Introdução: Navegar no mercado global de motores de arranque

In today’s competitive automotive landscape, sourcing high-quality starter motors poses a significant challenge for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. The starter motor is a critical component that ensures the efficient operation of internal combustion engines, making it essential for a wide range of applications—from passenger vehicles to heavy-duty machinery. However, the complexities involved in selecting the right starter motor, including understanding various types, applications, supplier reliability, and cost implications, can overwhelm even the most seasoned procurement professionals.

This comprehensive guide is designed to empower B2B buyers with the insights and tools necessary to make informed purchasing decisions. Within its pages, you will find detailed analyses of different starter motor types, their applications across various industries, and crucial tips for vetting suppliers to ensure quality and reliability. Additionally, we will explore cost factors and market trends that can impact your sourcing strategy.

By equipping you with this knowledge, our guide aims to streamline your procurement process, helping you navigate the global market for starter motors with confidence. Whether you are based in bustling urban centers or remote regions, understanding these critical components will enable you to optimize your operations and enhance your competitive edge.

Índice

- Top 3 Starting Motor Manufacturers & Suppliers List

- Introdução: Navegar no mercado global de motores de arranque

- Compreender os tipos e as variações do motor de arranque

- Principais aplicações industriais do motor de arranque

- 3 pontos problemáticos comuns dos utilizadores para o ‘motor de arranque’ e respectivas soluções

- Guia de seleção de materiais estratégicos para o motor de arranque

- Análise aprofundada: Processos de fabrico e garantia de qualidade para o motor de arranque

- Guia prático de abastecimento: Uma lista de controlo passo a passo para o ‘motor de arranque’

- Análise abrangente de custos e preços para o fornecimento de motores de arranque

- Análise de alternativas: Comparação do motor de arranque com outras soluções

- Caraterísticas técnicas essenciais e terminologia comercial do motor de arranque

- Navegar pela dinâmica do mercado e pelas tendências de abastecimento no sector dos motores de arranque

- Perguntas mais frequentes (FAQs) para compradores B2B de motor de arranque

- Conclusão sobre o aprovisionamento estratégico e perspectivas para o motor de arranque

- Aviso legal importante e termos de utilização

Compreender os tipos e as variações do motor de arranque

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| DC Starter Motors | Operate on direct current; commonly used in vehicles. | Automotive, commercial vehicles, machinery. | Prós: Fiável e económico. Contras: Limited lifespan due to wear. |

| Gear Reduction Motors | Use gears to enhance torque and reduce size. | Heavy machinery, marine applications. | Prós: Compact design, high torque. Contras: Instalação mais complexa. |

| Permanent Magnet Motors | Utilize permanent magnets for efficient operation. | Electric vehicles, hybrid systems. | Prós: High efficiency, lightweight. Contras: Higher initial costs. |

| High-Performance Motors | Designed for performance vehicles with enhanced features. | Racing, high-end automotive sectors. | Prós: Superior starting power, durability. Contras: Expensive, specialized fitment. |

| Solenoid Starter Motors | Employ solenoids for engagement with the flywheel. | Standard automotive applications. | Prós: Simple design, easy to replace. Contras: Can be prone to electrical issues. |

What Are the Characteristics of DC Starter Motors?

DC starter motors are the most prevalent type used in vehicles and machinery, operating on direct current. These motors are known for their reliability and cost-effectiveness, making them suitable for a wide range of applications, including automotive and commercial vehicles. B2B buyers should consider the lifespan and maintenance requirements, as these motors may experience wear over time, necessitating regular checks and potential replacements.

Why Choose Gear Reduction Motors for Heavy Machinery?

Gear reduction motors are engineered to enhance torque while minimizing size, making them ideal for heavy machinery and marine applications. Their design allows for a high starting torque, which is crucial in environments where heavy loads must be moved. B2B buyers should evaluate the complexity of installation and ensure compatibility with existing systems, as these motors may require specific mounting configurations.

What Makes Permanent Magnet Motors Efficient for Electric Vehicles?

Permanent magnet motors leverage permanent magnets to achieve high efficiency and performance, particularly in electric and hybrid vehicles. Their lightweight construction contributes to overall vehicle efficiency, making them increasingly popular in modern automotive design. Buyers in the B2B sector should weigh the initial investment against long-term savings on energy costs, as these motors typically offer a higher return on investment through enhanced fuel efficiency.

When Are High-Performance Motors Necessary?

High-performance starter motors are specifically designed for performance vehicles, offering enhanced features that cater to the demands of racing and high-end automotive sectors. These motors provide superior starting power and durability, essential for vehicles that operate under extreme conditions. However, B2B buyers must consider the higher costs and ensure that the motors are compatible with their specific vehicle models.

How Do Solenoid Starter Motors Work in Standard Applications?

Solenoid starter motors are commonly used in standard automotive applications, utilizing solenoids to engage with the flywheel. Their straightforward design simplifies replacement and maintenance, making them a popular choice among B2B buyers seeking reliable solutions for everyday vehicles. However, potential electrical issues may arise, so it’s vital to ensure proper electrical connections and system compatibility when purchasing these motors.

Principais aplicações industriais do motor de arranque

| Indústria/Setor | Aplicação específica do motor de arranque | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Automotivo | Starting motors in passenger and commercial vehicles | Ensures reliable engine ignition, reducing downtime and repair costs | Compatibility with various vehicle models and maintenance support |

| Agricultura | Starting motors in agricultural machinery like tractors | Enhances operational efficiency in fieldwork, minimizing delays | Durability to withstand harsh environmental conditions |

| Construção | Starting motors in heavy construction equipment | Facilitates timely project completion through reliable equipment | Robust design to handle high-frequency use and potential vibration |

| Marinha | Starting motors in boats and marine vessels | Essential for safe navigation and operational reliability | Resistance to corrosion and water exposure, especially in saltwater |

| Mineração | Starting motors in mining machinery and vehicles | Increases productivity by ensuring equipment readiness | Ability to perform in extreme conditions, including dust and moisture |

How Are Starting Motors Used in the Automotive Industry?

In the automotive sector, starting motors are critical components that initiate the engine’s operation, whether in passenger cars or commercial vehicles. They engage the flywheel to crank the engine, enabling fuel combustion. For B2B buyers, sourcing high-quality starting motors that are compatible with a range of vehicle models is essential. Additionally, businesses should consider suppliers that offer maintenance support and reliability guarantees to minimize downtime and repair costs.

Qual o papel dos motores de arranque na agricultura?

Starting motors are vital in agricultural machinery, such as tractors and harvesters, where they ensure the engines start efficiently and reliably. This reliability is crucial for farmers who depend on timely operations to maximize yield. Buyers in this sector should focus on sourcing durable motors that can withstand harsh environmental conditions, such as dust and moisture, to ensure longevity and optimal performance during peak farming seasons.

How Are Starting Motors Applied in Construction?

In the construction industry, starting motors are used in heavy machinery, including excavators and bulldozers. These motors are essential for ensuring that equipment can start promptly, contributing to the timely completion of projects. B2B buyers should prioritize sourcing robust starting motors designed to handle high-frequency use and vibrations, ensuring that they can withstand the demanding conditions typical on construction sites.

Why Are Starting Motors Important for Marine Applications?

Starting motors are indispensable in marine applications, powering boats and vessels to ensure safe navigation and operational reliability. Given the unique challenges posed by marine environments, such as exposure to saltwater, sourcing starting motors that are resistant to corrosion is crucial. Buyers should look for motors specifically designed for marine use, ensuring they meet industry standards for durability and performance in challenging conditions.

What Is the Importance of Starting Motors in Mining Equipment?

In the mining sector, starting motors are critical for the reliable operation of heavy machinery, such as drills and haul trucks. These motors ensure that equipment is ready for use, directly impacting productivity levels. B2B buyers in mining must consider sourcing starting motors that can operate effectively in extreme conditions, including high dust levels and moisture, to maintain continuous operations and minimize equipment failure.

3 pontos problemáticos comuns dos utilizadores para o ‘motor de arranque’ e respectivas soluções

Scenario 1: Difficulty in Sourcing Quality Starter Motors

O problema:

B2B buyers often struggle to find reliable suppliers for starter motors that meet specific performance and regulatory standards. This issue is particularly pronounced in regions with less established automotive supply chains, such as parts of Africa and South America. Buyers may encounter low-quality products that not only fail to perform effectively but can also lead to increased downtime for their fleets. This creates a significant challenge as businesses aim to maintain operational efficiency and minimize repair costs.

A solução:

To overcome sourcing difficulties, buyers should invest time in researching and vetting suppliers. Start by seeking manufacturers with a proven track record in producing high-quality starter motors. Look for certifications that indicate compliance with international standards, such as ISO 9001. Establishing relationships with suppliers who provide transparent information about their production processes and materials can also help ensure quality. Additionally, consider local suppliers who understand the regional market and can provide timely support and parts. Engaging in supplier audits can further ensure that the manufacturing practices meet your specific requirements, thus protecting your investment in starter motors.

Scenario 2: Understanding Technical Specifications for Optimal Performance

O problema:

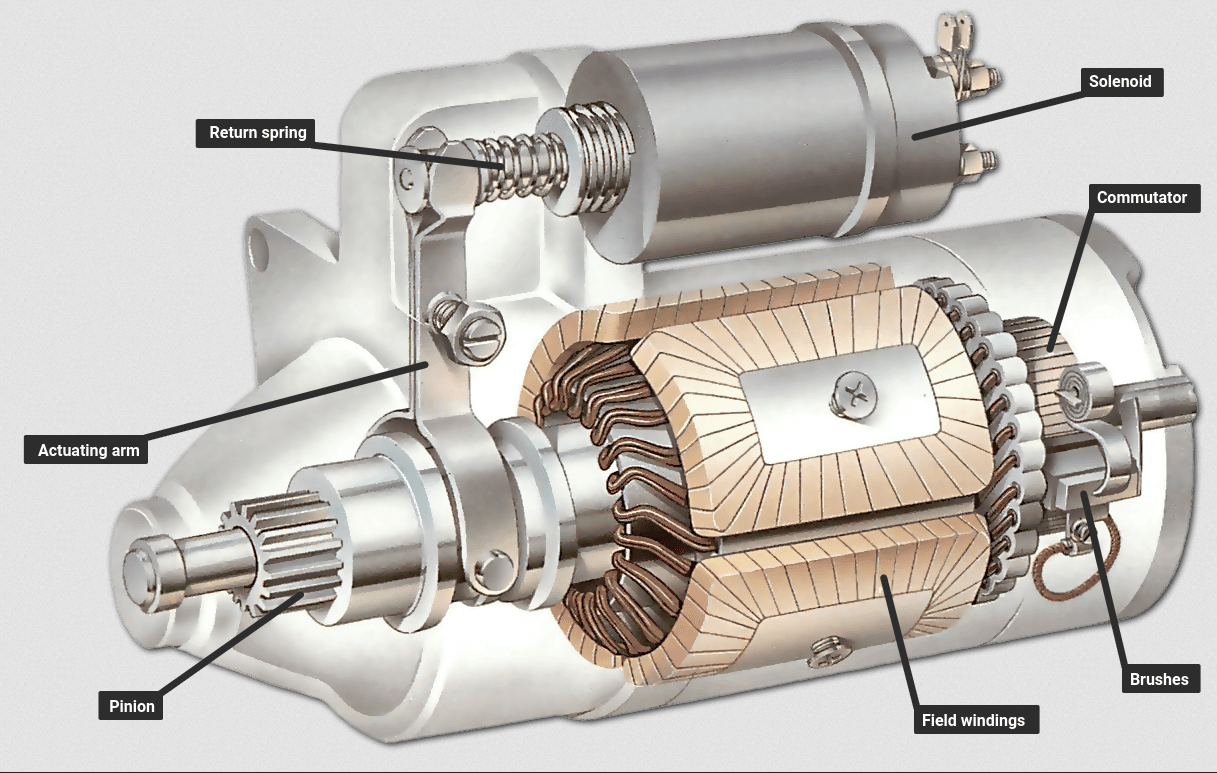

Many B2B buyers lack the technical expertise required to choose the right starter motor for their specific applications. This is particularly true when dealing with diverse vehicle types or specialized machinery, where the wrong specifications can lead to compatibility issues or inadequate performance. Misunderstanding the importance of components such as the solenoid, pinion gear, or armature can result in unnecessary costs and operational inefficiencies.

A solução:

To navigate technical specifications effectively, buyers should engage in thorough consultations with manufacturers or technical experts. When sourcing starter motors, request detailed datasheets that outline the specifications and compatibility for each model. It’s also beneficial to participate in training sessions or webinars focused on starter motor technology, which can provide deeper insights into how different components affect overall performance. Utilizing simulation tools or software can aid in visualizing how various starter motors will perform under different operational conditions. This knowledge will empower buyers to make informed decisions, ensuring they select the right starter motor that enhances vehicle reliability and performance.

Scenario 3: Managing Maintenance and Troubleshooting Common Issues

O problema:

After purchasing starter motors, B2B buyers often face challenges related to maintenance and troubleshooting. Common issues such as overheating, electrical faults, or mechanical failures can lead to unexpected downtime and repair costs. Many businesses do not have a structured maintenance program in place, making it difficult to identify issues before they escalate.

A solução:

Implementing a proactive maintenance schedule is crucial for managing starter motor performance. Buyers should develop a routine inspection protocol that includes checking electrical connections, monitoring for unusual sounds during operation, and ensuring adequate lubrication of mechanical components. Training staff on common troubleshooting techniques can also be invaluable. For instance, teaching them how to recognize signs of wear, such as slow cranking or excessive heat, can facilitate early intervention. Additionally, consider partnering with a professional service provider for regular maintenance checks, which can help to extend the lifespan of the starter motors and minimize costly repairs. Leveraging data analytics to monitor performance trends can also assist in predicting potential failures, allowing businesses to act swiftly and maintain operational efficiency.

Guia de seleção de materiais estratégicos para o motor de arranque

What Are the Key Materials Used in Starter Motors?

When selecting materials for starter motors, it’s essential to consider properties that affect performance, durability, and manufacturing complexity. Below, we analyze four common materials used in starter motor components, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Copper Benefit Starter Motor Performance?

Copper is widely used in starter motors, particularly for wiring and electrical connections due to its excellent electrical conductivity. Key properties include a high melting point (around 1,085°C) and good corrosion resistance, especially when plated.

Prós: Copper’s high conductivity ensures efficient energy transfer, which is critical for quick engine starts. It is also relatively easy to work with, allowing for efficient manufacturing processes.

Contras: The primary disadvantage is cost; copper is more expensive than alternatives like aluminum. Additionally, it can be prone to corrosion if not properly treated, which may affect longevity in harsh environments.

Impacto na aplicação: Copper is compatible with various electrical systems and can handle the electrical demands of modern vehicles. However, in regions with high humidity or corrosive environments, additional protective coatings may be necessary.

Considerações para compradores internacionais: Buyers in Africa and South America should ensure compliance with local electrical standards, such as IEC or ASTM. Additionally, sourcing from suppliers who offer corrosion-resistant treatments can be beneficial.

Qual é o papel do aço na construção do motor de arranque?

Steel, particularly carbon steel, is commonly used for the housing and structural components of starter motors. Its properties include high tensile strength and good wear resistance, making it suitable for the mechanical demands of starter motors.

Prós: Steel is highly durable and can withstand significant mechanical stress, which is essential for the repeated engagement and disengagement of the starter motor. It is also relatively low-cost, making it an economical choice for manufacturers.

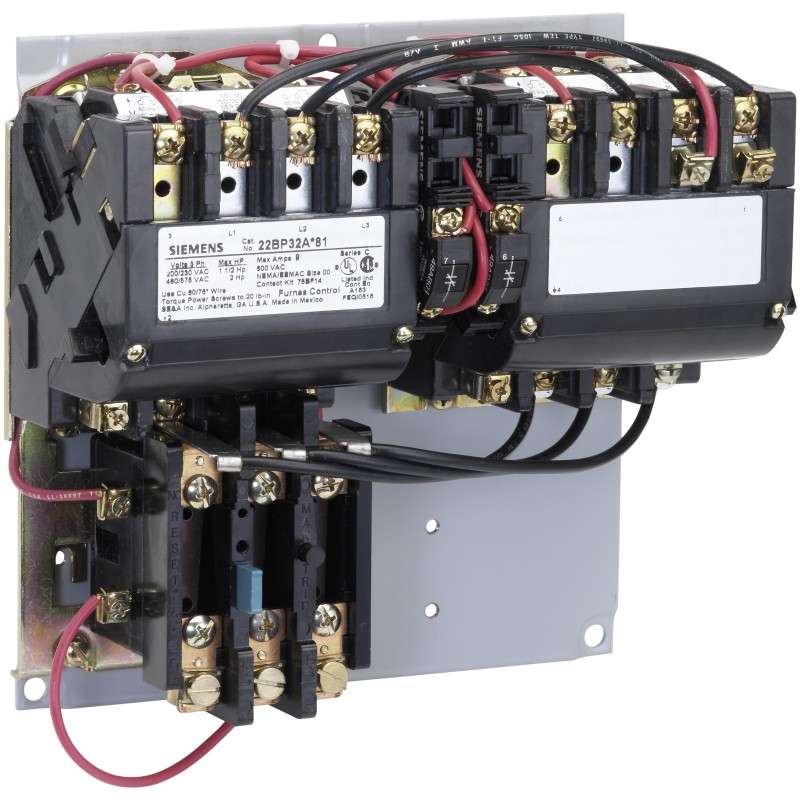

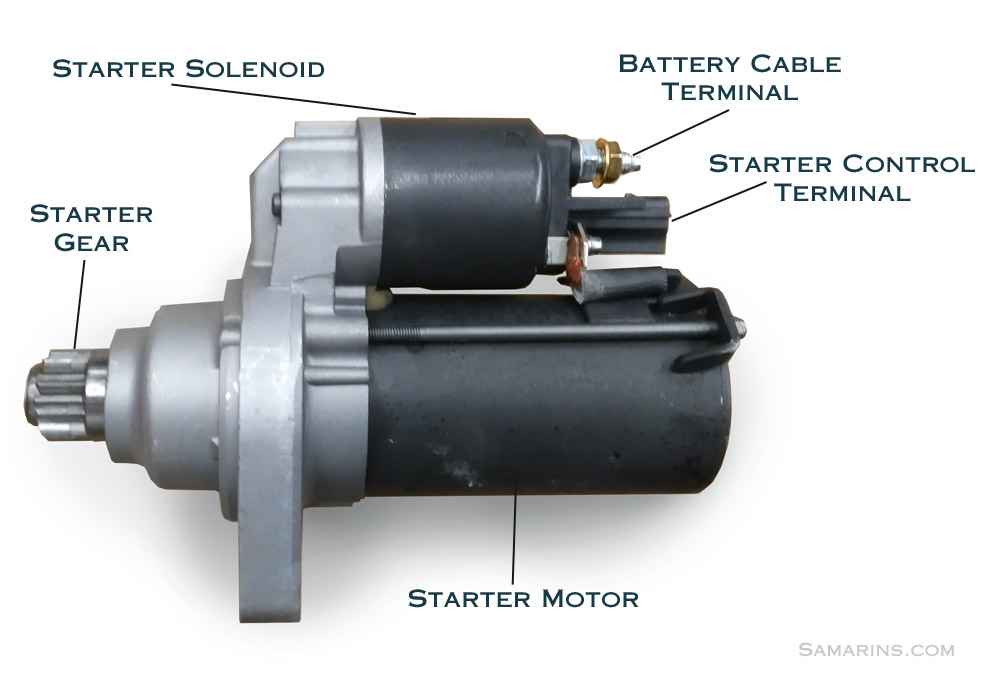

Imagem ilustrativa relacionada com o motor de arranque

Contras: Steel can be susceptible to rust and corrosion if not properly treated, which may limit its lifespan in certain environments. Additionally, it is heavier than some alternatives, which may impact overall vehicle weight.

Impacto na aplicação: Steel’s strength makes it ideal for components that require durability, but it may not be suitable for lightweight applications. In regions with high humidity or salt exposure, corrosion-resistant coatings are advisable.

Considerações para compradores internacionais: Buyers should be aware of local standards for steel quality (e.g., ASTM A36) and consider suppliers who can provide treated options to enhance corrosion resistance.

Como é que o alumínio aumenta a eficiência do motor de arranque?

Aluminum is increasingly used in starter motor components, especially in housings and brackets. Its properties include a low density and good thermal conductivity, with a melting point of approximately 660°C.

Prós: Aluminum is lightweight, which can improve overall vehicle efficiency and performance. It also has good corrosion resistance, particularly when anodized, making it suitable for various environmental conditions.

Contras: While aluminum is easier to manufacture into complex shapes, it is generally less strong than steel, which may limit its use in high-stress applications. Additionally, the cost can be higher than that of standard steel.

Impacto na aplicação: Aluminum’s lightweight nature is beneficial for fuel efficiency, but it may not be suitable for components that require high tensile strength. Buyers must consider the specific application and stress levels.

Considerações para compradores internacionais: Buyers in Europe may prefer aluminum components due to stringent weight regulations. Compliance with EU standards for aluminum alloys (e.g., EN 573) is essential.

What About Plastic Composites in Starter Motors?

Plastic composites are used in non-structural components of starter motors, such as housings and insulators. Key properties include low weight, good electrical insulation, and resistance to corrosion.

Imagem ilustrativa relacionada com o motor de arranque

Prós: The use of plastic composites can significantly reduce the weight of starter motors, which is advantageous for fuel efficiency. They are also resistant to many chemicals and moisture, enhancing durability.

Contras: Plastic composites may not withstand high temperatures as well as metals, which can limit their application in high-stress areas. They can also be more expensive to manufacture due to complex molding processes.

Impacto na aplicação: While plastic composites are excellent for insulation and lightweight applications, they may not be suitable for load-bearing components. Buyers should assess the specific use case carefully.

Considerações para compradores internacionais: Buyers should ensure that the materials meet local standards for thermal and mechanical performance, especially in regions with extreme temperatures.

Tabela resumida da seleção de materiais para motores de arranque

| Material | Caso de utilização típico para o motor de arranque | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Fiação e ligações elétricas | Excelente condutividade elétrica | Higher cost, corrosion potential | Alto |

| Aço | Componentes estruturais e de alojamento | Alta durabilidade e resistência | Susceptible to rust, heavier | Médio |

| Alumínio | Caixas e suportes | Leve e resistente à corrosão | Less strength than steel | Medium to High |

| Compósitos plásticos | Componentes não estruturais | Leve e resistente a produtos químicos | Tolerância limitada a altas temperaturas | Médio |

This strategic material selection guide provides insights into the materials commonly used in starter motors, helping international B2B buyers make informed decisions based on performance, cost, and regional requirements.

Análise aprofundada: Processos de fabrico e garantia de qualidade para o motor de arranque

Quais são as principais etapas da fabricação de um motor de arranque?

Manufacturing a starter motor involves several intricate stages that ensure the component is both efficient and reliable. These stages can be broadly categorized into material preparation, forming, assembly, and finishing.

Como é que o material é preparado para a produção de motores de arranque?

The manufacturing process begins with material preparation. High-quality materials, such as copper for electrical components and durable steel for structural parts, are sourced from reputable suppliers. Suppliers should adhere to international standards like ISO 9001, which ensures consistent quality management systems. Material checks are performed to confirm that they meet specific requirements, including conductivity and tensile strength, which are critical for starter motor performance.

Que técnicas de conformação são utilizadas no fabrico de motores de arranque?

Once the materials are prepared, forming techniques come into play. Key components such as the armature, commutator, and field coils undergo processes like stamping, forging, and machining. Stamping is often used for producing the armature laminations, while machining is essential for creating precise grooves on the commutator. Advanced techniques, such as computer numerical control (CNC) machining, are employed to achieve high precision, which is vital for the effective engagement of the starter motor with the engine’s flywheel.

Como são montados os motores de arranque?

The assembly stage is where the various components come together. The assembly line is typically organized to optimize efficiency, often employing automated systems for tasks such as inserting brushes and soldering connections. During assembly, it is crucial to adhere to specific torque settings and operational protocols to ensure reliability. Each unit is assembled with care to prevent misalignment, which can lead to premature failure.

What Are the Finishing Processes for Starter Motors?

Finishing processes include surface treatments and testing. Components may undergo processes like electroplating or powder coating to enhance corrosion resistance, especially important for regions with harsh environmental conditions. After finishing, each starter motor undergoes functional testing to verify its performance under load conditions, ensuring it meets the required specifications.

What Quality Control Standards Should B2B Buyers Expect?

Quality assurance is integral to the manufacturing process of starter motors. International standards such as ISO 9001 provide a framework for quality management, while industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) ensure compliance with particular regulations. These certifications indicate that the product meets safety and environmental standards, which is crucial for B2B buyers operating in diverse markets.

Quais são os principais pontos de verificação do controlo de qualidade?

Quality control checkpoints are strategically placed throughout the manufacturing process. Incoming Quality Control (IQC) checks materials upon arrival, ensuring they meet specified standards. In-Process Quality Control (IPQC) involves monitoring the assembly process to catch any discrepancies early. Finally, Final Quality Control (FQC) involves comprehensive testing of the finished product to confirm it operates as intended.

Which Testing Methods Are Commonly Used in Starter Motor Production?

Common testing methods include electrical resistance testing, load testing, and thermal testing. Electrical resistance testing ensures that the motor conducts electricity properly, while load testing simulates real-world conditions to verify performance under stress. Thermal testing helps assess the motor’s capability to withstand heat generated during operation, which is crucial for longevity.

Como podem os compradores B2B verificar os processos de controlo de qualidade dos fornecedores?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Conducting audits of the manufacturing facility can provide insights into their operational standards and practices. Requesting quality assurance reports and certifications can further validate compliance with international standards. Engaging third-party inspection services can also ensure that the products meet the expected quality before shipment.

Quais são as nuances de controle de qualidade e certificação para compradores B2B internacionais?

International B2B buyers must navigate various certification requirements and nuances specific to their regions. For example, in Europe, CE marking is crucial for compliance, while buyers in the Middle East may require adherence to local standards. Additionally, understanding the implications of tariffs and trade regulations can affect the overall cost and quality assurance of starter motors. It is advisable for buyers to establish clear communication with suppliers regarding these requirements to ensure smooth transactions.

Conclusion: The Importance of Quality in Starter Motor Manufacturing

In conclusion, the manufacturing processes and quality assurance for starter motors are critical to ensuring reliable and efficient performance. By understanding the stages of production, the importance of adhering to international standards, and the methods for verifying supplier quality, B2B buyers can make informed decisions. This diligence not only ensures the procurement of high-quality starter motors but also fosters long-term partnerships with reliable suppliers across the globe.

Guia prático de abastecimento: Uma lista de controlo passo a passo para o ‘motor de arranque’

In the competitive landscape of B2B procurement, sourcing a reliable starter motor is essential for ensuring optimal performance in your automotive operations. This guide offers a practical checklist to help you navigate the complexities of the sourcing process, focusing on crucial considerations that will lead to successful procurement.

Passo 1: Defina as suas especificações técnicas

Establishing clear technical specifications is the foundation of successful procurement. Consider the type of vehicles you service and the specific requirements of each model. Key factors to define include:

– Voltage and Power Ratings: Ensure compatibility with the vehicle’s electrical system.

– Dimensions and Mounting Options: Assess the available space and fitting requirements for the starter motor.

Passo 2: Antecedentes dos fornecedores de investigação

A thorough investigation into potential suppliers can prevent future issues. Look for suppliers with a proven track record in the starter motor market, paying attention to:

– Experiência no sector: Suppliers with extensive experience often have better insights into quality and performance.

– Client Testimonials: Seek reviews or case studies from businesses similar to yours to gauge reliability and service quality.

Imagem ilustrativa relacionada com o motor de arranque

Passo 3: Avaliar as certificações dos fornecedores

Validating supplier certifications is critical to ensuring product quality and compliance. Look for certifications such as:

– ISO 9001: Indicates a commitment to quality management systems.

– Normas SAE: Ensures adherence to industry standards for automotive components.

Passo 4: Solicitar amostras de produtos

Before making a bulk purchase, request samples of the starter motors. This allows you to:

– Test for Performance: Assess the functionality and compatibility with your vehicles.

– Evaluate Build Quality: Inspect materials and craftsmanship to ensure durability and reliability.

Passo 5: Negociar termos e condições

Establishing clear terms and conditions is vital for a smooth transaction. Discuss aspects such as:

– Pricing Structures: Understand the cost implications of bulk orders and potential discounts.

– Delivery Schedules: Ensure that the supplier can meet your timelines to avoid disruptions in operations.

Passo 6: Establish After-Sales Support and Warranty

After-sales support can significantly impact your experience with the starter motors. Inquire about:

– Condições de garantia: A robust warranty can protect your investment and provide peace of mind.

– Suporte técnico: Ensure that the supplier offers assistance for installation or troubleshooting.

Passo 7: Monitor Supplier Performance Post-Purchase

Once the procurement is complete, keep track of the supplier’s performance. Important aspects to monitor include:

– Delivery Timeliness: Ensure that future orders are received on schedule.

– Product Quality Consistency: Regularly evaluate the quality of the starter motors to maintain operational standards.

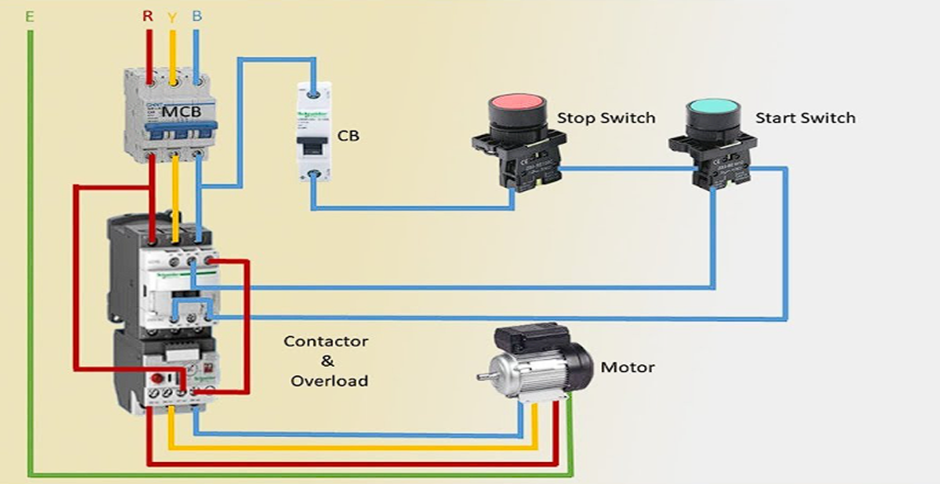

Imagem ilustrativa relacionada com o motor de arranque

By following this checklist, B2B buyers can confidently navigate the sourcing process for starter motors, ensuring they select a supplier that aligns with their technical needs and operational goals. This structured approach not only minimizes risks but also enhances the overall efficiency of your procurement strategy.

Análise abrangente de custos e preços para o fornecimento de motores de arranque

What Are the Key Cost Components in Starting Motor Sourcing?

When considering the sourcing of starting motors, it is essential to understand the various cost components involved. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materiais: The primary materials for starter motors include metals like steel and aluminum, as well as electrical components such as copper and plastic. The quality and origin of these materials can significantly impact costs. For instance, sourcing high-quality copper from established suppliers may be more expensive but can enhance the motor’s performance and longevity.

-

Trabalho: Labor costs vary by region and depend on local wage standards. In countries with lower labor costs, such as some in Africa and South America, manufacturers can offer more competitive pricing. However, it’s crucial to ensure that labor quality meets international standards.

-

Custos indiretos de produção: This encompasses indirect costs like utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize overhead, thereby reducing the overall cost of starter motors.

-

Ferramentas: The cost of tooling can be substantial, especially for custom or specialized starter motors. Tooling costs are typically spread over the production volume, so higher volumes can lead to lower per-unit costs.

-

Controlo de Qualidade (QC): Implementing rigorous QC processes ensures the reliability and performance of starter motors, but it also adds to the cost. Investing in quality assurance can reduce long-term costs associated with warranty claims and replacements.

-

Logística: This includes transportation and handling costs, which can fluctuate based on distance, shipping methods, and Incoterms. For international buyers, understanding logistics costs is vital, as they can significantly affect the total cost of ownership.

-

Margem: Suppliers will apply a profit margin to cover their risks and ensure sustainability. This margin can vary based on market conditions, competition, and the supplier’s pricing strategy.

How Do Price Influencers Impact Starting Motor Sourcing?

Several factors can influence the pricing of starter motors, particularly for international buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Higher volumes often lead to discounts, making bulk purchasing a cost-effective strategy for businesses.

-

Especificações e personalização: Custom specifications can increase costs due to the need for specialized materials or tooling. Buyers should evaluate whether custom features are essential or if standard options suffice.

-

Qualidade dos materiais e certificações: The use of high-quality materials and compliance with international certifications can increase initial costs but may lead to savings in maintenance and durability, thereby reducing the total cost of ownership.

-

Fatores relacionados ao fornecedor: The reputation and reliability of suppliers can impact pricing. Established suppliers with a history of quality may charge more but can offer better assurance of performance and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions as they define the responsibilities of buyers and sellers in shipping, insurance, and tariffs. This knowledge can help buyers avoid unexpected costs and streamline the purchasing process.

What Are the Best Practices for Negotiating Starter Motor Prices?

International B2B buyers should adopt several strategies to negotiate favorable pricing for starter motors:

Imagem ilustrativa relacionada com o motor de arranque

-

Pesquisar preços de mercado: Conducting thorough market research can provide insights into average pricing, helping buyers negotiate from an informed position.

-

Criar relações: Establishing strong relationships with suppliers can lead to better pricing and terms over time. Trust and rapport can facilitate negotiations and foster long-term partnerships.

-

Avaliar o custo total de propriedade (TCO): Buyers should consider the TCO rather than just the initial purchase price. Factors like longevity, warranty, and maintenance costs can significantly impact the overall expense.

-

Aproveitar os descontos por volume: If feasible, consolidate orders to reach higher volume thresholds, which can lead to significant cost savings.

-

Avaliar vários fornecedores: Getting quotes from multiple suppliers can create competition, which may result in better pricing and terms.

Conclusion: What Should International Buyers Keep in Mind?

Sourcing starter motors involves navigating a complex landscape of costs and pricing strategies. By understanding the components that contribute to the cost structure and the influencers that affect pricing, international buyers can make informed decisions that align with their operational needs and budget constraints. Always approach negotiations with a clear understanding of market dynamics and supplier capabilities to maximize value in your sourcing endeavors.

Isenção de responsabilidade: Prices and costs mentioned in this analysis are indicative and may vary based on market conditions and supplier negotiations. Always conduct detailed due diligence before making purchasing decisions.

Análise de alternativas: Comparação do motor de arranque com outras soluções

Exploring Alternatives to Starter Motors: Key Comparisons for B2B Buyers

In the automotive and machinery sectors, the starter motor plays a crucial role in initiating engine operation. However, various alternatives can also achieve this function, each with distinct advantages and disadvantages. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and application needs.

| Aspecto comparativo | ‘Starting Motor’ | Alternative 1: Electric Crankshaft Starter | Alternative 2: Manual Start Systems |

|---|---|---|---|

| Desempenho | Reliable for internal combustion engines; quick engagement. | High torque output; suitable for heavy machinery. | Limited to smaller engines; requires physical effort. |

| Custo | Moderate initial investment; variable maintenance costs. | Higher upfront costs; potential long-term savings on maintenance. | Low initial costs; minimal maintenance. |

| Facilidade de implementação | Standard installation in most vehicles; requires electrical compatibility. | May require specialized installation; adaptable for certain engines. | Simple installation; requires user training. |

| Manutenção | Regular checks necessary; can fail due to wear. | Lower maintenance due to fewer moving parts; but may require expert servicing. | Minimal maintenance; user-dependent reliability. |

| Melhor caso de uso | Ideal for conventional vehicles (petrol/diesel). | Best for heavy-duty applications (trucks, construction). | Suitable for small engines (lawnmowers, small generators). |

What Are the Benefits and Drawbacks of Electric Crankshaft Starters?

Electric crankshaft starters are designed to deliver a high torque output, making them suitable for heavy machinery and large engines. Their efficiency allows for a more powerful start, especially in environments where engines face high resistance. However, the initial investment for electric crankshaft starters can be significantly higher than traditional starter motors. Furthermore, they may require specialized installation and maintenance, which could be a barrier for some businesses. On the upside, their durability and lower long-term maintenance can justify the upfront costs, particularly for users who rely on heavy machinery.

How Do Manual Start Systems Compare to Electric Starters?

Manual start systems, such as pull cords or hand cranks, are often found in smaller engines, like those used in lawn equipment or portable generators. The primary advantage of manual systems is their low cost and simplicity. They require minimal maintenance and are highly reliable in remote areas without electrical access. However, they demand physical effort from the user, which can be a limitation for some. Additionally, manual systems may not be suitable for larger engines where high torque is necessary. While they can be an excellent choice for specific applications, their performance may not match that of electric starters in demanding environments.

How to Choose the Right Starting Solution for Your Needs

When selecting a starting solution, B2B buyers should carefully consider their specific operational requirements, including the types of engines they are working with and the environments in which they operate. Factors such as performance needs, budget constraints, and maintenance capabilities should guide the decision-making process. For businesses relying on conventional vehicles, a starter motor remains a robust choice. However, for those operating heavy machinery or in remote locations, exploring electric crankshaft starters or manual systems may yield better long-term benefits. Ultimately, aligning the chosen solution with operational demands will ensure optimal performance and cost-effectiveness.

Caraterísticas técnicas essenciais e terminologia comercial do motor de arranque

What Are the Key Technical Properties of Starting Motors That B2B Buyers Should Know?

When considering the procurement of starting motors, understanding their technical properties is crucial. Here are several essential specifications that international B2B buyers should prioritize:

1. Grau do material

Starting motors are typically constructed from high-grade materials like steel and copper. Steel is often used for the housing to provide durability and resistance to wear, while copper is favored for electrical components due to its superior conductivity. The choice of material directly impacts the motor’s efficiency and lifespan, which are critical for operational reliability in diverse environments.

Imagem ilustrativa relacionada com o motor de arranque

2. Classificação de binário

Torque rating measures the rotational force that the motor can exert, typically expressed in Newton-meters (Nm). A higher torque rating means that the starting motor can effectively crank larger engines, which is vital for vehicles in regions with diverse vehicle types. Understanding torque requirements helps buyers match motors to specific applications, ensuring optimal performance.

3. Tensão nominal

Most starting motors operate at standard voltages, commonly 12V or 24V. This specification is essential for compatibility with the vehicle’s electrical system. Buyers must ensure that the voltage rating aligns with the intended application to prevent electrical failures or inefficiencies that could arise from mismatched systems.

4. Ciclo de trabalho

The duty cycle indicates the amount of time a starting motor can run before it requires a cooldown period. For instance, a motor designed for a high duty cycle can handle more frequent starts without overheating. This property is particularly important in regions where vehicles may experience extreme conditions or frequent stop-and-go traffic, as it impacts the overall reliability and performance.

5. Níveis de tolerância

Tolerance levels refer to the allowable deviation from specified dimensions in the manufacturing process. High tolerance levels ensure that the motor components fit together correctly, minimizing the risk of mechanical failure. For B2B buyers, understanding tolerance specifications can aid in selecting high-quality products that meet operational standards.

What Trade Terms Are Essential for B2B Buyers of Starting Motors?

Navigating the procurement landscape involves familiarizing oneself with common industry jargon. Here are several key terms that B2B buyers should understand:

Imagem ilustrativa relacionada com o motor de arranque

1. OEM (Fabricante de Equipamento Original)

OEM refers to companies that produce parts that are then used in another company’s product. For starting motors, purchasing OEM parts often guarantees compatibility and quality, as these components are designed to meet the specifications of the original vehicle manufacturer.

2. MOQ (Quantidade mínima de encomenda)

MOQ signifies the smallest number of units that a supplier is willing to sell. Understanding the MOQ is essential for budget-conscious buyers, as it can impact inventory costs and cash flow. Buyers should negotiate MOQs that align with their operational needs while ensuring they receive competitive pricing.

3. RFQ (Pedido de Orçamento)

An RFQ is a formal document that buyers send to suppliers to solicit price quotes for specific products. Issuing an RFQ for starting motors allows buyers to compare prices, evaluate suppliers, and ensure they are making informed purchasing decisions.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risk management, and delivery responsibilities, which are critical in global supply chains.

5. Prazo de entrega

Lead time refers to the duration from placing an order to receiving the product. For starting motors, understanding lead times is essential for effective inventory management and ensuring that operational needs are met without delays.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge necessary to make informed decisions, ensuring they procure starting motors that meet their specific requirements effectively and efficiently.

Navegar pela dinâmica do mercado e pelas tendências de abastecimento no sector dos motores de arranque

What Are the Key Trends Shaping the Global Starting Motor Market?

The global starting motor market is witnessing significant growth, driven by increasing vehicle production and the rising demand for efficient ignition systems. Key trends include the adoption of advanced technologies such as brushless motors and integrated electronic controls, which enhance performance and reliability. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can provide innovative solutions that meet stringent quality standards.

Furthermore, the market is shifting towards electric vehicles (EVs), prompting a reevaluation of starting motor designs and functionalities. With the growing penetration of EVs, traditional starter motors are being re-engineered to accommodate new propulsion technologies. This transition is not only a response to regulatory pressures for reduced emissions but also reflects consumer preferences for greener options. As a result, B2B buyers should focus on suppliers who are adapting to these changes by investing in R&D for electric and hybrid vehicle applications.

Additionally, regional dynamics play a critical role in sourcing strategies. For instance, buyers in Africa and South America are increasingly looking for local manufacturing partners to reduce lead times and shipping costs. Meanwhile, European buyers are prioritizing suppliers with a proven track record in quality assurance and compliance with international standards. Understanding these market dynamics will enable B2B buyers to make informed sourcing decisions that align with their operational goals.

How Can Sustainability and Ethical Sourcing Impact the Starting Motor Supply Chain?

As global awareness of environmental issues rises, sustainability and ethical sourcing have become crucial considerations for B2B buyers in the starting motor sector. The production of starter motors involves various materials, some of which can have significant environmental impacts. For instance, sourcing metals and plastics responsibly is essential to minimize ecological footprints.

Imagem ilustrativa relacionada com o motor de arranque

Buyers should prioritize suppliers who demonstrate commitment to sustainable practices, such as using recycled materials or implementing energy-efficient manufacturing processes. Certifications like ISO 14001 for environmental management and materials with ‘green’ labels can serve as indicators of a supplier’s dedication to sustainability. Moreover, engaging in ethical sourcing ensures that materials are obtained without exploitative practices, fostering a more equitable supply chain.

The importance of sustainability extends beyond regulatory compliance; it can also enhance brand reputation and customer loyalty. B2B buyers who align with eco-friendly suppliers are likely to attract environmentally-conscious consumers, thereby gaining a competitive edge in the market. Therefore, integrating sustainability into sourcing strategies not only addresses ethical concerns but also aligns with broader market trends towards greener business practices.

What Is the Historical Context of the Starting Motor Market Evolution?

The starting motor has evolved significantly since its inception in the early 20th century. Initially, vehicles relied on hand-crank systems, which posed challenges for drivers. The introduction of the electric starter motor revolutionized vehicle ignition, making it more accessible and user-friendly. This innovation not only improved convenience but also laid the foundation for the modern automotive industry.

Over the decades, advancements in technology have led to more efficient starter motors. The integration of electronic components and improved materials has enhanced performance and reliability, catering to the increasing demands of contemporary vehicles. As the automotive landscape shifts towards electric and hybrid models, the starting motor’s design continues to adapt, reflecting the industry’s commitment to innovation and sustainability. Understanding this historical context allows B2B buyers to appreciate the advancements that have shaped the current market and anticipate future trends.

Perguntas mais frequentes (FAQs) para compradores B2B de motor de arranque

-

How do I solve issues with a malfunctioning starter motor?

To address issues with a malfunctioning starter motor, first, check the battery to ensure it’s fully charged and the connections are secure. A weak battery can often mimic starter motor failure. Next, inspect the solenoid and starter connections for corrosion or loose wires. If the starter motor makes a clicking sound but doesn’t engage, the pinion gear may be stuck or damaged. If problems persist, it’s advisable to consult a qualified technician who can perform diagnostic tests and determine if the starter motor needs repair or replacement. -

What is the best starter motor for commercial vehicles?

The best starter motor for commercial vehicles depends on the engine type and size, as well as the specific application requirements. Heavy-duty starter motors designed for larger diesel engines typically offer higher torque and durability. Brands known for reliability in commercial applications include Bosch, Delco Remy, and Hitachi. When selecting a starter motor, consider factors such as environmental conditions, frequency of use, and maintenance support to ensure optimal performance and longevity. -

Que fatores devo considerar ao adquirir motores de arranque internacionalmente?

When sourcing starter motors internationally, consider factors such as supplier reliability, quality certifications, and compliance with international standards. Evaluate the supplier’s experience in the automotive industry, especially in your specific market. Additionally, assess their capacity for customization and ability to meet your volume requirements. Logistics and shipping times are crucial, so partner with suppliers who have efficient distribution networks and can manage customs requirements effectively. -

How can I vet suppliers of starter motors for quality assurance?

To vet suppliers of starter motors, start by checking for industry certifications such as ISO 9001, which indicates a commitment to quality management. Request product samples to assess their quality firsthand and review their testing protocols. Engage in discussions about their manufacturing processes and quality control measures. Additionally, seek references from other businesses that have sourced from them and look for online reviews to gauge their reputation within the industry. -

Qual é a quantidade mínima de encomenda (MOQ) típica para motores de arranque?

The typical minimum order quantity (MOQ) for starter motors can vary widely among suppliers, often ranging from 50 to 500 units. Factors influencing MOQ include the supplier’s production capacity, the type of starter motor, and the customization options required. For smaller businesses or first-time buyers, some suppliers may offer lower MOQs to facilitate entry into the market. Always communicate your needs upfront to negotiate favorable terms that align with your purchasing strategy. -

What payment terms are commonly offered by international suppliers?

Common payment terms offered by international suppliers of starter motors typically include options such as advance payment, letter of credit, and payment on delivery. Many suppliers may require a deposit (usually 30-50%) before production begins, with the balance due upon shipment or delivery. It’s important to clarify payment terms early in negotiations to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially for larger transactions. -

How can I ensure timely delivery of starter motors from international suppliers?

To ensure timely delivery of starter motors from international suppliers, establish clear shipping timelines and communicate regularly throughout the process. Utilize suppliers with established logistics networks that can provide tracking information and manage customs processes efficiently. Consider incorporating buffer time into your project timelines to accommodate potential delays. Establishing a good relationship with your supplier can also facilitate smoother communication and problem resolution if issues arise. -

Quais são os sinais comuns que indicam que um motor de arranque precisa de ser substituído?

Common signs that indicate a starter motor may need replacement include unusual noises such as grinding or clicking when turning the ignition, the engine not cranking, or intermittent starting issues. If the dashboard lights dim significantly when attempting to start the vehicle, it could indicate electrical problems. Additionally, if the starter motor engages but fails to turn the engine over, it may be time for replacement. Regular maintenance checks can help identify these issues before they lead to complete failure.

Top 3 Starting Motor Manufacturers & Suppliers List

1. AutoElectro - Motores de arranque

Domínio: autoelectro.pt

Registado: 1999 (26 anos)

Introdução: Starter motors are essential components in vehicles that enable the engine to turn over and start. When the ignition key is turned, the starter motor engages, turning the engine over to create suction for air intake, which is necessary for fuel combustion. Key components of a starter motor include:

– Armature: An electromagnet mounted on the drive shaft, made of a laminated soft iron core wrapped…

2. Haynes – Ignition System Essentials

Domínio: us.haynes.com

Registado: 1996 (29 anos)

Introdução: This company, Haynes – Ignition System Essentials, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. RAC – Starter Motors

Domínio: rac.co.uk

Registado: 1996 (29 anos)

Introdução: Starter motor is an electric component essential for starting the engine in internal combustion vehicles. It engages the engine’s rotation when the ignition is activated. Common causes of failure include broken solenoids, mechanical issues, electrical faults, overheating, and wear and tear. The starter motor is typically located at the back of the engine. It does not continuously drain the battery…

Conclusão sobre o aprovisionamento estratégico e perspectivas para o motor de arranque

In conclusion, strategic sourcing of starter motors is essential for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Understanding the intricacies of starter motor technology—such as the roles of key components like solenoids, armatures, and brushes—enables buyers to make informed decisions. Prioritizing quality sourcing not only enhances vehicle performance but also minimizes operational disruptions caused by starter motor failures.

As the global automotive landscape evolves, the demand for reliable and efficient starter motors continues to grow. Buyers should focus on establishing partnerships with reputable manufacturers and suppliers who prioritize quality and innovation. This approach will ensure access to advanced starter motor solutions that meet the specific needs of various vehicle types and markets.

Imagem ilustrativa relacionada com o motor de arranque

Looking ahead, B2B buyers are encouraged to stay abreast of technological advancements and industry trends that can influence sourcing strategies. By investing in strategic sourcing now, businesses can secure a competitive edge in the market and drive sustainable growth. Engage with trusted suppliers today to strengthen your supply chain and enhance the reliability of your automotive offerings.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.