Introduction: Navigating the Global Market for how to know if starter relay is bad

When it comes to understanding how to know if a starter relay is bad, international B2B buyers face the significant challenge of ensuring reliability and efficiency in their automotive purchases. Whether you are sourcing components for vehicle maintenance or manufacturing, recognizing the signs of a malfunctioning starter relay is crucial for minimizing downtime and enhancing operational productivity. A faulty starter relay can lead to frustrating vehicle failures, impacting service delivery and customer satisfaction.

This comprehensive guide delves into the various types of starter relays and their applications across different vehicle models, providing a thorough overview of potential issues and their implications. It includes insights into effective supplier vetting processes, ensuring you partner with reliable manufacturers who adhere to quality standards. Additionally, the guide addresses cost considerations, helping you to budget effectively while maintaining high standards in your procurement strategy.

By equipping B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, with actionable knowledge on diagnosing and sourcing quality starter relays, this guide empowers informed purchasing decisions. With the right information, businesses can mitigate risks associated with faulty components, ultimately leading to improved operational efficiency and customer satisfaction.

Índice

- Top 4 How To Know If Starter Relay Is Bad Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to know if starter relay is bad

- Understanding how to know if starter relay is bad Types and Variations

- Key Industrial Applications of how to know if starter relay is bad

- 3 Common User Pain Points for ‘how to know if starter relay is bad’ & Their Solutions

- Strategic Material Selection Guide for how to know if starter relay is bad

- In-depth Look: Manufacturing Processes and Quality Assurance for how to know if starter relay is bad

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if starter relay is bad’

- Comprehensive Cost and Pricing Analysis for how to know if starter relay is bad Sourcing

- Alternatives Analysis: Comparing how to know if starter relay is bad With Other Solutions

- Essential Technical Properties and Trade Terminology for how to know if starter relay is bad

- Navigating Market Dynamics and Sourcing Trends in the how to know if starter relay is bad Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to know if starter relay is bad

- Strategic Sourcing Conclusion and Outlook for how to know if starter relay is bad

- Aviso legal importante e termos de utilização

Understanding how to know if starter relay is bad Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Single Click Diagnosis | Engine clicks but does not turn over; indicates solenoid issue. | Oficinas de reparação automóvel | Prós: Quick identification. Contras: May require further testing. |

| No Response Test | No sound or response when the ignition is turned. | Fleet management and logistics | Prós: Indicates potential electrical failure. Contras: May involve complex diagnostics. |

| Intermittent Functionality | Engine starts sporadically; indicates a failing relay or solenoid. | Vehicle rental services | Prós: Helps in preventive maintenance. Contras: May lead to customer dissatisfaction if unresolved. |

| Continuous Engagement Issue | Starter engages without key; indicates solenoid malfunction. | Automotive manufacturing | Prós: Immediate safety concern addressed. Contras: Potential for additional starter damage. |

| Testing with Multimeter | Uses multimeter to check voltage and continuity. | Automotive parts suppliers | Prós: Accurate diagnostics. Contras: Requires technical expertise. |

What Are the Key Features of the Single Click Diagnosis Type?

The Single Click Diagnosis is characterized by a distinct clicking sound when attempting to start the engine, without any further response. This typically indicates that the solenoid is attempting to engage but is unable to do so effectively. This type of diagnosis is particularly useful for automotive repair shops, allowing technicians to quickly pinpoint solenoid issues. For buyers, the advantage lies in rapid identification, although it may necessitate additional testing to confirm the exact problem.

How Does the No Response Test Work for Identifying Issues?

The No Response Test is identified when turning the ignition key results in no sound or movement from the engine. This lack of response can indicate a variety of electrical failures, including a faulty starter relay. This diagnostic method is essential for fleet management and logistics companies, where vehicle uptime is critical. The primary benefit is the identification of potential electrical issues, but it may require complex diagnostics that can be time-consuming.

What is the Importance of Intermittent Functionality in Diagnosing Problems?

Intermittent Functionality refers to situations where the engine starts sporadically, which can signal a failing relay or solenoid. This type is vital for vehicle rental services, as it assists in preventive maintenance and helps avoid unexpected breakdowns. While it can aid in maintaining customer satisfaction, unresolved intermittent issues may lead to customer dissatisfaction and increased operational costs.

Why is Continuous Engagement a Concern for Buyers?

The Continuous Engagement Issue arises when the starter engages without turning the key, indicating a malfunctioning solenoid. This scenario is critical for automotive manufacturers and repair services, as it poses immediate safety concerns and potential damage to the starter. Addressing this issue promptly is advantageous for maintaining vehicle safety, although it may result in additional costs if the starter itself is damaged.

How Does Testing with a Multimeter Enhance Diagnosis?

Testing with a multimeter involves checking voltage and continuity to diagnose starter relay issues accurately. This method is especially relevant for automotive parts suppliers and technicians who require precise diagnostics for effective repairs. The main advantage of using a multimeter is its accuracy, enabling precise identification of electrical issues. However, it does require a certain level of technical expertise, which may limit its accessibility for some buyers.

Key Industrial Applications of how to know if starter relay is bad

| Indústria/Setor | Specific Application of how to know if starter relay is bad | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Oficinas de reparação automóvel | Diagnosticar problemas de arranque em veículos | Reduced downtime for repairs, enhancing customer satisfaction | Quality of diagnostic tools, availability of replacement parts |

| Gestão de frotas | Ensuring reliable vehicle operation | Increased fleet uptime, reduced operational costs | Bulk purchasing options, compatibility with various vehicle models |

| Equipamento de construção | Maintenance of heavy machinery | Evita avarias dispendiosas e atrasos nos projectos | Robustness of components, supplier reliability |

| Serviços de transporte | Ensuring vehicle readiness for transport | Improved service reliability, customer trust | Quick delivery times, warranty and support services |

| Equipamento agrícola | Ensuring functionality of tractors and harvesters | Maximizes productivity during critical harvest periods | Availability of specialized parts for different machinery types |

How is ‘how to know if starter relay is bad’ applied in Automotive Repair Shops?

In automotive repair shops, the ability to diagnose issues related to the starter relay is critical for efficient vehicle maintenance. Technicians utilize various diagnostic methods to identify whether the starter relay is malfunctioning, which helps in pinpointing the root cause of starting issues. By addressing these problems promptly, repair shops can minimize downtime for vehicles, thereby enhancing customer satisfaction and loyalty. For international buyers, sourcing high-quality diagnostic tools and reliable replacement parts is essential to maintain service standards.

What role does ‘how to know if starter relay is bad’ play in Fleet Management?

In fleet management, understanding the signs of a failing starter relay is vital for maintaining operational efficiency. Fleet managers can proactively monitor vehicle performance to ensure that starting issues are resolved before they lead to breakdowns. This not only increases the uptime of vehicles but also reduces operational costs associated with emergency repairs and delays. For businesses operating in diverse regions, sourcing compatible parts and ensuring bulk purchasing options can significantly streamline maintenance processes.

Why is ‘how to know if starter relay is bad’ important for Construction Equipment?

For construction equipment, the functionality of machinery is paramount, as any breakdown can result in significant project delays and financial losses. By recognizing the symptoms of a bad starter relay, operators can perform timely maintenance on heavy machinery, ensuring continuous operation during critical phases of construction. When sourcing components, businesses should prioritize the robustness and durability of parts, especially in harsh working conditions typical of construction sites.

How does ‘how to know if starter relay is bad’ benefit Transportation Services?

Transportation services heavily rely on their vehicles’ readiness to ensure timely deliveries. Understanding how to identify starter relay issues allows transport companies to maintain a fleet that operates smoothly, thereby improving service reliability and customer trust. In this sector, quick delivery times and reliable warranty services from suppliers are crucial considerations for businesses looking to minimize disruptions in their operations.

In what way does ‘how to know if starter relay is bad’ assist Agricultural Equipment?

Agricultural equipment, such as tractors and harvesters, must function optimally during peak seasons. Recognizing the signs of a bad starter relay allows farmers to maintain their machinery effectively, maximizing productivity during critical harvesting periods. Buyers in this sector should seek suppliers who can provide specialized parts tailored to different machinery types, ensuring that their equipment remains operational during the busiest times of the year.

3 Common User Pain Points for ‘how to know if starter relay is bad’ & Their Solutions

Cenário 1: Problemas de arranque intermitente em veículos da frota

O problema:

B2B buyers managing fleets often encounter intermittent starting issues with their vehicles, which can lead to significant downtime and lost productivity. When a vehicle fails to start sporadically, it creates uncertainty among drivers and can disrupt schedules. This problem may stem from a faulty starter relay or solenoid, which may not consistently engage the starter motor. Fleet managers need to identify the root cause quickly to minimize disruptions to operations, but the symptoms can often be mistaken for other issues, such as a weak battery or faulty ignition switch.

A solução:

To effectively diagnose and address these intermittent starting problems, fleet managers should implement a systematic approach. First, they should perform a thorough visual inspection of the starter relay and solenoid, checking for signs of corrosion, loose connections, or damaged wiring. Using a multimeter, they can test the relay and solenoid for continuity and proper voltage. If the components are functioning intermittently, replacing the starter relay with a high-quality, OEM (Original Equipment Manufacturer) part can provide a more reliable solution. Additionally, incorporating regular maintenance checks into the fleet management schedule can help identify potential issues before they lead to significant downtime.

Scenario 2: Confusion Between Starter Relay and Solenoid Functions

O problema:

International buyers, especially those new to automotive maintenance, often face confusion regarding the roles of starter relays and solenoids. Misunderstanding these components can lead to misdiagnosis of starting issues, resulting in unnecessary part replacements and increased costs. This confusion is compounded in diverse markets where terminology and product specifications may differ significantly.

A solução:

To combat this issue, B2B buyers should invest in training for their maintenance staff, focusing on the distinct functions of starter relays and solenoids. Providing hands-on workshops or online courses can enhance the team’s technical knowledge and confidence. Furthermore, buyers should utilize detailed product manuals and technical resources from reputable manufacturers to clarify how these components interact within the vehicle’s electrical system. When sourcing parts, opting for suppliers that offer comprehensive support and guidance can also help ensure that the right components are selected for repairs.

Scenario 3: High Repair Costs Due to Misdiagnosis

O problema:

For many businesses, misdiagnosing the cause of starting issues can lead to high repair costs. A faulty starter relay may be overlooked, leading technicians to replace more expensive components like the starter motor unnecessarily. This not only inflates repair bills but also increases the time vehicles spend off the road, affecting overall business operations. For companies operating on tight budgets, these unexpected expenses can significantly impact their bottom line.

A solução:

To minimize misdiagnosis and associated repair costs, B2B buyers should establish a rigorous diagnostic protocol. This protocol should include a checklist that covers all potential causes of starting failures, starting with the simplest (like checking battery connections) and progressing to more complex components. Encouraging technicians to utilize diagnostic tools, such as scan tools that can read vehicle error codes, can also provide valuable insights into underlying issues. Additionally, partnering with a reliable parts supplier that offers diagnostic support can further streamline the repair process and ensure that the right components are replaced, thus reducing costs over time.

Strategic Material Selection Guide for how to know if starter relay is bad

What Materials Are Commonly Used in Starter Relays and Their Performance?

When assessing the materials used in starter relays, it’s essential to understand how these materials influence performance and reliability. The selection of materials directly impacts the relay’s ability to withstand environmental conditions, electrical demands, and overall durability. Below are some common materials used in starter relays, along with their properties and considerations for international B2B buyers.

What Are the Key Properties of Copper in Starter Relays?

Principais propriedades: Copper is known for its excellent electrical conductivity, thermal conductivity, and corrosion resistance. It can operate effectively at high temperatures, making it suitable for automotive applications where heat generation is a concern.

Prós e contras: The primary advantage of copper is its superior conductivity, which ensures efficient power transfer. However, copper is relatively expensive compared to other materials, and its susceptibility to corrosion can be a drawback in humid or saline environments.

Impacto na aplicação: Copper’s compatibility with high electrical loads makes it ideal for starter relays. However, in regions with high humidity, such as parts of Africa and South America, additional coatings may be required to enhance corrosion resistance.

Considerações para compradores internacionais: Compliance with international standards, such as ASTM B170 for copper wire, is crucial. Buyers should also consider local regulations regarding material sourcing and environmental impact, especially in Europe.

How Does Aluminum Perform in Starter Relays?

Principais propriedades: Aluminum is lightweight, has good thermal conductivity, and offers decent electrical conductivity. It is also resistant to corrosion due to the formation of a protective oxide layer.

Prós e contras: The lightweight nature of aluminum makes it advantageous for automotive applications where weight reduction is critical. However, its electrical conductivity is lower than that of copper, which may necessitate larger cross-sectional areas for the same current capacity, potentially increasing manufacturing complexity.

Impacto na aplicação: Aluminum can be suitable for starter relays, especially in applications where weight is a concern. However, its lower conductivity may affect performance in high-demand scenarios.

Considerações para compradores internacionais: Buyers should ensure compliance with standards such as DIN 17615 for aluminum materials. Additionally, cost-effective sourcing options may vary by region, impacting overall procurement strategies.

What Role Does Plastic Play in Starter Relay Construction?

Principais propriedades: Plastics, particularly thermoplastics, are used for housings and insulators in starter relays. They offer excellent electrical insulation properties and can withstand a range of temperatures.

Prós e contras: The primary advantage of using plastics is their lightweight nature and resistance to corrosion. However, they may not withstand extreme temperatures as well as metals, and their mechanical strength can be lower, leading to potential durability issues.

Impacto na aplicação: Plastics are ideal for non-conductive components of starter relays. However, in high-temperature environments, such as those found in the Middle East, careful selection of heat-resistant plastics is necessary.

Considerações para compradores internacionais: Compliance with international standards like ISO 9001 for quality management is essential when sourcing plastic components. Buyers should also consider the environmental impact of plastic disposal and recycling in their regions.

Como é que o aço contribui para a durabilidade dos relés de arranque?

Principais propriedades: Steel is known for its high tensile strength and durability. It can withstand significant mechanical stress and is often used in structural components of starter relays.

Prós e contras: The primary advantage of steel is its robustness, making it suitable for heavy-duty applications. However, it is heavier than other materials and can be prone to corrosion if not properly treated.

Impacto na aplicação: Steel components can enhance the mechanical integrity of starter relays, especially in rugged environments. However, in coastal regions or areas with high moisture, additional protective coatings may be necessary.

Considerações para compradores internacionais: Buyers should be aware of corrosion-resistant coatings and ensure compliance with standards such as JIS G3101 for steel quality. Understanding local sourcing options can also impact procurement strategies.

Tabela de resumo da seleção de materiais para relés de arranque

| Material | Typical Use Case for how to know if starter relay is bad | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Ligações eléctricas nos relés de arranque | Condutividade superior | High cost, corrosion susceptibility | Alto |

| Alumínio | Componentes estruturais e de alojamento | Leve, resistente à corrosão | Lower conductivity, increased size for capacity | Médio |

| Plástico | Insulating housings and non-conductive parts | Lightweight, excellent insulation | Limited temperature tolerance, lower mechanical strength | Baixo |

| Aço | Componentes estruturais para maior durabilidade | High strength and robustness | Mais pesado, propenso à corrosão | Médio |

This analysis provides a comprehensive overview of the materials commonly used in starter relays, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers. Understanding these factors can assist businesses in making informed decisions regarding the procurement and application of starter relay components.

In-depth Look: Manufacturing Processes and Quality Assurance for how to know if starter relay is bad

Quais são as principais fases de fabrico de um relé de arranque?

The manufacturing process for starter relays involves several critical stages that ensure the final product is reliable and meets industry standards. Understanding these stages can help B2B buyers assess potential suppliers.

Material Preparation: What Materials Are Used in Starter Relay Manufacturing?

The manufacturing process begins with the selection of high-quality materials, which typically include:

- Conductive Metals: Copper or aluminum is often used for wiring and contacts due to their excellent conductivity.

- Materiais isolantes: Plastics or ceramics are chosen to insulate components and prevent electrical short circuits.

- Magnetic Materials: These are essential for the solenoid operation, often including iron or specialized alloys.

Before assembly, these materials undergo rigorous quality checks to ensure they meet specified standards. B2B buyers should inquire about the sourcing of these materials and whether they comply with international standards.

Illustrative image related to how to know if starter relay is bad

Forming: How Are Components Shaped and Assembled?

The forming stage involves several techniques to create the necessary components of the starter relay:

- Estampagem: Metal sheets are stamped to create contact points and housing parts. This process requires precision to ensure that each component fits perfectly during assembly.

- Enrolamento: For solenoid coils, copper wire is wound around a magnetic core. This is a critical step, as the number of turns and the tension during winding directly impact the relay’s performance.

- Moldagem por injeção: Plastic components are often produced using injection molding, allowing for complex shapes and designs that are essential for housing and insulating parts.

Each component is crafted to precise specifications, which is crucial for the relay’s functionality.

Assembly: What Are the Key Steps in Assembling a Starter Relay?

Once components are formed, they move to the assembly line, where the following steps take place:

- Integração de componentes: Individual components, such as the solenoid and relay contacts, are assembled together. This often involves soldering or crimping connections to ensure secure electrical contact.

- Quality Checks: During assembly, visual inspections and measurements are performed to ensure all components meet quality standards. This includes checking for proper alignment and fit.

- Montagem final: The assembled parts are enclosed in the housing, followed by final electrical connections and sealing to protect against environmental factors.

B2B buyers should consider the efficiency and technology used in the assembly process, as these can significantly affect the final product’s reliability.

Finishing: What Finishing Processes Are Applied to Starter Relays?

The finishing stage includes treatments that enhance the starter relay’s durability and performance:

- Revestimento: Corrosion-resistant coatings may be applied to metal parts to extend the product’s lifespan, especially in harsh environments.

- Labeling: Each relay is labeled with essential information, such as part numbers and specifications, which aids in inventory management and traceability.

- Packaging: Proper packaging is crucial for protecting the product during transit. Buyers should ensure that suppliers use robust packaging materials to prevent damage.

What Quality Assurance Processes Are Critical for Starter Relays?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that starter relays function reliably under various conditions.

Que normas internacionais devem os compradores B2B considerar?

For manufacturers aiming to produce high-quality starter relays, adhering to international standards is essential:

- ISO 9001: This standard outlines the criteria for a quality management system. Companies certified under ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- Marcação CE: For suppliers in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- Padrões API: In certain industries, such as automotive, compliance with API standards can be critical for ensuring product reliability.

Understanding these standards helps B2B buyers evaluate potential suppliers’ commitment to quality.

Quais são os principais pontos de verificação do controlo de qualidade?

Quality control (QC) checkpoints throughout the manufacturing process help catch defects early:

- Controlo de Qualidade de Entrada (IQC): This involves inspecting raw materials and components before they enter production. Buyers should ask suppliers how they perform IQC and what criteria are used.

- Controlo de qualidade em processo (IPQC): During manufacturing, regular checks ensure that processes remain within specified limits. This might include monitoring dimensions and electrical resistance.

- Controlo de Qualidade Final (FQC): Before packaging, finished relays undergo rigorous testing to confirm they meet performance specifications. Common tests include electrical continuity checks and durability assessments.

B2B buyers can enhance their procurement strategy by understanding how suppliers implement these QC checkpoints.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

To ensure that suppliers maintain rigorous quality control, B2B buyers should consider the following verification methods:

- Auditorias: Regular audits of suppliers can provide insights into their manufacturing processes and quality management practices. Buyers should ask for audit reports to assess compliance with international standards.

- Relatórios de testes: Requesting testing reports for specific batches can help verify that products meet required specifications. This is particularly important for critical applications.

- Inspeções por terceiros: Engaging independent inspectors to evaluate suppliers can provide an unbiased assessment of their quality practices. This is especially crucial for international transactions, where language and cultural barriers may exist.

A que nuances devem estar atentos os compradores B2B internacionais?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of international quality assurance can be vital:

- Conformidade regulamentar: Each region may have specific regulatory requirements that must be met. Buyers should familiarize themselves with local laws concerning product safety and environmental impact.

- Considerações culturais: Communication styles and business practices can vary significantly between regions. Buyers should consider these differences when negotiating quality expectations and delivery timelines.

- Desafios logísticos: International shipping can introduce complexities in maintaining quality. Buyers should verify how suppliers manage logistics to ensure that products arrive in optimal condition.

In conclusion, understanding the manufacturing processes and quality assurance measures for starter relays is critical for B2B buyers. By evaluating suppliers based on these criteria, companies can ensure they procure reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if starter relay is bad’

Introdução

Understanding how to determine if a starter relay is malfunctioning is crucial for automotive professionals and B2B buyers in the automotive sector. This guide provides a structured approach to assessing starter relay issues, ensuring you can make informed procurement decisions and maintain the efficiency of your operations.

Passo 1: Identify Common Symptoms of a Bad Starter Relay

Before investigating further, familiarize yourself with the typical signs of a malfunctioning starter relay. Key symptoms include a single click when turning the ignition, intermittent starting issues, or complete failure to start the engine. Recognizing these symptoms early can save time and reduce repair costs.

Illustrative image related to how to know if starter relay is bad

Passo 2: Conduct a Visual Inspection

Perform a thorough visual check of the starter relay and surrounding components. Look for signs of corrosion, burnt connections, or damaged wires, which can all indicate a problem. This step is vital as visual cues often provide immediate insights into the relay’s condition without needing specialized tools.

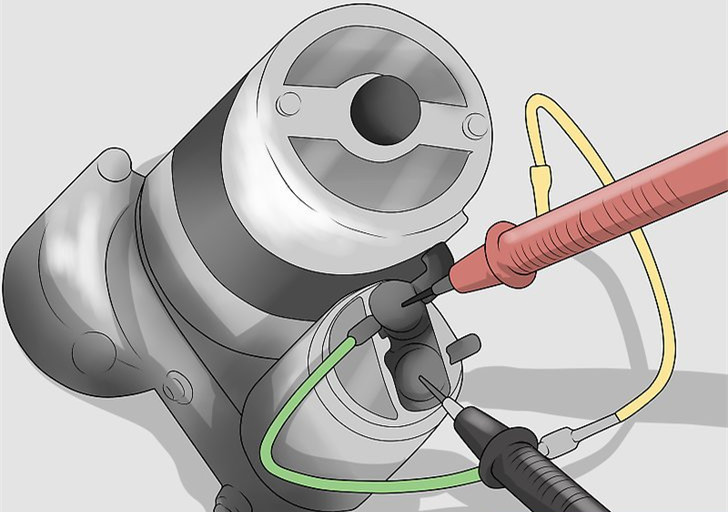

Passo 3: Test the Relay with a Multimeter

Using a multimeter, check the relay for continuity. Set the multimeter to the ohms setting and test the relay terminals. If there is no continuity or if the resistance is outside the normal range, the relay likely needs replacement. This step is essential for verifying whether the relay is functioning properly before proceeding with a replacement.

Passo 4: Evaluate the Starter Circuit

Assess the entire starter circuit, including wiring and connectors. Look for any broken, corroded, or loose connections that could impact the relay’s performance. This step is crucial as a bad connection can mimic a faulty relay, leading to unnecessary replacements and increased costs.

Passo 5: Check the Battery Health

Ensure that the battery is in good condition and fully charged. A weak or dead battery can prevent the starter relay from functioning correctly. Testing the battery’s voltage and load capacity will help you confirm that it is not the root cause of starting issues before replacing the relay.

Passo 6: Considerar os factores ambientais

Take into account the operating environment of the vehicle. Extreme temperatures, moisture, and dust can affect the performance of electrical components like starter relays. Understanding these factors can help you choose more durable components that are better suited to your specific geographic and operational conditions.

Illustrative image related to how to know if starter relay is bad

Passo 7: Consult Technical Manuals or Experts

Refer to the vehicle’s technical manual for specific troubleshooting steps or consult with automotive experts. Manufacturer guidelines often provide detailed insights into common issues and their solutions. Engaging with professionals can also enhance your understanding and ensure you are making the right procurement decisions.

In conclusion, following this checklist will empower B2B buyers and automotive professionals to effectively diagnose and address starter relay issues. This proactive approach not only streamlines maintenance processes but also supports better decision-making in the procurement of automotive parts.

Comprehensive Cost and Pricing Analysis for how to know if starter relay is bad Sourcing

What Are the Key Cost Components for Sourcing Starter Relays?

When sourcing starter relays, several cost components need careful consideration to ensure a comprehensive analysis. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materiais: The cost of raw materials, such as copper for wiring and various plastics or metals for the housing, can fluctuate based on market demand and availability. High-quality materials often lead to better performance and longevity, which can justify a higher initial investment.

-

Trabalho: The cost of labor varies significantly by region. For instance, labor costs in Europe may be higher than in parts of Africa or South America. Understanding local labor rates can help buyers negotiate better terms.

-

Custos indiretos de produção: This includes utilities, equipment maintenance, and factory rent. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Ferramentas: Specialized tools and molds for production can incur substantial upfront costs. Buyers should consider the potential for economies of scale; larger orders can spread these costs over more units, lowering the per-unit price.

-

Controlo de Qualidade (QC): Implementing robust QC processes ensures that the starter relays meet necessary specifications and safety standards, which can affect pricing. Buyers should inquire about the supplier’s QC practices and certifications.

-

Logística: Shipping costs can vary based on distance, mode of transport, and the chosen Incoterms. For international buyers, understanding these factors is crucial for calculating total costs accurately.

-

Margem: Suppliers will typically include a margin in their pricing to cover risks and ensure profitability. This margin can vary based on market conditions, competition, and the supplier’s overall business strategy.

How Do Price Influencers Affect Sourcing Decisions for Starter Relays?

Several factors influence the pricing of starter relays, which buyers should evaluate carefully.

-

Volume/MOQ (Quantidade mínima de encomenda): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers optimize their purchasing strategy to secure lower prices.

-

Especificações e personalização: Custom specifications may lead to higher costs due to the need for specialized materials or processes. Buyers should weigh the benefits of customization against the potential price increases.

-

Materiais: The choice of materials directly impacts costs. Higher-grade materials may cost more upfront but can lead to lower failure rates and longer lifespans, reducing Total Cost of Ownership (TCO).

-

Qualidade e certificações: Products that meet international standards or have specific certifications often come at a premium. However, these certifications can also reduce risks associated with product failures.

-

Fatores relacionados ao fornecedor: The supplier’s reputation, production capacity, and reliability can influence pricing. Established suppliers with proven track records may charge more but can provide peace of mind.

-

Incoterms: Understanding Incoterms is vital for international transactions, as they dictate who is responsible for costs and risks at various stages of the shipping process. This knowledge can lead to better negotiation outcomes.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Starter Relays?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, there are strategic approaches to enhance cost-efficiency.

-

Negociação: Engage suppliers in discussions about pricing, especially when placing large orders. Highlighting long-term relationships can also lead to better terms.

-

Custo total de propriedade (TCO): Focus on the TCO rather than just the purchase price. Consider factors such as installation, maintenance, and potential downtime caused by failures.

-

Nuances de preços para compradores internacionais: Be aware of currency fluctuations and tariffs that can impact costs. Developing a good understanding of local market conditions and supplier dynamics can offer leverage in negotiations.

-

Diversificação de fornecedores: Establish relationships with multiple suppliers to create competitive tension, which can lead to better pricing and terms.

Isenção de responsabilidade para preços indicativos

Pricing for starter relays can vary significantly based on the aforementioned factors. This analysis provides a framework for understanding the cost structure, but buyers should conduct their due diligence and obtain quotes tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing how to know if starter relay is bad With Other Solutions

Exploring Alternatives to Determine if a Starter Relay is Bad

When dealing with automotive electrical issues, particularly concerning starter relays, it’s essential for B2B buyers to evaluate various methods for diagnosis. Understanding how to identify a bad starter relay is crucial, but exploring alternative solutions can provide additional insights, cost savings, and efficiency. Below, we compare the traditional method of checking a starter relay against two viable alternatives: a digital multimeter test and a professional diagnostic tool.

| Aspecto comparativo | How To Know If Starter Relay Is Bad | Teste de multímetro digital | Professional Diagnostic Tool |

|---|---|---|---|

| Desempenho | Reliable for basic diagnosis | Accurate and precise | Diagnósticos abrangentes |

| Custo | Baixo (são necessárias ferramentas básicas) | Moderado (custo do multímetro) | High (tool and software costs) |

| Facilidade de implementação | Simples, requer conhecimentos básicos | Requires some expertise | User-friendly, but expensive training may be needed |

| Manutenção | Minimal (occasional tool checks) | Moderate (calibration needed) | High (software updates needed) |

| Melhor caso de uso | Initial troubleshooting | Detailed electrical analysis | Full vehicle diagnostics |

What Are the Advantages and Disadvantages of Using a Digital Multimeter Test?

A digital multimeter (DMM) provides an effective alternative for diagnosing a bad starter relay. This tool measures voltage, current, and resistance, allowing for precise diagnostics. The primary advantage of using a DMM is its accuracy; it can detect voltage drops and continuity issues that indicate a relay malfunction. However, it requires some expertise to interpret the readings correctly, which might pose a challenge for inexperienced technicians. Furthermore, while the initial investment in a multimeter is moderate, ongoing calibration and maintenance of the tool may add to the overall cost.

How Does a Professional Diagnostic Tool Enhance the Detection Process?

Professional diagnostic tools offer an extensive range of functionalities that go beyond just checking the starter relay. They can interface with the vehicle’s onboard computer to provide real-time data, error codes, and insights into various systems. This comprehensive approach ensures that users can identify not only starter relay issues but also other potential electrical problems. However, the significant drawback is the cost associated with purchasing and maintaining such equipment, along with the need for proper training to utilize its full capabilities effectively.

Illustrative image related to how to know if starter relay is bad

How Can B2B Buyers Choose the Right Solution for Their Specific Needs?

When selecting the right solution for diagnosing starter relay issues, B2B buyers should consider several factors, including their budget, the complexity of the vehicles they service, and the expertise of their technicians. For businesses operating on a tight budget or those with less complex vehicle systems, learning to identify a bad starter relay through traditional methods may suffice. Conversely, companies that require in-depth diagnostics for a wide range of vehicles might benefit more from investing in a professional diagnostic tool, despite the higher initial costs. Ultimately, the decision should align with the specific operational needs and long-term goals of the business.

Essential Technical Properties and Trade Terminology for how to know if starter relay is bad

What Are the Essential Technical Properties of a Starter Relay?

Understanding the critical specifications of a starter relay is vital for B2B buyers in the automotive sector. These specifications can influence purchasing decisions, impact vehicle performance, and ensure compatibility with various vehicle models. Here are some key properties to consider:

1. Grau do material

The material grade of a starter relay refers to the type of metals and plastics used in its construction. Common materials include high-grade copper for electrical contacts and durable plastics for housing. The choice of materials affects not only the relay’s durability but also its electrical conductivity. For B2B buyers, selecting relays made from superior materials can lead to longer-lasting products, reducing replacement frequency and maintenance costs.

2. Classificação atual

The current rating indicates the maximum amount of electrical current that the relay can handle without failing. This specification is crucial, as a relay with a higher current rating can support more demanding starter systems, especially in heavy-duty vehicles. Buyers should ensure that the current rating matches or exceeds the vehicle’s starter requirements to prevent failures and ensure reliability.

3. Tensão da bobina

Coil voltage refers to the electrical voltage required to activate the relay. Common coil voltages include 12V and 24V, which correspond to the electrical systems of most vehicles. Understanding the coil voltage is essential for compatibility; mismatched voltage can lead to malfunction or complete failure of the starter system. B2B buyers should verify the coil voltage against their vehicle specifications to ensure proper operation.

4. Classificação de temperatura

Temperature rating specifies the range of temperatures within which the relay can operate effectively. Extreme temperatures can affect the relay’s performance and lifespan. For businesses operating in regions with harsh climates, selecting relays with appropriate temperature ratings is critical to avoid premature failures and ensure consistent vehicle performance.

5. Estilo de montagem

The mounting style of a starter relay can vary, with options like plug-in, bolt-on, or screw-mounted designs. Each style has implications for installation ease and space requirements in the engine compartment. B2B buyers should consider the mounting style that best fits their vehicles to simplify installation and maintenance processes.

Illustrative image related to how to know if starter relay is bad

What Are Common Trade Terms Related to Starter Relays?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are several common trade terms that buyers should know:

1. OEM (Fabricante de Equipamento Original)

OEM refers to parts made by the vehicle’s original manufacturer. These parts are typically of higher quality and designed specifically for the vehicle model, ensuring compatibility and performance. For B2B buyers, sourcing OEM starter relays can enhance vehicle reliability and maintain warranty compliance.

2. MOQ (Quantidade mínima de encomenda)

MOQ is the minimum number of units that a supplier is willing to sell in a single order. Understanding MOQ is crucial for inventory management and budgeting. Buyers should negotiate MOQs that align with their operational needs to avoid overstocking or stockouts.

3. RFQ (Pedido de Orçamento)

An RFQ is a formal request to suppliers for pricing and terms regarding specific products. In the context of starter relays, issuing an RFQ allows buyers to compare options from different suppliers, ensuring they secure the best pricing and terms for their needs.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms define the responsibilities of buyers and sellers in international shipping agreements. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and delivery responsibilities, which is essential for planning and logistics in the procurement process.

5. Prazo de entrega

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times for starter relays helps buyers manage their supply chain and inventory levels effectively, ensuring that they can meet customer demands without unnecessary delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing starter relays, enhancing their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the how to know if starter relay is bad Sector

What Are the Current Market Dynamics and Key Trends in the Starter Relay Sector?

The global automotive industry is undergoing rapid transformation, driven by technological advancements and shifting consumer demands. In regions like Africa, South America, the Middle East, and Europe, there is a growing emphasis on efficient and reliable automotive components, including starter relays. The increasing prevalence of electric and hybrid vehicles necessitates a deeper understanding of starter systems, as these vehicles often employ advanced electronic controls that integrate starter relays and solenoids.

Key trends influencing the market include the adoption of smart technologies in vehicle components, such as IoT-enabled diagnostics that allow for real-time monitoring of starter relay performance. This technology helps international B2B buyers identify potential failures before they occur, enhancing reliability and reducing downtime. Additionally, as the global push for sustainability continues, manufacturers are incorporating more eco-friendly materials in their production processes, which is becoming a decisive factor for buyers who prioritize sustainable sourcing.

Moreover, the demand for aftermarket parts is increasing, particularly in emerging markets where vehicle maintenance is often prioritized. Understanding local market conditions and regulatory environments is critical for B2B buyers seeking to navigate these dynamics effectively. This includes recognizing the importance of quality assurance and certification standards, which are becoming increasingly important in regions like Europe and Brazil, where regulatory compliance can significantly impact sourcing decisions.

How Is Sustainability and Ethical Sourcing Reshaping the Starter Relay Supply Chain?

Sustainability is becoming a cornerstone of procurement strategies in the automotive industry, including components such as starter relays. The environmental impact of automotive production and waste is prompting B2B buyers to seek suppliers committed to ethical sourcing practices. This includes the use of recycled materials, reduction of carbon footprints, and adherence to fair labor practices in the supply chain.

Buyers are increasingly looking for suppliers with ‘green’ certifications that demonstrate a commitment to sustainability. These certifications can include ISO 14001 for environmental management systems or certifications from organizations like the Forest Stewardship Council (FSC) for materials sourced from responsibly managed forests. For instance, manufacturers focusing on starter relays may utilize recyclable plastics and metals, reducing waste and promoting circular economy principles.

Furthermore, the shift towards electric vehicles (EVs) presents an opportunity to source components that are not only energy-efficient but also minimize environmental impact throughout their lifecycle. By aligning with suppliers who prioritize sustainability, international B2B buyers can enhance their brand reputation, meet regulatory demands, and cater to an increasingly eco-conscious market.

What Is the Brief Evolution of Starter Relay Technology?

The technology behind starter relays has evolved significantly over the years, reflecting broader advancements in automotive engineering. Initially, starter relays were simple electromechanical devices, primarily used to control the high-current circuit that engages the starter motor. As vehicles became more complex, the need for more reliable and efficient systems grew.

In the 1980s and 1990s, the introduction of electronic ignition systems and advanced computer controls began to change the landscape. Starter relays became integrated into these systems, allowing for more precise control and diagnostics. The rise of microcontrollers in the 2000s further advanced starter relay technology, enabling features such as remote starting and improved safety mechanisms.

Today, the integration of smart technology into starter systems is revolutionizing how these components are designed and utilized. This evolution not only enhances performance but also aligns with the modern demands for connectivity and sustainability in the automotive sector, making it essential for B2B buyers to stay informed about these advancements as they source starter relay solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of how to know if starter relay is bad

-

How do I determine if a starter relay is bad?

To assess whether a starter relay is faulty, first, listen for clicking sounds when you turn the ignition key. If you hear a single click or no sound at all, the relay may be malfunctioning. Additionally, check if the dashboard lights and other electrical components are functioning; if they are, the issue likely lies with the relay. Testing the relay with a multimeter can also confirm its operational status by measuring continuity and voltage. If the relay fails to pass these tests, it should be replaced. -

What are common symptoms of a bad starter relay?

Common symptoms indicating a bad starter relay include the engine failing to crank, a single clicking sound when attempting to start, or intermittent starting issues. You might also notice that the engine starts without turning the key or that it engages but does not disengage immediately. These signs suggest that the relay is not effectively transmitting power to the starter, potentially leading to more significant electrical issues if not addressed. -

How does a starter relay differ from a starter solenoid?

The starter relay and starter solenoid serve similar functions but are distinct components. The relay is typically a small cube located in the fuse box, while the solenoid is usually mounted directly on the starter motor. The relay controls the high-power circuit that engages the solenoid, which then activates the starter motor. Understanding this difference is crucial when diagnosing starting issues, as it can affect the parts you may need to replace. -

What should I consider when sourcing starter relays internationally?

When sourcing starter relays from international suppliers, consider the quality certifications and standards applicable in your region. Ensure the supplier can provide detailed specifications and compliance documents. Additionally, assess the supplier’s reputation through reviews and references. It’s important to evaluate lead times, shipping costs, and any tariffs that may apply to your imports, particularly when dealing with suppliers from different continents. -

What is the minimum order quantity (MOQ) for starter relays?

Minimum order quantities for starter relays can vary significantly between suppliers. Many manufacturers set MOQs based on production costs and inventory considerations, which can range from as low as 50 units to over 1,000 units. It’s advisable to negotiate MOQs with suppliers, especially if you are a smaller business or if you require a trial order for quality assessment. Understanding your own demand forecast can help in these negotiations. -

How can I ensure the quality of starter relays from suppliers?

To ensure quality, request samples before placing a bulk order. Verify the supplier’s quality assurance processes, including any certifications like ISO 9001. Conduct factory audits if feasible, or utilize third-party inspection services to evaluate products before shipment. Establishing clear quality expectations in your purchase agreement will also help mitigate risks associated with defective products. -

What payment terms are typical for international purchases of automotive parts?

Typical payment terms for international purchases of automotive parts, including starter relays, may include options like payment in advance, letter of credit, or net 30/60/90 days after delivery. Negotiating favorable terms is essential, especially for large orders. Be mindful of currency fluctuations and transaction fees, and consider using secure payment methods to protect your investment. -

How do logistics impact the sourcing of starter relays?

Logistics play a critical role in the sourcing of starter relays. Factors such as shipping methods, customs clearance, and local regulations can affect delivery times and costs. Consider working with suppliers who have established logistics partnerships to streamline the process. Additionally, understanding the local infrastructure in your region, including port facilities and transport networks, can help you anticipate potential delays and plan accordingly for inventory management.

Top 4 How To Know If Starter Relay Is Bad Manufacturers & Suppliers List

1. Aliontimer – Essential Relay Solutions

Domínio: aliontimer.com

Registada: 2016 (9 anos)

Introdução: 1. Protection Relay – Critical Components of Electrical Power Grid 2. Floatless Relay – Automatic Water Supply and Drainage Control 3. Modular Timer Relay – Essential Part of Motor Control 4. Multifunction Timer Relay – Multi-range Timer Delay Relay

2. Jeep – Starting Issues

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: 2008 Jeep Patriot; issue: car won’t start; symptoms: all lights and radio work, single click noise when attempting to start; potential problems: starter relay fuse or starter.

3. Facebook – Starter Relay Troubleshooting

Domínio: facebook.com

Registado: 1997 (28 anos)

Introdução: This company, Facebook – Starter Relay Troubleshooting, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. MGEXP – 30 Amp Starter Relay

Domínio: mgexp.com

Registado: 2011 (14 anos)

Introdução: Generic 30 amp starter relay, compatible with MG models; can be a common type relay similar to fog light or fan relay; 40A Signal-Stat relay also mentioned; Bosch relay with four spades (30, 87, 85, 86) suggested; cost around $5-$6; troubleshooting methods for testing starter relay and solenoid.

Strategic Sourcing Conclusion and Outlook for how to know if starter relay is bad

In conclusion, recognizing the signs of a failing starter relay or solenoid is crucial for maintaining operational efficiency in any fleet or vehicle maintenance strategy. Key indicators such as the absence of response when turning the ignition, unusual clicking sounds, or intermittent starting issues should prompt immediate investigation. These symptoms often signal underlying electrical issues that, if left unaddressed, could lead to more significant operational disruptions and increased maintenance costs.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic sourcing of reliable automotive components is essential. Partnering with trusted suppliers who understand the intricacies of your regional markets can ensure that you have access to high-quality parts that meet your operational needs.

Looking ahead, businesses should proactively implement diagnostic tools and training for their teams to swiftly identify and address starter relay issues. By investing in preventive measures and nurturing supplier relationships, organizations can enhance their vehicle reliability and minimize downtime. Embrace these strategies to secure a robust automotive maintenance framework that supports your business objectives and drives growth.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.