Introduction: Navigating the Global Market for car alternator failure

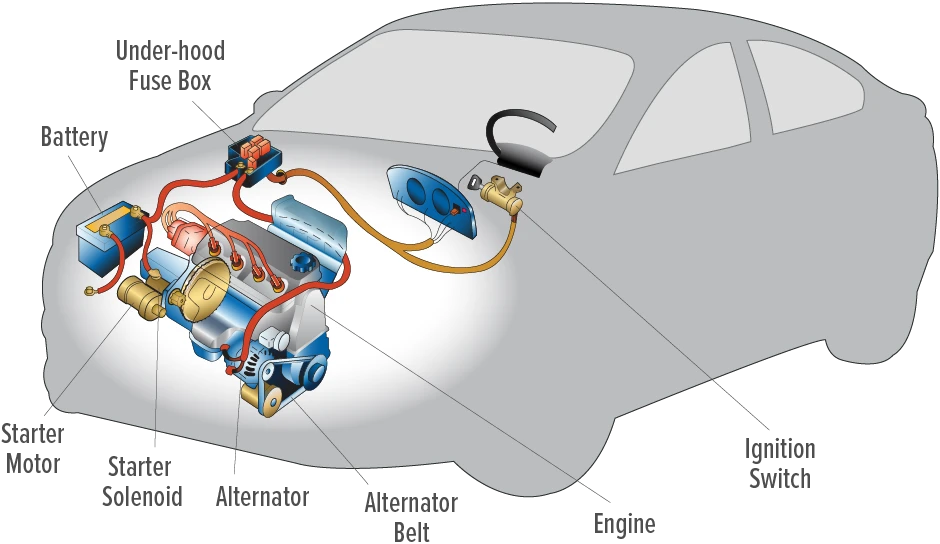

Navigating the complexities of car alternator failure is a significant challenge for international B2B buyers, particularly those operating in emerging markets such as Africa, South America, the Middle East, and Europe. The alternator plays a crucial role in a vehicle’s electrical system, and understanding its failure can lead to costly disruptions and operational inefficiencies. This guide delves into the multifaceted landscape of car alternator issues, examining the types of failures, their applications across various vehicle models, and the critical need for reliable supplier vetting.

In an industry where downtime can translate to lost revenue, making informed purchasing decisions is paramount. This guide equips B2B buyers with the knowledge to identify common causes of alternator failure—such as wiring issues, mechanical wear, and environmental factors—and the implications these may have on their operations. Additionally, we provide insights into cost considerations, maintenance practices, and best practices for sourcing high-quality alternators and components.

By empowering buyers with actionable insights and a thorough understanding of the market, this comprehensive guide aims to facilitate smarter procurement strategies, ensuring that businesses can maintain operational continuity and enhance their overall productivity. Whether you are in Nigeria, Vietnam, or beyond, the information contained within this guide is tailored to support your specific needs in the global automotive market.

Table Of Contents

- Top 3 Car Alternator Failure Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car alternator failure

- Understanding car alternator failure Types and Variations

- Key Industrial Applications of car alternator failure

- 3 Common User Pain Points for ‘car alternator failure’ & Their Solutions

- Strategic Material Selection Guide for car alternator failure

- In-depth Look: Manufacturing Processes and Quality Assurance for car alternator failure

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car alternator failure’

- Comprehensive Cost and Pricing Analysis for car alternator failure Sourcing

- Alternatives Analysis: Comparing car alternator failure With Other Solutions

- Essential Technical Properties and Trade Terminology for car alternator failure

- Navigating Market Dynamics and Sourcing Trends in the car alternator failure Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car alternator failure

- Strategic Sourcing Conclusion and Outlook for car alternator failure

- Important Disclaimer & Terms of Use

Understanding car alternator failure Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electrical Failure | Sudden loss of electrical output; typically due to wiring issues or a blown fuse. | Automotive repair shops, parts suppliers | Pros: Quick diagnosis; Cons: May require extensive troubleshooting. |

| Mechanical Failure | Issues with the alternator’s belt or pulley leading to performance decline. | Fleet maintenance, automotive workshops | Pros: Often preventable with regular maintenance; Cons: Can lead to more extensive engine damage if ignored. |

| Wear and Tear | Gradual degradation of components; common in older vehicles. | Used car dealerships, fleet operators | Pros: Predictable lifespan; Cons: Replacement costs can vary significantly. |

| Overheating | Caused by excessive load or poor ventilation; can damage internal components. | Heavy-duty vehicle maintenance, logistics companies | Pros: High awareness of overheating signs; Cons: May require complete unit replacement. |

| Corrosion and Contamination | Damage from environmental factors like moisture or dirt affecting connections. | Automotive parts distributors, repair services | Pros: Often fixable with cleaning; Cons: May require replacement of affected components. |

What Characterizes Electrical Failure in Alternators?

Electrical failure in alternators is often marked by a sudden loss of power output, which can stem from issues such as wiring faults or blown fuses. This type of failure can disrupt the vehicle’s electrical systems, leading to operational inefficiencies. For B2B buyers, particularly those in automotive repair or parts supply, understanding the signs of electrical failure is crucial for timely interventions. Quick diagnosis tools can enhance service offerings, but extensive troubleshooting may be necessary, which could affect turnaround times.

How Does Mechanical Failure Impact Vehicle Performance?

Mechanical failure primarily involves the alternator’s belt or pulley system, which can wear out over time and lead to decreased performance. This type of failure is particularly relevant for fleet maintenance providers and automotive workshops, as regular inspections can prevent more severe damage. By prioritizing preventive maintenance, businesses can save on future repair costs. However, if ignored, mechanical failures can escalate into more significant issues, necessitating a more costly repair.

Why is Wear and Tear a Common Issue for Older Vehicles?

Wear and tear is a natural process, especially for older vehicles where components may degrade over time. This type of failure is significant for used car dealerships and fleet operators, as it can directly influence resale value and operational reliability. B2B buyers should consider the predictable lifespan of alternators when assessing vehicle condition. However, replacement costs can vary widely based on the vehicle’s make and model, making it essential to maintain accurate cost forecasts.

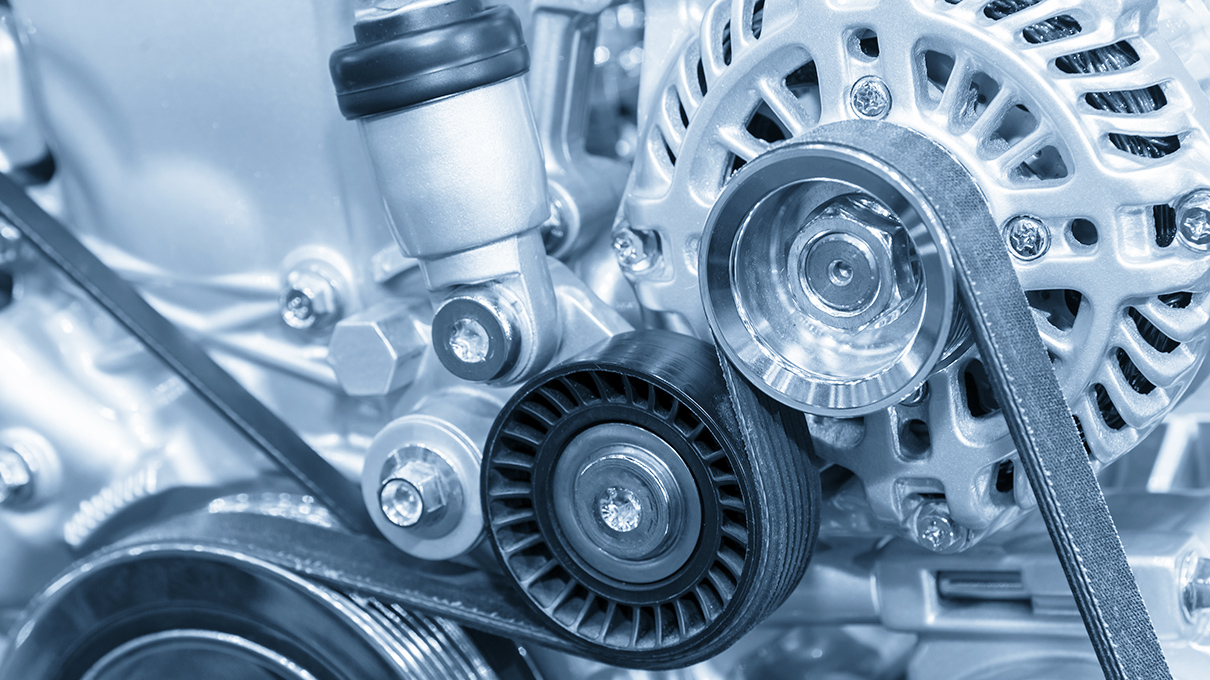

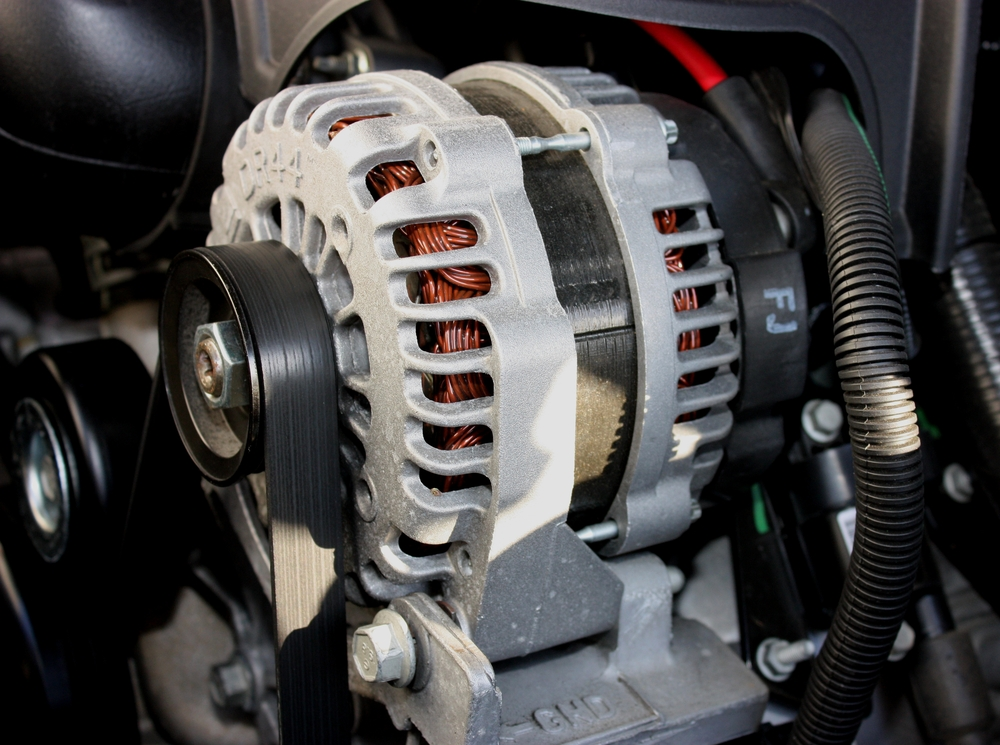

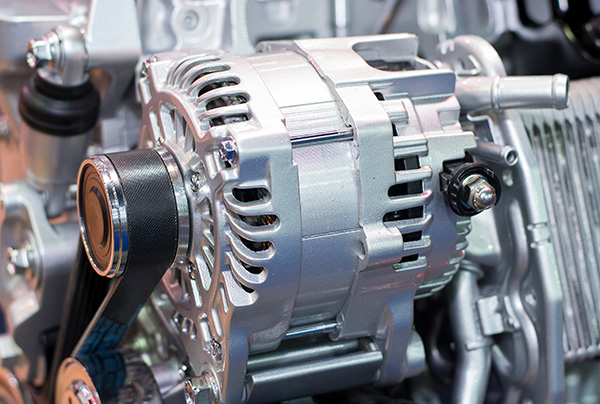

Illustrative image related to car alternator failure

What Causes Alternators to Overheat?

Overheating in alternators can occur due to excessive electrical loads or inadequate ventilation. This type of failure is particularly relevant for heavy-duty vehicles, where the demands on the alternator are more significant. For logistics companies and maintenance providers, recognizing the signs of overheating can lead to proactive measures that extend the lifespan of the alternator. However, once damage occurs, it often necessitates a complete unit replacement, which can be costly.

How Do Corrosion and Contamination Affect Alternators?

Corrosion and contamination are significant concerns for alternators, particularly in environments with high moisture or dirt exposure. This type of failure can damage electrical connections and reduce efficiency. Automotive parts distributors and repair services should be aware of the potential for these issues and offer solutions that include both cleaning and component replacement. While many corrosion issues can be resolved with maintenance, severe cases may require more extensive repairs, impacting both time and costs for B2B buyers.

Key Industrial Applications of car alternator failure

| Industry/Sector | Specific Application of car alternator failure | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnostics and Repair Services | Enhanced service offerings, improved customer retention | Availability of quality replacement parts, technical expertise of staff |

| Transportation & Logistics | Fleet Management and Maintenance | Reduced downtime, improved operational efficiency | Reliability of alternator suppliers, warranty options |

| Agriculture | Agricultural Equipment Maintenance | Ensured operational continuity, reduced repair costs | Access to specialized parts for agricultural machinery |

| Construction | Heavy Machinery Power Systems | Increased machinery uptime, enhanced productivity | Quality assurance in sourcing alternators for heavy use |

| Renewable Energy | Hybrid Vehicle Systems | Supporting sustainable transport, operational reliability | Compatibility with various vehicle models, performance specifications |

How is Car Alternator Failure Relevant in Automotive Repair Services?

In the automotive repair sector, understanding car alternator failure is crucial for diagnostics and repair services. Technicians often encounter issues stemming from alternator malfunctions, which can lead to electrical failures and battery issues. By identifying these problems early, repair shops can enhance their service offerings and improve customer satisfaction. For international buyers, particularly in developing markets like Africa and South America, sourcing quality replacement parts and ensuring staff are trained in modern diagnostic techniques are essential considerations to maintain competitiveness.

Why is Car Alternator Failure a Concern for Transportation and Logistics?

In the transportation and logistics industry, car alternator failure can significantly impact fleet management. A malfunctioning alternator can lead to unexpected breakdowns, resulting in costly downtime. By investing in preventive maintenance and understanding alternator issues, companies can improve their operational efficiency. For buyers in Europe and the Middle East, sourcing reliable alternators with robust warranties is vital to minimize risks associated with vehicle failures.

What Role Does Car Alternator Failure Play in Agricultural Equipment Maintenance?

For agricultural businesses, the reliability of machinery is paramount, and alternator failure can disrupt operations. Agricultural equipment often relies on robust electrical systems for functionality, and a failing alternator can lead to equipment downtime and increased repair costs. Buyers in regions like Africa, where agriculture is a critical economic sector, should prioritize sourcing alternators that meet the specific demands of agricultural machinery, ensuring compatibility and durability under harsh conditions.

How Does Car Alternator Failure Affect Heavy Machinery in Construction?

In the construction industry, heavy machinery is essential for productivity, and alternator failures can lead to significant downtime. Understanding the implications of alternator issues allows construction companies to implement proactive maintenance strategies. For international buyers, especially in developing regions, sourcing high-quality alternators that can withstand the demanding environments of construction sites is crucial for ensuring machinery uptime and operational efficiency.

Why is Understanding Car Alternator Failure Important in Renewable Energy Applications?

In the renewable energy sector, particularly with hybrid vehicles, alternator failure can hinder the efficiency of electric power systems. The alternator is vital for charging batteries and ensuring that electric components function properly. Buyers in this sector need to ensure that alternators are compatible with various hybrid models and meet performance specifications. This focus on compatibility and reliability supports sustainable transport solutions and enhances operational reliability for businesses involved in renewable energy initiatives.

3 Common User Pain Points for ‘car alternator failure’ & Their Solutions

Scenario 1: Unexpected Downtime Due to Alternator Failure

The Problem: B2B buyers managing fleets, particularly in regions with limited access to automotive repair facilities, often face significant challenges when a vehicle’s alternator fails unexpectedly. This can lead to unplanned downtime, which impacts operational efficiency and increases costs. For instance, a logistics company in Nigeria might find that several trucks are immobilized due to alternator issues, leading to delayed deliveries and dissatisfied clients. The inability to quickly identify and address the problem exacerbates the situation, as the fleet manager scrambles to find local repair services.

The Solution: To mitigate unexpected alternator failures, fleet managers should establish a proactive maintenance program that includes regular inspections of alternators and associated components. This can involve scheduling routine checks every 5,000 kilometers or every six months, depending on the vehicle’s usage. Additionally, sourcing high-quality alternators and components from reputable suppliers can prevent premature failures. Implementing an inventory management system for spare parts, including alternators, can also ensure that replacements are readily available when needed. Collaborating with local automotive service providers can facilitate faster repairs and reduce downtime.

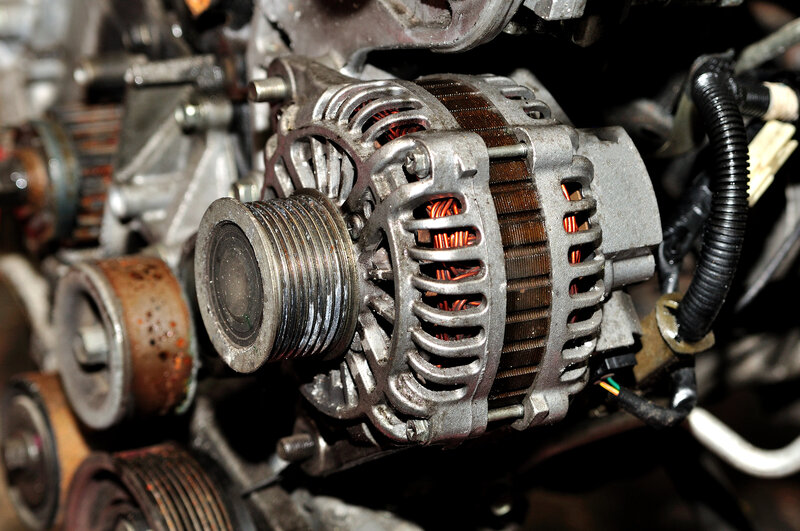

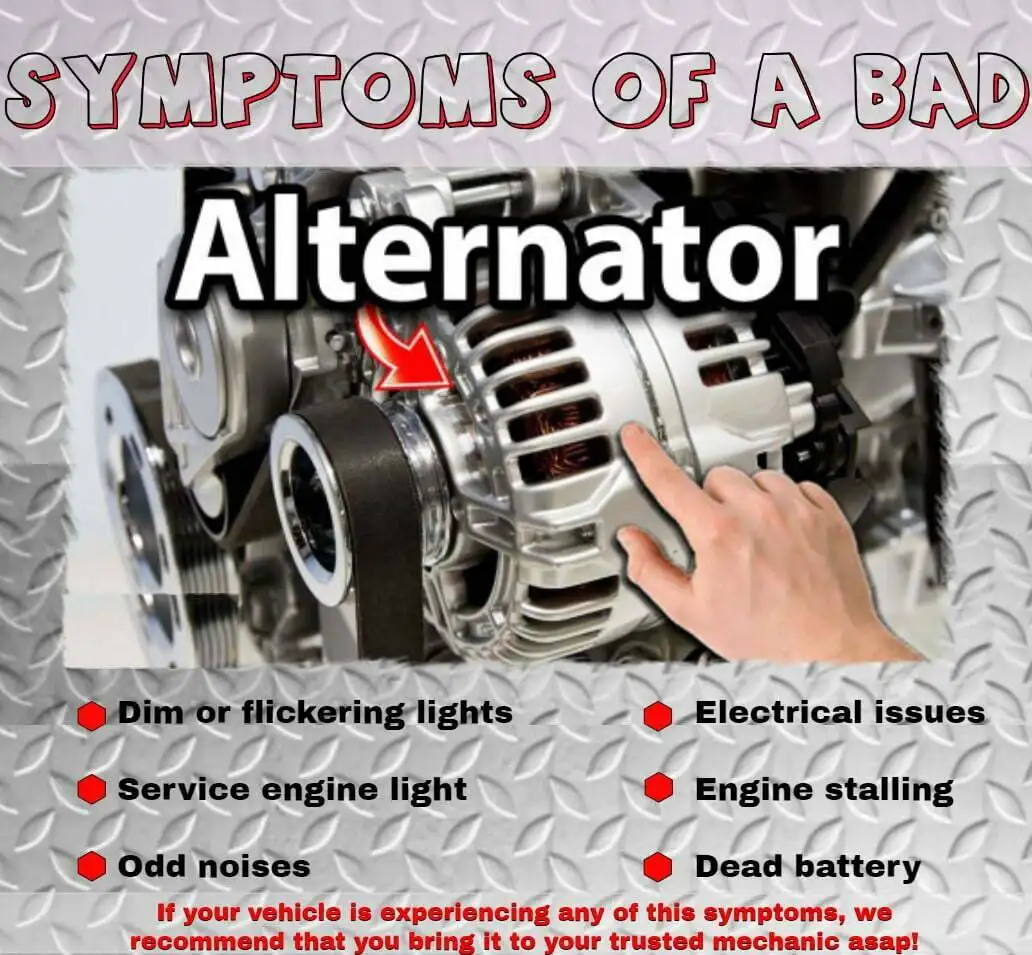

Illustrative image related to car alternator failure

Scenario 2: Difficulty in Identifying Alternator Issues

The Problem: Many B2B buyers, such as small transportation companies or auto rental services, struggle with diagnosing alternator-related problems. Symptoms like dimming lights or frequent battery failures may be misattributed to other electrical issues, leading to unnecessary repairs and costs. For instance, a car rental agency in South America may receive vehicles back with complaints of electrical failures, but without a clear understanding of whether the alternator is to blame, they may waste time and resources on incorrect diagnostics.

The Solution: Investing in diagnostic tools and training for staff can significantly improve the identification of alternator issues. Diagnostic scanners that can read fault codes related to the vehicle’s electrical system should be a standard part of the maintenance toolkit. Additionally, providing training for technicians on recognizing the signs of alternator failure—such as unusual noises, dashboard warning lights, and electrical malfunctions—can enhance the team’s ability to quickly pinpoint the root cause of problems. Establishing a checklist for common symptoms can streamline the diagnostic process and ensure that alternator issues are addressed promptly, thus reducing repair costs and improving vehicle availability.

Scenario 3: High Replacement Costs for Alternators

The Problem: For international buyers, especially in emerging markets, the high cost of alternator replacement can pose a significant financial burden. A fleet manager in Europe may find that the average replacement cost of an alternator, which can range from €250 to €800, negatively impacts the budget, especially when multiple vehicles require service simultaneously. This can lead to tough decisions about vehicle maintenance versus other operational expenditures.

The Solution: To tackle the high costs associated with alternator replacements, B2B buyers should consider investing in refurbished or remanufactured alternators, which can provide a cost-effective alternative without compromising quality. Establishing relationships with trusted suppliers who specialize in refurbished parts can lead to substantial savings. Additionally, fostering a culture of preventive maintenance can extend the lifespan of alternators and reduce the frequency of replacements. Implementing regular checks of belts and wiring can prevent issues that lead to alternator failure, ultimately lowering overall maintenance costs. Buyers should also explore warranties and service agreements that cover alternator replacements, ensuring budget predictability and mitigating financial strain.

Strategic Material Selection Guide for car alternator failure

What Materials Are Commonly Used in Car Alternators and Their Impact on Performance?

When selecting materials for car alternators, it’s crucial to consider their properties, advantages, and disadvantages. The materials used can significantly affect the performance, durability, and overall reliability of the alternator, which is essential for preventing failures that can lead to costly repairs and downtime.

How Does Aluminum Perform in Car Alternators?

Aluminum is a widely used material in car alternators due to its lightweight and excellent conductivity. Key properties include a high strength-to-weight ratio and good corrosion resistance, making it suitable for automotive applications exposed to various environmental conditions.

Pros: Aluminum is durable and cost-effective, allowing manufacturers to produce lightweight components that enhance fuel efficiency. It also has a lower thermal expansion rate, which is beneficial for maintaining dimensional stability under varying temperatures.

Cons: While aluminum is resistant to corrosion, it can be prone to fatigue over time, particularly in high-stress applications. Additionally, it may not be as strong as other materials like steel, which could limit its use in certain high-load scenarios.

Impact on Application: Aluminum’s compatibility with electrical components makes it ideal for use in alternators, where efficient electrical conduction is critical.

Considerations for International Buyers: Buyers should ensure that aluminum components meet international standards such as ASTM B221 for extruded aluminum and consider local regulations regarding material sourcing and recycling.

What Role Does Copper Play in Alternator Design?

Copper is another common material used in car alternators, particularly for windings and electrical connections due to its superior electrical conductivity.

Pros: Copper has excellent thermal and electrical conductivity, which enhances the efficiency of the alternator. It is also highly ductile, allowing for complex shapes and configurations in winding designs.

Cons: The primary drawback of copper is its susceptibility to corrosion, especially in humid environments, which can lead to electrical failures. Additionally, copper is generally more expensive than aluminum, impacting the overall cost of the alternator.

Impact on Application: Copper’s high conductivity ensures optimal performance in electrical systems, making it essential for reliable alternator operation.

Considerations for International Buyers: Compliance with standards like ASTM B170 for copper wire is essential. Buyers in regions with high humidity, such as parts of Africa and South America, should consider copper’s corrosion resistance and potential protective coatings.

How Do Plastics Contribute to Alternator Functionality?

Plastics are often used in alternator housings and insulators due to their lightweight and insulating properties.

Pros: Plastics are resistant to corrosion and can be molded into complex shapes, making them suitable for various components. They also provide excellent electrical insulation, which is vital for safety.

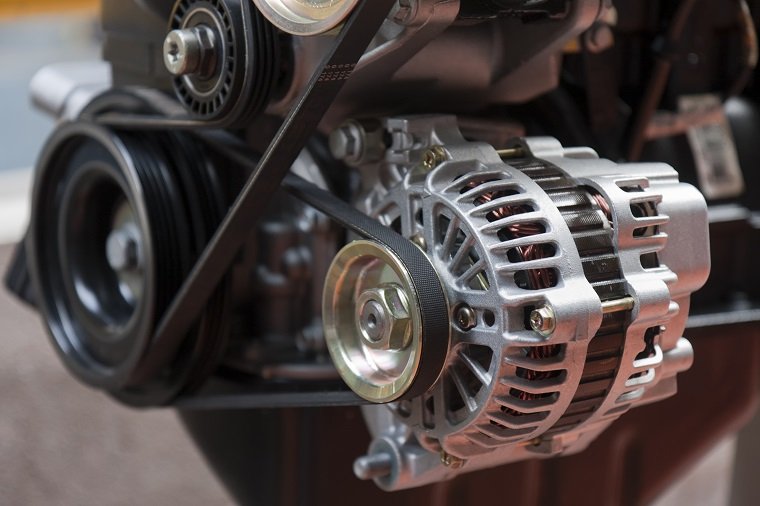

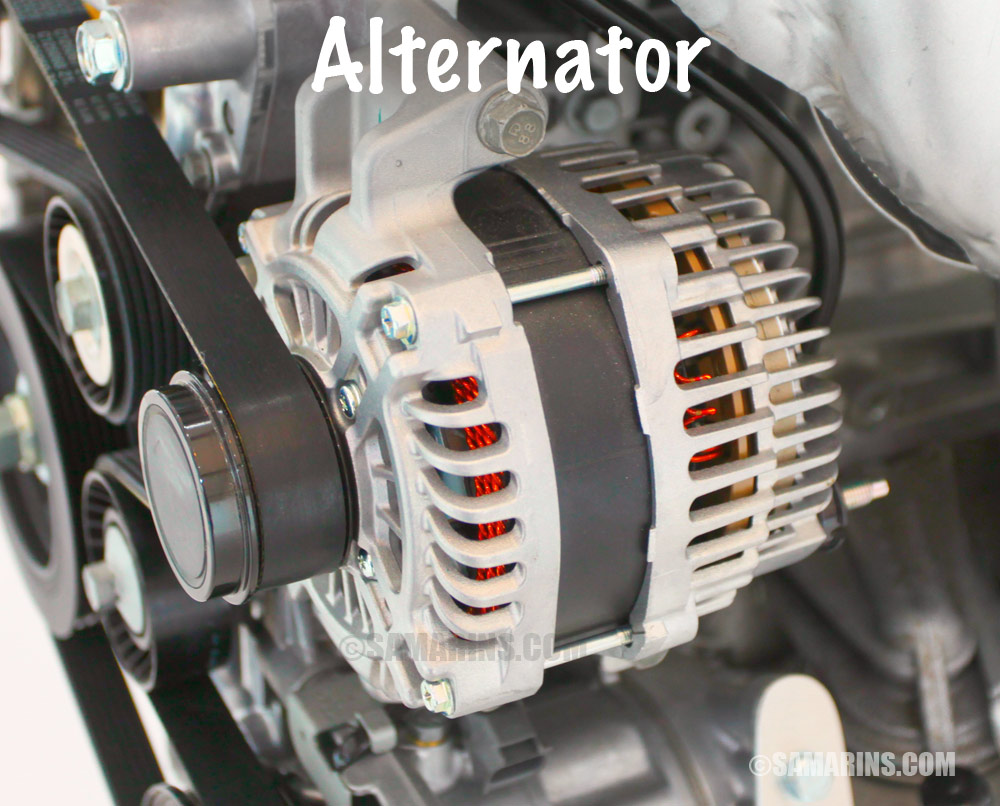

Illustrative image related to car alternator failure

Cons: Plastics may not withstand high temperatures as effectively as metals, leading to potential deformation or failure in extreme conditions. They can also be less durable than metals over time.

Impact on Application: The use of plastics in non-load-bearing components can reduce overall weight and improve fuel efficiency without compromising electrical insulation.

Considerations for International Buyers: Buyers should ensure that plastics comply with international standards such as ISO 9001 for quality management. Additionally, they should consider the temperature ratings of plastics to ensure they are suitable for local climate conditions.

What About Steel in Alternator Manufacturing?

Steel is used in some alternator components, particularly in structural parts like brackets and frames due to its strength and durability.

Pros: Steel offers high tensile strength and resistance to wear and tear, making it suitable for load-bearing applications. It is also relatively cost-effective compared to other metals.

Cons: Steel is heavier than aluminum and can be prone to rust if not properly treated. This can lead to increased weight and potential corrosion issues in humid environments.

Impact on Application: Steel’s strength is beneficial for components that require high durability, but its weight may impact fuel efficiency.

Illustrative image related to car alternator failure

Considerations for International Buyers: Buyers should ensure that steel components meet standards like ASTM A36 for structural steel. In humid climates, additional protective coatings may be necessary to prevent rust.

Summary Table of Material Selection for Car Alternator Failure

| Material | Typical Use Case for car alternator failure | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Prone to fatigue over time | Medium |

| Copper | Windings and electrical connections | Superior electrical conductivity | Susceptible to corrosion | High |

| Plastics | Insulators and non-load-bearing components | Excellent insulation and corrosion resistance | Limited high-temperature performance | Low |

| Steel | Structural parts like brackets and frames | High strength and durability | Heavier and prone to rust | Medium |

This analysis provides B2B buyers with a comprehensive overview of material options for car alternators, emphasizing the importance of material selection in preventing failures and ensuring reliable performance across diverse geographical markets.

In-depth Look: Manufacturing Processes and Quality Assurance for car alternator failure

What Are the Key Stages in the Manufacturing Process of Car Alternators?

The manufacturing process of car alternators involves several critical stages that ensure the final product meets the necessary performance and quality standards. Understanding these stages is essential for B2B buyers who seek reliable alternators for their automotive needs.

Material Preparation: What Raw Materials Are Used?

The first stage in manufacturing alternators is the preparation of raw materials. Typically, these materials include high-grade aluminum for the housing, copper for the windings, and various types of steel for the rotor and stator components. Quality control begins at this stage, as the selection of materials significantly impacts the durability and efficiency of the alternator.

Manufacturers often perform chemical analyses and mechanical tests on these materials to verify their integrity. Suppliers should be able to provide certificates of conformity or material safety data sheets (MSDS) to assure buyers of the quality of the raw materials used.

How Are Alternator Components Formed?

Once the materials are prepared, the next step is forming the individual components of the alternator. This involves processes like die-casting for the aluminum housing, stamping for the steel components, and winding for the copper coils.

Advanced techniques, such as Computer Numerical Control (CNC) machining, are often employed to achieve high precision in component manufacturing. For B2B buyers, understanding the specific techniques used can be crucial, as they directly affect the alternator’s performance and reliability.

What Are the Assembly and Finishing Processes for Alternators?

What Does the Assembly Process Involve?

After the components are formed, they are assembled into the final alternator unit. This stage typically involves fitting the rotor into the stator, connecting the winding, and securing the housing. Quality assurance during assembly is vital, as any misalignment or improper connections can lead to premature alternator failure.

Illustrative image related to car alternator failure

Manufacturers often implement assembly line techniques that allow for efficient production while maintaining high quality. B2B buyers should inquire about the assembly methods used and whether they include automated inspection systems to catch defects early.

How Is the Finishing Stage Performed?

The finishing stage involves applying protective coatings and conducting final inspections. This can include processes like anodizing aluminum parts to prevent corrosion, as well as painting for aesthetic purposes. Additionally, finishing may involve electrical testing to ensure that the alternator meets specific voltage and current output standards.

What Quality Control Standards Are Relevant for Alternator Manufacturing?

Which International Standards Should Buyers Look For?

B2B buyers must consider the quality assurance protocols that manufacturers adhere to. The ISO 9001 standard is a globally recognized quality management system that emphasizes consistency and continuous improvement. Manufacturers that are ISO 9001 certified demonstrate a commitment to quality management, which can assure buyers of their reliability.

In addition to ISO standards, industry-specific certifications like CE marking for compliance with European safety directives and API standards for automotive parts may be relevant. These certifications provide an additional layer of assurance that the alternators meet both safety and performance standards.

What Are the Key Quality Checkpoints in Manufacturing?

Quality checkpoints throughout the manufacturing process are essential for ensuring that the final product meets specifications. These checkpoints typically include:

- Incoming Quality Control (IQC): This is where raw materials are inspected upon arrival to ensure they meet quality standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to catch defects early. This may involve visual inspections or measurements taken during the forming and assembly stages.

- Final Quality Control (FQC): Before the alternators are shipped, a final inspection is performed. This may include functional testing to ensure the alternator operates within specified parameters.

How Can B2B Buyers Verify Supplier Quality Control?

What Should Buyers Look For in Supplier Audits and Reports?

To ensure that a manufacturer meets quality standards, B2B buyers should conduct thorough audits. These audits can be either pre-qualifying or ongoing, focusing on the manufacturer’s quality management systems, production capabilities, and adherence to international standards.

Buyers should request quality control reports that detail inspection results and any corrective actions taken. This transparency helps build trust and verifies that the manufacturer is committed to producing high-quality alternators.

Are Third-Party Inspections Necessary?

Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can perform random checks and audits to validate the manufacturer’s quality claims. For B2B buyers, especially those sourcing from regions with varying quality standards, third-party inspections can provide peace of mind.

Illustrative image related to car alternator failure

What Are the Quality Control Nuances for International B2B Buyers?

How Do Regional Standards Affect Quality Assurance?

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding regional standards is crucial. Different countries may have specific regulations regarding automotive parts, affecting the type of certifications and tests required. Buyers should be aware of these nuances to ensure compliance and avoid potential issues when importing alternators.

What Are the Common Challenges in Quality Assurance?

Challenges such as inconsistent quality from suppliers or variations in manufacturing practices can pose risks. B2B buyers should establish clear communication channels with manufacturers to address these challenges proactively. Additionally, considering suppliers with a proven track record in their respective regions can mitigate risks associated with alternator failure.

In conclusion, understanding the manufacturing processes and quality assurance protocols for car alternators is essential for B2B buyers. By focusing on material quality, manufacturing techniques, and robust quality control measures, buyers can make informed decisions that enhance their supply chain and reduce the risk of alternator failures.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car alternator failure’

This practical sourcing guide aims to assist B2B buyers in efficiently procuring solutions related to car alternator failure. Alternators are crucial for the operation of vehicles, and understanding how to source the right products and services can significantly impact vehicle performance and reliability.

Step 1: Identify Your Needs and Specifications

Begin by clearly defining the technical requirements for the alternators or related components you need. Consider factors such as vehicle make and model, expected lifespan, and specific electrical demands. This step is essential to ensure compatibility and optimal performance, minimizing the risk of future failures.

Illustrative image related to car alternator failure

Step 2: Research Reliable Suppliers

Conduct comprehensive research to identify reputable suppliers specializing in automotive electrical components. Look for suppliers with a proven track record in the industry and positive reviews from clients. Reliable suppliers often provide warranties and support, which can be crucial for ongoing maintenance.

- Sub-bullet: Investigate online platforms and trade shows to find potential suppliers.

- Sub-bullet: Join industry forums to gather recommendations from peers.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that your potential suppliers hold relevant certifications and comply with international quality standards. Certifications like ISO 9001 indicate a commitment to quality management, which is critical for ensuring the reliability of the products you intend to purchase.

Step 4: Request Product Samples

It’s wise to request samples of the alternators or components you are considering. Testing samples allows you to assess quality, durability, and compatibility with your vehicles. This hands-on evaluation can prevent costly mistakes and ensure you are making informed purchasing decisions.

Illustrative image related to car alternator failure

Step 5: Assess Pricing and Terms of Sale

Compare pricing among different suppliers while also considering the terms of sale. Look for transparency regarding shipping costs, payment terms, and return policies. Understanding the total cost of ownership, including potential repair and maintenance expenses, can help you make a more informed decision.

- Sub-bullet: Inquire about bulk purchasing discounts if you plan to order large quantities.

- Sub-bullet: Confirm warranty terms and conditions for the products.

Step 6: Establish Communication Channels

Effective communication with your suppliers is vital for a successful procurement process. Ensure that you establish clear lines of communication for addressing any queries, concerns, or issues that may arise. This can facilitate smoother transactions and better service levels.

Step 7: Plan for Ongoing Support and Maintenance

Lastly, consider the long-term support and maintenance options provided by your suppliers. Establishing a partnership with a supplier who offers ongoing support can enhance your operational efficiency. This includes access to technical assistance, training, and reliable replacement parts.

By following these steps, B2B buyers can navigate the complexities of sourcing solutions for car alternator failure effectively, ensuring they secure high-quality products and services that meet their specific needs.

Comprehensive Cost and Pricing Analysis for car alternator failure Sourcing

What are the Key Cost Components in Sourcing for Car Alternator Failure?

When sourcing components related to car alternator failure, understanding the cost structure is crucial for B2B buyers. The major cost components include:

-

Materials: The quality and type of materials used in alternator production significantly influence costs. High-grade copper for windings, durable plastics for casings, and robust metals for structural components are essential for reliability and longevity. Sourcing materials from local suppliers can sometimes reduce costs but may compromise on quality.

-

Labor: Labor costs vary widely based on geographic location and labor market conditions. Regions with a skilled workforce may have higher labor costs, but this can lead to better craftsmanship and reliability.

-

Manufacturing Overhead: This includes costs related to the facility, utilities, and equipment used in production. Efficient manufacturing processes can reduce overhead costs, which can be passed on to buyers.

-

Tooling: The initial setup for manufacturing alternators requires investment in tooling, which can be a significant upfront cost. For custom or specialized alternators, these costs can increase.

-

Quality Control (QC): Ensuring that alternators meet specific quality standards incurs additional costs. Investing in rigorous QC processes can prevent future failures, ultimately saving money in the long term.

-

Logistics: Shipping and handling costs can vary significantly based on the supplier’s location and the destination. Buyers must consider both local and international logistics, including customs duties and potential delays.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on competition, demand, and the uniqueness of their product offerings.

What Influences Pricing in the Alternator Market?

Several factors can influence pricing for alternator components and replacements:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract discounts. Establishing a long-term relationship with suppliers can allow buyers to negotiate better terms based on anticipated volumes.

-

Specifications and Customization: Custom alternators or specific features can lead to higher costs. Buyers should evaluate whether customization is necessary or if standard models will suffice.

-

Materials and Quality Certifications: Alternators with higher-quality materials or those that meet specific international quality standards (e.g., ISO certifications) may command higher prices, but they also offer better reliability.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers may charge more but often provide better warranties and customer service.

-

Incoterms: Understanding the terms of delivery (Incoterms) is vital. Costs can vary significantly based on whether the buyer or seller is responsible for shipping and insurance.

How Can Buyers Optimize Costs and Pricing Strategies?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, several strategies can help optimize costs:

-

Negotiation: Engage suppliers in discussions to lower prices, especially if you can guarantee larger orders or longer contracts. Understanding the supplier’s cost structure can provide leverage in negotiations.

-

Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, warranty, and potential downtime due to alternator failures. Sometimes, investing in a higher-quality alternator may lead to lower TCO.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and regional economic conditions that may affect pricing. Additionally, consider local regulations that might influence costs, such as import tariffs or environmental regulations.

Conclusion and Disclaimer

Understanding the comprehensive cost and pricing structure associated with car alternator sourcing is essential for making informed purchasing decisions. Prices can vary widely based on numerous factors, including material quality, supplier reputation, and order size.

Buyers are encouraged to conduct thorough market research and engage with multiple suppliers to ensure they receive the best possible value. The pricing information presented is indicative and can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements.

Illustrative image related to car alternator failure

Alternatives Analysis: Comparing car alternator failure With Other Solutions

Understanding Alternatives to Car Alternator Failure

When discussing car alternator failure, it is essential to consider viable alternatives that can prevent or address issues related to vehicle electrical systems. This analysis compares traditional car alternators with two alternatives: battery management systems (BMS) and regenerative braking systems. By understanding these alternatives, B2B buyers can make informed decisions about vehicle maintenance and technology investments.

| Comparison Aspect | Car Alternator Failure | Battery Management System (BMS) | Regenerative Braking System |

|---|---|---|---|

| Performance | Essential for charging the battery and powering electrical systems; failure leads to total loss of functionality. | Optimizes battery usage, extends battery life, and prevents overcharging; enhances overall vehicle efficiency. | Converts kinetic energy back into usable electrical energy, improving overall vehicle efficiency and reducing wear on traditional systems. |

| Cost | Replacement costs can range from £250 to £800 depending on vehicle type and service. | Initial setup can be expensive but reduces long-term battery replacement costs. | Higher upfront investment; however, it can lead to reduced fuel consumption and lower maintenance costs. |

| Ease of Implementation | Replacement typically involves professional service, which can be time-consuming. | Integration requires expertise; can be complex depending on vehicle design. | Requires retrofitting existing vehicles; complexity depends on vehicle type and existing systems. |

| Maintenance | Regular inspections needed; repairs can be costly if not addressed timely. | Minimal maintenance required once installed; software updates may be necessary. | Requires periodic checks but generally low maintenance once installed correctly. |

| Best Use Case | Suitable for traditional internal combustion engine vehicles; necessary for basic functionality. | Ideal for electric and hybrid vehicles where battery longevity is critical. | Best for electric and hybrid vehicles to enhance efficiency and energy recovery. |

What Are the Advantages and Disadvantages of a Battery Management System (BMS)?

A Battery Management System (BMS) is designed to monitor and manage battery performance, ensuring optimal charging and discharging cycles. The primary advantage of a BMS is its ability to extend the life of batteries, which is particularly beneficial for electric and hybrid vehicles. By preventing overcharging and deep discharging, BMS enhances overall vehicle efficiency and reduces the frequency of battery replacements. However, the initial investment for a BMS can be high, which may deter some buyers. Additionally, the integration process can be complex, requiring specialized knowledge and skills.

How Does a Regenerative Braking System Work as an Alternative?

Regenerative braking systems offer a unique solution by converting kinetic energy generated during braking back into electrical energy, which can then be used to recharge the vehicle’s battery. This technology not only increases the overall efficiency of electric and hybrid vehicles but also reduces reliance on traditional alternators. The main advantage is the reduction in energy waste, leading to lower fuel consumption and decreased wear on conventional braking systems. However, the initial setup can be costly, and retrofitting existing vehicles may present challenges depending on the vehicle’s design and existing systems.

Illustrative image related to car alternator failure

How Should B2B Buyers Choose the Right Solution?

When deciding between traditional car alternators, battery management systems, and regenerative braking systems, B2B buyers should consider several factors, including vehicle type, intended use, and budget constraints. For businesses operating fleets of traditional vehicles, ensuring reliable alternator performance is critical. Conversely, companies looking to invest in electric or hybrid technology may find BMS and regenerative braking systems more aligned with their efficiency goals and long-term cost savings. Ultimately, the best solution will depend on the specific operational needs and financial considerations of the business.

Essential Technical Properties and Trade Terminology for car alternator failure

What Are the Key Technical Properties of Car Alternators?

Understanding the essential technical properties of car alternators is crucial for B2B buyers, especially when sourcing components for repair or manufacturing. Here are some critical specifications to consider:

1. Material Grade

The materials used in alternator construction significantly affect durability and performance. Common materials include aluminum for the housing and copper for windings. High-grade materials ensure better conductivity, resistance to corrosion, and overall longevity. For buyers, selecting alternators made from high-quality materials can lead to reduced failure rates and lower maintenance costs.

2. Output Rating (Amperage)

The output rating, typically measured in amperes (A), indicates the amount of electrical current an alternator can produce. Most vehicle alternators range from 40A to over 150A, depending on the vehicle’s electrical demands. Understanding the appropriate amperage is essential for ensuring that the alternator meets the electrical needs of the vehicle, preventing overloads or failures.

3. Voltage Regulation

Alternators typically operate at a standard voltage of 12V for most vehicles. Voltage regulation is crucial to maintain stable output regardless of engine speed. A well-regulated alternator prevents electrical surges that can damage sensitive components. Buyers should ensure that the alternators they source have reliable voltage regulation systems to enhance vehicle performance and safety.

4. Bearing Type

The type of bearings used in the alternator affects its efficiency and noise levels. Common types include ball bearings and bushings. Ball bearings generally provide smoother operation and longer life but may come at a higher cost. Understanding bearing types can help buyers choose alternators that align with their performance and budget needs.

5. Tolerance Levels

Tolerance levels refer to the permissible limits of variation in the dimensions of alternator components. High tolerance levels are crucial for ensuring proper fit and function, particularly in applications where vibration and heat are prevalent. Buyers should prioritize suppliers who adhere to strict tolerance specifications to minimize the risk of premature failure.

6. Cooling Mechanism

Some alternators come equipped with built-in cooling mechanisms, such as fans or heat sinks, to dissipate heat generated during operation. A robust cooling system extends the life of the alternator, especially in high-demand situations. Buyers should assess the cooling capabilities of alternators to ensure they can handle the operating conditions of the vehicles they service.

What Are Common Trade Terms Related to Car Alternator Failure?

Familiarity with industry jargon can enhance communication and streamline procurement processes. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts produced by the vehicle manufacturer or its authorized suppliers. OEM alternators are designed to match the exact specifications of the original components, ensuring compatibility and reliability. Buyers often prefer OEM parts for their quality assurance and warranty coverage.

Illustrative image related to car alternator failure

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory effectively and reduce costs. Suppliers with flexible MOQs can facilitate better purchasing strategies for businesses with varying needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting pricing and terms for specific products or services. Issuing an RFQ for alternators allows buyers to compare offers from multiple suppliers, ensuring they receive competitive pricing and favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping and delivery. Understanding these terms helps businesses clarify shipping costs, risks, and responsibilities, facilitating smoother international transactions.

5. Aftermarket

The aftermarket refers to parts and accessories that are not sourced from the original manufacturer. Aftermarket alternators can offer cost-effective alternatives but may vary in quality. Buyers should evaluate aftermarket options carefully to ensure they meet performance standards.

6. Warranty

A warranty is a guarantee provided by the manufacturer or supplier that covers repairs or replacements for a specified period. Understanding warranty terms is essential for B2B buyers to protect their investments and mitigate risks associated with alternator failures.

Navigating Market Dynamics and Sourcing Trends in the car alternator failure Sector

What Are the Current Market Dynamics Influencing Car Alternator Failure?

The global automotive sector is undergoing significant transformations driven by technological advancements and changing consumer expectations. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for strategic sourcing decisions. One of the primary drivers of alternator failure is the growing complexity of vehicle electrical systems, which place higher demands on alternators. As vehicles become increasingly reliant on electronic components for functions such as infotainment and safety systems, the likelihood of alternator-related issues rises, presenting both challenges and opportunities for suppliers.

Emerging trends in the automotive market include a shift towards electric vehicles (EVs) and hybrid models, which utilize alternators differently compared to traditional combustion engines. This shift necessitates a reevaluation of sourcing strategies, as suppliers must adapt to new technologies that influence alternator design and functionality. Additionally, the rise of digital platforms for parts procurement is transforming how businesses source components. B2B buyers can leverage online marketplaces and data analytics to identify reliable suppliers and optimize inventory management.

Furthermore, the increasing focus on vehicle maintenance and preventative care highlights the importance of quality assurance in alternator components. Buyers are now more inclined to invest in high-quality parts that offer longevity and reliability, rather than opting for the cheapest alternatives. This trend is particularly relevant in developing markets, where the cost of vehicle downtime can significantly impact operations.

How Can Sustainability and Ethical Sourcing Impact the Car Alternator Sector?

Sustainability is becoming a pivotal consideration in the automotive supply chain, particularly in the context of car alternator failure. The environmental impact of sourcing materials and manufacturing processes has drawn scrutiny, with buyers increasingly favoring suppliers that prioritize eco-friendly practices. This includes the use of sustainable materials and energy-efficient manufacturing processes, which not only reduce carbon footprints but also enhance brand reputation.

Illustrative image related to car alternator failure

Ethical sourcing has gained prominence as consumers demand transparency in supply chains. For B2B buyers, this means selecting suppliers who adhere to ethical labor practices and prioritize fair trade. Certifications such as ISO 14001 for environmental management and ISO 26000 for social responsibility can serve as benchmarks for assessing potential suppliers.

Additionally, the trend towards circular economy principles is reshaping the landscape for alternator production. Suppliers that incorporate recycled materials or offer refurbishment services for faulty alternators can appeal to environmentally conscious buyers. Emphasizing sustainability not only aligns with global environmental goals but can also lead to cost savings through improved resource efficiency.

What Is the Historical Context of Car Alternator Technology?

The evolution of car alternators dates back to the early 20th century when vehicles primarily relied on direct current (DC) generators. The introduction of the alternator in the 1960s marked a significant technological advancement, enabling more efficient power generation and battery charging. As automotive technology progressed, alternators evolved to meet the increasing electrical demands of modern vehicles.

The development of smart alternators, which can adjust output based on real-time energy needs, represents the latest innovation in this sector. This historical context is crucial for B2B buyers, as understanding the technological advancements can inform sourcing decisions and highlight the importance of compatibility with newer vehicle models.

In summary, navigating the complexities of the car alternator failure sector requires an awareness of market dynamics, an emphasis on sustainability, and an understanding of the historical evolution of technology. These insights empower international B2B buyers to make informed decisions that align with both operational needs and broader industry trends.

Frequently Asked Questions (FAQs) for B2B Buyers of car alternator failure

-

How do I identify the signs of car alternator failure?

Identifying the signs of alternator failure is crucial for maintaining vehicle performance. Common indicators include a dashboard warning light resembling a battery, dim or flickering headlights, and difficulty starting the engine. Additionally, unusual noises from the engine, such as grinding or a burning rubber smell, may suggest alternator issues. Regular inspections and monitoring these symptoms can help prevent larger electrical problems and costly repairs, ensuring your fleet remains operational. -

What is the best way to source replacement alternators for my fleet?

When sourcing replacement alternators, prioritize suppliers that offer high-quality products with a proven track record. Look for manufacturers that provide warranties and have certifications for quality assurance. It’s beneficial to evaluate suppliers through trade shows, industry directories, or recommendations from trusted sources. Consider suppliers that can customize products to fit specific vehicle models in your fleet, which can enhance performance and reliability. -

What are the typical lead times for ordering car alternators?

Lead times for ordering car alternators can vary significantly based on the supplier and the complexity of your order. Generally, expect anywhere from one week to several weeks, depending on whether the alternators are in stock or need to be manufactured. For international orders, customs processing may add additional time. To minimize delays, communicate your needs clearly and confirm the supplier’s ability to meet your timeline before placing an order. -

What payment terms should I consider when purchasing alternators internationally?

When purchasing alternators internationally, consider payment terms that protect both parties. Common options include advance payments, letters of credit, or payment upon delivery. Ensure that the terms are clearly outlined in your contract to avoid misunderstandings. Additionally, assess the supplier’s reputation and financial stability to mitigate risks. Establishing a mutual agreement on payment terms can help foster a strong business relationship. -

How can I ensure quality assurance for alternators sourced from international suppliers?

To ensure quality assurance for alternators sourced internationally, request detailed specifications and certifications from suppliers. Consider implementing a quality control process that includes pre-shipment inspections and testing of the alternators. Collaborating with third-party inspection services can provide an unbiased assessment of product quality. Additionally, establishing a clear return and warranty policy can safeguard your investment against defective products. -

What are the minimum order quantities (MOQ) for alternators, and how do they affect pricing?

Minimum order quantities (MOQ) for alternators can vary by supplier and are often influenced by production costs. Typically, higher MOQs can lead to lower per-unit prices, while smaller orders may incur higher costs due to limited production runs. When negotiating with suppliers, consider your inventory needs and explore options for bulk purchasing or phased orders to optimize pricing without overcommitting your resources. -

How do wiring issues contribute to alternator failure, and what preventive measures can I take?

Wiring issues can significantly contribute to alternator failure, as damaged or frayed wires can disrupt the electrical flow needed for proper function. To prevent these issues, conduct regular inspections of the vehicle’s wiring system, focusing on connections and insulation. Implementing a preventive maintenance schedule that includes checking and replacing worn wiring can enhance the longevity of your alternators and reduce the likelihood of failure. -

What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider logistics factors such as shipping methods, customs regulations, and import duties. Choose a reliable freight forwarder with experience in handling automotive parts to ensure timely delivery. Familiarize yourself with the local regulations in your country regarding the import of automotive components to avoid unexpected delays. Proper planning and communication with your supplier can streamline the logistics process and reduce costs.

Top 3 Car Alternator Failure Manufacturers & Suppliers List

1. Honda Odyssey – Alternator Troubleshooting

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Honda Odyssey, alternator issue, battery jump start, AAA towing service ($54 membership + $57 tow), mechanic labor and parts ($400), oil change included, ‘Check Charge System’ warning, 50 miles driven after warning before battery died.

2. Alternator Replacement Cost – UK Overview

Domain: rac.co.uk

Registered: 1996 (29 years)

Introduction: Alternator replacement cost in the UK ranges from £250 to £800, with an average cost of £535.05 for parts and labor. Average replacement costs by manufacturer include: Audi £628.59, BMW £603.37, Citroen £629.99, Ford £494.90, Mercedes £614.57, MINI £549.36, Nissan £482.06, Peugeot £663.06, Renault £587.78, Toyota £477.93, Vauxhall £477.93, Volkswagen £507.07, Volvo £539.62.

3. Dodge Avenger – Alternator Issues

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: 2012 Dodge Avenger SXT, 2.4 L GEMA I4 DOHC 16V Dual VVT, 6-speed automatic, FWD, alternator issues, premature failure, second alternator replacement, first alternator failed at 40,000 miles, current mileage 74,000, potential causes include mechanical failure, over-tightened belt, quality of parts, oil/fuel leaks, and debris.

Strategic Sourcing Conclusion and Outlook for car alternator failure

In navigating the complexities of car alternator failure, strategic sourcing emerges as a critical component for international B2B buyers. Understanding the primary causes—such as wiring issues, worn-out components, and the need for regular maintenance—enables buyers to make informed decisions. By prioritizing quality parts and reliable suppliers, businesses can mitigate downtime and enhance operational efficiency, ultimately leading to improved customer satisfaction.

Investing in high-quality alternators and components can yield long-term savings by reducing the frequency of replacements and repairs. Additionally, fostering relationships with reputable manufacturers ensures access to the latest technologies and innovations, which can be pivotal in regions facing unique challenges, such as those in Africa, South America, the Middle East, and Europe.

Illustrative image related to car alternator failure

Looking ahead, the automotive sector is expected to evolve rapidly, influenced by advances in electric vehicles and sustainability initiatives. Now is the time for B2B buyers to reassess their sourcing strategies and align with partners who share a commitment to quality and innovation. By doing so, they can position themselves competitively in an ever-changing market landscape. Embrace this opportunity to enhance your supply chain and drive growth in your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.