Introduction: Navigating the Global Market for what is an alternator car

In the rapidly evolving automotive landscape, understanding what an alternator car entails is crucial for international B2B buyers navigating the complexities of vehicle sourcing. An alternator not only powers essential electrical components but also ensures the seamless operation of the vehicle’s battery, making it a vital piece of technology for combustion engine vehicles. As businesses look to procure reliable vehicles for various applications, recognizing the role of alternators can significantly influence purchasing decisions, particularly in regions like Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Germany.

This comprehensive guide delves into the intricacies of alternators, covering their types, applications, and the nuances of supplier vetting. It also addresses key factors such as installation costs, maintenance considerations, and the implications of alternator performance on overall vehicle efficiency. By equipping B2B buyers with the knowledge needed to assess alternator specifications and their impact on vehicle reliability, this guide empowers informed purchasing decisions.

With an authoritative and solution-oriented approach, we aim to enhance your understanding of alternators in the automotive sector, ensuring that you can confidently source vehicles that meet the demands of your business while optimizing operational efficiency.

Table Of Contents

- Top 3 What Is An Alternator Car Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is an alternator car

- Understanding what is an alternator car Types and Variations

- Key Industrial Applications of what is an alternator car

- 3 Common User Pain Points for ‘what is an alternator car’ & Their Solutions

- Strategic Material Selection Guide for what is an alternator car

- In-depth Look: Manufacturing Processes and Quality Assurance for what is an alternator car

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is an alternator car’

- Comprehensive Cost and Pricing Analysis for what is an alternator car Sourcing

- Alternatives Analysis: Comparing what is an alternator car With Other Solutions

- Essential Technical Properties and Trade Terminology for what is an alternator car

- Navigating Market Dynamics and Sourcing Trends in the what is an alternator car Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is an alternator car

- Strategic Sourcing Conclusion and Outlook for what is an alternator car

- Important Disclaimer & Terms of Use

Understanding what is an alternator car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Alternator | Uses electromagnetic induction; common in most vehicles. | Standard passenger vehicles, light trucks | Pros: Reliable, widely available. Cons: Can be less efficient at low RPMs. |

| High-Output Alternator | Designed for high electrical demands; larger output capacity. | Performance vehicles, commercial trucks | Pros: Supports heavy electrical loads. Cons: Higher cost, may require modifications. |

| Smart Alternator | Incorporates advanced electronics for improved efficiency. | Hybrid and electric vehicles | Pros: Optimizes battery life, energy-efficient. Cons: More complex, potentially costly repairs. |

| Brushless Alternator | Eliminates brushes for reduced wear and longer lifespan. | High-performance and luxury vehicles | Pros: Longer lifespan, less maintenance. Cons: Higher initial cost, specific applications. |

| Dual-Voltage Alternator | Provides both 12V and 24V output for versatile applications. | Heavy machinery, fleet vehicles | Pros: Versatile power supply. Cons: More complex, potentially heavier design. |

What Are the Characteristics of Conventional Alternators?

Conventional alternators are the standard type found in most vehicles. They operate using electromagnetic induction to convert mechanical energy from the engine into electrical energy. These alternators are suitable for typical passenger vehicles and light trucks where electrical demands are moderate. When considering a purchase, B2B buyers should evaluate the vehicle’s electrical load requirements and ensure compatibility with standard automotive systems. Their reliability and widespread availability make them a cost-effective choice for many businesses.

How Do High-Output Alternators Meet Increased Electrical Demands?

High-output alternators are specifically designed to cater to vehicles with significant electrical demands, such as performance cars and commercial trucks. They provide a larger output capacity, making them ideal for systems that require more power, such as aftermarket sound systems or additional lighting. B2B buyers should consider the specific power needs of their fleet or vehicles when opting for high-output models. While they offer enhanced performance, the higher cost and potential need for vehicle modifications are important factors to weigh.

What Are the Advantages of Smart Alternators for Modern Vehicles?

Smart alternators utilize advanced electronics to optimize energy efficiency and battery life, making them particularly suitable for hybrid and electric vehicles. They adjust the charging rate based on the battery’s state of charge and the vehicle’s electrical load. For B2B buyers in the automotive sector, investing in smart alternators can lead to long-term cost savings and improved vehicle performance. However, their complexity may result in higher repair costs, which should be factored into purchasing decisions.

Why Choose Brushless Alternators for Luxury and Performance Vehicles?

Brushless alternators are designed without brushes, resulting in reduced wear and a longer lifespan. This makes them particularly appealing for high-performance and luxury vehicles where reliability is paramount. B2B buyers should consider the long-term maintenance costs and the specific applications when selecting brushless models. While they can be more expensive initially, the reduced maintenance needs may justify the investment for businesses focused on premium vehicle performance.

How Do Dual-Voltage Alternators Offer Versatility?

Dual-voltage alternators provide both 12V and 24V outputs, making them suitable for a wide range of applications, including heavy machinery and fleet vehicles. Their versatility allows businesses to power various systems without needing multiple alternators, streamlining operations. B2B buyers should assess the specific power requirements of their equipment to determine if a dual-voltage alternator is the right fit. While they offer flexibility, the added complexity and potential weight may be considerations in their overall design and functionality.

Key Industrial Applications of what is an alternator car

| Industry/Sector | Specific Application of what is an alternator car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of electric and hybrid vehicles | Enhances vehicle reliability and efficiency | Sourcing high-quality alternators that meet OEM standards |

| Transportation and Logistics | Fleet management for commercial vehicles | Reduces downtime and maintenance costs | Bulk purchasing options and warranty support |

| Renewable Energy | Integration in electric vehicle charging stations | Supports sustainable energy solutions | Compatibility with various vehicle models and charging systems |

| Mining and Construction | Use in heavy-duty machinery and vehicles | Ensures continuous operation in rugged environments | Durability and high-performance specifications |

| Agriculture | Powering agricultural machinery | Increases productivity and efficiency in farming tasks | Availability of replacement parts and service support |

How is ‘what is an alternator car’ utilized in Automotive Manufacturing?

In the automotive manufacturing sector, alternators are pivotal for both electric and hybrid vehicles. They convert mechanical energy generated by the engine into electrical energy, ensuring that all electrical components function optimally. This is particularly important in modern vehicles where electronic systems are extensively used. Manufacturers must ensure the sourcing of high-quality alternators that comply with OEM standards to maintain vehicle reliability and efficiency, thus enhancing brand reputation and customer satisfaction.

What role does ‘what is an alternator car’ play in Transportation and Logistics?

In the transportation and logistics industry, commercial fleets rely heavily on the functionality of alternators to maintain operational efficiency. A well-functioning alternator powers essential vehicle systems, reducing the risk of breakdowns and costly downtime. Fleet managers should consider bulk purchasing options for alternators, as well as warranty support, to minimize maintenance costs and ensure that vehicles remain in service. This proactive approach can lead to significant savings and improved service delivery.

How does ‘what is an alternator car’ contribute to Renewable Energy initiatives?

The renewable energy sector is increasingly integrating alternators in electric vehicle (EV) charging stations. These systems require reliable energy conversion to support the growing demand for EVs. By employing high-performance alternators, businesses can enhance their sustainability initiatives, contributing to a cleaner environment. Buyers in this sector must ensure compatibility with various vehicle models and charging systems to maximize the effectiveness of their installations, thus supporting broader energy transition goals.

In what ways is ‘what is an alternator car’ essential in Mining and Construction?

Heavy-duty machinery used in mining and construction often relies on robust alternators to ensure continuous operation in harsh conditions. These vehicles require alternators that can withstand extreme environments while providing consistent electrical output. Companies should prioritize sourcing durable alternators with high-performance specifications to minimize operational disruptions. This ensures that machinery remains functional, thereby enhancing productivity and safety on job sites.

What benefits does ‘what is an alternator car’ provide in Agriculture?

In agriculture, alternators are crucial for powering various machinery, including tractors and harvesters. A reliable alternator ensures that these machines operate efficiently, which directly impacts productivity in farming operations. Agricultural businesses should focus on the availability of replacement parts and service support when sourcing alternators, as this can significantly reduce downtime during critical planting and harvesting seasons. By ensuring that their equipment is always operational, farmers can maximize yield and profitability.

3 Common User Pain Points for ‘what is an alternator car’ & Their Solutions

Scenario 1: Difficulty Identifying Alternator vs. Battery Issues

The Problem: B2B buyers, particularly fleet managers and automotive service providers, often encounter challenges in diagnosing electrical issues within vehicles. When a vehicle fails to start or exhibits dim lighting, it can be unclear whether the problem lies with the alternator or the battery. This uncertainty can lead to unnecessary repairs, increased downtime, and potential losses in productivity and revenue.

The Solution: To mitigate this issue, implement a systematic diagnostic approach. First, educate your team on the signs of a failing alternator versus a failing battery. For instance, if the vehicle’s headlights are dim when the engine is off, the battery may be at fault. Conversely, if the headlights brighten upon starting the vehicle but then dim while running, it is likely a failing alternator. Investing in diagnostic tools, such as a multimeter, can streamline this process, allowing for accurate voltage readings to determine which component requires service. Additionally, regular training on electrical systems can enhance your team’s proficiency in identifying and resolving these issues quickly, thus minimizing downtime.

Scenario 2: High Replacement Costs Due to Poor Quality Parts

The Problem: B2B buyers frequently face the issue of high costs associated with alternator replacements due to the procurement of low-quality parts. This is particularly relevant for international buyers in regions with limited access to reputable suppliers. Poor-quality alternators can fail prematurely, leading to repeated replacements, increased labor costs, and potential disruptions in operations, especially for businesses relying on vehicle fleets.

Illustrative image related to what is an alternator car

The Solution: Establish strong partnerships with reputable manufacturers and suppliers that specialize in high-quality automotive parts. Conduct thorough research to identify suppliers who provide warranties and have a proven track record of reliability. Consider leveraging bulk purchasing agreements to obtain better pricing on quality alternators. Additionally, implement a robust quality assurance process for incoming parts, including inspections and testing, to ensure that only top-tier components are used in your vehicle maintenance. This proactive approach will not only reduce long-term costs but also enhance the overall reliability of your fleet.

Scenario 3: Lack of Knowledge About Alternator Maintenance

The Problem: Many B2B buyers, especially those new to the automotive industry, may lack a comprehensive understanding of alternator maintenance and its importance. This knowledge gap can lead to neglecting regular inspections, resulting in unexpected failures that can disrupt business operations and incur costly repairs. For example, failing to recognize the signs of a failing alternator can lead to vehicle breakdowns at inopportune times.

The Solution: Implement a preventive maintenance program that includes regular inspections of the alternator and associated components. Create a checklist that outlines key indicators of alternator health, such as unusual noises, dashboard warning lights, and irregular electrical performance in accessories. Additionally, develop training modules for staff to enhance their understanding of the alternator’s role and maintenance needs. By fostering a culture of proactive care, you can minimize the risk of unexpected failures and ensure that vehicles remain operational. Furthermore, consider leveraging digital tools and platforms to track maintenance schedules and alerts, enhancing the overall efficiency of your fleet management.

Strategic Material Selection Guide for what is an alternator car

What Materials Are Commonly Used in Alternator Cars?

When considering the materials used in alternators for cars, several key materials stand out due to their unique properties and performance characteristics. Each material offers distinct advantages and disadvantages that can significantly impact the performance and longevity of the alternator, making them crucial for B2B buyers to understand.

What Are the Key Properties of Aluminum in Alternators?

Aluminum is a popular choice for alternator housings and components due to its lightweight and excellent corrosion resistance. Its thermal conductivity allows for efficient heat dissipation, which is critical in automotive applications where heat buildup can lead to component failure. Aluminum typically performs well under moderate temperatures and pressures, making it suitable for most automotive environments.

Pros: Aluminum is lightweight, which can enhance fuel efficiency and reduce overall vehicle weight. It is also relatively inexpensive and easy to manufacture, allowing for cost-effective production methods.

Cons: While aluminum is resistant to corrosion, it can be less durable than other metals under extreme mechanical stress. It may not perform well in high-temperature applications without proper alloying.

Impact on Application: Aluminum’s compatibility with various automotive fluids and its ability to withstand typical automotive conditions make it a reliable choice for alternators.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as DIN or ASTM for aluminum alloys used in automotive applications.

Illustrative image related to what is an alternator car

How Does Copper Enhance Alternator Performance?

Copper is often used in the windings of alternators due to its excellent electrical conductivity. This property allows for efficient energy transfer, which is essential for the alternator’s function of converting mechanical energy into electrical energy. Copper can withstand high temperatures, making it suitable for the heat generated during operation.

Pros: The high conductivity of copper results in lower energy losses, improving overall efficiency. It is also highly durable and resistant to corrosion when properly treated.

Cons: Copper is more expensive than aluminum, which can increase the overall cost of the alternator. Additionally, it is heavier, which may not align with the trend towards lightweight automotive components.

Impact on Application: Copper’s compatibility with high electrical loads makes it ideal for alternators that power multiple electronic accessories in modern vehicles.

Considerations for International Buyers: Buyers should be aware of the global copper market fluctuations and ensure that their suppliers meet relevant international standards for electrical components.

What Role Does Steel Play in Alternator Manufacturing?

Steel is commonly used for the structural components of alternators, including the casing and brackets. Its strength and durability make it suitable for withstanding mechanical stresses encountered during vehicle operation. Steel also offers good resistance to wear and tear, which is essential for components that experience frequent movement.

Pros: Steel is highly durable and can withstand high mechanical loads, making it ideal for structural components. It is also relatively cost-effective compared to other materials.

Cons: Steel is heavier than aluminum and may not offer the same level of corrosion resistance unless treated. This can lead to increased weight in the vehicle, affecting fuel efficiency.

Impact on Application: Steel’s strength ensures that the alternator can endure the rigors of automotive environments, but its weight may be a consideration for performance-focused designs.

Illustrative image related to what is an alternator car

Considerations for International Buyers: Buyers should consider the specific grades of steel used and ensure they comply with local standards, such as JIS in Japan or ASTM in the U.S.

Why Is Plastic Used in Alternator Components?

Plastic is increasingly being used for non-structural components of alternators, such as covers and insulators. It offers excellent resistance to corrosion and can be molded into complex shapes, which is beneficial for design flexibility.

Pros: Plastic is lightweight and can reduce the overall weight of the alternator. It is also resistant to many automotive fluids, enhancing durability.

Cons: Plastic may not withstand high temperatures as well as metals and can degrade over time when exposed to UV light or extreme heat.

Impact on Application: While plastic components can lower weight, their performance in high-temperature environments must be carefully considered.

Considerations for International Buyers: Buyers should ensure that the plastics used meet relevant automotive safety and performance standards, particularly in regions with stringent regulations.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for what is an alternator car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings and structural components | Lightweight and corrosion-resistant | Less durable under extreme stress | Medium |

| Copper | Electrical windings | High electrical conductivity | Higher cost and weight | High |

| Steel | Structural components and brackets | Highly durable and cost-effective | Heavier and less corrosion-resistant | Low |

| Plastic | Covers and insulators | Lightweight and corrosion-resistant | May degrade under high temperatures | Low |

This analysis provides B2B buyers with a comprehensive understanding of the materials used in alternators, helping them make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for what is an alternator car

What Are the Main Stages of Manufacturing an Alternator for Cars?

The manufacturing process of an automotive alternator involves several critical stages, each essential for ensuring the final product meets stringent quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Alternator Manufacturing?

The first step in manufacturing an alternator is material preparation. This involves sourcing high-quality raw materials, such as aluminum for the casing, copper for the windings, and various plastics for insulation. Suppliers must adhere to international standards like ISO 9001 to ensure material quality.

Once materials are sourced, they undergo rigorous quality checks to confirm their compliance with specifications. This includes verifying chemical compositions and physical properties, which are crucial for the alternator’s performance and longevity.

Illustrative image related to what is an alternator car

What Forming Techniques Are Used in Alternator Production?

The forming stage encompasses the shaping of raw materials into usable components. Key techniques include die casting for the aluminum housing and machining for precision parts such as the rotor and stator.

Die casting allows manufacturers to create complex shapes with high dimensional accuracy, which is essential for optimal fit and function. Machining processes, such as CNC milling, are employed to refine components, ensuring they meet precise tolerances.

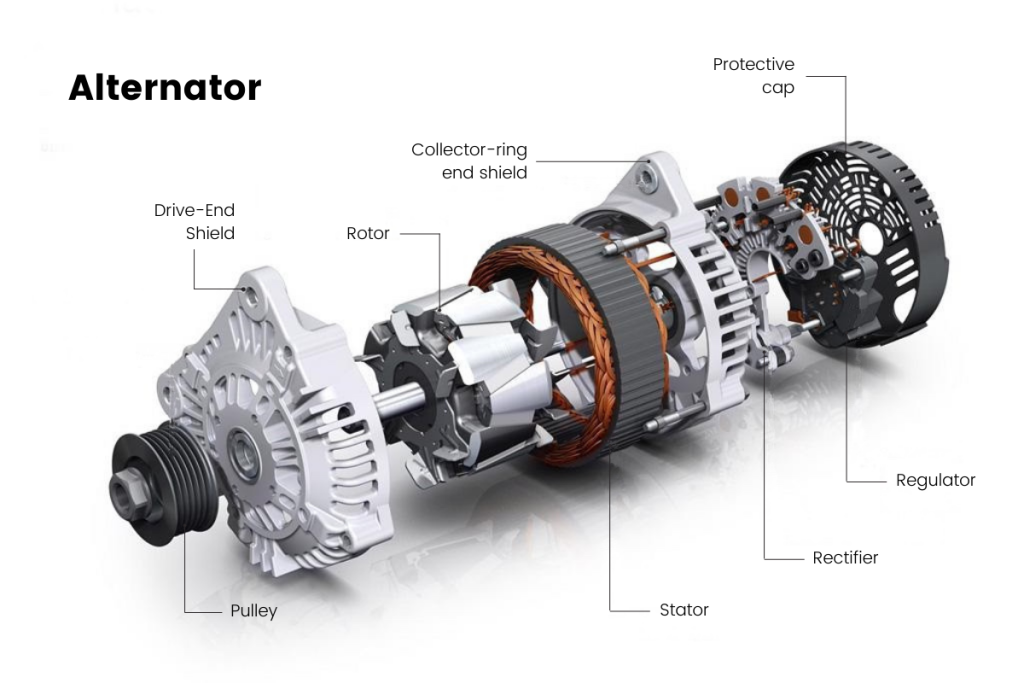

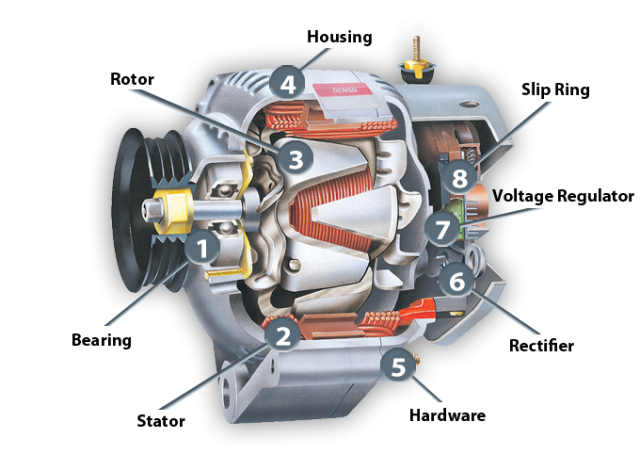

How Is the Assembly Process Conducted for Alternators?

During the assembly phase, individual components are brought together to create the alternator. This step typically involves several sub-assemblies, including the rotor, stator, voltage regulator, and housing.

Automated assembly lines often enhance efficiency and consistency. Skilled workers oversee the process, ensuring that each component is correctly installed and connected. Quality control checkpoints are integrated into the assembly line to monitor each phase of the process, reducing the likelihood of defects in the final product.

Illustrative image related to what is an alternator car

What Finishing Techniques Are Applied to Alternators?

Finishing processes include surface treatments, painting, and testing. Surface treatments enhance corrosion resistance and durability, while painting provides an aesthetic finish and additional protection.

Once the alternator is assembled, it undergoes functional testing to ensure it meets performance specifications. This includes checks for output voltage, noise levels, and overall efficiency.

What Quality Control Standards Are Relevant for Alternator Manufacturing?

Quality assurance is crucial in alternator manufacturing, as it directly impacts reliability and performance. International standards such as ISO 9001 provide a framework for quality management systems, ensuring consistent product quality.

Illustrative image related to what is an alternator car

In addition to ISO standards, industry-specific certifications such as CE marking in Europe and API standards in the Middle East may apply. These certifications indicate that products meet required safety and environmental criteria, which is especially important for B2B buyers in regulated markets.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with several critical checkpoints, including:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter production. Ensuring that materials meet specifications is vital to prevent defects downstream.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves continuous monitoring of processes. This includes measuring dimensions, inspecting assembly techniques, and conducting interim tests to catch issues early.

-

Final Quality Control (FQC): After assembly, the final product undergoes comprehensive testing to verify that it meets performance standards. This may involve stress tests, electrical testing, and operational checks to ensure the alternator functions correctly under load.

What Common Testing Methods Are Used to Ensure Alternator Quality?

Several testing methods are utilized to ensure the quality and reliability of alternators:

-

Electrical Testing: This involves verifying output voltage and current under various loads to ensure the alternator operates within specified parameters.

-

Thermal Testing: Alternators are subjected to high-temperature conditions to test their performance and durability, simulating real-world operating conditions.

-

Vibration Testing: This test assesses the alternator’s ability to withstand operational vibrations, ensuring that it remains functional over its lifespan.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, ensuring supplier quality control is paramount. Here are several strategies:

Illustrative image related to what is an alternator car

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to evaluate their manufacturing processes and quality control measures.

-

Quality Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their QC practices, including testing methodologies and historical performance metrics.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can occur at various stages of production, from raw material sourcing to final assembly.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers must navigate various quality control nuances, including differing regional standards and regulations. For instance, while CE marking is crucial for products sold in Europe, buyers in the Middle East may prioritize compliance with local standards such as GCC regulations.

Understanding these nuances is vital for ensuring that products not only meet quality expectations but also comply with regulatory requirements in the buyer’s market. Buyers should maintain open communication with suppliers to clarify these requirements and ensure alignment with their quality standards.

In conclusion, the manufacturing and quality assurance processes for automotive alternators are intricate and crucial for ensuring product reliability and performance. For B2B buyers, understanding these processes, standards, and verification methods is essential for making informed purchasing decisions in a competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is an alternator car’

To assist B2B buyers in understanding and sourcing alternator components effectively, this guide provides a clear checklist for navigating the procurement process. An alternator is a crucial element in a vehicle’s electrical system, responsible for converting mechanical energy into electrical energy, thus powering various electrical components. Ensuring you procure quality alternators is vital for vehicle performance and longevity.

Illustrative image related to what is an alternator car

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical requirements for the alternators you need. Consider factors such as voltage output, amperage, and compatibility with specific vehicle models. This clarity will streamline your sourcing process and ensure that you find products that meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in automotive components, particularly alternators. Look for companies with a strong reputation in the industry, positive customer reviews, and a proven track record of reliability. This step is essential to ensure that you partner with suppliers who deliver quality products consistently.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold necessary industry certifications, such as ISO or TS16949. These certifications indicate adherence to quality management standards and can significantly reduce the risk of receiving subpar components. Inquire about their quality assurance processes to ensure they meet international standards.

Step 4: Request Samples for Testing

Before placing a large order, request samples of the alternators. Testing these samples will allow you to assess their performance, durability, and compatibility with your vehicles. This step is crucial to ensure that the products meet your quality standards and operational requirements.

Step 5: Analyze Pricing Structures

Compare pricing structures from different suppliers to determine the best value for your investment. While lower prices can be attractive, consider the total cost of ownership, including potential shipping fees, warranty terms, and after-sales support. This comprehensive analysis will help you make an informed decision.

Step 6: Inquire About Warranty and Support

Always ask about warranty options and the level of customer support provided by the supplier. A robust warranty can protect your investment against manufacturing defects and performance issues. Additionally, responsive customer support will be invaluable if you encounter problems after the purchase.

Step 7: Establish Communication Channels

Maintain open lines of communication with your selected supplier throughout the procurement process. Clear communication can help resolve any issues quickly and ensure that you stay informed about order status, shipping times, and product updates. Building a strong relationship with your supplier can lead to better service and potential future collaborations.

By following these steps, B2B buyers can effectively navigate the procurement of alternators, ensuring they secure high-quality components that meet their operational needs.

Comprehensive Cost and Pricing Analysis for what is an alternator car Sourcing

What Are the Key Cost Components for Sourcing Alternators in the Automotive Sector?

When sourcing alternators for vehicles, understanding the cost structure is crucial for international B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary materials used in alternator production include copper for windings, steel for the casing, and various magnets. The fluctuating prices of these raw materials can significantly impact overall costs. Buyers should consider sourcing from regions where these materials are abundant to mitigate costs.

-

Labor: Labor costs can vary greatly depending on the country of production. For instance, countries with lower labor costs, such as some in Southeast Asia, may offer competitive pricing compared to Europe or North America. However, the expertise and skill level of the workforce can affect the quality of the alternators produced.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities and maintenance. Efficient manufacturing processes can reduce overhead costs, which should be factored into pricing negotiations.

-

Tooling: The initial setup costs for manufacturing alternators can be substantial, particularly if custom tooling is required for specific designs or specifications. Understanding these costs is essential for assessing the total investment needed for sourcing.

-

Quality Control: Implementing strict QC measures is vital to ensure the reliability and performance of alternators. While these measures add to the cost, they can prevent costly failures and warranty claims in the long run.

-

Logistics: Shipping costs can vary based on distance, shipping method, and current freight rates. Buyers should evaluate logistics options and consider Incoterms that best suit their needs to manage these costs effectively.

-

Margin: Suppliers will include a profit margin in their pricing, which can be influenced by demand, competition, and market conditions. Understanding typical margins in different regions can aid in negotiations.

What Influences the Pricing of Alternators in International Markets?

Several factors influence the pricing of alternators, particularly for international buyers from regions such as Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Purchasing in larger quantities often results in lower per-unit costs. Buyers should assess their projected needs to negotiate favorable terms based on Minimum Order Quantities (MOQs).

-

Specifications and Customization: Customized alternators designed for specific vehicles may incur additional costs. Buyers should clarify their specifications upfront to receive accurate quotes.

-

Materials and Quality Certifications: The quality of materials used can affect both the performance and longevity of alternators. Buyers should inquire about quality certifications (e.g., ISO standards) to ensure they are sourcing reliable products.

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers may charge more but offer better quality assurance and after-sales support.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) can influence the total cost of ownership, including shipping and insurance. Understanding these terms is essential for effective budgeting.

What Are the Best Practices for Negotiating Alternator Prices?

For international B2B buyers, employing strategic negotiation tactics can lead to cost savings and better terms.

-

Understand the Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like shipping, duties, and potential warranty claims. A lower upfront cost may not always translate to savings if the product is of inferior quality.

-

Leverage Market Knowledge: Being informed about market rates and competitor pricing can strengthen your negotiation position. Researching typical price ranges for alternators in your target market can provide leverage.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and terms. Suppliers may be more willing to negotiate with repeat customers who demonstrate loyalty.

-

Consider Local Partnerships: In regions like Africa and South America, partnering with local distributors or manufacturers can reduce shipping costs and facilitate smoother transactions.

-

Timing and Flexibility: Be aware of seasonal trends in pricing and production schedules. Flexibility in order timing can sometimes lead to better pricing opportunities.

Conclusion

The sourcing of alternators involves a complex interplay of costs and pricing factors that vary by region and supplier. By understanding the intricacies of cost components and the influences on pricing, international B2B buyers can make informed decisions that optimize their sourcing strategies while ensuring quality and reliability in their automotive needs.

Alternatives Analysis: Comparing what is an alternator car With Other Solutions

Exploring Alternatives to Alternator Cars: A Comparative Analysis

In the automotive industry, the alternator plays a crucial role in powering a vehicle’s electrical systems. However, as technology evolves, alternative solutions have emerged that serve similar purposes. This section will compare traditional alternator cars with two viable alternatives: electric vehicles (EVs) and hybrid vehicles. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and specific use cases.

| Comparison Aspect | What Is An Alternator Car | Electric Vehicle (EV) | Hybrid Vehicle |

|---|---|---|---|

| Performance | Reliable power generation while driving; supports all electrical components. | Instant torque; quiet operation; zero emissions. | Combines gas and electric for improved fuel efficiency. |

| Cost | Typically lower initial cost; ongoing maintenance required. | Higher upfront cost; lower operating costs due to energy efficiency. | Moderate initial cost; fuel savings offset some costs. |

| Ease of Implementation | Widely available and compatible with existing infrastructure. | Requires charging infrastructure; limited range in some models. | Compatible with existing gas stations; dual power sources. |

| Maintenance | Regular checks required; lifespan of 7-10 years. | Minimal maintenance; fewer moving parts. | Requires maintenance for both gas and electric systems. |

| Best Use Case | Ideal for traditional combustion engine vehicles with reliable electrical needs. | Best for urban environments with access to charging stations. | Suitable for drivers seeking fuel efficiency without range anxiety. |

What Are the Pros and Cons of Electric Vehicles (EVs)?

Electric vehicles operate entirely on electricity, eliminating the need for an alternator. They offer exceptional performance due to instant torque and a smooth driving experience. Additionally, EVs have lower operating costs, as electricity is typically cheaper than gasoline and requires less maintenance due to fewer moving parts. However, the initial investment can be significantly higher, and charging infrastructure may be limited, particularly in rural areas. B2B buyers focusing on sustainability and long-term savings may find EVs appealing, especially if they operate in urban settings.

How Do Hybrid Vehicles Compare to Alternator Cars?

Hybrid vehicles combine a gasoline engine with an electric motor, allowing for improved fuel efficiency and lower emissions. They often use regenerative braking to recharge the battery, making them more efficient than traditional combustion vehicles. While hybrids can operate on gasoline alone, they also provide the benefits of electric power, particularly in stop-and-go traffic. The initial cost is moderate, and fuel savings can offset some expenses. However, maintenance can be more complex due to the dual systems, and the performance may not match that of a pure electric vehicle. B2B buyers looking for versatility and efficiency might find hybrids suitable for various driving conditions.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a vehicle solution, B2B buyers should consider their specific operational needs, budget constraints, and environmental impact goals. Traditional alternator cars remain a reliable choice for many businesses, especially those with established infrastructure and moderate driving requirements. However, electric and hybrid vehicles offer compelling alternatives for organizations aiming to enhance sustainability and reduce long-term operating costs. Ultimately, the choice will depend on factors such as the availability of charging stations, the typical driving range required, and the overall cost-benefit analysis for the business. By carefully evaluating these alternatives, buyers can make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for what is an alternator car

Understanding the technical specifications and terminology associated with alternators is crucial for B2B buyers in the automotive industry. This knowledge enables informed decision-making regarding procurement, maintenance, and partnerships.

What Are the Key Technical Properties of an Alternator?

What Specifications Should Buyers Consider for Alternators?

-

Output Voltage (V):

The output voltage of an alternator typically ranges from 12 to 14.5 volts. This specification is crucial as it indicates the alternator’s ability to charge the battery and power the vehicle’s electrical systems. A consistent output voltage ensures that all electrical components function optimally, reducing the risk of failures that could lead to costly repairs. -

Current Rating (Amperes):

This specification defines the maximum current the alternator can produce, generally ranging from 50A to 200A, depending on the vehicle’s electrical demands. Understanding the current rating helps buyers match the alternator to the specific requirements of different vehicle models, ensuring reliability and efficiency in power delivery. -

Material Grade:

Alternators are typically made from materials like aluminum or composite plastics for the casing, and copper for the windings. The choice of material affects durability, weight, and heat dissipation. Buyers should consider these aspects, especially in regions with extreme climates, as they impact the alternator’s performance and lifespan. -

Bearing Type:

Alternators may use ball bearings or sleeve bearings. Ball bearings generally provide longer life and better performance under high speeds, making them preferable for high-performance applications. Understanding bearing types can guide buyers in selecting alternators that align with the expected operational conditions of their vehicles. -

Regulator Type:

Alternators can be equipped with either internal or external voltage regulators. Internal regulators are more common due to their compact design and ease of installation. Buyers need to understand the differences to ensure compatibility with the vehicle’s electrical system. -

Heat Tolerance:

Alternators are rated for specific operating temperatures, usually between -40°C to 125°C. This specification is vital for buyers in hot or cold climates, as overheating can lead to premature failure. Ensuring the alternator can withstand local temperature extremes can enhance vehicle reliability.

Which Trade Terms Are Important in the Alternator Market?

What Are Common Jargon and Trade Terms Related to Alternators?

-

OEM (Original Equipment Manufacturer):

This term refers to companies that produce parts that are used in vehicles during the manufacturing process. OEM alternators are typically preferred for their guaranteed fit and performance, making them a reliable choice for buyers seeking quality replacements. -

MOQ (Minimum Order Quantity):

MOQ is the minimum number of units a supplier is willing to sell. Understanding MOQ helps buyers negotiate better pricing and manage inventory levels effectively, particularly when sourcing alternators for fleet vehicles. -

RFQ (Request for Quotation):

An RFQ is a document sent to suppliers requesting pricing and terms for specific products, such as alternators. Utilizing RFQs can streamline the procurement process, ensuring buyers receive competitive quotes and can make informed purchasing decisions. -

Incoterms (International Commercial Terms):

These are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international buyers to avoid misunderstandings and ensure smooth transactions when sourcing alternators from global suppliers. -

Aftermarket Parts:

These are parts not made by the OEM but designed to fit and function like the original. Understanding the difference between OEM and aftermarket parts helps buyers evaluate options based on cost, performance, and warranty considerations. -

Warranty Period:

The warranty period indicates how long the alternator is covered for defects or failures. This term is crucial for buyers assessing the long-term value and reliability of their investment in alternators, especially in competitive markets where warranty terms can vary significantly.

By grasping these technical specifications and trade terminologies, B2B buyers can navigate the complexities of the alternator market more effectively, ensuring they make informed decisions that enhance their operations and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the what is an alternator car Sector

What Are the Key Market Dynamics Driving the Alternator Car Sector?

The alternator car sector is experiencing significant growth, driven by several global trends. First, the increasing demand for vehicles with advanced electrical systems, including infotainment and safety features, has amplified the need for reliable alternators. In regions such as Africa and South America, where the automotive market is expanding rapidly, there is a rising demand for both new vehicles and replacement parts, particularly in urban areas where the concentration of vehicles is increasing.

Emerging technologies in the automotive sector, such as electric vehicles (EVs) and hybrid models, are also reshaping the landscape. While traditional combustion engines still dominate, manufacturers are investing in alternators designed for hybrid and electric vehicles to improve efficiency and battery life. This transition is evident in Europe, where stringent emissions regulations are pushing automakers toward more sustainable practices. International B2B buyers must stay informed about these technological advancements to ensure they source the right components that meet evolving regulatory standards.

Additionally, the global supply chain is becoming increasingly interconnected, prompting buyers to consider sourcing from a wider array of suppliers. Trends in digital procurement and e-commerce are facilitating easier access to global markets, allowing companies to compare prices and quality more effectively. In regions like the Middle East, where the automotive aftermarket is burgeoning, leveraging these technologies can enhance purchasing efficiency and reduce costs.

How Can Sustainability and Ethical Sourcing Impact the Alternator Car Sector?

Sustainability is becoming a pivotal concern within the automotive industry, particularly for B2B buyers. The environmental impact of manufacturing alternators, which often involves metals and other materials that can be harmful if not responsibly sourced, has led to a heightened emphasis on ethical supply chains. Buyers are increasingly looking for suppliers who can provide transparency regarding their sourcing practices, ensuring that materials are obtained responsibly and sustainably.

Incorporating ‘green’ certifications and materials into the supply chain can also significantly enhance a company’s market reputation. Certifications such as ISO 14001 for environmental management can act as a competitive differentiator, particularly in regions like Europe, where consumers are more environmentally conscious. By sourcing alternators that utilize recycled materials or are manufactured using energy-efficient processes, businesses can not only reduce their carbon footprint but also appeal to a growing segment of eco-aware customers.

Moreover, the shift towards electric and hybrid vehicles presents a unique opportunity for B2B buyers to invest in sustainable technologies. As the market for green vehicles expands, so does the potential for suppliers who focus on producing energy-efficient alternators. Buyers who prioritize sustainability in their sourcing strategies are likely to benefit from enhanced customer loyalty and increased market share.

What Is the Brief Evolution of the Alternator in the Automotive Sector?

The alternator has evolved significantly since its introduction in the early 20th century. Initially used in larger vehicles, the alternator became standard in most cars by the 1960s, replacing the less efficient generator systems. This shift was driven by the increasing electrical demands of modern vehicles, which required a more robust power supply to support advancements in automotive technology.

Over the decades, advancements in materials and technology have led to the development of more efficient and compact alternators. With the advent of hybrid and electric vehicles, the focus has shifted to optimizing alternator designs to work in tandem with advanced battery systems. This evolution reflects the automotive industry’s broader trend toward electrification and sustainability, making it essential for B2B buyers to stay updated on the latest innovations and market shifts.

In conclusion, navigating the complexities of the alternator car sector requires an understanding of market dynamics, a commitment to sustainability, and awareness of technological advancements. By prioritizing these factors, international B2B buyers can position themselves for success in a rapidly changing automotive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of what is an alternator car

-

How do I solve common alternator issues in vehicles?

To address alternator issues, first, identify symptoms such as dim lights, difficulty starting the vehicle, or warning lights on the dashboard. Conduct a thorough inspection of the alternator and related components like the battery and voltage regulator. If the alternator is faulty, consider replacing it with a quality part sourced from reputable suppliers. Regular maintenance checks can also help prevent unexpected failures. If you lack the expertise, engage a trusted local mechanic or automotive service provider to ensure proper diagnostics and repairs. -

What is the best alternator type for commercial vehicles?

The best alternator type for commercial vehicles typically depends on the vehicle’s electrical demands. High-output alternators, which can generate more power, are ideal for vehicles with multiple electrical accessories or heavy-duty applications. Look for alternators with a durable construction and a warranty, as reliability is crucial for commercial operations. Engaging with suppliers who specialize in automotive parts for commercial vehicles can also provide insights into the best options available in your region. -

How can I vet suppliers for alternators in international markets?

When vetting suppliers for alternators in international markets, start by researching their reputation and experience in the automotive industry. Request references from previous clients and look for reviews or testimonials online. Verify their certifications and compliance with international quality standards. It’s also beneficial to visit their facilities, if possible, to assess their production capabilities and quality control processes. Establishing a relationship through direct communication can further ensure that you find a reliable partner. -

What customization options are available for alternators?

Customization options for alternators can include variations in output capacity, mounting styles, and electrical connections to fit specific vehicle models. Some manufacturers may offer custom finishes or branding options for B2B buyers looking to enhance their product offerings. Discuss your specific requirements with suppliers to determine what is feasible and whether they can accommodate your needs without significantly affecting lead times or costs. -

What is the minimum order quantity (MOQ) for alternators?

Minimum order quantities (MOQ) for alternators can vary widely among suppliers, often ranging from 10 to 100 units, depending on the manufacturer and the specific alternator model. Larger orders may lead to discounts, while smaller orders might incur higher per-unit costs. When negotiating with suppliers, clarify the MOQ upfront to ensure it aligns with your purchasing strategy and inventory management. -

What payment terms should I expect when sourcing alternators?

Payment terms for sourcing alternators can differ based on the supplier and the nature of the transaction. Common terms include upfront deposits, net 30 or net 60 days for payment, and possibly letter of credit for larger orders. It’s essential to discuss and negotiate payment terms before finalizing any agreements to avoid cash flow issues. Always ensure that terms are documented in the purchase contract for clarity and protection. -

How do I ensure quality assurance for imported alternators?

To ensure quality assurance for imported alternators, request detailed product specifications and compliance certifications from your suppliers. Conduct pre-shipment inspections to verify that the products meet your quality standards. Establish clear return and warranty policies to protect against defective items. Collaborating with third-party inspection services can also provide an additional layer of quality control, ensuring that the alternators received are in optimal condition. -

What logistics considerations should I keep in mind when sourcing alternators internationally?

When sourcing alternators internationally, consider logistics factors such as shipping methods, lead times, and import duties. Evaluate the reliability of the shipping partners and ensure they have experience with automotive parts. Understand the customs regulations in your country to avoid delays at the border. Additionally, factor in warehousing and distribution capabilities to ensure timely delivery to your customers or end-users. Planning these logistics carefully can help streamline your supply chain and minimize costs.

Top 3 What Is An Alternator Car Manufacturers & Suppliers List

1. Reddit – Alternator Function Explained

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Alternator Function Explained, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Kia – Alternator

Domain: kia.com

Registered: 1996 (29 years)

Introduction: An alternator is an integral part of every combustion engine vehicle, responsible for converting chemical energy to electrical energy to charge and replenish the battery and power other electrical components. It works as part of the vehicle’s charging system, which includes the car battery, voltage regulator, and alternator itself. The alternator converts mechanical energy to electrical energy wit…

3. Nationwide – Alternator Essentials

Domain: blog.nationwide.com

Registered: 1994 (31 years)

Introduction: The alternator is a critical component of a car’s charging system, producing the majority of the vehicle’s electricity and recharging the battery. It is about the size of a coconut and is generally mounted to the front of the engine, driven by the engine’s crankshaft via a serpentine belt. Key components include: 1. Rotor and Stator: The rotor spins inside the stator, creating electricity through …

Strategic Sourcing Conclusion and Outlook for what is an alternator car

What Are the Key Takeaways for B2B Buyers of Alternator Cars?

Understanding the critical role of the alternator in vehicle functionality is essential for B2B buyers in the automotive sector. The alternator not only powers essential electrical components but also recharges the vehicle’s battery, ensuring reliable performance. For international markets, especially in Africa, South America, the Middle East, and Europe, sourcing high-quality alternators can significantly impact vehicle longevity and customer satisfaction.

How Can Strategic Sourcing Enhance Your Automotive Business?

Strategic sourcing of alternators involves selecting reliable suppliers who provide durable products that meet industry standards. This process ensures that your fleet remains operational, minimizing downtime and maintenance costs. Engaging with reputable manufacturers can also facilitate better pricing and availability, ultimately enhancing your competitive edge in the market.

What’s Next for International B2B Buyers?

As the automotive landscape evolves, staying informed about technological advancements in alternator design and efficiency will be crucial. By prioritizing strategic sourcing, businesses can not only improve their operational efficiency but also adapt to shifting market demands. We encourage you to explore partnerships with leading suppliers and invest in quality components that will drive your success in the global automotive industry. Your proactive approach today can pave the way for sustainable growth tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.