Introdução: Navegar no mercado global de custos de alternadores para automóveis

No complexo panorama dos componentes automóveis, compreender o custo dos alternadores para automóveis é crucial para os compradores B2B internacionais que procuram otimizar as suas cadeias de fornecimento e gerir as despesas de forma eficaz. O fornecimento de alternadores de alta qualidade que satisfaçam os requisitos específicos dos veículos pode representar um desafio, particularmente quando se navega em condições de mercado variáveis em regiões como África, América do Sul, Médio Oriente e Europa. As flutuações nos preços, as diferenças nas normas de fabrico e a disponibilidade de peças novas versus peças remanufacturadas desempenham um papel significativo na despesa global.

Este guia serve como um recurso abrangente, detalhando os factores que influenciam o preço do alternador, incluindo especificações como a amperagem, estilos de montagem e opções de garantia. Também explora as diversas aplicações dos alternadores em diferentes marcas e modelos de veículos, assegurando que os compradores podem tomar decisões informadas e adaptadas às suas necessidades específicas. Para além disso, fornecemos informações sobre processos eficazes de verificação de fornecedores, ajudando as empresas a identificar fabricantes e distribuidores de renome no mercado global.

Ao dotar os compradores internacionais de conhecimentos práticos e considerações estratégicas, este guia permite-lhes navegar pelos meandros dos custos dos alternadores para automóveis. Quer esteja a adquirir peças para uma frota no Brasil ou a gerir cadeias de abastecimento automóvel na Nigéria, a nossa experiência irá melhorar as suas estratégias de compra, conduzindo, em última análise, a melhores resultados financeiros e eficiência operacional.

Índice

- Lista dos 1 principais fabricantes e fornecedores de custo do alternador para automóveis

- Introdução: Navegar no mercado global de custos de alternadores para automóveis

- Compreender o custo do alternador para automóvel Tipos e variações

- Principais aplicações industriais do custo do alternador para automóveis

- 3 Pontos de dor comuns dos utilizadores para ‘custo do alternador do carro’ e respectivas soluções

- Guia de seleção estratégica de materiais para o custo do alternador para automóveis

- Análise aprofundada: Processos de fabrico e garantia de qualidade para o custo do alternador para automóveis

- Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘custo do alternador do carro’

- Análise exaustiva dos custos e dos preços do alternador para automóveis Sourcing

- Análise de alternativas: Comparação do custo do alternador do automóvel com outras soluções

- Caraterísticas técnicas essenciais e terminologia comercial do custo do alternador para automóveis

- Navegar na dinâmica do mercado e nas tendências de abastecimento no sector do custo dos alternadores para automóveis

- Perguntas frequentes (FAQs) para compradores B2B de custo do alternador para automóveis

- Conclusão sobre o aprovisionamento estratégico e perspectivas para o custo do alternador para automóveis

- Aviso legal importante e termos de utilização

Compreender o custo do alternador para automóvel Tipos e variações

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Novos alternadores | Novo, qualidade OEM, normalmente com garantia | Concessionários, serviços de frota, oficinas de reparação topo de gama | Prós: Fiabilidade, especificações OEM, vida útil mais longa. Contras: Custo inicial mais elevado, potenciais problemas de excesso de stock. |

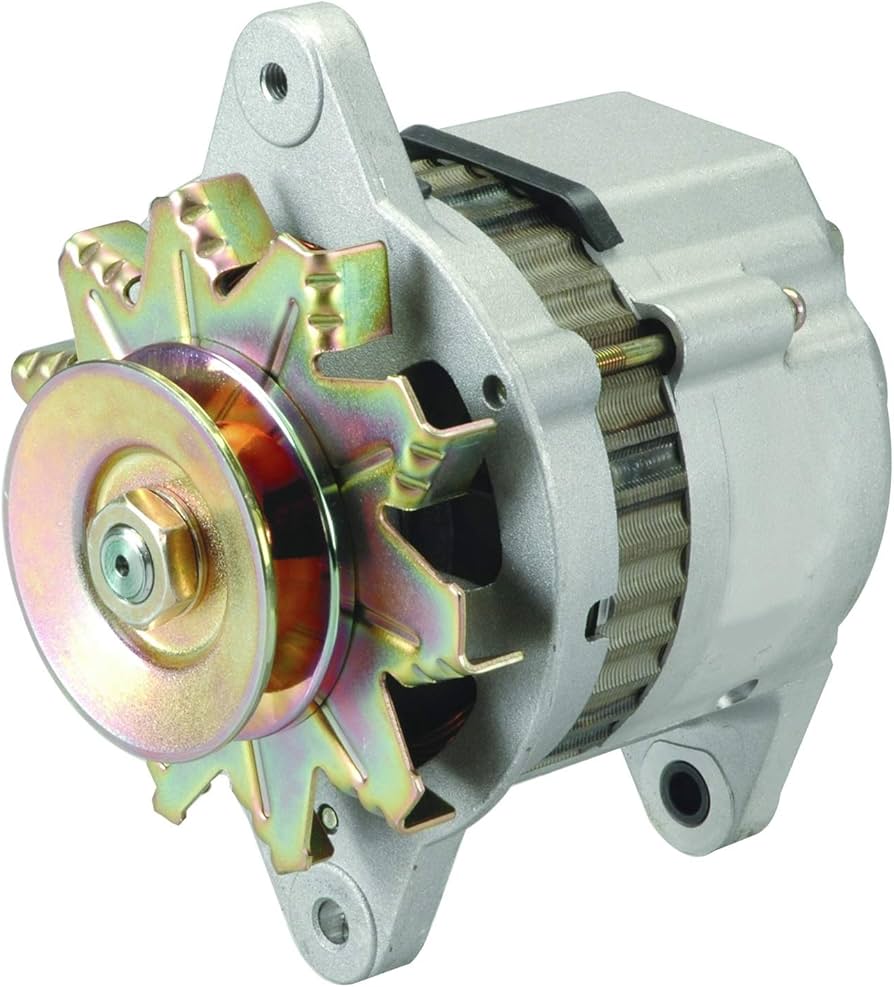

| Alternadores remanufaturados | Reconstruído a partir de núcleos usados, restaurado de acordo com as especificações de fábrica | Oficinas de reparação independentes, compradores preocupados com o orçamento | Prós: Económica e muitas vezes com garantia. Contras: Podem ter um tempo de vida mais curto do que os novos, a qualidade pode variar consoante o fabricante. |

| Alternadores de alto desempenho | Concebida para um elevado rendimento, materiais actualizados para uma maior eficiência | Equipas de corrida, actualizações de veículos de desempenho | Prós: Maior potência de saída, especializada para aplicações de alta demanda. Contras: Custo mais elevado, pode exigir modificações adicionais para se adaptar a veículos de série. |

| Alternadores para trabalhos pesados | Concebido para veículos de maiores dimensões e aplicações exigentes | Frotas comerciais, maquinaria pesada, camiões | Prós: Maior durabilidade, maior amperagem de saída. Contras: Mais pesado, potencialmente mais caro, aplicação limitada a veículos de passageiros normais. |

| Alternadores especiais | Concebidos à medida para modelos de veículos específicos ou aplicações únicas | Restauros de automóveis clássicos, construções personalizadas | Prós: Ajuste à medida, muitas vezes com caraterísticas únicas. Contras: Custo mais elevado, prazos de entrega mais longos, disponibilidade limitada. |

Quais são as principais caraterísticas dos novos alternadores?

Os alternadores novos são fabricados para cumprir ou exceder as especificações OEM, proporcionando fiabilidade e paz de espírito aos compradores B2B. Normalmente, são fornecidos com uma garantia, assegurando a cobertura de quaisquer defeitos de fabrico. Adequados para concessionários e oficinas de reparação topo de gama, estes alternadores são ideais para empresas que dão prioridade à qualidade e à satisfação do cliente. No entanto, o custo inicial mais elevado pode ser uma consideração para os compradores preocupados com o orçamento.

Como é que os alternadores remanufacturados se comparam em termos de custo e qualidade?

Os alternadores refabricados são uma alternativa económica às unidades novas, uma vez que são reconstruídos a partir de núcleos usados e restaurados de acordo com as especificações de fábrica. Esta opção é popular entre as oficinas de reparação independentes e os compradores conscientes do orçamento que procuram manter a qualidade sem gastar muito. Embora sejam frequentemente fornecidos com garantias, a qualidade pode variar consoante o fabricante, pelo que é essencial que os compradores examinem cuidadosamente os fornecedores.

Que vantagens oferecem os alternadores de desempenho?

Os alternadores de desempenho são especificamente concebidos para proporcionar uma maior potência e eficiência, tornando-os adequados para equipas de competição e actualizações de veículos de desempenho. Estes alternadores utilizam materiais melhorados para lidar com maiores exigências eléctricas. Embora ofereçam vantagens significativas em termos de potência, o custo mais elevado e a potencial necessidade de modificações adicionais podem constituir um obstáculo para alguns compradores.

Porquê escolher alternadores para trabalhos pesados para aplicações comerciais?

Os alternadores para trabalhos pesados são construídos para suportar os rigores da utilização comercial, oferecendo uma maior durabilidade e uma saída de amperagem mais elevada. São ideais para frotas comerciais, maquinaria pesada e camiões que requerem energia fiável. Embora ofereçam benefícios essenciais para aplicações exigentes, podem ser mais pesados e mais caros do que os alternadores normais, limitando a sua utilização em veículos de passageiros.

O que é que os compradores devem saber sobre os alternadores especiais?

Os alternadores especiais são concebidos à medida para modelos de veículos específicos ou aplicações únicas, como restauros de automóveis clássicos ou construções personalizadas. Oferecem um ajuste à medida e caraterísticas únicas que melhoram o desempenho. No entanto, o custo é normalmente mais elevado e a disponibilidade pode ser limitada, pelo que é importante que os compradores planeiem com antecedência e se certifiquem de que se abastecem junto de fabricantes reputados.

Principais aplicações industriais do custo do alternador para automóveis

| Indústria/Setor | Aplicação específica do custo do alternador para automóveis | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Substituição de alternadores em veículos | Assegura um funcionamento fiável do veículo, reduzindo o tempo de inatividade e os custos de reparação | Compatibilidade com várias marcas e modelos de veículos, disponibilidade de opções remanufacturadas |

| Gestão de frotas | Aquisição a granel para frotas comerciais | Poupança de custos através da aquisição de volumes, maior fiabilidade dos veículos | Opções de garantia, acordos de serviço e prazos de entrega |

| Agricultura | Fonte de alimentação para equipamento agrícola | Aumenta a eficiência operacional e minimiza as falhas do equipamento | Requisitos de amperagem específicos para o equipamento, com recurso a fornecedores locais para uma resposta rápida |

| Construção | Sistemas eléctricos em máquinas pesadas | Reduz os custos de manutenção e melhora o tempo de funcionamento do equipamento | Durabilidade em condições adversas, especificações adequadas de tensão e amperagem |

| Sistemas de energia renovável | Integração em veículos híbridos ou eléctricos | Apoia práticas sustentáveis, reduz a dependência de combustíveis fósseis | Conformidade com as normas internacionais, desempenho em condições ambientais variáveis |

Como é que o ‘custo do alternador do carro’ é aplicado na reparação automóvel?

Na indústria de reparação automóvel, o custo dos alternadores para automóveis desempenha um papel crucial para garantir que os veículos permanecem operacionais. As oficinas de reparação substituem frequentemente os alternadores para resolver problemas eléctricos, como baterias gastas ou componentes electrónicos defeituosos. Ao adquirir alternadores que se adaptam a marcas e modelos de veículos específicos, as empresas de reparação podem garantir a fiabilidade e a satisfação do cliente. Para os compradores internacionais, particularmente em regiões como África e América do Sul, compreender as especificações locais dos veículos e a disponibilidade de opções remanufacturadas pode levar a poupanças de custos significativas.

Qual o valor do custo do alternador para a gestão de frotas?

As empresas de gestão de frotas enfrentam frequentemente o desafio de manter um grande número de veículos. O custo dos alternadores para automóveis torna-se um fator crítico quando se fazem compras em grandes quantidades para a manutenção dos veículos. Ao adquirir alternadores em grandes quantidades, os gestores de frotas podem beneficiar de preços reduzidos e garantir que os seus veículos têm menos probabilidades de sofrer falhas eléctricas. Os compradores internacionais devem considerar as opções de garantia e os acordos de serviço, bem como a logística de entrega atempada para minimizar o tempo de inatividade do veículo.

Qual é a relevância do custo do alternador para a agricultura?

No sector agrícola, a fiabilidade dos equipamentos é fundamental para a produtividade. O custo dos alternadores para automóveis é essencial para alimentar as máquinas agrícolas, assegurando o bom funcionamento das operações. Os agricultores beneficiam do fornecimento de alternadores que satisfazem requisitos de amperagem específicos adaptados ao seu equipamento. Para os compradores em regiões como a Nigéria e o Brasil, o fornecimento local pode proporcionar tempos de resposta mais rápidos e reduzir o risco de falha do equipamento durante períodos agrícolas críticos.

Porque é que o custo do alternador do automóvel é importante na construção?

A indústria da construção depende fortemente de maquinaria pesada que requer uma fonte de alimentação consistente. O custo dos alternadores para automóveis tem um impacto direto na eficiência operacional destas máquinas. A aquisição de alternadores de alta qualidade garante que o equipamento se mantém funcional e minimiza o risco de paragens dispendiosas. Os compradores têm de prestar atenção à durabilidade e às especificações que respondem às duras condições de trabalho, especialmente no Médio Oriente, onde as temperaturas extremas podem afetar o desempenho.

Qual é o impacto do custo do alternador do automóvel nos sistemas de energia renovável?

No domínio crescente das energias renováveis, em particular com os veículos híbridos e eléctricos, o custo dos alternadores para automóveis é crucial para a integração de sistemas de energia eficientes. Estes sistemas requerem alternadores que possam apoiar práticas sustentáveis e reduzir a dependência das fontes de energia tradicionais. Os compradores internacionais devem assegurar-se de que os alternadores que selecionam cumprem as normas internacionais e podem funcionar eficazmente em condições ambientais variáveis, promovendo assim a adoção de tecnologias ecológicas.

3 Pontos de dor comuns dos utilizadores para ‘custo do alternador do carro’ e respectivas soluções

Cenário 1: Compreender o custo real dos alternadores para diferentes modelos de veículos

O problema: Os compradores B2B têm frequentemente dificuldade em compreender a vasta gama de preços dos alternadores, que pode variar significativamente consoante a marca, o modelo e o ano do veículo. Por exemplo, um alternador para um veículo de luxo pode custar substancialmente mais do que um para um sedan normal, devido à complexidade e aos requisitos específicos do sistema elétrico. Esta discrepância pode levar a problemas orçamentais e a despesas inesperadas, complicando as estratégias de aquisição, especialmente para as empresas que dependem de uma frota de diversos veículos.

A solução: Para navegar eficazmente por estas complexidades, os compradores devem investir tempo a compreender as especificações necessárias para cada modelo de veículo da sua frota. Isto inclui conhecer a amperagem, os requisitos de tensão e o tipo de alternador (novo ou remanufacturado). É crucial estabelecer relações com fornecedores fiáveis que possam fornecer informações detalhadas sobre os produtos e preços competitivos. A utilização de plataformas que ofereçam ferramentas de comparação também pode ajudar a identificar as melhores ofertas, assegurando o ajuste correto para cada veículo. Além disso, a implementação de um sistema de gestão de inventário centralizado pode ajudar a rastrear os alternadores necessários para vários modelos, ajudando as empresas a prever os custos com maior exatidão.

Cenário 2: Equilíbrio entre qualidade e custo na compra de alternadores

O problema: Outra questão comum enfrentada pelos compradores B2B é o compromisso entre o custo e a qualidade quando adquirem alternadores. Embora possa ser tentador optar pela opção mais económica, as peças de qualidade inferior podem levar a custos mais elevados a longo prazo devido a falhas frequentes e à necessidade de substituições. Isto é particularmente problemático para as empresas com orçamentos operacionais apertados, onde o custo do tempo de inatividade pode ter um impacto significativo na rentabilidade.

A solução: Para equilibrar qualidade e custo de forma eficaz, os compradores devem dar prioridade ao fornecimento de alternadores de fabricantes que ofereçam garantias e tenham uma reputação de fiabilidade. Investir em alternadores de maior qualidade pode resultar em custos iniciais mais elevados, mas pode poupar dinheiro a longo prazo, reduzindo a frequência das substituições e os custos de mão de obra associados. A realização de uma pesquisa exaustiva sobre os fornecedores e a análise do feedback dos clientes também podem fornecer informações sobre a durabilidade e o desempenho de diferentes alternadores. Estabelecer uma relação com grossistas de renome que ofereçam descontos em compras a granel pode aumentar ainda mais a eficiência dos custos, garantindo simultaneamente a qualidade.

Cenário 3: Gerir o impacto das taxas de base nos custos dos alternadores

O problema: Os encargos principais podem ser um ponto de dificuldade significativo para os compradores B2B aquando da substituição de alternadores. Muitos fornecedores exigem uma taxa de base - uma taxa adicional que é reembolsada aquando da devolução do alternador antigo - o que pode complicar a gestão do orçamento e do fluxo de caixa. Esta despesa inesperada pode não ser inicialmente considerada no custo total da substituição, levando a problemas de fluxo de caixa para empresas que operam com margens apertadas.

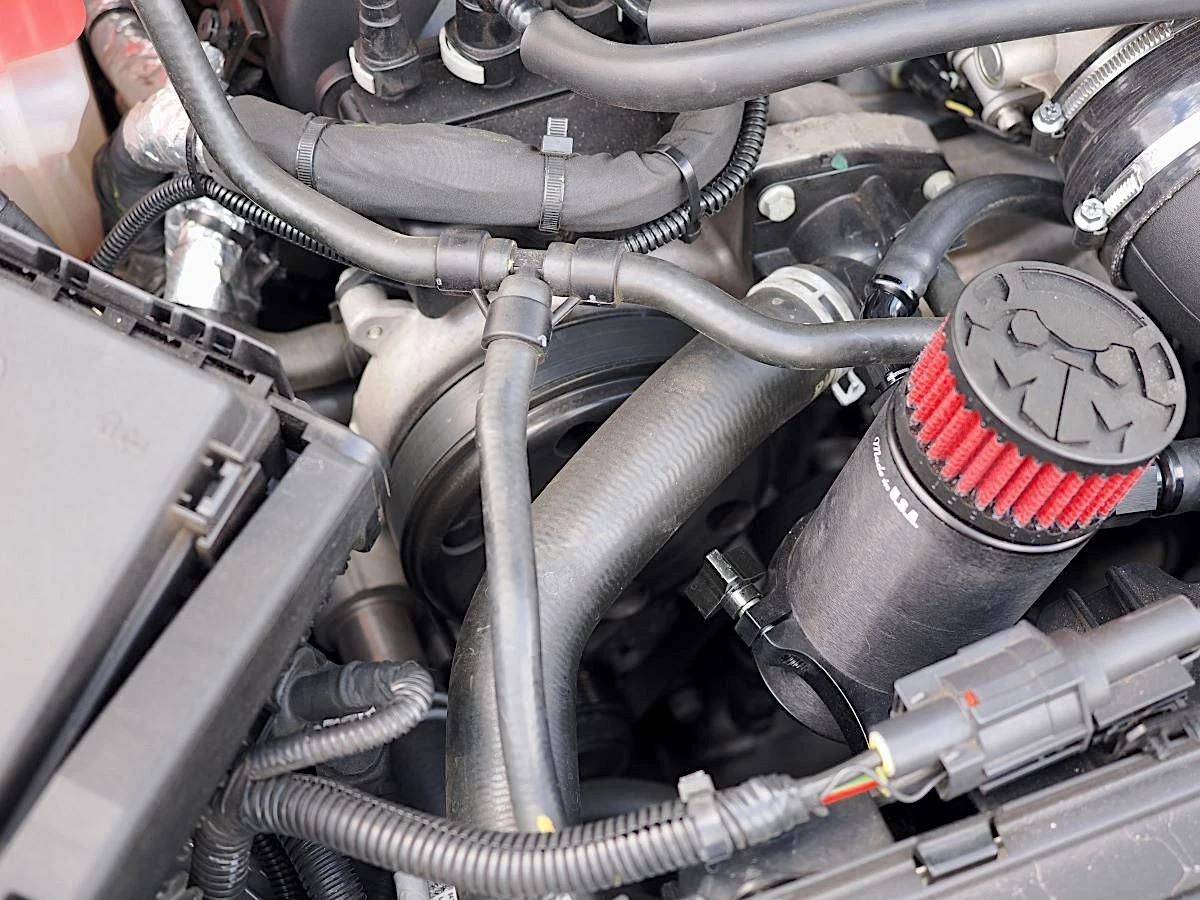

Imagem ilustrativa relacionada com o custo do alternador do automóvel

A solução: Para mitigar a pressão financeira causada pelos encargos de base, as empresas devem desenvolver uma abordagem sistemática para devolver prontamente os alternadores antigos. Isto inclui manter um registo de todos os encargos de núcleo aplicados durante as compras e assegurar que as unidades antigas são devolvidas dentro do prazo especificado para se qualificarem para reembolsos. Os compradores também podem negociar com os fornecedores para ver se podem renunciar aos encargos do núcleo para compras de grande volume ou estabelecer um programa de troca de núcleo. Informar as equipas de compras sobre estes encargos ajudá-las-á a integrá-los no seu processo de orçamentação geral, reduzindo as hipóteses de surpresas financeiras ao adquirir novos alternadores.

Guia de seleção estratégica de materiais para o custo do alternador para automóveis

Que materiais são habitualmente utilizados nos alternadores para automóveis e qual o seu impacto no custo?

Ao selecionar materiais para alternadores de automóveis, devem ser considerados vários componentes-chave, incluindo cobre, alumínio, aço e plástico. Cada material tem propriedades únicas que influenciam o desempenho, a durabilidade e o custo, tornando-os cruciais para os compradores B2B nos mercados internacionais.

Como é que o cobre afecta o desempenho e o custo do alternador do automóvel?

O cobre é amplamente utilizado em alternadores de automóveis, principalmente pela sua excelente condutividade eléctrica e propriedades térmicas. Tem um ponto de fusão elevado de aproximadamente 1.984°F (1.085°C) e mantém o desempenho em várias condições de temperatura, o que o torna adequado para aplicações automóveis.

Prós: A condutividade superior do cobre assegura uma transferência de energia eficiente, o que é fundamental para o desempenho do alternador. É também altamente durável e resistente à corrosão, prolongando a vida útil do alternador.

Contras: A principal desvantagem do cobre é o seu custo; é um dos materiais mais caros utilizados nos alternadores. Além disso, o processo de fabrico pode ser complexo, exigindo uma engenharia precisa para garantir um desempenho ótimo.

Impacto na aplicação: A compatibilidade do cobre com altas temperaturas e cargas eléctricas torna-o ideal para alternadores, que devem funcionar de forma fiável sob o stress dos ambientes automóveis.

Considerações para compradores internacionais: Os compradores de regiões como África e América do Sul devem estar cientes da flutuação dos preços do cobre e de potenciais problemas na cadeia de abastecimento. O cumprimento de normas internacionais como a ASTM para a qualidade do material é essencial para garantir a fiabilidade.

Qual é o papel do alumínio na fabricação de alternadores?

O alumínio é outro material comummente utilizado nos alternadores para automóveis, particularmente para as caixas e invólucros, devido à sua natureza leve e resistência à corrosão. Normalmente, suporta temperaturas até cerca de 660°C (1.220°F).

Imagem ilustrativa relacionada com o custo do alternador do automóvel

Prós: O alumínio é significativamente mais leve do que o cobre, o que pode contribuir para a redução global do peso do veículo. É também mais económico do que o cobre, o que o torna uma opção atractiva para os fabricantes que procuram reduzir os custos de produção.

Contras: Embora o alumínio seja resistente à corrosão, não é tão condutor como o cobre, o que pode afetar a eficiência do alternador. Além disso, o alumínio pode necessitar de tratamentos adicionais para aumentar a sua durabilidade.

Impacto na aplicação: A natureza leve do alumínio pode melhorar a eficiência do combustível nos veículos, tornando-o uma escolha popular para os designs automóveis modernos.

Considerações para compradores internacionais: Os compradores devem considerar as capacidades locais de fabrico de componentes de alumínio e garantir a conformidade com as normas relevantes, como a DIN na Europa, para manter a qualidade.

Imagem ilustrativa relacionada com o custo do alternador do automóvel

Porque é que o aço é utilizado em determinados componentes do alternador?

O aço é frequentemente utilizado na produção de estruturas de alternadores e suportes de montagem devido à sua resistência e durabilidade. O aço pode suportar tensões mecânicas significativas, o que é essencial para a integridade estrutural do alternador.

Prós: A elevada resistência à tração do aço torna-o ideal para componentes que requerem robustez. É também relativamente barato em comparação com o cobre e o alumínio, o que pode reduzir os custos globais de produção.

Contras: O aço é mais pesado do que o cobre e o alumínio, o que pode contribuir para aumentar o peso do veículo. Além disso, é suscetível à ferrugem e à corrosão se não for devidamente tratado.

Impacto na aplicação: Os componentes de aço são os mais adequados para as partes do alternador que não requerem condutividade eléctrica, mas que têm de suportar tensões físicas.

Considerações para compradores internacionais: Os compradores devem assegurar-se de que os componentes de aço cumprem as normas internacionais de qualidade e resistência à corrosão, especialmente em regiões com elevada humidade ou exposição ao sal.

Como é que o plástico é considerado no design do alternador?

O plástico é cada vez mais utilizado nos alternadores para componentes não estruturais, tais como coberturas e isoladores, devido às suas propriedades de leveza e isolamento.

Prós: O plástico é leve, o que ajuda a reduzir o peso total do alternador. Também é resistente à corrosão e pode ser moldado em formas complexas, permitindo designs versáteis.

Contras: Embora o plástico seja económico, pode não suportar temperaturas elevadas tão bem como os metais, o que pode levar a problemas de desempenho em condições extremas.

Impacto na aplicação: Os componentes de plástico são adequados para peças que não requerem elevada resistência ou condutividade, servindo principalmente como elementos de proteção ou isolamento.

Imagem ilustrativa relacionada com o custo do alternador do automóvel

Considerações para compradores internacionais: Os compradores devem avaliar a qualidade dos materiais plásticos utilizados e garantir que cumprem as normas internacionais para evitar problemas relacionados com a durabilidade e o desempenho.

Quadro resumo da seleção de materiais para alternadores de automóveis

| Material | Caso de utilização típico para o custo do alternador do automóvel | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Enrolamentos e ligações elétricas | Excelente condutividade | Custo elevado e fabrico complexo | Alto |

| Alumínio | Carcaças e invólucros | Leve e económico | Condutividade inferior à do cobre | Médio |

| Aço | Molduras e suportes de fixação | Alta resistência e durabilidade | Mais pesado e suscetível à ferrugem | Baixo |

| Plástico | Coberturas e isoladores | Leve e resistente à corrosão | Tolerância limitada a altas temperaturas | Baixo |

Esta análise da seleção de materiais fornece aos compradores B2B informações críticas sobre a forma como os diferentes materiais afectam o custo e o desempenho dos alternadores para automóveis, permitindo decisões de compra informadas e adaptadas às necessidades regionais específicas.

Análise aprofundada: Processos de fabrico e garantia de qualidade para o custo do alternador para automóveis

Quais são as principais fases do processo de fabrico dos alternadores para automóveis?

O fabrico de alternadores para automóveis envolve várias fases críticas, cada uma concebida para garantir que o produto final cumpre as especificações exigidas em termos de desempenho e durabilidade. A compreensão destas fases pode ajudar os compradores B2B a avaliar a qualidade e a fiabilidade dos alternadores que estão a considerar para aquisição.

1. Preparação do material

A primeira fase do processo de fabrico é a preparação dos materiais. Os materiais de alta qualidade são essenciais para produzir alternadores eficientes e duradouros. Os principais componentes incluem:

- Enrolamentos de cobre: O cobre é o material preferido para os enrolamentos devido à sua excelente condutividade. Os fabricantes normalmente utilizam cobre de alta pureza para minimizar a resistência e melhorar o desempenho.

- Aço magnético: Utilizado para o rotor e o estator, o aço magnético é crucial para o eletromagnetismo necessário à produção de eletricidade.

- Materiais da habitação: As caixas do alternador são frequentemente fabricadas em alumínio ou plástico de alta resistência, que são leves mas duradouros.

Antes da produção, os materiais são submetidos a rigorosos controlos de qualidade para verificar as suas especificações e garantir a conformidade com as normas da indústria. Isto pode incluir testes de condutividade eléctrica, resistência à tração e resistência à corrosão.

Imagem ilustrativa relacionada com o custo do alternador do automóvel

2. Processos de conformação

Após a preparação do material, a etapa seguinte consiste em moldar os diferentes componentes do alternador. Isto inclui:

- Fabrico de estator e rotor: O estator e o rotor são normalmente criados através de processos como a estampagem ou a maquinagem. A precisão é fundamental aqui, uma vez que o alinhamento destes componentes tem um impacto direto na eficiência do alternador.

- Enrolar as bobinas: O fio de cobre é enrolado à volta do estator num padrão específico para criar o campo magnético necessário para a produção de energia. São frequentemente utilizadas máquinas de enrolamento automatizadas para garantir a consistência e a precisão.

Estes processos requerem maquinaria avançada e técnicos qualificados para manter uma elevada precisão durante todo o processo.

3. Montagem

Uma vez preparados os componentes individuais, estes são montados na unidade final do alternador. O processo de montagem pode incluir:

- Junção do estator e do rotor: Isto é muitas vezes feito utilizando dispositivos especializados para garantir um alinhamento correto e um ajuste seguro.

- Instalação de ligações eléctricas: Isto envolve a ligação dos enrolamentos ao retificador e ao regulador de tensão, componentes críticos que convertem e regulam a tensão de saída.

- Montagem da caixa: Os componentes montados são encerrados na caixa, que é selada para proteger contra factores ambientais.

A qualidade durante a montagem é crucial; qualquer desalinhamento ou ligações deficientes pode levar a problemas de desempenho.

4. Acabamento

A fase final do fabrico envolve processos de acabamento que melhoram a durabilidade e o desempenho do alternador. Isto pode incluir:

- Revestimento e pintura: Os revestimentos de proteção são aplicados para evitar a corrosão e o desgaste, especialmente nos componentes expostos a condições adversas.

- Inspeção da montagem final: Cada alternador é submetido a uma inspeção minuciosa para verificar a existência de defeitos, a montagem correta e a funcionalidade.

Como é implementada a garantia de qualidade no fabrico de alternadores para automóveis?

A garantia de qualidade (GQ) é um aspeto crítico do processo de fabrico, assegurando que os alternadores cumprem as normas internacionais e as expectativas dos clientes. Os principais elementos da GQ incluem:

Normas internacionais relevantes

Os compradores B2B devem estar cientes das normas internacionais que regem a qualidade dos componentes automóveis:

- ISO 9001: Esta norma define uma estrutura para os sistemas de gestão da qualidade, dando ênfase à melhoria contínua e à satisfação do cliente.

- Marcação CE: Na Europa, a marcação CE indica que um produto está em conformidade com as normas de saúde, segurança e proteção ambiental.

- Padrões API: Para os alternadores utilizados em aplicações específicas, a adesão às normas API (American Petroleum Institute) pode também ser relevante.

A compreensão destas normas ajuda os compradores a garantir que os seus fornecedores mantêm um compromisso com a qualidade.

Imagem ilustrativa relacionada com o custo do alternador do automóvel

Pontos de verificação do controlo de qualidade

Ao longo do processo de fabrico, são estabelecidos vários pontos de controlo de qualidade (CQ):

- Controlo de Qualidade de Entrada (IQC): Isto implica a inspeção de matérias-primas e componentes à chegada para garantir que cumprem as normas especificadas.

- Controlo de qualidade em processo (IPQC): Durante o fabrico, são efectuados controlos periódicos para monitorizar os processos e detetar quaisquer desvios às normas de qualidade.

- Controlo de Qualidade Final (FQC): Antes de os produtos serem expedidos, é efectuada uma inspeção final abrangente para garantir que cada alternador cumpre as especificações de desempenho.

Que métodos de teste comuns são utilizados para garantir a qualidade do alternador?

Para verificar a qualidade e o desempenho dos alternadores para automóveis, os fabricantes utilizam vários métodos de ensaio, incluindo:

- Testes elétricos: Isto inclui a verificação da tensão de saída e da corrente em condições de carga para garantir que o alternador funciona dentro dos intervalos especificados.

- Testes térmicos: A avaliação do desempenho do alternador a altas temperaturas ajuda a determinar a sua fiabilidade em condições reais.

- Testes mecânicos: Isto pode incluir ensaios de vibração para avaliar a durabilidade dos componentes do alternador sob tensão.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

Para os compradores B2B internacionais, especialmente os de regiões como África, América do Sul, Médio Oriente e Europa, é essencial verificar as práticas de controlo de qualidade de um fornecedor. Aqui estão algumas estratégias:

- Auditorias a fornecedores: A realização de auditorias no local a potenciais fornecedores permite aos compradores avaliar diretamente os seus processos de fabrico e as medidas de garantia de qualidade. Este facto pode revelar as verdadeiras capacidades de um fornecedor.

- Pedido de relatórios de qualidade: Os compradores podem solicitar relatórios de qualidade pormenorizados que descrevem os resultados de vários métodos de ensaio e inspecções.

- Inspeções por terceiros: A contratação de serviços de inspeção por terceiros pode fornecer uma avaliação imparcial dos processos de controlo de qualidade do fornecedor e da fiabilidade do produto.

Quais são as nuances do controlo de qualidade para compradores B2B internacionais?

Os compradores internacionais devem navegar por nuances específicas relativas ao controlo de qualidade que podem variar consoante a região:

- Conformidade regulamentar: Diferentes países têm diferentes requisitos regulamentares, que podem afetar a conceção e o ensaio dos alternadores. Compreender estes regulamentos é crucial para a conformidade.

- Considerações culturais: Os estilos de comunicação e as práticas comerciais podem diferir significativamente. Estabelecer expectativas e processos de qualidade claros é vital para evitar mal-entendidos.

- Questões relacionadas com a logística e a cadeia de abastecimento: Os compradores devem considerar a logística do transporte de alternadores, uma vez que a qualidade pode ser comprometida durante o transporte. Assegurar condições adequadas de manuseamento e armazenamento pode reduzir os riscos.

Ao compreender os processos de fabrico e as medidas de garantia de qualidade associadas aos alternadores para automóveis, os compradores B2B podem tomar decisões informadas que garantam a aquisição de produtos de alta qualidade que satisfaçam as suas necessidades operacionais.

Imagem ilustrativa relacionada com o custo do alternador do automóvel

Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘custo do alternador do carro’

Introdução

No panorama competitivo da aquisição de peças para automóveis, compreender os factores de custo e as estratégias de fornecimento de alternadores para automóveis é crucial para os compradores B2B. Este guia fornece uma lista de verificação passo-a-passo para garantir que toma decisões de compra informadas que se alinham com as necessidades e orçamentos da sua empresa.

Passo 1: Defina as suas especificações técnicas

Especificações exactas são essenciais para selecionar o alternador certo para a sua frota de veículos. Considere o ano, a marca, o modelo e o tamanho do motor dos veículos no seu inventário. Além disso, avalie a amperagem necessária com base nas exigências eléctricas dos seus veículos. Este passo é vital para evitar problemas de compatibilidade e garantir um desempenho ótimo.

Passo 2: Pesquisar preços de mercado

Compreender a gama de preços de mercado dos alternadores ajudá-lo-á a negociar eficazmente com os fornecedores. Geralmente, o custo pode variar entre $100 e $1.000, dependendo de factores como a marca, o tipo (novo ou remanufacturado) e os termos da garantia. Ao recolher dados de preços de várias fontes, pode identificar ofertas competitivas e definir um orçamento razoável.

Passo 3: Avalie potenciais fornecedores

Antes de se comprometer com um fornecedor, é essencial efetuar uma verificação minuciosa. Solicite perfis de empresas, estudos de caso e referências de outros compradores em sectores ou regiões semelhantes. Procure fornecedores com um historial comprovado no sector das peças para automóveis, especialmente no que diz respeito aos alternadores, para garantir fiabilidade e qualidade.

Passo 4: Verificar as normas de qualidade e conformidade

A garantia de qualidade é fundamental quando se adquire alternadores. Certifique-se de que os potenciais fornecedores cumprem as normas e certificações internacionais, como a ISO ou a TS16949. Isto não só garante a qualidade do produto, como também minimiza o risco de devoluções e reparações dispendiosas devido a peças defeituosas.

Passo 5: Avaliar a garantia e o apoio pós-venda

As garantias podem influenciar significativamente o custo total de propriedade. Compare os períodos de garantia oferecidos por diferentes fornecedores e considere o âmbito da cobertura. Além disso, informe-se sobre o apoio pós-venda, uma vez que uma equipa de apoio recetiva pode ajudar na resolução de problemas que possam surgir após a compra.

Passo 6: Compreender os custos de envio e de importação

Tenha em conta o transporte e os direitos de importação ao calcular o custo total da aquisição. Diferentes fornecedores podem ter diferentes políticas e custos de envio, especialmente se estiver a importar de mercados internacionais. Esteja atento a eventuais atrasos nos prazos de expedição, que podem afetar os seus níveis de inventário e a eficiência operacional.

Passo 7: Negociar as condições e finalizar a compra

Depois de reunir todas as informações necessárias, entre em negociações com o fornecedor escolhido. Discuta as condições de pagamento, os prazos de entrega e quaisquer descontos para compras em massa que possam estar disponíveis. Uma comunicação clara durante esta fase é crucial para garantir um acordo favorável que satisfaça os seus objectivos comerciais.

Seguindo estes passos, os compradores B2B podem navegar eficazmente pelas complexidades do aprovisionamento de alternadores para automóveis, assegurando que tomam decisões informadas que beneficiam as suas operações e resultados.

Análise exaustiva dos custos e dos preços do alternador para automóveis Sourcing

Quais são os principais componentes de custo na produção de alternadores para automóveis?

A compreensão da estrutura de custos dos alternadores para automóveis é crucial para os compradores B2B que procuram obter estes componentes de forma eficaz. Os principais componentes de custo incluem:

-

Materiais: Os materiais de alta qualidade, como o cobre para os enrolamentos, o alumínio para as caixas e vários componentes eléctricos, representam uma parte significativa do custo. A escolha dos materiais influencia diretamente o desempenho e a durabilidade, afectando o valor a longo prazo.

-

Trabalho: Os custos de mão de obra podem variar significativamente consoante o local de produção. As regiões com custos de mão de obra mais baixos podem oferecer preços mais competitivos, mas é essencial equilibrar este aspeto com a qualidade e a fiabilidade.

-

Custos indiretos de produção: Inclui as despesas relacionadas com as operações da fábrica, os serviços públicos e a manutenção. Processos de fabrico eficientes podem ajudar a reduzir as despesas gerais, com impacto no preço final.

-

Ferramentas: As ferramentas e os moldes especializados necessários para a produção de alternadores podem implicar investimentos iniciais elevados. No entanto, estes custos são amortizados ao longo do volume de produção, o que torna vantajoso para os compradores considerarem contratos a longo prazo.

-

Controlo de Qualidade (QC): Processos rigorosos de controlo de qualidade garantem que os alternadores cumprem as normas de segurança e desempenho. Embora isto possa aumentar os custos iniciais, ajuda a minimizar as falhas e os pedidos de garantia, contribuindo para a eficiência global dos custos.

-

Logística: Os custos de transporte, especialmente para envios internacionais, podem afetar significativamente os preços. Factores como a distância, o método de envio e os direitos aduaneiros devem ser tidos em conta no custo total.

-

Margem: As margens dos fornecedores variam consoante as condições de mercado e a concorrência. A compreensão destas margens pode ajudar nas negociações e ajudar os compradores a identificar o melhor valor.

Como é que os influenciadores de preços afectam os custos do alternador para automóvel?

Vários factores podem influenciar o preço dos alternadores para automóveis, que os compradores devem ter em conta:

-

Volume/MOQ (Quantidade mínima de encomenda): As compras em grande quantidade conduzem frequentemente a descontos nos preços. Os fornecedores podem oferecer melhores preços para encomendas maiores, o que torna vantajoso para os compradores consolidar as suas necessidades.

-

Especificações e personalização: Os alternadores personalizados, adaptados às necessidades específicas de cada veículo, podem implicar custos adicionais. Os compradores devem avaliar se as vantagens da personalização compensam os custos.

-

Qualidade dos materiais e certificações: Os materiais e as certificações de maior qualidade (como as normas ISO ou específicas da indústria) implicam normalmente preços mais elevados, mas podem conduzir a uma maior fiabilidade e desempenho.

-

Fatores relacionados ao fornecedor: A reputação do fornecedor, as suas capacidades de produção e a sua localização geográfica podem influenciar os preços. A contratação de fornecedores de renome pode garantir a qualidade, mas pode ter um preço mais elevado.

-

Incoterms: Compreender os Incoterms (Termos Comerciais Internacionais) é vital para as transacções internacionais. Estes ditam as responsabilidades dos compradores e dos vendedores em matéria de transporte, seguro e tarifas, afectando o custo global.

Que dicas podem ajudar os compradores a negociar melhores preços para os alternadores de automóveis?

Para otimizar as estratégias de aquisição e garantir uma boa relação custo-eficácia, considere as seguintes sugestões:

-

Negociar termos: Estabelecer uma boa relação com os fornecedores pode facilitar a obtenção de melhores preços e condições. Não hesite em negociar descontos por volume, condições de pagamento e prazos de entrega.

-

Avalie o custo total de propriedade (TCO): Considere não só o preço de compra, mas também os custos de instalação, manutenção e eventual substituição ao longo da vida útil do alternador. Um custo inicial mais elevado pode resultar em despesas globais mais baixas se durar mais tempo e tiver um melhor desempenho.

-

Compreenda as nuances dos preços nos mercados internacionais: Ao abastecer-se em diversas regiões como África, América do Sul, Médio Oriente e Europa, tenha em atenção as condições do mercado local, as flutuações cambiais e os regulamentos comerciais que podem afetar os preços.

-

Pesquisar e comparar fornecedores: Efectue uma pesquisa de mercado exaustiva para comparar as ofertas de vários fornecedores. A avaliação de vários orçamentos pode ajudar a identificar o melhor valor para as suas necessidades.

-

Atenção aos preços indicativos: Os preços podem flutuar com base na procura do mercado, nos custos dos materiais e em factores geopolíticos. É crucial procurar preços indicativos, mas manter a flexibilidade nas negociações para se adaptar às mudanças do mercado.

Ao tirar partido destas informações, os compradores B2B podem tomar decisões informadas, optimizando as suas estratégias de abastecimento de alternadores para automóveis, garantindo simultaneamente valor e fiabilidade.

Análise de alternativas: Comparação do custo do alternador do automóvel com outras soluções

Compreender as soluções alternativas para os custos do alternador do automóvel

Na indústria automóvel, compreender os custos associados aos alternadores para automóveis é crucial para os compradores B2B, especialmente quando se consideram alternativas. Embora os alternadores tradicionais proporcionem uma produção de energia fiável para os veículos, existem soluções alternativas que podem oferecer diferentes benefícios, dependendo das necessidades específicas de uma empresa. Esta análise fornece uma comparação dos alternadores para automóveis em relação a duas alternativas viáveis: sistemas de bateria e unidades de energia híbridas.

| Aspecto comparativo | Custo do alternador para automóvel | Sistema de bateria | Unidade de potência híbrida |

|---|---|---|---|

| Desempenho | Saída de 13,5-14,5 volts, fiável para veículos normais | Limitado pela capacidade da bateria, necessita de ser carregado | Combina motor e energia eléctrica, eficiente |

| Custo | $100 - $1.000 (novo) | $200 - $800 (depende da capacidade) | $1,500 - $5,000 (investimento inicial) |

| Facilidade de implementação | Moderado; requer conhecimentos técnicos para a instalação | Fácil para configurações simples; complexo para sistemas maiores | Complexo; requer instalação e manutenção especializadas |

| Manutenção | Moderado; controlos regulares e eventuais substituições | Baixo; as pilhas precisam de ser substituídas periodicamente | Elevado; requer manutenção do motor e do sistema elétrico |

| Melhor caso de uso | Veículos standard que requerem uma potência constante | Aplicações fora da rede, veículos eléctricos | Veículos ecológicos, deslocações urbanas |

Discriminação detalhada das alternativas

Sistema de bateria

Os sistemas de baterias funcionam como uma alternativa aos alternadores tradicionais, fornecendo uma fonte de energia eléctrica. São particularmente úteis em cenários em que o veículo está fora da rede ou funciona em modos exclusivamente eléctricos. A principal vantagem dos sistemas de bateria reside na sua capacidade de armazenar energia, o que os torna essenciais para os veículos eléctricos (VE) e modelos híbridos. No entanto, o desempenho dos sistemas de baterias depende dos níveis de carga e podem exigir recargas frequentes, o que pode ser uma desvantagem em cenários de utilização contínua. Além disso, embora os custos iniciais possam ser inferiores aos de uma configuração de alternador, o investimento a longo prazo na substituição de baterias pode acumular-se.

Unidade de potência híbrida

As unidades de potência híbridas representam uma solução mais avançada que combina um motor de combustão tradicional com um motor elétrico. Esta tecnologia permite uma distribuição de potência mais eficiente, reduzindo o consumo de combustível e as emissões. O investimento inicial nos sistemas híbridos é significativamente mais elevado em comparação com os alternadores normais, devido à complexidade da tecnologia e à necessidade de uma instalação especializada. No entanto, proporcionam um desempenho superior em termos de eficiência de combustível e impacto ambiental reduzido, o que os torna ideais para empresas orientadas para a sustentabilidade. A manutenção dos sistemas híbridos pode ser mais exigente, uma vez que requer conhecimentos especializados em sistemas eléctricos e mecânicos.

Conclusão: Escolher a solução de energia correta para as suas necessidades

Ao selecionar a solução de energia certa para as suas necessidades automóveis, os compradores B2B devem considerar vários factores, como os requisitos de desempenho, a relação custo-eficácia, a facilidade de implementação e a manutenção. Os alternadores para automóveis continuam a ser uma escolha fiável para veículos de série, mas as empresas que procuram soluções inovadoras podem beneficiar da exploração de sistemas de bateria ou unidades de energia híbrida. Compreender o caso de utilização específico e os objectivos operacionais a longo prazo ajudará a tomar uma decisão informada que se alinhe tanto com o orçamento como com as expectativas de desempenho. Ao avaliar estas alternativas, os compradores podem investir estrategicamente na tecnologia de produção de energia mais adequada para as suas frotas ou operações.

Caraterísticas técnicas essenciais e terminologia comercial do custo do alternador para automóveis

Quais são as principais propriedades técnicas dos alternadores para automóveis que afectam o custo?

Ao avaliar o custo dos alternadores para automóveis, várias especificações técnicas são fundamentais para determinar o desempenho e o preço. A compreensão destas propriedades pode ajudar os compradores B2B a tomar decisões informadas.

1. Classificação da amperagem

A classificação de amperagem indica a corrente eléctrica máxima que o alternador pode produzir. As classificações comuns variam entre 70 e mais de 200 amperes. Os alternadores de amperagem mais elevada são normalmente necessários para veículos com sistemas eléctricos extensos, como os equipados com sistemas avançados de infoentretenimento, múltiplos acessórios de potência ou componentes híbridos/eléctricos. Esta classificação influencia diretamente o custo; uma maior potência equivale geralmente a um preço mais elevado devido ao aumento das complexidades de material e de fabrico envolvidas.

Imagem ilustrativa relacionada com o custo do alternador do automóvel

2. Saída de tensão

A maioria dos alternadores para automóveis funciona com uma gama de tensão de 12 a 14,5 volts. Esta especificação é crucial para garantir o bom funcionamento do sistema elétrico. Se um alternador produzir uma tensão demasiado baixa ou demasiado alta, pode provocar danos na bateria ou avarias nos componentes eléctricos. A precisão desta regulação da tensão pode afetar os custos de fabrico e, em última análise, a estrutura de preços do alternador.

3. Estilo de montagem

O estilo de montagem determina como o alternador se encaixa no compartimento do motor de um veículo. Diferentes marcas e modelos podem exigir configurações de montagem únicas, o que afecta a conceção do alternador e os custos de produção. Os compradores B2B devem garantir a compatibilidade com os modelos específicos dos seus veículos para evitar custos adicionais com devoluções ou substituições.

4. Composição dos materiais

Os materiais utilizados na construção do alternador, particularmente os enrolamentos de cobre e os ímanes, têm um impacto significativo no desempenho e no custo. Os materiais de qualidade superior proporcionam uma melhor condutividade e durabilidade, o que pode aumentar o tempo de vida do alternador. Nos mercados onde os preços são competitivos, optar por materiais de qualidade inferior pode reduzir os custos, mas pode levar a um aumento das taxas de avaria e dos pedidos de garantia.

Imagem ilustrativa relacionada com o custo do alternador do automóvel

5. Condições de garantia

A cobertura da garantia varia muito entre fabricantes e pode influenciar as decisões de compra. Um período de garantia mais longo, como uma garantia vitalícia, sugere normalmente uma maior qualidade e fiabilidade, mas pode ter um preço inicial mais elevado. Os compradores devem considerar o custo total de propriedade, incluindo potenciais custos de substituição, ao avaliarem as opções de garantia.

Que termos comerciais são essenciais para compreender os custos do alternador para automóvel?

Compreender a terminologia do sector é crucial para uma comunicação e negociação eficazes no mercado B2B. Aqui estão alguns termos comerciais comuns relevantes para os alternadores de automóveis.

1. OEM (Fabricante de Equipamento Original)

As peças OEM são as produzidas pelo fabricante original do veículo. São concebidas para cumprir normas específicas do veículo e têm frequentemente um preço superior. Os compradores podem optar por alternadores OEM pela fiabilidade, especialmente em aplicações de alto risco em que o desempenho é fundamental.

Imagem ilustrativa relacionada com o custo do alternador do automóvel

2. MOQ (Quantidade mínima de encomenda)

O MOQ refere-se ao número mais pequeno de unidades que um fornecedor está disposto a vender numa única encomenda. Este termo é vital para os compradores B2B, uma vez que afecta a gestão do inventário e os custos iniciais. Compreender o MOQ pode ajudar os compradores a negociar melhores condições ou a decidir se devem abastecer-se junto de um fornecedor diferente.

3. RFQ (Pedido de Cotação)

Um pedido de cotação é um documento enviado aos fornecedores solicitando preços e condições para produtos específicos. Esta é uma prática comum nas transacções B2B, permitindo aos compradores comparar preços, prazos de entrega e condições de vários fornecedores antes de tomarem uma decisão.

4. Incoterms

Os Incoterms são termos comerciais internacionais que definem as responsabilidades dos compradores e vendedores no comércio internacional. Definem quem é responsável pelo transporte, seguro e tarifas, o que pode afetar significativamente o custo global da compra de alternadores a fornecedores estrangeiros.

5. Carga de base

Uma taxa de núcleo é uma taxa adicionada ao preço de um alternador remanufacturado. É reembolsada quando o comprador devolve o alternador antigo. Compreender as taxas de núcleo pode ajudar os compradores a gerir o seu fluxo de caixa e os custos gerais quando compram peças remanufacturadas.

Imagem ilustrativa relacionada com o custo do alternador do automóvel

Ao compreender estas propriedades técnicas e termos do sector, os compradores B2B podem melhorar as suas estratégias de aquisição, garantindo que tomam decisões de compra informadas que se alinham com as suas necessidades operacionais e restrições orçamentais.

Navegar na dinâmica do mercado e nas tendências de abastecimento no sector do custo dos alternadores para automóveis

Quais são as principais dinâmicas e tendências do mercado que afectam os custos do alternador para automóveis?

O mercado global de alternadores para automóveis é influenciado por vários factores críticos, incluindo os avanços na tecnologia automóvel, a alteração das preferências dos consumidores e factores económicos. À medida que os veículos se tornam tecnologicamente mais avançados, a procura de alternadores de alto desempenho aumentou, levando os fabricantes a inovar. Nos mercados emergentes, em particular em África e na América do Sul, há uma ênfase crescente em peças automóveis acessíveis mas fiáveis, o que conduz a um aumento da procura de alternadores remanufacturados. Esta tendência alinha-se com a crescente sensibilidade aos custos entre os compradores internacionais B2B, que procuram cada vez mais soluções económicas sem comprometer a qualidade.

As tendências de abastecimento também estão a evoluir, com as plataformas digitais e o comércio eletrónico a desempenharem um papel fundamental na ligação entre compradores e fornecedores a nível mundial. Os compradores internacionais B2B estão a tirar partido da tecnologia para aceder a uma gama mais vasta de fornecedores, comparar preços e avaliar as especificações dos produtos de forma mais eficiente. Em regiões como a Europa e o Médio Oriente, há uma tendência notável para o aprovisionamento de fabricantes locais para reduzir os prazos de entrega e os custos de envio. Além disso, à medida que a sustentabilidade se torna uma prioridade, os compradores estão a gravitar em torno de fornecedores que oferecem produtos amigos do ambiente, incluindo alternadores fabricados a partir de materiais reciclados ou que cumprem certificações ambientais específicas.

Como é que a sustentabilidade está a moldar o fornecimento de alternadores para automóveis?

A sustentabilidade e o fornecimento ético são considerações cada vez mais importantes para os compradores B2B no mercado dos alternadores para automóveis. O impacto ambiental dos processos de fabrico, incluindo a extração de matérias-primas e o consumo de energia, levou muitos compradores a procurar fornecedores que dão prioridade a práticas ecológicas. Esta mudança não é apenas benéfica para o planeta, mas também se alinha com as expectativas dos consumidores em muitos mercados, onde existe uma procura crescente de produtos sustentáveis.

Os compradores devem procurar fornecedores que ofereçam certificações ‘verdes’, indicando o cumprimento de normas ambientais. Estas certificações podem incluir a ISO 14001 para sistemas de gestão ambiental ou outros rótulos ecológicos relevantes que verifiquem a utilização de materiais sustentáveis e práticas de fabrico responsáveis. Além disso, o refabrico de alternadores está a ganhar força como uma forma eficaz de minimizar os resíduos e reduzir a pegada de carbono associada à produção. Ao dar prioridade aos fornecedores que se concentram na sustentabilidade, os compradores B2B podem melhorar a reputação da sua marca e satisfazer a procura crescente de produtos ambientalmente responsáveis.

Qual é o contexto histórico do mercado de alternadores de automóveis?

O alternador automóvel evoluiu significativamente desde a sua criação no início do século XX. Inicialmente, os veículos dependiam de geradores para obter energia eléctrica, mas a introdução do alternador nos anos 60 revolucionou os sistemas eléctricos dos automóveis. A capacidade do alternador para produzir mais potência a baixas RPMs tornou-o a escolha preferida para os veículos modernos, acomodando o número crescente de componentes eléctricos.

Ao longo das décadas, os avanços nos materiais e nos processos de fabrico conduziram a uma maior eficiência e desempenho. A mudança para sistemas de controlo eletrónico e tecnologias híbridas influenciou ainda mais a conceção dos alternadores, resultando numa gama mais vasta de produtos atualmente disponíveis no mercado. Esta evolução reflecte as tendências mais amplas da indústria automóvel, em que a inovação e a eficiência são fundamentais, e continua a ser crucial para os compradores B2B que procuram soluções fiáveis e rentáveis no sector dos alternadores para automóveis.

Perguntas frequentes (FAQs) para compradores B2B de custo do alternador para automóveis

-

Como posso determinar o alternador correto para o meu veículo?

Para escolher o alternador correto, considere o ano, a marca e o modelo do veículo, bem como o tamanho do motor. Além disso, avalie os requisitos de amperagem com base na carga eléctrica do seu veículo. É essencial corresponder às especificações do alternador para garantir um desempenho e uma compatibilidade óptimos. Consulte os fornecedores que podem fornecer especificações detalhadas e potencialmente oferecer serviços de teste para verificar a adequação do alternador. -

Que factores influenciam o custo de um alternador?

O custo de um alternador pode variar com base em vários factores, incluindo a marca, o estado novo ou remanufacturado, a amperagem e a cobertura da garantia. As especificações únicas, como o estilo de montagem e as ligações eléctricas, também desempenham um papel importante. Além disso, as diferenças regionais do mercado podem afetar os preços, especialmente no comércio internacional. Solicite sempre vários orçamentos para comparar opções e garantir que está a receber o melhor valor. -

Qual é o prazo de entrega típico para o fornecimento de alternadores a nível internacional?

Os prazos de entrega para o aprovisionamento internacional podem variar significativamente com base na localização do fornecedor, no método de envio e no processamento alfandegário. Em geral, é de esperar entre alguns dias e várias semanas. É aconselhável comunicar diretamente com os fornecedores para obter prazos específicos e ter em conta possíveis atrasos devido a regulamentos alfandegários ou locais, especialmente ao importar para regiões como África ou América do Sul. -

Como é que posso verificar os fornecedores de alternadores?

Para avaliar os fornecedores, comece por verificar a sua reputação no sector através de críticas e classificações de clientes anteriores. Peça referências e verifique as suas licenças e certificações comerciais. Além disso, considere a possibilidade de efetuar uma visita à fábrica ou utilizar serviços de inspeção de terceiros para avaliar as suas capacidades de produção e processos de garantia de qualidade. Estabelecer uma relação com um fornecedor fiável é crucial para o sucesso a longo prazo. -

Existem quantidades mínimas de encomenda (MOQ) na compra de alternadores?

Sim, muitos fornecedores impõem uma quantidade mínima de encomenda (MOQ) que pode variar consoante o produto e o fornecedor. As MOQs comuns para alternadores podem variar de algumas unidades a várias dúzias. Compreender a MOQ é essencial para o planeamento do orçamento e da logística. Negociar as condições com os fornecedores para ver se podem acomodar encomendas mais pequenas, especialmente para novos compradores ou empresas em fase de arranque. -

Que condições de pagamento devo esperar quando forneço alternadores?

As condições de pagamento podem variar muito entre fornecedores, mas as opções comuns incluem pagamento antecipado, net 30 ou mesmo acordos de consignação para clientes de confiança. As transacções internacionais podem exigir métodos de pagamento seguros, como cartas de crédito ou serviços de caução, para reduzir os riscos. Esclareça sempre as condições de pagamento antecipadamente e certifique-se de que estão alinhadas com as suas estratégias de gestão do fluxo de caixa. -

Como é que posso garantir a qualidade dos alternadores importados?

Para garantir a qualidade, solicite certificações ao fornecedor, como a ISO 9001, que indica a adesão a normas de gestão da qualidade. Considere a implementação de uma inspeção por terceiros antes do envio para verificar se os alternadores cumprem as suas especificações e expectativas de qualidade. Além disso, estabeleça uma política clara de devolução de produtos defeituosos para proteger o seu investimento. -

Quais são as considerações logísticas para a importação de alternadores?

A logística de importação de alternadores envolve vários factores, incluindo o método de envio, os direitos aduaneiros e o transporte local. Escolha entre frete aéreo ou marítimo com base no orçamento e na urgência. Familiarize-se com os regulamentos de importação do seu país para evitar tarifas ou atrasos inesperados. A colaboração com um transitário pode simplificar o processo e garantir a conformidade com toda a documentação necessária.

Lista dos 1 principais fabricantes e fornecedores de custo do alternador para automóveis

1. Toyota - RAV4 Substituição do Alternador

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: Substituição do alternador do Toyota RAV4 2006, custo total de $450 incluindo mão de obra.

Conclusão sobre o aprovisionamento estratégico e perspectivas para o custo do alternador para automóveis

Ao navegar pelas complexidades dos custos dos alternadores para automóveis, os compradores B2B internacionais devem dar prioridade ao aprovisionamento estratégico para melhorar a eficiência das suas aquisições e otimizar os resultados financeiros. O custo dos alternadores pode flutuar significativamente com base em factores como a marca, o modelo, a amperagem e o facto de a peça ser nova ou remanufacturada. Ao compreender estas variáveis, os compradores podem tomar decisões informadas que se alinham com as suas necessidades operacionais e restrições orçamentais.

O sourcing estratégico não só assegura o acesso a preços competitivos, como também promove relações fortes com os fornecedores, o que pode levar a melhores resultados de negociação e a melhores níveis de serviço. Para as empresas que operam em mercados diversificados como África, América do Sul, Médio Oriente e Europa, o recurso a fornecedores locais pode também reduzir os custos logísticos e os prazos de entrega, aumentando a resiliência global da cadeia de abastecimento.

Imagem ilustrativa relacionada com o custo do alternador do automóvel

À medida que a indústria automóvel evolui com os avanços tecnológicos, será crucial manter a flexibilidade nas estratégias de aprovisionamento. Os compradores são encorajados a manterem-se informados sobre as tendências do mercado e as tecnologias emergentes no fabrico de alternadores. Ao fazê-lo, podem capitalizar as oportunidades que conduzem a poupanças de custos e eficiências operacionais. Chegou o momento de reavaliar as suas estratégias de abastecimento e reforçar as parcerias que apoiarão o crescimento da sua empresa no dinâmico panorama automóvel.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.