Introduction: Navigating the Global Market for aftermarket starters

In an increasingly interconnected world, sourcing high-quality aftermarket starters presents a unique challenge for B2B buyers across diverse regions such as Africa, South America, the Middle East, and Europe. As vehicles age and demand for reliable performance rises, understanding the intricacies of aftermarket starters becomes essential. This guide serves as a comprehensive resource, addressing the various types of starters available, their applications across different vehicle models, and the critical factors involved in supplier vetting.

Navigating the global market requires an informed approach, especially when it comes to assessing the cost versus quality of aftermarket options. The implications of choosing the right starter extend beyond immediate performance; they can impact long-term operational efficiency and maintenance costs. By providing insights on sourcing strategies, industry trends, and best practices, this guide empowers international B2B buyers to make educated purchasing decisions that align with their specific needs.

Furthermore, with a focus on the distinct requirements of buyers in regions like Saudi Arabia and Germany, the guide highlights regional market dynamics, ensuring that buyers can adapt their strategies accordingly. Whether you are a fleet manager seeking to optimize vehicle uptime or a parts distributor looking to expand your offerings, this guide equips you with the knowledge and tools necessary to thrive in the competitive aftermarket starter landscape.

Table Of Contents

- Top 4 Aftermarket Starters Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for aftermarket starters

- Understanding aftermarket starters Types and Variations

- Key Industrial Applications of aftermarket starters

- 3 Common User Pain Points for ‘aftermarket starters’ & Their Solutions

- Strategic Material Selection Guide for aftermarket starters

- In-depth Look: Manufacturing Processes and Quality Assurance for aftermarket starters

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘aftermarket starters’

- Comprehensive Cost and Pricing Analysis for aftermarket starters Sourcing

- Alternatives Analysis: Comparing aftermarket starters With Other Solutions

- Essential Technical Properties and Trade Terminology for aftermarket starters

- Navigating Market Dynamics and Sourcing Trends in the aftermarket starters Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of aftermarket starters

- Strategic Sourcing Conclusion and Outlook for aftermarket starters

- Important Disclaimer & Terms of Use

Understanding aftermarket starters Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Starters | Basic design, often remanufactured, OEM specifications. | Passenger vehicles, light-duty trucks. | Pros: Cost-effective; Cons: Limited longevity compared to premium options. |

| High-Performance Starters | Enhanced torque output, designed for heavy-duty use. | Racing vehicles, high-performance cars. | Pros: Improved reliability; Cons: Higher cost. |

| Marine Starters | Corrosion-resistant materials, designed for wet environments. | Boats, marine equipment. | Pros: Durability in harsh conditions; Cons: Specific to marine applications. |

| Agricultural Starters | Built for rugged use, often larger and more robust. | Tractors, agricultural machinery. | Pros: High endurance; Cons: Bulkier design may limit compatibility. |

| Universal Starters | Versatile design, adaptable to various applications. | Multiple vehicle types, aftermarket repairs. | Pros: Flexibility in use; Cons: May not match OEM specifications perfectly. |

What are Standard Starters and Their B2B Suitability?

Standard starters are typically remanufactured units that meet original equipment manufacturer (OEM) specifications. They are designed for everyday passenger vehicles and light-duty trucks, making them a popular choice for fleet operators and independent garages. When purchasing standard starters, B2B buyers should consider the warranty offered, as well as the reputation of the remanufacturer, to ensure reliability and performance.

How Do High-Performance Starters Benefit Specialized Applications?

High-performance starters are engineered to deliver enhanced torque output, making them ideal for racing vehicles and high-performance cars. These starters often feature advanced materials and designs that can withstand extreme conditions. B2B buyers in the automotive racing sector should prioritize these starters for their ability to provide reliable starts under high-stress situations. However, the higher upfront cost may be a consideration for budget-conscious businesses.

What Makes Marine Starters Unique for B2B Buyers?

Marine starters are specifically designed to resist corrosion and operate efficiently in wet environments, making them essential for boats and marine equipment. Their construction often includes sealed components to protect against moisture and saltwater. For B2B buyers in the marine industry, selecting the right marine starter is crucial for ensuring longevity and reliability, especially in harsh conditions. Price may vary based on the materials used, so it is important to assess the total cost of ownership.

Why Choose Agricultural Starters for Heavy-Duty Equipment?

Agricultural starters are built for rugged use, featuring robust designs that can handle the demands of tractors and other agricultural machinery. These starters are larger and more durable, catering to the specific needs of the farming industry. B2B buyers should evaluate the compatibility with their existing machinery and consider the operational environment when selecting agricultural starters, as these factors can significantly impact performance and lifespan.

How Do Universal Starters Provide Flexibility for Various Applications?

Universal starters offer a versatile solution for B2B buyers looking to service multiple vehicle types or perform aftermarket repairs. Their adaptable design allows them to fit a range of engines and applications, making them a practical choice for parts suppliers and repair shops. However, buyers should be cautious about potential discrepancies with OEM specifications, which can affect performance and reliability. Ensuring compatibility with specific vehicle models is key to maximizing the benefits of universal starters.

Key Industrial Applications of aftermarket starters

| Industry/Sector | Specific Application of aftermarket starters | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Replacement starters for various vehicle models | Cost-effective solutions that ensure reliable vehicle operation | Compatibility with OEM specifications and local regulations |

| Agricultural Machinery | Starters for tractors and heavy farming equipment | Enhanced productivity and reduced downtime during planting season | Durability under extreme conditions and availability of parts |

| Marine and Boating | Starters for inboard and outboard engines | Improved reliability and performance for recreational and commercial vessels | Resistance to corrosion and high-quality materials |

| Construction Equipment | Starters for heavy machinery like excavators and cranes | Increased operational efficiency and reduced maintenance costs | OEM fitment and adaptability to harsh environments |

| Public Transportation | Starters for buses and commercial vehicles | Ensures timely service and reliability in passenger transport | Compliance with safety and performance standards |

How Are Aftermarket Starters Used in the Automotive Repair Sector?

In the automotive repair industry, aftermarket starters are vital for replacing defective units in a wide range of vehicle models. These starters offer a cost-effective alternative to OEM parts, making them attractive for repair shops aiming to keep operational costs low. International buyers, particularly from regions like Africa and South America, must ensure that the aftermarket starters meet local vehicle specifications and regulatory standards to avoid compatibility issues and performance setbacks.

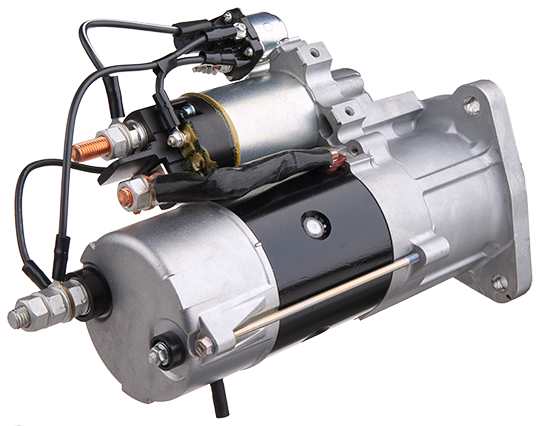

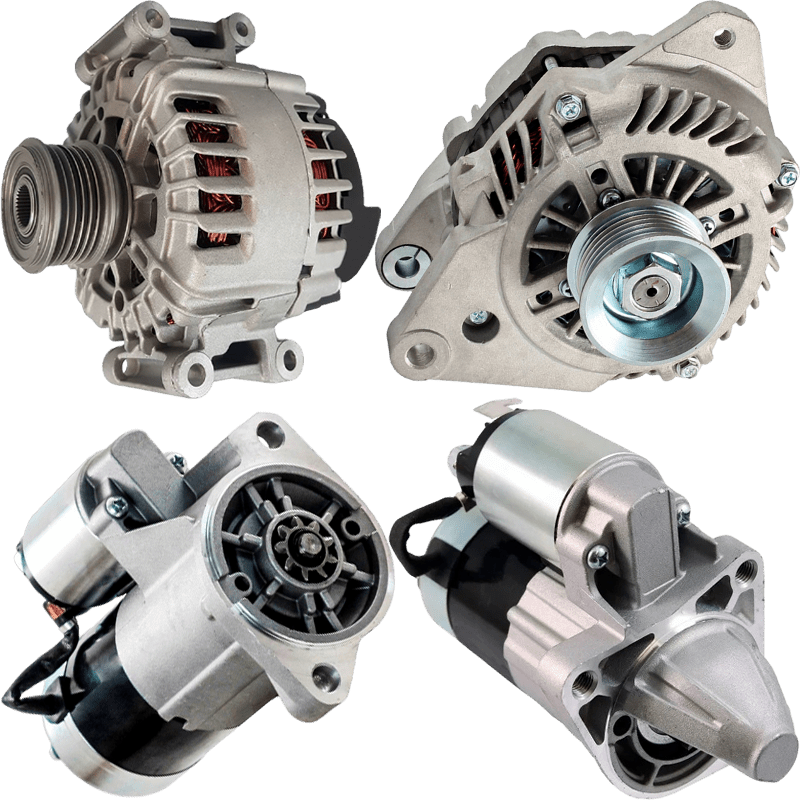

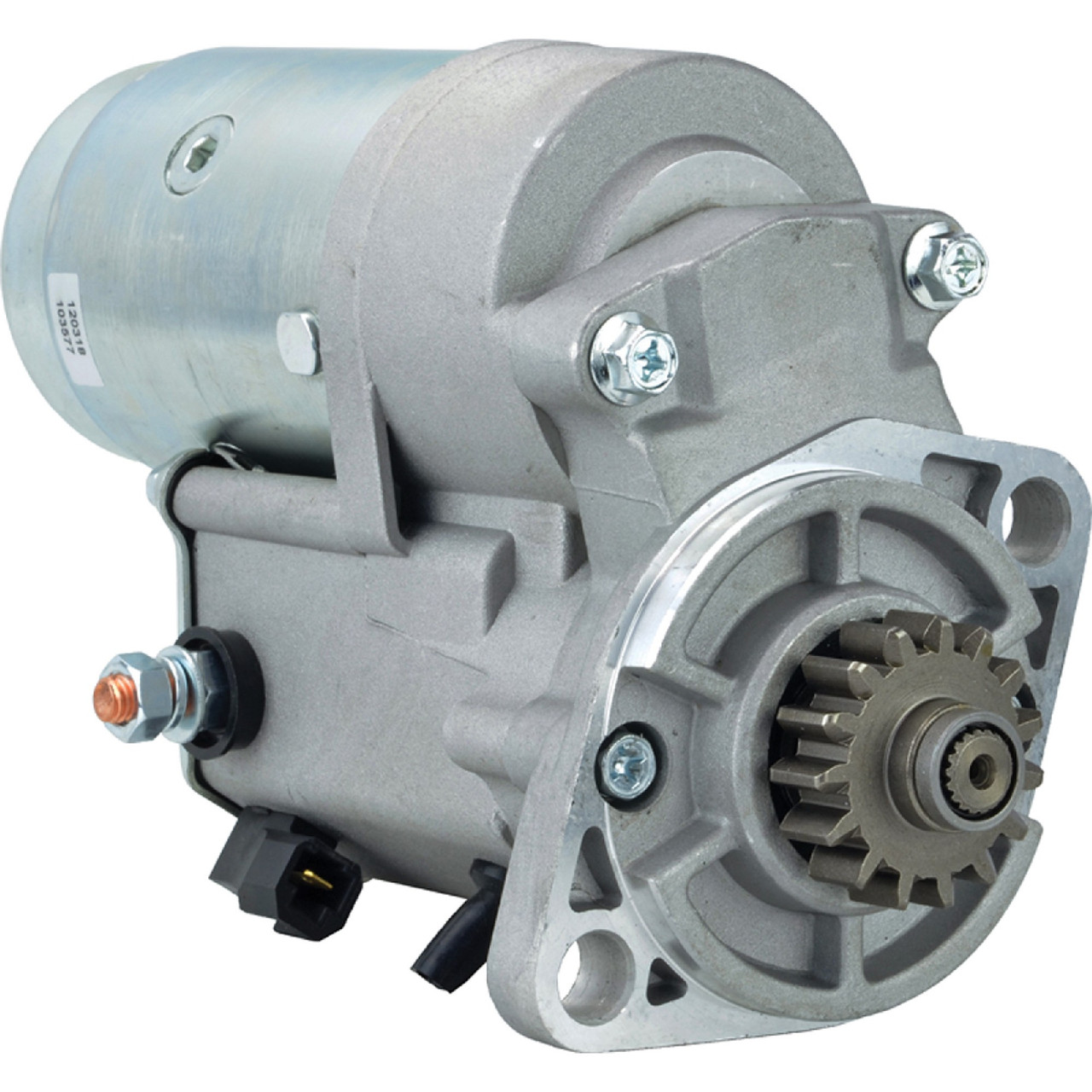

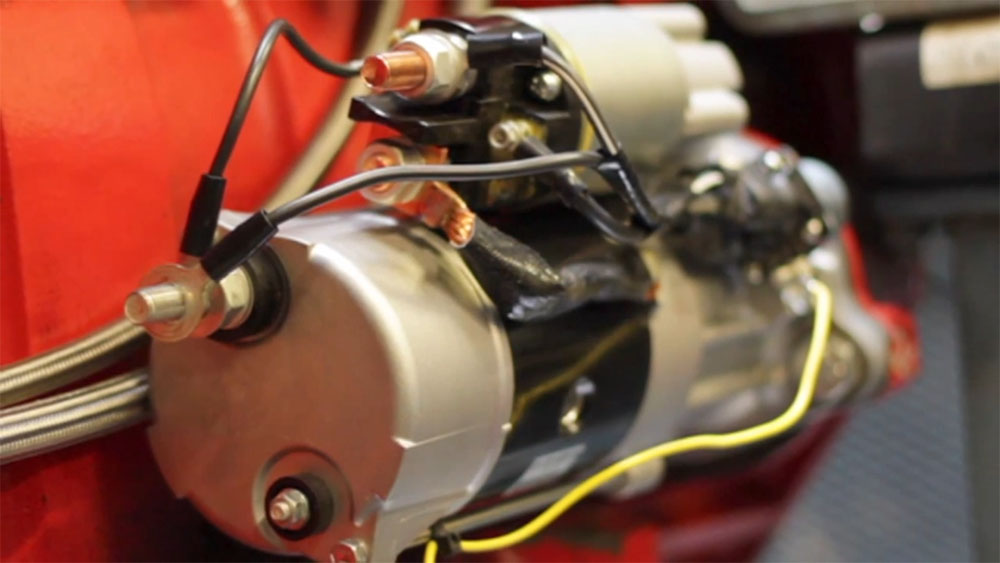

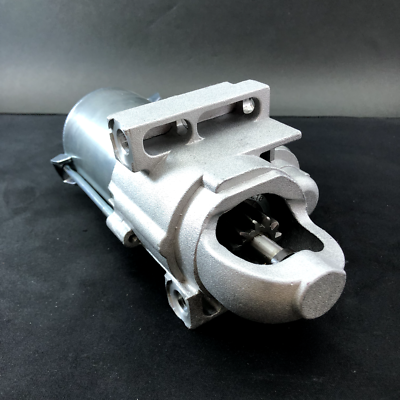

Illustrative image related to aftermarket starters

What Role Do Aftermarket Starters Play in Agricultural Machinery?

Aftermarket starters are essential in the agricultural sector, particularly for tractors and heavy machinery. These starters are designed to withstand the rigors of farming environments, where equipment is often exposed to dirt, moisture, and extreme temperatures. By sourcing durable aftermarket starters, farmers can minimize downtime during critical planting and harvest seasons. Buyers should prioritize starters that offer high torque and reliability, ensuring they can handle the demanding start-up conditions typical in agricultural settings.

Why Are Aftermarket Starters Important for Marine and Boating Applications?

In marine applications, aftermarket starters are crucial for both inboard and outboard engines. They ensure that vessels operate reliably, whether for commercial fishing or recreational boating. Given the corrosive nature of marine environments, international buyers should focus on starters made with high-quality, corrosion-resistant materials. This consideration not only extends the life of the starter but also enhances overall vessel performance, providing peace of mind for operators in regions such as the Middle East and Europe.

How Do Aftermarket Starters Benefit Construction Equipment?

In the construction industry, aftermarket starters are vital for heavy machinery like excavators, cranes, and bulldozers. These starters help maintain operational efficiency, particularly in projects that demand consistent performance. Buyers from harsh climate regions need to consider the durability and adaptability of starters to ensure they can withstand extreme conditions. Additionally, sourcing starters that align with OEM fitment standards can significantly reduce maintenance costs and enhance equipment reliability.

What Is the Significance of Aftermarket Starters in Public Transportation?

Aftermarket starters are key components in the public transportation sector, particularly for buses and commercial vehicles. They ensure that vehicles start reliably, which is critical for maintaining schedules and service quality. International buyers must ensure that the starters comply with safety and performance standards specific to their regions, particularly in Europe and the Middle East, where regulations are stringent. Investing in high-quality aftermarket starters can lead to better service reliability and lower overall operational costs.

3 Common User Pain Points for ‘aftermarket starters’ & Their Solutions

Scenario 1: Sourcing Quality Aftermarket Starters at Competitive Prices

The Problem: Many B2B buyers face the challenge of sourcing high-quality aftermarket starters that meet OEM specifications while remaining cost-effective. In regions like Africa and South America, where supply chains can be disrupted, ensuring the reliability of the starters is crucial. A poor-quality starter can lead to increased vehicle downtime and costly repairs, ultimately affecting the bottom line for businesses reliant on transportation. Buyers often find themselves overwhelmed by the variety of options available, struggling to differentiate between premium and subpar products.

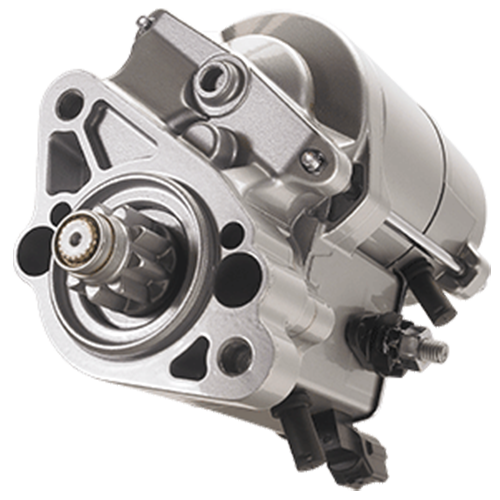

Illustrative image related to aftermarket starters

The Solution: To effectively source quality aftermarket starters, buyers should establish relationships with reputable manufacturers and distributors known for their adherence to high production standards. Conduct thorough research to identify suppliers who provide detailed product specifications and testing results. Look for brands that utilize premium materials and have a robust quality assurance process, including multipoint testing before shipping. Additionally, leveraging technology, such as online platforms that specialize in automotive parts, can streamline the search for OEM-spec products. Utilize filtering options based on vehicle type and engine specifications to ensure a precise match. Finally, consider bulk purchasing agreements that can lead to significant cost savings while ensuring consistent quality.

Scenario 2: Understanding the Compatibility of Aftermarket Starters with Various Vehicle Models

The Problem: Compatibility issues are a significant pain point for B2B buyers, especially when dealing with a diverse fleet of vehicles. In regions like the Middle East and Europe, where vehicle models can vary widely, selecting the right aftermarket starter is critical. Buyers often encounter difficulties confirming whether a particular starter will fit and function correctly in their specific vehicle models, which can lead to delays and increased operational costs.

The Solution: To address compatibility concerns, buyers should prioritize sourcing from suppliers who offer comprehensive databases or tools that allow for precise part matching. Before making a purchase, it is essential to verify the vehicle identification number (VIN) and consult the manufacturer’s specifications to ensure that the starter is compatible. Many reputable suppliers provide online tools where buyers can input their vehicle details to find the correct starter. Additionally, maintaining an updated inventory management system that tracks vehicle specifications can help streamline future purchasing decisions. Engaging with supplier customer service teams for expert advice can also clarify any uncertainties regarding compatibility.

Scenario 3: Managing the Installation and Maintenance of Aftermarket Starters

The Problem: Aftermarket starters, while often more affordable than OEM parts, can present challenges during installation and maintenance. B2B buyers, particularly those managing fleets in regions with varying technical expertise among mechanics, may struggle with ensuring that starters are installed correctly. Improper installation can lead to premature failure, resulting in increased downtime and maintenance costs.

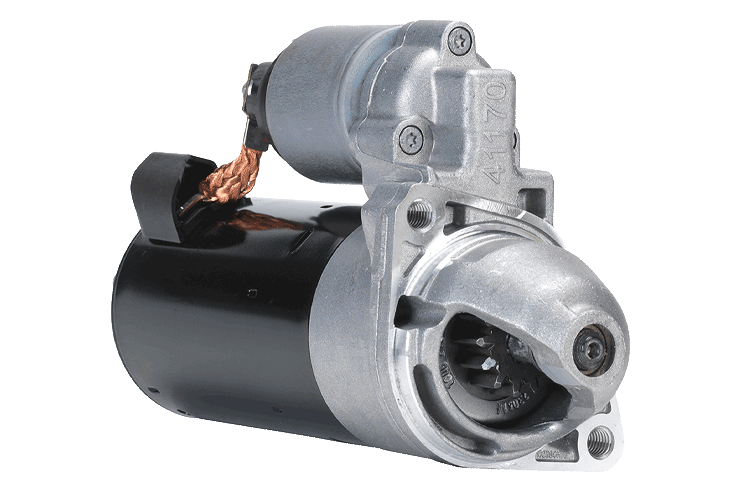

Illustrative image related to aftermarket starters

The Solution: To mitigate installation challenges, buyers should invest in comprehensive training programs for their mechanics that focus on the specific requirements for installing aftermarket starters. Collaborating with suppliers that provide detailed installation guides, videos, or even on-site training can ensure that mechanics are well-equipped to handle the installation process. Additionally, establishing a partnership with local workshops or certified mechanics who specialize in aftermarket parts can provide an extra layer of assurance. Regular maintenance schedules should also be implemented, including checks on starter connections and electrical systems, to prolong the lifespan of the starters and reduce the risk of failure. By fostering a culture of continuous learning and utilizing reliable resources, businesses can enhance their operational efficiency and reduce costs associated with starter failures.

Strategic Material Selection Guide for aftermarket starters

What Are the Key Materials Used in Aftermarket Starters?

In the aftermarket starter industry, the selection of materials is crucial for ensuring performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the construction of aftermarket starters, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Copper Influence Starter Performance?

Copper is widely used in starter windings and connections due to its excellent electrical conductivity. It has a high melting point (approximately 1,984°F or 1,085°C) and is resistant to corrosion, making it suitable for various operating environments.

Pros: Copper’s superior conductivity enhances the efficiency of the starter, leading to faster engine cranking and reduced energy consumption. It is also relatively easy to work with during manufacturing.

Cons: The primary drawback of copper is its cost, which can be significantly higher than alternatives like aluminum. Additionally, while it is durable, it can be susceptible to oxidation if not properly coated.

Impact on Application: Copper’s compatibility with high-temperature environments makes it ideal for automotive applications, especially in regions with extreme weather conditions.

Illustrative image related to aftermarket starters

Considerations for International Buyers: Buyers from Africa and the Middle East should ensure that copper components meet local electrical standards, such as IEC or JIS, to guarantee safety and performance.

Why Is Steel a Common Choice for Starter Housings?

Steel is often utilized for the outer housing of starters due to its strength and resistance to mechanical wear. It can withstand significant pressure and impacts, making it suitable for heavy-duty applications.

Pros: Steel is highly durable and can be manufactured in various grades, allowing for customization based on specific needs. It is also cost-effective compared to other materials like stainless steel.

Illustrative image related to aftermarket starters

Cons: While steel is strong, it is prone to rust and corrosion if not properly treated or coated. This can lead to premature failure in harsh environments.

Impact on Application: Steel housings are particularly effective in agricultural and industrial starter applications, where robustness is paramount.

Considerations for International Buyers: Buyers in Europe, especially Germany, should ensure that steel components comply with DIN standards for material quality and corrosion resistance.

What Role Does Aluminum Play in Starter Design?

Aluminum is increasingly popular in starter design due to its lightweight nature and good thermal conductivity. It is often used in components where weight reduction is crucial.

Illustrative image related to aftermarket starters

Pros: The lightweight characteristic of aluminum allows for easier installation and improved fuel efficiency in vehicles. It also offers decent corrosion resistance, especially when anodized.

Cons: Aluminum is less durable than steel and may not withstand heavy impacts as effectively. Additionally, its cost can be higher than steel, depending on the grade.

Impact on Application: Aluminum starters are particularly beneficial in performance vehicles and motorcycles, where weight savings can enhance overall performance.

Considerations for International Buyers: Buyers from South America should consider local availability and pricing of aluminum components, as these can vary significantly by region.

How Does Plastic Enhance Starter Component Design?

Plastic is often used for non-structural components of starters, such as covers and insulators. It is lightweight and can be molded into complex shapes.

Pros: The primary advantage of plastic is its resistance to corrosion and electrical insulation properties. It is also cost-effective and allows for intricate designs that can improve airflow and cooling.

Cons: Plastic components may not withstand high temperatures or mechanical stresses as well as metals, leading to potential failure in demanding applications.

Impact on Application: Plastic is suitable for lighter-duty starters, particularly in automotive and small engine applications.

Considerations for International Buyers: Compliance with international standards for plastic materials, such as ASTM or ISO, is essential for ensuring product safety and reliability.

Summary Table of Material Selection for Aftermarket Starters

| Material | Typical Use Case for aftermarket starters | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical windings and connections | Excellent electrical conductivity | High cost, oxidation risk | High |

| Steel | Outer housing for heavy-duty starters | High durability and strength | Prone to rust without treatment | Medium |

| Aluminum | Lightweight components in performance vehicles | Lightweight, good thermal conductivity | Less durable than steel | Medium |

| Plastic | Non-structural components like covers | Corrosion resistance, cost-effective | Limited high-temperature resistance | Low |

This guide provides a comprehensive overview of material selection for aftermarket starters, equipping international B2B buyers with the necessary insights to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for aftermarket starters

What Are the Main Stages of Manufacturing Aftermarket Starters?

The manufacturing process for aftermarket starters involves several critical stages that ensure the final product meets performance and durability standards. Understanding these stages can help B2B buyers identify reputable suppliers and make informed purchasing decisions.

Material Preparation: What Materials Are Used and Why?

The first step in the manufacturing process is material preparation, where high-quality raw materials are sourced. Common materials include copper for windings, steel for housings, and specialized alloys for components like brushes and bearings. The choice of materials is crucial; for instance, using high-grade magnets and field coils enhances the starter’s efficiency and longevity. Suppliers often work with trusted manufacturers to ensure that these materials comply with international quality standards.

How Are Aftermarket Starters Formed?

Following material preparation, the next stage is forming. This involves shaping the raw materials into the necessary components through processes like stamping, machining, and molding. CNC (Computer Numerical Control) machining is frequently employed for precision parts, ensuring that dimensions are accurate and consistent. This precision reduces the likelihood of failure during operation, a key concern for B2B buyers who depend on reliability.

What Does the Assembly Process Involve?

Assembly is where all the individual components come together. Skilled technicians or automated systems assemble the starters, incorporating quality control measures at each step. The assembly process typically follows a set protocol to ensure that every starter meets OEM specifications. For instance, the alignment of components, the torque applied to bolts, and the installation of electrical connections are all carefully monitored to prevent defects.

What Finishing Techniques Are Applied to Aftermarket Starters?

Finishing touches are vital for enhancing the durability and aesthetics of aftermarket starters. Processes such as painting, plating, or coating are applied to protect against corrosion and wear. These finishing techniques also serve a functional purpose; for example, a corrosion-resistant coating can significantly extend the starter’s life, which is particularly important for buyers operating in harsh environments.

What Quality Assurance Standards Are Relevant for Aftermarket Starters?

Quality assurance (QA) is critical in the production of aftermarket starters, ensuring that each product is reliable and meets industry standards. B2B buyers should be familiar with the various quality standards that suppliers might adhere to.

Illustrative image related to aftermarket starters

Which International Standards Should B2B Buyers Look For?

ISO 9001 is the most recognized international quality management standard, focusing on consistent quality and customer satisfaction. Suppliers adhering to ISO 9001 demonstrate a commitment to quality processes and continuous improvement. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can indicate compliance with specific industry requirements, providing further assurance of quality.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is integrated throughout the manufacturing process, with several checkpoints established to catch defects early.

How Are Incoming Quality Control (IQC) Measures Implemented?

Incoming Quality Control (IQC) involves inspecting materials and components upon arrival at the manufacturing facility. Suppliers often conduct tests to verify the integrity and specifications of raw materials. This stage is crucial for preventing substandard materials from entering the production line, ensuring that only the highest quality inputs are used in the manufacturing of aftermarket starters.

Illustrative image related to aftermarket starters

What Is In-Process Quality Control (IPQC) and Why Is It Important?

In-Process Quality Control (IPQC) is conducted during the manufacturing process to monitor critical parameters such as component alignment, assembly torque, and electrical continuity. Regular checks at this stage can identify issues before the product reaches the final assembly phase, thus reducing the risk of defects in the finished starter.

How Does Final Quality Control (FQC) Ensure Product Integrity?

Final Quality Control (FQC) is the last line of defense before products are shipped to customers. This stage typically includes functional testing of the starter under simulated operating conditions, ensuring it meets performance specifications. Common testing methods include bench tests for electrical components and load testing to assess the starter’s ability to crank an engine.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control measures employed by potential suppliers.

What Audits and Reports Should Buyers Request?

Requesting audits and quality reports from suppliers is a crucial step in the verification process. Buyers should look for documentation that details the supplier’s adherence to quality standards, including any relevant certifications. Regular audits by third-party organizations can provide an unbiased assessment of a supplier’s quality management system.

Illustrative image related to aftermarket starters

How Do Third-Party Inspections Add Value?

Engaging third-party inspectors can further validate a supplier’s quality claims. These independent evaluations can help B2B buyers ensure that the manufacturing processes and quality assurance measures are up to industry standards. Third-party inspections can be particularly valuable for buyers in regions like Africa and South America, where local suppliers may not always have robust quality control systems.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate additional complexities when sourcing aftermarket starters from different regions.

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying quality standards and regulations. For example, European buyers may prioritize CE certification, while those in the Middle East may require compliance with local safety standards. Understanding these nuances is essential for B2B buyers to ensure that the products they source not only meet their specific requirements but also comply with local regulations.

Conclusion: How to Choose the Right Supplier for Aftermarket Starters

In conclusion, understanding the manufacturing processes and quality assurance practices for aftermarket starters is vital for B2B buyers. By focusing on the key stages of manufacturing, quality standards, and verification methods, buyers can make informed decisions that lead to successful partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aftermarket starters’

To assist international B2B buyers in sourcing aftermarket starters effectively, this guide provides a structured checklist to streamline the procurement process. Following these steps will ensure that you select high-quality starters that meet your operational needs while optimizing costs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure compatibility with your vehicles or machinery. This includes the make, model, and engine type for which the starter is intended. Additionally, consider the performance requirements, such as torque and durability, to ensure the starter can handle operational demands.

- Identify OEM Standards: Look for starters that meet or exceed Original Equipment Manufacturer (OEM) standards to guarantee quality and fitment.

- Assess Environmental Conditions: Consider the climate and usage conditions (e.g., extreme temperatures, dust) that may affect starter performance.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing structures helps in making informed purchasing decisions. Analyze the pricing of various aftermarket starters to identify competitive rates and avoid overpaying.

- Compare Suppliers: Use online platforms and industry reports to compare prices among different suppliers.

- Consider Total Cost of Ownership: Factor in shipping, installation, and potential warranty costs when evaluating the overall expense.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers to ensure they can meet your needs. Assess their reputation, reliability, and experience in the aftermarket sector.

- Request Documentation: Ask for company profiles, certifications, and references from other clients in your industry.

- Assess Customer Service: Consider how responsive and knowledgeable their support team is, as this can significantly impact your procurement experience.

Step 4: Verify Quality Assurance Processes

Quality assurance is essential for ensuring that the starters you purchase are reliable and durable. Investigate the supplier’s testing and quality control measures.

Illustrative image related to aftermarket starters

- Inquire About Testing Protocols: Find out if the starters undergo rigorous testing before being sold, such as performance tests and durability assessments.

- Look for Warranty Offers: A solid warranty can indicate the supplier’s confidence in their product quality.

Step 5: Review Logistics and Delivery Options

Efficient logistics and delivery services are vital to ensure timely access to your aftermarket starters. Confirm the supplier’s shipping policies and delivery timelines.

- Understand Lead Times: Clarify expected lead times for order fulfillment and shipping, especially if you are working with tight deadlines.

- Evaluate Shipping Costs: Compare shipping options and costs to find the most economical solution without compromising delivery speed.

Step 6: Establish Payment Terms

Before finalizing your purchase, negotiate payment terms that are favorable for your business. This can help manage cash flow and financial planning.

- Explore Payment Methods: Discuss various payment options, such as credit terms, upfront payments, or installment plans.

- Consider Bulk Purchase Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

Step 7: Finalize the Purchase Agreement

Once you are satisfied with the supplier’s offerings and terms, finalize the purchase agreement. Ensure all details are documented clearly to avoid misunderstandings.

- Review Contract Details: Pay attention to terms regarding warranty, returns, and service support to ensure comprehensive coverage.

- Maintain Open Communication: Keep lines of communication open with the supplier for any follow-up questions or issues that may arise post-purchase.

By following this checklist, B2B buyers can effectively source aftermarket starters that meet their technical and operational requirements while ensuring quality and cost-effectiveness.

Comprehensive Cost and Pricing Analysis for aftermarket starters Sourcing

What Are the Key Cost Components in Aftermarket Starters?

When sourcing aftermarket starters, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to aftermarket starters

Materials form the backbone of starter production. High-quality components such as magnets, coils, brushes, and bearings significantly influence the performance and lifespan of the starters. Premium materials may incur higher upfront costs but can lead to lower failure rates and longer service life, impacting overall cost efficiency.

Labor costs are tied to the skill level required for assembly and testing. Skilled labor typically commands higher wages, but it also results in better craftsmanship, which can further enhance product reliability.

Manufacturing overhead encompasses indirect costs associated with the production process, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help keep these costs down.

Illustrative image related to aftermarket starters

Tooling refers to the equipment and machinery necessary for production. Investing in advanced machinery can lead to economies of scale, reducing per-unit costs as production volume increases.

Quality Control (QC) is essential in ensuring that every starter meets OEM standards. Rigorous testing protocols may add to initial costs but are vital for maintaining brand reputation and minimizing warranty claims.

Logistics costs include warehousing, transportation, and distribution. These can vary significantly depending on the geographical location of suppliers and buyers, particularly for international transactions.

Finally, the profit margin varies by supplier and is influenced by the overall market demand, competition, and pricing strategies.

How Do Price Influencers Affect Aftermarket Starter Costs?

Several factors can influence the pricing of aftermarket starters, including volume or minimum order quantity (MOQ), specifications and customization, materials, quality certifications, and supplier dynamics.

Volume/MOQ plays a significant role in pricing. Suppliers often offer discounts for larger orders, which can make sourcing more cost-effective for buyers. Understanding the MOQ can help buyers negotiate better terms.

Specifications and customization can also impact pricing. Custom-designed starters that meet specific vehicle requirements or unique performance standards typically come at a premium. Buyers should clearly communicate their needs to avoid unexpected costs.

The choice of materials directly affects the quality and durability of starters. As mentioned earlier, opting for premium materials can enhance performance but may increase costs. Buyers should weigh the long-term benefits against initial expenditures.

Quality certifications can be a price influencer as well. Products that meet international quality standards may come at a higher price but offer assurance in performance and reliability, essential for maintaining a competitive edge.

Supplier factors, including reputation, reliability, and geographical location, can also affect pricing. Establishing relationships with trusted suppliers can lead to more favorable terms and consistent product quality.

Incoterms dictate the responsibilities of buyers and sellers in international transactions. Understanding these terms can help buyers anticipate additional costs related to shipping, insurance, and customs duties.

What Buyer Tips Can Enhance Cost-Efficiency for Aftermarket Starters?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, strategic approaches can enhance cost-efficiency when sourcing aftermarket starters.

Negotiation is critical. Buyers should engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building a good relationship can yield better deals and flexibility.

Considering Total Cost of Ownership (TCO) is essential. While the upfront cost is important, evaluating the long-term costs associated with maintenance, warranty claims, and downtime can lead to more informed purchasing decisions.

Pricing nuances for international buyers must be considered. Exchange rates, tariffs, and local regulations can affect final pricing. Buyers should stay updated on these factors to avoid surprises.

Finally, leveraging technology such as online platforms can help buyers compare prices, specifications, and reviews from different suppliers. This can lead to more competitive pricing and better-informed decisions.

Disclaimer

The prices and cost structures mentioned are indicative and can vary based on supplier, region, and market conditions. It is advisable for buyers to conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing aftermarket starters With Other Solutions

When considering solutions for vehicle starting systems, aftermarket starters represent a viable option; however, it is essential to explore alternative technologies and methods that can achieve similar outcomes. Understanding these alternatives helps B2B buyers make informed decisions that align with their operational needs and budget constraints.

| Comparison Aspect | Aftermarket Starters | Remanufactured Starters | OEM Starters |

|---|---|---|---|

| Performance | High-quality materials ensure reliability | Generally good but can vary in quality | Built to manufacturer specifications |

| Cost | Typically 30% less than OEM | Moderate savings, but quality varies | Higher initial cost, no savings |

| Ease of Implementation | Direct fit for most vehicles | Requires professional installation | Direct fit with no additional modifications |

| Maintenance | Low maintenance, long lifespan | May require more frequent checks | Minimal maintenance required |

| Best Use Case | Cost-effective for fleet operations | Suitable for budget-conscious buyers | Ideal for high-end or specialized vehicles |

What Are Remanufactured Starters and Their Advantages?

Remanufactured starters are salvaged units that have been restored to meet OEM specifications. They undergo a thorough refurbishment process, which includes replacing worn components and testing for performance. The primary advantage of remanufactured starters is cost savings compared to new OEM parts, making them appealing for businesses with tight budgets. However, their performance can be inconsistent based on the quality of the refurbishment process, and they may require more frequent maintenance checks to ensure reliability.

How Do OEM Starters Compare to Aftermarket Options?

OEM (Original Equipment Manufacturer) starters are produced by the vehicle manufacturer and are designed to meet exact specifications. These starters guarantee compatibility and optimal performance, making them the safest choice for high-end or specialized vehicles where reliability is paramount. The downside is the significantly higher cost associated with OEM starters, which can be prohibitive for businesses operating with tight budgets or managing large fleets. Their installation is straightforward, but the long-term savings associated with aftermarket solutions can be compelling.

Why Consider Aftermarket Starters for Fleet Operations?

Aftermarket starters provide a balance of performance, cost, and ease of use, making them an excellent choice for fleet operations. With factory-direct pricing often saving buyers up to 30% off OEM prices, these starters deliver reliable performance without breaking the bank. They are designed to meet or exceed OEM standards and are rigorously tested to ensure longevity and efficiency. Businesses looking to maximize their operational budget while maintaining reliable vehicle performance will find aftermarket starters to be a suitable solution.

Conclusion: How to Choose the Right Starting Solution for Your Needs

When selecting the right starting solution for your vehicles, it is crucial to assess your specific operational requirements, budget constraints, and performance expectations. Aftermarket starters offer a compelling value proposition for many businesses, particularly in fleet management, while remanufactured and OEM options may suit specific use cases where reliability and performance are non-negotiable. By evaluating the pros and cons of each option, B2B buyers can make strategic decisions that optimize their fleet’s performance while ensuring cost-effectiveness.

Essential Technical Properties and Trade Terminology for aftermarket starters

What Are the Key Technical Properties of Aftermarket Starters?

When sourcing aftermarket starters, understanding specific technical properties is vital for ensuring product quality and performance. Here are several critical specifications that B2B buyers should consider:

1. Material Grade

The materials used in manufacturing starters significantly affect durability and performance. Premium-grade steel and copper are common in high-quality starters. Steel is often used for the housing due to its strength, while copper is favored for windings because of its excellent conductivity. Choosing starters made from superior materials can lead to longer service life and reduced failure rates, ultimately benefiting your bottom line.

2. Torque Rating

Torque rating is a measure of the rotational force the starter can generate. It is essential for ensuring that the starter can effectively crank the engine, especially in larger vehicles or those with high compression engines. For B2B buyers, understanding the torque requirements of specific vehicle models is crucial to prevent underperformance or damage.

3. Electrical Resistance

Electrical resistance impacts the efficiency of the starter motor. Low resistance is desirable as it allows for better electrical flow, resulting in faster starts and less wear on the motor. Buyers should look for starters with specifications indicating low electrical resistance, as this can lead to improved performance and energy efficiency.

4. Fitment Specifications

Fitment specifications dictate whether a starter will properly integrate with a vehicle’s engine. Starters must meet OEM (Original Equipment Manufacturer) standards for compatibility. Ensuring that the aftermarket starter matches the fitment specifications of the vehicle not only guarantees optimal performance but also minimizes installation issues.

5. Multi-Point Testing

Reputable manufacturers will conduct multi-point testing on their starters before they reach the market. This testing ensures that each unit meets specific performance criteria, such as starting speed, engagement, and electrical integrity. For B2B buyers, selecting starters that have undergone rigorous testing can provide peace of mind regarding quality and reliability.

What Are Common Trade Terms Used in the Aftermarket Starter Industry?

Familiarity with industry jargon can enhance communication and decision-making in the procurement process. Here are several essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to the original manufacturer of the vehicle’s components. In the context of aftermarket starters, OEM specifications indicate that the parts are designed to match the original equipment in quality and fit. Buyers seeking OEM-compliant starters can ensure compatibility and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it impacts inventory management and cash flow. Suppliers may offer better pricing for larger orders, making it essential to balance the need for stock with financial considerations.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting price quotes for specific products. This process allows buyers to compare prices and terms from multiple vendors, facilitating informed purchasing decisions. A well-structured RFQ can lead to better negotiation outcomes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. These terms clarify aspects such as shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers engaged in international sourcing, as they dictate who bears costs and risks during transportation.

5. Warranty Period

The warranty period is the timeframe during which the manufacturer guarantees the product against defects. A longer warranty period often indicates higher confidence in product quality. For buyers, evaluating warranty terms can provide insights into expected product lifespan and the manufacturer’s commitment to customer satisfaction.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing aftermarket starters, leading to enhanced operational efficiency and long-term value.

Navigating Market Dynamics and Sourcing Trends in the aftermarket starters Sector

What Are the Key Trends Shaping the Aftermarket Starters Market?

The aftermarket starters market is witnessing significant growth driven by several global factors. Increased vehicle ownership in emerging markets such as Africa and South America is fueling demand for reliable replacement parts. This rise in consumer base, coupled with the growing trend toward vehicle longevity and maintenance, has prompted international B2B buyers to seek high-quality aftermarket starters that can deliver performance comparable to OEM parts but at reduced costs.

Technological advancements are also reshaping sourcing strategies in this sector. The integration of e-commerce platforms allows buyers to access a broader range of products and suppliers, facilitating price comparisons and enhancing procurement efficiency. Additionally, the rise of digital tools for inventory management and real-time data analytics is enabling companies to optimize their supply chains and reduce lead times. Buyers are increasingly looking for suppliers who offer robust online support and detailed product information, which can aid in decision-making and ensure compatibility with various vehicle models.

Moreover, there is a noticeable shift towards customization in the aftermarket starter offerings. Suppliers are responding to the needs of diverse markets by providing tailored solutions, including specific designs for different vehicle types or models, thus catering to the unique requirements of buyers from regions like the Middle East and Europe. This adaptability is crucial as it helps businesses maintain a competitive edge in a market that values both quality and cost-effectiveness.

How Does Sustainability and Ethical Sourcing Impact Aftermarket Starters?

Sustainability has become a key consideration in the sourcing of aftermarket starters, driven by increasing consumer awareness and regulatory pressures. The environmental impact of automotive manufacturing and waste is significant, prompting buyers to seek suppliers committed to sustainable practices. This includes the use of eco-friendly materials, responsible waste management, and energy-efficient production processes.

Ethical sourcing is also gaining importance, with B2B buyers prioritizing suppliers that uphold fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By choosing suppliers with these certifications, businesses not only enhance their brand reputation but also align with the growing consumer demand for environmentally responsible products.

Furthermore, the trend towards using recycled materials in the production of aftermarket starters is gaining traction. This not only reduces the carbon footprint associated with manufacturing but also addresses the challenge of resource scarcity. By sourcing starters made from recycled components, companies can contribute to a circular economy while also appealing to environmentally-conscious customers.

What Is the Historical Context of Aftermarket Starters in B2B Markets?

The concept of the starter motor dates back to the early 20th century when the first electric starter was introduced by Charles Kettering and Henry Leland in 1911. This innovation revolutionized vehicle operation by eliminating the need for manual cranking, thereby enhancing convenience and safety. Over the decades, the design and functionality of starters have evolved significantly, with advancements in materials and technology leading to improved performance and longevity.

In the B2B context, the aftermarket for starters began to gain traction as vehicles aged and the need for replacement parts became apparent. Initially, the focus was primarily on OEM replacements, but as the market matured, the emergence of high-quality aftermarket alternatives provided buyers with more options. Today, the aftermarket starter sector is characterized by a diverse range of products that cater to various vehicle types and specifications, reflecting the growing complexity and variety of modern automobiles. This evolution underscores the importance of choosing the right supplier who can provide reliable, high-performance starters that meet or exceed OEM standards.

Frequently Asked Questions (FAQs) for B2B Buyers of aftermarket starters

-

How do I choose the right aftermarket starter for my vehicles?

Selecting the appropriate aftermarket starter requires considering several factors. First, identify the specific vehicle make, model, and engine type, as compatibility is crucial. Secondly, assess the quality of materials and craftsmanship; premium starters often provide better durability and performance. Look for suppliers that adhere to OEM standards to ensure fitment and reliability. Lastly, consider the warranty offered, as this reflects the manufacturer’s confidence in their product. Conducting thorough research and consulting with suppliers can help you make an informed decision. -

What are the advantages of using aftermarket starters over OEM parts?

Aftermarket starters typically offer significant cost savings compared to OEM parts while still meeting or exceeding quality standards. They are often manufactured using premium materials that enhance performance and longevity. Many aftermarket starters undergo rigorous testing to ensure reliability, providing peace of mind for buyers. Additionally, the availability of a wider variety of options allows buyers to choose a starter that best fits their specific needs and budget, making aftermarket starters a practical choice for many businesses. -

What is the typical minimum order quantity (MOQ) for aftermarket starters?

Minimum order quantities for aftermarket starters can vary significantly between suppliers. Many suppliers set MOQs based on their production capabilities and inventory levels, with common MOQs ranging from 10 to 100 units. It’s advisable to discuss your requirements directly with potential suppliers to negotiate the MOQ based on your business needs. For international buyers, understanding the MOQ is essential for managing shipping costs and ensuring you have adequate inventory to meet demand. -

How can I ensure the quality of aftermarket starters before purchasing?

To ensure quality, verify that the supplier adheres to industry standards and certifications, such as ISO or TS certifications. Request detailed specifications on materials used and inquire about the testing processes each starter undergoes before sale. It’s also beneficial to seek samples or conduct bench tests to evaluate performance. Reading customer reviews and testimonials can provide insights into the reliability of the starters. Building a strong relationship with reputable suppliers can further ensure consistent quality. -

What payment terms should I expect when sourcing aftermarket starters?

Payment terms can vary by supplier and often depend on the buyer’s creditworthiness and relationship with the supplier. Common terms include upfront payments, a percentage deposit with the balance due upon delivery, or net 30/60 days terms for established relationships. It’s important to clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms. Negotiating favorable terms that align with your cash flow and business operations can help facilitate smoother transactions. -

How do I handle logistics when importing aftermarket starters?

When importing aftermarket starters, consider engaging a freight forwarder or logistics provider familiar with international shipping regulations. This will streamline the process and ensure compliance with customs requirements. Evaluate shipping options, such as air freight for speed or sea freight for cost-effectiveness, based on your timelines and budget. Additionally, be prepared for potential duties and taxes, and ensure that your supplier provides the necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance. -

Can I customize aftermarket starters for my specific applications?

Many aftermarket starter manufacturers offer customization options to cater to specific requirements. Customizations can include modifications to fit particular vehicle models, changes in power output, or adjustments to the design for unique applications. When seeking customization, provide detailed specifications and work closely with the manufacturer to ensure feasibility. Keep in mind that custom orders may have different lead times and pricing structures, so it’s important to discuss these factors upfront. -

What should I know about warranty and return policies for aftermarket starters?

Understanding warranty and return policies is crucial when sourcing aftermarket starters. Most reputable suppliers offer warranties that cover defects in materials and workmanship for a specified period, typically ranging from 1 to 3 years. Review the terms carefully to understand what is covered and any conditions that may void the warranty. Additionally, inquire about the return policy in case the starter does not meet your expectations or is incompatible with your vehicles. Clear communication about these policies can help mitigate potential issues in the future.

Top 4 Aftermarket Starters Manufacturers & Suppliers List

1. OEM Starters – Reliability vs. Aftermarket Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Aftermarket starters are generally less reliable compared to OEM starters. OEM starters are more expensive but are known to work better and last longer. Some users report that aftermarket starters can be a gamble, with some lasting long enough to be satisfactory while others fail prematurely. There are concerns about warranties from aftermarket parts, as even with a ‘lifetime warranty’, repeated f…

2. DB Electrical – Premium Starters

Domain: dbelectrical.com

Registered: 2000 (25 years)

Introduction: Starters for automotive, motorcycle, and lawn mower applications. Premium starters at factory-direct pricing. High-quality materials and craftsmanship ensure better performance and longer service life. Meets OEM standards for quality and fitment. Rigorous multipoint testing for reliability. Sealed housings and bearings for efficiency. Savings of up to 30% off retail OEM prices. Fast, free delivery…

3. Discount Starter & Alternator – Infiniti QX60 Starter

Domain: discountstarterandalternator.com

Registered: 2004 (21 years)

Introduction: Aftermarket Car Starters available at Discount Starter & Alternator. Key products include: 1. Starter for Infiniti QX60 2.5L Hybrid (2014-2018) – SKU: 10972N_DSA-1, Condition: New, Price: $119.06. 2. Starter for Ford Fusion / Mercury Milan 3.0L (2006-2009) – SKU: 17945N_DSA-PS-1, Condition: New, Price: $99.06. 3. Starter for Lincoln Zephyr 3.0L (2006) – SKU: 17945N_DSA-PS-2, Condition: New, Price:…

4. Delco Remy – Heavy Duty Starters

Domain: delcoremy.com

Registered: 1998 (27 years)

Introduction: Delco Remy Heavy Duty Starters are designed for heavy duty and off-road vehicles, providing industry-leading reliability and durability. Key features include: complete coverage for all truck classes, buses, off-highway vehicles, and locomotives; Integrated Over Crank Protection (IOCP) to prevent thermal damage; electrical soft-start for reliable engagement; and patented Internal Magnetic Switch So…

Strategic Sourcing Conclusion and Outlook for aftermarket starters

As the aftermarket starter landscape continues to evolve, strategic sourcing emerges as a crucial element for businesses seeking to optimize their supply chain and enhance operational efficiency. By prioritizing quality and performance over mere cost, B2B buyers can secure products that not only meet but exceed OEM standards. This focus on high-quality materials and rigorous testing protocols results in starters that deliver reliable performance and longer service life, ultimately contributing to lower maintenance costs and improved customer satisfaction.

International buyers from regions such as Africa, South America, the Middle East, and Europe should leverage the competitive pricing and advanced technology offered by reputable suppliers. Engaging with manufacturers that maintain stringent quality controls and offer factory-direct pricing can lead to significant savings—often up to 30% off traditional retail prices.

Looking ahead, the demand for premium aftermarket starters is expected to grow, driven by the increasing reliance on vehicles in diverse industries. Now is the time to take action: evaluate your sourcing strategy, partner with trusted suppliers, and position your business for success in a competitive global market. By doing so, you not only enhance your operational capabilities but also ensure that your customers receive the best products available.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.