Introdução: Navegando no mercado global de como substituir o motor de arranque

No panorama automóvel em constante evolução, o fornecimento de componentes fiáveis, como os motores de arranque, é um desafio crítico para os compradores B2B internacionais. Compreender como substituir um motor de arranque de forma eficiente pode ter um impacto significativo no tempo de atividade operacional e na satisfação do cliente. Este guia abrangente analisa os vários tipos de motores de arranque, as suas aplicações em diferentes modelos de veículos e as práticas essenciais de verificação de fornecedores. Ao abordar considerações importantes, como preços, garantia de qualidade e factores logísticos, pretendemos equipar os decisores com os conhecimentos necessários para navegar nas complexidades do aprovisionamento global.

Este guia foi especialmente concebido para empresas que operam em África, na América do Sul, no Médio Oriente e na Europa, incluindo mercados emergentes como a Arábia Saudita e o Vietname. Reconhecemos que estas regiões enfrentam desafios únicos na aquisição de peças automóveis, desde a flutuação das tarifas de importação até às diferentes normas de qualidade. Por isso, o nosso recurso foi concebido para capacitar os compradores B2B, fornecendo estratégias acionáveis para identificar fornecedores de confiança e garantir a adequação às suas necessidades específicas. Ao compreender as nuances da substituição do motor de arranque, as empresas podem tomar decisões de compra informadas que melhoram as suas ofertas de serviços e aumentam a sua vantagem competitiva no mercado.

Índice

- Lista dos 2 principais fabricantes e fornecedores de Como substituir o motor de arranque

- Introdução: Navegando no mercado global de como substituir o motor de arranque

- Compreender como substituir o arrancador Tipos e variações

- Principais aplicações industriais de como substituir o motor de arranque

- 3 pontos de dor comuns dos utilizadores para ‘como substituir o motor de arranque’ e as suas soluções

- Guia de seleção de materiais estratégicos para substituir o motor de arranque

- Análise aprofundada: Processos de fabrico e garantia de qualidade para saber como substituir o motor de arranque

- Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘como substituir o motor de arranque’

- Análise exaustiva de custos e preços para substituir o Sourcing para iniciantes

- Análise de alternativas: Comparação de como substituir o motor de arranque com outras soluções

- Propriedades técnicas essenciais e terminologia comercial para saber como substituir o arrancador

- Como navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector dos motores de arranque

- Perguntas mais frequentes (FAQs) para compradores B2B sobre como substituir o motor de arranque

- Strategic Sourcing Conclusão e perspectivas sobre como substituir o motor de arranque

- Aviso legal importante e termos de utilização

Compreender como substituir o arrancador Tipos e variações

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Substituição direta | Implica a substituição do motor de arranque antigo por uma unidade nova idêntica. | Oficinas de reparação automóvel, manutenção de frotas | Prós: Económica e simples. Contras: Requer uma correspondência exacta das peças. |

| Arrancador atualizado | Desempenho melhorado com maior binário e eficiência. | Modificações de veículos de alto desempenho | Prós: Maior fiabilidade de arranque; melhor para aplicações de elevada exigência. Contras: Custo inicial mais elevado. |

| Arrancador reconstruído | Componentes recondicionados que cumprem as especificações OEM. | Empresas preocupadas com o orçamento, frotas mais antigas | Prós: Custo inferior ao de um novo; amigo do ambiente. Contras: Podem ter um tempo de vida mais curto do que os novos arrancadores. |

| Arrancador de alto desempenho | Concebidos para aplicações de competição ou para trabalhos pesados, frequentemente mais leves e mais eficientes. | Equipas de corrida, operadores de máquinas pesadas | Prós: Desempenho superior; peso reduzido. Contras: Caro; pode não ser necessário para uma utilização normal. |

| Arrancador universal | Compatível com várias marcas e modelos, frequentemente ajustável. | Pequenas oficinas de reparação, entusiastas da bricolage | Prós: Versátil; fácil de armazenar. Contras: Pode não encaixar na perfeição; potencial para um desempenho reduzido. |

Quais são as caraterísticas dos motores de arranque de substituição direta?

Os motores de arranque de substituição direta são concebidos para corresponderem exatamente ao motor de arranque original em termos de ajuste e funcionamento. Este tipo é adequado para empresas que requerem reparações rápidas e fiáveis sem necessidade de modificações. Ao adquirir estes motores de arranque, os compradores B2B devem certificar-se de que têm as especificações corretas, incluindo a marca, o modelo e o ano do veículo. Isto assegura uma integração perfeita, reduzindo o tempo de trabalho e minimizando o risco de falhas futuras.

Como é que os arrancadores actualizados beneficiam as aplicações B2B?

Os motores de arranque actualizados oferecem caraterísticas de desempenho melhoradas, tais como maior binário e eficiência, tornando-os ideais para aplicações de elevada exigência ou veículos de desempenho. As empresas envolvidas em modificações automóveis ou as que operam em ambientes exigentes devem considerar estas opções. Aquando da compra, os compradores devem avaliar os ganhos de desempenho específicos e determinar se o investimento se adequa às suas necessidades operacionais e restrições orçamentais.

O que é que os compradores devem saber sobre arrancadores reconstruídos?

Os motores de arranque reconstruídos são versões renovadas de peças originais dos fabricantes de equipamento (OEM). Constituem uma solução económica para as empresas que gerem frotas mais antigas ou que têm restrições orçamentais. Os compradores devem considerar a garantia e a garantia de qualidade fornecidas pelo fornecedor, uma vez que estes factores podem influenciar a fiabilidade da unidade reconstruída. Embora possam ter um tempo de vida mais curto do que os novos motores de arranque, oferecem um equilíbrio prático entre custo e funcionalidade.

O que torna os arrancadores de alto desempenho únicos?

Os motores de arranque de elevado desempenho são especificamente concebidos para aplicações de competição ou para trabalhos pesados, oferecendo caraterísticas como menor peso e maior eficiência. Estes arrancadores são cruciais para as empresas envolvidas em desportos motorizados ou para as que operam maquinaria pesada que requer um arranque fiável em condições extremas. Embora tenham um preço superior, os benefícios em termos de desempenho e fiabilidade podem justificar o custo para os operadores sérios.

Porquê escolher arrancadores universais para flexibilidade?

Os motores de arranque universais são concebidos para se adaptarem a uma vasta gama de veículos, o que os torna uma opção versátil para pequenas oficinas de reparação e entusiastas da bricolage. Permitem uma gestão mais fácil do inventário, uma vez que as empresas podem armazenar menos números de peças. No entanto, os compradores devem estar cientes de que, embora ofereçam flexibilidade, o encaixe pode nem sempre ser perfeito, afectando potencialmente o desempenho. As empresas devem ponderar a conveniência da universalidade contra a potencial necessidade de ajustes durante a instalação.

Principais aplicações industriais de como substituir o motor de arranque

| Indústria/Setor | Aplicação específica de como substituir o motor de arranque | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Substituição de motores de arranque em veículos de passageiros e comerciais | Reduz o tempo de inatividade do veículo e melhora a satisfação do cliente | Compatibilidade com vários modelos de veículos; garantia e serviços de assistência |

| Maquinaria pesada | Substituição de motores de arranque para equipamento de construção e agrícola | Assegura a eficiência operacional e minimiza os custos de reparação | Disponibilidade de motores de arranque de qualidade industrial; cumprimento das normas de segurança |

| Transporte e Logística | Substituição rápida do motor de arranque em veículos de frota | Aumenta a fiabilidade da frota e reduz os custos de manutenção | Opções de compra a granel; fiabilidade do fornecedor e prazos de entrega |

| Mineração | Substituição de arrancadores para equipamento mineiro | Aumenta a produtividade ao minimizar as falhas do equipamento | Durabilidade em condições adversas; conhecimento especializado do equipamento |

| Transportes públicos | Substituição de motores de arranque em autocarros e comboios | Melhora a fiabilidade e a segurança do serviço público | Conformidade com a regulamentação local; abastecimento de fornecedores certificados |

Como é que ‘como substituir o motor de arranque’ é utilizado na indústria de reparação automóvel?

No sector da reparação automóvel, o processo de substituição dos motores de arranque é essencial tanto para os veículos de passageiros como para os veículos comerciais. Um motor de arranque avariado pode levar a um tempo de inatividade significativo do veículo, afectando a satisfação do cliente e as receitas. As oficinas de reparação automóvel devem garantir que têm acesso a uma vasta gama de motores de arranque compatíveis para satisfazer as várias marcas e modelos. Além disso, a oferta de garantias e de apoio pós-venda pode aumentar a confiança e a fidelidade dos clientes, o que torna crucial para as empresas de reparação o estabelecimento de relações fortes com fornecedores fiáveis.

Qual é a importância da substituição do motor de arranque na maquinaria pesada?

A maquinaria pesada, como o equipamento de construção e agrícola, depende fortemente de motores de arranque funcionais para um funcionamento eficiente. Um motor de arranque avariado pode parar a produtividade, levando a atrasos dispendiosos. Por conseguinte, as empresas deste sector beneficiam do fornecimento de motores de arranque duradouros e de qualidade industrial, capazes de resistir a ambientes exigentes. Os fornecedores devem fornecer informações sobre as normas de segurança e a compatibilidade com vários tipos de máquinas, garantindo que o equipamento permanece operacional e que os custos de manutenção são reduzidos ao mínimo.

Qual o impacto da substituição de motores de arranque no sector dos transportes e da logística?

No sector dos transportes e da logística, os veículos da frota necessitam de motores de arranque fiáveis para evitar avarias que podem perturbar a prestação de serviços. A substituição rápida dos motores de arranque garante que os veículos permanecem operacionais, aumentando assim a fiabilidade da frota e reduzindo os custos de manutenção. As empresas devem considerar opções de compra a granel de motores de arranque para gerir eficazmente as despesas. Além disso, a fiabilidade dos fornecedores e os seus prazos de entrega são factores críticos para garantir que as peças de substituição estão disponíveis quando necessário.

Imagem ilustrativa relacionada com a substituição do motor de arranque

Porque é que a substituição do motor de arranque é crítica na indústria mineira?

O sector mineiro opera frequentemente em condições adversas, tornando a fiabilidade do equipamento, incluindo os motores de arranque, crucial para a produtividade. A substituição regular dos motores de arranque no equipamento mineiro pode evitar falhas inesperadas que podem levar a um tempo de inatividade significativo. As empresas precisam de obter motores de arranque que sejam especificamente concebidos para durabilidade em ambientes extremos. Compreender o equipamento específico e os seus requisitos é essencial para que os fornecedores forneçam as soluções certas e assegurem operações mineiras ininterruptas.

Como é que a substituição do motor de arranque influencia os transportes públicos?

Nos transportes públicos, a fiabilidade dos autocarros e comboios é fundamental para garantir a segurança e a satisfação dos passageiros. Um motor de arranque defeituoso pode levar a interrupções de serviço, afectando negativamente a perceção do público e a eficiência operacional. Por conseguinte, as autoridades de transportes devem dar prioridade ao fornecimento de motores de arranque que cumpram os regulamentos e normas locais. O estabelecimento de parcerias com fornecedores certificados pode ajudar a garantir a utilização de componentes de qualidade, conduzindo, em última análise, a uma maior fiabilidade do serviço e à confiança do público.

3 pontos de dor comuns dos utilizadores para ‘como substituir o motor de arranque’ e as suas soluções

Cenário 1: Dificuldade em identificar a substituição correta do motor de arranque

O problema: Um dos desafios mais significativos que os compradores B2B enfrentam quando substituem um motor de arranque é identificar a peça correta para o seu modelo de veículo específico. Dada a vasta gama de motores de arranque disponíveis no mercado, incluindo variações de tamanho, especificações eléctricas e compatibilidade com diferentes tipos de motores, pode ser esmagador. Este problema é agravado nos mercados internacionais, onde o acesso a especificações detalhadas pode ser limitado, levando a compras incorrectas e a potenciais atrasos nas reparações.

A solução: Para encontrar efetivamente o motor de arranque certo, os compradores devem utilizar bases de dados ou plataformas abrangentes que ofereçam ferramentas de referência cruzada com base nas especificações do veículo. É aconselhável recolher informações detalhadas sobre o veículo, incluindo a marca, o modelo, o ano e o tipo de motor. Além disso, a utilização de números de peças OEM (Original Equipment Manufacturer) pode simplificar significativamente o processo de seleção. Os compradores devem também consultar os seus manuais de serviço ou bases de dados automóveis de confiança que forneçam tabelas de compatibilidade. Esta abordagem proactiva minimiza o risco de erros e assegura um processo de substituição suave, reduzindo o tempo de inatividade da frota.

Cenário 2: Falta de conhecimentos técnicos para a instalação

O problema: Muitos compradores B2B podem não ter os conhecimentos técnicos necessários para instalar corretamente um motor de arranque, o que pode levar a potenciais contratempos durante o processo de instalação. Este problema pode ser particularmente acentuado em regiões com acesso limitado a mão de obra especializada ou onde os programas de formação automóvel não estão amplamente disponíveis. Uma má instalação pode resultar em mais problemas no veículo, tais como avarias eléctricas ou mesmo danos no novo motor de arranque.

A solução: Para colmatar esta lacuna de conhecimentos, as empresas devem investir em programas de formação ou workshops centrados nas competências básicas de reparação automóvel, especialmente para o seu pessoal de manutenção. Além disso, a criação ou o acesso a materiais de instrução passo-a-passo, incluindo tutoriais em vídeo ou guias detalhados, pode capacitar os funcionários para efectuarem as instalações corretamente. Além disso, o incentivo a parcerias com especialistas ou técnicos locais do sector automóvel que possam prestar formação ou assistência no local pode garantir que as instalações sejam efectuadas de forma eficiente e precisa. Este investimento no desenvolvimento de competências não só melhora a eficiência operacional, como também cria confiança na equipa.

Cenário 3: Gerir os custos e os desafios da cadeia de abastecimento

O problema: A gestão de custos é uma preocupação fundamental para os compradores B2B quando substituem os iniciadores, especialmente em mercados flutuantes. Os compradores internacionais enfrentam frequentemente desafios na cadeia de fornecimento que podem levar ao aumento dos preços e a prazos de entrega alargados. Esta imprevisibilidade pode afetar os orçamentos e perturbar as operações, especialmente para as empresas que dependem de uma frota de veículos para os seus serviços.

A solução: Para mitigar estes riscos financeiros, os compradores devem estabelecer relações de longo prazo com fornecedores fiáveis que possam fornecer preços consistentes e entregas atempadas. A celebração de acordos de compra a granel também pode resultar em poupanças de custos e garantir um fornecimento constante de peças essenciais. Além disso, a implementação de sistemas de gestão de inventário que monitorizam as taxas de utilização pode ajudar a prever quando os motores de arranque têm de ser substituídos, permitindo uma encomenda proactiva antes de surgirem problemas de fornecimento. Por último, a exploração de opções de fornecimento alternativas, como fabricantes ou distribuidores locais, pode proporcionar preços mais flexíveis e reduzir a dependência do transporte internacional, estabilizando ainda mais os custos e aumentando a resiliência da cadeia de fornecimento.

Guia de seleção de materiais estratégicos para substituir o motor de arranque

Quais são os principais materiais para a substituição de motores de arranque em veículos?

Ao considerar a substituição de motores de arranque para automóveis, a seleção dos materiais certos é crucial para garantir a durabilidade, fiabilidade e desempenho. Aqui, analisamos quatro materiais comuns utilizados no fabrico de motores de arranque: aço, alumínio, cobre e materiais compósitos. Cada um destes materiais tem propriedades, vantagens e limitações distintas que são importantes para os compradores B2B internacionais compreenderem.

Qual o desempenho do aço em aplicações de arranque?

O aço é um material amplamente utilizado para caixas e componentes de arrancadores devido à sua elevada resistência e durabilidade. Normalmente, tem uma excelente resistência à temperatura, o que o torna adequado para aplicações de elevado desempenho. A resistência à corrosão do aço pode ser melhorada através de galvanização ou revestimentos, o que é essencial em regiões com ambientes húmidos ou salgados.

Prós: O aço é geralmente económico e oferece uma elevada resistência à tração, o que o torna adequado para aplicações pesadas. Está também facilmente disponível e é fácil de fabricar.

Contras: A principal desvantagem do aço é o seu peso, que pode afetar o desempenho geral do veículo. Além disso, se não for corretamente tratado, o aço pode corroer-se com o tempo, especialmente em ambientes agressivos.

Impacto na aplicação: Os motores de arranque em aço são compatíveis com uma vasta gama de veículos, incluindo camiões pesados e veículos comerciais, o que os torna versáteis para vários mercados.

Considerações para compradores internacionais: Os compradores em regiões como África e Médio Oriente devem garantir que os componentes de aço cumprem as normas locais de resistência à corrosão, como ASTM ou JIS, para assegurar a longevidade em climas difíceis.

Que papel desempenha o alumínio no fabrico de arrancadores?

O alumínio é outra escolha popular para componentes de arranque, particularmente pelas suas propriedades de leveza. Tem uma boa relação força/peso e uma excelente resistência à corrosão, o que o torna adequado para aplicações automóveis em que a redução de peso é uma prioridade.

Prós: A natureza leve do alumínio contribui para melhorar a eficiência e o desempenho do combustível. Tem também uma boa condutividade térmica, o que pode ajudar a dissipar o calor gerado durante o funcionamento do motor de arranque.

Contras: O alumínio pode ser mais caro do que o aço e a sua resistência pode não ser suficiente para todas as aplicações, especialmente em ambientes pesados. Para além disso, pode ser mais difícil de maquinar e fabricar do que o aço.

Imagem ilustrativa relacionada com a substituição do motor de arranque

Impacto na aplicação: Os motores de arranque em alumínio são ideais para veículos de passageiros e automóveis de desempenho em que a redução do peso é fundamental.

Considerações para compradores internacionais: Os compradores na Europa e na América do Sul podem preferir componentes de alumínio devido às suas vantagens de leveza, mas devem ter em conta os custos mais elevados e assegurar o cumprimento das normas de fabrico locais.

Como é que o cobre melhora a funcionalidade do arrancador?

O cobre é frequentemente utilizado nas ligações eléctricas e nos enrolamentos dos motores de arranque devido à sua excelente condutividade eléctrica. Desempenha um papel crucial para assegurar uma transferência de energia eficiente da bateria para o motor de arranque.

Prós: A elevada condutividade do cobre permite um arranque rápido e eficiente, o que é vital em aplicações automóveis. O cobre é também relativamente resistente à corrosão, especialmente quando revestido.

Contras: O cobre é mais caro do que o aço e o alumínio, o que pode aumentar o custo global da produção de arrancadores. Para além disso, os componentes de cobre podem ser mais pesados, o que pode não estar de acordo com a tendência para designs leves.

Impacto na aplicação: O cobre é essencial para arranques de alto desempenho em que é necessário um engate rápido, tornando-o adequado para veículos de competição e de alto desempenho.

Considerações para compradores internacionais: Os compradores devem considerar as implicações de custo da utilização do cobre e garantir que se abastecem junto de fornecedores que cumprem as normas internacionais para componentes eléctricos.

Que vantagens oferecem os materiais compósitos aos principiantes?

Os materiais compósitos, como os plásticos reforçados, estão a ser cada vez mais utilizados em aplicações de arranque devido às suas propriedades de leveza e resistência à corrosão. Estes materiais podem ser projectados para caraterísticas de desempenho específicas, o que os torna versáteis.

Prós: Composites can significantly reduce weight and are often resistant to corrosion and chemical damage. They can also be molded into complex shapes, allowing for innovative designs.

Contras: The main limitation of composite materials is their lower thermal and mechanical properties compared to metals, which can affect durability in high-stress applications. They may also be more expensive to produce.

Imagem ilustrativa relacionada com a substituição do motor de arranque

Impacto na aplicação: Composites are suitable for starters in passenger vehicles where weight savings are prioritized, but they may not be ideal for heavy-duty applications.

Considerações para compradores internacionais: Buyers should verify that composite materials meet relevant international standards for automotive components, especially in regions with stringent regulations.

Summary Table of Material Properties for Starter Replacement

| Material | Typical Use Case for how to replace starter | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Aço | Heavy-duty starters in trucks | Alta resistência e durabilidade | Heavier, potential for corrosion | Baixo |

| Alumínio | Starters in passenger and performance cars | Leve, boa resistência à corrosão | Higher cost, lower strength | Med |

| Cobre | Ligações eléctricas nos motores de arranque | Excelente condutividade elétrica | High cost, heavier | Alto |

| Compósito | Lightweight starters in passenger vehicles | Corrosion resistance, lightweight | Lower strength, higher production cost | Med |

This analysis provides a comprehensive overview of the materials used in starter replacements, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

Análise aprofundada: Processos de fabrico e garantia de qualidade para saber como substituir o motor de arranque

Quais são as principais fases do processo de fabrico de arrancadores?

The manufacturing process for automotive starters involves several critical stages, each designed to ensure the final product meets rigorous performance and reliability standards. These stages typically include material preparation, forming, assembly, and finishing.

Imagem ilustrativa relacionada com a substituição do motor de arranque

Preparação do material

The first step involves selecting high-quality materials that can withstand the operational demands of a starter. Common materials include steel for the casing, copper for electrical connections, and high-temperature plastics for insulation. These materials undergo rigorous quality checks to ensure they meet international standards. Suppliers often use advanced techniques such as spectrometry and tensile testing to verify material integrity before proceeding.

Formando

Once materials are prepared, they are shaped into the required components. This can involve processes such as stamping, machining, and die-casting. Stamping is commonly used for creating metal parts, while die-casting is utilized for producing complex shapes with high precision. Automated robotic systems often assist in this stage to enhance accuracy and reduce production time. Each component is carefully monitored for dimensional accuracy and surface finish to ensure they meet specifications.

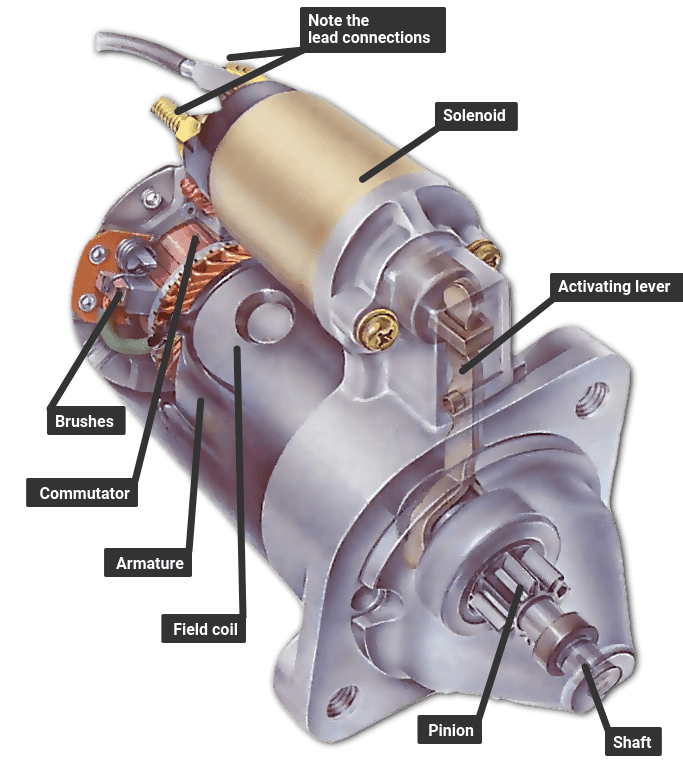

Montagem

The assembly stage is where the various components come together to form the complete starter. This process usually involves several sub-assemblies, including the motor, solenoid, and housing. Automated assembly lines may be employed to increase efficiency, but manual assembly is also common, especially for quality-sensitive tasks. Key assembly techniques include torque control to ensure that all fastenings are secure and that components are aligned correctly.

Acabamento

The finishing stage includes surface treatments such as coating and painting to enhance corrosion resistance and aesthetic appeal. This may involve electroplating or powder coating, depending on the application requirements. After finishing, each starter undergoes a thorough inspection to ensure it meets visual and mechanical standards.

Como é implementada a garantia de qualidade no fabrico de arranque?

Quality assurance (QA) is a critical aspect of the starter manufacturing process. It encompasses various international standards and industry-specific regulations designed to ensure product reliability and safety.

What Are the Relevant International Standards for Starters?

Many manufacturers adhere to ISO 9001, an international standard for quality management systems. This framework helps organizations consistently meet customer and regulatory requirements while enhancing satisfaction. In addition to ISO 9001, other certifications like CE mark and API standards may apply, particularly for products intended for specific markets or applications.

Quais são os principais pontos de verificação do controlo de qualidade?

Quality control (QC) is implemented at various stages of the manufacturing process. Key checkpoints include:

-

Controlo de Qualidade de Entrada (IQC): This stage involves inspecting raw materials and components upon arrival to ensure they meet specified standards. Non-conforming materials are rejected to prevent defects downstream.

-

Controlo de qualidade em processo (IPQC): During production, regular inspections are conducted to verify that processes remain within defined parameters. This includes monitoring temperature, pressure, and dimensions throughout the forming and assembly stages.

-

Controlo de Qualidade Final (FQC): After assembly, each starter undergoes comprehensive testing, which may include electrical performance tests, durability assessments, and operational simulations. This ensures that each unit functions correctly before shipment.

Que métodos de teste comuns são utilizados para garantir a qualidade do arrancador?

Testing is a vital component of quality assurance for starters. Common methods include:

-

Testes elétricos: Each starter is tested for electrical integrity, including resistance, current draw, and voltage output. These tests ensure that the starter will perform effectively under operational conditions.

-

Teste de durabilidade: Starters undergo rigorous endurance tests to assess their performance over time. This may include simulating start cycles to evaluate wear and fatigue.

-

Testes térmicos: Given the high temperatures starters may encounter, thermal testing is conducted to ensure components can withstand extreme conditions without failing.

Como os compradores B2B podem verificar as práticas de controlo de qualidade dos fornecedores?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial to ensuring product reliability.

What Steps Should Buyers Take for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess quality control measures. Buyers should request documentation of the supplier’s quality management system, including ISO certifications and internal audit reports. On-site audits can provide insights into the manufacturing environment and adherence to quality standards.

What Role Do Reports and Third-Party Inspections Play?

Buyers should also look for third-party inspection reports, which can provide an unbiased assessment of a supplier’s manufacturing and quality processes. Engaging independent inspection services can offer additional assurance that products meet required specifications before shipment.

Imagem ilustrativa relacionada com a substituição do motor de arranque

Quais são as nuances do controlo de qualidade e da certificação para os compradores internacionais?

International buyers must be aware of specific certification requirements that vary by region. For instance, products sold within the European Union must bear the CE mark, indicating compliance with health and safety standards. In contrast, products intended for markets in the Middle East may require adherence to local standards such as the Gulf Cooperation Council (GCC) regulations.

Additionally, understanding the supply chain dynamics, including logistics and customs regulations, is essential for seamless procurement. Buyers should ensure that suppliers are prepared to provide necessary documentation and certifications to facilitate smooth transactions across borders.

Conclusão

Manufacturing starters involves a complex interplay of material selection, precise engineering, and stringent quality assurance. For B2B buyers, especially those operating in diverse international markets, understanding these processes and quality control measures is vital for sourcing reliable products. By leveraging international standards, conducting thorough audits, and verifying supplier practices, buyers can mitigate risks and ensure they procure high-quality automotive starters that meet their operational needs.

Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘como substituir o motor de arranque’

To effectively navigate the procurement process for replacing starters, B2B buyers must follow a structured approach. This checklist is designed to help you source high-quality starters while ensuring compatibility and reliability for your specific vehicle applications.

Passo 1: Defina as suas especificações técnicas

Understanding the technical specifications of the starter you need is crucial. This includes the starter type, size, and power requirements, which can vary significantly between vehicle models and manufacturers.

– Principais considerações:

– Review the vehicle’s service manual for specifications.

– Note the original part number for precise matching.

Passo 2: Identifique fornecedores confiáveis

Finding trustworthy suppliers is essential for ensuring the quality and reliability of your purchase. Research potential suppliers who specialize in automotive components and have a solid reputation in the industry.

– Principais considerações:

– Look for suppliers with experience in your region (e.g., Africa, South America).

– Check for online reviews and ratings from other B2B clients.

Passo 3: Avaliar as certificações dos fornecedores

Before making a commitment, verify that your potential suppliers hold relevant certifications. Certifications such as ISO 9001 or specific automotive industry standards can indicate a commitment to quality and reliability.

– Principais considerações:

– Request copies of certifications and quality assurance processes.

– Ensure they comply with local and international automotive regulations.

Passo 4: Solicitar informações detalhadas sobre o produto

Gathering detailed product information helps you make informed decisions. Request datasheets or catalogs that provide specifications, installation instructions, and warranty information for the starters.

– Principais considerações:

– Compare the features of various starter models.

– Ensure the product meets or exceeds OEM standards.

Passo 5: Inquire About Pricing and Payment Terms

Understanding the pricing structure and payment terms is critical for budget management. Engage with multiple suppliers to gather quotes and evaluate their pricing strategies, including bulk discounts or payment flexibility.

– Principais considerações:

– Clarify shipping costs and delivery times.

– Look for suppliers that offer favorable credit terms or payment options.

Passo 6: Check for After-Sales Support

After-sales support can significantly impact your overall satisfaction with the purchase. Assess the level of customer service provided by the supplier, including warranty services and technical support.

– Principais considerações:

– Inquire about the return policy and warranty terms.

– Evaluate responsiveness to technical queries and support availability.

Passo 7: Finalize Your Order and Logistics

Once you have selected a supplier, finalize your order while ensuring that logistics are efficiently managed. Confirm delivery schedules and shipping methods to ensure timely receipt of your starters.

– Principais considerações:

– Keep communication lines open for updates on order status.

– Ensure all documentation is in order for customs clearance if importing.

By following this checklist, B2B buyers can ensure a smoother procurement process for replacing starters, ultimately leading to better operational efficiency and reduced downtime in their fleet management.

Análise exaustiva de custos e preços para substituir o Sourcing para iniciantes

Quais são os principais componentes de custo para a substituição de um motor de arranque?

When evaluating the total cost of replacing a starter, several components must be considered. The primary cost factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

-

Materiais: The cost of the starter itself is a significant portion of the total expense. Prices can vary widely based on the type of starter (e.g., standard, high-performance, or customized) and the materials used (e.g., steel, copper). Buyers should anticipate a range of $50 to $300, depending on specifications and quality.

-

Trabalho: Labor costs involve the time required for installation, which varies by vehicle type and complexity. Typically, labor rates can range from $50 to $150 per hour, depending on the region and expertise required.

-

Custos indiretos de produção: This includes indirect costs such as utilities, rent, and administrative expenses associated with producing starters. These costs are usually factored into the material pricing but can vary significantly between manufacturers.

-

Tooling and QC: Tooling costs for producing starters can affect pricing, especially for specialized or custom designs. Quality control processes ensure that the products meet specific industry standards and can add to overall expenses.

-

Logística: Shipping and transportation costs also play a role. International buyers must consider additional fees related to customs and import duties, which can vary by region.

-

Margem: Supplier margins typically range from 10% to 30%, depending on market demand and competition.

Como é que os influenciadores de preços afectam os custos de substituição de arrancadores?

Several factors can influence the pricing structure for starters, particularly in B2B contexts:

-

Volume/MOQ: Bulk purchasing can lead to significant discounts. Suppliers often have minimum order quantities (MOQs), and negotiating for larger volumes can drive down the per-unit cost.

-

Especificações e personalização: Customized starters will generally cost more due to the additional design and manufacturing processes involved. Buyers should clearly define their specifications to avoid unexpected costs.

-

Materiais e certificações de qualidade: Higher quality materials and certifications (e.g., ISO, OEM standards) can increase costs but may provide better performance and longevity, which is critical for businesses looking to minimize downtime.

-

Fatores relacionados ao fornecedor: The reputation and reliability of the supplier can also affect pricing. Established suppliers with a history of quality and service may charge a premium.

-

Incoterms: The choice of Incoterms can impact the total cost, as they define the responsibilities of buyers and sellers in shipping and logistics. Understanding these terms can help buyers negotiate better terms and manage costs effectively.

What Are Effective Buyer Tips for Cost-Efficiency in Starter Replacement?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, several strategies can help maximize cost-efficiency:

-

Negociar termos: Always negotiate pricing and payment terms. Building a good relationship with suppliers can lead to better deals and favorable terms.

-

Considere o custo total de propriedade (TCO): Focus not just on the initial purchase price but on the TCO, which includes installation, maintenance, and potential downtime. High-quality starters may have a higher upfront cost but could save money in the long run through reduced failures and maintenance needs.

-

Research Local Regulations: Understanding local import duties, taxes, and compliance requirements can prevent unexpected costs. This is especially relevant for buyers in regions with complex trade regulations.

-

Avaliar vários fornecedores: Comparing offers from different suppliers can provide insights into competitive pricing and help identify the best value for your needs.

Conclusão

Replacing a starter involves a complex interplay of costs and pricing factors that vary significantly based on several influences. By understanding these components and employing strategic purchasing practices, B2B buyers can effectively manage their expenses while ensuring quality and reliability in their vehicle operations. Always seek indicative prices as a baseline for negotiation, keeping in mind that actual costs may vary based on specific circumstances and market conditions.

Análise de alternativas: Comparação de como substituir o motor de arranque com outras soluções

Exploring Alternatives to Traditional Starter Replacement Methods

In the automotive sector, the starter is a critical component for vehicle functionality. While replacing a faulty starter is a common practice, several alternative solutions can also resolve the underlying issues. Understanding these options can help B2B buyers make informed decisions tailored to their operational needs.

| Aspecto comparativo | How To Replace Starter | Starter Relay Replacement | Jump Starting the Vehicle |

|---|---|---|---|

| Desempenho | Restores full starter functionality; reliable for long-term use. | Can resolve starting issues temporarily; effective if the relay is faulty. | Offers immediate solution to start a vehicle; only a temporary fix. |

| Custo | Moderate cost for parts and labor; typically ranges from $150 to $500. | Low-cost solution; relay parts usually under $50. | Minimal cost if using another vehicle; may require purchasing cables ($20-$100). |

| Facilidade de implementação | Requires technical skills; can be labor-intensive and time-consuming. | Simple and quick to replace; often DIY-friendly. | Very easy; can be done in minutes with basic knowledge. |

| Manutenção | Low maintenance post-installation; new starters have a long lifespan. | May require future replacements; dependent on vehicle usage. | No maintenance; but reliance on external power source can be an issue. |

| Melhor caso de uso | Ideal for long-term vehicle reliability; necessary when the starter is beyond repair. | Best for diagnosing electrical issues quickly; a stop-gap solution. | Useful for emergency situations or when immediate travel is necessary. |

What Are the Pros and Cons of Starter Relay Replacement?

Replacing a starter relay can be an effective alternative to directly replacing the starter motor. This method is particularly beneficial when the relay is identified as the source of the problem. The primary advantage lies in the lower cost and simplicity of the procedure, making it accessible even for those with limited mechanical skills. However, it is important to note that this solution is often temporary; if the starter motor itself is faulty, the underlying issue will remain unresolved, potentially leading to future breakdowns.

Imagem ilustrativa relacionada com a substituição do motor de arranque

How Does Jump Starting the Vehicle Compare?

Jump starting a vehicle provides an immediate solution for starting issues, especially in cases where the battery is low or dead. This method is advantageous due to its simplicity and the minimal cost involved, particularly if a second vehicle or jump starter is available. However, it is merely a stop-gap solution and does not address the root cause of the problem. Over-reliance on jump starting can lead to further complications down the line, such as repeated battery failures or starter issues.

Fazer a escolha certa para as necessidades da sua empresa

For B2B buyers, selecting the right solution for starter issues hinges on various factors such as budget, the urgency of the situation, and long-term reliability. If the vehicle’s starter is confirmed to be faulty, investing in a replacement will ensure reliable performance. Conversely, for less critical situations or when immediate action is needed, exploring alternatives like starter relay replacement or jump starting may suffice. Evaluating the specific operational context and anticipated vehicle usage will guide buyers toward the most appropriate choice, ensuring they maintain their fleet’s efficiency and performance.

Propriedades técnicas essenciais e terminologia comercial para saber como substituir o arrancador

What Are the Critical Technical Properties for Replacing a Starter?

When considering the replacement of a vehicle starter, understanding its technical properties is essential for ensuring compatibility, performance, and longevity. Here are some critical specifications to consider:

-

Grau do material

– The starter motor’s housing is typically made from materials like aluminum or high-grade steel. These materials must withstand high temperatures and resist corrosion. In B2B contexts, selecting starters made from superior materials can lead to longer product lifespans and reduced warranty claims. -

Especificações de binário

– Torque ratings indicate the amount of rotational force the starter can produce to turn the engine over. This specification is vital for ensuring that the starter can handle the engine’s requirements. B2B buyers should ensure that the starter’s torque specifications match or exceed those of the original equipment to avoid performance issues. -

Resistência elétrica

– The electrical resistance of the starter windings affects its efficiency and performance. A lower resistance typically indicates better conductivity, leading to quicker engine starts. For businesses, understanding electrical resistance can help in selecting starters that provide reliable performance and minimize energy waste. -

Tolerâncias dimensionais

– Accurate dimensions and tolerances are critical for proper installation and functionality. Starters must fit securely within the designated space in the engine compartment. In B2B transactions, precise measurements can prevent costly installation errors and ensure compatibility with various vehicle models. -

Solenoid Specifications

– The solenoid is a critical component that engages the starter motor. Specifications such as the number of terminals and voltage ratings must match the vehicle’s requirements. For international buyers, this ensures that the product can be integrated without modifications, reducing the risk of operational delays.

What Common Trade Terminology Should B2B Buyers Understand When Replacing a Starter?

Navigating the automotive parts market requires familiarity with specific trade terminology that can affect procurement processes. Here are some common terms:

-

OEM (Fabricante de Equipamento Original)

– OEM parts are manufactured by the same company that produced the original part for the vehicle. In B2B transactions, OEM starters often guarantee compatibility and reliability, making them a preferred choice for many businesses focused on quality. -

MOQ (Quantidade mínima de encomenda)

– MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory effectively and minimize excess stock, particularly in regions with fluctuating demand. -

RFQ (Pedido de Orçamento)

– An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products or services. B2B buyers should utilize RFQs to compare offers from different manufacturers, ensuring they secure the best deal while considering factors like quality and delivery times. -

Incoterms (Termos Comerciais Internacionais)

– Incoterms are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs. For B2B buyers, understanding Incoterms can help mitigate risks associated with cross-border transactions and ensure compliance with international shipping regulations. -

Prazo de entrega

– Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses that rely on timely deliveries, knowing the lead time for starter replacements is essential for planning maintenance schedules and minimizing downtime. -

Termos da garantia

– Warranty terms outline the conditions under which a product can be returned or repaired. Understanding warranty policies is vital for B2B buyers to ensure they are protected against defects and can manage potential costs associated with product failures.

By grasping these essential technical properties and industry terms, B2B buyers can make informed decisions that align with their operational needs and enhance their purchasing strategies in the automotive sector.

Como navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector dos motores de arranque

What Are the Current Market Dynamics and Key Trends in the Starter Replacement Sector?

The automotive starter replacement market is witnessing significant growth driven by several global factors. Increased vehicle ownership in emerging markets, particularly in Africa and South America, is propelling demand for starter replacements. Additionally, advancements in automotive technology, such as the rise of electric vehicles (EVs), are altering traditional starter designs and functionalities. For international B2B buyers, understanding the implications of these changes is crucial. Suppliers are increasingly focusing on the development of high-efficiency starters that cater to both conventional and electric vehicles, presenting a unique sourcing opportunity.

In terms of sourcing trends, digitalization is reshaping how businesses interact with suppliers and customers alike. E-commerce platforms and online marketplaces are becoming prevalent, providing B2B buyers with easier access to a wider range of starter products and competitive pricing. Moreover, the use of data analytics is on the rise, allowing companies to forecast demand more accurately and optimize inventory management. This trend is particularly relevant for buyers in Europe and the Middle East, where market saturation and competition are intense.

Furthermore, regional dynamics are influencing sourcing strategies. Buyers from the Middle East and Africa may prioritize local suppliers to minimize logistics costs and improve lead times, while those in Europe may seek partnerships with manufacturers offering innovative starter solutions. Understanding these dynamics will enable B2B buyers to make informed decisions and strengthen their competitive advantage in the market.

Como é que a sustentabilidade está a moldar o fornecimento de entradas no B2B?

Sustainability is becoming a pivotal consideration in the sourcing of automotive components, including starters. The environmental impact of traditional manufacturing processes has led to increasing scrutiny from consumers and regulators alike. B2B buyers are now more inclined to partner with suppliers who prioritize sustainable practices, ensuring that their sourcing strategies align with global sustainability goals.

Ethical sourcing is also gaining traction, as businesses recognize the importance of responsible supply chains. Buyers are encouraged to evaluate their suppliers based on their adherence to ethical labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 26000 (Social Responsibility) are becoming essential benchmarks for assessing supplier sustainability.

In the context of starter replacements, the demand for “green” materials is on the rise. Buyers should seek manufacturers that utilize recyclable materials and eco-friendly production methods. This not only helps reduce the carbon footprint associated with starter manufacturing but also positions businesses favorably in a market increasingly driven by consumer preferences for sustainable products.

What Is the Historical Context of Starter Replacement in the Automotive Industry?

The automotive starter has evolved significantly since its inception in the early 20th century. Initially, starters were mechanical devices requiring manual operation. However, the introduction of the electric starter in the 1910s revolutionized vehicle ignition systems, making them more reliable and user-friendly. Over the decades, advancements in materials and technology have led to the development of more efficient starters that consume less energy and offer enhanced performance.

In recent years, the rise of electric and hybrid vehicles has further transformed the starter market. Modern starters are now designed to accommodate the unique demands of these vehicles, incorporating features such as regenerative braking capabilities and integrated motor-generators. This evolution presents new opportunities for B2B buyers to source innovative starter solutions that meet the changing needs of the automotive market.

Understanding this historical context is vital for international B2B buyers, as it highlights the importance of adaptability and innovation in sourcing strategies. As the automotive landscape continues to evolve, staying informed about technological advancements will enable buyers to make strategic decisions that align with future market trends.

Perguntas mais frequentes (FAQs) para compradores B2B sobre como substituir o motor de arranque

-

How do I identify a faulty starter in my vehicle?

To determine if a starter is faulty, start by listening for unusual sounds when turning the ignition. A clicking sound or complete silence may indicate a starter issue. Additionally, inspect the battery terminals for corrosion and ensure connections are secure. If the battery is charged and the connections are clean yet the vehicle still fails to start, it is likely time to replace the starter. Always consult the vehicle’s service manual for specific diagnostics. -

What is the best type of starter for commercial vehicles?

The ideal starter for commercial vehicles typically varies based on the specific make and model. However, high-torque starters are generally preferred for their ability to handle the increased demands of larger engines. Look for starters with robust construction and warranty options to ensure reliability. Additionally, consider sourcing from reputable suppliers who offer OEM or equivalent parts to guarantee compatibility and performance. -

Como é que posso verificar os fornecedores de peças de substituição para motores de arranque?

To vet suppliers, start by researching their reputation in the industry. Look for reviews and testimonials from other businesses, particularly those in your region. Request certifications to ensure compliance with international standards. Additionally, consider visiting their facilities if possible, or arrange video calls to assess their operations. A reliable supplier should also provide transparent information about sourcing, quality control measures, and after-sales support. -

Quais são as quantidades mínimas de encomenda (MOQ) comuns para as entradas?

Minimum order quantities for starters can vary widely based on the supplier and type of starter. Typically, MOQs may range from 10 to 100 units. For larger orders, suppliers may offer discounts or better payment terms. It’s advisable to communicate your needs clearly with the supplier to negotiate MOQs that align with your business requirements while ensuring cost-effectiveness. -

Que condições de pagamento devo esperar quando forneço entradas a nível internacional?

Payment terms can differ significantly among international suppliers. Common terms include payment in advance, net 30, or letter of credit arrangements for larger orders. It’s important to negotiate terms that protect your cash flow while ensuring the supplier’s confidence in the transaction. Always confirm the accepted payment methods and consider using escrow services for high-value orders to mitigate risks. -

How do I ensure quality assurance when sourcing starters?

To ensure quality assurance, request certifications such as ISO or equivalent from your supplier. It’s beneficial to establish a quality control protocol, including pre-shipment inspections or third-party audits. Additionally, ask for samples before placing bulk orders to evaluate product quality firsthand. Building a strong relationship with your supplier can also facilitate better communication regarding quality standards. -

Que considerações logísticas devo ter em conta ao importar fermentos?

When importing starters, consider shipping methods, customs regulations, and lead times. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure that your supplier provides all necessary documentation for customs clearance, such as invoices and packing lists. Collaborate with a logistics provider who understands the nuances of international shipping to avoid delays and additional costs. -

Can I customize starters for my specific vehicle models?

Yes, many suppliers offer customization options for starters to fit specific vehicle models or requirements. This may include changes in size, power ratings, or terminal configurations. When discussing customization, provide detailed specifications and ensure that the supplier has the capability to meet your needs. Be prepared for potential minimum order quantities and longer lead times associated with custom products.

Lista dos 2 principais fabricantes e fornecedores de Como substituir o motor de arranque

1. eBay – Starter Replacement Kit

Domínio: ebay.com

Registrado: 1995 (30 anos)

Introdução: Project Duration: 1 to 2 hours, Skill Level: Intermediate, Starter Weight: 20 pounds or more, Special Starter Bolts: Required for replacement, Battery Cable: Must be in excellent condition, Inspection of Flexplate/Flywheel: Necessary, Starter Removal Tools: Wrench, Socket, Ratchet, Extensions, Safety Equipment: Floor jack, Jack stands, Ramps, Wheel cribs.

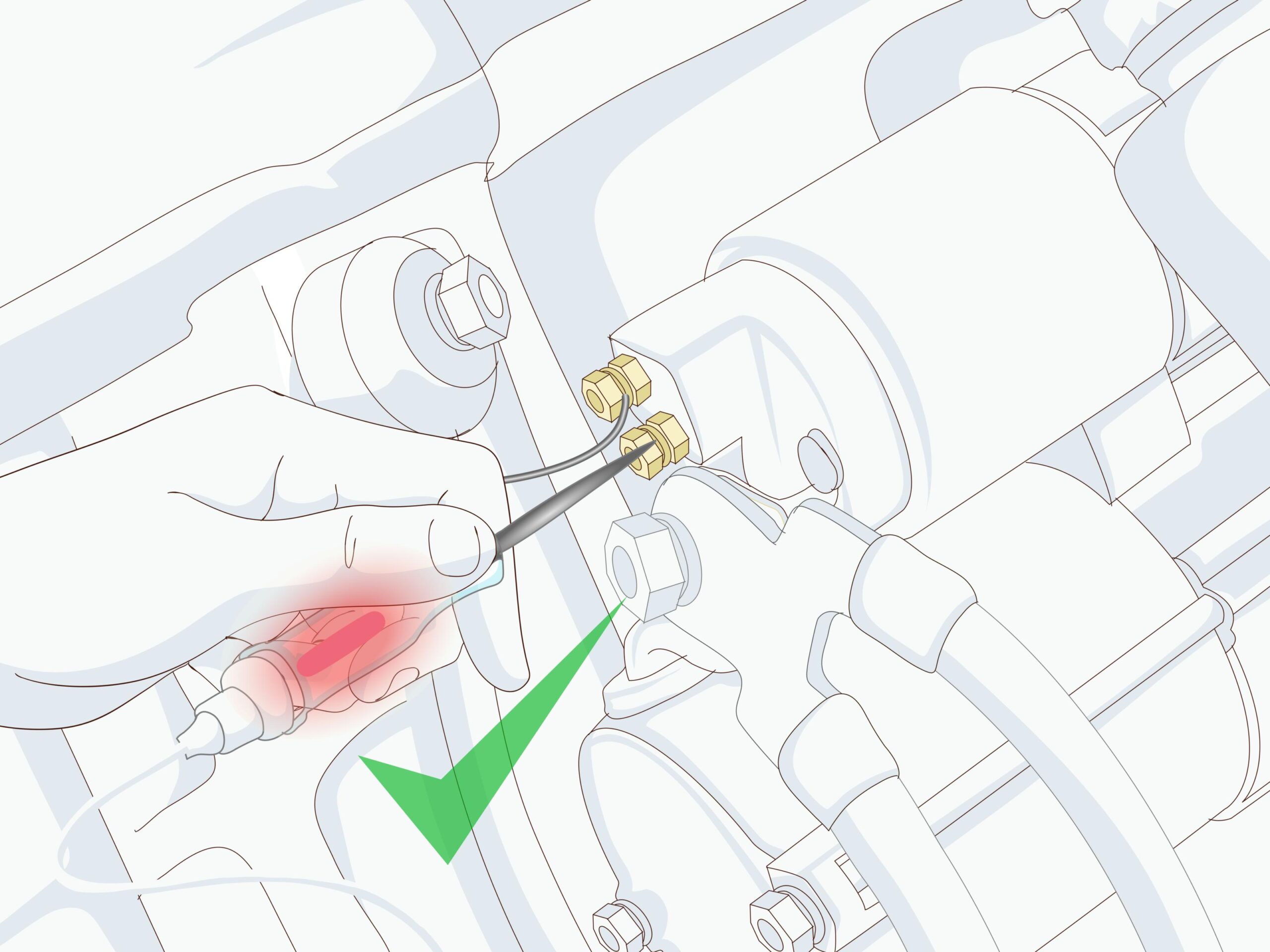

2. WikiHow – Guia de instalação do arrancador do carro

Domínio: wikihow.com

Registado: 2004 (21 anos)

Introdução: This article provides a step-by-step guide on how to install a car starter, including removing a bad starter and installing a new one. Key steps include disconnecting the battery, locating the starter, disconnecting wiring, removing retaining bolts, comparing the new starter with the old one, sliding the new starter into place, inserting retainer bolts, and reconnecting wiring. It emphasizes the i…

Strategic Sourcing Conclusão e perspectivas sobre como substituir o motor de arranque

What Are the Key Takeaways for B2B Buyers in Starter Replacement?

In conclusion, understanding the intricacies of starter replacement is vital for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Prioritizing strategic sourcing ensures that you procure reliable, high-quality starters that align with your specific vehicle requirements. This not only minimizes downtime but also enhances operational efficiency.

Establishing strong relationships with reputable suppliers can lead to better pricing and access to advanced starter technologies. Furthermore, investing in training and resources for your maintenance teams can dramatically reduce the likelihood of installation errors, ensuring that the new starters perform optimally from the outset.

Imagem ilustrativa relacionada com a substituição do motor de arranque

How Can You Prepare for Future Sourcing Needs?

As the automotive landscape continues to evolve, staying ahead of trends in starter technology and sourcing strategies will be crucial. Embrace digital platforms that facilitate supplier discovery and foster collaboration. By doing so, you can ensure that your sourcing practices are agile and responsive to market changes.

Take action now—assess your current sourcing strategies and identify opportunities for improvement. Engaging with local suppliers while exploring global partnerships will not only enhance your supply chain resilience but also position your business for sustained growth in an increasingly competitive environment.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Imagem ilustrativa relacionada com a substituição do motor de arranque

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.