Introduction: Navigating the Global Market for alternator & starter

In the rapidly evolving automotive industry, sourcing high-quality alternators and starters is a critical challenge for international B2B buyers. As vehicles become increasingly sophisticated, understanding the nuances between these essential components is vital for ensuring optimal performance and reliability. This comprehensive guide delves into the various types of alternators and starters, their specific applications across different vehicle categories, and the latest technological advancements shaping the market.

Moreover, it provides practical insights on supplier vetting processes, cost structures, and maintenance considerations, empowering businesses from Africa, South America, the Middle East, and Europe—such as those in Vietnam and Saudi Arabia—to make informed purchasing decisions. By addressing common pain points, including quality assurance and compatibility with diverse vehicle models, this guide equips buyers with the knowledge necessary to navigate the global marketplace confidently.

With a focus on actionable strategies and best practices, it aims to streamline the procurement process, mitigate risks, and ultimately enhance operational efficiency. Whether you are a seasoned buyer or new to the industry, this resource serves as your authoritative companion in securing reliable alternators and starters that meet your specific needs.

Índice

- Top 3 Alternator & Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator & starter

- Understanding alternator & starter Types and Variations

- Key Industrial Applications of alternator & starter

- 3 Common User Pain Points for ‘alternator & starter’ & Their Solutions

- Strategic Material Selection Guide for alternator & starter

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator & starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator & starter’

- Comprehensive Cost and Pricing Analysis for alternator & starter Sourcing

- Alternatives Analysis: Comparing alternator & starter With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator & starter

- Navigating Market Dynamics and Sourcing Trends in the alternator & starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator & starter

- Strategic Sourcing Conclusion and Outlook for alternator & starter

- Aviso legal importante e termos de utilização

Understanding alternator & starter Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Alternador convencional | Uses electromagnetic induction; standard in most vehicles. | Automotive manufacturing, fleet management. | Prós: Confiável, amplamente disponível. Contras: Pode ser menos eficiente a baixas rotações. |

| Alternador de alta potência | Higher voltage and current output; designed for performance. | Racing, heavy-duty vehicles, custom builds. | Prós: Enhanced performance, supports additional electrical loads. Contras: Custo mais elevado, pode exigir modificações. |

| Permanent Magnet Alternator | Compact design with permanent magnets; lightweight. | Motorcycles, small engines, hybrid vehicles. | Prós: Efficient, low maintenance. Contras: Limited power output for larger vehicles. |

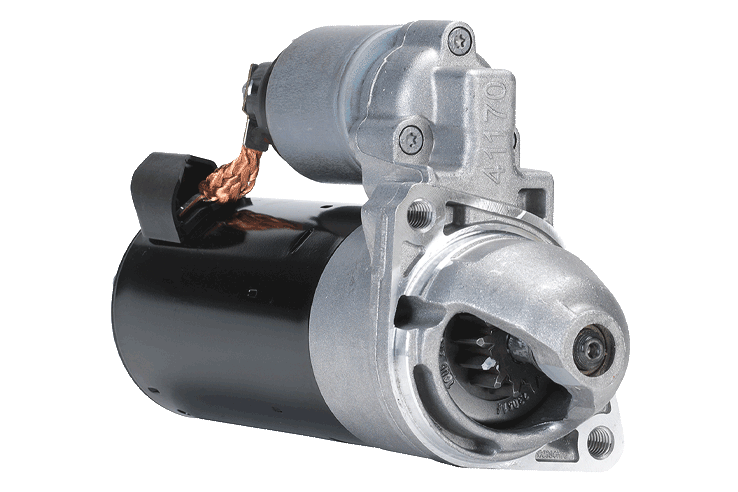

| Motor de arranque com redução de engrenagem | Smaller size with high torque output; uses gear reduction. | Sports cars, performance vehicles. | Prós: More efficient, lightweight. Contras: Can be more expensive, requires precise installation. |

| Bendix Drive Starter | Features a solenoid that engages the starter gear. | Standard in most passenger vehicles. | Prós: Reliable engagement, reduces wear. Contras: May have slower response time in extreme conditions. |

What Are the Characteristics and Suitability of Conventional Alternators?

Conventional alternators are the backbone of most automotive electrical systems, utilizing electromagnetic induction to generate electrical energy. They are suitable for a wide range of applications in the automotive sector, particularly in standard vehicles and fleet management. B2B buyers should consider their reliability and availability, making them a cost-effective choice for mass production. However, their efficiency can drop at lower RPMs, which may not meet the demands of performance-driven applications.

Why Choose High-Output Alternators for Specialized Applications?

High-output alternators are designed for applications requiring increased electrical power, such as racing and heavy-duty vehicles. Their ability to deliver higher voltage and current makes them ideal for systems with additional electrical loads, like sound systems or lighting. B2B buyers in specialized markets should weigh the benefits of enhanced performance against the higher costs and potential need for modifications in vehicle design.

Quais são as vantagens dos alternadores de ímanes permanentes?

Permanent magnet alternators are known for their compact design and lightweight construction, making them ideal for motorcycles, small engines, and hybrid vehicles. These alternators provide high efficiency and low maintenance, appealing to manufacturers looking to reduce overall vehicle weight. However, B2B buyers should note that their power output is limited compared to conventional options, making them less suitable for larger vehicles.

How Do Gear Reduction Starters Enhance Performance?

Gear reduction starters are engineered to deliver high torque in a smaller package, making them ideal for sports and performance vehicles. They improve efficiency and reduce weight, which can enhance overall vehicle performance. B2B buyers should consider the precise installation requirements and higher costs associated with these starters, as they may not be necessary for standard applications.

What Makes Bendix Drive Starters a Reliable Choice?

Bendix drive starters incorporate a solenoid that engages the starter gear, ensuring reliable engagement and reducing wear over time. They are commonly found in most passenger vehicles, making them a familiar choice for automotive manufacturers. B2B buyers should keep in mind that while these starters are generally reliable, they may exhibit slower response times under extreme conditions, which could be a consideration for specific applications.

Key Industrial Applications of alternator & starter

| Indústria/Setor | Specific Application of alternator & starter | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Automotivo | Vehicle assembly and maintenance | Assegura um desempenho fiável do veículo e a satisfação do cliente | Quality assurance, compatibility with various vehicle models, warranty terms |

| Agricultura | Agricultural machinery operation | Aumenta a eficiência operacional e reduz o tempo de inatividade | Durability for harsh environments, availability of replacement parts, performance under load |

| Construção | Máquinas e equipamentos pesados | Maximizes productivity and minimizes operational costs | Robust design, supplier reliability, support for international shipping |

| Transporte e Logística | Fleet vehicle management | Increases fleet reliability and reduces maintenance costs | Bulk purchasing options, compliance with local regulations, after-sales support |

| Energia renovável | Wind turbine and solar power systems | Supports sustainable energy solutions and reduces carbon footprint | Technical specifications for integration, supplier certifications, long-term performance guarantees |

How Are Alternators and Starters Used in the Automotive Industry?

In the automotive sector, alternators and starters are essential components for vehicle assembly and maintenance. The alternator charges the battery and powers electrical systems while the engine runs, ensuring that vehicles operate efficiently. Starters initiate the engine’s operation, crucial for both new vehicles and those in service. For international buyers, sourcing high-quality components that meet various vehicle specifications is vital to ensure reliability and customer satisfaction, particularly in regions where vehicle performance is paramount.

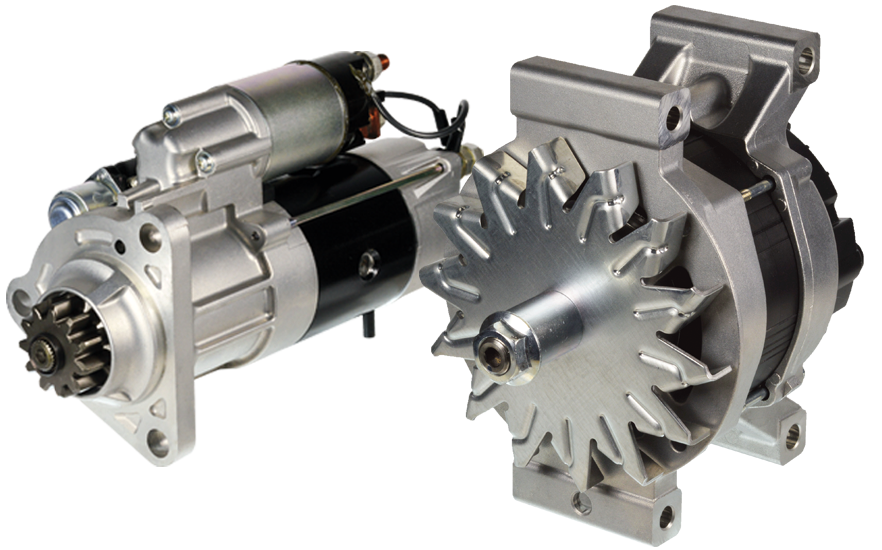

Illustrative image related to alternator & starter

What Role Do Alternators and Starters Play in Agriculture?

In agriculture, alternators and starters are integral to the operation of machinery such as tractors and harvesters. The alternator provides the necessary electrical power to run various systems, while the starter is crucial for engine ignition. This combination enhances operational efficiency, allowing farmers to maximize productivity during critical planting and harvest seasons. Buyers in this sector should prioritize sourcing durable components capable of withstanding harsh working conditions and ensure the availability of replacement parts to minimize equipment downtime.

How Are Alternators and Starters Utilized in Construction?

Heavy machinery and equipment in construction depend on reliable alternators and starters for optimal performance. The alternator ensures that equipment functions smoothly throughout the workday by maintaining battery charge, while the starter is vital for engine ignition. This reliability translates to increased productivity and reduced operational costs. For construction businesses, sourcing from reputable suppliers that offer robust designs and reliable delivery options is crucial, especially when operating in remote locations.

How Do Alternators and Starters Impact Transportation and Logistics?

In the transportation and logistics industry, alternators and starters are critical for fleet vehicle management. They ensure that vehicles start reliably and operate efficiently, which is essential for meeting delivery schedules and reducing maintenance costs. For international buyers, considerations include bulk purchasing options and compliance with local regulations to ensure that sourced components meet specific operational standards. After-sales support is also vital for managing any issues that may arise post-purchase.

What Is the Importance of Alternators and Starters in Renewable Energy Systems?

In renewable energy applications, such as wind turbines and solar power systems, alternators and starters play a key role in converting mechanical energy into electrical energy. The alternator is responsible for generating power, while the starter is crucial for initiating the system. This functionality supports sustainable energy solutions and helps reduce the carbon footprint. Buyers should focus on sourcing components that meet technical specifications for integration, as well as those that come with supplier certifications and long-term performance guarantees to ensure reliability in energy production.

3 Common User Pain Points for ‘alternator & starter’ & Their Solutions

Scenario 1: Difficulty Diagnosing Alternator vs. Starter Issues

O problema:

B2B buyers, particularly those in automotive repair or fleet management, often encounter challenges in accurately diagnosing issues related to alternators and starters. Misdiagnosis can lead to unnecessary repairs or replacements, resulting in increased operational costs and downtime. For instance, a fleet manager may receive complaints about vehicle failures, only to discover that the underlying issue lies in the alternator or starter but has been misidentified as a battery problem. This confusion is exacerbated by the overlapping symptoms between these components, creating frustration and inefficiency.

A solução:

To address this issue, buyers should invest in comprehensive diagnostic tools that can accurately assess the performance of both the alternator and starter. Utilizing a multimeter can help measure voltage output; a functioning alternator should produce between 13.7 and 14.7 volts when the engine is running. Additionally, educating technicians on the distinct symptoms associated with each component can streamline the diagnostic process. Providing training sessions or workshops can enhance staff skills, enabling them to identify signs such as dimming lights for alternator failure or clicking noises for starter issues. By implementing these measures, businesses can reduce misdiagnosis, lower repair costs, and improve overall vehicle reliability.

Scenario 2: High Costs of Replacement Parts

O problema:

For international B2B buyers, sourcing high-quality alternators and starters at reasonable prices can be a significant challenge, particularly in regions with limited access to reliable suppliers. The high costs associated with OEM parts can strain budgets, especially for small to medium-sized enterprises that rely heavily on their vehicle fleets for operations. Buyers may feel pressured to opt for cheaper, lower-quality alternatives, which can lead to increased failures and maintenance issues down the line.

A solução:

To mitigate these costs, buyers should explore partnerships with reputable remanufacturers or wholesalers who specialize in alternators and starters. Establishing long-term relationships with suppliers can lead to volume discounts and better pricing strategies. Furthermore, conducting thorough market research to identify local suppliers who provide high-quality remanufactured parts can ensure that businesses do not compromise on quality while saving costs. Buyers should also negotiate warranties and return policies to safeguard their investments, ensuring that they receive value for their purchases.

Scenario 3: Integration with Advanced Vehicle Technologies

O problema:

As vehicles become more technologically advanced, the integration of alternators and starters with various electronic systems complicates replacement and repair processes. B2B buyers may face difficulties sourcing compatible components for modern vehicles that rely on sophisticated electrical systems, particularly in regions where such technologies are rapidly evolving. This challenge can lead to extended downtimes and operational inefficiencies as buyers struggle to find the right parts that meet the specifications of advanced vehicles.

A solução:

To overcome these integration challenges, buyers should focus on building strong relationships with manufacturers that are at the forefront of automotive technology. Staying informed about the latest advancements in vehicle electrical systems can help buyers anticipate future needs and adapt their sourcing strategies accordingly. Additionally, investing in training for technicians on the latest technologies and repair techniques can enhance their ability to work with advanced systems. Collaborating with manufacturers to develop tailored solutions for specific vehicle models can also streamline the replacement process, ensuring that businesses remain competitive and efficient in their operations.

Strategic Material Selection Guide for alternator & starter

What Are the Key Materials Used in Alternators and Starters?

When selecting materials for alternators and starters, it is essential to consider their performance characteristics, costs, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of these components: aluminum, copper, steel, and plastic composites.

How Does Aluminum Perform in Alternators and Starters?

Aluminum is widely used in the construction of alternator housings and some starter components. Its key properties include a high strength-to-weight ratio and excellent corrosion resistance, making it suitable for automotive applications where weight reduction is vital.

Prós: Aluminum is lightweight, which helps improve fuel efficiency in vehicles. It also has good thermal conductivity, aiding in heat dissipation during operation.

Contras: While aluminum is durable, it can be more expensive than other metals and may require specialized manufacturing processes, such as die-casting, which can increase production costs.

Impacto na aplicação: Aluminum is compatible with various automotive fluids and can withstand the thermal stresses encountered in engine compartments.

Considerações para compradores internacionais: Compliance with international standards such as ASTM for material properties is crucial. Buyers in regions like Africa and South America should also consider local sourcing options to mitigate costs.

What Role Does Copper Play in Alternators and Starters?

Copper is primarily used in the wiring and windings of alternators and starters due to its excellent electrical conductivity.

Prós: Copper’s high conductivity allows for efficient power transfer, reducing energy losses. It also has good ductility, which facilitates complex wiring designs.

Contras: Copper is more expensive than aluminum and can be prone to corrosion if not adequately protected, which may lead to performance issues over time.

Impacto na aplicação: Copper is highly effective in applications requiring high current flow, such as starter motors. Its compatibility with automotive electrical systems is generally excellent.

Considerações para compradores internacionais: Buyers should be aware of the fluctuating copper prices and consider the implications for total cost. Compliance with electrical standards is also essential, particularly in Europe and the Middle East.

Illustrative image related to alternator & starter

Why Is Steel Important for Alternators and Starters?

Steel is commonly used for structural components in alternators and starters, including brackets and casings.

Prós: Steel offers high tensile strength and durability, making it suitable for components that endure mechanical stress. It is also relatively cost-effective compared to aluminum and copper.

Contras: Steel is heavier than aluminum, which could negatively impact vehicle fuel efficiency. Additionally, it may require protective coatings to prevent rust and corrosion.

Impacto na aplicação: Steel’s strength makes it ideal for high-stress applications, but its weight can be a disadvantage in lightweight vehicle designs.

Considerações para compradores internacionais: Buyers should ensure that the steel used meets relevant standards, such as ASTM or DIN, to guarantee quality and performance.

How Do Plastic Composites Enhance Alternator and Starter Design?

Plastic composites are increasingly used in non-structural components of alternators and starters, such as housings and insulators.

Prós: Plastic composites are lightweight and resistant to corrosion, which can enhance the longevity of components. They also allow for complex shapes that can reduce assembly time.

Contras: While they are cost-effective, plastic composites may not withstand high temperatures as well as metals, limiting their use in high-heat applications.

Impacto na aplicação: These materials are suitable for low-stress applications where weight savings are critical, but they may not be appropriate for components exposed to extreme conditions.

Considerações para compradores internacionais: It is essential to verify that plastic composites meet the necessary automotive standards for heat resistance and durability, particularly in regions with extreme climates.

Summary Table of Material Selection for Alternators and Starters

| Material | Typical Use Case for alternator & starter | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Caixas, suportes | Leve, boa resistência à corrosão | Higher cost, complex manufacturing | Alto |

| Cobre | Cablagem e enrolamentos | Excelente condutividade elétrica | Expensive, prone to corrosion | Alto |

| Aço | Componentes estruturais | Alta resistência, rentável | Heavier, requires protective coatings | Médio |

| Compósitos plásticos | Componentes não estruturais | Leve, resistente à corrosão | Desempenho limitado em altas temperaturas | Baixo |

This analysis provides B2B buyers with actionable insights into material selection for alternators and starters, ensuring they can make informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator & starter

What Are the Main Stages of Manufacturing Alternators and Starters?

The manufacturing of alternators and starters involves several critical stages that ensure high-quality output. Understanding these processes helps B2B buyers make informed decisions when sourcing components.

1. Material Preparation: What Materials Are Used?

The first step in the manufacturing process is material preparation. High-quality materials are essential for durability and performance. Common materials used include:

Illustrative image related to alternator & starter

- Cobre: For windings due to its excellent conductivity.

- Alumínio: Often used for housing due to its lightweight and cost-effectiveness.

- Aço: Utilized for structural components, providing strength and resilience.

- Plásticos: Employed for insulation and non-structural parts, contributing to weight reduction.

Suppliers should be able to provide documentation on the origin and quality of these materials, which is crucial for international buyers who need to ensure compliance with local regulations.

2. Conformação: Como é que os componentes são moldados?

Once the materials are ready, the forming process begins. This stage includes several techniques such as:

- Estampagem: Used for creating metal parts, including housings and brackets.

- Fundição: Employed for complex shapes, particularly in alternator housings.

- Usinagem: Precision tools are used to achieve exact dimensions and surface finishes.

These methods are critical as they directly impact the performance and lifespan of the alternator and starter. B2B buyers should inquire about the machinery and technology used in the forming process to ensure modern, efficient production.

3. Assembly: What Does the Assembly Process Involve?

After forming, the components are assembled into final products. This includes:

- Enrolamento: Copper wire is wound around the rotor and stator to create magnetic fields.

- Integração de componentes: Motors, solenoids, and other parts are integrated based on design specifications.

- Controlos de qualidade: Initial quality checks are performed at this stage to catch any issues early.

The assembly process is often automated but may involve manual labor for complex tasks. Understanding the assembly techniques can help buyers assess the supplier’s capabilities.

Illustrative image related to alternator & starter

4. Finishing: How Are Products Prepared for Delivery?

The finishing stage involves several processes that enhance the product’s durability and appearance:

- Revestimento: Protective coatings are applied to prevent corrosion and wear.

- Polimento: Surfaces are polished to improve aesthetics and reduce friction in moving parts.

- Labeling: Final products are labeled according to industry standards.

These finishing touches not only improve the product’s longevity but also ensure compliance with international branding and packaging regulations.

What Are the Key Quality Assurance Standards for Alternators and Starters?

Quality assurance (QA) is critical in the manufacturing of alternators and starters, ensuring that products meet both regulatory and customer expectations.

Illustrative image related to alternator & starter

Que normas internacionais devem ser conhecidas pelos compradores B2B?

International standards such as ISO 9001 are fundamental in the manufacturing process. ISO 9001 focuses on quality management systems and is applicable across various industries, including automotive components. Suppliers should demonstrate compliance with these standards, which indicates a commitment to quality.

Additionally, industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) are vital for buyers in regions like Europe and the Middle East. These certifications ensure that products meet necessary safety and performance criteria.

What Are the Common QC Checkpoints During Manufacturing?

Quality control (QC) checkpoints are essential in maintaining high standards throughout the manufacturing process. Key checkpoints include:

-

Controlo de Qualidade de Entrada (IQC): This initial stage checks the quality of raw materials and components before they enter production. This is crucial for ensuring that defective materials do not compromise the final product.

-

Controlo de qualidade em processo (IPQC): Conducted during the manufacturing process, IPQC focuses on monitoring production activities to catch defects early. Techniques such as visual inspections and dimensional checks are common.

-

Controlo de Qualidade Final (FQC): This final checkpoint assesses the completed product against specifications and standards. Tests may include performance evaluations, safety tests, and durability assessments.

What Testing Methods Are Commonly Used for Alternators and Starters?

Testing is a crucial aspect of quality assurance, ensuring that each alternator and starter meets performance standards. Common testing methods include:

Illustrative image related to alternator & starter

-

Testes elétricos: Measures voltage, current, and resistance to ensure that the components function correctly under load.

-

Testes mecânicos: Involves stress tests to evaluate the durability of components and assemblies.

-

Ensaios ambientais: Simulates conditions such as temperature extremes and humidity to assess performance in diverse environments.

B2B buyers should request detailed reports on testing outcomes to verify the reliability of the products they intend to purchase.

Como os compradores B2B podem verificar as práticas de controlo de qualidade dos fornecedores?

Verifying a supplier’s quality control practices is essential for B2B buyers, particularly those in international markets. Here are several strategies to consider:

-

Auditorias a fornecedores: Conducting an on-site audit allows buyers to assess the supplier’s manufacturing processes and QA practices directly. This firsthand observation can provide valuable insights into the supplier’s operational integrity.

-

Relatórios de qualidade: Requesting quality assurance reports from suppliers can help buyers understand the testing and inspection outcomes. Regular reports indicate consistent quality control practices.

-

Third-party Inspections: Engaging a third-party inspection service can provide an unbiased assessment of the supplier’s quality standards. This is particularly useful for international buyers who may not have the resources for on-site inspections.

Quais são as nuances de controle de qualidade e certificação para compradores B2B internacionais?

International buyers must navigate various QC and certification nuances that differ by region:

-

Considerações culturais: Understanding local manufacturing practices and quality expectations is critical. For instance, buyers from Africa might prioritize durability in harsh climates, while European buyers may focus on environmental compliance.

-

Conformidade regulamentar: Ensure that the products meet the regulatory requirements of the target market. This may involve additional certifications or modifications to the products.

-

Communication: Clear communication with suppliers regarding quality expectations and standards is vital. Establishing strong relationships can facilitate smoother transactions and ensure alignment on quality objectives.

By understanding the manufacturing processes and quality assurance measures for alternators and starters, B2B buyers can make informed decisions that enhance their supply chain effectiveness and product reliability.

Illustrative image related to alternator & starter

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator & starter’

This guide aims to provide a comprehensive checklist for B2B buyers looking to procure alternators and starters. Understanding the intricacies involved in sourcing these critical components can help ensure reliable performance and longevity in your vehicles.

Passo 1: Defina as suas especificações técnicas

Before sourcing alternators and starters, it’s essential to clearly outline the technical specifications required for your vehicles. Consider factors such as voltage output, compatibility with various engine types, and performance ratings. This clarity will help you narrow down potential suppliers who can meet your specific needs.

Passo 2: Pesquisar fornecedores de renome

Conduct thorough research to identify suppliers with a solid reputation in the industry. Look for companies that specialize in automotive parts, particularly alternators and starters, and have a proven track record. Check online reviews, ratings, and testimonials to gauge their reliability and quality of service.

Passo 3: Avaliar as certificações e normas do fornecedor

Verify that potential suppliers meet international quality standards and certifications. Look for ISO certifications or other relevant industry-specific qualifications that demonstrate adherence to quality control processes. This step is vital to ensure that the components you procure will be durable and reliable.

Passo 4: Request Samples for Quality Assessment

Once you have shortlisted suppliers, request samples of the alternators and starters. Performing a hands-on assessment allows you to evaluate the build quality, materials used, and overall performance. Pay attention to any warranties or guarantees offered, as these can indicate the supplier’s confidence in their products.

Illustrative image related to alternator & starter

Passo 5: Analyze Cost Structures and Payment Terms

Evaluate the pricing models and payment terms presented by different suppliers. Consider not just the upfront costs of the alternators and starters but also additional expenses such as shipping, taxes, and import duties. Understanding the total cost will help you make informed decisions that align with your budget constraints.

Passo 6: Confirm Availability and Lead Times

Check the availability of the components and the lead times for delivery. This information is crucial for planning your inventory and ensuring that you can meet your operational demands without unnecessary delays. Suppliers should provide clear timelines to ensure timely procurement.

Passo 7: Estabeleça um plano de comunicação

Finally, establish a clear communication plan with your chosen supplier. Regular updates regarding order status, shipment tracking, and any potential issues should be part of this plan. Effective communication fosters a strong partnership and helps mitigate risks associated with procurement delays or quality concerns.

By following this checklist, B2B buyers can ensure a more streamlined and effective sourcing process for alternators and starters, ultimately leading to better operational efficiency and reliability in their vehicle fleets.

Illustrative image related to alternator & starter

Comprehensive Cost and Pricing Analysis for alternator & starter Sourcing

What Are the Key Cost Components for Alternator and Starter Sourcing?

When sourcing alternators and starters, understanding the cost structure is essential for B2B buyers. The primary components influencing cost include:

-

Materiais: The quality and type of materials used directly affect the price. High-grade metals, electronic components, and durable plastics can increase costs but enhance performance and longevity.

-

Trabalho: Labor costs vary significantly based on geographic location and labor laws. In regions with higher labor costs, such as Europe, the overall price may be inflated compared to manufacturers in Asia or South America.

-

Custos indiretos de produção: This encompasses utilities, equipment maintenance, and factory operations. Manufacturers with advanced automation may have lower overhead costs, translating into competitive pricing.

-

Ferramentas: Custom tooling for specific alternator or starter designs can be a significant upfront cost. Buyers should consider whether they require customized products or can work with standard models to minimize expenses.

-

Controlo de Qualidade (QC): Rigorous QC processes ensure product reliability, especially in automotive applications. Manufacturers that invest in quality assurance might charge more, but this can lead to reduced warranty claims and maintenance costs for buyers.

-

Logística: Shipping and handling costs vary based on distance, shipping methods, and packaging requirements. Buyers should evaluate the total cost of shipping when negotiating prices.

-

Margem: Finally, the supplier’s profit margin will influence the final price. Understanding the market dynamics and average margins can aid in negotiation.

How Do Price Influencers Impact Alternator and Starter Costs?

Several factors can significantly influence the pricing of alternators and starters:

-

Volume e quantidade mínima de encomenda (MOQ): Bulk purchases often lead to discounts. Establishing a long-term relationship with suppliers can also yield better pricing options.

-

Especificações e personalização: Custom designs or unique specifications often lead to higher prices due to increased production complexity. Standardized products typically offer better pricing.

-

Qualidade dos materiais e certificações: Components that meet specific industry standards or certifications (such as ISO or IATF) may be priced higher but provide assurance of quality and compliance.

-

Fatores relacionados ao fornecedor: The reputation and reliability of the supplier can affect pricing. Established suppliers with a history of delivering quality products may charge more but can reduce risks associated with sourcing.

-

Incoterms: Understanding shipping terms (like FOB, CIF) is crucial for calculating total landed costs. Different Incoterms can lead to variations in pricing due to shipping responsibilities.

What Are the Best Buyer Tips for Cost-Efficiency in Alternator and Starter Sourcing?

To maximize cost-efficiency when sourcing alternators and starters, consider the following tips:

-

Negociar eficazmente: Leverage volume and long-term commitment to negotiate better pricing. Be aware of market prices and use this knowledge during discussions.

-

Foco no custo total de propriedade (TCO): Evaluate not just the purchase price but also maintenance, warranty, and operational costs. A lower initial price may lead to higher long-term costs if the product is less reliable.

-

Be Mindful of Pricing Nuances for International Sourcing: Understand the economic conditions and market dynamics in your target region. For instance, sourcing from countries with lower labor costs can result in significant savings, but be cautious of potential quality trade-offs.

-

Evaluate Supplier Stability: Research potential suppliers to ensure they have a solid financial background and a good reputation in the market. This can mitigate risks related to supply chain disruptions.

Isenção de responsabilidade para preços indicativos

Prices for alternators and starters can vary widely based on several factors, including geographic location, supplier terms, and market conditions. The information provided here serves as a guideline and may not reflect real-time pricing. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing tailored to your specific needs.

Alternatives Analysis: Comparing alternator & starter With Other Solutions

Exploring Alternatives to Alternators and Starters

In the automotive industry, understanding the alternatives to traditional components like alternators and starters can empower B2B buyers to make informed decisions. While these components are essential for vehicle operation, several emerging technologies and methods can serve similar functions. This section explores viable alternatives, comparing them against conventional alternators and starters.

Tabela comparativa

| Aspecto comparativo | Alternator & Starter | Lithium-Ion Battery Systems | Gerador de arranque integrado (ISG) |

|---|---|---|---|

| Desempenho | High reliability for engine start and battery charging | Excellent energy density; longer life cycle | Combines starter and generator functionalities for efficient operation |

| Custo | $400 – $900 (parts + labor) | $300 – $800 (battery only) | $600 – $1,200 (including installation) |

| Facilidade de implementação | Standard installation; requires knowledge of vehicle electrical systems | Installation can be complex, especially for retrofitting | Moderate complexity; requires specific vehicle compatibility |

| Manutenção | Regular checks needed; replacement every 5-10 years | Minimal maintenance; eventual replacement required | Similar maintenance to alternators; integrated systems may require specialized service |

| Melhor caso de uso | Conventional internal combustion engines | Veículos eléctricos e híbridos | Modern vehicles with enhanced fuel efficiency requirements |

Discriminação detalhada das alternativas

Lithium-Ion Battery Systems

Lithium-ion batteries have gained traction in the automotive sector, especially for electric and hybrid vehicles. Their high energy density allows for longer driving ranges and reduced weight compared to traditional lead-acid batteries. However, the initial cost can be high, and retrofitting older vehicles can complicate installation. Maintenance is minimal but requires eventual replacement, making them a long-term investment. B2B buyers considering electric vehicle production or integration should evaluate lithium-ion systems for their potential to enhance vehicle performance.

Illustrative image related to alternator & starter

Gerador de arranque integrado (ISG)

The Integrated Starter Generator combines the functionalities of a starter and an alternator into a single unit. This technology captures energy typically wasted during braking and uses it to power the vehicle’s electrical systems or recharge the battery. The ISG system offers improved fuel efficiency and reduced emissions, making it an attractive option for modern vehicles. However, the cost can be higher than traditional systems, and it may not be compatible with all vehicle types. B2B buyers focused on sustainability and fuel efficiency should consider ISG as a viable alternative.

Conclusão: Como escolher a solução certa para as suas necessidades

When deciding between alternators and starters versus alternative solutions, B2B buyers should consider their specific requirements, including vehicle type, budget, and performance expectations. While traditional alternators and starters are reliable for most internal combustion engines, innovative technologies like lithium-ion batteries and integrated starter generators present compelling advantages for electric and hybrid vehicles. By assessing the performance, cost, and maintenance needs of each option, buyers can select the most suitable solution that aligns with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for alternator & starter

What Are the Key Technical Properties of Alternators and Starters?

Understanding the technical properties of alternators and starters is crucial for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, where quality and reliability are paramount. Here are several critical specifications that should be considered:

-

Grau do material

Alternators and starters are typically made from high-grade materials such as aluminum and copper. Aluminum is lightweight and corrosion-resistant, while copper is essential for its excellent conductivity. Selecting components with the appropriate material grade ensures durability and performance, particularly in harsh operating conditions. -

Tensão nominal

Most automotive alternators and starters operate on a standard voltage rating of 12V or 24V. The voltage rating is vital as it directly affects the performance of the electrical system. Buyers must ensure compatibility with their vehicle’s specifications to avoid electrical failures, which could lead to costly downtimes. -

Current Output (Amperage)

The current output of an alternator is measured in amperes (A) and indicates its ability to charge the battery and power the vehicle’s electrical systems. A higher amperage rating is essential for vehicles with additional electrical accessories. Understanding current output helps buyers choose components that meet their operational needs without overloading the system. -

Níveis de tolerância

Tolerance refers to the permissible limit of variation in a component’s dimensions. For starters and alternators, tight tolerances are crucial for ensuring proper fitment and function. Components with high tolerance levels reduce the risk of mechanical failure, which is particularly important in high-performance applications. -

Tipo de rolamento

Alternators and starters may use different types of bearings, such as ball bearings or sleeve bearings. The type of bearing affects the component’s efficiency, noise levels, and lifespan. Buyers should consider the bearing type based on the expected operational environment and frequency of use. -

Resistência térmica

Both starters and alternators generate heat during operation. Thermal resistance ratings indicate how well a component can withstand high temperatures without degrading. Choosing components with adequate thermal resistance is essential for preventing overheating and ensuring longevity, particularly in warmer climates.

What Are Common Trade Terms Related to Alternators and Starters?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

-

OEM (Fabricante de Equipamento Original)

OEM refers to parts made by the original manufacturer of the vehicle. Buying OEM parts often ensures compatibility and quality, making them a preferred choice for businesses aiming to maintain high standards. -

MOQ (Quantidade mínima de encomenda)

MOQ is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for buyers to manage inventory costs effectively and negotiate better pricing. -

RFQ (Pedido de Orçamento)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This is a crucial step in the procurement process, enabling buyers to compare offers and make informed purchasing decisions. -

Incoterms (Termos Comerciais Internacionais)

Incoterms define the responsibilities of buyers and sellers in international shipping. They clarify who is responsible for costs, risks, and logistics, helping to avoid disputes and ensuring smooth transactions. -

Mercado pós-venda

This term refers to parts and accessories not made by the original manufacturer but designed to fit a vehicle. Aftermarket components can be more affordable and offer different performance characteristics, making them an attractive option for cost-conscious buyers. -

Período de garantia

The warranty period is the timeframe during which a manufacturer guarantees the performance of a part. Understanding warranty terms can protect buyers from financial losses due to defective products and provides peace of mind.

By grasping these essential technical properties and industry terms, B2B buyers can make informed decisions when sourcing alternators and starters, ensuring they select high-quality components that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the alternator & starter Sector

What Are the Current Market Dynamics Affecting the Alternator & Starter Sector?

The alternator and starter market is influenced by several global drivers, including the increasing demand for electric vehicles (EVs) and advancements in automotive technology. As countries in Africa, South America, the Middle East, and Europe push for greener transportation solutions, manufacturers are pivoting towards more efficient and eco-friendly designs. The rise of hybrid and electric vehicles necessitates a shift in sourcing practices and the development of innovative components that can support these technologies. This evolution is also prompting suppliers to adopt more agile manufacturing techniques, allowing for quicker response times to changing consumer demands.

Emerging trends such as automation and digitalization are reshaping the way B2B buyers approach sourcing. Technologies like predictive maintenance and IoT are being integrated into the manufacturing processes, enabling better diagnostics and reducing downtime. International buyers are increasingly looking for suppliers who can offer not only high-quality products but also technological solutions that enhance operational efficiency. Additionally, the trend towards remanufactured parts is gaining traction as businesses seek cost-effective and sustainable options, particularly in emerging markets.

How Can Sustainability and Ethical Sourcing Be Integrated into the Alternator & Starter Supply Chain?

The environmental impact of manufacturing alternators and starters cannot be overlooked, given the resources involved and the waste generated. As global awareness of sustainability grows, B2B buyers are prioritizing suppliers who adhere to ethical sourcing practices. This includes transparency in their supply chains, responsible sourcing of raw materials, and commitment to reducing carbon footprints. By choosing suppliers that utilize ‘green’ certifications or materials, businesses can not only enhance their brand image but also contribute to a more sustainable future.

Ethical sourcing in this sector involves ensuring that materials are acquired responsibly, with minimal environmental impact and fair labor practices. Certifications such as ISO 14001 for environmental management systems and adherence to REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations are becoming increasingly important for buyers. Suppliers that demonstrate compliance with these standards are more likely to be favored by international buyers, especially in regions where environmental regulations are stringent.

What Is the Brief Evolution of Alternators and Starters in the Automotive Industry?

The evolution of alternators and starters has significantly impacted the automotive industry. Initially, vehicles relied on simple DC generators to charge batteries and start engines. However, with the advent of more complex electrical systems in modern vehicles, alternators have evolved to become more efficient, providing higher output and better energy management. The introduction of electronic control systems has also allowed for improved diagnostics, enabling quicker identification of issues related to these components.

Illustrative image related to alternator & starter

Starters have similarly advanced from basic mechanical systems to sophisticated electric motors that are capable of operating under various conditions. As vehicles become increasingly computerized, the integration of starters and alternators with vehicle management systems has enhanced their performance and reliability. This historical context is crucial for B2B buyers as it highlights the importance of investing in high-quality components that meet modern standards, ensuring the longevity and efficiency of their automotive systems.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator & starter

-

How do I diagnose whether the issue is with the alternator, starter, or battery?

To accurately diagnose the problem, start by observing the symptoms. If the engine fails to crank and you hear a clicking sound, the starter may be faulty. Conversely, if the engine cranks slowly or not at all but the dashboard lights are dim, the issue likely lies with the battery or alternator. A battery warning light on the dashboard typically indicates an alternator problem. Conducting simple tests, such as checking battery voltage or the brightness of headlights while revving the engine, can help pinpoint the issue. -

What is the best type of alternator or starter for heavy-duty applications?

For heavy-duty applications, consider investing in high-performance alternators and starters designed for increased durability and power. Look for brands that specialize in commercial or industrial-grade products, ensuring they meet the specific voltage and amperage requirements of your machinery. Additionally, remanufactured units can provide a cost-effective solution while still delivering reliability. Always check for warranties and customer reviews to ensure you are sourcing quality components that can withstand rigorous use. -

What should I look for when vetting suppliers for alternators and starters?

When vetting suppliers, prioritize their reputation in the industry, quality certifications, and customer feedback. Verify their experience with international trade, particularly in your region, to ensure they understand the logistics and compliance requirements. Request samples or product specifications to assess quality firsthand. Additionally, inquire about their supply chain practices, lead times, and return policies, as these factors significantly impact your purchasing decision and overall satisfaction. -

What are the typical minimum order quantities (MOQs) for alternators and starters?

MOQs can vary widely depending on the supplier and the type of alternator or starter you are sourcing. Generally, for bulk orders, MOQs may range from 50 to 200 units. However, some manufacturers might offer lower MOQs for customized or specialized products. Always clarify this with your supplier to negotiate terms that align with your purchasing capacity and needs. Smaller orders may incur higher per-unit costs, so consider your overall strategy when planning purchases. -

What payment terms should I expect when sourcing alternators and starters internationally?

Payment terms for international purchases can vary but typically include options such as advance payment, letters of credit, or payment upon delivery. Commonly, suppliers may require a partial upfront payment (30-50%) with the balance due upon shipment. Ensure you understand the terms and negotiate them based on your cash flow and risk management strategies. Also, consider using escrow services for added security, especially when dealing with new suppliers. -

How can I ensure quality assurance (QA) when sourcing alternators and starters?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Implement a robust QA process that includes pre-shipment inspections, either conducted by your team or a third-party service. Additionally, consider establishing a quality control agreement that outlines testing procedures and standards. Having a clear return policy in place will also safeguard your investment against defective products. -

What logistics considerations should I keep in mind when importing alternators and starters?

Logistics plays a crucial role in importing alternators and starters. Assess the shipping methods available, such as air or sea freight, and choose one based on cost, urgency, and the nature of your products. Understand the customs regulations in your country to avoid delays and additional costs. Collaborate with a reliable freight forwarder who can manage documentation, customs clearance, and transportation, ensuring your products arrive on time and in good condition. -

What are the common signs that indicate a need for replacement of alternators or starters?

Common signs that an alternator may need replacement include dimming headlights, a battery warning light on the dashboard, and unusual noises like grinding or whining. For starters, listen for clicking sounds when attempting to start the engine or observe if the engine fails to crank entirely. If the vehicle shows these symptoms, it’s crucial to diagnose the issue promptly to avoid further complications and ensure reliable vehicle operation. Regular maintenance checks can help identify these signs early.

Top 3 Alternator & Starter Manufacturers & Suppliers List

1. Discount Starter and Alternator – High Quality Aftermarket Starters & Alternators

Domínio: discountstarterandalternator.com

Registado: 2004 (21 anos)

Introdução: High Quality Aftermarket Starters & Alternators at the Lowest Price. Fast Shipping on all U.S. orders. Same-Day Shipping if ordered before 3 p.m. EST. 12 Month Warranty on all products with an option for extended warranty. Easy Returns within 30 days for a full refund. Categories include Agricultural, Industrial, Lawn & Garden, Marine, Powersports, Towing, Commercial, and Golf Cart. Customer servi…

2. Sartorial Auto Repairs – Alternators & Starters

Domínio: sartorialautorepairs.com

Registado: 2009 (16 anos)

Introdução: Sartorial Auto Repairs offers services related to alternators and starters, which are critical components of a car’s electrical system. The starter is responsible for starting the engine, while the alternator charges the battery and powers electrical components once the engine is running. The shop provides professional repair services for issues related to both components, ensuring reliable perfor…

3. Jiffy Lube – Automotive Battery Services

Domínio: jiffylube.com

Registrado: 1995 (30 anos)

Introdução: The battery stores electrical energy and powers the starter, ignition, and other components during startup. The starter motor converts the battery’s electrical energy into mechanical energy to crank the engine. The alternator charges the battery and supplies power to the vehicle’s electrical components while the engine is running, converting mechanical energy into electrical energy. Common signs o…

Strategic Sourcing Conclusion and Outlook for alternator & starter

As the automotive industry continues to evolve, the importance of strategic sourcing for alternators and starters cannot be overstated. These components are essential not only for vehicle performance but also for customer satisfaction and operational efficiency. By understanding the distinct roles of alternators and starters, international B2B buyers can make informed purchasing decisions that enhance their supply chains and reduce maintenance costs.

Investing in quality components from reliable suppliers is crucial. Look for brands that are recognized for their durability and performance, as these factors can significantly impact long-term operational success. Furthermore, consider the advantages of remanufactured parts as a cost-effective alternative that does not compromise on quality.

As the demand for reliable automotive solutions grows across Africa, South America, the Middle East, and Europe, now is the time for B2B buyers to solidify partnerships with trustworthy manufacturers and distributors. By prioritizing strategic sourcing, businesses can ensure they remain competitive and responsive to market needs.

Act now to strengthen your supply chain and position your business for future success in the automotive sector. Explore partnerships that offer innovation, reliability, and value—your business deserves it.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Illustrative image related to alternator & starter

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.