Introduction: Navigating the Global Market for battery vs alternator vs starter symptoms

Navigating the complexities of diagnosing battery, alternator, and starter symptoms can pose a significant challenge for B2B buyers in the automotive sector. Whether sourcing components for fleet maintenance or ensuring the reliability of commercial vehicles, understanding the nuanced interplay between these essential parts is crucial. Each component serves a vital role in the vehicle’s electrical system, and misdiagnosing a fault can lead to costly downtime and inefficient operations.

This comprehensive guide delves into the distinct symptoms associated with battery, alternator, and starter failures, offering actionable insights for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Brazil. Readers will explore various symptom indicators, troubleshooting techniques, and the implications of environmental factors on component longevity.

Moreover, the guide provides detailed information on supplier vetting processes, pricing structures, and best practices for procurement, empowering buyers to make informed decisions. By understanding the intricacies of these components, businesses can enhance their operational efficiency and reduce the risk of unexpected vehicle failures, ultimately driving profitability and customer satisfaction in a competitive global market.

Índice

- Top 4 Battery Vs Alternator Vs Starter Symptoms Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for battery vs alternator vs starter symptoms

- Understanding battery vs alternator vs starter symptoms Types and Variations

- Key Industrial Applications of battery vs alternator vs starter symptoms

- 3 Common User Pain Points for ‘battery vs alternator vs starter symptoms’ & Their Solutions

- Strategic Material Selection Guide for battery vs alternator vs starter symptoms

- In-depth Look: Manufacturing Processes and Quality Assurance for battery vs alternator vs starter symptoms

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘battery vs alternator vs starter symptoms’

- Comprehensive Cost and Pricing Analysis for battery vs alternator vs starter symptoms Sourcing

- Alternatives Analysis: Comparing battery vs alternator vs starter symptoms With Other Solutions

- Essential Technical Properties and Trade Terminology for battery vs alternator vs starter symptoms

- Navigating Market Dynamics and Sourcing Trends in the battery vs alternator vs starter symptoms Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of battery vs alternator vs starter symptoms

- Strategic Sourcing Conclusion and Outlook for battery vs alternator vs starter symptoms

- Aviso legal importante e termos de utilização

Understanding battery vs alternator vs starter symptoms Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Battery Failure Symptoms | Slow engine cranking, dim lights, bloated casing | Oficinas de reparação automóvel, serviços de frotas | Prós: Fácil de diagnosticar; Contras: High replacement frequency, disposal concerns. |

| Alternator Malfunction Signs | Flickering lights, unusual noises, battery drain | Vehicle maintenance, electric systems | Prós: Critical for vehicle operation; Contras: Complex testing and replacement. |

| Starter Issues Indicators | Clicking sounds, engine not cranking, smoking | Automotive service centers, fleet operations | Prós: Clear signs of failure; Contras: May require professional installation. |

| Diagnostic Testing Symptoms | Voltage irregularities, jump-start results | Automotive diagnostics, vehicle inspections | Prós: Comprehensive understanding of issues; Contras: Requer equipamento especializado. |

| Environmental Impact Signs | Corrosion, water damage, temperature sensitivity | Parts manufacturers, automotive recyclers | Prós: Promotes sustainability; Contras: Additional costs for durable parts. |

What Are the Key Characteristics of Battery Failure Symptoms?

Battery failure symptoms are often characterized by a combination of physical and performance indicators. A failing battery may exhibit slow engine cranking, dimming interior lights, or even a bloated casing. These signs are critical for B2B buyers in the automotive sector, as they indicate the need for timely battery replacement or servicing. When purchasing batteries, consider factors such as warranty, lifespan, and compatibility with various vehicle models to ensure reliable performance and minimize downtime.

How Can You Identify Alternator Malfunction Signs?

Alternator malfunction signs are typically more subtle but can significantly impact vehicle performance. Common indicators include flickering headlights, unusual grinding noises, and frequent battery drain. For B2B buyers in vehicle maintenance, understanding these symptoms is essential for providing effective service. When selecting alternators, prioritize quality and reliability, as these components are vital for the overall electrical system of vehicles, influencing customer satisfaction and retention.

What Are the Indicators of Starter Issues?

Starter issues can present clear and unmistakable signs, such as clicking noises or failure to crank the engine. In some cases, overheating may result in smoke. For B2B automotive service centers, recognizing these symptoms can lead to quicker diagnoses and repairs, enhancing service efficiency. Buyers should focus on sourcing durable starters that offer a good warranty, as they are integral to vehicle functionality and can significantly affect the customer experience.

Why Are Diagnostic Testing Symptoms Important?

Diagnostic testing symptoms, such as voltage irregularities or results from jump-start attempts, provide a comprehensive overview of a vehicle’s electrical health. For B2B buyers in automotive diagnostics, these symptoms are essential for accurate troubleshooting. Investing in quality diagnostic tools is crucial, as they allow for effective identification of underlying issues, reducing repair times and improving service quality.

How Do Environmental Impact Signs Affect Component Longevity?

Environmental impact signs, including corrosion and water damage, can drastically reduce the lifespan of batteries, alternators, and starters. B2B buyers, particularly in regions with extreme weather conditions, should consider components designed to withstand such environments. This not only enhances product longevity but also aligns with sustainability goals, as investing in durable parts can minimize waste and encourage responsible recycling practices.

Key Industrial Applications of battery vs alternator vs starter symptoms

| Indústria/Setor | Specific Application of battery vs alternator vs starter symptoms | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Fabricação Automotiva | Diagnosing electrical issues in assembly line vehicles | Reduces downtime and improves production efficiency | Quality components, compatibility with various models |

| Logística e transportes | Fleet vehicle maintenance and troubleshooting | Aumenta a fiabilidade da frota e minimiza as interrupções operacionais | Cost-effectiveness, availability of parts, local support |

| Agricultura | Equipment maintenance for farm machinery | Ensures continuous operation and reduces repair costs | Robustness of components, resistance to environmental conditions |

| Construção | Reliability of heavy machinery and tools | Minimizes project delays and increases productivity | Durability, ease of replacement, technical support |

| Energia renovável | Manutenção de veículos eléctricos e sistemas híbridos | Supports sustainability goals and reduces carbon footprint | Compatibility with renewable systems, sourcing from eco-friendly manufacturers |

How Are Battery, Alternator, and Starter Symptoms Used in Automotive Manufacturing?

In automotive manufacturing, understanding battery, alternator, and starter symptoms is crucial for diagnosing electrical issues in assembly line vehicles. Quick identification of malfunctioning components can significantly reduce downtime, allowing for smoother production processes. Buyers in this sector should prioritize sourcing high-quality components that are compatible with various vehicle models to ensure seamless integration and reliability in their manufacturing operations.

What Role Do These Symptoms Play in Logistics and Transport?

In the logistics and transport industry, fleet vehicle maintenance hinges on recognizing battery, alternator, and starter symptoms. Regular checks can prevent unexpected breakdowns, enhancing fleet reliability and minimizing operational disruptions. B2B buyers in this sector must consider cost-effective sourcing of spare parts and seek suppliers that provide local support and quick delivery to maintain fleet performance and reduce repair times.

Why Are These Symptoms Important for Agricultural Equipment?

For agricultural machinery, the ability to diagnose battery, alternator, and starter symptoms is vital for ensuring continuous operation. Equipment failure can lead to significant productivity losses, especially during peak seasons. Businesses in this sector should focus on sourcing robust components that can withstand harsh environmental conditions, thereby reducing repair costs and ensuring optimal performance of their machinery.

How Do These Symptoms Affect Construction Projects?

In the construction industry, the reliability of heavy machinery and tools is paramount, and understanding battery, alternator, and starter symptoms can prevent project delays. By promptly addressing electrical issues, companies can maintain productivity and adhere to project timelines. Buyers should prioritize durability and ease of replacement when sourcing components, as well as ensure that suppliers offer technical support for troubleshooting.

How Are These Symptoms Relevant in Renewable Energy Applications?

In the renewable energy sector, maintaining electric vehicles and hybrid systems is essential for supporting sustainability goals. Recognizing battery, alternator, and starter symptoms enables timely maintenance, helping to reduce the carbon footprint of operations. B2B buyers should seek components that are compatible with renewable systems and consider sourcing from manufacturers committed to eco-friendly practices, thereby aligning with their sustainability objectives.

3 Common User Pain Points for ‘battery vs alternator vs starter symptoms’ & Their Solutions

Scenario 1: Misdiagnosing Electrical Issues in Fleet Vehicles

O problema: B2B buyers managing fleets often encounter significant operational challenges when their vehicles exhibit symptoms related to the battery, alternator, or starter. For instance, a fleet manager might receive multiple reports of vehicles failing to start, leading to frustration and downtime. Misdiagnosing the issue can result in unnecessary repairs, additional costs, and a prolonged disruption of services. This not only affects the operational efficiency of the business but also impacts customer satisfaction and trust.

A solução: To address this problem effectively, fleet managers should implement a systematic diagnostic approach for vehicle electrical issues. Begin by training your maintenance staff on the specific symptoms associated with battery, alternator, and starter problems. Utilize diagnostic tools that can read error codes and monitor battery voltage levels to pinpoint the exact issue. For example, if a vehicle shows signs of slow cranking and dim lights, conduct a jump-start test to determine if the battery or starter is at fault. Additionally, maintaining a well-documented history of each vehicle’s electrical repairs can help identify patterns and preemptively address potential failures before they lead to costly downtimes.

Scenario 2: High Replacement Costs Due to Component Misunderstanding

O problema: B2B buyers, particularly in regions with limited access to automotive parts, often face the challenge of high replacement costs associated with battery, alternator, and starter components. When a vehicle experiences electrical failure, the lack of understanding about which component has failed can lead to unnecessary replacements, further straining budgets. This situation is exacerbated in markets where the availability of reliable parts is limited, leading to reliance on overpriced or subpar components.

A solução: To mitigate these costs, businesses should prioritize establishing relationships with reputable suppliers who can provide quality parts at competitive prices. Educate your procurement team on the distinct symptoms of each component’s failure. For instance, if an alternator is suspected, look for signs like flickering headlights or a low voltage gauge before making any purchases. Developing a checklist for troubleshooting can assist in making informed decisions. Furthermore, consider investing in training sessions for your mechanics on identifying these symptoms accurately, thereby reducing the risk of misdiagnosis and unnecessary spending on parts.

Scenario 3: Lack of Knowledge on Preventive Maintenance Practices

O problema: Many B2B buyers are unaware of the importance of preventive maintenance for their vehicle’s battery, alternator, and starter systems. This lack of knowledge can lead to unexpected failures, increased repair costs, and operational interruptions. For example, a construction company might find that a crucial vehicle is out of service due to a dead battery that could have been prevented with regular checks and maintenance. This not only affects project timelines but also results in additional labor costs to manage the situation.

A solução: Implementing a robust preventive maintenance program is key to avoiding these issues. Begin by scheduling regular inspections of the battery, alternator, and starter systems across your fleet. This should include checking battery terminals for corrosion, testing the alternator’s output, and listening for unusual sounds from the starter. Additionally, create a maintenance log that tracks these checks and any findings, which can be invaluable for identifying trends over time. Providing your team with educational resources on the signs of wear and tear can further enhance their ability to address potential issues proactively, ultimately leading to increased vehicle uptime and reduced repair costs.

Strategic Material Selection Guide for battery vs alternator vs starter symptoms

What Are the Key Materials Used in Battery, Alternator, and Starter Components?

When evaluating the symptoms of battery, alternator, and starter issues, the materials used in these components play a crucial role in their performance and longevity. Understanding the properties, advantages, and limitations of these materials can help international B2B buyers make informed decisions.

Quais são as principais propriedades das baterias de chumbo-ácido?

Lead-acid batteries are the most common type used in automotive applications. They consist of lead dioxide (positive plate), sponge lead (negative plate), and sulfuric acid (electrolyte).

- Propriedades principais: Lead-acid batteries can operate effectively within a temperature range of -20°C to 50°C. They have a high discharge rate, making them suitable for starting engines.

- Prós e contras: They are relatively inexpensive and widely available, but they are heavy and have a shorter lifespan (3-5 years). Additionally, they require regular maintenance to prevent sulfation.

- Impacto na aplicação: Lead-acid batteries are sensitive to temperature fluctuations, which can affect performance in extreme climates.

- Considerações para compradores internacionais: Compliance with standards such as ISO 9001 is essential, particularly in regions like Africa and South America, where quality assurance is critical. Buyers should also consider local recycling regulations for lead-acid batteries.

How Does Copper Influence Alternator Performance?

Copper is the primary material used in the windings of alternators due to its excellent electrical conductivity.

- Propriedades principais: Copper has a high thermal and electrical conductivity, with a melting point of 1,984°F (1,085°C), making it suitable for high-performance applications.

- Prós e contras: While copper is highly efficient, it is also more expensive than alternatives like aluminum. Its susceptibility to corrosion necessitates protective coatings.

- Impacto na aplicação: The performance of alternators can degrade if the copper windings corrode, leading to reduced electrical output and potential failure.

- Considerações para compradores internacionais: Buyers should ensure compliance with electrical standards like IEC or UL, particularly in Europe and the Middle East, where stringent regulations exist regarding electrical components.

What Role Does Steel Play in Starter Motors?

Steel is commonly used in the housing and components of starter motors due to its strength and durability.

- Propriedades principais: Steel can withstand high pressures and temperatures, with a tensile strength that allows it to endure mechanical stress.

- Prós e contras: While steel is durable and cost-effective, it is heavier than alternative materials, which can impact overall vehicle weight and fuel efficiency.

- Impacto na aplicação: The robustness of steel components can enhance the longevity of starter motors, but improper installation can lead to misalignment and premature wear.

- Considerações para compradores internacionais: It’s important for buyers to consider local manufacturing capabilities and standards, such as ASTM for steel quality, especially in regions like Nigeria and Brazil where local sourcing may be preferred.

What Are the Implications of Using Plastic in Battery Casings?

Plastics, particularly polypropylene, are often used for battery casings due to their lightweight and corrosion-resistant properties.

- Propriedades principais: Plastic casings can withstand a wide temperature range and are resistant to many chemicals, including sulfuric acid.

- Prós e contras: They are lightweight and cost-effective, but they can be less durable than metals and may degrade over time when exposed to UV light.

- Impacto na aplicação: The choice of plastic can affect the battery’s overall weight and performance, particularly in high-temperature environments.

- Considerações para compradores internacionais: Buyers should ensure that the plastics used comply with environmental regulations, especially in Europe where there are stringent laws regarding plastic use and recycling.

Quadro recapitulativo da seleção de materiais

| Material | Typical Use Case for battery vs alternator vs starter symptoms | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Chumbo-ácido | Batteries for starting engines | Económica e amplamente disponível | Short lifespan and heavy | Baixo |

| Cobre | Enrolamentos em alternadores | Excelente condutividade elétrica | Custo elevado e suscetibilidade à corrosão | Alto |

| Aço | Housing and components of starter motors | Durável e resistente | Heavy and can lead to misalignment | Médio |

| Plástico | Casings for batteries | Leve e resistente à corrosão | Less durable and UV degradation | Médio |

Understanding these materials and their implications can empower B2B buyers to make strategic decisions that enhance the reliability and performance of battery, alternator, and starter systems in their operations.

In-depth Look: Manufacturing Processes and Quality Assurance for battery vs alternator vs starter symptoms

What Are the Main Stages of Manufacturing for Batteries, Alternators, and Starters?

The manufacturing processes for batteries, alternators, and starters involve several key stages, each crucial for ensuring the final product meets quality standards. Understanding these processes can help B2B buyers in evaluating potential suppliers and their capabilities.

Material Preparation: What Materials Are Used in Manufacturing?

The first step in manufacturing involves sourcing and preparing materials. For batteries, lead, sulfuric acid, and plastic for casings are commonly used. Alternators typically require copper wire, magnets, and durable steel for housings, while starters rely on copper windings, steel gears, and various electronic components. Quality assurance begins at this stage, as the selection of high-grade materials is critical. Suppliers should provide certifications for raw materials that comply with international standards.

Forming: How Are Components Shaped and Assembled?

The forming stage involves shaping the prepared materials into the necessary components. For batteries, this includes casting lead plates and assembling them into cells. Alternators undergo winding of copper wire and the assembly of the rotor and stator. In starter manufacturing, the assembly of the motor and gear mechanism is paramount. Advanced techniques such as die-casting for battery casings and precision machining for alternator components are often employed. B2B buyers should inquire about the technologies used in forming to gauge precision and reliability.

Assembly: What Does the Assembly Process Entail?

Assembly is a critical phase where individual components are brought together to create the final product. For batteries, this involves connecting cells and sealing the unit. Alternators require the integration of electronic circuitry and mechanical parts, while starters necessitate the assembly of the solenoid and motor. Quality control checks during assembly, such as torque testing and continuity checks, ensure that the components fit together correctly. Buyers should seek suppliers with robust assembly processes to minimize the risk of defects.

Finishing: How Are Products Prepared for Distribution?

The finishing stage includes surface treatment, packaging, and labeling. For batteries, this may involve applying protective coatings and ensuring proper labeling for safety. Alternators and starters often undergo testing for electrical performance and durability before being packaged. It is essential for B2B buyers to confirm that suppliers adhere to finishing standards that ensure products are ready for use in various environments, especially considering the diverse climates across regions like Africa and South America.

What Quality Assurance Practices Are Essential for Battery, Alternator, and Starter Manufacturing?

Quality assurance (QA) is critical throughout the manufacturing process to ensure that the products meet international standards and customer expectations.

Which International Standards Are Relevant for Manufacturing?

Suppliers should adhere to internationally recognized standards such as ISO 9001, which outlines the criteria for a quality management system. This certification indicates that a supplier has established processes to enhance customer satisfaction and ensure quality in production. Additionally, certifications like CE mark for compliance with European safety standards and API for automotive parts are crucial, especially for buyers in Europe and the Middle East.

Quais são os principais pontos de verificação do controlo de qualidade?

Quality control checkpoints are implemented at various stages of production:

- Controlo de Qualidade de Entrada (IQC): Isto implica a inspeção das matérias-primas à chegada para garantir que cumprem as normas especificadas.

- Controlo de qualidade em processo (IPQC): Continuous monitoring during manufacturing processes helps identify issues early. Techniques like statistical process control (SPC) can be beneficial.

- Controlo de Qualidade Final (FQC): Before products are shipped, they undergo final inspections and testing to ensure they perform as expected. This may include electrical testing for starters and alternators, and capacity testing for batteries.

Quais são os métodos de teste comuns utilizados na garantia de qualidade?

Os métodos de teste comuns incluem:

- Testes elétricos: Ensures components function correctly under load conditions.

- Ensaios ambientais: Assesses product performance in various temperature and humidity levels, particularly relevant for regions with extreme weather conditions.

- Teste de durabilidade: Evaluates how well products withstand wear and tear over time, critical for automotive components that face constant use.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

For B2B buyers, especially those operating in diverse markets like Africa, South America, and the Middle East, verifying supplier quality control is essential.

O que é que os compradores devem procurar nas auditorias aos fornecedores?

Buyers should request detailed audit reports from suppliers, which should include information on their quality management systems, certifications, and past performance. Regular audits conducted by third-party organizations can provide an unbiased assessment of a supplier’s quality practices.

How Can Buyers Ensure Compliance with International Standards?

To ensure compliance with international standards, buyers can:

- Solicitar documentação: Suppliers should provide certificates of compliance and testing reports.

- Conduct On-Site Inspections: Visiting manufacturing facilities allows buyers to observe processes firsthand and evaluate adherence to quality standards.

- Engage Third-Party Inspection Services: Independent inspectors can assess product quality before shipment, providing an additional layer of assurance.

Quais são as nuances do controlo de qualidade para os compradores internacionais?

B2B buyers operating internationally must consider various quality control nuances:

- Conformidade regulamentar: Different countries have varying regulations for automotive components. Understanding local requirements, such as safety standards in Nigeria versus Brazil, is crucial.

- Supply Chain Complexity: Navigating the complexities of international supply chains can introduce risks. Establishing clear communication with suppliers about quality expectations is essential.

- Diferenças culturais: Cultural factors may influence quality perceptions and practices. Building strong relationships with suppliers can help mitigate misunderstandings.

In summary, a thorough understanding of manufacturing processes and quality assurance practices for batteries, alternators, and starters is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control measures, buyers can make informed decisions and select reliable suppliers to meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘battery vs alternator vs starter symptoms’

Introdução

Understanding the symptoms of battery, alternator, and starter issues is vital for businesses that rely on vehicles for operations. This guide will provide a practical checklist to help B2B buyers identify the right components and solutions for their automotive needs. By following these steps, you can ensure efficient procurement and maintenance of your fleet, minimizing downtime and enhancing operational efficiency.

Passo 1: Identificar sintomas comuns

Begin by familiarizing yourself with the typical signs of failure associated with batteries, alternators, and starters. This is crucial for accurate diagnosis and timely intervention. Common symptoms include:

– Battery: Slow engine cranking, dim lights, and a check battery light.

– Alternador: Flickering headlights, unusual noises, or a dead battery that won’t hold charge.

– Starter: Clicking sounds, a single click without engine crank, or erratic starting behavior.

Passo 2: Conduct Preliminary Diagnostic Tests

Before procuring new components, perform basic diagnostic tests to narrow down the issue. This can save time and resources by confirming the faulty component.

– Jump-start Test: If the vehicle starts with a jump but dies when cables are removed, the alternator may be faulty.

– Voltage Check: Use a multimeter to assess the voltage output of the alternator; it should typically read between 13.7 to 14.7 volts when the engine is running.

Passo 3: Defina as suas especificações técnicas

Establish clear technical specifications for the components you need based on your vehicle’s make and model. This ensures compatibility and optimal performance.

– Battery: Note the required amp-hour rating and physical dimensions.

– Alternador: Check the output amperage and mounting style.

– Starter: Confirm the required torque and gear type.

Passo 4: Pesquisar fornecedores de renome

Select suppliers with a proven track record in your region. This is essential for quality assurance and reliable service.

– Look for suppliers with positive reviews from businesses similar to yours.

– Verify their experience in handling specific brands or models you operate.

Passo 5: Pedir amostras e especificações

Before finalizing a purchase, request product samples and detailed specifications. This step allows you to evaluate the quality and ensure it meets your operational needs.

– Check for warranty information and compliance with local regulations.

– Evaluate the materials and construction quality, especially for high-wear components like starters and alternators.

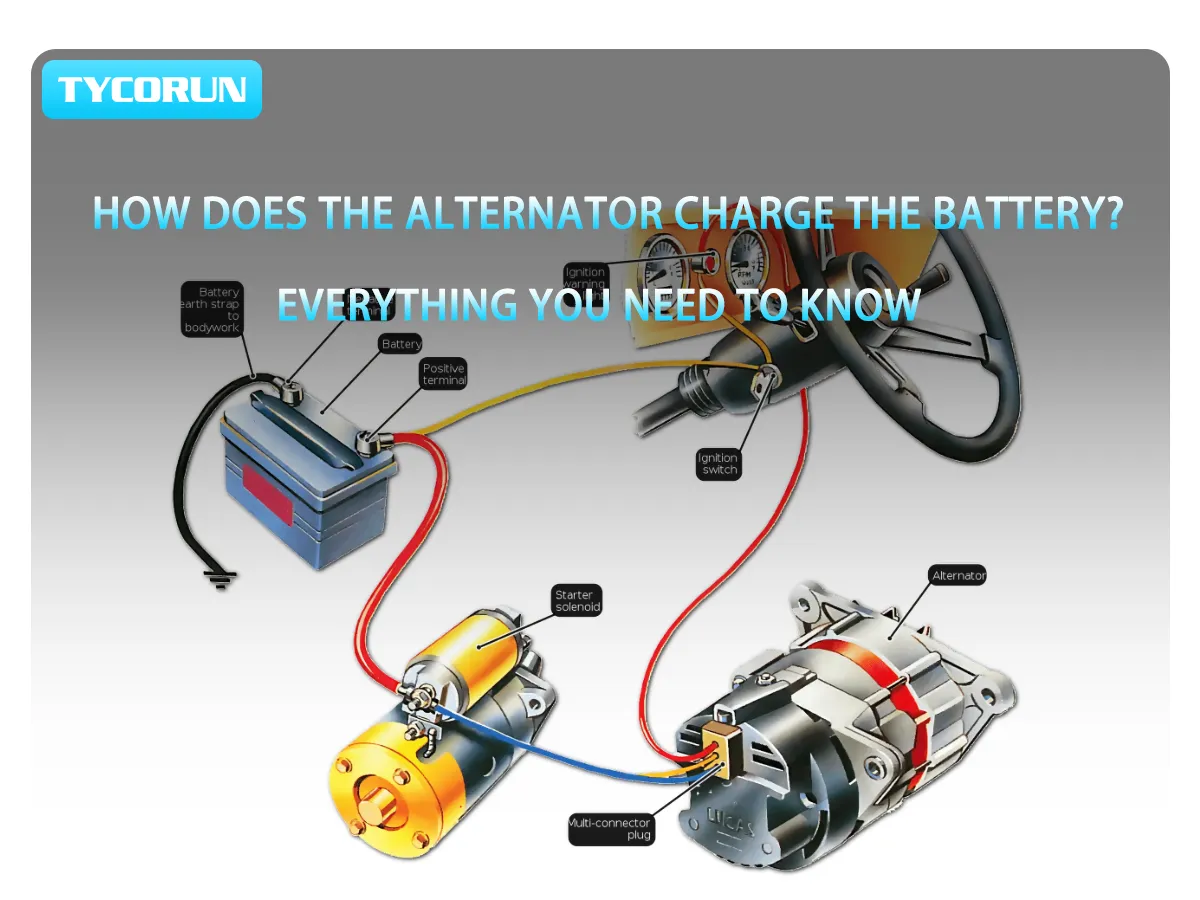

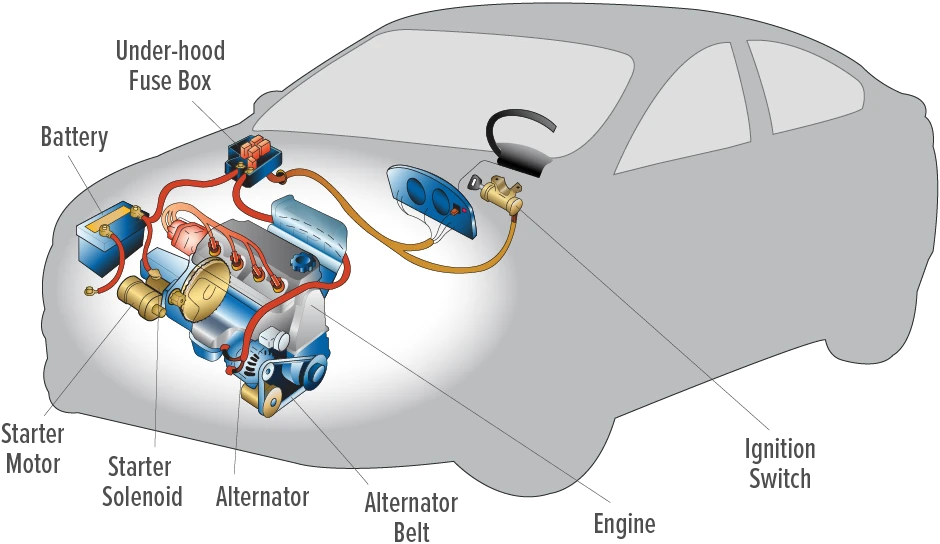

Illustrative image related to battery vs alternator vs starter symptoms

Passo 6: Evaluate After-Sales Support

Consider the level of after-sales support offered by the supplier. Strong support can significantly impact your maintenance operations.

– Inquire about technical assistance, warranty claims, and availability of spare parts.

– Ensure they provide a clear channel for addressing any issues that may arise post-purchase.

Passo 7: Make Informed Purchase Decisions

Finally, based on your research and evaluations, make informed decisions that align with your operational requirements and budget.

– Compare pricing and terms from different suppliers.

– Factor in the total cost of ownership, including installation and maintenance, to ensure long-term value.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing battery, alternator, and starter components, ultimately enhancing the reliability and performance of their vehicle fleets.

Illustrative image related to battery vs alternator vs starter symptoms

Comprehensive Cost and Pricing Analysis for battery vs alternator vs starter symptoms Sourcing

What Are the Key Cost Components for Sourcing Batteries, Alternators, and Starters?

When sourcing batteries, alternators, and starters, understanding the cost structure is crucial for B2B buyers. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materiais: The quality of raw materials significantly influences the cost. For batteries, lead and acid are primary components; for alternators, copper and aluminum are vital; starters often require durable metals and electrical components. Sourcing high-quality materials can reduce long-term failures and enhance performance.

-

Trabalho: The workforce involved in manufacturing directly affects pricing. Labor costs can vary greatly by region, with countries in Africa or South America potentially having lower labor costs compared to Europe. However, quality and expertise should not be compromised, as skilled labor ensures better assembly and quality control.

-

Custos indiretos de produção: This includes costs related to factory operations, utilities, and indirect labor. Efficient manufacturing processes can help reduce these overhead costs, allowing suppliers to offer competitive prices.

-

Ferramentas: Initial investments in tooling and machinery can be significant but are amortized over production runs. Buyers should inquire about tooling costs, especially for customized orders that may require specialized equipment.

-

Controlo de Qualidade (QC): Rigorous QC processes are essential for ensuring product reliability. However, extensive QC can increase costs. B2B buyers should prioritize suppliers with robust QC measures, as this can lead to fewer failures and lower warranty claims in the long run.

-

Logística: Transportation costs are critical, particularly for international buyers. These costs can fluctuate based on the shipping method, distance, and incoterms. Understanding the logistics involved helps in negotiating better shipping terms and reducing overall costs.

-

Margem: Suppliers typically incorporate a profit margin that reflects their operational costs and market conditions. Buyers should be aware of the average margins in their industry to negotiate effectively.

How Do Price Influencers Affect Sourcing Decisions for Batteries, Alternators, and Starters?

Several factors can influence pricing in the sourcing of automotive electrical components.

-

Volume/MOQ (Quantidade mínima de encomenda): Suppliers often provide discounts for bulk orders. Buyers should assess their needs and potential for future growth to negotiate favorable terms.

-

Especificações e personalização: Custom specifications can lead to increased costs due to additional engineering and tooling. Buyers should balance the need for customization with cost-effectiveness.

-

Materiais e certificações de qualidade: The choice of materials and relevant certifications can significantly affect the price. For example, sourcing batteries that meet international standards might incur higher upfront costs but can result in savings through enhanced performance and reliability.

-

Fatores relacionados ao fornecedor: The reputation and reliability of suppliers are crucial. Established suppliers may charge more due to their reputation for quality, but they can also offer better service and reliability.

-

Incoterms: Understanding the implications of different Incoterms (International Commercial Terms) is vital for international transactions. These terms determine who bears the risk and cost at various stages of shipping, affecting the overall pricing structure.

What Are the Best Negotiation Tips for B2B Buyers in International Markets?

International B2B buyers should adopt strategic negotiation practices to enhance cost-efficiency:

-

Alavancar o custo total de propriedade (TCO): Focus on the long-term costs associated with sourcing, including maintenance, warranty, and operational efficiency, rather than just the purchase price.

-

Pesquisar as condições do mercado local: Understanding regional pricing trends and economic factors can provide leverage during negotiations. This is especially relevant for buyers in Africa, South America, and the Middle East, where market dynamics can vary widely.

-

Criar relações com os fornecedores: Establishing strong relationships can lead to better terms, improved service, and access to new products.

-

Pedir amostras: Before committing to large orders, ask for samples to evaluate quality. This helps prevent costly mistakes in bulk orders.

-

Esteja ciente das nuances dos preços: Recognize that currency fluctuations, import tariffs, and local regulations can impact costs. This understanding aids in making informed sourcing decisions.

Isenção de responsabilidade para preços indicativos

Prices for batteries, alternators, and starters can vary widely based on numerous factors, including market conditions, supplier negotiations, and specific component specifications. B2B buyers are encouraged to conduct thorough market research and supplier evaluations to determine accurate pricing for their specific needs.

Alternatives Analysis: Comparing battery vs alternator vs starter symptoms With Other Solutions

Exploring Alternatives: Battery vs Alternator vs Starter Symptoms

In the automotive industry, diagnosing issues related to the battery, alternator, and starter is crucial for maintaining vehicle performance. However, there are alternative solutions and technologies that can help streamline diagnostics and enhance vehicle reliability. This section provides a comparative analysis of the symptoms associated with these three components against alternative solutions, enabling B2B buyers to make informed decisions.

| Aspecto comparativo | Battery Vs Alternator Vs Starter Symptoms | Ferramentas de diagnóstico avançadas | Hybrid Power Systems |

|---|---|---|---|

| Desempenho | Relies on manual troubleshooting; can be time-consuming | Provides precise diagnostics quickly | Offers improved efficiency and reduced dependency on traditional components |

| Custo | Generally low-cost; requires basic tools | Higher initial investment for diagnostic equipment | Medium to high investment; cost-effective in the long run |

| Facilidade de implementação | Requires knowledge of vehicle systems | User-friendly interfaces; often requires training | Installation can be complex; requires specialized knowledge |

| Manutenção | Regular checks needed for each component | Minimal maintenance; software updates required | Requires periodic maintenance of the hybrid system |

| Melhor caso de uso | Ideal for basic diagnostics in older vehicles | Best for workshops or fleets needing quick diagnostics | Suitable for modern vehicles aiming for energy efficiency |

What Are Advanced Diagnostic Tools and Their Benefits?

Advanced diagnostic tools, such as OBD-II scanners, allow technicians to quickly identify issues in the battery, alternator, or starter systems. These tools interface with the vehicle’s onboard computer, providing real-time data and diagnostic trouble codes (DTCs). The advantages of using these tools include faster troubleshooting, reduced labor costs, and improved accuracy in diagnosing electrical issues. However, the initial investment in such technology can be significant, and proper training is often necessary for effective use.

How Do Hybrid Power Systems Compare?

Hybrid power systems integrate traditional internal combustion engines with electric propulsion, offering a unique alternative to conventional battery, alternator, and starter setups. This technology enhances fuel efficiency and reduces emissions, making it increasingly popular in modern vehicles. The primary benefits include lower operational costs and reduced reliance on traditional components. However, the complexity of hybrid systems requires specialized knowledge for installation and maintenance, which can be a barrier for some businesses.

Conclusão: como os compradores B2B devem escolher a solução certa?

When considering the best solution for vehicle diagnostics and performance, B2B buyers should evaluate their specific operational needs, budget, and technical capabilities. For businesses with older vehicles or those requiring basic diagnostics, traditional battery, alternator, and starter symptom checks may suffice. Conversely, workshops aiming for efficiency and accuracy might benefit from investing in advanced diagnostic tools. Lastly, businesses focused on sustainability and long-term cost savings could explore hybrid power systems, despite the higher initial investment and complexity. By aligning the chosen solution with operational goals, buyers can enhance their vehicle maintenance strategies effectively.

Essential Technical Properties and Trade Terminology for battery vs alternator vs starter symptoms

What Are the Key Technical Properties of Batteries, Alternators, and Starters?

Understanding the technical specifications of batteries, alternators, and starters is crucial for B2B buyers involved in automotive parts procurement. Here are some essential properties that can impact performance and longevity:

1. Tensão nominal

The voltage rating, typically 12V for automotive batteries, is critical for compatibility with vehicle electrical systems. B2B buyers must ensure that the components they source meet the required voltage specifications to avoid system failures or inefficiencies.

2. Amperes de arranque a frio (CCA)

CCA measures a battery’s ability to start an engine in cold conditions. A higher CCA rating is essential for regions with extreme weather, such as Northern Europe or parts of South America. B2B buyers should evaluate CCA ratings to ensure reliable performance in their specific operational environments.

3. Amp-Hour (Ah) Capacity

The amp-hour capacity indicates how much energy a battery can store and deliver over time. Understanding this specification helps businesses choose batteries that meet their operational demands without frequent replacements, thus reducing downtime and maintenance costs.

4. Composição do material

The materials used in batteries (e.g., lead-acid, lithium-ion) and alternators (e.g., copper windings, aluminum casings) influence durability and efficiency. B2B buyers should consider the material grades to ensure they are sourcing high-quality components that provide better performance and longevity.

5. Intervalo de temperatura de funcionamento

Each component has a specified operating temperature range that affects its performance. Extreme temperatures can lead to failure or reduced efficiency. B2B buyers must assess this range, especially when sourcing components for vehicles operating in diverse climates across Africa, the Middle East, and beyond.

6. Período de garantia

Warranty duration is a critical consideration that reflects manufacturer confidence in their product. A longer warranty can indicate better quality and reliability, which is vital for B2B relationships where trust and accountability are paramount.

What Are the Common Trade Terms Related to Batteries, Alternators, and Starters?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B sector. Here are some common trade terms relevant to batteries, alternators, and starters:

1. OEM (Fabricante de Equipamento Original)

OEM refers to parts made by the original manufacturer of the vehicle. Sourcing OEM components is often preferred for ensuring compatibility and quality. B2B buyers should prioritize OEM parts to maintain vehicle integrity.

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory costs effectively and ensure they can meet their operational needs without overcommitting financially.

3. RFQ (Pedido de Orçamento)

An RFQ is a document issued by buyers to solicit price quotes from suppliers for specific products. This is a critical step in the procurement process, allowing B2B buyers to compare prices and terms from different suppliers before making purchasing decisions.

Illustrative image related to battery vs alternator vs starter symptoms

4. Incoterms (Termos Comerciais Internacionais)

Incoterms define the responsibilities of buyers and sellers in international transactions, including delivery, risk, and costs. B2B buyers must be familiar with these terms to negotiate shipping and delivery conditions effectively, especially when sourcing from global suppliers.

5. Peças de reposição

Aftermarket parts are components made by third-party manufacturers rather than the OEM. While often less expensive, quality can vary significantly. B2B buyers should evaluate the reliability and performance of aftermarket parts to avoid potential issues down the line.

6. Prazo de entrega

Lead time refers to the time taken from placing an order to delivery. Understanding lead times is crucial for B2B buyers to plan their inventory and avoid disruptions in operations, especially in regions with variable supply chain dynamics.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement processes and ultimately contribute to the efficiency of their operations.

Navigating Market Dynamics and Sourcing Trends in the battery vs alternator vs starter symptoms Sector

What Are the Key Global Drivers Impacting the Battery, Alternator, and Starter Symptoms Market?

The battery, alternator, and starter components are integral to vehicle functionality, and their market dynamics are influenced by a variety of global drivers. The increasing demand for electric vehicles (EVs) and hybrid models is reshaping the landscape, as these vehicles require advanced battery technologies, leading to heightened competition and innovation in sourcing. Additionally, the rise in automotive technology and smart vehicle systems necessitates more reliable and efficient components, pushing manufacturers to prioritize quality and performance in their supply chains.

Illustrative image related to battery vs alternator vs starter symptoms

Emerging markets in Africa and South America, particularly in countries like Nigeria and Brazil, are witnessing a surge in vehicle ownership. This trend is driving the demand for aftermarket components and services, as older vehicles often require replacements and repairs. Buyers in these regions are increasingly looking for cost-effective solutions while ensuring quality and reliability, thereby influencing sourcing strategies. Furthermore, globalization and digital transformation are enhancing accessibility to global suppliers, allowing B2B buyers to explore diverse sourcing options for these critical components.

How Are Sustainability and Ethical Sourcing Influencing the Battery, Alternator, and Starter Market?

As environmental concerns grow, sustainability is becoming a crucial factor in the sourcing of automotive components. The production of batteries, alternators, and starters often involves materials that can have significant environmental impacts, such as lead, lithium, and cobalt. B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices and demonstrate commitment to reducing their carbon footprint. This shift is leading to a greater emphasis on ethical sourcing, where suppliers are expected to ensure responsible mining and production processes.

Moreover, the demand for ‘green’ certifications and materials is on the rise. Buyers are looking for products that not only meet performance standards but also comply with environmental regulations. Companies that can showcase their sustainability efforts, whether through eco-friendly materials or waste reduction practices, are likely to gain a competitive edge in the marketplace. Engaging with certified suppliers can enhance brand reputation and align with the values of environmentally-conscious consumers, making ethical sourcing a strategic priority for B2B buyers in this sector.

What Is the Historical Context of Battery, Alternator, and Starter Technology in the Automotive Industry?

The evolution of battery, alternator, and starter technology has significantly shaped the automotive industry over the decades. The introduction of the electric starter in the early 20th century revolutionized vehicle operation, replacing the cumbersome hand-crank systems. This innovation paved the way for advancements in battery technology, leading to the development of lead-acid batteries that remain widely used today.

Throughout the latter half of the 20th century, the automotive sector saw significant improvements in alternator efficiency and reliability, driven by increasing electrical demands from vehicle systems. The rise of electronic components and onboard diagnostics in modern vehicles necessitated further enhancements in battery and starter technologies. As the industry continues to embrace electrification and smart technologies, the ongoing evolution of these components will play a pivotal role in meeting the demands of the next generation of vehicles, influencing sourcing strategies and market dynamics for B2B buyers across the globe.

Illustrative image related to battery vs alternator vs starter symptoms

Frequently Asked Questions (FAQs) for B2B Buyers of battery vs alternator vs starter symptoms

-

How do I diagnose issues with my vehicle’s battery, alternator, or starter?

Diagnosing electrical issues in a vehicle requires a systematic approach. Begin by checking for common symptoms: if the engine cranks slowly or not at all, the battery may be failing. Look for dim lights or unusual noises when starting; these can indicate alternator or starter issues. A quick jump-start test can help identify the problem. If the vehicle starts but dies after disconnecting jumper cables, it points to a faulty alternator. For persistent issues, consult a professional technician to ensure accurate diagnostics and recommendations. -

What is the best battery for commercial vehicles in harsh climates?

For commercial vehicles operating in extreme temperatures, look for batteries designed for high cranking power and durability. Opt for AGM (Absorbent Glass Mat) or deep-cycle batteries, which withstand temperature fluctuations and heavy usage. Brands with a strong reputation in regions like Africa or South America often offer models specifically engineered for these conditions. Always check for warranties and performance ratings to ensure the battery meets your operational needs and provides reliable service. -

How can I ensure the quality of the batteries, alternators, and starters I purchase?

To ensure quality, source components from reputable manufacturers with established certifications and positive reviews. Request samples and conduct independent testing where possible. Additionally, inquire about the supplier’s quality assurance processes, including warranty terms and return policies. Building relationships with suppliers through regular communication can also help maintain quality standards and address any concerns promptly. -

What minimum order quantities (MOQ) should I expect when sourcing automotive parts internationally?

MOQs can vary significantly by supplier and product type. Typically, for automotive parts like batteries, alternators, and starters, MOQs may range from 100 to 500 units. However, some manufacturers might offer flexibility for first-time buyers or smaller businesses. Always discuss MOQs during negotiations to find a balance that meets your inventory needs while ensuring cost-effectiveness. -

What payment terms are common for international suppliers of automotive components?

Payment terms can differ widely based on the supplier’s policies and your negotiation leverage. Common terms include upfront payments (30-50%), with the balance due upon shipment or delivery. Some suppliers may offer net payment terms (30, 60, or 90 days) for established relationships. Ensure to clarify all terms in writing to avoid misunderstandings and protect your investment. -

How do I vet suppliers for batteries, alternators, and starters in the international market?

Vetting suppliers involves several steps: verify their business licenses and certifications, request references from other B2B clients, and assess their reputation in the industry. Conduct online research and check for reviews on platforms like Alibaba or TradeIndia. It’s also advisable to request product samples and review their production capabilities to ensure they meet your quality requirements. -

Que considerações logísticas devo ter em conta ao importar peças para automóveis?

Logistics for importing automotive parts includes understanding shipping costs, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in automotive logistics to navigate customs clearance efficiently. Also, consider the shipping method (air vs. sea) based on urgency and budget. Be aware of potential delays and plan for contingencies, especially in regions with less predictable infrastructure. -

How can I customize batteries, alternators, or starters to fit specific needs?

Customization options often depend on the manufacturer’s capabilities. Discuss your specific requirements such as voltage, size, or unique features with potential suppliers. Many manufacturers can tailor products to meet particular performance standards or branding requirements. Be prepared to share detailed specifications and possibly commit to larger orders to facilitate customization, as this may impact production timelines and costs.

Top 4 Battery Vs Alternator Vs Starter Symptoms Manufacturers & Suppliers List

1. Reddit – Vehicle Electrical Issues

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: The text discusses the differences between alternator, battery, and starter problems in a vehicle. Key points include: 1. The battery provides power to all electronics and the starter. 2. The alternator charges the battery when the engine is running. 3. The starter uses battery power to turn over the engine. 4. A dead battery is suggested as the likely issue if there is no power at all. 5. A faili…

2. Capitol Chevy – Vehicle Battery & Starter Symptoms

Domínio: capitol-chevy.com

Registado: 1999 (26 anos)

Introdução: The text discusses the symptoms related to issues with a vehicle’s battery, starter, or alternator. Key symptoms include: 1. Dim or flickering lights indicating a failing alternator. 2. Dash lights turning on but the car not starting, suggesting a faulty starter. 3. Successful jump start indicating a battery issue. 4. Unsuccessful jump start pointing to a starter problem or an old battery. 5. Engi…

3. Honda – Starter Troubleshooting

Domínio: mechanics.stackexchange.com

Registado: 2009 (16 anos)

Introdução: 2006 Honda Civic EX 1.8L 4 Cylinder; symptoms include weak cranking, failure to start, single click sound when attempting to start; issues suspected with starter or alternator; previous battery replaced; voltage readings suggested for diagnosis; potential issues with positive battery cable or connections.

4. Facebook – Automotive Troubleshooting Guide

Domínio: facebook.com

Registado: 1997 (28 anos)

Introdução: This company, Facebook – Automotive Troubleshooting Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for battery vs alternator vs starter symptoms

In summary, understanding the symptoms of battery, alternator, and starter issues is crucial for maintaining vehicle performance and minimizing downtime. International B2B buyers should prioritize strategic sourcing of high-quality automotive components to ensure reliable operations. The interplay between these three components can complicate diagnostics, making it essential to collaborate with trusted suppliers who offer comprehensive support and expertise.

For businesses in Africa, South America, the Middle East, and Europe, investing in reliable parts and professional services can significantly reduce operational disruptions. By establishing strong supplier relationships, companies can secure timely access to essential components, ultimately enhancing their service offerings and customer satisfaction.

As we look to the future, the automotive industry will continue to evolve, and so will the technologies surrounding battery, alternator, and starter systems. By staying informed and proactive in sourcing strategies, B2B buyers can position themselves advantageously in a competitive landscape. Engage with reliable partners today to ensure your fleet remains efficient and well-equipped for the challenges ahead.

Illustrative image related to battery vs alternator vs starter symptoms

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.