Introduction: Navigating the Global Market for how to tell if its battery or alternator

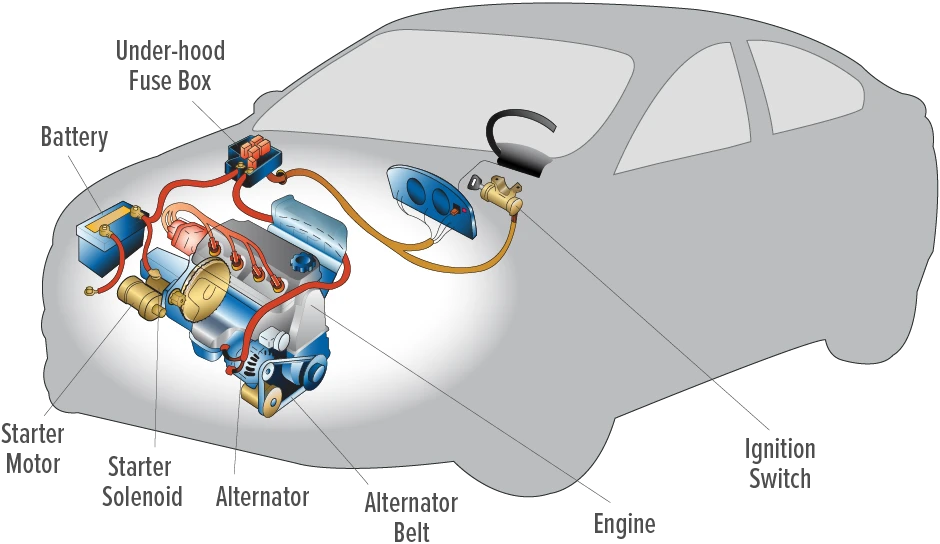

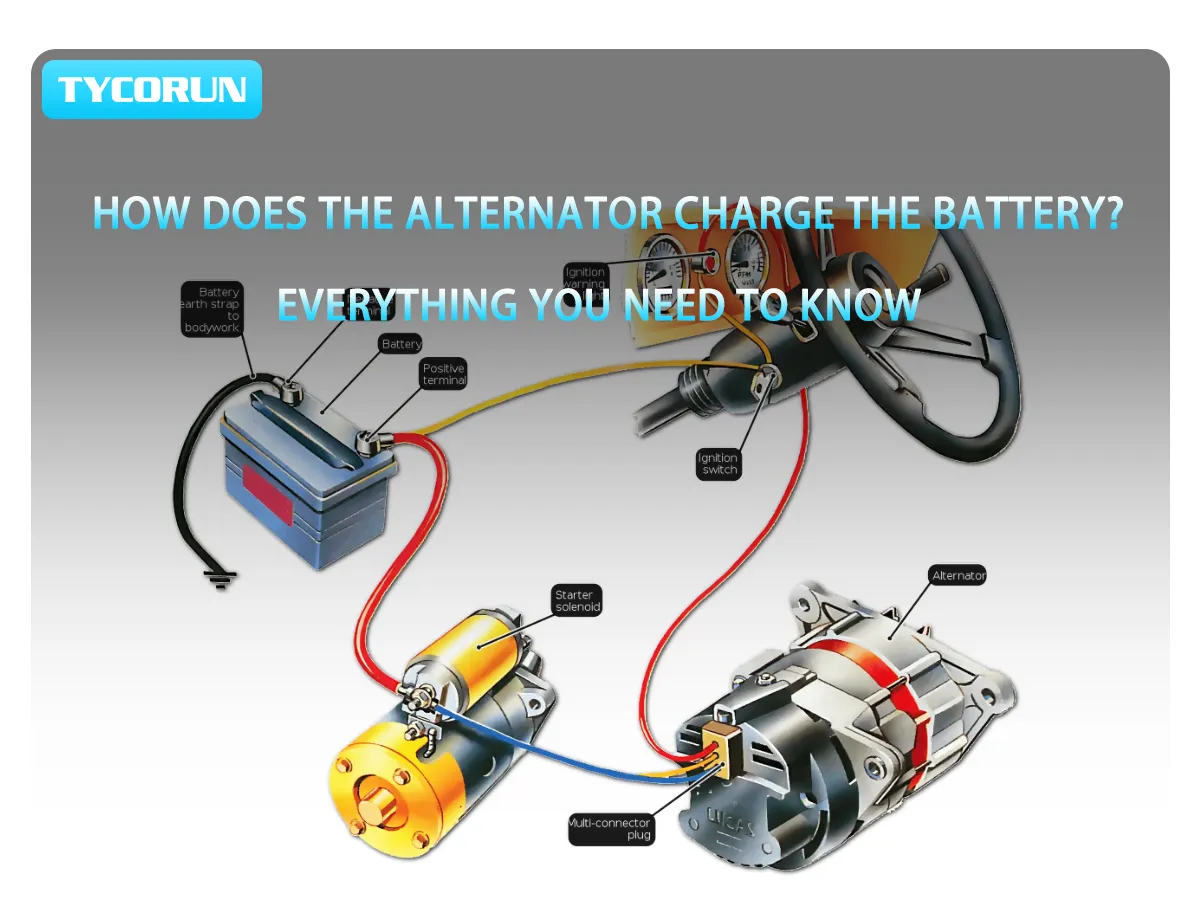

In the ever-evolving landscape of automotive maintenance, understanding the distinction between battery and alternator issues is critical for businesses reliant on vehicle performance. For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe—where transportation reliability is paramount—knowing how to diagnose whether it’s a battery or alternator problem can save both time and costs associated with vehicle downtime. This comprehensive guide delves into the intricacies of battery and alternator functionalities, offering insights into their respective roles within a vehicle’s electrical system.

Within this resource, we explore various types of batteries and alternators, their applications in different vehicle models, and the essential steps for effective diagnosis. Furthermore, we provide practical advice on supplier vetting, ensuring that you source high-quality components that meet your operational needs. Cost considerations and maintenance tips are also addressed, empowering you to make informed purchasing decisions.

By equipping yourself with this knowledge, you can not only enhance the reliability of your fleet but also optimize your budget. Whether you’re managing a logistics company or maintaining a fleet of service vehicles, this guide serves as a vital tool in navigating the complexities of automotive electrical systems, ultimately leading to greater operational efficiency and reduced downtime.

Table Of Contents

- Top 3 How To Tell If Its Battery Or Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to tell if its battery or alternator

- Understanding how to tell if its battery or alternator Types and Variations

- Key Industrial Applications of how to tell if its battery or alternator

- 3 Common User Pain Points for ‘how to tell if its battery or alternator’ & Their Solutions

- Strategic Material Selection Guide for how to tell if its battery or alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for how to tell if its battery or alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to tell if its battery or alternator’

- Comprehensive Cost and Pricing Analysis for how to tell if its battery or alternator Sourcing

- Alternatives Analysis: Comparing how to tell if its battery or alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for how to tell if its battery or alternator

- Navigating Market Dynamics and Sourcing Trends in the how to tell if its battery or alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to tell if its battery or alternator

- Strategic Sourcing Conclusion and Outlook for how to tell if its battery or alternator

- Important Disclaimer & Terms of Use

Understanding how to tell if its battery or alternator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Voltage Testing | Measures battery voltage with a multimeter | Automotive repair shops, fleet maintenance services | Pros: Accurate diagnosis; Cons: Requires equipment and know-how. |

| Load Testing | Tests battery under load to assess performance | Battery retailers, automotive service centers | Pros: Reveals true battery condition; Cons: More time-consuming. |

| Visual Inspection | Checks for physical signs of wear or damage | Vehicle inspections, maintenance services | Pros: Quick and easy; Cons: May miss underlying issues. |

| Electrical System Check | Comprehensive assessment of battery and alternator performance | Automotive diagnostics, fleet management | Pros: Thorough; Cons: Requires specialized knowledge and tools. |

| Jump Start Test | Attempts to start the vehicle to determine battery health | Towing services, roadside assistance | Pros: Simple; Cons: May not reveal alternator issues. |

What is Voltage Testing and Its B2B Relevance?

Voltage testing involves using a multimeter to measure the voltage output of a battery. A healthy battery typically shows around 12.6 volts, while anything below indicates potential issues. This method is particularly useful for automotive repair shops and fleet maintenance services, as it allows for quick diagnostics without extensive equipment. However, it requires skilled personnel to interpret the results accurately, which can be a limitation for some buyers.

How Does Load Testing Benefit B2B Buyers?

Load testing evaluates a battery’s ability to perform under pressure by simulating a starting condition. This test is essential for battery retailers and automotive service centers, as it provides a clear picture of battery health. Although it offers a precise assessment, it is time-consuming and requires specialized equipment, which may be a drawback for businesses with limited resources.

Why is Visual Inspection Important?

Visual inspection involves examining the battery and alternator for physical signs of damage, such as corrosion or leaks. This method is commonly utilized in vehicle inspections and maintenance services due to its simplicity and speed. While it can quickly identify visible issues, it may not detect deeper problems within the electrical system, which is a significant consideration for B2B buyers seeking comprehensive solutions.

What is Involved in an Electrical System Check?

An electrical system check is a thorough assessment of both the battery and alternator’s performance. This method is crucial for automotive diagnostics and fleet management, ensuring that all components function optimally. Although it provides a complete overview, it requires specialized knowledge and tools, making it less accessible for smaller operations.

How Effective is the Jump Start Test?

The jump start test involves attempting to start the vehicle to see if the battery can hold a charge. This method is often used by towing services and roadside assistance teams due to its simplicity. While it can quickly indicate battery health, it may not reveal underlying alternator issues, which can be a significant limitation for businesses that rely on accurate diagnostics.

Key Industrial Applications of how to tell if its battery or alternator

| Industry/Sector | Specific Application of how to tell if its battery or alternator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnosing vehicle electrical issues in repair shops | Reduces downtime and increases customer satisfaction | Quality diagnostic tools, training for technicians |

| Transportation & Logistics | Fleet maintenance for commercial vehicles | Ensures reliability and safety of fleet operations | Bulk purchasing of batteries and alternators, local support |

| Mining & Heavy Equipment | Maintenance of heavy machinery and vehicles | Minimizes operational disruptions and costly repairs | Sourcing durable components, understanding local conditions |

| Renewable Energy | Storage systems for solar or wind energy systems | Maximizes energy efficiency and system reliability | Compatibility with existing systems, sourcing local parts |

| Agriculture | Operation of agricultural machinery and vehicles | Enhances productivity and reduces maintenance costs | Availability of rugged components, local supplier relationships |

How is ‘how to tell if its battery or alternator’ applied in the Automotive Repair Sector?

In automotive repair shops, diagnosing whether a vehicle’s issue stems from the battery or the alternator is crucial for efficient service. Technicians utilize multimeters and other diagnostic tools to determine the root cause of electrical failures. This process reduces vehicle downtime, ensuring that customers receive timely repairs. For international buyers, sourcing high-quality diagnostic equipment and ensuring technicians are trained in proper testing methods are key considerations, particularly in regions with varying vehicle models and electrical systems.

What role does ‘how to tell if its battery or alternator’ play in Transportation & Logistics?

For businesses in transportation and logistics, maintaining a fleet of vehicles is essential for operational efficiency. Regular checks on battery and alternator health prevent unexpected breakdowns that can lead to costly delays. By implementing a systematic approach to diagnose electrical issues, fleet managers can ensure reliability and safety across their operations. B2B buyers in this sector should focus on bulk sourcing of batteries and alternators, as well as establishing relationships with local suppliers for timely maintenance support.

How does ‘how to tell if its battery or alternator’ benefit Mining & Heavy Equipment?

In the mining industry, heavy machinery is often subjected to harsh conditions that can strain electrical systems. Understanding how to diagnose battery and alternator issues can significantly minimize operational disruptions. Companies can save on repair costs and enhance productivity by conducting regular maintenance and timely replacements. When sourcing components, buyers should consider durability and compatibility with existing equipment, as well as the availability of local support services to address issues quickly.

Why is ‘how to tell if its battery or alternator’ important for Renewable Energy Systems?

In renewable energy applications, such as solar or wind power systems, the reliability of battery storage is vital for maximizing energy efficiency. Understanding the differences between battery and alternator functionality helps in diagnosing issues that could affect energy output. Businesses can optimize their energy systems by ensuring that all components are functioning correctly. Buyers in this sector should prioritize compatibility with existing systems and the sourcing of high-quality components to ensure long-term reliability.

How does ‘how to tell if its battery or alternator’ affect Agricultural Operations?

In agriculture, the performance of machinery and vehicles directly impacts productivity. Diagnosing battery and alternator issues ensures that equipment operates efficiently, preventing delays during critical planting or harvesting seasons. Regular maintenance checks can lead to significant cost savings in repairs and downtime. B2B buyers should focus on sourcing rugged components suitable for agricultural environments, as well as establishing strong supplier relationships to ensure quick access to replacements and support.

Illustrative image related to how to tell if its battery or alternator

3 Common User Pain Points for ‘how to tell if its battery or alternator’ & Their Solutions

Scenario 1: Diagnosing Electrical System Failures in Fleet Vehicles

The Problem: For businesses operating fleets, ensuring vehicle reliability is paramount. A common issue arises when a vehicle fails to start, leaving operators unsure whether the problem is related to the battery or the alternator. This uncertainty can lead to delays in service, increased maintenance costs, and potential loss of revenue. Fleet managers may lack the technical expertise to diagnose the issue effectively, leading to unnecessary replacements or repairs.

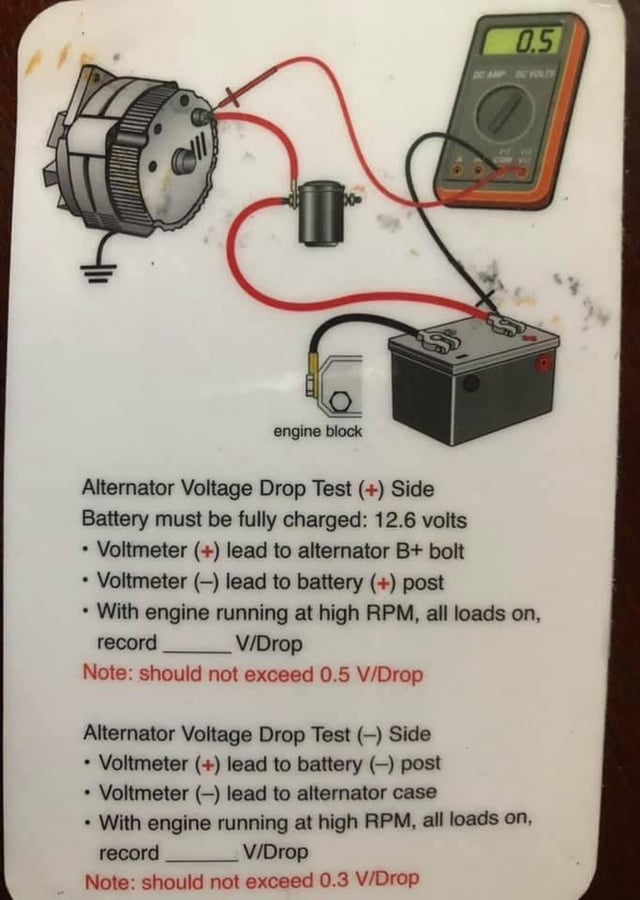

The Solution: Implement a systematic approach to diagnosing electrical issues in fleet vehicles. Encourage fleet managers to train staff on using a multimeter for testing both the battery and alternator. For instance, a fully charged battery should read approximately 12.6 volts; anything lower may indicate a battery issue. Next, start the vehicle and measure the voltage across the battery terminals again. A reading between 13 and 14.5 volts suggests the alternator is functioning properly. If the reading is below this range, the alternator may need to be inspected or replaced. Regular training and clear diagnostic procedures can minimize downtime and optimize repair costs.

Scenario 2: Managing Costs of Battery and Alternator Replacements

The Problem: International buyers, especially those in regions with fluctuating supply chains, often face challenges in managing the costs associated with battery and alternator replacements. Misdiagnosing the issue can lead to purchasing unnecessary components, resulting in wasted resources and increased operational costs. This problem is exacerbated in markets where quality parts may be hard to find, leading to reliance on subpar products that may fail prematurely.

Illustrative image related to how to tell if its battery or alternator

The Solution: To mitigate these costs, businesses should establish relationships with reliable suppliers who can provide high-quality batteries and alternators tailored to specific vehicle needs. Additionally, implementing a robust diagnostic protocol can help accurately identify whether a battery or alternator is at fault, thereby preventing unnecessary purchases. Investing in training for technicians on the latest diagnostic tools and techniques will enhance their ability to make informed decisions. Businesses could also consider maintaining an inventory of commonly used parts to avoid delays when replacements are necessary, ensuring operational efficiency.

Scenario 3: Addressing Environmental and Sustainability Concerns

The Problem: As businesses increasingly focus on sustainability, the disposal of batteries and alternators poses environmental challenges. Improper disposal can lead to harmful chemicals leaching into the environment, creating regulatory and reputational risks for companies. Buyers are often concerned about the ecological impact of their vehicle maintenance practices, particularly in regions where environmental regulations are becoming stricter.

The Solution: To address these concerns, businesses should develop a comprehensive recycling program for batteries and alternators. Partnering with certified recycling facilities ensures that old parts are disposed of responsibly. Additionally, buyers should consider sourcing products from manufacturers that prioritize sustainable practices and offer eco-friendly options. Educating employees on the importance of proper disposal and recycling can foster a culture of environmental responsibility within the organization. By integrating sustainability into their operational strategies, companies can enhance their brand reputation while complying with environmental regulations.

Strategic Material Selection Guide for how to tell if its battery or alternator

What Materials Are Commonly Used to Diagnose Battery or Alternator Issues?

When diagnosing whether a vehicle’s issue stems from the battery or the alternator, specific materials are employed in diagnostic tools and components. Understanding the properties, advantages, and limitations of these materials is crucial for B2B buyers, especially when considering international standards and preferences.

Illustrative image related to how to tell if its battery or alternator

What Are the Key Properties of Multimeters in Battery and Alternator Testing?

Multimeters are essential tools for diagnosing battery and alternator issues. They measure voltage, current, and resistance, providing critical data for troubleshooting. Key properties include a temperature rating typically between -10°C to 50°C, which is suitable for most automotive environments. Additionally, multimeters often have a high input impedance, which minimizes the loading effect on the circuit being tested.

Pros & Cons: Multimeters are durable, portable, and relatively low-cost. However, they require a certain level of user knowledge to operate effectively, which may limit their usability for less experienced technicians.

Impact on Application: The compatibility of multimeters with various automotive electrical systems is significant, as they can be used across different vehicle types and models.

International Considerations: Buyers in regions like Africa or South America should ensure that the multimeters comply with local electrical safety standards, such as IEC or ANSI. In Europe, compliance with CE marking is essential.

How Do Battery Load Testers Function in Diagnosing Battery Issues?

Battery load testers are designed to evaluate a battery’s ability to hold a charge under load conditions. They typically utilize materials like copper for conductors due to its excellent conductivity and resistance to corrosion.

Pros & Cons: These testers are effective for quickly assessing battery health, but they can be more expensive than basic multimeters. Additionally, they may require calibration to ensure accuracy, adding to manufacturing complexity.

Impact on Application: Battery load testers are particularly effective in environments where batteries are frequently cycled, such as in commercial fleets.

International Considerations: B2B buyers should consider the availability of replacement parts and service for battery testers in their region, ensuring they can maintain equipment longevity.

What Role Do Oscilloscopes Play in Alternator Diagnostics?

Oscilloscopes are advanced diagnostic tools that visualize electrical signals, making them invaluable for diagnosing alternator performance. They can capture voltage fluctuations and waveform patterns, providing insights into the alternator’s output.

Pros & Cons: Oscilloscopes offer high precision and detailed analysis but come at a higher cost. They also require skilled technicians to interpret the data accurately, which can be a barrier in less developed regions.

Impact on Application: Their ability to diagnose complex electrical issues makes oscilloscopes suitable for high-end automotive diagnostics and research applications.

International Considerations: Buyers should ensure that oscilloscopes meet international safety and performance standards, such as ISO or IEC, to avoid compliance issues.

What Are the Benefits of Using Diagnostic Software in Battery and Alternator Testing?

Diagnostic software is increasingly used in conjunction with hardware tools to provide comprehensive analysis of battery and alternator systems. This software often operates on standard computing materials and requires robust processing capabilities.

Pros & Cons: Software solutions can enhance diagnostic capabilities and streamline the testing process, but they may require ongoing updates and subscriptions, which can increase long-term costs.

Impact on Application: Software can integrate with various diagnostic tools to provide a holistic view of vehicle health, making it suitable for workshops and fleets.

International Considerations: B2B buyers should consider software compatibility with local languages and regulatory requirements, especially in multilingual regions.

Summary Table of Material Selection for Battery and Alternator Diagnosis

| Material | Typical Use Case for how to tell if its battery or alternator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Multimeter | Measuring voltage and current in batteries and alternators | Portable and versatile | Requires user knowledge | Low |

| Battery Load Tester | Testing battery capacity under load | Quick assessment of battery health | Higher cost, needs calibration | Med |

| Oscilloscope | Visualizing electrical signals from alternators | High precision and detail | Expensive and requires skilled use | High |

| Diagnostic Software | Comprehensive analysis of battery and alternator systems | Enhances diagnostic capabilities | Ongoing costs for updates | Med |

This guide provides valuable insights for B2B buyers in selecting appropriate materials and tools for diagnosing battery and alternator issues, ensuring compliance and suitability for their specific regional needs.

In-depth Look: Manufacturing Processes and Quality Assurance for how to tell if its battery or alternator

What Are the Main Stages in the Manufacturing Process for Batteries and Alternators?

The manufacturing processes for batteries and alternators involve several critical stages, each essential to ensuring product reliability and performance. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used?

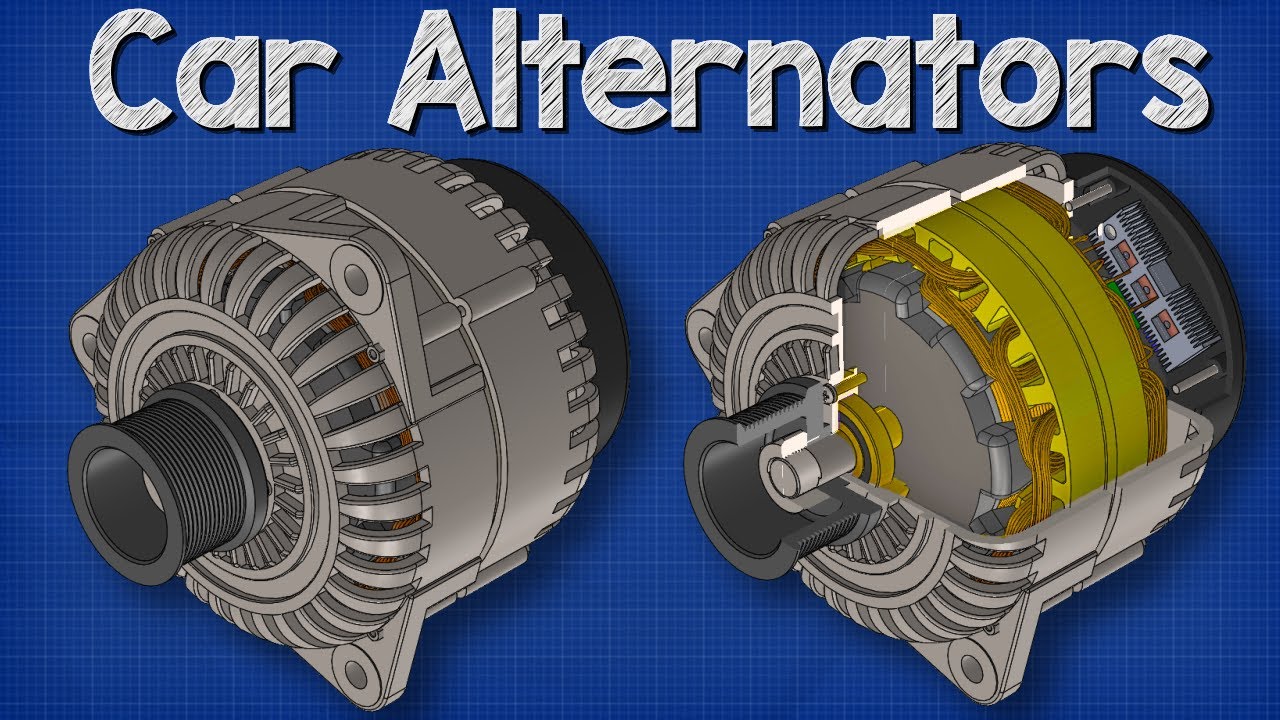

In the initial stage, raw materials are carefully selected based on their properties and suitability for battery or alternator production. For batteries, lead, sulfuric acid, and other chemical components are sourced to create lead-acid batteries, while lithium-ion batteries require lithium, cobalt, nickel, and graphite. For alternators, materials like aluminum and copper are essential for windings and housing. Quality control begins here, as the purity and grade of these materials are critical for performance and safety.

How Are Batteries and Alternators Formed?

The forming process for batteries often involves casting lead plates and assembling them into cells. These cells are filled with electrolyte and sealed to prevent leakage. In contrast, alternators are manufactured through a series of stamping and machining processes. Stamped metal components are shaped into the necessary parts, including the rotor and stator, which are vital for the alternator’s function. Precision in this stage ensures that the components fit together seamlessly, which is crucial for efficiency.

What Does the Assembly Process Entail for Batteries and Alternators?

The assembly phase is where individual components come together to create the final product. For batteries, this involves stacking the formed cells, connecting them, and installing safety features such as venting systems. Quality checks during assembly may include visual inspections and electrical tests to confirm that connections are secure.

For alternators, assembly involves fitting the rotor into the stator, securing the housing, and integrating the voltage regulator. The assembly line often employs automated machinery to enhance precision and speed, but manual inspections remain essential to catch any discrepancies.

How Are Finishing Processes Conducted in Battery and Alternator Manufacturing?

Finishing processes typically include cleaning, coating, and final assembly adjustments. Batteries are often coated to prevent corrosion and improve durability. Testing at this stage may involve checking for leaks or verifying that the battery holds its charge under specific conditions.

Illustrative image related to how to tell if its battery or alternator

For alternators, finishing may include installing bearings, ensuring proper lubrication, and conducting electrical tests to confirm that the output voltage meets specifications. This stage is critical, as any deficiencies could lead to performance failures in the field.

What Quality Assurance Measures Are in Place for Batteries and Alternators?

Quality assurance (QA) is vital throughout the manufacturing process to ensure that both batteries and alternators meet international standards. Adherence to ISO 9001 is common, as it establishes a framework for maintaining quality management systems.

What International Standards Should B2B Buyers Be Aware Of?

International standards relevant to battery and alternator manufacturing include the CE mark for compliance with European safety directives, and API standards for automotive applications. B2B buyers should verify that suppliers have appropriate certifications to assure product quality and safety.

Illustrative image related to how to tell if its battery or alternator

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are typically categorized into three stages: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials upon arrival to ensure they meet specified standards.

- IPQC focuses on monitoring the production process, including machinery calibration and workflow efficiency, to identify issues before products are completed.

- FQC entails comprehensive testing of finished products to ensure they perform to specifications, including voltage tests for batteries and output tests for alternators.

What Testing Methods Are Commonly Used in Battery and Alternator Production?

Common testing methods include electrical performance tests, thermal cycling tests, and mechanical stress tests. For batteries, capacity tests measure how much charge the battery can hold, while alternators are tested for output voltage and amperage under load conditions. These tests help identify potential failures early in the production cycle.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can verify a supplier’s quality control processes through several methods. Conducting audits of the manufacturing facility is one effective way to assess compliance with international standards. Buyers should also request detailed quality reports, including test results and certification documents.

Why Are Third-Party Inspections Important?

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and quality assurance practices. This is especially important for buyers in regions like Africa, South America, the Middle East, and Europe, where supply chain complexities can introduce additional risks. Third-party inspectors can verify that suppliers adhere to both local and international standards, ensuring that products meet the necessary quality benchmarks.

Illustrative image related to how to tell if its battery or alternator

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing batteries and alternators from different regions. These nuances can include differing regulatory requirements, language barriers, and variations in manufacturing practices. Buyers should invest time in understanding these differences and establishing clear communication channels with suppliers to ensure that quality expectations are met consistently.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for batteries and alternators is essential for B2B buyers. By focusing on quality at every stage of production and verifying supplier practices, businesses can mitigate risks and ensure the reliability of their products in the marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to tell if its battery or alternator’

Introduction

Understanding whether the issue with your vehicle’s electrical system stems from the battery or the alternator is crucial for effective maintenance and procurement. This guide provides a step-by-step checklist designed for B2B buyers who need to diagnose these issues accurately. By following these steps, you can ensure you source the right tools and services to assess the condition of batteries and alternators effectively.

Step 1: Identify Common Symptoms

Before conducting any tests, familiarize yourself with the common symptoms of battery and alternator issues. Recognizing these signs early can save time and prevent further damage.

– Battery Symptoms: Look for slow cranking, clicking sounds, or failure to start.

– Alternator Symptoms: Pay attention to dimming lights or erratic electrical performance.

Step 2: Gather Diagnostic Tools

Procure essential diagnostic tools such as a multimeter to measure voltage and amperage. These tools are vital for accurate testing and help in distinguishing between battery and alternator problems.

– Multimeter: Ensure the device can measure both voltage and current.

– Battery Tester: Consider investing in a specialized battery tester for comprehensive assessments.

Step 3: Conduct a Battery Voltage Test

Using the multimeter, test the battery voltage to determine its health. A fully charged battery should read around 12.6 volts; anything lower may indicate a problem.

– Procedure: Connect the multimeter leads to the battery terminals and record the reading. If below 12.4 volts, the battery may require charging or replacement.

Step 4: Evaluate Alternator Output

Start the vehicle and measure the voltage across the battery terminals again. The voltage should ideally be between 13 and 14.5 volts, indicating that the alternator is functioning properly.

– Check Under Load: Test while turning on electrical components (like headlights) to see if the voltage remains stable, which indicates a healthy alternator.

Step 5: Inspect Connections and Cables

Poor connections can lead to misdiagnosed issues. Inspect battery terminals and alternator connections for corrosion or looseness.

– Cleaning: Use a wire brush to clean terminals and apply dielectric grease to prevent future corrosion.

– Cable Integrity: Ensure cables are not frayed or damaged, which could affect performance.

Step 6: Consult Supplier Capabilities

When sourcing batteries and alternators, evaluate suppliers based on their technical support and product range. This is essential for ensuring you have access to the right products for your specific needs.

– Product Variety: Check if they offer different sizes and specifications suited for your vehicle types.

– Technical Support: Ensure they provide guidance on installation and troubleshooting.

Illustrative image related to how to tell if its battery or alternator

Step 7: Request Warranty and Return Policies

Before finalizing a purchase, ensure that the suppliers offer robust warranty and return policies. This protects your investment should the components fail prematurely.

– Warranty Duration: Look for warranties that cover at least 1-2 years.

– Return Process: Understand the steps involved in returning defective products to minimize downtime.

By following this checklist, B2B buyers can make informed decisions when diagnosing and sourcing solutions for battery and alternator issues, ultimately enhancing operational efficiency and vehicle reliability.

Comprehensive Cost and Pricing Analysis for how to tell if its battery or alternator Sourcing

When evaluating the costs associated with diagnosing whether a vehicle issue stems from the battery or the alternator, it is essential to understand the various components that contribute to the overall pricing structure. This analysis will help international B2B buyers make informed decisions regarding sourcing diagnostics and repair services.

What Are the Key Cost Components in Battery and Alternator Diagnostics?

-

Materials: The primary materials involved include diagnostic tools like multimeters and battery testers, as well as replacement parts such as batteries and alternators. Costs can vary significantly based on the quality and specifications of these components. Higher-quality tools may come with certifications that ensure reliability, which could justify a higher price point.

-

Labor: Labor costs are influenced by the complexity of the diagnostic process and the expertise of the technicians. In regions like Europe, where labor costs are generally higher, you might see increased service fees. Conversely, in regions such as Africa or South America, labor rates may be lower, but this can also impact the quality of service.

-

Manufacturing Overhead: This encompasses the indirect costs associated with the production of diagnostic tools and replacement parts, including utilities, rent, and administrative expenses. Companies that produce these items should factor these costs into their pricing strategy.

-

Tooling: The costs of specialized equipment needed for diagnostics can also affect pricing. Advanced diagnostic tools may require significant investment, which can be reflected in the pricing of services.

-

Quality Control (QC): Ensuring that diagnostic tools and replacement parts meet industry standards can incur additional costs. Suppliers who prioritize QC may charge more, but this can lead to better reliability and performance.

-

Logistics: Shipping and handling costs, especially for international buyers, can significantly impact the total cost. Factors like distance, shipping methods, and customs duties must be considered when sourcing from different regions.

-

Margin: Suppliers will typically add a markup to cover their overhead and profit margins. Understanding the standard margins in the automotive parts industry can help buyers negotiate better prices.

What Influences Pricing for Battery and Alternator Diagnostics?

-

Volume and Minimum Order Quantity (MOQ): Pricing can vary based on the volume of tools or parts ordered. Bulk purchases often lead to discounts, making it financially advantageous for businesses that require regular supplies.

-

Specifications and Customization: Custom diagnostic tools or specialized batteries and alternators may cost more due to the additional engineering and materials involved. Buyers should assess whether they need customized solutions or if standard options suffice.

-

Material Quality and Certifications: The level of quality assurance and certifications can also influence pricing. Products that meet higher standards, such as ISO certifications, often come at a premium but can offer better performance and longevity.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may command higher prices, but they often provide better service and support.

-

Incoterms: Understanding international trade terms is crucial for buyers. Incoterms define the responsibilities of buyers and sellers in shipping, which can affect the final cost. For example, FOB (Free On Board) pricing may differ significantly from CIF (Cost, Insurance, and Freight).

How Can Buyers Optimize Costs for Battery and Alternator Diagnostics?

-

Negotiation: Effective negotiation can lead to significant savings. Buyers should be prepared to discuss pricing based on volume and long-term contracts, particularly when dealing with established suppliers.

-

Cost-Efficiency: Consider the total cost of ownership (TCO), which includes not just the purchase price but also maintenance and replacement costs. Investing in higher-quality tools may reduce long-term expenses.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should be aware of currency fluctuations and local market conditions that may affect pricing. Building relationships with local suppliers can also help mitigate these challenges.

In conclusion, understanding the comprehensive cost structure and pricing dynamics associated with diagnosing battery and alternator issues is vital for international B2B buyers. By considering these factors, businesses can make informed decisions that lead to cost savings and improved operational efficiency.

Alternatives Analysis: Comparing how to tell if its battery or alternator With Other Solutions

Introduction: Exploring Alternatives for Diagnosing Battery and Alternator Issues

In the automotive industry, diagnosing electrical issues such as whether a vehicle’s problem lies with the battery or the alternator is crucial for efficient maintenance and repair. While traditional methods offer effective solutions, various alternative technologies and methodologies can enhance diagnostic accuracy, reduce costs, and streamline processes. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | How To Tell If Its Battery Or Alternator | Battery Tester | Diagnostic Scan Tool |

|---|---|---|---|

| Performance | High accuracy in diagnosing specific issues | Good for battery health checks | Provides comprehensive diagnostics for various systems |

| Cost | Minimal cost if DIY; moderate if professional help is needed | Low to moderate (typically $20-$100) | Moderate to high ($100-$1,000) depending on features |

| Ease of Implementation | Requires basic tools and knowledge | Simple, user-friendly | Requires training and familiarity with software |

| Maintenance | Low maintenance if tools are kept in good condition | Minimal; occasional battery replacement | Software updates needed; requires care to avoid damage |

| Best Use Case | Ideal for immediate troubleshooting of starting issues | Best for routine battery checks | Suitable for comprehensive vehicle diagnostics beyond just battery/alternator |

Detailed Breakdown of Alternatives

1. Battery Tester: Is it a Practical Solution?

A battery tester is an effective tool for assessing battery health. It measures voltage and can perform load tests to determine if the battery can hold a charge. The primary advantage of a battery tester is its affordability and ease of use. Most testers are portable and require minimal setup, making them accessible for both professionals and DIY enthusiasts. However, while it provides valuable insights into battery performance, it does not diagnose alternator issues, which can lead to incomplete assessments. Thus, while it’s a practical choice for battery health monitoring, it lacks the comprehensive diagnostic capabilities needed for complete electrical system analysis.

2. Diagnostic Scan Tool: A Comprehensive Alternative?

Diagnostic scan tools offer a broader scope of vehicle diagnostics, allowing users to assess various systems, including the electrical system, engine, and transmission. These tools can identify error codes and provide real-time data, making them invaluable for a complete vehicle health assessment. The main advantage of using a scan tool is its ability to pinpoint issues across multiple components, not just the battery or alternator. However, the cost can be prohibitive for smaller businesses, and there is a steeper learning curve involved in effectively utilizing these tools. For organizations that require detailed diagnostics and have the budget for it, a diagnostic scan tool can be an excellent investment.

Conclusion: How to Choose the Right Solution for Your Needs

When considering how to diagnose battery or alternator issues, B2B buyers must assess their operational requirements, budget, and the level of diagnostic detail needed. For quick checks and immediate troubleshooting, traditional methods like testing the battery directly may suffice. In contrast, businesses looking for comprehensive insights into vehicle performance should consider investing in diagnostic scan tools. Ultimately, the choice will depend on the balance between cost, ease of use, and the depth of diagnostics required to maintain operational efficiency in their fleet or service offerings.

Essential Technical Properties and Trade Terminology for how to tell if its battery or alternator

What Are the Key Technical Properties to Consider When Diagnosing Battery or Alternator Issues?

Understanding the essential technical properties of batteries and alternators is crucial for B2B buyers, particularly those in automotive supply chains. Here are some critical specifications to consider:

-

Voltage Output

Batteries typically operate at a nominal voltage of 12 volts, while alternators produce between 13 and 14.5 volts during operation. This voltage range is vital for ensuring that the vehicle’s electrical systems function correctly. B2B buyers should prioritize products that meet these voltage specifications to maintain compatibility with standard automotive systems. -

Amperage Rating

The amperage output of alternators can vary significantly, typically ranging from 130 to 200 amps for passenger vehicles, with some high-performance models exceeding 400 amps. Understanding the amperage requirements is essential for applications with high electrical demand, such as vehicles equipped with advanced infotainment systems or heavy electrical loads. Buyers should consider the specific amperage needs of their vehicles to avoid underperformance or damage. -

Cold Cranking Amps (CCA)

CCA measures a battery’s ability to start an engine in cold temperatures. It is particularly important in regions with extreme weather conditions. A higher CCA rating indicates better performance in cold starts. B2B buyers must evaluate CCA ratings when selecting batteries for climates that experience low temperatures, ensuring reliability in various operating conditions. -

State of Charge (SoC)

This property refers to the current charge level of a battery expressed as a percentage of its capacity. Regular monitoring of SoC is critical for battery longevity and performance. For B2B buyers, understanding SoC can facilitate better inventory management and maintenance schedules, reducing the risk of unexpected failures. -

Cycle Life

Cycle life indicates how many complete charge and discharge cycles a battery can undergo before its capacity falls below a certain threshold. Batteries with a longer cycle life are more cost-effective over time. B2B buyers should consider cycle life when sourcing batteries for applications where frequent discharges are expected.

What Are Common Trade Terms Related to Battery and Alternator Diagnostics?

Familiarity with industry-specific terminology enhances communication and decision-making for B2B buyers. Here are some key terms:

Illustrative image related to how to tell if its battery or alternator

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of batteries and alternators, sourcing OEM parts ensures compatibility and reliability, which is critical for maintaining vehicle performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to optimize their inventory and manage costs effectively. Buyers should negotiate MOQs that align with their operational needs without overcommitting capital. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. This process is essential for comparing prices and ensuring competitive sourcing of batteries and alternators, allowing for informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the shipping process. Understanding these terms is vital for B2B transactions, as they affect pricing, risk management, and logistics planning when importing or exporting automotive parts. -

Load Test

A load test assesses a battery’s ability to deliver current under a specific load for a defined period. This testing is crucial for diagnosing battery health and determining whether replacement is necessary. B2B buyers should ensure that suppliers can provide load testing services or results to guarantee product reliability.

By leveraging these technical properties and trade terms, B2B buyers can make more informed decisions when diagnosing battery or alternator issues, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the how to tell if its battery or alternator Sector

What Are the Current Market Dynamics Affecting Battery and Alternator Sourcing?

The global market for automotive batteries and alternators is experiencing significant transformations driven by technological advancements, shifting consumer preferences, and regulatory changes. Key drivers include the increasing adoption of electric vehicles (EVs) and hybrid technologies, which are reshaping the demand for both traditional batteries and alternative energy storage solutions. Additionally, the growing trend of smart automotive technologies necessitates high-performance alternators capable of supporting a variety of electrical systems.

In regions like Africa, South America, and the Middle East, where automotive markets are expanding rapidly, international B2B buyers must be attuned to local sourcing challenges and opportunities. For instance, the availability of quality components can vary widely, necessitating partnerships with reliable suppliers that can ensure both product quality and timely delivery. European markets, particularly Germany, are setting benchmarks for quality standards and sustainability, influencing sourcing decisions globally.

Emerging technologies, such as battery management systems (BMS) and advanced diagnostic tools, are also becoming essential in assessing battery and alternator health, allowing for more informed purchasing decisions. As B2B buyers navigate these complexities, understanding the interplay between market dynamics and sourcing trends will be crucial for maintaining competitive advantage.

How Are Sustainability and Ethical Sourcing Shaping the Battery and Alternator Market?

Sustainability has become a cornerstone of modern B2B sourcing, particularly in the automotive sector. The environmental impact of battery production, especially with lead-acid and lithium-ion batteries, is significant, prompting buyers to seek suppliers who prioritize eco-friendly practices. Ethical sourcing is increasingly important, as companies are held accountable for their supply chains. This includes ensuring that raw materials are sourced responsibly, minimizing carbon footprints, and adhering to fair labor practices.

For B2B buyers in this sector, certifications such as ISO 14001 for environmental management and responsible sourcing certifications can provide assurance of a supplier’s commitment to sustainable practices. Additionally, the use of recyclable materials and innovations in battery chemistry that reduce harmful substances are becoming critical factors in supplier evaluations.

As the demand for electric vehicles grows, the sourcing of sustainable battery technologies is also gaining traction. Buyers are encouraged to collaborate with manufacturers who are investing in green technologies, such as solid-state batteries, which promise enhanced performance with lower environmental impact. In this evolving landscape, aligning sourcing strategies with sustainability goals can enhance brand reputation and meet regulatory requirements.

What Is the Brief History of Battery and Alternator Technologies?

The evolution of battery and alternator technologies has been marked by significant advancements that reflect broader trends in automotive engineering. The first automotive batteries were simple lead-acid types, developed in the late 19th century, primarily serving the purpose of starting the engine and powering basic electrical systems. Over the decades, innovations such as sealed lead-acid and lithium-ion batteries emerged, offering improved performance and longevity.

The alternator, introduced in the 1960s, replaced the earlier generator systems, providing a more efficient means of generating electricity for vehicle operations. This shift was crucial as it allowed for higher electrical demands driven by the proliferation of electronic components in modern vehicles.

Today, the focus is on developing batteries and alternators that not only meet increasing energy demands but also adhere to sustainability standards. The integration of smart technologies and enhanced diagnostics is paving the way for the next generation of automotive electrical systems, ensuring that B2B buyers have access to reliable, efficient, and environmentally responsible products.

Illustrative image related to how to tell if its battery or alternator

Frequently Asked Questions (FAQs) for B2B Buyers of how to tell if its battery or alternator

-

How can I determine if my vehicle’s issue is with the battery or the alternator?

To identify whether the problem lies with the battery or the alternator, start by checking for symptoms. A dead battery often results in a complete failure to start, accompanied by a clicking sound. In contrast, alternator issues might manifest as dimming lights or electrical accessories behaving erratically. You can test the battery’s voltage with a multimeter; a healthy battery should read around 12.6 volts. For the alternator, check the voltage while the engine is running; it should be between 13 and 14.5 volts. If it fluctuates or drops below 13 volts, the alternator may be faulty. -

What are the key characteristics to look for in a battery or alternator supplier?

When sourcing a battery or alternator supplier, consider their reputation, product range, and compliance with international standards. Look for suppliers with certifications like ISO or those compliant with local regulations in your target market. Additionally, evaluate their supply chain reliability, including lead times and logistics capabilities, especially if you’re operating across regions like Africa or South America. Customer service and after-sales support are also critical; a supplier should provide technical assistance and warranty services to ensure product reliability. -

What is the best way to vet potential suppliers for automotive batteries and alternators?

Vetting potential suppliers involves conducting thorough research and due diligence. Start by checking their business credentials, reviews, and industry reputation. Request product samples to evaluate quality firsthand and seek references from other B2B buyers. Additionally, inquire about their manufacturing processes and quality assurance measures. If possible, visit their facilities or use third-party inspection services to verify compliance with your quality standards and regulatory requirements, ensuring they can meet your needs effectively. -

How do minimum order quantities (MOQs) affect my sourcing strategy?

Minimum order quantities (MOQs) can significantly impact your sourcing strategy, especially for batteries and alternators, which can be bulky and costly to ship. Understanding the MOQ set by suppliers helps you gauge whether you can meet demand without overcommitting resources. If MOQs are too high, consider negotiating for smaller batches or exploring multiple suppliers to diversify your risk. Additionally, evaluate your inventory management practices to ensure you can handle larger orders without incurring excess costs or storage issues. -

What payment terms should I negotiate with battery and alternator suppliers?

When negotiating payment terms with suppliers, aim for conditions that enhance cash flow while minimizing risk. Common terms include upfront payments, net 30/60/90 days, or letters of credit. Assess the supplier’s reliability and your relationship history when determining how much credit to request. It’s also beneficial to explore options for discounts on early payments or bulk purchases. Ensure that all payment terms are clearly outlined in the contract to avoid misunderstandings and protect both parties. -

How can I ensure quality assurance when purchasing automotive batteries and alternators?

To ensure quality assurance when sourcing batteries and alternators, require suppliers to provide detailed documentation, including certifications and test reports. Implement a quality control process that includes pre-shipment inspections and random sampling of products upon arrival. Establish clear specifications for product performance and durability, and maintain open communication with suppliers regarding quality standards. Additionally, consider forming partnerships with suppliers that have a proven track record of reliability and customer satisfaction. -

What logistics considerations should I be aware of when importing batteries and alternators?

Logistics plays a crucial role in importing batteries and alternators, particularly due to their weight and potential hazardous materials. Be aware of shipping regulations and customs requirements in your region, especially in Africa or South America. Work closely with your supplier to determine the best shipping methods and routes, considering factors such as cost, transit time, and reliability. Additionally, ensure you have appropriate insurance coverage for your shipments to mitigate risks associated with loss or damage during transit. -

What are the common customization options available for automotive batteries and alternators?

Many suppliers offer customization options for automotive batteries and alternators, including variations in capacity, size, and terminal configurations. Custom branding or labeling can also be requested to align with your company’s identity. When discussing customization, clearly communicate your specific requirements and target applications, as this helps suppliers tailor their offerings to meet your needs. Ensure that any customized products still adhere to safety and performance standards relevant to your market, enhancing your brand’s reputation and customer satisfaction.

Top 3 How To Tell If Its Battery Or Alternator Manufacturers & Suppliers List

1. Reddit – Automotive Battery Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The battery provides power to all electronics on board, including the starter. The alternator charges the battery when the engine is running. The starter uses power from the battery to turn over the engine. A dead battery is a likely issue if there is no power at all. A failing alternator may be indicated by a battery light on the dashboard while the engine is running.

2. Nationwide – Alternator & Battery Insights

Domain: blog.nationwide.com

Registered: 1994 (31 years)

Introduction: Alternator: Powers the car when the engine is running, lasts the lifetime of the car but can wear out. Signs of a bad alternator include dim interior lights, dim or overly bright headlights, growling noises, and burning smells. Battery: Stores power, starts the engine, delivers electricity to the ignition system, works with the alternator, and regulates voltage. Signs of a bad battery include dim …

3. Alternator Testing – Risks of Removing Battery Lead

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: The text discusses a technique to test an alternator by removing a 12V battery lead while the vehicle is running. It explains that this method is not recommended as it can damage the vehicle’s electronics and the alternator itself. The battery plays a crucial role in filtering spikes and transients, and removing it can lead to potential damage to the car’s ECU and other components. A safer alterna…

Strategic Sourcing Conclusion and Outlook for how to tell if its battery or alternator

In conclusion, understanding the distinction between battery and alternator issues is crucial for maintaining vehicle reliability and reducing operational downtime. Key indicators such as starting difficulties, fluctuating voltage readings, and dimming lights can guide diagnostics effectively. B2B buyers should prioritize sourcing high-quality batteries and alternators, ensuring they meet specific performance requirements tailored to their vehicle fleets.

Strategic sourcing not only streamlines procurement processes but also enhances supply chain resilience, especially in regions like Africa, South America, the Middle East, and Europe. By investing in reliable components and leveraging local partnerships, businesses can mitigate risks associated with vehicle failures and improve overall operational efficiency.

Looking ahead, we encourage international buyers to stay informed about advancements in battery and alternator technologies, as innovations in this sector can lead to more efficient and sustainable solutions. Engage with trusted suppliers and explore options that align with your long-term strategic goals. This proactive approach will enable you to maintain a competitive edge in the ever-evolving automotive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how to tell if its battery or alternator