Introduction: Navigating the Global Market for starter motor

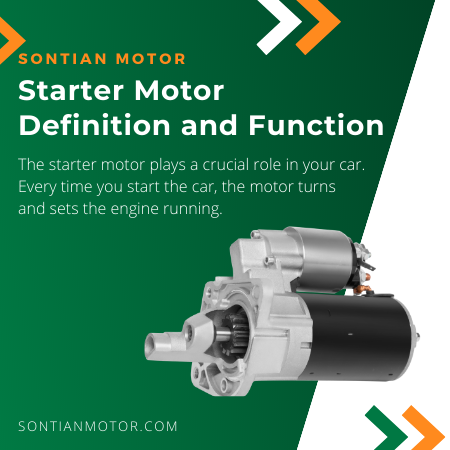

In the complex landscape of automotive components, sourcing a reliable starter motor can pose significant challenges for international B2B buyers. The starter motor is a crucial element in internal combustion engines, responsible for initiating the engine’s operation. Understanding the intricacies of this component is essential for businesses in regions like Africa, South America, the Middle East, and Europe, where diverse vehicle types and varying market conditions exist.

This comprehensive guide delves into the various types of starter motors available, their applications across different vehicle models, and the importance of proper supplier vetting to ensure quality and reliability. Additionally, it covers critical factors such as cost considerations and maintenance practices that can impact overall operational efficiency. By providing actionable insights and expert recommendations, this guide empowers B2B buyers to make informed purchasing decisions that align with their specific operational needs and market dynamics.

With the automotive industry continually evolving, having access to reliable information and resources is vital for staying competitive. This guide serves as a valuable tool for businesses seeking to navigate the global market for starter motors, ensuring they can source the best products while minimizing risks and maximizing value.

Table Of Contents

- Top 5 Starter Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter motor

- Understanding starter motor Types and Variations

- Key Industrial Applications of starter motor

- 3 Common User Pain Points for ‘starter motor’ & Their Solutions

- Strategic Material Selection Guide for starter motor

- In-depth Look: Manufacturing Processes and Quality Assurance for starter motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor’

- Comprehensive Cost and Pricing Analysis for starter motor Sourcing

- Alternatives Analysis: Comparing starter motor With Other Solutions

- Essential Technical Properties and Trade Terminology for starter motor

- Navigating Market Dynamics and Sourcing Trends in the starter motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter motor

- Strategic Sourcing Conclusion and Outlook for starter motor

- Important Disclaimer & Terms of Use

Understanding starter motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Permanent Magnet | Utilizes permanent magnets for the rotor; compact design. | Automotive, motorcycles, small engines. | Pros: Lightweight, efficient. Cons: Limited torque output. |

| Series Wound | Features a winding configuration that increases torque. | Heavy machinery, trucks, construction. | Pros: High starting torque. Cons: Less efficient, can overheat. |

| Gear Reduction | Incorporates gears to amplify motor torque and reduce size. | Commercial vehicles, agricultural equipment. | Pros: Compact size, high torque. Cons: More complex, higher maintenance. |

| DC Motor | Operates on direct current, simple design, widely available. | General automotive, industrial applications. | Pros: Easy to replace, cost-effective. Cons: Less efficient than alternatives. |

| Brushless Motor | Lacks brushes, reducing wear and maintenance needs. | High-performance vehicles, aerospace. | Pros: Longer lifespan, high efficiency. Cons: Higher initial cost. |

What Are the Characteristics of Permanent Magnet Starter Motors?

Permanent magnet starter motors are characterized by their use of permanent magnets in the rotor, which allows for a more compact design. These motors are commonly found in smaller vehicles and motorcycles due to their lightweight and efficient operation. For B2B buyers, the primary consideration is the application of these motors in automotive and small engine markets. While they are efficient, the torque output may be limited compared to other types, which is an essential factor for heavy-duty applications.

Why Choose Series Wound Starter Motors for Heavy Machinery?

Series wound starter motors are designed with a winding configuration that enhances torque output, making them ideal for heavy machinery and trucks. They are particularly suitable for environments requiring high starting torque, such as construction sites and industrial applications. B2B buyers should weigh the high torque benefits against the potential inefficiencies and overheating risks associated with these motors. This type of starter is often favored in sectors where power demands are significant.

How Do Gear Reduction Starter Motors Benefit Commercial Vehicles?

Gear reduction starter motors leverage a gear system to increase torque while reducing the overall size of the motor. This feature makes them particularly advantageous for commercial vehicles and agricultural equipment, where space and power efficiency are critical. For B2B buyers, the compact design and high torque output are appealing; however, the complexity of the system may lead to increased maintenance needs, which should be factored into purchasing decisions.

What Makes DC Motors a Popular Choice in General Applications?

DC motors are known for their straightforward design and operation on direct current, making them widely available and easy to replace. They are commonly utilized in general automotive and industrial applications. B2B buyers often find DC motors to be cost-effective solutions, but they may be less efficient than other advanced types. This trade-off should be carefully considered, especially in applications where energy efficiency is paramount.

Why Are Brushless Motors Gaining Popularity in High-Performance Sectors?

Brushless motors are distinguished by their absence of brushes, which reduces wear and lowers maintenance requirements. These motors are increasingly used in high-performance vehicles and aerospace applications due to their longer lifespan and superior efficiency. For B2B buyers, the initial higher cost can be justified by the long-term savings on maintenance and energy efficiency. This makes brushless motors a compelling choice for businesses focused on performance and reliability.

Key Industrial Applications of starter motor

| Industry/Sector | Specific Application of Starter Motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Passenger and Commercial Vehicles | Ensures reliable vehicle start-up, reducing downtime | Quality assurance, compatibility with vehicle models |

| Construction | Heavy Machinery | Facilitates engine start in heavy equipment, enhancing productivity | Durability under extreme conditions, maintenance support |

| Agriculture | Tractors and Farm Equipment | Provides dependable engine ignition for agricultural operations | Resistance to environmental factors, sourcing from reliable manufacturers |

| Marine | Boats and Yachts | Initiates engine operation for safe navigation | Corrosion resistance, compatibility with marine engines |

| Mining | Excavators and Drilling Equipment | Essential for starting large machinery, optimizing operational efficiency | High-performance standards, availability of spare parts |

How is the Starter Motor Used in the Automotive Industry?

In the automotive sector, starter motors play a crucial role in both passenger and commercial vehicles. They initiate engine ignition, ensuring that vehicles can start reliably, thereby minimizing downtime for businesses reliant on transportation. For international buyers, especially in regions like Africa and South America, sourcing starter motors requires attention to quality assurance and compatibility with various vehicle models to ensure long-term performance and reliability.

What Role Does the Starter Motor Play in Construction Equipment?

Heavy machinery in the construction industry heavily depends on starter motors for quick engine start-ups. This reliability is vital for maintaining productivity on job sites where downtime can lead to significant financial losses. Buyers should focus on sourcing starter motors that are durable and designed to withstand extreme operating conditions, ensuring that equipment remains operational even in harsh environments.

How is the Starter Motor Critical for Agricultural Operations?

In agriculture, starter motors are essential for tractors and farm equipment, enabling dependable engine ignition for various farming operations. This reliability is crucial during critical planting and harvesting seasons. Buyers in this sector should consider starter motors that are resistant to environmental factors like dust and moisture, ensuring longevity and consistent performance in challenging outdoor conditions.

What Importance Does the Starter Motor Have in Marine Applications?

In the marine industry, starter motors are vital for boats and yachts, initiating engine operation for safe navigation. The harsh marine environment necessitates starter motors that are corrosion-resistant and compatible with marine engines. International buyers should prioritize sourcing from manufacturers that meet these specific requirements to ensure safe and reliable maritime operations.

How Does the Starter Motor Enhance Efficiency in Mining Equipment?

In mining operations, starter motors are crucial for starting excavators and drilling equipment, directly impacting operational efficiency. The ability to quickly start large machinery can significantly reduce downtime and enhance productivity. Buyers should look for starter motors that adhere to high-performance standards and ensure the availability of spare parts, which is essential for maintaining continuous operations in remote mining locations.

3 Common User Pain Points for ‘starter motor’ & Their Solutions

Scenario 1: Unexpected Downtime Due to Starter Motor Failures

The Problem: For B2B buyers managing fleets or automotive services, an unexpected failure of a starter motor can lead to significant downtime and operational inefficiencies. When vehicles fail to start due to a malfunctioning starter motor, it disrupts schedules, delays deliveries, and can result in lost revenue. This issue is particularly pronounced in regions where access to quality parts and skilled technicians may be limited, making repairs more time-consuming and costly.

The Solution: To mitigate the risk of unexpected starter motor failures, B2B buyers should invest in high-quality starter motors from reputable manufacturers. Establishing partnerships with reliable suppliers can ensure consistent access to OEM or high-grade aftermarket parts. Additionally, implementing a proactive maintenance schedule that includes regular inspections of the starter motor, battery, and related electrical systems can help identify potential issues before they escalate. Buyers should also consider investing in diagnostic tools that can provide early warnings of electrical faults, thus enabling timely interventions and minimizing downtime.

Scenario 2: Difficulty Sourcing Compatible Starter Motors for Diverse Fleet Vehicles

The Problem: Many B2B buyers operate fleets with a mix of vehicle makes and models, each requiring specific starter motor types. This diversity can create challenges in sourcing compatible starter motors, leading to delays in repairs and increased inventory costs. The risk of purchasing incorrect parts is high, especially when suppliers do not provide clear compatibility information.

The Solution: To address this challenge, B2B buyers should leverage technology by utilizing parts management software that includes comprehensive databases of vehicle specifications and compatible parts. This software can help streamline the procurement process by allowing buyers to filter and find the exact starter motor needed based on the vehicle’s make, model, and year. Additionally, maintaining strong relationships with multiple suppliers can enhance the availability of diverse starter motors, thus reducing lead times. Buyers should also consider creating a standardized parts list for their fleet, which can simplify ordering processes and improve inventory management.

Scenario 3: High Replacement Costs Leading to Budget Constraints

The Problem: The cost of replacing starter motors can vary significantly depending on the vehicle type, model, and manufacturer, often straining budgets for B2B buyers. For companies managing large fleets, frequent starter motor replacements can lead to unanticipated expenses that impact overall financial planning and operational budgets.

The Solution: To control replacement costs, B2B buyers should focus on preventive maintenance and the selection of durable starter motors designed for longevity. Investing in quality parts upfront may result in higher initial costs but can lead to lower overall expenses due to reduced failure rates and longer service life. Furthermore, buyers should consider bulk purchasing agreements with suppliers, which can offer significant discounts and better payment terms. Additionally, exploring remanufactured starter motors can provide a cost-effective alternative without compromising on quality, allowing businesses to manage budgets more effectively while maintaining operational efficiency.

By proactively addressing these scenarios, B2B buyers can enhance their operational efficiency, reduce costs, and ensure the reliability of their vehicles in the field.

Strategic Material Selection Guide for starter motor

What Are the Common Materials Used in Starter Motors?

When selecting materials for starter motors, it’s crucial to understand their properties and how they impact performance, durability, and cost. Here, we analyze four common materials used in the construction of starter motors, focusing on their key properties, advantages and disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Steel in Starter Motors?

Steel is a widely used material in starter motors due to its excellent mechanical properties. It offers high tensile strength, making it suitable for components that experience significant stress during operation. Additionally, steel can withstand high temperatures, which is essential given the heat generated during engine start-up.

Illustrative image related to starter motor

Pros and Cons: Steel is durable and cost-effective, but it can be susceptible to corrosion if not properly treated. The manufacturing complexity is moderate, as steel components can be easily machined or welded. However, the need for protective coatings can increase production costs.

Impact on Application: Steel is compatible with various automotive fluids, but its corrosion resistance must be enhanced for applications in humid or coastal environments.

International Considerations: Buyers from regions like Africa and the Middle East should ensure that steel components meet local corrosion resistance standards, such as ASTM A123 for galvanized steel.

Illustrative image related to starter motor

How Does Aluminum Benefit Starter Motor Design?

Aluminum is another popular choice for starter motors, especially for components that require lightweight properties without compromising strength. Its low density helps reduce the overall weight of the starter motor, improving fuel efficiency in vehicles.

Pros and Cons: Aluminum has excellent corrosion resistance and thermal conductivity, making it suitable for high-temperature applications. However, it is generally more expensive than steel and can be more challenging to machine, which may complicate manufacturing processes.

Impact on Application: Aluminum is compatible with most automotive fluids and can withstand high temperatures, but it may not perform as well under extreme mechanical stress compared to steel.

Illustrative image related to starter motor

International Considerations: Buyers should look for compliance with international standards such as ASTM B221 for aluminum extrusions, particularly in regions with stringent material regulations like Europe.

What Role Does Copper Play in Starter Motors?

Copper is primarily used for electrical components within starter motors, such as windings and connectors, due to its excellent electrical conductivity. This property is crucial for efficient energy transfer, which is vital for the performance of starter motors.

Pros and Cons: The main advantage of copper is its superior conductivity, which leads to better performance. However, copper is relatively expensive compared to other materials and can be prone to corrosion if not adequately protected.

Impact on Application: Copper components are highly effective in electrical applications but may require protective coatings to prevent oxidation, especially in humid environments.

Illustrative image related to starter motor

International Considerations: Buyers should ensure that copper components comply with standards like ASTM B170 for copper and copper alloys, which is particularly relevant for markets with strict electrical performance requirements.

Why Is Plastic Used in Some Starter Motor Components?

Plastic materials, particularly engineering plastics, are increasingly being utilized in starter motors for non-structural components such as housings and insulation. These materials offer a combination of lightweight properties and good electrical insulation.

Pros and Cons: Plastics are generally less expensive and easier to mold than metals, allowing for complex shapes and designs. However, they may not withstand high temperatures as well as metals and can degrade over time under UV exposure.

Impact on Application: While plastics are suitable for insulation and lightweight applications, they may not be appropriate for components that experience high mechanical stress or extreme temperatures.

Illustrative image related to starter motor

International Considerations: Buyers should verify that plastics meet relevant standards such as ISO 9001 for quality management, especially in regions like South America where material quality can vary.

Summary Table of Material Selection for Starter Motors

| Material | Typical Use Case for starter motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components (housing, gears) | High tensile strength | Susceptible to corrosion | Med |

| Aluminum | Lightweight components (casings) | Excellent corrosion resistance | More expensive and harder to machine | High |

| Copper | Electrical windings and connectors | Superior electrical conductivity | Expensive and prone to corrosion | High |

| Plastic | Insulation and non-structural parts | Lightweight and cost-effective | Limited temperature resistance | Low |

This material selection guide provides a comprehensive overview for international B2B buyers, ensuring informed decisions that align with performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for starter motor

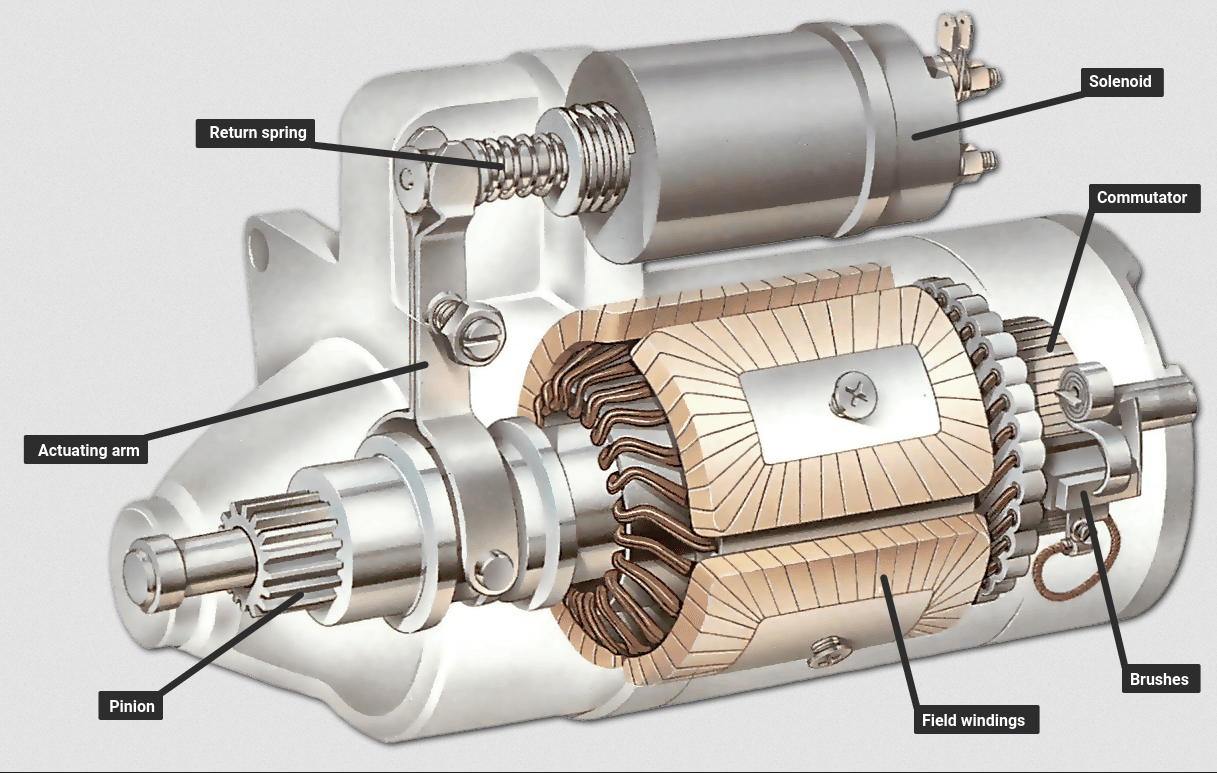

What Are the Main Stages of Starter Motor Manufacturing?

The manufacturing process for starter motors involves several critical stages that ensure the final product is reliable and efficient. Understanding these stages is crucial for B2B buyers looking to procure quality starter motors.

How Are Materials Prepared for Starter Motors?

The first step in the manufacturing of starter motors is material preparation. Manufacturers typically use high-grade steel for the motor housing and copper for the windings due to their durability and excellent conductivity. The raw materials undergo rigorous inspection to verify compliance with industry standards. This stage may also include cutting, shaping, and treating materials to enhance their mechanical properties, ensuring that they can withstand operational stresses.

What Techniques Are Used in Forming Starter Motors?

Once the materials are prepared, the forming stage begins. This involves various techniques such as stamping, machining, and molding. Stamping is often used for creating the metal components, while precision machining ensures that parts like the armature and rotor are manufactured to exact specifications. The use of advanced CNC (Computer Numerical Control) machines helps maintain high precision, which is essential for the performance of the starter motor.

Illustrative image related to starter motor

How Is the Assembly Process Conducted for Starter Motors?

The assembly process is a critical phase where individual components come together to form the complete starter motor. This typically involves the following steps:

- Coiling: Copper wire is wound around the armature to create the electromagnetic field necessary for operation.

- Integration: Key components, including the solenoid, starter drive, and housing, are assembled. This is often done in a cleanroom environment to prevent contamination.

- Wiring: Electrical connections are established, ensuring that the starter motor can receive power effectively.

Each assembly line is often designed for efficiency and to minimize the risk of errors. Automation plays a significant role in this stage, reducing the potential for human error and ensuring consistent quality.

What Finishing Processes Are Applied to Starter Motors?

Finishing processes ensure that the starter motors are ready for market. This may include painting or coating the motor housing to protect against corrosion and improve aesthetics. Additionally, the components are subjected to final inspections to confirm that they meet quality standards. These finishing touches not only enhance the product’s durability but also its market appeal.

What Quality Assurance Measures Are in Place for Starter Motors?

Quality assurance (QA) is vital in the manufacturing of starter motors to ensure reliability and performance. Manufacturers typically adhere to international standards such as ISO 9001, which outlines quality management systems that help organizations meet customer and regulatory requirements.

Which International Standards Are Relevant for Starter Motor Quality Control?

International standards provide a benchmark for quality assurance in manufacturing. For starter motors, key standards include:

- ISO 9001: Focuses on quality management systems and continuous improvement.

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- API Standards: Relevant for automotive components, ensuring they meet performance and safety criteria.

B2B buyers should verify that suppliers hold these certifications, as they reflect a commitment to quality and safety.

What Are the Key QC Checkpoints During Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): Regular inspections during the manufacturing process ensure that any deviations from quality standards are identified and corrected promptly.

- Final Quality Control (FQC): The completed starter motors undergo a comprehensive evaluation, including functional testing and performance assessments.

These checkpoints help maintain high standards and minimize defects in the final product.

What Testing Methods Are Commonly Used for Starter Motors?

Various testing methods are employed to verify the functionality and reliability of starter motors. Common testing techniques include:

Illustrative image related to starter motor

- Electrical Testing: Measures the motor’s electrical performance, ensuring it operates within specified parameters.

- Load Testing: Assesses how the starter motor performs under load conditions, simulating real-world scenarios.

- Durability Testing: Involves subjecting the motor to extreme conditions to evaluate its longevity and resilience.

These tests are essential for identifying potential issues before the product reaches the market.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are several ways to conduct due diligence:

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their quality management systems and practices.

- Requesting Quality Reports: Suppliers should be willing to provide documentation demonstrating compliance with international standards and results from quality inspections.

- Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased assessment of the manufacturing processes and product quality.

What QC and Certification Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification. Factors such as regional regulatory requirements, import/export standards, and local market conditions can influence the procurement process.

For instance, in markets like Saudi Arabia and Vietnam, understanding local compliance requirements and logistics is essential for smooth transactions. Additionally, language barriers and cultural differences may impact negotiations and communication, making it vital to engage with suppliers who are familiar with international trade practices.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions that ensure they procure high-quality starter motors that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor’

This practical sourcing guide is designed to assist B2B buyers in effectively procuring starter motors. With the increasing demand for reliable automotive components, it’s essential to follow a structured approach to ensure quality, compatibility, and value for your investment.

Step 1: Define Your Technical Specifications

Before beginning the sourcing process, clearly outline the technical specifications required for your starter motors. This includes voltage, size, and type (e.g., gear reduction or direct drive). Understanding your vehicle or machinery requirements will help narrow down options and prevent compatibility issues later on.

Step 2: Research Market Trends and Pricing

Stay informed about current market trends and pricing for starter motors. Monitor fluctuations in raw material costs and technological advancements that may affect performance and pricing. This knowledge will empower you to negotiate better prices and avoid overpaying.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality and reliability standards. Request detailed company profiles, including their manufacturing processes, quality control measures, and customer testimonials. Look for suppliers with a proven track record in your industry to mitigate risks.

- Sub-bullet: Check for industry certifications, such as ISO 9001, which indicate adherence to quality management standards.

Step 4: Verify Product Quality and Compliance

Confirm that the starter motors comply with international quality and safety standards. Request product samples or test reports to evaluate performance metrics, such as durability and efficiency. Ensuring compliance will help avoid costly failures in the field.

- Sub-bullet: Investigate any warranties or guarantees offered, as these can provide additional assurance of product quality.

Step 5: Assess Supply Chain Reliability

Evaluate the supplier’s supply chain capabilities to ensure timely delivery and availability of starter motors. Investigate their inventory management practices and logistics partners to understand their ability to meet your demand, especially if you require bulk orders or just-in-time deliveries.

Illustrative image related to starter motor

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear communication at this stage can prevent misunderstandings later on. Ensure that all agreements are documented to protect both parties.

- Sub-bullet: Consider discussing options for bulk discounts or long-term contracts to secure better rates.

Step 7: Establish a Feedback Loop

After the procurement process, establish a feedback mechanism to evaluate the performance of the starter motors and the supplier’s service. Regularly assess product quality and supplier responsiveness to ensure ongoing satisfaction and make informed decisions for future purchases.

By following this step-by-step checklist, B2B buyers can streamline the sourcing of starter motors, ensuring they acquire high-quality products that meet their operational needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for starter motor Sourcing

What Are the Key Cost Components of Starter Motor Sourcing?

When analyzing the cost structure for sourcing starter motors, several critical components must be considered.

-

Materials: The primary materials include steel, copper, and various plastics. The cost of these materials can fluctuate based on global commodity prices and availability. High-quality materials can lead to longer-lasting starter motors, which can justify higher upfront costs.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs, such as those in parts of Asia and South America, may offer a competitive advantage. However, this can be offset by the need for skilled labor in manufacturing processes, which can drive costs up in regions with higher wage demands.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities and rent. Efficient manufacturing processes can minimize overhead costs, making it essential to consider a supplier’s operational efficiency.

-

Tooling: The initial investment in tooling can be substantial, especially for customized starter motors. This cost is often amortized over the production run, making it crucial to assess the expected order volume.

-

Quality Control (QC): Robust QC processes ensure that each starter motor meets safety and performance standards. While this adds to costs, it can reduce the total cost of ownership by minimizing failures and warranty claims.

-

Logistics: Transportation costs, including shipping and customs duties, can significantly impact the overall cost. Incoterms play a vital role in determining who bears these costs, which can vary by supplier and shipping method.

-

Margin: Supplier margins will vary based on market competition and the perceived value of their products. Understanding the average margin in your specific market can aid in negotiations.

How Do Price Influencers Affect Starter Motor Costs?

Several factors influence the pricing of starter motors in the B2B market:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it beneficial for companies to consolidate orders.

-

Specifications and Customization: Custom starter motors designed for specific applications often come with higher costs due to the additional engineering and tooling required. Buyers should weigh the benefits of customization against the price premium.

-

Materials and Quality Certifications: The use of premium materials and adherence to quality certifications (such as ISO or TS standards) can increase costs but may also lead to better performance and reliability.

-

Supplier Factors: The reputation and reliability of a supplier can impact pricing. Established suppliers with proven track records may charge more, but they often provide better support and warranty terms.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they dictate who is responsible for shipping costs and risks. This can affect the final landed cost of the starter motors.

What Tips Can Help B2B Buyers Negotiate Better Starter Motor Prices?

For international B2B buyers, especially from diverse markets such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Building a strong relationship with suppliers can lead to better pricing and payment terms. Don’t hesitate to negotiate based on order size and long-term partnership potential.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and potential downtime costs. A higher-quality starter motor may have a higher upfront cost but could offer savings in the long run.

-

Pricing Nuances: Be aware of regional pricing differences and market conditions. For instance, tariffs and trade agreements can impact costs, particularly in regions like the Middle East or South America.

-

Supplier Diversification: Engaging with multiple suppliers can foster competition, leading to better pricing. However, ensure that all suppliers meet your quality and delivery standards.

-

Market Research: Stay informed about market trends, material costs, and technological advancements. This knowledge can provide leverage in negotiations and help you anticipate future pricing shifts.

Disclaimer for Indicative Prices

It’s important to note that prices for starter motors can vary widely based on the factors mentioned above. The information provided serves as a general guide and should be tailored to specific needs and market conditions. Always consult multiple suppliers to obtain the most accurate pricing for your requirements.

Alternatives Analysis: Comparing starter motor With Other Solutions

Exploring Alternatives to Starter Motors for Vehicle Engine Initiation

In the automotive industry, the starter motor is a critical component for initiating the combustion process in internal combustion engines. However, there are alternative solutions and technologies that can achieve similar outcomes. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and specific use cases.

| Comparison Aspect | Starter Motor | Lithium-Ion Battery Start Systems | Integrated Starter Generator (ISG) |

|---|---|---|---|

| Performance | Efficient for conventional engines; quick start response | High efficiency; capable of multiple starts | Combines starting and generating functions; smooth operation |

| Cost | Generally low initial cost; replacement can be expensive | Higher upfront costs; potential long-term savings on fuel | Moderate cost; may require additional components |

| Ease of Implementation | Standard in most vehicles; easy installation | Requires compatible vehicle design | More complex installation; integration with hybrid systems needed |

| Maintenance | Regular checks needed; can fail due to wear and tear | Low maintenance; longer lifespan | Requires periodic checks; may need system recalibration |

| Best Use Case | Traditional internal combustion engines | Hybrid and electric vehicles; stop-start systems | Hybrid vehicles and high-efficiency combustion engines |

What Are the Advantages and Disadvantages of Lithium-Ion Battery Start Systems?

Lithium-ion battery start systems are gaining popularity, particularly in hybrid and electric vehicles. Their primary advantage lies in their efficiency, allowing for quick restarts without the mechanical wear associated with traditional starter motors. However, the initial investment is significantly higher, which may deter some buyers. Additionally, these systems are best suited for vehicles designed to accommodate them, limiting their application in older models.

How Do Integrated Starter Generators (ISG) Enhance Vehicle Performance?

Integrated Starter Generators (ISG) offer a novel approach by combining the starting and generating functions into one unit. This technology provides a smoother start and enhances fuel efficiency by recovering energy during braking. While ISGs require a more complex installation and integration with existing vehicle systems, they are particularly advantageous for hybrid vehicles. The upfront costs can be offset by fuel savings over time, making ISGs an attractive option for certain markets.

Conclusion: How Should B2B Buyers Select the Right Engine Starting Solution?

When evaluating alternatives to starter motors, B2B buyers must consider their specific operational needs and vehicle types. While starter motors remain the standard choice for traditional combustion engines, lithium-ion battery systems and integrated starter generators present compelling alternatives for modern vehicles focused on efficiency and sustainability. Assessing factors such as initial cost, ease of integration, and maintenance requirements will enable buyers to select the best solution tailored to their operational goals and market demands.

Essential Technical Properties and Trade Terminology for starter motor

What Are the Key Technical Properties of a Starter Motor?

Understanding the technical properties of a starter motor is crucial for B2B buyers, especially when sourcing reliable components for automotive applications. Here are some essential specifications that should be considered:

1. Material Grade

Starter motors are typically constructed from high-grade materials like steel, aluminum, and copper. The choice of material affects the motor’s durability, weight, and efficiency. For instance, a copper winding in the motor enhances conductivity, leading to better performance. Buyers should prioritize OEM (Original Equipment Manufacturer) standards to ensure compatibility and longevity.

2. Torque Rating

Torque rating, usually measured in Newton-meters (Nm), indicates the rotational force the starter motor can produce to crank the engine. A higher torque rating is critical for vehicles with larger engines or those operating in extreme conditions. Understanding torque requirements helps buyers select a starter motor that meets specific vehicle demands.

3. Voltage Rating

Most starter motors operate at 12 volts, but some may require 24 volts, especially in larger vehicles or heavy machinery. The voltage rating is essential for ensuring the motor functions correctly within the vehicle’s electrical system. Buyers should confirm the voltage compatibility to prevent electrical failures.

4. Current Draw

The current draw, measured in amperes (A), indicates how much electrical current the starter motor consumes when engaged. A higher current draw may lead to faster wear on the vehicle’s battery and electrical system. It’s vital for buyers to assess current draw to ensure it aligns with the vehicle’s battery capacity to avoid premature failure.

5. Operational Temperature Range

Starter motors must operate effectively across a range of temperatures. Understanding the operational temperature range helps buyers determine whether a motor can withstand specific environmental conditions, such as extreme heat in the Middle East or cold climates in Europe. Selecting a motor with an appropriate temperature range is crucial for reliability.

Illustrative image related to starter motor

6. Lifespan

Typically, starter motors last between 100,000 to 150,000 miles, depending on usage and maintenance. Buyers should inquire about the expected lifespan of the starter motor to better plan for replacements, which can help in budgeting and inventory management.

What Are the Common Trade Terms Related to Starter Motors?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several common terms used in the starter motor industry:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold to vehicle manufacturers. When sourcing starter motors, buyers often look for OEM parts to ensure quality and compatibility with existing vehicles.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is critical for buyers, as it impacts inventory levels and cash flow. Buyers should negotiate MOQs that align with their purchasing strategy.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting price quotes for specific products or services. For starter motors, issuing an RFQ allows buyers to compare prices, terms, and conditions from multiple suppliers, facilitating informed decision-making.

Illustrative image related to starter motor

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in global trade. They clarify aspects like shipping costs, risk transfer, and delivery points. Understanding Incoterms is crucial for buyers importing starter motors from different countries, as it affects total landed costs.

5. Warranty Period

The warranty period refers to the duration for which the manufacturer guarantees the starter motor against defects. Buyers should always inquire about the warranty details, as this can indicate the manufacturer’s confidence in the product and provide peace of mind regarding potential future costs.

6. Lead Time

Lead time is the time taken from placing an order to receiving the product. In the automotive sector, understanding lead times for starter motors is essential for inventory management and ensuring timely repairs and maintenance.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, optimize procurement processes, and enhance the efficiency of their operations in the automotive industry.

Illustrative image related to starter motor

Navigating Market Dynamics and Sourcing Trends in the starter motor Sector

What Are the Key Market Dynamics and Trends Influencing the Starter Motor Sector?

The global starter motor market is experiencing significant growth driven by the increasing demand for internal combustion engine (ICE) vehicles and the rising popularity of hybrid and electric vehicles (EVs). As automotive technology evolves, international B2B buyers must adapt to these changes. In regions like Africa and South America, where vehicle ownership is expanding, the need for reliable starter motors is paramount. Conversely, in Europe and the Middle East, stringent emissions regulations are pushing manufacturers to innovate more efficient starter motor designs.

Emerging trends such as the adoption of smart technologies in automotive components are revolutionizing the starter motor sector. The integration of IoT (Internet of Things) capabilities allows for real-time monitoring of starter motor performance, enabling predictive maintenance and reducing downtime. B2B buyers should look for suppliers who offer advanced diagnostics and support for these technologies. Additionally, the rise of e-commerce platforms is reshaping how international buyers source starter motors, allowing for greater access to diverse suppliers and competitive pricing.

Another key dynamic is the shift towards localized production and supply chains. International buyers are increasingly prioritizing suppliers who can provide quicker delivery times and reduced shipping costs. This trend is particularly relevant for regions like Africa and South America, where infrastructure challenges can hinder timely access to components. As a result, sourcing strategies that emphasize regional partnerships are becoming vital for maintaining competitive advantage.

How Can Sustainability and Ethical Sourcing Impact the Starter Motor Supply Chain?

Sustainability has become a critical consideration for B2B buyers in the starter motor sector. The environmental impact of manufacturing processes and material sourcing is under increased scrutiny, prompting companies to adopt greener practices. This includes the use of eco-friendly materials and energy-efficient production methods. Buyers should actively seek out suppliers with certifications such as ISO 14001, which demonstrates a commitment to environmental management.

The importance of ethical sourcing cannot be overstated. Ensuring that the materials used in starter motors are sourced from responsible suppliers minimizes the risk of labor exploitation and environmental degradation. B2B buyers should prioritize manufacturers who provide transparency in their supply chains, including those who utilize recycled materials or sustainable practices in their production processes.

Furthermore, the shift towards electric vehicles is influencing sourcing trends. As the automotive industry moves towards electrification, the demand for components like starter motors that cater to hybrid systems or support regenerative braking is on the rise. This transition offers opportunities for suppliers to innovate and align with sustainable practices, thus enhancing their appeal to conscientious buyers.

What Is the Historical Context of the Starter Motor’s Development?

The starter motor has undergone significant evolution since its inception in the early 20th century. Initially, vehicles were started manually using a hand crank, which was labor-intensive and impractical. The introduction of the electric starter motor in 1912 revolutionized the automotive industry, making it easier and safer to start internal combustion engines.

As automotive technology advanced, so too did the starter motor’s design and functionality. Innovations such as the reduction gear starter and high-torque motors emerged to meet the demands of more powerful engines. In recent years, the focus has shifted towards integrating starter motors with vehicle electronics and enhancing their efficiency to support the growing trend of hybrid and electric vehicles.

Understanding this historical context is essential for B2B buyers as it highlights the technological advancements that have shaped the current market landscape. Buyers can leverage this knowledge to make informed decisions when sourcing starter motors, ensuring they select suppliers who are at the forefront of innovation in this evolving sector.

Frequently Asked Questions (FAQs) for B2B Buyers of starter motor

-

How do I solve issues with a faulty starter motor?

To address problems with a faulty starter motor, first check the battery voltage and connections, as a weak battery can mimic starter motor issues. If the battery is functional, listen for clicking sounds when attempting to start the vehicle, which may indicate a faulty solenoid or connections. If the starter motor does not engage, it may need to be replaced. Regular maintenance and diagnostics can help identify and resolve these issues early, reducing downtime and repair costs. -

What is the best starter motor for my fleet vehicles?

The best starter motor for your fleet depends on the vehicle specifications and operational requirements. Factors such as engine size, vehicle type, and environmental conditions should guide your choice. OEM (Original Equipment Manufacturer) parts are generally recommended for their reliability and performance. Additionally, consider suppliers that offer warranties and after-sales support to ensure long-term serviceability. -

What are the key considerations when sourcing starter motors internationally?

When sourcing starter motors internationally, consider the supplier’s reputation, certifications, and compliance with international quality standards. Evaluate their manufacturing capabilities and ability to customize products based on your specifications. Logistics and shipping costs, as well as lead times, are also crucial factors. It’s advisable to request samples and conduct quality assurance tests before finalizing bulk orders. -

What is the minimum order quantity (MOQ) for starter motors from suppliers?

Minimum order quantities for starter motors can vary significantly between suppliers. Some manufacturers may set MOQs as low as 50 units, while others may require 500 or more. Always discuss your needs with the supplier to negotiate favorable terms, especially if you are a small business or a new buyer. Understanding their production capabilities can help you make informed decisions. -

What payment terms should I expect when purchasing starter motors?

Payment terms for purchasing starter motors often include options such as upfront payment, partial payment before shipment, or net 30/60 days after delivery. Suppliers may also offer letters of credit or escrow services for larger transactions. It’s important to clarify these terms before committing to ensure they align with your cash flow management strategies. -

How can I ensure quality assurance when sourcing starter motors?

To ensure quality assurance when sourcing starter motors, request detailed product specifications, certifications, and compliance documentation from your supplier. Conduct factory audits or ask for third-party inspections to verify manufacturing processes. Establish clear quality standards and testing protocols for the products you receive to minimize defects and ensure reliability in your operations. -

What logistics considerations should I keep in mind when importing starter motors?

When importing starter motors, consider shipping methods, customs regulations, and tariffs that may affect costs. Choose reliable freight forwarders who can navigate complex logistics and ensure timely delivery. Additionally, factor in lead times for production and shipping to avoid disruptions in your supply chain. Having a clear understanding of local import regulations in your country is also essential. -

How can I vet potential suppliers for starter motors?

To vet potential suppliers for starter motors, begin by researching their market reputation and customer reviews. Request references from previous clients and analyze their experience in your specific industry. Evaluate their production capabilities, certifications, and compliance with international standards. Conducting site visits or virtual audits can further help assess their operational integrity and product quality before making a purchasing decision.

Top 5 Starter Motor Manufacturers & Suppliers List

1. Haynes – Starter Motors

Domain: us.haynes.com

Registered: 1996 (29 years)

Introduction: This company, Haynes – Starter Motors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. RAC – Starter Motor

Domain: rac.co.uk

Registered: 1996 (29 years)

Introduction: Starter Motor: An essential electric component in internal combustion vehicles that starts the engine’s rotation when the ignition is engaged. It is tested during MOT and service checks. Common causes of failure include broken solenoids, mechanical issues, electrical faults, overheating, and wear and tear. Location: Typically found at the back of the engine, lower part of the housing. It does not …

3. Autoelectro – Starter Motors

Domain: autoelectro.co.uk

Registered: 1999 (26 years)

Introduction: Starter motors are essential components in vehicles that engage the engine during ignition. They work by turning the engine over to create suction for air intake, which is necessary for fuel combustion. Key components include:

– Armature: An electromagnet mounted on the drive shaft, wrapped with conductor loops.

– Commutator: A section of the shaft that conducts electricity through brushes.

– B…

4. ScienceDirect – Starter Motor

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: A starter motor is a device required to run an internal combustion engine up to a speed sufficient for satisfactory carburation. It engages with the flywheel through a pinion, utilizing inertia-engaged or pre-engaged methods to transmit torque from the motor to the engine. Key features include:

– Mounted on the engine casing with a pinion that engages with the flywheel teeth.

– Gear ratio between …

5. The AA – Starter Motor Solutions

Domain: theaa.com

Registered: 1997 (28 years)

Introduction: Common starter motor problems include: 1. Engine won’t start – A faulty starter motor can prevent the engine from starting, often indicated by no response or a clicking noise when the key is turned. 2. Clicking noise – This suggests the starter motor is trying to engage but lacks power, possibly due to a weak battery or poor electrical connections. 3. Starter motor doesn’t turn – This can be cause…

Strategic Sourcing Conclusion and Outlook for starter motor

Why Is Strategic Sourcing Essential for Starter Motors?

In today’s competitive landscape, strategic sourcing for starter motors is crucial for businesses looking to optimize performance while minimizing costs. By understanding the complexities of starter motor technologies, including their functionality, potential failure points, and maintenance requirements, international buyers can make informed purchasing decisions that enhance their operational efficiency.

What Are the Key Considerations for B2B Buyers?

Buyers must prioritize quality and reliability when sourcing starter motors, especially given their role in the performance of internal combustion vehicles. It’s important to establish partnerships with reputable suppliers who can provide high-quality components backed by robust warranties. Additionally, staying abreast of regional sourcing trends can help businesses capitalize on emerging markets, particularly in Africa, South America, the Middle East, and Europe.

How Can You Future-Proof Your Sourcing Strategy?

Looking ahead, the demand for starter motors is expected to evolve with advancements in automotive technology and the increasing shift towards electric vehicles. Therefore, it is imperative for B2B buyers to adopt a proactive approach in their sourcing strategies, considering not only current needs but also future market dynamics. Engage with suppliers who demonstrate innovation and adaptability to ensure your business remains at the forefront of industry developments. Take action today by evaluating your sourcing practices and exploring new partnerships that align with your growth objectives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.