Introdução: Navegando no mercado global de alternadores c1

Navegar pelas complexidades do aprovisionamento de alternadores C1 pode representar desafios significativos para os compradores B2B internacionais, particularmente os de regiões como África, América do Sul, Médio Oriente e Europa, incluindo a Alemanha e o Brasil. Com a crescente procura de peças automóveis fiáveis, as empresas têm de identificar não só o tipo certo de alternador, mas também fornecedores de confiança que possam cumprir os seus padrões de qualidade e de preços. Este guia serve como um recurso abrangente, detalhando vários tipos de alternadores C1, suas aplicações e melhores práticas para a verificação de fornecedores.

Compreender as nuances dos alternadores C1 - desde as suas especificações até à sua compatibilidade com diferentes modelos de veículos - permitirá às empresas tomar decisões de compra informadas. Iremos aprofundar factores críticos, tais como considerações de custo, requisitos de instalação e a importância de utilizar peças OEM para garantir a longevidade e o desempenho. Além disso, este guia destacará estratégias para navegar no mercado global, incluindo dicas para negociar com fornecedores e avaliar a logística de envio.

Ao dotar os compradores de conhecimentos valiosos e estratégias acionáveis, este guia visa melhorar o processo de aprovisionamento, conduzindo, em última análise, a operações mais eficientes e a clientes satisfeitos. Quer seja um profissional de aprovisionamento experiente ou novo no mercado de peças automóveis, este recurso facilitará o seu percurso para encontrar o alternador C1 ideal para as suas necessidades específicas.

Índice

- Lista dos 5 principais fabricantes e fornecedores de alternadores C1

- Introdução: Navegando no mercado global de alternadores c1

- Compreender os tipos e as variações do alternador c1

- Principais aplicações industriais do alternador c1

- 3 Pontos de dor comuns dos utilizadores para ‘c1 alternator’ e respectivas soluções

- Guia de seleção de materiais estratégicos para o alternador c1

- Análise aprofundada: Processos de fabrico e garantia de qualidade para o alternador c1

- Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘alternador c1’

- Análise exaustiva dos custos e dos preços do alternador c1 Sourcing

- Análise de alternativas: Comparação do alternador c1 com outras soluções

- Caraterísticas técnicas essenciais e terminologia comercial do alternador c1

- Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector dos alternadores c1

- Perguntas mais frequentes (FAQs) para compradores B2B de alternador c1

- Conclusão sobre o aprovisionamento estratégico e perspectivas para o alternador c1

- Aviso legal importante e termos de utilização

Compreender os tipos e as variações do alternador c1

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Alternador C1 standard | Normalmente OEM, saída de 12V, concebida para modelos específicos | Oficinas mecânicas, concessionárias | Prós: Fiável, especificações OEM; Contras: Custo mais elevado, adaptabilidade limitada. |

| Alternador de um fio | Instalação simplificada, ligação com um único fio | Construções personalizadas, actualizações pós-venda | Prós: Fácil instalação, menos cablagem; Contras: Funcionalidade limitada, perda potencial do tacómetro. |

| Alternador de acionamento do tacômetro | Inclui tacómetro para monitorização do desempenho | Restauro de automóveis clássicos, afinação do desempenho | Prós: Mantém a funcionalidade original; Contras: Mais caro, pode exigir montagens personalizadas. |

| Alternador de alta potência | Maior amperagem para sistemas eléctricos exigentes | Aplicações de competição, veículos pesados | Prós: Suporta cargas eléctricas elevadas; Contras: Custo mais elevado, potencialmente excessivo para utilização normal. |

| Alternador reconstruído/usado | Unidades recondicionadas, muitas vezes a custos mais baixos | Compradores preocupados com o orçamento, sustentabilidade | Prós: Económico e amigo do ambiente; Contras: Duração de vida mais curta, pode não ter garantia. |

Quais são as caraterísticas de um alternador C1 standard?

O Alternador C1 Standard foi concebido para cumprir as especificações do fabricante do equipamento original (OEM) para modelos de veículos específicos. Funciona normalmente a 12V e é amplamente utilizado em oficinas de reparação automóvel e concessionários para substituições. Os compradores B2B devem ter em conta a fiabilidade destas unidades, embora tenham frequentemente um custo mais elevado em comparação com as opções do mercado de substituição. Além disso, a sua compatibilidade é limitada a modelos específicos, o que pode restringir a sua aplicação em diversos ambientes automóveis.

Como é que um alternador de um só fio simplifica a instalação?

O alternador de um só fio é preferido pelo seu processo de instalação simplificado, apresentando uma ligação de um só fio que reduz a complexidade. Este tipo é popular entre os construtores personalizados e as actualizações do mercado pós-venda, particularmente em ambientes onde o tempo e os custos de mão de obra são críticos. Embora ofereçam facilidade de instalação, os compradores devem ponderar os potenciais inconvenientes, como a funcionalidade limitada e o risco de perder caraterísticas essenciais, como o tacómetro.

Porquê escolher um alternador com transmissão por tacômetro para monitorizar o desempenho?

Os alternadores Tach Drive são especificamente concebidos para incluir um tacómetro, o que os torna ideais para restauros de automóveis clássicos e afinação do desempenho. Esta caraterística permite a monitorização do desempenho em tempo real, o que é crucial tanto para entusiastas como para profissionais. No entanto, estas unidades tendem a ser mais caras e podem exigir soluções de montagem personalizadas, o que pode complicar a decisão de compra para os compradores B2B.

Quais são as vantagens de um alternador de alto rendimento?

Os Alternadores de Alto Rendimento são concebidos para fornecer uma maior amperagem, atendendo a veículos com sistemas eléctricos exigentes, tais como aplicações de competição ou veículos pesados. Estas unidades são essenciais para suportar cargas eléctricas elevadas, tornando-as uma escolha preferida em indústrias especializadas. No entanto, o seu custo mais elevado e a possibilidade de serem demasiado especificados para aplicações padrão devem ser considerados pelos compradores quando avaliam as suas necessidades.

Como é que os alternadores reconstruídos ou usados podem beneficiar os compradores preocupados com o orçamento?

Os alternadores recondicionados ou usados apresentam uma solução económica para compradores preocupados com o orçamento, ao mesmo tempo que promovem a sustentabilidade através da redução de resíduos. Estas unidades recondicionadas estão frequentemente disponíveis a preços mais baixos, o que as torna atractivas para oficinas e empresas que procuram gerir as despesas. No entanto, os compradores devem estar cientes de que estas unidades podem ter uma vida útil mais curta e podem não ter garantias, o que pode levar a custos adicionais a longo prazo.

Principais aplicações industriais do alternador c1

| Indústria/Setor | Aplicação específica do alternador c1 | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Fabricação Automotiva | Substituição em veículos compactos como o Citroën C1 | Aumenta a fiabilidade e o desempenho do veículo | Assegurar a compatibilidade com modelos específicos e normas OEM |

| Equipamento agrícola | Alimentação de equipamentos como tractores e ceifeiras | Aumenta a eficiência operacional e reduz o tempo de inatividade | Considerar as cadeias de abastecimento locais e a disponibilidade de serviços |

| Máquinas industriais | Utilizado em geradores para sistemas de energia de reserva | Fornece uma fonte de alimentação consistente para operações críticas | Avaliar os requisitos de tensão e as configurações de instalação |

| Aplicações marítimas | Apoio aos sistemas eléctricos de bordo em pequenas embarcações | Melhora a segurança e a funcionalidade das operações marítimas | Avaliar as especificações de resistência às intempéries e de durabilidade |

| Sistemas de energia renovável | Integração em sistemas de energia solar ou eólica | Facilita o armazenamento e a distribuição de energia | Procurar a compatibilidade com instalações de energias renováveis |

Como é que o alternador c1 é utilizado no fabrico de automóveis?

No sector da indústria automóvel, o alternador c1 é normalmente utilizado como substituto do equipamento de origem em veículos compactos como o Citroën C1. Melhora a fiabilidade e o desempenho do veículo, resolvendo problemas como as falhas de carregamento da bateria que podem levar a avarias no veículo. Os compradores deste sector têm de garantir que o alternador cumpre as normas específicas do OEM em termos de compatibilidade, especialmente para modelos populares na Europa e na América do Sul. Para além disso, a aquisição a fornecedores de renome pode garantir a qualidade e a longevidade do produto.

Qual é o papel do alternador c1 no equipamento agrícola?

O alternador c1 é crucial no equipamento agrícola, alimentando máquinas como tractores e ceifeiras. Aumenta a eficiência operacional ao fornecer uma fonte de energia fiável, o que é essencial durante as épocas de pico das colheitas, quando o equipamento tem de ter um desempenho ótimo. Para os compradores internacionais, em particular em África e na América do Sul, as considerações relativas ao fornecimento incluem a disponibilidade local, a competitividade dos preços e a capacidade de apoiar o serviço pós-venda para manutenção e reparações.

Como é que o alternador c1 apoia as máquinas industriais?

Em ambientes industriais, o alternador c1 é utilizado em geradores para sistemas de energia de reserva, assegurando que as operações críticas podem continuar sem interrupção durante as falhas de energia. Esta fiabilidade é vital para as empresas que dependem de processos de produção contínuos. Os compradores devem avaliar os requisitos de tensão e as configurações de instalação para garantir uma integração perfeita nos sistemas existentes, particularmente em regiões com fornecimento de energia inconsistente.

Porque é que o alternador c1 é importante para as aplicações marítimas?

Em aplicações marítimas, o alternador c1 suporta sistemas eléctricos a bordo de pequenas embarcações, aumentando a segurança e a funcionalidade. Alimenta equipamentos essenciais como sistemas de navegação e luzes, que são fundamentais para operações seguras no mar. Os compradores têm de avaliar as especificações de resistência às intempéries e durabilidade do alternador para garantir que este consegue suportar ambientes marítimos adversos, especialmente para as empresas que operam no Médio Oriente e nas regiões costeiras de África.

Como é que o alternador c1 pode beneficiar os sistemas de energias renováveis?

O alternador c1 pode ser integrado em sistemas de energia renovável, tais como instalações de energia solar ou eólica, para facilitar o armazenamento e a distribuição de energia. Esta aplicação é particularmente relevante para as empresas que procuram melhorar a sustentabilidade e reduzir os custos energéticos. Ao adquirir para esta aplicação, os compradores devem procurar a compatibilidade com configurações específicas de energia renovável e garantir que o alternador pode lidar eficazmente com os requisitos de produção de energia.

3 Pontos de dor comuns dos utilizadores para ‘c1 alternator’ e respectivas soluções

Cenário 1: Confusão de compatibilidade com alternadores C1

O problema:

Os compradores B2B enfrentam frequentemente desafios para garantir a compatibilidade dos alternadores C1 com modelos de veículos específicos. Por exemplo, um comprador pode comprar um alternador para um Citroën C1 e descobrir que não serve devido a diferenças subtis na montagem ou nas ligações eléctricas. Este problema é exacerbado pela variedade de fornecedores e marcas disponíveis no mercado, o que gera confusão e frustração. Estas incompatibilidades não só atrasam os processos de reparação, como também podem resultar em perdas financeiras devido aos custos de devolução e à perda de tempo.

A solução:

Para mitigar os problemas de compatibilidade, os compradores devem dar prioridade à aquisição de alternadores de fornecedores reputados que forneçam especificações detalhadas e tabelas de compatibilidade. Faça sempre uma referência cruzada dos números de peça OEM - como 27060-0Q130 para o Citroën C1 - ao efetuar uma compra. Além disso, a consulta do VIN (Número de Identificação do Veículo) pode ajudar a confirmar que o alternador corresponde à configuração específica do veículo. Também é aconselhável consultar os fornecedores sobre as suas políticas de devolução e opções de garantia, assegurando que existe recurso se a peça não se ajustar como esperado. O contacto com mecânicos locais ou peritos automóveis familiarizados com alternadores C1 pode fornecer mais informações, assegurando que a peça certa é adquirida à primeira.

Cenário 2: Preocupações com o desempenho e a fiabilidade

O problema:

Outro ponto problemático comum para os compradores B2B é a preocupação com o desempenho e a fiabilidade dos alternadores C1 do mercado de substituição. Os compradores podem estar apreensivos quanto à compra de alternadores usados ou remanufacturados, receando que possam não ter o mesmo desempenho que as peças originais. Esta preocupação é particularmente acentuada em regiões onde o tempo de inatividade dos veículos pode afetar gravemente as operações comerciais. A produção de energia inadequada ou a falha prematura de um alternador pode levar a reparações dispendiosas e à perda de produtividade.

A solução:

Para garantir a fiabilidade dos alternadores C1, os compradores devem concentrar-se na aquisição de peças de fabricantes estabelecidos que ofereçam garantias sobre os seus produtos. É aconselhável procurar alternadores que tenham sido certificados em termos de qualidade e desempenho, especialmente aqueles que são submetidos a testes rigorosos antes de serem vendidos. Os compradores podem também considerar investir em unidades remanufacturadas que mantêm as especificações originais e são renovadas para cumprir as normas OEM. Além disso, a implementação de um programa de manutenção preventiva que inclua a inspeção regular do alternador e dos componentes associados - como a correia de transmissão - pode ajudar a identificar potenciais problemas antes que estes conduzam a uma falha. Esta abordagem proactiva não só aumenta a fiabilidade como também maximiza a vida útil do alternador.

Cenário 3: Gestão de custos e restrições orçamentais

O problema:

A gestão de custos é uma preocupação crítica para os compradores B2B, particularmente em regiões com moedas flutuantes e incertezas económicas. Os compradores debatem-se frequentemente com a necessidade de encontrar um equilíbrio entre a qualidade e a acessibilidade económica ao adquirirem alternadores C1. A tentação de optar pelas alternativas mais baratas pode levar a um desempenho inferior, enquanto que as peças de maior qualidade podem sobrecarregar as restrições orçamentais. Este ato de equilíbrio financeiro pode levar ao stress e à indecisão, dificultando os processos de aquisição e reparação atempados.

A solução:

Para gerir eficazmente os custos e, ao mesmo tempo, garantir a qualidade, os compradores devem explorar opções de compra a granel ou estabelecer relações de longo prazo com os fornecedores para obter melhores preços. A negociação de contratos que incluam descontos por volume pode reduzir significativamente os custos unitários. Além disso, os compradores devem efetuar uma análise de custo-benefício, comparando o custo total de propriedade - tendo em conta a fiabilidade, a garantia e o potencial tempo de inatividade - com o preço de compra inicial. Investir num alternador ligeiramente mais caro, mas de maior qualidade, pode resultar em poupanças a longo prazo através da redução das avarias e dos custos de manutenção. A utilização de fornecedores regionais ou distribuidores locais também pode ajudar a minimizar as despesas de envio, permitindo um processo de aquisição mais económico.

Guia de seleção de materiais estratégicos para o alternador c1

Ao selecionar os materiais para o alternador C1, é essencial considerar vários factores que afectam o desempenho, a durabilidade e a relação custo-eficácia. A escolha dos materiais pode afetar significativamente a eficiência, a longevidade e a adequação do alternador a aplicações específicas. Segue-se uma análise de quatro materiais comuns utilizados no fabrico de alternadores C1.

Quais são as principais propriedades do alumínio nos alternadores C1?

O alumínio é amplamente utilizado em caixas de alternadores devido à sua natureza leve e excelente condutividade térmica. Com um ponto de fusão de cerca de 660°C, o alumínio pode suportar temperaturas elevadas, tornando-o adequado para aplicações automóveis. Além disso, oferece uma boa resistência à corrosão, particularmente quando anodizado, o que aumenta a sua longevidade em vários ambientes.

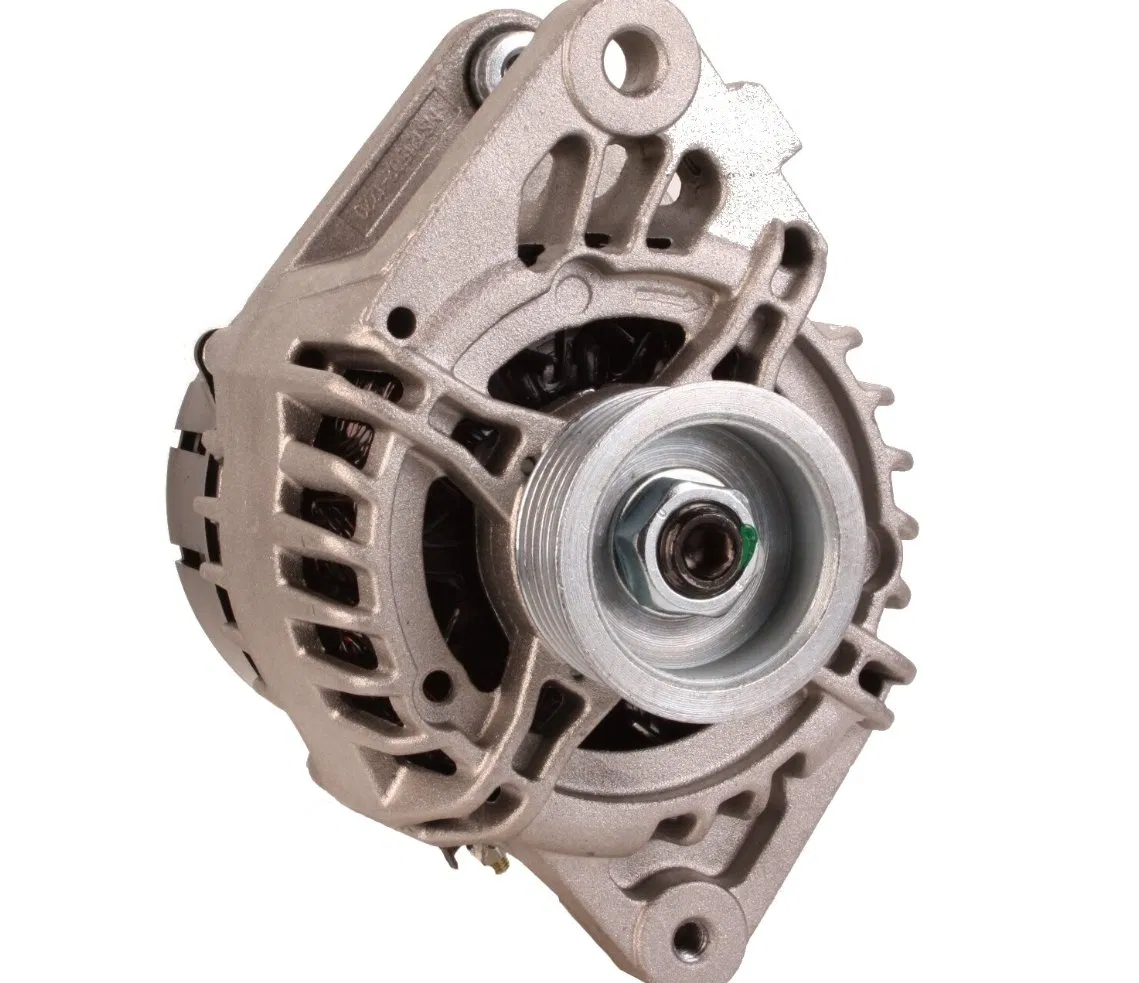

Imagem ilustrativa relacionada com o alternador c1

Prós e contras: A principal vantagem do alumínio é o seu baixo peso, que contribui para a eficiência global do veículo. No entanto, pode ser mais caro do que outros materiais como o aço e pode exigir processos de fabrico mais complexos, como a fundição sob pressão ou a extrusão, o que pode aumentar os custos de produção.

Impacto na aplicação: A compatibilidade do alumínio com diferentes meios, incluindo o óleo e o líquido de refrigeração, torna-o uma escolha versátil para os alternadores. É particularmente vantajoso em regiões com elevada humidade ou ambientes corrosivos, como as zonas costeiras de África e da América do Sul.

Como é que o aço é comparado com os alternadores C1?

O aço, particularmente o aço inoxidável, é outro material comum para os alternadores C1. Possui uma elevada resistência à tração e uma excelente durabilidade, o que o torna adequado para componentes que sofrem um esforço mecânico significativo. O aço pode suportar pressões e temperaturas elevadas, com um ponto de fusão superior a 1400°C.

Prós e contras: A principal vantagem do aço é a sua robustez, que garante uma longa duração de vida em condições exigentes. No entanto, é mais pesado do que o alumínio, o que pode afetar o desempenho do veículo. Além disso, o aço é propenso a enferrujar se não for corretamente revestido, necessitando de tratamentos adicionais que podem aumentar a complexidade e o custo de fabrico.

Imagem ilustrativa relacionada com o alternador c1

Impacto na aplicação: O aço é particularmente eficaz em regiões com flutuações extremas de temperatura, como o Médio Oriente, onde o calor elevado pode ser uma preocupação. No entanto, o seu peso pode ser uma desvantagem em mercados que dão prioridade à eficiência do combustível.

Que papel desempenha o cobre nos alternadores C1?

O cobre é predominantemente utilizado para enrolamentos e ligações eléctricas dentro do alternador devido à sua excelente condutividade eléctrica. Com um ponto de fusão de cerca de 1085°C, o cobre pode suportar as tensões térmicas associadas aos componentes eléctricos.

Prós e contras: A principal vantagem do cobre é a sua condutividade superior, que aumenta a eficiência do alternador. No entanto, o cobre é mais caro do que o alumínio e pode exigir um isolamento adicional para evitar curto-circuitos, aumentando a complexidade do fabrico.

Impacto na aplicação: Em regiões com elevada procura de eletricidade, como partes da Europa, a eficiência proporcionada pelo cobre pode levar a um melhor desempenho global. No entanto, os compradores devem considerar as implicações de custo da utilização do cobre nos seus projectos.

Porque é que o plástico é utilizado nos alternadores C1?

Os plásticos, particularmente os plásticos de engenharia como o policarbonato e o nylon, são frequentemente utilizados para componentes não estruturais em alternadores. Oferecem uma boa resistência química e podem suportar temperaturas moderadas, o que os torna adequados para várias aplicações automóveis.

Prós e contras: A principal vantagem dos plásticos é a sua leveza e resistência à corrosão. No entanto, podem não suportar temperaturas elevadas tão eficazmente como os metais, o que limita a sua utilização em áreas de elevada tensão. Além disso, os plásticos podem ser menos duráveis ao longo do tempo em comparação com os metais, o que suscita preocupações quanto à fiabilidade a longo prazo.

Impacto na aplicação: Em regiões com condições ambientais menos extremas, como algumas partes da Europa e da América do Sul, os plásticos podem constituir uma solução económica para componentes não críticos. No entanto, os compradores em climas mais rigorosos podem preferir alternativas metálicas para garantir a durabilidade.

Quadro recapitulativo da seleção de materiais para os alternadores C1

| Material | Caso de utilização típico para o alternador c1 | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Componentes estruturais e de alojamento | Leve e resistente à corrosão | Maior complexidade de fabrico | Médio |

| Aço | Componentes estruturais | Alta resistência e durabilidade | Mais pesado e propenso a ferrugem | Médio |

| Cobre | Enrolamentos e ligações elétricas | Condutividade elétrica superior | Custo elevado e necessidade de isolamento | Alto |

| Plástico | Componentes não estruturais | Leve e resistente a produtos químicos | Tolerância de temperatura limitada | Baixo |

Este guia estratégico de seleção de materiais fornece informações essenciais para os compradores B2B internacionais que consideram os alternadores C1. Compreender as propriedades, vantagens e limitações de cada material ajudará a tomar decisões informadas que se alinham com os requisitos de desempenho e considerações de custo em diversos mercados.

Análise aprofundada: Processos de fabrico e garantia de qualidade para o alternador c1

Quais são as principais etapas do processo de fabrico dos alternadores C1?

O processo de fabrico dos alternadores C1 envolve várias fases críticas, assegurando que o produto final cumpre os padrões de elevado desempenho. A compreensão destas etapas pode ajudar os compradores B2B a avaliar a qualidade e a fiabilidade dos alternadores que pretendem adquirir.

1. Preparação do material

O primeiro passo no fabrico de alternadores C1 envolve o fornecimento de matérias-primas de alta qualidade. Os principais componentes incluem cobre para o enrolamento, alumínio ou aço para a caixa e plásticos duráveis para o isolamento. Os fornecedores aderem frequentemente a normas internacionais de materiais para garantir que os materiais podem suportar tensões operacionais. São realizados testes de materiais para garantir que cumprem as especificações de condutividade eléctrica, resistência térmica e resistência mecânica.

2. Técnicas de conformação

Uma vez preparados os materiais, a fase seguinte é a moldagem. Normalmente, esta fase envolve processos como a estampagem e a maquinagem. A estampagem é utilizada para criar os componentes do estator e do rotor, enquanto a maquinagem é empregue para obter dimensões precisas em várias peças, como a caixa e os suportes de montagem. As máquinas CNC (Controlo Numérico Computadorizado) avançadas são frequentemente utilizadas para uma elevada precisão, garantindo que cada componente se encaixa perfeitamente durante a montagem.

3. Processo de montagem

A montagem dos alternadores C1 é um processo altamente organizado. Trabalhadores ou robots montam cuidadosamente o estator, o rotor e outros componentes. Esta fase pode envolver a soldadura ou o engaste de ligações eléctricas para garantir durabilidade e fiabilidade. As linhas de montagem automatizadas são cada vez mais comuns, permitindo uma qualidade consistente e taxas de produção mais rápidas. Cada linha de montagem segue normalmente um protocolo rigoroso para minimizar os erros e garantir que cada alternador cumpre as especificações do projeto.

4. Processos de acabamento

A fase final do fabrico envolve processos de acabamento que melhoram a durabilidade e o aspeto estético do alternador. Isto inclui a pintura, o revestimento e, por vezes, a anodização para proteção contra a corrosão e o desgaste. São efectuadas verificações de controlo de qualidade durante todo o processo de acabamento para garantir que os produtos cumprem as especificações desejadas.

Como é implementada a garantia de qualidade no fabrico do alternador C1?

A garantia de qualidade (GQ) é crucial no fabrico de alternadores C1 para assegurar o seu desempenho fiável em várias condições. Os compradores B2B devem estar cientes das normas e práticas relevantes que garantem a qualidade do produto.

Que normas internacionais devem os compradores considerar?

Os fabricantes de alternadores C1 cumprem frequentemente as normas internacionais de gestão da qualidade, como a ISO 9001. Esta certificação indica que a empresa estabeleceu um sistema de gestão da qualidade que cumpre os requisitos do cliente e regulamentares. Além disso, a adesão a normas específicas da indústria, como a marcação CE para produtos vendidos na Europa, significa o cumprimento dos requisitos de segurança e ambientais.

Quais são os principais pontos de verificação do controlo de qualidade?

Os pontos de controlo de qualidade fazem parte integrante do processo de fabrico. Os pontos de controlo comuns incluem:

-

Controlo de Qualidade de Entrada (IQC): Esta fase verifica se os materiais recebidos cumprem as normas especificadas antes de entrarem em produção. Os testes podem incluir verificações da integridade do material e inspecções dimensionais.

-

Controlo de qualidade em processo (IPQC): Realizado durante o processo de fabrico, envolve a monitorização de parâmetros críticos como as tolerâncias de montagem e o desempenho elétrico. Quaisquer desvios são tratados imediatamente para evitar que os produtos defeituosos passem à fase seguinte.

-

Controlo de Qualidade Final (FQC): Antes do envio, cada alternador é submetido a testes rigorosos para garantir que cumpre as normas de desempenho. Isto pode incluir testes de carga, testes de continuidade eléctrica e avaliações do nível de ruído.

Que métodos de ensaio são habitualmente utilizados para os alternadores C1?

Os métodos de ensaio dos alternadores C1 desempenham um papel fundamental na validação do seu desempenho e fiabilidade. Os compradores B2B devem compreender estes métodos para avaliar melhor os potenciais fornecedores.

-

Testes elétricos: Inclui a verificação da saída de tensão, do consumo de corrente e da resistência do isolamento. Os testes eléctricos garantem que o alternador pode funcionar eficazmente dentro da gama especificada.

-

Testes térmicos: Uma vez que os alternadores podem gerar calor durante o funcionamento, os ensaios térmicos avaliam a capacidade do alternador para dissipar o calor e manter o desempenho em diferentes condições.

-

Testes mecânicos: Trata-se de avaliar a durabilidade da caixa, dos suportes e de outros componentes físicos. Podem ser efectuados testes de vibração e testes de queda para simular condições reais.

Como os compradores B2B podem verificar as práticas de controlo de qualidade dos fornecedores?

Os compradores B2B que procuram obter alternadores C1 devem adotar uma abordagem proactiva para verificar as práticas de controlo de qualidade dos potenciais fornecedores.

O que é que os compradores devem procurar nas auditorias aos fornecedores?

As auditorias aos fornecedores são uma ferramenta essencial para avaliar as capacidades de fabrico. Os compradores devem solicitar relatórios de auditoria recentes que especifiquem a conformidade com as normas ISO e outras certificações relevantes. As auditorias devem abranger domínios como:

-

Processos de fabrico: Exame do fluxo de fabrico, desde o abastecimento de materiais até à montagem final, para garantir que as melhores práticas são seguidas.

-

Sistemas de gestão da qualidade: Revisão do sistema de gestão da qualidade do fornecedor para confirmar a adesão às normas internacionais.

Como os compradores podem usar inspeções de terceiros?

A contratação de serviços de inspeção por terceiros pode proporcionar uma avaliação imparcial das práticas de qualidade de um fornecedor. Os compradores podem solicitar inspecções durante várias fases de produção, garantindo que os alternadores cumprem as normas especificadas antes da expedição.

Que nuances devem os compradores internacionais B2B considerar na garantia de qualidade?

Para os compradores B2B de diversas regiões, incluindo África, América do Sul, Médio Oriente e Europa, é essencial compreender os regulamentos e normas locais.

Imagem ilustrativa relacionada com o alternador c1

-

Conformidade regulamentar: As diferentes regiões podem ter requisitos específicos para os componentes automóveis. Os compradores devem certificar-se de que os alternadores cumprem os regulamentos locais, que podem afetar a importação e a utilização.

-

Práticas de sustentabilidade: Como os mercados globais dão cada vez mais ênfase à sustentabilidade, os fabricantes podem adotar práticas ecológicas. Os compradores devem informar-se sobre o compromisso de um fornecedor para com a sustentabilidade, incluindo a redução de resíduos e o aprovisionamento responsável.

Ao compreender os processos de fabrico e as medidas de garantia de qualidade associadas aos alternadores C1, os compradores B2B podem tomar decisões informadas, assegurando que adquirem produtos de alta qualidade que satisfazem as suas necessidades operacionais.

Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘alternador c1’

Introdução

Este guia foi concebido para ajudar os compradores B2B a obterem eficazmente alternadores C1, um componente crítico para várias aplicações automóveis. Com foco nos mercados internacionais, incluindo África, América do Sul, Médio Oriente e Europa, esta lista de verificação garantirá que toma decisões de compra informadas enquanto navega pelas opções do fornecedor, especificações técnicas e considerações logísticas.

Passo 1: Defina as suas especificações técnicas

Comece por delinear os requisitos técnicos específicos para o alternador C1 de que necessita. Isto inclui conhecer a tensão, a amperagem e a compatibilidade com o modelo do veículo. Ao definir claramente estas especificações, pode evitar comprar um alternador que não satisfaça as suas necessidades, reduzindo assim as taxas de devolução e aumentando a eficiência operacional.

- Tensão e amperagem: Assegurar que o alternador satisfaz as necessidades eléctricas do veículo.

- Compatibilidade: Verifique os números OEM para confirmar a compatibilidade com o modelo pretendido.

Passo 2: Pesquisar potenciais fornecedores

Realizar uma pesquisa exaustiva para identificar potenciais fornecedores especializados em peças automóveis, especificamente alternadores C1. A utilização de diretórios e fóruns específicos da indústria pode fornecer informações sobre fornecedores de renome. Este passo é essencial para evitar fornecedores pouco fiáveis e garante que está a adquirir a empresas estabelecidas com um historial comprovado.

- Comentários online: Procure comentários e classificações de clientes em sítios de terceiros.

- Reputação no sector: Participar em fóruns do sector para recolher recomendações.

Passo 3: Avaliar as certificações dos fornecedores

Antes de finalizar qualquer fornecedor, verifique as suas certificações e a conformidade com as normas de qualidade internacionais. Certificações como a ISO 9001 indicam um compromisso com a gestão da qualidade, que pode ser crucial para garantir a fiabilidade dos alternadores que adquire.

- Garantia de qualidade: Pedir cópias das certificações e dos processos de controlo de qualidade.

- Informações sobre garantia: Compreender as condições de garantia oferecidas pelo fornecedor.

Passo 4: Pedir amostras e testar o desempenho

Sempre que possível, solicite amostras do alternador C1 para testar o desempenho e a compatibilidade com as suas aplicações. Este passo ajuda a mitigar os riscos associados às compras a granel e garante que o produto cumpre as suas normas operacionais.

- Procedimentos de teste: Aplicar um protocolo de ensaio para avaliar o desempenho do alternador em carga.

- Controlos de instalação: Assegurar-se de que o alternador se adapta fisicamente ao modelo de veículo previsto.

Passo 5: Negociar preços e condições

Depois de identificar os fornecedores adequados e de avaliar os seus produtos, encetar negociações sobre os preços e as condições de entrega. Este é um passo importante para garantir o melhor negócio possível, assegurando simultaneamente que a qualidade do produto não é comprometida.

- Descontos por atacado: Informe-se sobre as estruturas de preços para grandes encomendas.

- Condições de pagamento: Discuta os métodos de pagamento que são seguros e convenientes para a sua empresa.

Passo 6: Avaliar a logística e as opções de entrega

Considere a logística de envio e entrega do fornecedor escolhido. Avalie as suas capacidades de expedição e os prazos de entrega estimados para garantir que se alinham com os prazos do seu projeto. Este passo é crucial para manter a eficiência da sua cadeia de fornecimento.

- Custos de envio: Inclua quaisquer custos adicionais associados ao envio para a sua localização.

- Alfândegas e direitos aduaneiros: Ter em atenção os regulamentos de importação que possam ser aplicáveis.

Passo 7: Estabeleça uma relação de longo prazo

Por último, procure estabelecer uma relação a longo prazo com o seu fornecedor. Uma parceria fiável pode levar a melhores preços, serviço prioritário e acesso a novas linhas de produtos. A comunicação e o feedback regulares podem melhorar a colaboração.

- Revisões regulares: Programar revisões periódicas para avaliar o desempenho e discutir as necessidades futuras.

- Mecanismo de feedback: Criar um sistema para dar feedback sobre a qualidade do produto e do serviço.

Seguindo este guia completo de aprovisionamento, pode simplificar o seu processo de aquisição de alternadores C1, garantindo produtos de qualidade e operações eficientes para a sua empresa.

Análise exaustiva dos custos e dos preços do alternador c1 Sourcing

Quais são os principais componentes de custo no fornecimento de alternadores C1?

Ao adquirir alternadores C1, é essencial compreender a estrutura de custos para tomar decisões de compra informadas. Os principais componentes de custo incluem:

-

Materiais: A qualidade e o tipo de materiais utilizados no alternador influenciam significativamente o custo. Os metais e componentes de alta qualidade, como os enrolamentos de cobre e as carcaças robustas, são mais caros, mas oferecem um melhor desempenho e longevidade.

-

Trabalho: Os custos de mão de obra variam consoante a região e a complexidade do processo de fabrico. É necessária mão de obra especializada para a montagem e o controlo de qualidade, o que pode aumentar a despesa global.

-

Custos indiretos de produção: Inclui os custos associados às operações da fábrica, tais como os serviços públicos, a manutenção do equipamento e a gestão da fábrica. Processos de fabrico eficientes podem ajudar a reduzir estes custos gerais.

-

Ferramentas: Os custos iniciais de instalação das ferramentas e máquinas necessárias para a produção podem ser substanciais. Estes custos são normalmente amortizados ao longo do volume de produção.

-

Controlo de Qualidade (QC): O investimento em processos de controlo de qualidade garante que os alternadores cumprem as especificações e normas exigidas, o que pode evitar devoluções dispendiosas e retrabalho.

-

Logística: Os custos de transporte e de expedição são críticos, especialmente para os compradores internacionais. Factores como a distância, o método de envio e as taxas de frete terão impacto no custo total.

-

Margem: Os fornecedores acrescentam normalmente uma margem de lucro para cobrir os seus custos e riscos operacionais. Esta margem pode variar muito em função das condições de mercado e das relações com os fornecedores.

Como é que os influenciadores de preços afectam os custos do alternador C1?

Vários factores podem influenciar o preço dos alternadores C1:

-

Volume/MOQ: A compra a granel conduz frequentemente a descontos. Os fornecedores podem ter quantidades mínimas de encomenda (MOQ) que podem afetar os preços. É aconselhável negociar preços mais baixos com base em encomendas maiores.

-

Especificações e personalização: As caraterísticas ou especificações personalizadas podem aumentar os custos. Os compradores devem ponderar as vantagens da personalização em função das restrições orçamentais.

-

Materiais e certificações de qualidade: Os alternadores que possuem certificações de qualidade, como as normas ISO ou OEM, podem ter um preço mais elevado, mas podem oferecer garantias de fiabilidade e desempenho.

-

Fatores relacionados ao fornecedor: A reputação e a fiabilidade do fornecedor podem afetar os preços. Os fornecedores estabelecidos podem cobrar mais devido ao seu historial comprovado, mas muitas vezes oferecem melhor apoio e garantia de qualidade.

-

Incoterms: A compreensão das condições de envio é crucial para as transacções internacionais. Incoterms diferentes (como FOB, CIF) podem afetar o custo total e o risco envolvido no processo de envio.

Que dicas os compradores devem considerar para obter eficiência de custos no fornecimento de alternadores C1?

Para maximizar a relação custo-eficácia ao adquirir alternadores C1, os compradores devem considerar as seguintes estratégias:

-

Negociar termos: Negoceie sempre os preços e as condições de pagamento. Os fornecedores podem ter flexibilidade, especialmente quando lhes é apresentada uma encomenda substancial.

-

Avalie o custo total de propriedade (TCO): Considere não só o preço de compra, mas também os custos a longo prazo associados à manutenção, garantia e potenciais falhas. Custos iniciais mais elevados podem levar a um TCO mais baixo se o produto tiver uma maior durabilidade.

-

Pesquisar e comparar fornecedores: Reserve algum tempo para avaliar vários fornecedores. Compare os seus preços, condições e qualidade. Isto pode proporcionar uma vantagem durante as negociações.

-

Compreender as nuances dos preços regionais: Tenha em atenção as condições do mercado regional, as tarifas e os direitos aduaneiros que podem afetar os preços. As diferentes regiões podem ter uma disponibilidade variável de peças e custos associados, especialmente para compradores em África, América do Sul, Médio Oriente e Europa.

-

Mantenha-se informado sobre as tendências do mercado: Mantenha-se a par das tendências do sector que podem afetar os preços. As mudanças económicas, a escassez de material ou as alterações na procura podem levar a flutuações de preços.

Isenção de responsabilidade sobre preços

Os preços dos alternadores C1 podem variar significativamente em função dos factores supracitados. Os preços indicativos indicados nesta análise estão sujeitos a alterações e devem ser verificados junto dos fornecedores para obter as taxas mais actuais. Efectue sempre uma pesquisa exaustiva e a devida diligência ao tomar decisões de compra.

Análise de alternativas: Comparação do alternador c1 com outras soluções

Explorando alternativas ao alternador C1: Uma comparação abrangente

Ao considerar alternativas ao alternador C1, é essencial avaliar várias opções que cumpram os mesmos requisitos funcionais, tendo em conta factores como o desempenho, o custo e a facilidade de implementação. A escolha correta dependerá das necessidades específicas da empresa, do contexto operacional e das restrições orçamentais. Esta análise compara o alternador C1 com duas alternativas notáveis: o alternador de um fio e o gerador reconstruído.

| Aspecto comparativo | Alternador C1 | Alternador de um fio | Gerador reconstruído |

|---|---|---|---|

| Desempenho | Fiável, mantém as especificações originais | Instalação simples, mas menos fiável para utilização com tacómetro | Desempenho original, mas pode variar consoante a qualidade da reconstrução |

| Custo | Aproximadamente 170 euros - 213 euros | Normalmente, menos de 100 euros | Entre 80 e 150 euros, consoante o prestador de serviços |

| Facilidade de implementação | Moderado; pode exigir montagens específicas | Fácil; é necessária uma cablagem mínima | Moderado; requer mão de obra especializada para a reconstrução |

| Manutenção | Baixo; concebido para a longevidade | Baixo; geralmente durável | Moderado; depende da qualidade da reconstrução |

| Melhor caso de uso | Restauros de automóveis clássicos, substituições OEM | Correcções rápidas para aplicações sem taquímetro | Económica para veículos antigos que necessitam de peças originais |

Análise aprofundada das alternativas

Quais são as vantagens e desvantagens de um alternador de um só fio?

O alternador de um só fio é uma opção apelativa para muitos utilizadores devido ao seu processo de instalação simples, exigindo apenas uma ligação de um só fio à bateria. Esta simplicidade pode ser vantajosa para reparações ou actualizações rápidas. No entanto, uma desvantagem significativa é a perda de funcionalidade dos tacómetros, que pode ser crítica em aplicações de desempenho. Além disso, se o estator falhar, os utilizadores podem não receber qualquer aviso até o veículo parar, o que representa um risco de paragem operacional.

Como é que um gerador reconstruído se compara com o alternador C1?

Os geradores reconstruídos oferecem uma solução económica para quem procura manter a estética e a funcionalidade originais dos veículos antigos. Muitas vezes, podem ser restaurados para funcionarem tão bem como as unidades novas, mas a fiabilidade depende muito da qualidade da reconstrução. Alguns compradores podem achar que as unidades reconstruídas podem variar significativamente em termos de desempenho, levando a potenciais preocupações sobre a longevidade e a frequência de manutenção. Esta opção é ideal para os entusiastas de automóveis clássicos que dão prioridade à originalidade e estão dispostos a investir em inspecções minuciosas.

Conclusão: Como é que os compradores B2B podem escolher a solução certa?

A seleção da solução de alternador certa para a sua empresa requer uma análise cuidadosa das suas necessidades específicas e do contexto operacional. Se a manutenção da autenticidade dos veículos clássicos for uma prioridade, o alternador C1 ou o gerador reconstruído podem ser as melhores opções. Por outro lado, para reparações rápidas ou aplicações menos críticas, o alternador de um só fio pode ser uma alternativa prática. Em última análise, a ponderação do desempenho, do custo, da facilidade de implementação e da manutenção orientá-lo-á para a escolha mais adequada aos requisitos da sua organização.

Caraterísticas técnicas essenciais e terminologia comercial do alternador c1

Quais são as principais caraterísticas técnicas de um alternador C1?

Compreender as especificações técnicas essenciais de um alternador C1 é crucial para os compradores B2B, em particular os envolvidos nas cadeias de fornecimento do sector automóvel. Eis algumas das especificações críticas a considerar:

-

Tensão nominal: A tensão nominal indica o potencial elétrico produzido pelo alternador. A maioria dos alternadores C1 funciona a 12 volts, que é a norma para as aplicações automóveis. É essencial para garantir a compatibilidade com o sistema elétrico do veículo. Os compradores devem verificar esta classificação para evitar danos potenciais nos componentes electrónicos.

-

Amperagem de saída: Esta especificação define a corrente que o alternador pode fornecer ao sistema elétrico do veículo. As saídas comuns para os alternadores C1 variam entre 40 e 100 amperes. Uma saída de amperagem mais elevada é essencial para veículos com numerosos dispositivos electrónicos, assegurando que todos os componentes recebem energia adequada.

-

Configuração de montagem: Esta propriedade refere-se à conceção física do alternador, incluindo os seus pontos de montagem e orientação. O alternador C1 deve corresponder à conceção do veículo para uma instalação correta. Os compradores devem verificar a compatibilidade com os modelos dos seus veículos para evitar modificações dispendiosas.

-

Especificações OEM: As especificações do fabricante de equipamento original (OEM) garantem que o alternador cumpre os critérios de conceção originais definidos pelo fabricante do veículo. A utilização de peças OEM é essencial para manter o desempenho e a fiabilidade do veículo, o que faz com que seja um fator crítico para os compradores B2B centrados na qualidade.

-

Composição do material: Os materiais utilizados no alternador, como o alumínio ou o aço para a caixa e o cobre para os enrolamentos, afectam a durabilidade e a eficiência. Materiais de alta qualidade podem levar a um melhor desempenho e a uma vida útil mais longa, o que é uma consideração importante para os compradores que procuram minimizar os custos de manutenção.

-

Mecanismo de arrefecimento: Os alternadores geram calor durante o funcionamento, pelo que um mecanismo de arrefecimento eficiente é crucial. Caraterísticas como designs ventilados ou ventoinhas de arrefecimento integradas ajudam a manter temperaturas de funcionamento óptimas, reduzindo o risco de sobreaquecimento e avaria.

Quais são os termos comerciais comuns relacionados com os alternadores C1?

A familiaridade com o jargão da indústria é essencial para uma comunicação e negociações eficazes no sector B2B. Eis alguns dos termos mais utilizados:

-

OEM (Fabricante de Equipamento Original): Refere-se a peças fabricadas pelo fabricante que forneceu originalmente o veículo. As peças OEM são preferidas pela sua compatibilidade e qualidade garantidas, o que as torna uma consideração fundamental para os compradores que procuram fiabilidade.

-

MOQ (Quantidade mínima de encomenda): Este termo indica a quantidade mais pequena de um produto que um fornecedor está disposto a vender. Compreender o MOQ é crucial para os compradores optimizarem os níveis de inventário e gerirem os custos de forma eficaz, especialmente quando adquirem alternadores a granel.

-

RFQ (Pedido de Orçamento): Um pedido de cotação é um documento enviado aos fornecedores solicitando preços e condições para produtos específicos. Para os compradores B2B, esta é uma etapa vital no processo de aquisição, permitindo-lhes comparar ofertas e negociar melhores negócios.

-

Incoterms (Termos Comerciais Internacionais): Trata-se de termos comerciais normalizados que definem as responsabilidades dos compradores e vendedores relativamente ao transporte, seguro e tarifas. A familiaridade com os Incoterms ajuda os compradores a compreender os custos de envio e a atribuição de riscos, essenciais para as transacções internacionais.

-

Prazo de entrega: Este termo refere-se ao tempo que decorre entre a realização de uma encomenda e a receção do produto. A compreensão dos prazos de entrega ajuda os compradores a planear o seu inventário e a garantir a disponibilidade atempada das peças, o que é fundamental para manter a eficiência operacional.

-

Mercado pós-venda: Este termo refere-se a peças e acessórios não fabricados pelo OEM mas concebidos para corresponder às mesmas especificações. Os alternadores do mercado de substituição podem oferecer poupanças de custos e opções alternativas, tornando-os uma consideração importante para os compradores que procuram equilibrar qualidade e orçamento.

Em suma, ter uma compreensão clara das propriedades técnicas e da terminologia comercial relacionadas com os alternadores C1 dota os compradores B2B dos conhecimentos necessários para uma tomada de decisões informada, conduzindo, em última análise, a melhores estratégias de aquisição e eficiência operacional.

Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector dos alternadores c1

Quais são as actuais dinâmicas de mercado que influenciam o sector dos alternadores C1?

O mercado de alternadores C1 está a registar mudanças significativas impulsionadas por vários factores globais. Um dos principais factores é a procura crescente de sistemas eléctricos fiáveis e eficientes nos veículos, particularmente nos mercados emergentes de África e da América do Sul. À medida que estas regiões testemunham um aumento da propriedade de veículos, a necessidade de alternadores duradouros e económicos torna-se primordial. Ao mesmo tempo, a Europa, especialmente a Alemanha, está a inclinar-se para tecnologias automóveis avançadas, como os veículos eléctricos (VE), que estão a influenciar a conceção e o fabrico tradicionais de alternadores.

As tendências actuais indicam um interesse crescente em alternadores modulares e adaptáveis que podem ser facilmente integrados em vários modelos de veículos. Esta adaptabilidade é crucial para os compradores B2B internacionais que precisam de obter componentes que se adaptem a várias aplicações sem grandes modificações. Além disso, a ascensão das plataformas de comércio eletrónico simplificou os processos de abastecimento, permitindo aos compradores de diversas regiões aceder a uma gama mais vasta de produtos com preços competitivos.

Imagem ilustrativa relacionada com o alternador c1

As tendências de aprovisionamento também estão a evoluir com a integração das tecnologias digitais. A utilização da inteligência artificial (IA) e da análise de dados na gestão da cadeia de abastecimento está a tornar-se mais prevalecente. Esta tecnologia permite que os fabricantes e fornecedores prevejam padrões de procura, optimizem o inventário e melhorem os prazos de entrega, melhorando assim a experiência global de aquisição para os compradores B2B.

Como é que a sustentabilidade e o fornecimento ético estão a moldar o mercado de alternadores C1?

A sustentabilidade tornou-se uma consideração crítica no sector dos alternadores C1, reflectindo uma mudança mais ampla na indústria automóvel para práticas mais ecológicas. As avaliações de impacto ambiental são cada vez mais importantes, com os fabricantes e fornecedores a serem instados a minimizar os resíduos e o consumo de energia durante a produção. Isto é particularmente relevante para os compradores internacionais que estão a dar prioridade aos parceiros que aderem a práticas sustentáveis.

O fornecimento ético é outro aspeto vital para os compradores B2B. A procura de transparência nas cadeias de fornecimento está a crescer, com as empresas a procurarem garantir que os seus componentes são produzidos em condições de trabalho justas e com o mínimo de degradação ambiental. Certificações como a ISO 14001 para gestão ambiental e outras certificações “verdes” estão a tornar-se essenciais para os fornecedores que pretendem atrair compradores conscientes.

No mercado dos alternadores C1, a utilização de materiais e componentes reciclados está a ganhar força. Ao optarem por alternadores fabricados a partir de materiais reciclados, os compradores não só reduzem a sua pegada de carbono como também apoiam uma economia circular. Esta tendência alinha-se com as crescentes pressões regulamentares e as expectativas dos consumidores relativamente a produtos sustentáveis.

Qual é o contexto histórico dos alternadores C1 no sector automóvel?

O alternador C1 evoluiu significativamente desde a sua criação, principalmente em resposta aos avanços da tecnologia automóvel e às exigências dos consumidores. Originalmente, os veículos estavam equipados com geradores, que eram menos eficientes do que os alternadores modernos. A transição para os alternadores começou em meados do século XX, uma vez que estes ofereciam um melhor desempenho, fiabilidade e eficiência.

À medida que a indústria automóvel avançava, o mesmo acontecia com o design e a funcionalidade dos alternadores. A introdução de designs compactos e leves permitiu uma melhor eficiência de combustível e desempenho nos veículos. Atualmente, o alternador C1 é um componente crítico tanto nos veículos convencionais como nos eléctricos, reflectindo uma mistura de engenharia tradicional e tecnologia moderna.

Compreender esta evolução é crucial para os compradores B2B, uma vez que realça a importância da inovação e da adaptação nas estratégias de aprovisionamento. Os compradores devem ter em conta não só as especificações actuais dos alternadores C1, mas também o seu desempenho e fiabilidade históricos ao tomarem decisões de aquisição num mercado em rápida evolução.

Perguntas mais frequentes (FAQs) para compradores B2B de alternador c1

-

Como é que resolvo os problemas de compatibilidade ao adquirir um alternador C1?

Para resolver problemas de compatibilidade ao adquirir um alternador C1, faça sempre uma referência cruzada dos números de peça OEM com as especificações do veículo. Por exemplo, se estiver a lidar com um Citroën C1, certifique-se de que verifica números como 27060-0Q130 ou 28-5623. A contratação de fornecedores que forneçam tabelas de compatibilidade detalhadas e que possam efetuar a verificação com base no VIN do seu veículo pode ajudar a minimizar os riscos. Além disso, considere a possibilidade de comprar a revendedores de renome que tenham uma política de devolução, permitindo-lhe trocar os produtos se estes não se ajustarem como esperado. -

Qual é a melhor forma de avaliar a qualidade de um alternador C1?

Ao avaliar a qualidade de um alternador C1, procure produtos que tenham sido testados e certificados. Os fornecedores fiáveis oferecem frequentemente alternadores com uma garantia e especificações detalhadas sobre o seu estado (por exemplo, novo, renovado ou usado). Verifique as opiniões e classificações dos clientes para avaliar o desempenho e a fiabilidade do alternador. Além disso, informe-se se o alternador cumpre ou excede as normas OEM, uma vez que isto pode ser um forte indicador de qualidade. -

Que condições de pagamento devo esperar ao abastecer-me de alternadores C1 a nível internacional?

As condições de pagamento para compras internacionais de alternadores C1 podem variar muito consoante o fornecedor. As práticas comuns incluem pagamentos adiantados, pagamentos parciais (por exemplo, depósito 30%) ou pagamento aquando da entrega. É aconselhável negociar termos que se adaptem ao seu fluxo de caixa, tais como períodos de pagamento alargados ou planos de pagamento. Certifique-se sempre de que os métodos de pagamento são seguros e considere a utilização de serviços de caução para proteger o seu investimento até receber os bens. -

Quais são as quantidades mínimas de encomenda (MOQ) para os alternadores C1?

As quantidades mínimas de encomenda para alternadores C1 podem variar significativamente consoante os fornecedores. Alguns podem oferecer vendas de uma única unidade, enquanto outros podem exigir um MOQ de 10 ou mais. Ao adquirir, confirme sempre o MOQ e explore se o fornecedor é flexível, especialmente se for um novo comprador. A compra a granel pode muitas vezes levar a descontos, por isso, considere as suas necessidades de inventário e a potencial procura futura ao negociar. -

Como é que posso verificar os fornecedores de alternadores C1?

Verificar os fornecedores é crucial para garantir que recebe produtos de qualidade. Comece por verificar as suas credenciais comerciais, incluindo o registo e as licenças comerciais. Procure testemunhos de clientes e críticas de outros compradores B2B e peça referências. Também é vantajoso efetuar uma visita à fábrica, se possível, ou utilizar serviços de inspeção de terceiros para avaliar as suas capacidades de fabrico. A participação em fóruns ou redes do sector pode fornecer informações sobre fornecedores de renome. -

Que considerações logísticas devo ter em conta ao importar alternadores C1?

Ao importar alternadores C1, tenha em conta os custos de transporte, os prazos de entrega e os direitos aduaneiros. Escolha um transitário fiável que possa tratar da logística e garantir o cumprimento dos regulamentos de envio internacionais. Certifique-se de que tem em conta potenciais atrasos na alfândega, especialmente em regiões com regulamentos de importação rigorosos. Além disso, esclareça junto do seu fornecedor se este oferece opções de envio, incluindo entrega expresso ou normal, para cumprir os seus prazos operacionais. -

Posso personalizar os alternadores C1 para os adaptar a aplicações específicas?

Muitos fornecedores oferecem opções de personalização para alternadores C1, permitindo-lhe adaptar especificações como a saída de tensão, configurações de montagem ou tipos de conectores. Se necessitar de modificações específicas, comunique claramente as suas necessidades ao fornecedor, incluindo quaisquer desenhos ou requisitos técnicos. Não se esqueça de que as encomendas personalizadas podem implicar prazos de entrega mais longos e custos mais elevados, pelo que deve ter em conta estes factores no seu planeamento. -

Que processos de garantia de qualidade devem ser aplicados aos alternadores C1?

Os processos de garantia de qualidade para alternadores C1 devem incluir testes rigorosos de desempenho elétrico, integridade mecânica e funcionalidade geral antes da expedição. Procure fornecedores que implementem controlos de qualidade padrão, como a certificação ISO ou a conformidade com as normas automóveis internacionais. Além disso, informe-se sobre a sua política de devolução e ofertas de garantia, uma vez que estas reflectem a sua confiança na fiabilidade e desempenho do produto.

Lista dos 5 principais fabricantes e fornecedores de alternadores C1

1. Corvette - Soluções para o alternador C1

Domínio: corvetteforum.com

Registado: 1999 (26 anos)

Introdução: Alternador C1 com acionamento por tacha; opções para substituir o gerador original; custo potencial inferior a $100 para alternadores industriais; considerações sobre a configuração da montagem; as alternativas incluem a reconstrução do gerador original ou a utilização de alternadores de um só fio; sugestões de alternadores com acionamento por tacha em classicgenerator.com e gener-nator.com.

2. Facebook - Unidade Remanufacturada

Domínio: facebook.com

Registado: 1997 (28 anos)

Introdução: Esta empresa, Facebook - Remanufactured Unit, é uma entidade notável no mercado. Para obter detalhes específicos do produto, recomenda-se que visite diretamente o seu sítio Web.

3. Citroën - Problemas com o alternador

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: Alternador para Citroën C1; problema com a porca superior que não bloqueia no lugar durante a instalação; o alternador antigo tinha um ajuste confortável e estava corretamente bloqueado; as tentativas de calçar o novo alternador falharam.

4. Citroën - Alternador

Domínio: autoparts-24.com

Registado: 2021 (4 anos)

Introdução: {“Nome do produto”: ”Alternador”, ”Veículo compatível”: ”Citroën C1 (PM_, PN_)”, ”Número original”: ”27060 0Q020 / 80 AMP”, ”Número do artigo”: ”A_0006_N11392″, ”Marca”: ”Citroën”, ”Ano”: ”2007″, ”Quilometragem”: ”209000 km”, ”Código do motor”: ”CFA (384F/1KR-FE)”, ”Tipo de motor”: ”1.0EK”, ”Sistema de combustível”: ”Benzina”, ”Tipo de transmissão”: ”Manual de 5 velocidades”, ”Potência”: ”68 CV (50 kW)”, ”Estado”: ”B1 - Peça usada testada”, ”Preço”: ”217,61...

5. PEUGEOT - ALTERNADOR 107 / CITROEN C1

Domínio: africaboyzonline.com

Registada: 2018 (7 anos)

Introdução: {“product_name”: “ALTERNADOR PEUGEOT 107 / CITROEN C1”, “preço”: “R 2.480,00”, “part_number”: “KTR391820160”, “compatibility”: “Para uma precisão total, utilize o formulário Contacte-nos e inclua o seu número VIN/Chassis de 17 dígitos.”, “entrega”: “As encomendas são processadas no prazo de 1-2 dias úteis. Serviço de correio rápido porta-a-porta em todo o país.”, “returns_support”: “Clique aqui para ver as nossas políticas de envio e devolução.”}

Conclusão sobre o aprovisionamento estratégico e perspectivas para o alternador c1

Ao navegar pelas complexidades do fornecimento de alternadores C1, os compradores B2B internacionais devem concentrar-se em parcerias estratégicas e fornecedores fiáveis. As principais conclusões da nossa exploração destacam a importância do fornecimento de peças de qualidade que garantam a compatibilidade e o desempenho, especialmente para veículos como o Citroën C1 e o Peugeot 107. A colaboração com fornecedores estabelecidos que fornecem componentes OEM verificados pode reduzir significativamente os riscos operacionais e, ao mesmo tempo, aumentar a fiabilidade do veículo.

Além disso, compreender as variações regionais em termos de preços e disponibilidade é crucial para os compradores em África, na América do Sul, no Médio Oriente e na Europa. Por exemplo, aproveitar os fornecedores locais pode levar a eficiências de custos e a tempos de resposta mais rápidos, que são vitais para manter a vantagem competitiva nos mercados automóveis.

Ao olharmos para o futuro, é provável que a procura de práticas sustentáveis no aprovisionamento aumente. Os compradores são encorajados a considerar alternadores recondicionados ou remanufacturados, que não só oferecem poupanças de custos como também contribuem para a sustentabilidade ambiental. A adoção destas práticas estratégicas de aprovisionamento posicionará as empresas de forma favorável num panorama de mercado em evolução.

Convidamo-lo a estabelecer contacto com fornecedores fiáveis e a explorar estratégias de aprovisionamento inovadoras que se alinham com os seus objectivos comerciais para garantir o crescimento sustentado e o sucesso do seu aprovisionamento de peças para automóveis.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.