição da bateria |

|---|---|---|---|

| Desempenho | Restaura a funcionalidade eléctrica total | Comparável ao novo, mas pode variar em termos de longevidade | Limitado à energia da bateria; não é uma solução a longo prazo |

| Custo | $100 – $1.000 | $50 – $300 | $70 - $200 |

| Facilidade de implementação | Moderado; requer serviço profissional | Moderado; muitas vezes de bricolage ou profissional | Fácil; normalmente, faça você mesmo |

| Manutenção | Mínimo; duradouro se for corretamente instalado | Moderado; pode necessitar de futuras substituições | Frequente; o tempo de vida da bateria é mais curto |

| Melhor caso de uso | Quando a avaria do alternador é confirmada | Económico para veículos mais antigos | Quando surgem problemas de bateria sem problemas de alternador |

Quais são as vantagens e desvantagens dos alternadores remanufaturados?

Os alternadores remanufacturados podem ser uma alternativa económica às novas substituições, particularmente para veículos mais antigos onde as peças OEM podem ser caras ou difíceis de encontrar. Normalmente, proporcionam níveis de desempenho semelhantes aos dos alternadores novos e vêm com garantias, o que os torna uma escolha fiável. No entanto, a desvantagem é que a sua longevidade pode não corresponder à de um alternador novo e a qualidade pode variar significativamente entre fabricantes. As empresas devem considerar a reputação do fornecedor de peças remanufacturadas para garantir que recebem um produto fiável.

Como é que a substituição da bateria se compara à substituição do alternador?

A substituição da bateria é outra opção que as empresas podem considerar se surgirem problemas eléctricos. Embora uma bateria nova possa resolver temporariamente os problemas de arranque e de fornecimento de energia, não resolve o problema subjacente se o alternador estiver avariado. Os custos associados à substituição de baterias são geralmente mais baixos e o processo pode ser simples, muitas vezes gerido por pessoal interno. No entanto, confiar apenas numa bateria nova é uma solução a curto prazo; se o alternador não estiver a funcionar corretamente, a bateria nova acabará por falhar também.

Como é que os compradores B2B podem escolher a solução certa para as suas necessidades?

Ao determinar o melhor curso de ação, os compradores B2B devem avaliar as necessidades específicas da sua frota ou operações. Se o veículo for relativamente novo e ainda estiver dentro da garantia, optar por uma substituição padrão do alternador pode ser a decisão mais prudente. No entanto, para modelos mais antigos ou veículos com utilização limitada, a exploração de peças remanufacturadas pode resultar em poupanças significativas sem sacrificar a fiabilidade. Entretanto, se os sintomas sugerirem um problema de bateria em vez de uma falha do alternador, a substituição da bateria pode ser suficiente. Em última análise, compreender as necessidades eléctricas do veículo, o orçamento operacional e o tempo de vida esperado da solução escolhida orientará as empresas para a decisão mais eficaz.

Propriedades técnicas essenciais e terminologia comercial para quanto custa a substituição de um alternador

Quais são as propriedades técnicas críticas a ter em conta na substituição de um alternador?

Compreender as especificações de um alternador é crucial para os compradores B2B que procuram substituir este componente automóvel essencial. Eis algumas propriedades fundamentais a considerar:

1. Classificação de amperagem

A amperagem indica a corrente máxima que o alternador pode produzir. É essencial para garantir que o alternador satisfaz as necessidades eléctricas do veículo, que podem variar em função do número de componentes eléctricos utilizados. Por exemplo, os veículos equipados com tecnologia avançada (como GPS, bancos aquecidos e sensores adicionais) podem exigir alternadores com amperagens mais elevadas. Os compradores devem fazer corresponder a amperagem às especificações do veículo para evitar falhas eléctricas.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

2. Saída de tensão

Normalmente, os alternadores devem manter uma tensão de saída entre 13,5 e 14,5 volts. Esta especificação é fundamental, uma vez que afecta o carregamento da bateria e o sistema elétrico em geral. Um alternador que produza uma tensão inconsistente pode provocar danos na bateria ou avarias nos componentes eléctricos, pelo que é vital que os compradores assegurem a compatibilidade com os requisitos eléctricos do seu veículo.

3. Estilo de montagem

Os alternadores são fornecidos em vários estilos de montagem, que ditam a forma como são instalados no veículo. Diferentes fabricantes podem ter especificações únicas para a montagem, e selecionar um alternador que se adapte corretamente é essencial para evitar problemas de instalação. Os compradores B2B devem confirmar que o estilo de montagem corresponde ao design do veículo para facilitar um processo de substituição sem problemas.

4. Termos da garantia

As garantias variam significativamente entre fabricantes, com alguns a oferecerem garantias limitadas e outros a oferecerem cobertura vitalícia. Compreender os termos da garantia é crucial para os compradores B2B, uma vez que uma garantia mais longa pode indicar uma maior confiança do fabricante na durabilidade do produto. Isto também pode proporcionar paz de espírito relativamente a futuras reparações ou substituições.

5. Disponibilidade do núcleo para refabricação

Muitos alternadores são remanufacturados, o que pode reduzir significativamente os custos. No entanto, a disponibilidade de núcleos (alternadores antigos devolvidos para remanufacturação) tem impacto nos preços e no fornecimento. Os compradores devem informar-se sobre a disponibilidade de núcleos, especialmente para modelos de veículos menos comuns, uma vez que tal pode influenciar os prazos de entrega e os custos globais.

Quais são os termos comerciais comuns relacionados com a substituição do alternador?

A familiaridade com o jargão do sector pode ajudar os compradores B2B a navegar no processo de aquisição de forma mais eficaz. Aqui estão alguns termos essenciais:

1. OEM (Fabricante de Equipamento Original)

OEM refere-se a peças fabricadas pelo mesmo fabricante que produziu os componentes originais do veículo. Embora sejam normalmente mais caras, as peças OEM são frequentemente preferidas pela sua compatibilidade e qualidade garantidas. Os compradores devem considerar as opções OEM quando substituem componentes críticos como os alternadores para garantir um desempenho ótimo.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

2. MOQ (Quantidade mínima de encomenda)

O MOQ é o número mais pequeno de unidades que um fornecedor está disposto a vender. Compreender o MOQ é essencial para os compradores B2B, especialmente quando gerem o inventário ou quando procuram negociar acordos de compra em massa. Isto pode ter impacto nos custos globais e na eficiência da cadeia de fornecimento.

3. RFQ (Pedido de Orçamento)

Um pedido de cotação é um processo formal em que os compradores solicitam cotações de preços aos fornecedores. Isto é crucial para comparar custos, prazos de entrega e condições de vários fornecedores. Um pedido de cotação bem preparado pode facilitar as negociações e ajudar a garantir os melhores negócios para substituições de alternadores.

4. Incoterms (Termos Comerciais Internacionais)

Os Incoterms são termos de comércio internacional que definem as responsabilidades dos compradores e vendedores no transporte e na logística. A familiaridade com estes termos pode ajudar os compradores B2B a compreender os custos de envio, os seguros e os riscos durante o transporte. Isto é particularmente importante para transacções internacionais que envolvam alternadores.

5. Mercado pós-venda

O mercado pós-venda refere-se a peças e acessórios fabricados para veículos depois de estes terem sido vendidos. Embora os alternadores do mercado pós-venda possam ser menos dispendiosos do que as opções OEM, os compradores devem garantir que cumprem as normas de qualidade para evitar futuros problemas de fiabilidade. A avaliação das opções do mercado pós-venda é fundamental para uma aquisição económica.

Ao compreender estas propriedades técnicas e termos comerciais, os compradores B2B podem tomar decisões informadas relativamente às substituições de alternadores, garantindo compatibilidade, qualidade e valor para os seus investimentos.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector do quanto custa substituir um alternador

Quais são as principais tendências que afectam o mercado de substituição de alternadores?

O mercado de substituição de alternadores está a sofrer alterações significativas impulsionadas por vários factores globais. Um dos principais factores é a crescente dependência de sistemas electrónicos nos veículos, o que aumentou a procura de alternadores eficientes. À medida que os veículos se tornam mais avançados, com caraterísticas como a tecnologia start-stop e sistemas de info-entretenimento integrados, a necessidade de alternadores de alto rendimento aumentou. Esta tendência é particularmente acentuada em regiões como a Europa e o Médio Oriente, onde as normas regulamentares estão a exigir uma maior eficiência energética e a redução das emissões.

As tecnologias emergentes, incluindo os veículos eléctricos e híbridos, estão a remodelar o panorama do sourcing. Os compradores B2B devem estar atentos aos fabricantes que estão a inovar neste espaço, à medida que os designs tradicionais dos alternadores evoluem para satisfazer os requisitos exclusivos dos grupos motopropulsores eléctricos. Além disso, o aumento das plataformas de comércio eletrónico está a transformar a forma como os compradores internacionais adquirem alternadores, proporcionando acesso a preços competitivos e a uma gama mais vasta de produtos.

Nos mercados de África e da América do Sul, o foco na acessibilidade e no preço é fundamental. Os compradores procuram cada vez mais soluções económicas, optando frequentemente por alternadores remanufacturados que proporcionam um equilíbrio entre qualidade e preço. Esta tendência sublinha a importância de estabelecer parcerias fiáveis com fornecedores que possam oferecer opções novas e remanufacturadas adaptadas às necessidades do mercado local.

Como é que a sustentabilidade e o fornecimento ético podem ter impacto no sector da substituição de alternadores?

A sustentabilidade e o fornecimento ético estão a tornar-se considerações críticas para os compradores B2B no mercado de substituição de alternadores. O impacto ambiental dos componentes automóveis, incluindo os alternadores, está a ser analisado, o que leva os compradores a procurar fornecedores que dêem prioridade a práticas sustentáveis. Isto inclui a utilização de materiais reciclados no processo de produção e a implementação de técnicas de fabrico eficientes em termos energéticos.

A importância das cadeias de abastecimento éticas não pode ser sobrestimada, especialmente porque os consumidores exigem cada vez mais transparência das marcas. Os fornecedores que conseguem demonstrar um compromisso com o abastecimento ético têm mais probabilidades de ganhar uma vantagem competitiva no mercado. Certificações como a ISO 14001 para sistemas de gestão ambiental e a adesão a práticas laborais justas podem melhorar a reputação de um fornecedor e apelar a compradores conscienciosos.

Além disso, a mudança para certificações e materiais “verdes” está a remodelar a oferta de produtos. Os compradores são encorajados a considerar fornecedores que forneçam alternadores amigos do ambiente ou que utilizem materiais sustentáveis, uma vez que isto se alinha com os esforços globais para reduzir as pegadas de carbono. Ao dar prioridade à sustentabilidade, as empresas não só contribuem para a preservação do ambiente, como também se posicionam favoravelmente num mercado que valoriza cada vez mais a responsabilidade empresarial.

Qual é o contexto histórico da substituição do alternador?

A evolução do mercado de substituição de alternadores reflecte mudanças mais amplas na tecnologia automóvel e no comportamento dos consumidores. Inicialmente, os veículos dependiam de geradores simples de corrente contínua (CC), que eram limitados em termos de eficiência e potência. A introdução de alternadores nos anos 60 revolucionou os sistemas eléctricos dos veículos, permitindo uma maior potência e uma maior fiabilidade.

Imagem ilustrativa relacionada com quanto custa substituir um alternador

Ao longo das décadas, os avanços tecnológicos levaram ao desenvolvimento de alternadores mais sofisticados, incluindo aqueles com reguladores de tensão integrados e saídas de amperagem mais elevadas. A mudança para veículos eléctricos e híbridos nos últimos anos acelerou ainda mais a inovação, levando os fabricantes a adaptar as suas ofertas para satisfazer as novas exigências.

À medida que o mercado continua a evoluir, os compradores B2B devem manter-se informados sobre estas tendências históricas para melhor compreenderem as actuais ofertas de produtos e anteciparem futuros desenvolvimentos. Reconhecer a trajetória da tecnologia dos alternadores pode fornecer informações valiosas sobre estratégias de fornecimento e oportunidades de investimento neste sector dinâmico.

Perguntas mais frequentes (FAQs) para compradores B2B de quanto custa substituir um alternador

-

Como posso determinar o custo de substituição de um alternador?

Para estimar o custo da substituição do alternador, considere factores como a marca e o modelo do veículo, o tipo de alternador necessário e as taxas de mão de obra locais. Geralmente, os preços variam entre $100 e $1.000, incluindo peças e mão de obra. Para os compradores B2B, é crucial obter cotações de vários fornecedores e avaliar se oferecem peças OEM ou alternativas pós-venda, uma vez que isto pode afetar significativamente o preço e a qualidade. -

Que factores influenciam o preço da substituição de um alternador?

O preço da substituição de um alternador é influenciado por vários factores, incluindo as especificações do veículo (ano, marca, modelo), a classificação de amperagem do alternador e o período de garantia fornecido. Além disso, os custos de mão de obra podem variar consoante a complexidade da instalação, os preços regionais e a experiência do mecânico. A compreensão destes factores pode ajudar os compradores B2B a tomar decisões de compra informadas. -

Como posso encontrar fornecedores fiáveis de alternadores?

Ao adquirir alternadores, é essencial examinar minuciosamente os fornecedores. Procure fornecedores com uma forte reputação na indústria de peças automóveis e verifique as suas certificações. Solicite amostras ou especificações do produto para avaliar a qualidade. Além disso, considere os fornecedores que oferecem garantias abrangentes e políticas de devolução, uma vez que estes podem ser indicadores de um parceiro fiável para relações comerciais a longo prazo. -

O que devo ter em conta ao comprar alternadores a nível internacional?

As compras internacionais requerem uma análise cuidadosa dos direitos de importação, custos de envio e conformidade com os regulamentos locais. Certifique-se de que as especificações do alternador correspondem aos requisitos do veículo na sua região. Além disso, tenha em conta os prazos de logística e os processos de desalfandegamento, que podem variar significativamente entre regiões, particularmente em África, na América do Sul e no Médio Oriente. -

Quais são as quantidades mínimas de encomenda (MOQs) para os alternadores?

As quantidades mínimas de encomenda de alternadores podem variar muito consoante o fornecedor e o modelo específico. Alguns fabricantes podem exigir quantidades mínimas de encomenda de 10 a 100 unidades, enquanto outros podem ser mais flexíveis, especialmente para os primeiros compradores. Confirme sempre as quantidades mínimas de encomenda com os fornecedores e informe-se sobre os descontos por volume para otimizar a sua estratégia de aquisição. -

Que condições de pagamento devo esperar quando forneço alternadores?

As condições de pagamento podem variar significativamente consoante os fornecedores. Os acordos comuns incluem 30 ou 60 dias líquidos, exigindo o pagamento após a entrega ou dentro de um período específico. Para transacções internacionais, considere opções como cartas de crédito ou serviços de caução para reduzir os riscos. Discuta sempre as condições de pagamento antecipadamente para garantir a compreensão mútua e evitar potenciais litígios. -

Como posso assegurar a garantia de qualidade ao adquirir alternadores?

A garantia de qualidade é fundamental para o aprovisionamento de alternadores. Solicite certificações e documentação de controlo de qualidade aos fornecedores, tais como certificações ISO ou conformidade com as normas automóveis locais. Além disso, considere a implementação de um processo de inspeção de qualidade após a receção das mercadorias para verificar se os alternadores cumprem as suas especificações e expectativas de desempenho. -

Que considerações logísticas devo ter em conta para os envios de alternadores?

Ao planear a logística para os envios de alternadores, considere factores como os métodos de envio, os tempos de trânsito e os potenciais atrasos na alfândega. Escolha um transitário fiável com experiência em peças automóveis para navegar pelas complexidades do transporte internacional. Além disso, avalie os requisitos de embalagem para evitar danos durante o transporte, bem como as opções de seguro para proteger o seu investimento.

Lista dos 2 principais fabricantes e fornecedores de Quanto custa a substituição de um alternador

1. JD Power - Custos de substituição do alternador

Domínio: jdpower.com

Registrado: 1995 (30 anos)

Introdução: Os custos de substituição do alternador variam entre $350 e $900, com as peças a custarem, em média, entre $100 e $350 e os modelos de luxo entre $500 e $700. Os custos de mão de obra podem acrescentar mais $350 a $500 se forem efectuados num concessionário. Estão disponíveis alternadores reconstruídos, que são remanufacturados com peças de equipamento original, e normalmente vêm com uma garantia. A instalação "faça-você-mesmo" é possível para pessoas qualificadas, s...

2. CarTalk - Custos de substituição do alternador

Domínio: cartalk.com

Registrado: 1995 (30 anos)

Introdução: O custo de substituição de um alternador varia entre $600 e $1.500. Um alternador é um componente crítico que mantém a carga da bateria e alimenta vários sistemas eléctricos do veículo. Normalmente, é acionado por uma correia de acessórios no compartimento do motor. Os sinais de uma avaria do alternador incluem uma luz de verificação do motor, faróis a escurecer e a necessidade de arranques rápidos. Os alternadores podem falhar devido a...

Conclusão e perspectivas do aprovisionamento estratégico para quanto custa substituir um alternador

Em resumo, compreender o custo da substituição do alternador é crucial para os compradores B2B no sector automóvel. O preço global pode variar entre $100 e $1.000, influenciado por factores como a marca e o modelo do veículo, as especificações do alternador e os custos de mão de obra. O aprovisionamento estratégico desempenha um papel vital na garantia de componentes de alta qualidade e na gestão das despesas. Os compradores devem dar prioridade às peças OEM pela sua fiabilidade, mas também devem considerar as opções do mercado pós-venda respeitáveis que podem oferecer poupanças significativas sem comprometer a qualidade.

À medida que os mercados globais continuam a evoluir, a procura de peças automóveis eficientes e fiáveis só irá aumentar. As empresas que operam em regiões como a África, a América do Sul, o Médio Oriente e a Europa devem manter-se vigilantes nas suas estratégias de aprovisionamento para capitalizarem as tendências e tecnologias emergentes. Ao alavancar fortes relações com os fornecedores e ao manter-se informado sobre a dinâmica do mercado, os compradores B2B podem garantir que estão bem equipados para satisfazer as necessidades dos seus clientes.

Chegou o momento de avaliar as suas estratégias de aprovisionamento e investir em parcerias que impulsionem a eficiência e a inovação. Juntos, vamos preparar-nos para o futuro da manutenção e reparação automóvel, assegurando que a sua empresa se mantém competitiva e responde às novas exigências do mercado.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.