Introdução: Navegando no mercado global de custo médio para substituir um motor de arranque

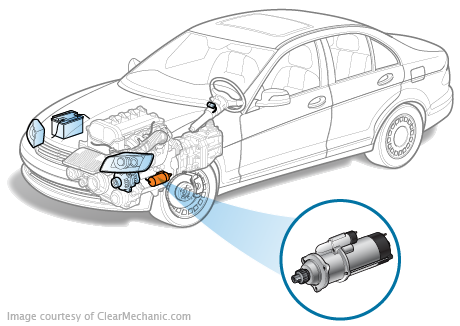

No panorama competitivo do fornecimento de peças automóveis, compreender o custo médio de substituição de um motor de arranque é crucial para os compradores B2B internacionais. O motor de arranque é um componente essencial no sistema elétrico de um veículo, e os problemas com ele podem levar a um tempo de inatividade operacional e a custos de reparação significativos. No entanto, o preço da substituição de um motor de arranque pode variar drasticamente com base na marca, no modelo e nas condições do mercado regional do veículo, o que torna essencial que os compradores naveguem eficazmente nesta complexidade.

Este guia abrangente irá aprofundar os vários factores que influenciam os custos de substituição do motor de arranque, incluindo a disponibilidade de peças, as despesas de mão de obra e as tendências regionais de preços nos principais mercados de África, América do Sul, Médio Oriente e Europa. Iremos explorar diferentes tipos de motores de arranque, desde modelos standard a modelos de alto desempenho, e as suas aplicações em várias categorias de veículos. Além disso, o guia fornecerá informações sobre a verificação de fornecedores para garantir a qualidade e a fiabilidade nas suas decisões de aprovisionamento.

Ao equipar os compradores B2B com informações acionáveis e uma compreensão clara da dinâmica do mercado, este guia permite-lhe tomar decisões de compra informadas. Quer esteja a gerir uma frota, a operar uma oficina de reparação ou a supervisionar o aprovisionamento de uma empresa automóvel, compreender as nuances dos custos de substituição de motores de arranque pode levar a investimentos mais estratégicos e a uma maior eficiência operacional.

Índice

- Lista dos 4 principais fabricantes e fornecedores do custo médio para substituir um motor de arranque

- Introdução: Navegando no mercado global de custo médio para substituir um motor de arranque

- Compreender o custo médio de substituição de um motor de arranque Tipos e variações

- Principais aplicações industriais do custo médio para substituir um motor de arranque

- 3 Pontos de dor comuns dos utilizadores para ‘custo médio para substituir um motor de arranque’ e respectivas soluções

- Guia de seleção de materiais estratégicos para o custo médio de substituição de um motor de arranque

- Análise aprofundada: Processos de fabrico e garantia de qualidade para o custo médio de substituição de um motor de arranque

- Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘custo médio para substituir um arranque’

- Análise abrangente de custos e preços para o custo médio para substituir um motor de arranque Sourcing

- Análise de alternativas: Comparação do custo médio para substituir um motor de arranque com outras soluções

- Propriedades técnicas essenciais e terminologia comercial para o custo médio de substituição de um motor de arranque

- Navegar na dinâmica do mercado e tendências de fornecimento no custo médio para substituir um sector de arranque

- Perguntas frequentes (FAQs) para compradores B2B sobre o custo médio de substituição de um motor de arranque

- Strategic Sourcing Conclusion and Outlook for average cost to replace a starter

- Aviso legal importante e termos de utilização

Compreender o custo médio de substituição de um motor de arranque Tipos e variações

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Substituição padrão | Substituição básica do motor de arranque utilizando peças OEM ou de substituição. | Oficinas de reparação automóvel em geral | Prós: Económico, amplamente disponível. Contras: Pode não ter garantia para peças de substituição. |

| Arrancador de alto desempenho | Arrancador atualizado com maior durabilidade e eficiência. | Lojas de automóveis de alto desempenho | Prós: Maior fiabilidade, melhor para aplicações de alta tensão. Contras: Custo inicial mais elevado. |

| Arrancador reconstruído | Arrancador recondicionado utilizando componentes existentes, muitas vezes com garantia. | Oficinas de reparação sensíveis aos custos | Prós: Custo inferior ao de um novo, muitas vezes com garantia. Contras: A qualidade pode variar; pode não durar o mesmo tempo que um novo. |

| Arrancador/Alternador integrado | Unidade combinada que funciona como motor de arranque e alternador. | Fabricantes de veículos modernos | Prós: Economia de espaço, eficiência. Contras: Instalação mais cara e complexa. |

| Kit de iniciação DIY | Kit completo com todas as peças necessárias e instruções de substituição. | Entusiastas da bricolage, pequenas oficinas de reparação | Prós: Poupança de custos, capacitação de pessoas qualificadas. Contras: Requer conhecimentos especializados, ferramentas e tempo. |

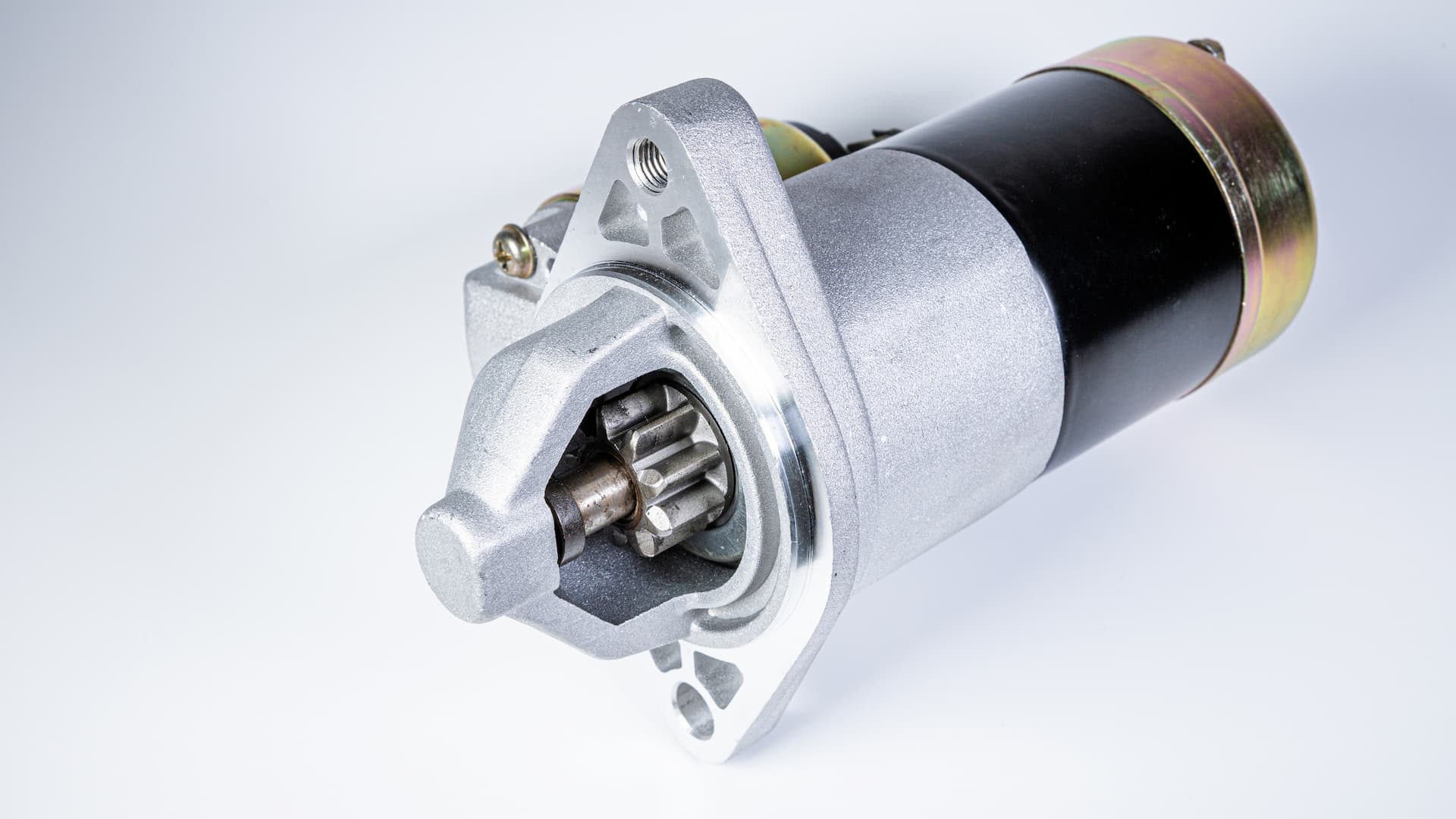

Quais são as caraterísticas de um motor de arranque de substituição padrão?

Um motor de arranque de substituição padrão utiliza normalmente peças OEM (Fabricante de Equipamento Original) ou peças de substituição para restaurar a funcionalidade do veículo. Esta opção é amplamente utilizada em oficinas de reparação automóvel devido à sua relação custo-eficácia e disponibilidade. Os compradores B2B devem ter em consideração a garantia e a qualidade das peças, uma vez que os componentes do mercado de substituição podem, por vezes, não ter a fiabilidade das peças OEM. Esta opção é adequada para reparações gerais em que as restrições orçamentais são uma prioridade.

Como é que os arrancadores de alto desempenho diferem em termos de funcionalidade?

Os motores de arranque de alto desempenho são concebidos para veículos que exigem mais do sistema de arranque, tais como aplicações de competição ou de serviço pesado. Estes motores de arranque apresentam frequentemente uma maior durabilidade e eficiência, o que os torna ideais para oficinas de automóveis de alto desempenho. Embora o investimento inicial seja mais elevado, os benefícios a longo prazo de uma maior fiabilidade podem justificar o custo para as empresas que se dedicam a modificações de desempenho. Os compradores devem avaliar a compatibilidade com modelos de veículos específicos.

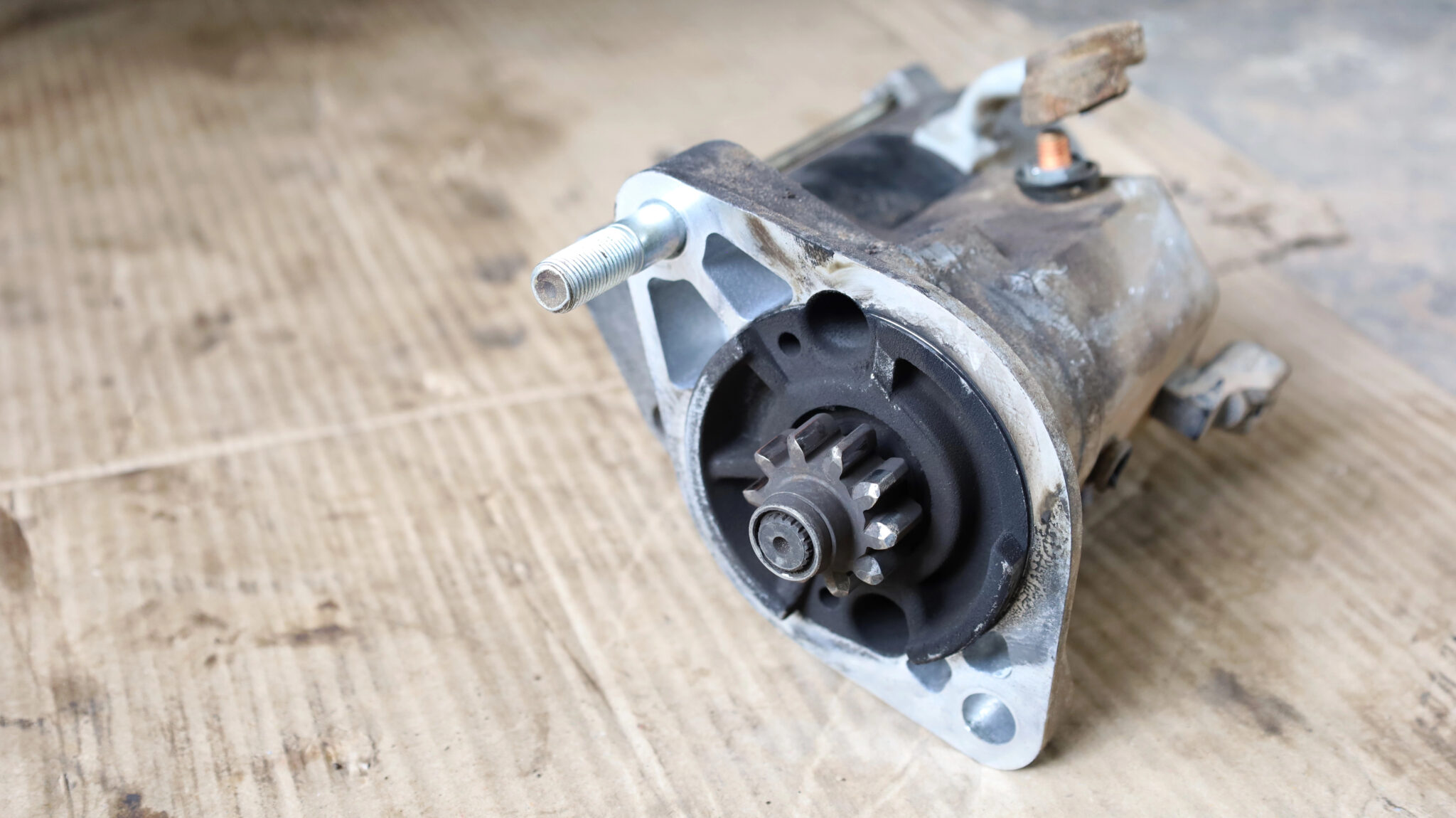

O que deve saber sobre arrancadores reconstruídos?

Os motores de arranque reconstruídos são uma alternativa económica às unidades novas, utilizando componentes renovados para fornecer um motor de arranque funcional a um preço mais baixo. Esta opção é particularmente atractiva para as oficinas de reparação sensíveis aos custos que procuram manter as margens de lucro enquanto prestam um serviço de qualidade. Os compradores devem ser cautelosos, uma vez que a qualidade das unidades reconstruídas pode variar significativamente. Estes produtos são frequentemente acompanhados de uma garantia, o que proporciona uma segurança adicional aos compradores B2B.

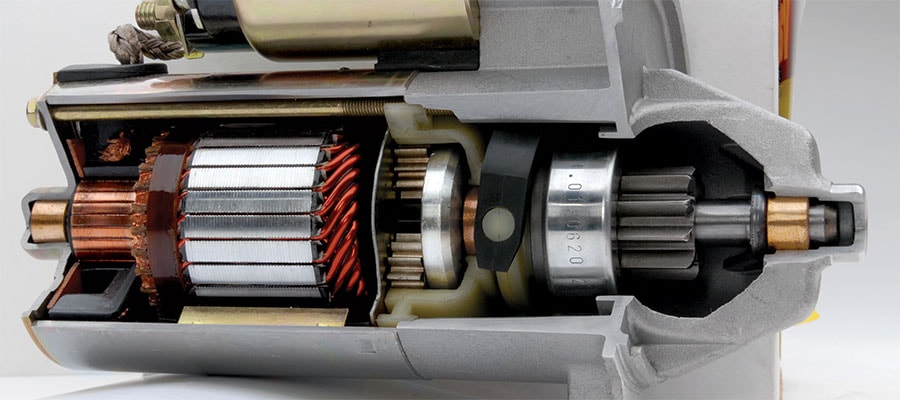

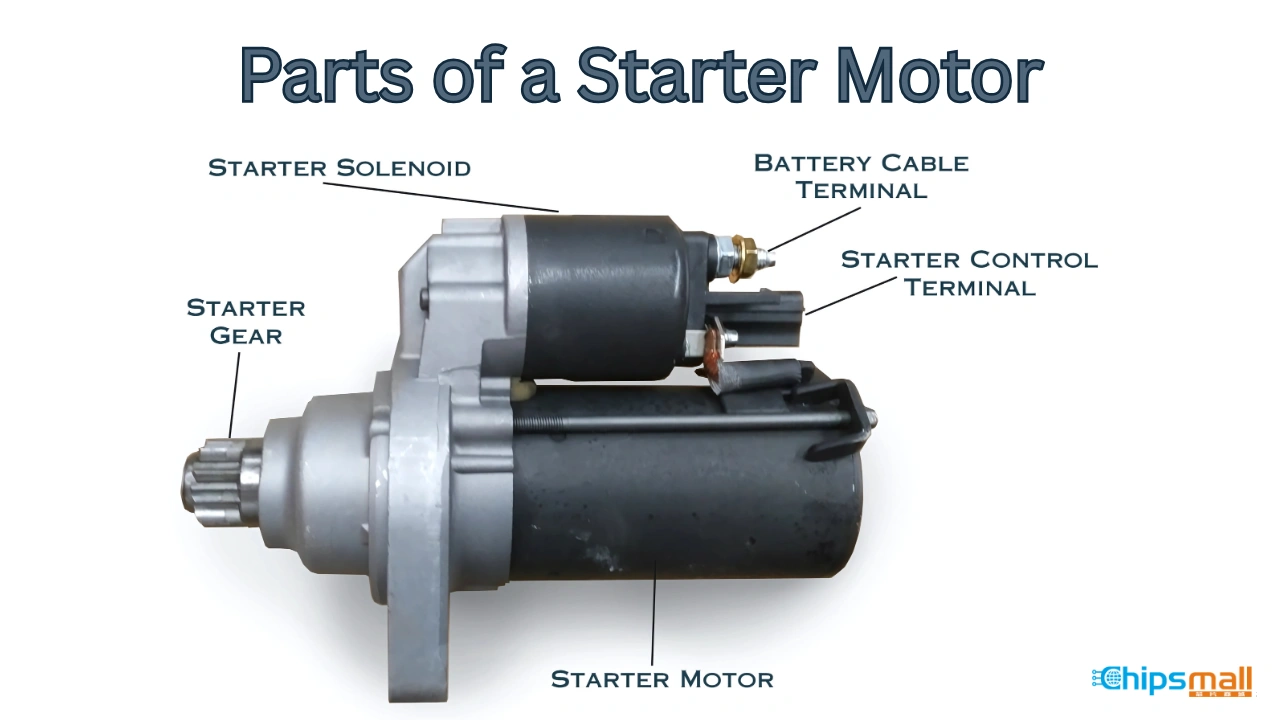

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

Quais são as vantagens das unidades integradas de arranque/alternador?

As unidades integradas de arranque/alternador combinam as funções de ambos os componentes numa única unidade, oferecendo benefícios de economia de espaço e maior eficiência. Esta tecnologia é cada vez mais utilizada nos veículos modernos, o que a torna relevante para os fabricantes e oficinas especializadas em sistemas automóveis contemporâneos. Embora estas unidades tendam a ser mais caras e complexas de instalar, a sua dupla funcionalidade pode levar a uma redução das necessidades de manutenção ao longo do tempo, apelando aos compradores B2B interessados em valor a longo prazo.

Porquê considerar um kit de iniciação DIY?

Os kits de arranque "faça você mesmo" fornecem todos os componentes e instruções necessários para que indivíduos ou pequenas oficinas de reparação possam substituir os arrancadores sem assistência profissional. Esta opção pode ser particularmente atractiva para os compradores B2B que dispõem de técnicos qualificados mas que pretendem poupar nos custos de mão de obra. No entanto, os potenciais compradores devem avaliar os conhecimentos da sua equipa e as ferramentas disponíveis, uma vez que uma instalação bem sucedida requer um certo nível de conhecimentos mecânicos e experiência.

Principais aplicações industriais do custo médio para substituir um motor de arranque

| Indústria/Setor | Aplicação específica do custo médio de substituição de um motor de arranque | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Manutenção de frotas de veículos comerciais | Reduz o tempo de inatividade e os custos de manutenção | Qualidade das peças, disponibilidade de mão de obra especializada, preços regionais |

| Transporte e Logística | Operações com camiões pesados | Assegura a fiabilidade e a segurança do transporte | Compatibilidade com vários modelos de camiões, opções de garantia |

| Agricultura | Manutenção de máquinas e equipamentos agrícolas | Maximiza a eficiência operacional e a produtividade | Disponibilidade de motores de arranque especializados para equipamento agrícola |

| Construção | Fiabilidade do equipamento de construção | Minimiza os atrasos nos projectos e aumenta a segurança | Aquisição de produtos a fornecedores locais para reduzir os prazos de entrega e os custos logísticos |

| Mineração | Máquinas pesadas para exploração mineira | Reduz as interrupções operacionais e os custos de manutenção | Durabilidade das peças em ambientes agressivos, capacidades de assistência local |

Como é que o custo médio de substituição de um motor de arranque é relevante na reparação automóvel e na manutenção da frota?

No sector da reparação automóvel, em particular na manutenção de frotas, compreender o custo médio de substituição de um motor de arranque é crucial para a gestão dos orçamentos operacionais. Os gestores de frotas lidam frequentemente com vários veículos, o que torna essencial minimizar o tempo de inatividade. Ao estimar com precisão os custos de substituição de motores de arranque, as empresas podem afetar recursos de forma eficaz, negociar melhor com os fornecedores e manter um fluxo de trabalho estável. Para os compradores internacionais, particularmente em regiões como a África e a América do Sul, o fornecimento de peças fiáveis que possam resistir às condições locais e que sejam rentáveis é uma prioridade.

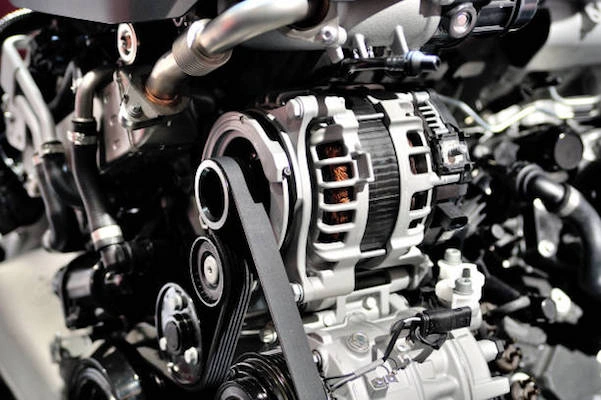

Porque é que o custo médio de substituição de um motor de arranque é importante para os transportes e a logística?

No sector dos transportes e da logística, o custo médio de substituição de um motor de arranque tem um impacto direto na fiabilidade dos camiões pesados. Um motor de arranque avariado pode levar a atrasos significativos, afectando os prazos de entrega e a satisfação do cliente. A compreensão dos custos de substituição permite às empresas de logística planear a manutenção e evitar despesas inesperadas. Para as empresas que operam na Europa e no Médio Oriente, considerações como a disponibilidade de peças compatíveis com vários modelos de camiões e os termos da garantia são essenciais para assegurar a eficiência operacional a longo prazo.

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

Que papel desempenha o custo médio de substituição de um arrancador na agricultura?

Para as empresas agrícolas, o custo médio de substituição de um motor de arranque em máquinas agrícolas é um fator crítico na manutenção da produtividade. As falhas de equipamento podem interromper as operações durante as épocas altas, levando a perdas financeiras. Ao conhecer os custos de substituição, os agricultores podem orçamentar a manutenção e tomar decisões informadas sobre reparações ou substituições. Em regiões como a América do Sul, onde as máquinas agrícolas podem enfrentar condições mais adversas, o fornecimento de motores de arranque duradouros que se adaptam a equipamentos específicos é vital para minimizar o tempo de inatividade e maximizar o rendimento.

Como é que o custo médio de substituição de um arrancador afecta os projectos de construção?

Na indústria da construção, o custo médio de substituição de um motor de arranque é essencial para garantir a fiabilidade do equipamento de construção. Os atrasos devidos a falhas no equipamento podem levar a derrapagens significativas no projeto. Ao compreender estes custos, os gestores de construção podem planear eficazmente os calendários de manutenção e gerir os orçamentos dos projectos. Para os compradores B2B no Médio Oriente e na Europa, o aprovisionamento de fornecedores locais pode reduzir os prazos de entrega e os custos logísticos, garantindo que o equipamento permanece operacional e que os projectos se mantêm no bom caminho.

Por que razão é fundamental compreender o custo médio de substituição de um arrancador no sector mineiro?

No sector mineiro, a maquinaria pesada é crucial para as operações, e o custo médio de substituição de um motor de arranque desempenha um papel significativo na manutenção da fiabilidade do equipamento. As falhas inesperadas podem levar a dispendiosas interrupções operacionais. Ao ter conhecimento dos custos de substituição, as empresas mineiras podem orçamentar as reparações necessárias e garantir que a maquinaria está sempre pronta a ser utilizada. Os compradores em regiões com condições extremas, como África, devem considerar a durabilidade dos motores de arranque e a disponibilidade de capacidades de serviço locais para garantir que o seu equipamento permanece funcional em ambientes desafiantes.

3 Pontos de dor comuns dos utilizadores para ‘custo médio para substituir um motor de arranque’ e respectivas soluções

Cenário 1: Navegar pela variabilidade dos custos de manutenção da frota

O problema:

Os compradores B2B que gerem frotas, particularmente em regiões como África e América do Sul, enfrentam frequentemente uma variabilidade significativa no custo das substituições de motores de arranque devido às diferenças nas marcas e modelos dos veículos. Muitas frotas são compostas por diversos veículos, o que torna difícil estimar com exatidão os custos de substituição. Esta imprevisibilidade pode levar a derrapagens orçamentais e a dificuldades na previsão financeira, especialmente quando uma grande parte da frota apresenta falhas nos motores de arranque em simultâneo.

A solução:

Para mitigar este problema, os gestores de frotas devem implementar um programa de manutenção de veículos padronizado que inclua um inventário abrangente de todos os veículos e as respectivas especificações dos motores de arranque. Ao tirar partido da telemática e das ferramentas de diagnóstico, podem monitorizar a saúde de cada motor de arranque e identificar potenciais falhas antes de estas ocorrerem. Além disso, o estabelecimento de relações com vários fornecedores pode garantir preços competitivos e disponibilidade de peças. É aconselhável desenvolver um guia de estimativa de custos com base em dados históricos de substituições anteriores, o que pode ajudar a definir orçamentos mais exactos e a reduzir as surpresas financeiras.

Cenário 2: Identificar a causa raiz dos problemas do arranque

O problema:

Em muitos casos, os compradores B2B podem erradamente atribuir os problemas de arranque diretamente a um motor de arranque defeituoso sem investigar outras causas potenciais. Este descuido pode levar a custos de substituição desnecessários e ao desperdício de recursos, especialmente em regiões onde a disponibilidade de mão de obra e peças pode atrasar as reparações. Por exemplo, se a bateria for a verdadeira culpada, a substituição do motor de arranque não resolveria o problema subjacente, resultando em falhas repetidas.

A solução:

A implementação de um protocolo de diagnóstico completo é essencial para identificar com exatidão a causa principal dos problemas de arranque. Os gestores de frotas devem formar as suas equipas de manutenção para realizarem uma inspeção sistemática do sistema de arranque do veículo, incluindo a bateria, os fusíveis e as ligações. A utilização de ferramentas de diagnóstico para avaliar os níveis de tensão e corrente também pode fornecer informações sobre se a falha é do motor de arranque ou de outro componente. Ao promover uma cultura de manutenção preventiva e educação, as empresas podem reduzir os custos de substituição desnecessários e aumentar a fiabilidade geral da frota.

Cenário 3: Equilíbrio entre qualidade e custo nas peças de substituição

O problema:

Os compradores B2B debatem-se frequentemente com o dilema de equilibrar o custo e a qualidade quando selecionam peças de substituição para motores de arranque. Optar por peças de substituição mais baratas pode poupar dinheiro à partida, mas pode levar a falhas mais frequentes e a custos mais elevados a longo prazo. Por outro lado, as peças originais do fabricante do equipamento (OEM), embora mais caras, podem proporcionar melhor durabilidade e desempenho, levando a menos substituições.

A solução:

Para enfrentar este desafio, as empresas devem efetuar uma análise de custo-benefício para avaliar os custos totais do ciclo de vida dos motores de arranque pós-venda e OEM. Esta análise deve incluir factores como os termos da garantia, o tempo de vida útil esperado e a frequência de manutenção. O envolvimento com fornecedores de confiança que podem fornecer informações sobre a fiabilidade de diferentes marcas e modelos também pode orientar decisões de compra informadas. Além disso, o estabelecimento de uma abordagem faseada para a aquisição de peças - em que os veículos críticos recebem peças OEM, enquanto outros podem utilizar opções de qualidade do mercado pós-venda - pode equilibrar eficazmente o custo e a fiabilidade em toda a frota. Ao adotar uma abordagem estratégica para o fornecimento de peças de substituição, as empresas podem otimizar os seus orçamentos de manutenção, assegurando simultaneamente que os seus veículos permanecem operacionais.

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

Guia de seleção de materiais estratégicos para o custo médio de substituição de um motor de arranque

Quais são os materiais mais comuns utilizados na substituição de arrancadores?

Quando se considera o custo médio de substituição de um motor de arranque, a escolha dos materiais desempenha um papel crucial no desempenho, na durabilidade e na relação custo-eficácia global. Aqui, analisamos quatro materiais comuns utilizados em motores de arranque, focando as suas propriedades, vantagens, desvantagens e considerações para os compradores B2B internacionais.

1. Cobre

Propriedades principais: O cobre é conhecido pela sua excelente condutividade eléctrica, elevada condutividade térmica e resistência à corrosão. Suporta temperaturas elevadas, o que o torna ideal para componentes que sofrem uma carga eléctrica significativa.

Prós e contras: A principal vantagem do cobre é a sua condutividade superior, que aumenta a eficiência do motor de arranque. No entanto, o cobre pode ser relativamente caro em comparação com outros materiais, e o seu peso pode ser uma desvantagem em aplicações onde a poupança de peso é crítica.

Impacto na aplicação: O cobre é particularmente adequado para ligações eléctricas no motor de arranque, garantindo um desempenho fiável em várias condições de funcionamento. A sua compatibilidade com os fluidos automóveis e a exposição a temperaturas elevadas fazem dele uma escolha preferencial.

Considerações para compradores internacionais: Os compradores em regiões como a Europa e o Médio Oriente podem ter de cumprir normas eléctricas específicas (por exemplo, normas IEC). Além disso, as flutuações nos preços do cobre podem ter impacto nos custos globais, pelo que os compradores devem ter em conta as tendências do mercado.

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

2. Aço

Propriedades principais: O aço é conhecido pela sua força, durabilidade e resistência ao desgaste. Suporta pressões elevadas e é frequentemente tratado para resistir à corrosão.

Prós e contras: A resistência do aço torna-o ideal para os componentes estruturais do motor de arranque, como a carcaça. No entanto, o seu peso pode ser uma desvantagem em aplicações onde a redução de peso é essencial. O aço pode também ser mais suscetível à ferrugem se não for devidamente revestido.

Impacto na aplicação: O aço é normalmente utilizado na construção de caixas de arranque e de outros componentes estruturais, proporcionando a rigidez e a proteção necessárias aos componentes internos. É compatível com vários ambientes automóveis, mas é necessário ter cuidado para garantir a resistência à corrosão.

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

Considerações para compradores internacionais: A conformidade com as normas locais (por exemplo, ASTM nos EUA ou DIN na Alemanha) é crucial aquando do aprovisionamento de componentes de aço. Os compradores devem também estar cientes da disponibilidade de opções de aço tratado para mitigar os riscos de corrosão em climas húmidos.

3. Alumínio

Propriedades principais: O alumínio é leve, tem boa resistência à corrosão e oferece uma condutividade térmica decente. Pode ser anodizado para proteção adicional contra a corrosão.

Prós e contras: A natureza leve do alumínio é uma vantagem significativa, especialmente em aplicações automóveis onde a redução do peso pode melhorar a eficiência do combustível. No entanto, o alumínio é menos durável do que o aço e o seu fabrico pode ser mais dispendioso.

Impacto na aplicação: O alumínio é frequentemente utilizado na caixa do motor de arranque e noutros componentes que não suportam carga. A sua resistência à corrosão torna-o adequado para ambientes onde a exposição à humidade é uma preocupação.

Considerações para compradores internacionais: Os compradores devem considerar os tipos específicos de alumínio que cumprem as normas e regulamentos locais. Em regiões com elevada humidade, como partes de África e da América do Sul, a resistência à corrosão do alumínio pode ser particularmente benéfica.

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

4. Compósitos plásticos

Propriedades principais: Os compósitos plásticos são leves, resistentes à corrosão e podem ser moldados em formas complexas. Têm frequentemente boas propriedades de isolamento elétrico.

Prós e contras: A principal vantagem dos compósitos plásticos é a sua versatilidade de conceção e o seu peso reduzido. No entanto, podem não resistir a temperaturas elevadas tão bem como os metais e podem ser menos duráveis sob tensão mecânica.

Impacto na aplicação: Os compósitos plásticos são frequentemente utilizados para componentes não estruturais, tais como coberturas e peças de isolamento, em motores de arranque. Proporcionam uma proteção eficaz contra os factores ambientais, reduzindo simultaneamente o peso total.

Considerações para compradores internacionais: A conformidade com os regulamentos ambientais relativos à utilização de plástico é essencial, especialmente na Europa, onde os regulamentos são rigorosos. Os compradores devem também considerar a durabilidade a longo prazo dos componentes de plástico em climas variáveis.

Tabela de resumo da seleção de materiais para a substituição do arrancador

| Material | Caso de utilização típico para o custo médio de substituição de um motor de arranque | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Ligações eléctricas e enrolamentos em motores de arranque | Condutividade elétrica superior | Custo e peso mais elevados | Alto |

| Aço | Componentes estruturais como caixas | Alta resistência e durabilidade | Mais pesado e suscetível à ferrugem | Médio |

| Alumínio | Invólucro e componentes não estruturais | Leve e resistente à corrosão | Menos durável do que o aço | Médio |

| Compósitos plásticos | Coberturas e peças de isolamento | Design versátil e leve | Menor resistência à temperatura e durabilidade | Baixo |

Este guia estratégico de seleção de materiais fornece aos compradores B2B informações essenciais sobre os materiais utilizados nas substituições de arrancadores, ajudando-os a tomar decisões informadas com base no desempenho, custo e considerações regionais.

Análise aprofundada: Processos de fabrico e garantia de qualidade para o custo médio de substituição de um motor de arranque

Quais são os principais processos de fabrico para a substituição de um motor de arranque?

O processo de fabrico de motores de arranque para automóveis envolve várias fases críticas que garantem a qualidade, o desempenho e a fiabilidade. Para os compradores B2B, compreender estes processos é vital para avaliar os fornecedores e tomar decisões de compra informadas.

Quais são as principais fases do fabrico de arrancadores?

-

Preparação do material

O processo começa com a seleção de matérias-primas de alta qualidade, normalmente metais como o aço, o cobre e o alumínio. Estes materiais são obtidos junto de fornecedores conceituados e são submetidos a testes exaustivos para garantir que cumprem as normas da indústria. Esta fase inclui o corte dos materiais nas formas e tamanhos necessários, garantindo que não apresentam defeitos. -

Formando

Durante a fase de conformação, os componentes são moldados utilizando técnicas como a estampagem, o forjamento ou a fundição. Para começar, as bobinas do campo eletromagnético e a armadura são componentes cruciais formados através de processos de maquinação precisos. Esta fase requer equipamento especializado para obter as dimensões e tolerâncias corretas, uma vez que mesmo pequenas discrepâncias podem afetar o desempenho. -

Montagem

A fase de montagem envolve a integração de vários componentes, incluindo o solenoide, as escovas e a engrenagem de acionamento. Cada peça é meticulosamente instalada, muitas vezes utilizando sistemas automatizados para aumentar a precisão. Técnicos especializados podem também efetuar a montagem manual para projectos de arranque mais complexos. Nesta fase, é essencial garantir que todos os componentes se encaixam perfeitamente, uma vez que qualquer desalinhamento pode levar a falhas de funcionamento. -

Acabamento

Após a montagem, os motores de arranque são submetidos a processos de acabamento, que podem incluir pintura, revestimento ou galvanização para evitar a corrosão e aumentar a durabilidade. São efectuados controlos de qualidade para garantir que o acabamento cumpre as normas estéticas e funcionais. Esta fase é crucial para os motores de arranque, uma vez que estão frequentemente expostos a condições ambientais adversas em aplicações automóveis.

Que normas de garantia de qualidade devem os compradores B2B considerar?

Para os compradores internacionais, particularmente os de regiões como África, América do Sul, Médio Oriente e Europa, é essencial compreender os processos de garantia de qualidade (QA). As normas internacionais fornecem uma estrutura para avaliar a fiabilidade e a segurança dos motores de arranque para automóveis.

Quais são as normas internacionais relevantes?

-

ISO 9001: Esta é a norma de gestão da qualidade mais reconhecida em todo o mundo. Dá ênfase a uma abordagem de processo para aumentar a satisfação do cliente e garantir uma qualidade consistente em produtos e serviços. Os fornecedores que aderem à ISO 9001 demonstram o seu empenhamento na qualidade e na melhoria contínua.

-

Marcação CE: No mercado europeu, os produtos devem cumprir requisitos específicos de segurança, saúde e proteção ambiental. A marcação CE indica que um arrancador cumpre estas normas regulamentares, tornando-o adequado para venda no Espaço Económico Europeu.

-

Padrões API: Para os compradores do sector do petróleo e do gás, as normas API (American Petroleum Institute) garantem que os componentes automóveis, incluindo os motores de arranque, cumprem rigorosos critérios de desempenho e segurança.

Como é implementado o controlo de qualidade em todo o processo de fabrico?

O controlo de qualidade (CQ) está integrado em todas as fases do processo de fabrico para garantir que as entradas cumprem as normas exigidas. Isto envolve vários pontos de controlo e métodos de teste.

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

Quais são os principais pontos de controlo de CQ?

-

Controlo de Qualidade de Entrada (IQC)

Neste ponto de controlo inicial, as matérias-primas são inspeccionadas à chegada. Os fornecedores devem fornecer certificação e resultados de testes para verificar a qualidade dos materiais. Todos os materiais que não cumpram as especificações são rejeitados e devolvidos. -

Controlo de qualidade em processo (IPQC)

Ao longo do processo de fabrico, são realizadas inspecções regulares para controlar a qualidade da produção. Isto inclui a verificação das dimensões, tolerâncias e precisão da montagem. Podem ser utilizados métodos de controlo estatístico do processo (SPC) para analisar dados e identificar tendências que possam indicar potenciais problemas de qualidade. -

Controlo de Qualidade Final (FQC)

Quando os arrancadores estão completamente montados, são submetidos a inspecções e testes finais. Isto pode incluir testes de desempenho sob várias condições para garantir a fiabilidade. Quaisquer arrancadores que não cumpram os critérios de desempenho são retrabalhados ou eliminados.

Que métodos de ensaio são normalmente utilizados no fabrico de arrancadores?

São utilizados vários métodos de ensaio para garantir que os motores de arranque cumprem as normas de desempenho e durabilidade:

-

Testes elétricos: Isto inclui a verificação da resistência, tensão e consumo de corrente do motor de arranque para garantir o seu funcionamento eficiente.

-

Testes mecânicos: Os arrancadores são submetidos a ensaios de esforço mecânico para avaliar a sua durabilidade e capacidade de resistência às condições de funcionamento.

-

Ensaios ambientais: Simula condições do mundo real, como temperaturas e humidade extremas, para avaliar o desempenho do arrancador sob vários factores ambientais.

Como podem os compradores B2B verificar os processos de controlo de qualidade dos fornecedores?

Os compradores B2B devem tomar medidas proactivas para verificar os processos de controlo de qualidade dos seus fornecedores:

-

Auditorias a fornecedores: A realização de auditorias regulares a potenciais fornecedores pode ajudar a garantir que estes cumprem as normas de qualidade. Isto inclui a revisão dos seus processos de fabrico, equipamento e procedimentos de controlo de qualidade.

-

Solicitação de relatórios de qualidade: Os fornecedores devem fornecer documentação sobre as suas medidas de controlo de qualidade, incluindo os resultados dos testes e a conformidade com as normas internacionais. Esta transparência é fundamental para criar confiança.

-

Inspeções por terceiros: A contratação de agências de inspeção de terceiros pode fornecer uma avaliação imparcial dos processos de controlo de qualidade de um fornecedor. Estas inspecções podem incluir avaliações no local e testes de produtos.

Quais são as nuances do controlo de qualidade para compradores B2B internacionais?

Os compradores B2B internacionais têm de navegar por várias nuances nos processos de controlo de qualidade:

-

Diferenças culturais: As diferentes regiões podem ter abordagens diferentes em relação à garantia de qualidade. Compreender estas nuances culturais pode ajudar os compradores a alinhar as suas expectativas com as práticas dos fornecedores.

-

Conformidade regulamentar: Os compradores devem certificar-se de que os fornecedores cumprem os regulamentos locais e as normas internacionais, que podem variar significativamente consoante a região. Isto é particularmente importante quando se abastecem em países com regulamentações menos rigorosas.

-

Transparência da cadeia de abastecimento: O estabelecimento de canais de comunicação claros com os fornecedores é essencial para manter a qualidade. Os compradores devem procurar fornecedores que estejam dispostos a partilhar informações sobre os seus processos de abastecimento, fabrico e controlo de qualidade.

Ao compreender os processos de fabrico e as medidas de garantia de qualidade envolvidas na produção de motores de arranque para automóveis, os compradores B2B podem tomar decisões informadas que melhoram a fiabilidade e a eficiência da sua cadeia de abastecimento.

Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘custo médio para substituir um arranque’

Introdução

Este guia fornece uma lista de verificação estruturada para compradores B2B que procuram compreender o custo médio de substituição de um motor de arranque. Quer esteja a adquirir peças para oficinas de reparação automóvel ou a gerir a manutenção de frotas, esta lista de verificação ajudá-lo-á a navegar eficazmente no processo de aquisição. Seguindo estes passos, pode garantir que está a tomar decisões informadas que equilibram o custo, a qualidade e a fiabilidade do fornecedor.

Passo 1: Avalie as necessidades da sua frota de veículos

Compreender os requisitos específicos da sua frota de veículos é crucial. Identifique as marcas e modelos que requerem substituições de motores de arranque, uma vez que esta informação irá orientar as suas decisões de aprovisionamento. Considere factores como a idade média da sua frota e a frequência dos problemas com os motores de arranque para dar prioridade aos esforços de aquisição.

Passo 2: Pesquisa de preços de mercado

Efectue uma pesquisa de mercado aprofundada para determinar os custos médios associados à substituição do motor de arranque. Os preços podem variar significativamente consoante o tipo de veículo e a região, pelo que deve recolher dados de várias fontes. Desta forma, terá uma base de referência para avaliar as ofertas dos fornecedores e garantir que não está a pagar demasiado.

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

- Dica: Utilize relatórios da indústria e fóruns automóveis online para comparar custos.

Passo 3: Defina as suas especificações técnicas

Defina claramente as especificações técnicas para os motores de arranque de que necessita. Isto inclui compreender os requisitos de tensão, tamanho e compatibilidade com os seus veículos. As especificações corretas ajudarão a evitar erros dispendiosos e a garantir que as peças que adquire se adaptam perfeitamente à sua frota.

- Considerar: Peças OEM versus peças de substituição, uma vez que podem diferir em termos de qualidade e preço.

Passo 4: Avalie potenciais fornecedores

Antes de se comprometer com qualquer fornecedor, examine minuciosamente as suas credenciais e fiabilidade. Solicite perfis de empresas, certificações e referências de empresas de sectores ou regiões semelhantes. A reputação de um fornecedor pode ter um impacto significativo na qualidade e fiabilidade das peças que recebe.

- Lista de controlo para fornecedores:

- Certificações (por exemplo, ISO, IATF)

- Comentários e testemunhos de clientes

- Histórico de entregas dentro do prazo

Passo 5: Comparar opções de garantia

Investigue as opções de garantia oferecidas pelos potenciais fornecedores. Uma garantia forte pode indicar a confiança do fornecedor nos seus produtos e protegê-lo de custos futuros. Compare os termos e condições, incluindo a duração da cobertura e o que está incluído, para selecionar um fornecedor que ofereça o melhor apoio.

Passo 6: Negociar preços e condições

Depois de identificar os fornecedores adequados, inicie negociações para garantir os melhores preços e condições. Discuta descontos para compras em massa, condições de pagamento e custos de envio. Uma negociação eficaz pode resultar em poupanças significativas, especialmente para encomendas maiores.

- Dica: Considere a possibilidade de estabelecer parcerias a longo prazo com fornecedores para obter melhores preços e fiabilidade.

Passo 7: Plano de instalação e manutenção

Por fim, pense na forma como vai gerir a instalação e a manutenção dos novos arrancadores. Decida se pretende efetuar substituições "faça você mesmo" ou contratar serviços profissionais. Certifique-se de que a sua equipa está equipada com as ferramentas e os conhecimentos necessários para minimizar o tempo de inatividade durante o processo de substituição.

Seguindo esta lista de verificação, os compradores B2B podem tomar decisões informadas relativamente ao custo médio de substituição dos motores de arranque, assegurando um equilíbrio entre qualidade, custo-eficácia e eficiência operacional.

Análise abrangente de custos e preços para o custo médio para substituir um motor de arranque Sourcing

Quais são os principais componentes de custo para a substituição de um motor de arranque?

Ao analisar a estrutura de custos para substituir um motor de arranque, entram em jogo vários componentes. Os principais componentes de custo incluem:

-

Materiais: Os materiais para a substituição de um motor de arranque podem variar muito, com peças de reconstrução que vão de $50 a $350 e motores de arranque novos de $80 a mais de $350. A escolha entre peças de substituição e peças OEM (Fabricante de Equipamento Original) pode afetar significativamente o custo total.

-

Trabalho: Os custos de mão de obra podem variar consoante a complexidade do trabalho. Para substituições simples, a mão de obra pode variar entre $150 e $300. No entanto, para veículos onde o motor de arranque é mais difícil de aceder, os custos de mão de obra podem exceder $1.100.

-

Custos indiretos de produção: Inclui os custos relacionados com a produção de motores de arranque, tais como as operações da fábrica, os serviços públicos e a depreciação do equipamento. As despesas gerais podem acrescentar uma percentagem significativa ao custo total, dependendo do local de fabrico.

-

Ferramentas: Os custos das ferramentas referem-se às despesas ligadas à criação e à manutenção das máquinas utilizadas para fabricar as entradas. Estes custos podem variar consoante a escala de produção e a tecnologia utilizada.

-

Controlo de Qualidade (QC): Assegurar a fiabilidade e a segurança dos motores de arranque através de controlos de qualidade rigorosos implica custos adicionais. Isto é particularmente importante para os compradores internacionais que podem exigir certificações e conformidade com normas específicas.

-

Logística: Os custos de transporte podem variar consoante a distância entre as instalações de fabrico e a localização do comprador. O transporte internacional, os direitos aduaneiros e as tarifas podem afetar significativamente o preço final.

-

Margem: Os fornecedores normalmente aumentam os preços para cobrir os seus custos operacionais e margens de lucro. Esta margem pode variar consoante a procura do mercado, a concorrência e o valor percebido da entrada.

O que influencia o preço das substituições de arrancadores?

Vários factores podem influenciar o preço dos substitutos de arranque para os compradores B2B:

-

Volume/MOQ (Quantidade mínima de encomenda): Os volumes de encomenda mais elevados conduzem frequentemente a descontos. Os compradores devem negociar condições que favoreçam as compras a granel, o que pode reduzir significativamente os custos por unidade.

-

Especificações e personalização: As entradas personalizadas ou com caraterísticas específicas podem implicar custos mais elevados. Os compradores devem definir claramente as suas necessidades para evitar despesas inesperadas.

-

Materiais: A escolha dos materiais tem um impacto direto na durabilidade e no desempenho. Os materiais de qualidade superior podem aumentar o custo inicial, mas podem conduzir a menores despesas de manutenção a longo prazo.

-

Qualidade e certificações: Os compradores de regiões com normas automóveis rigorosas podem ter de pagar mais por produtos certificados. É essencial verificar se os fornecedores podem cumprir os regulamentos locais.

-

Fatores relacionados ao fornecedor: A reputação e a fiabilidade do fornecedor podem influenciar os preços. Os fornecedores estabelecidos podem cobrar mais, mas oferecem melhor apoio e garantia de qualidade.

-

Incoterms: Compreender os Incoterms (Termos Comerciais Internacionais) é crucial para as transacções internacionais. Estes definem as responsabilidades em matéria de transporte, seguro e tarifas, que podem afetar os custos globais.

Quais são as melhores práticas para os compradores B2B na negociação dos preços de substituição do motor de arranque?

Os compradores B2B podem implementar várias estratégias para otimizar os custos quando procuram substitutos para os motores de arranque:

-

Realizar uma investigação exaustiva: Compreender os preços de mercado para os iniciadores e as necessidades específicas dos seus veículos. Este conhecimento permitir-lhe-á negociar.

-

Negociar termos: Não hesite em negociar preços e condições de pagamento. Pense em discutir descontos por volume ou períodos de pagamento mais longos para melhorar o fluxo de caixa.

-

Avalie o custo total de propriedade (TCO): Não se limite ao preço de compra inicial. Considere factores a longo prazo, como a fiabilidade, a garantia e os custos de manutenção. Um motor de arranque mais barato pode levar a um TCO mais elevado se falhar prematuramente.

-

Considere fornecedores locais: Para os compradores em África, na América do Sul e no Médio Oriente, a aquisição a fornecedores locais pode reduzir os custos de envio e os prazos de entrega. Além disso, os fornecedores locais podem estar mais familiarizados com as normas e requisitos regionais.

-

Solicitar várias cotações: A contratação de vários fornecedores pode criar uma pressão competitiva e proporcionar uma vantagem nas negociações. Certifique-se de que compara não só os preços, mas também a qualidade do serviço e os prazos de entrega.

Conclusão

Embora o custo médio para substituir um motor de arranque varie significativamente com base em vários factores, a compreensão dos componentes e dos factores que influenciam o preço pode permitir que os compradores B2B tomem decisões informadas. Ao utilizar estratégias de negociação e considerar o Custo Total de Propriedade, os compradores podem otimizar os seus processos de aquisição, conduzindo, em última análise, a melhores resultados financeiros.

Declaração de exoneração de responsabilidade: Os preços mencionados são indicativos e podem variar consoante as condições do mercado, os acordos com os fornecedores e os requisitos específicos do veículo.

Análise de alternativas: Comparação do custo médio para substituir um motor de arranque com outras soluções

Explorar soluções alternativas para os custos de substituição de arranque

Quando confrontados com a necessidade de substituir o motor de arranque de um veículo, os compradores B2B procuram frequentemente soluções alternativas que possam reduzir os custos, assegurando simultaneamente um desempenho fiável do veículo. Compreender a relação custo-eficácia e o carácter prático destas alternativas pode ajudar as empresas a tomar decisões informadas.

Tabela comparativa

| Aspecto comparativo | Custo médio de substituição de um motor de arranque | Reparação do motor de arranque | Substituição da bateria |

|---|---|---|---|

| Desempenho | Elevada fiabilidade após a substituição | Fiabilidade moderada, depende da extensão dos danos | Elevada fiabilidade se o problema for a bateria |

| Custo | $150 - $1,100 | $50 - $350 | $80 - $200 |

| Facilidade de implementação | Necessita de mecânicos profissionais | Pode ser feito em bricolage, se for especializado | Bricolage geralmente fácil |

| Manutenção | Mínimo após a instalação | Necessidade de controlos regulares | Verificações regulares e substituições necessárias |

| Melhor caso de uso | Falha total do motor de arranque | Pequenos problemas com os componentes do motor de arranque | Bateria fraca ou descarregada que causa problemas de arranque |

Discriminação detalhada das alternativas

1. Reparação do motor de arranque

A reparação do motor de arranque envolve o diagnóstico dos problemas específicos do motor de arranque e a substituição apenas dos componentes danificados. Esta abordagem pode ser económica, especialmente para problemas menores, como solenóides defeituosos ou escovas gastas. O custo médio das reparações varia normalmente entre $50 e $350, dependendo da gravidade dos danos e dos custos de mão de obra.

Prós:

- Custo reduzido em comparação com a substituição total.

- Menos resíduos, uma vez que apenas são substituídos componentes específicos.

Contras:

- Potencial para problemas recorrentes se os problemas subjacentes não forem resolvidos.

- Pode exigir assistência profissional, o que pode aumentar os custos e o tempo de inatividade.

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

2. Substituição da bateria

Em muitos casos, os problemas de arranque podem ser atribuídos a uma bateria avariada e não ao motor de arranque propriamente dito. A substituição de uma bateria velha ou fraca pode custar entre $80 e $200. Trata-se frequentemente de uma tarefa simples de bricolage que pode ser efectuada por pessoas com conhecimentos básicos de mecânica.

Prós:

- Custo geralmente mais baixo em comparação com a substituição do motor de arranque.

- Solução rápida se a bateria for efetivamente o problema.

Contras:

- Apenas aplicável se a bateria for o verdadeiro problema; não aborda questões relacionadas com o motor de arranque.

- Requer manutenção regular e substituição ao longo do tempo.

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

Conclusão: Fazer a escolha certa para a sua empresa

Para os compradores B2B, a escolha entre substituir um motor de arranque, repará-lo ou substituir a bateria depende de vários factores, incluindo a natureza do problema de arranque, as restrições orçamentais e a disponibilidade de mão de obra especializada. A avaliação dos sintomas específicos e a realização de diagnósticos exaustivos podem ajudar a determinar a solução mais económica. As empresas devem considerar não só os custos imediatos, mas também a fiabilidade e a manutenção a longo prazo ao tomarem a sua decisão. Ao ponderar estas alternativas, os compradores podem otimizar as suas estratégias de manutenção de veículos e minimizar as interrupções operacionais.

Propriedades técnicas essenciais e terminologia comercial para o custo médio de substituição de um motor de arranque

Quais são as principais propriedades técnicas que afectam o custo médio de substituição de um arrancador?

Ao considerar o custo médio para substituir um motor de arranque, várias propriedades técnicas são fundamentais para determinar tanto o preço como a qualidade geral da peça de substituição. A compreensão destas especificações ajuda os compradores B2B a tomar decisões de compra informadas.

-

Grau do material

O material utilizado no fabrico dos arrancadores pode ter um impacto significativo na durabilidade e no desempenho. Os materiais comuns incluem aço de alta qualidade para a caixa e cobre para a cablagem. Os materiais de qualidade superior aumentam normalmente a resistência do arrancador ao desgaste e ao calor, o que é crucial para manter a eficiência ao longo do tempo. Para os compradores B2B, o investimento em materiais de qualidade superior pode reduzir os custos a longo prazo associados a substituições e reparações. -

Corrente nominal (amperagem)

Os motores de arranque são classificados de acordo com a sua capacidade de lidar com níveis de amperagem específicos, normalmente entre 100 e 300 amperes. Esta classificação afecta a capacidade do motor de arranque de pôr o motor a trabalhar eficazmente, especialmente em veículos maiores ou com motores de alta compressão. Os decisores B2B devem considerar a classificação atual relevante para as especificações da sua frota ou veículo para evitar um desempenho inadequado que pode levar a períodos de inatividade operacional. -

Especificação do binário

O binário refere-se à força de rotação que o motor de arranque pode gerar. É fundamental para ultrapassar a resistência do motor durante o arranque. Os motores de arranque com binários mais elevados são frequentemente necessários para motores maiores ou mais potentes. Os compradores B2B devem certificar-se de que as especificações de binário dos motores de arranque de substituição estão em conformidade com os motores que estão a ser reparados para garantir um desempenho fiável. -

Peso

O peso de um arrancador pode influenciar os custos de instalação e de transporte. Os motores de arranque mais leves podem ser mais fáceis de manusear e instalar, reduzindo os custos de mão de obra. No entanto, os compradores devem equilibrar as considerações de peso com os requisitos de desempenho, uma vez que algumas aplicações de serviço pesado podem necessitar de componentes mais pesados para maior durabilidade. -

Classificação de temperatura

Os arrancadores são concebidos para funcionar dentro de intervalos de temperatura específicos. As temperaturas extremas podem afetar o desempenho e a longevidade. A compreensão das classificações de temperatura ajuda os compradores B2B a selecionar os motores de arranque adequados às condições ambientais em que os seus veículos funcionam, aumentando assim a fiabilidade e reduzindo as falhas.

Que termos comerciais são essenciais para compreender os custos de substituição do motor de arranque?

No domínio das transacções B2B para peças automóveis, é crucial familiarizar-se com a terminologia específica do sector. Abaixo estão os termos-chave que ajudarão a navegar pelos custos de substituição do motor de arranque.

-

OEM (Fabricante de Equipamento Original)

As peças OEM são fabricadas pelo fabricante original do veículo ou dos seus componentes. Estas peças têm, muitas vezes, um preço mais elevado, mas, normalmente, têm a garantia de se adaptarem e funcionarem como previsto. Os compradores B2B devem ponderar as vantagens das peças OEM em relação às opções pós-venda, especialmente no que respeita à garantia e à garantia de qualidade. -

MOQ (Quantidade mínima de encomenda)

O MOQ refere-se ao número mais pequeno de unidades que um fornecedor está disposto a vender numa única encomenda. Compreender o MOQ é vital para os compradores B2B que pretendem otimizar os seus custos de inventário. A colocação de encomendas maiores pode, por vezes, levar a descontos, mas os compradores devem garantir que têm a capacidade de gerir o stock. -

RFQ (Pedido de Orçamento)

Um RFQ é um documento que um comprador envia aos fornecedores solicitando uma cotação de preço detalhada com base em requisitos específicos. É uma ferramenta essencial para o aprovisionamento B2B, permitindo aos compradores comparar preços e especificações de vários fornecedores, assegurando que obtêm o melhor negócio para as substituições de motores de arranque. -

Incoterms (Termos Comerciais Internacionais)

Os Incoterms definem as responsabilidades dos compradores e vendedores no comércio internacional, incluindo custos de envio, seguro e responsabilidade. A familiaridade com estes termos ajuda os compradores B2B a compreender o custo total de aquisição de peças de arranque, especialmente quando lidam com fornecedores internacionais. -

Período de garantia

Este termo refere-se ao período durante o qual o fabricante garante o produto contra defeitos. Um período de garantia mais longo pode indicar uma maior confiança na durabilidade do produto. Os compradores B2B devem ter em conta os termos da garantia quando avaliam a relação custo-eficácia das substituições de motores de arranque.

Ao compreender estas propriedades técnicas e termos comerciais, os compradores internacionais B2B podem navegar pelas complexidades dos custos de substituição de motores de arranque com maior confiança, garantindo que tomam decisões informadas que se alinham com as suas necessidades operacionais.

Navegar na dinâmica do mercado e tendências de fornecimento no custo médio para substituir um sector de arranque

Panorama do mercado e principais tendências no sector da substituição de motores de arranque

O mercado de substituição de motores de arranque para automóveis está a registar um crescimento notável, impulsionado por vários factores globais. A crescente prevalência de veículos eléctricos e híbridos está a remodelar a dinâmica do mercado, exigindo uma mudança nas estratégias de abastecimento dos compradores B2B. Uma vez que estes veículos utilizam normalmente sistemas de arranque mais sofisticados, os fornecedores têm de se adaptar para satisfazer a procura de componentes de maior qualidade, o que pode resultar em estruturas de preços variadas consoante as regiões. Em mercados como África e América do Sul, onde a longevidade dos veículos é crucial, a procura de substitutos de motores de arranque acessíveis mas fiáveis continua a ser elevada, obrigando os fornecedores a equilibrar eficazmente o custo e a qualidade.

As tecnologias emergentes, como as plataformas de comércio eletrónico e as soluções digitais da cadeia de fornecimento, estão a melhorar o processo de aquisição para os compradores internacionais. Os compradores B2B estão a utilizar cada vez mais os mercados online para obter peças de arranque, permitindo uma comparação de preços mais fácil e o acesso a uma gama mais vasta de fornecedores. Além disso, o aumento da análise de dados na gestão de inventário está a ajudar as empresas a prever a procura com maior precisão, optimizando assim as suas estratégias de aprovisionamento.

Outra tendência importante é a crescente consciencialização das diferenças regionais nos custos de mão de obra, que podem influenciar significativamente o custo global da substituição do motor de arranque. Por exemplo, embora os custos de mão de obra na Europa possam ser mais elevados do que no Sudeste Asiático, a qualidade do serviço e a experiência justificam frequentemente a despesa para os compradores da primeira região. Como tal, compreender esta dinâmica de mercado é essencial para os compradores B2B internacionais que procuram navegar nas complexidades do aprovisionamento de substitutos de motores de arranque de forma eficaz.

Qual o impacto da sustentabilidade e do fornecimento ético no sector de substituição de motores de arranque?

A sustentabilidade tornou-se uma consideração crítica no sector automóvel, influenciando a forma como os compradores B2B abordam o fornecimento de substitutos de motores de arranque. O impacto ambiental dos componentes automóveis, incluindo os motores de arranque, sublinha a importância de cadeias de fornecimento éticas. Os compradores estão a procurar cada vez mais fornecedores que demonstrem um compromisso com práticas sustentáveis, como a utilização de materiais reciclados ou a minimização de resíduos durante a produção.

Certificações como a ISO 14001 (Gestão Ambiental) e a adesão aos regulamentos REACH (Registo, Avaliação, Autorização e Restrição de Produtos Químicos) estão a tornar-se essenciais para os fornecedores que pretendem atrair compradores conscientes. Estas certificações não só significam a conformidade com as normas ambientais, como também aumentam a credibilidade de um fornecedor no mercado.

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

Além disso, a procura de materiais e processos “ecológicos” está a remodelar o desenvolvimento de produtos no sector da substituição de motores de arranque. Os compradores B2B estão mais inclinados a estabelecer parcerias com fabricantes que dão prioridade a práticas ecológicas, tais como a utilização de técnicas de fabrico de baixo impacto e o fornecimento sustentável de matérias-primas. Esta mudança não só se alinha com os objectivos de responsabilidade social das empresas, como também vai ao encontro das expectativas de consumidores cada vez mais conscientes do ambiente, melhorando assim a reputação da marca e a competitividade no mercado.

Qual é a breve evolução/história das tecnologias de substituição de arrancadores?

A evolução das tecnologias de substituição de motores de arranque tem sido marcada por avanços significativos desde o início do século XX. Inicialmente, os veículos dependiam de motores de arranque de manivela manual, que eram trabalhosos e muitas vezes perigosos. A introdução do motor de arranque elétrico na década de 1910 revolucionou o funcionamento dos veículos, tornando-o mais seguro e mais conveniente para os condutores.

Ao longo das décadas, a tecnologia de arranque tem continuado a evoluir, com desenvolvimentos em materiais e design que melhoram o desempenho e a durabilidade. O aparecimento de motores de arranque de binário elevado na década de 1970 e a integração de eletrónica avançada nos motores de arranque modernos melhoraram a fiabilidade e a eficiência. À medida que os veículos eléctricos e híbridos ganham força, o mercado de substituição de motores de arranque está preparado para mais inovação, exigindo que os compradores B2B se mantenham informados sobre as mais recentes tecnologias e opções de fornecimento para se manterem competitivos num cenário em constante mudança.

Perguntas frequentes (FAQs) para compradores B2B sobre o custo médio de substituição de um motor de arranque

-

Como posso determinar o custo médio de substituição de um motor de arranque?

Para determinar o custo médio de substituição de um motor de arranque, considere as peças e a mão de obra. Normalmente, as peças do motor de arranque podem variar entre $50 e mais de $350, enquanto os custos de mão de obra podem variar significativamente com base no tipo de veículo e na localização, variando entre $150 e $1.100. É crucial identificar a marca, o modelo e o ano específicos do veículo para obter estimativas exactas. Além disso, as condições do mercado local e a disponibilidade de peças podem afetar os preços, pelo que a pesquisa de vários fornecedores pode permitir obter as melhores ofertas. -

Que factores influenciam o custo da substituição do motor de arranque?

Vários factores podem influenciar o custo da substituição do motor de arranque, incluindo o tipo de veículo, a complexidade da instalação e a localização geográfica. Os veículos de luxo e de maiores dimensões têm frequentemente custos mais elevados devido a peças especializadas e processos de instalação mais complexos. Além disso, as taxas de mão de obra locais e a disponibilidade de peças podem afetar as despesas gerais. É essencial avaliar se uma substituição ou reconstrução é mais económica com base no estado do motor de arranque e dos componentes circundantes. -

O que devo procurar ao selecionar fornecedores de peças de arranque?

Ao examinar os fornecedores de peças de arranque, dê prioridade a factores como fiabilidade, reputação e qualidade do produto. Verifique as certificações e a conformidade com as normas da indústria para garantir que fornecem peças duradouras. Além disso, informe-se sobre a sua experiência com envios internacionais, prazos de entrega e políticas de devolução. Ler as opiniões dos clientes e pedir amostras também pode ajudar a avaliar a qualidade do serviço. Estabelecer uma comunicação forte é vital para resolver problemas rapidamente e garantir um processo de compra tranquilo. -

Posso personalizar as peças de arranque para necessidades específicas do veículo?

Sim, muitos fornecedores oferecem opções de personalização para peças de arranque para satisfazer requisitos específicos dos veículos. A personalização pode incluir variações de tamanho, tensão ou materiais de componentes com base nas exigências operacionais de diferentes veículos. Ao discutir a personalização, forneça especificações detalhadas ao fornecedor para garantir a compatibilidade. Tenha em atenção que as encomendas personalizadas podem ter prazos de entrega mais longos e custos potencialmente mais elevados, pelo que deve ter isso em conta no calendário e orçamento do seu projeto. -

Qual é a quantidade mínima de encomenda (MOQ) para peças de arranque?

As quantidades mínimas de encomenda (MOQ) podem variar significativamente entre fornecedores, dependendo das suas capacidades de produção e da procura do mercado. Alguns fabricantes podem ter baixos MOQs para peças padrão, enquanto outros podem exigir encomendas maiores para componentes personalizados. Antes de efetuar uma encomenda, informe-se sobre as MOQs e quaisquer descontos associados a compras em massa. Compreender o MOQ ajudá-lo-á a planear o seu inventário e orçamento em conformidade, especialmente se estiver a adquirir para vários projectos. -

Que condições de pagamento devo esperar quando adquiro peças de arranque a nível internacional?

As condições de pagamento podem variar muito consoante o fornecedor e a natureza da transação. As condições comuns incluem o pagamento antecipado, 30/60/90 dias líquidos ou uma carta de crédito para encomendas maiores. É essencial negociar termos favoráveis que se alinhem com as suas necessidades de fluxo de caixa. Para além disso, considere métodos de pagamento que ofereçam segurança, como o PayPal ou transferências bancárias, e certifique-se de que quaisquer potenciais riscos cambiais são abordados antecipadamente. -

Como posso assegurar a garantia de qualidade (GQ) das peças de arranque?

Para assegurar a garantia de qualidade das peças de arranque, solicite ao seu fornecedor especificações e certificações detalhadas do produto. Estabeleça um processo de garantia de qualidade claro que inclua a inspeção das peças à chegada e antes da instalação. Considere a implementação de uma fase de teste para componentes críticos para verificar os padrões de desempenho. A comunicação regular com o seu fornecedor sobre questões de qualidade e feedback sobre o produto também pode ajudar a manter padrões elevados ao longo do processo de aquisição. -

Que considerações logísticas devo ter em conta quando forneço peças de arranque?

Ao adquirir peças de arranque, as considerações logísticas são cruciais para uma entrega atempada. Avalie as opções de envio e os prazos de entrega do fornecedor para garantir que se alinham com os prazos do seu projeto. Além disso, avalie a fiabilidade dos seus parceiros de expedição e os procedimentos de desalfandegamento, especialmente para expedições internacionais. Compreender o custo total, incluindo taxas e impostos, é essencial para um orçamento exato. Por fim, considere as opções de armazenamento se prevê a necessidade de um grande inventário para gerir as flutuações da procura.

Lista dos 4 principais fabricantes e fornecedores do custo médio para substituir um motor de arranque

1. AAA - Custos de substituição do motor de arranque do automóvel

Domínio: aaa.com

Registrado: 1990 (35 anos)

Introdução: O custo médio de substituição de um motor de arranque varia entre $700 e $1.200, influenciado por factores como a marca e o modelo, os custos de mão de obra e o tipo de motor de arranque. O preço de tabela da peça de arranque em si varia entre menos de $100 e mais de $400. As taxas de mão de obra na rede AAA Approved Auto Repair variam entre $100 e $250 por hora. Os sinais comuns de um motor de arranque defeituoso incluem arranque lento do motor, falha no arranque,...

2. Facebook - Custos de reparação automóvel

Domínio: facebook.com

Registado: 1997 (28 anos)

Introdução: custo para levar o carro à oficina e substituir o motor de arranque

3. CarTalk - Guia de substituição do motor de arranque

Domínio: cartalk.com

Registrado: 1995 (30 anos)

Introdução: Custo de substituição de um motor de arranque: $600 a $900 para veículos comuns; $900 a $1.400 para modelos de luxo. Os sintomas de um mau motor de arranque incluem um clique quando se tenta arrancar, sons de guinchos e funcionamento intermitente. Os motores de arranque podem ser novos, remanufacturados ou reparados, sendo os motores de arranque remanufacturados a escolha mais comum. Os veículos modernos com sistemas de paragem/arranque têm motores de arranque redesenhados que são robustos...

4. Tundras - Substituição do motor de arranque para Toyota Tundra CrewMax 2007

Domínio: tundras.com

Registada: 2000 (25 anos)

Introdução: Substituição do motor de arranque para um Toyota Tundra CrewMax 2007, custo cotado de $1500 (incluindo $900 para mão de obra e $650 para a peça). A peça a ser substituída é denșo 428000-4640. As discussões sugerem que as peças de substituição OEM podem ser em torno de $200, com os custos de mão de obra variando de acordo com o mecânico. Alguns utilizadores recomendam obter uma segunda opinião sobre o diagnóstico.

Strategic Sourcing Conclusion and Outlook for average cost to replace a starter

Em resumo, o custo médio para substituir um motor de arranque varia significativamente com base na marca, modelo e localização geográfica do veículo. Para os compradores B2B, compreender estas nuances é fundamental para uma orçamentação e tomada de decisões eficazes. O sourcing estratégico pode desempenhar um papel fundamental na otimização dos custos, permitindo que as empresas adquiram motores de arranque de alta qualidade a preços competitivos, tendo em conta factores como o transporte, as tarifas e a disponibilidade local.

Imagem ilustrativa relacionada com o custo médio para substituir um motor de arranque

Ao aproveitarem as relações com fornecedores fiáveis e ao utilizarem conhecimentos regionais, as empresas podem melhorar a sua eficiência operacional e reduzir o tempo de inatividade associado a falhas nos motores de arranque. Para além disso, é essencial manter-se informado sobre as tendências do mercado e os avanços tecnológicos que podem influenciar a conceção e a durabilidade dos motores de arranque, o que acaba por ter impacto nos custos de substituição.

Ao olharmos para o futuro, os compradores B2B internacionais, particularmente em África, na América do Sul, no Médio Oriente e na Europa, devem dar prioridade ao desenvolvimento de estratégias de fornecimento sólidas. Esta abordagem proactiva não só garantirá o acesso a peças de qualidade, como também promoverá a resiliência das cadeias de fornecimento. Envolva-se com fornecedores de confiança e invista em estudos de mercado para navegar eficazmente pelas complexidades dos custos de substituição de motores de arranque. O futuro da manutenção automóvel depende de decisões informadas e de parcerias estratégicas.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.