Introduction: Navigating the Global Market for que pasa cuando falla el alternador

In the dynamic landscape of the automotive industry, understanding “que pasa cuando falla el alternador” (what happens when the alternator fails) is crucial for B2B buyers focused on vehicle maintenance and repair. The alternator plays a vital role in a vehicle’s electrical system, and its failure can lead to a cascade of issues, including battery depletion, electrical malfunctions, and ultimately, vehicle breakdowns. This guide serves as a comprehensive resource for international buyers seeking to navigate the complexities of sourcing quality alternators and related components.

Throughout this guide, we will explore the various types of alternators, their applications across different vehicle models, and critical symptoms of failure that can impact operational efficiency. Additionally, we will provide insights into supplier vetting processes, cost considerations, and best practices for ensuring the reliability of components. By arming buyers with this knowledge, we empower them to make informed purchasing decisions that enhance their service offerings and ultimately improve customer satisfaction.

This resource is tailored for B2B stakeholders from diverse regions, including Africa, South America, the Middle East, and Europe, such as Vietnam and Saudi Arabia. Understanding these nuances will help businesses reduce downtime, optimize repair processes, and enhance their competitive edge in the market.

Table Of Contents

- Top 3 Que Pasa Cuando Falla El Alternador Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for que pasa cuando falla el alternador

- Understanding que pasa cuando falla el alternador Types and Variations

- Key Industrial Applications of que pasa cuando falla el alternador

- 3 Common User Pain Points for ‘que pasa cuando falla el alternador’ & Their Solutions

- Strategic Material Selection Guide for que pasa cuando falla el alternador

- In-depth Look: Manufacturing Processes and Quality Assurance for que pasa cuando falla el alternador

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘que pasa cuando falla el alternador’

- Comprehensive Cost and Pricing Analysis for que pasa cuando falla el alternador Sourcing

- Alternatives Analysis: Comparing que pasa cuando falla el alternador With Other Solutions

- Essential Technical Properties and Trade Terminology for que pasa cuando falla el alternador

- Navigating Market Dynamics and Sourcing Trends in the que pasa cuando falla el alternador Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of que pasa cuando falla el alternador

- Strategic Sourcing Conclusion and Outlook for que pasa cuando falla el alternador

- Important Disclaimer & Terms of Use

Understanding que pasa cuando falla el alternador Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electrical Failure | Symptoms include dim lights, malfunctioning electronics | Automotive repair shops, fleet management | Pros: Quick diagnosis; Cons: May require additional parts. |

| Charging Issues | Frequent battery drain, difficulty starting the vehicle | Vehicle maintenance services, logistics firms | Pros: Identifies root cause; Cons: Potential for costly repairs. |

| Performance Degradation | Loss of power, rough engine performance | Heavy machinery, automotive service centers | Pros: Enhances vehicle reliability; Cons: Downtime during repairs. |

| Noise and Vibration Problems | Unusual sounds from the alternator, indicating wear | Auto part suppliers, repair workshops | Pros: Early detection can prevent further damage; Cons: May indicate more extensive issues. |

| Overheating and Burning Smell | Signs of overheating, burnt rubber smell | Automotive diagnostics, repair shops | Pros: Prevents catastrophic failure; Cons: Requires immediate action. |

What Are the Key Characteristics of Electrical Failure in Alternators?

Electrical failure in alternators manifests through symptoms such as dimming lights and malfunctioning electronic components. These issues can lead to significant disruptions in vehicle operation. For B2B buyers, identifying these symptoms early can enhance service efficiency and reduce customer complaints. Automotive repair shops should invest in diagnostic tools that help quickly pinpoint electrical issues, allowing for faster turnaround times and improved customer satisfaction.

How Do Charging Issues Affect Vehicle Performance?

Charging issues often result in frequent battery drain and difficulties in starting the vehicle. This situation is particularly critical for businesses that rely on vehicle fleets, as it can lead to operational delays. B2B buyers should prioritize sourcing high-quality alternators that ensure reliable charging systems, which can significantly reduce the risk of vehicle downtime. Regular maintenance checks can also help in identifying potential charging problems before they escalate.

What Are the Implications of Performance Degradation?

Performance degradation due to a failing alternator can cause loss of power and rough engine performance. This is especially concerning for businesses operating heavy machinery or vehicles that require consistent performance levels. B2B buyers should consider investing in robust alternators that promise durability and efficiency. Additionally, understanding the correlation between alternator health and vehicle performance can help service centers provide better maintenance advice to their clients.

How Can Noise and Vibration Problems Indicate Alternator Issues?

Unusual noises and vibrations from the alternator can signal wear and potential failure. For auto part suppliers and repair workshops, early detection of these symptoms can prevent more extensive damage and costly repairs. B2B buyers should look for reliable diagnostic tools and training for technicians to recognize these warning signs promptly. This proactive approach can enhance service offerings and customer trust.

What Risks Are Associated with Overheating and Burning Smell?

Overheating and a burning smell are serious indicators of alternator failure, often signaling impending catastrophic failure. For automotive diagnostics and repair shops, recognizing these signs is crucial for preventing severe damage to the vehicle’s electrical system. B2B buyers should ensure they have access to high-quality alternators and components to provide effective replacements. Investing in training for staff to identify these critical issues can lead to better service outcomes and customer loyalty.

Key Industrial Applications of que pasa cuando falla el alternador

| Industry/Sector | Specific Application of que pasa cuando falla el alternador | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnosing electrical issues related to alternator failure | Enhances service efficiency and customer satisfaction | Need for reliable diagnostic tools and quality parts |

| Transportation & Logistics | Fleet maintenance and management | Reduces downtime and increases operational reliability | Importance of bulk purchasing and quick delivery times |

| Construction Equipment | Maintenance of heavy machinery | Ensures equipment reliability and reduces repair costs | Access to specialized alternators for various machinery |

| Agricultural Equipment | Repair and maintenance of farming machinery | Maximizes equipment uptime and productivity | Need for durable components suitable for harsh conditions |

| Renewable Energy | Maintenance of electric vehicles and hybrid systems | Supports sustainability goals and reduces energy costs | Demand for high-quality, efficient alternators |

How is ‘que pasa cuando falla el alternador’ Used in Automotive Repair?

In the automotive repair sector, understanding the implications of alternator failure is crucial. Mechanics often encounter vehicles with symptoms such as battery warning lights or difficulty starting. By accurately diagnosing these issues, repair shops can avoid unnecessary battery replacements, thereby enhancing service efficiency and customer satisfaction. International buyers should consider sourcing quality diagnostic tools and replacement parts to ensure reliable repairs, especially in regions with varying vehicle models and technologies.

What is the Importance of Diagnosing Alternator Issues in Transportation & Logistics?

For businesses in transportation and logistics, maintaining fleet vehicles is vital for operational efficiency. When alternators fail, it can lead to significant downtime, impacting delivery schedules and profitability. By implementing regular diagnostics and maintenance protocols, fleet managers can mitigate risks associated with electrical failures. Buyers in this sector should prioritize bulk purchasing agreements for alternators and associated components, ensuring timely access to parts that minimize vehicle downtime.

Why is Alternator Maintenance Critical in Construction Equipment?

In the construction industry, heavy machinery relies on robust electrical systems for operation. Alternator failures can halt projects, leading to costly delays. By ensuring regular maintenance and swift diagnosis of electrical issues, businesses can enhance equipment reliability and control repair costs. Buyers should seek out specialized alternators designed for various machinery types and consider suppliers that offer prompt support and technical assistance to optimize their maintenance programs.

How Does Alternator Functionality Impact Agricultural Equipment?

Agricultural equipment is often exposed to demanding conditions, making reliable electrical systems essential for operational success. Alternator failures can disrupt the functionality of tractors and harvesters, leading to reduced productivity. By maintaining these systems and addressing alternator issues proactively, farmers can maximize equipment uptime. Buyers should focus on sourcing durable alternators that can withstand harsh agricultural environments, ensuring they partner with suppliers who understand these specific requirements.

What Role Does the Alternator Play in Renewable Energy Applications?

In the renewable energy sector, especially with the rise of electric and hybrid vehicles, the alternator’s performance is critical. Failure can not only lead to vehicle inoperability but also undermine sustainability goals. Companies focused on electric mobility should prioritize sourcing high-quality, efficient alternators that meet stringent performance standards. This ensures that their vehicles operate optimally, reducing energy costs and enhancing their commitment to environmentally friendly practices.

3 Common User Pain Points for ‘que pasa cuando falla el alternador’ & Their Solutions

Scenario 1: Misdiagnosing Alternator Issues Leads to Increased Costs

The Problem: Many B2B buyers in the automotive repair industry face a significant challenge when their technicians misdiagnose alternator failures. Customers often report symptoms such as a dead battery or difficulty starting the vehicle, which technicians mistakenly attribute to battery issues. This misdiagnosis can lead to unnecessary replacement of batteries and other components, resulting in increased costs for both the repair shop and the customer. Furthermore, repeated customer visits due to unresolved issues can damage the shop’s reputation and lead to loss of business.

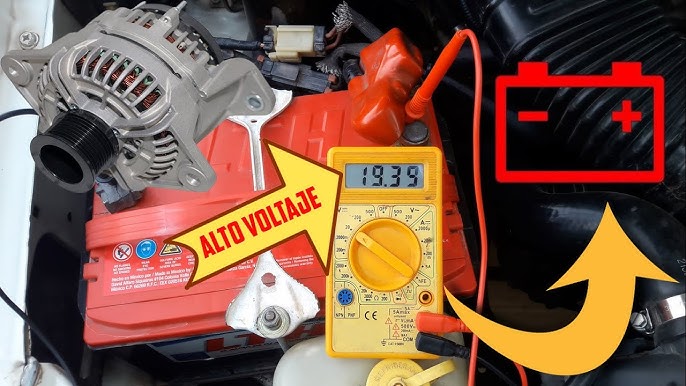

The Solution: To mitigate this issue, B2B buyers should invest in comprehensive training programs for their technicians focused on the nuances of diagnosing alternator problems. Utilizing diagnostic tools that can accurately assess the alternator’s performance is critical. For example, implementing digital multimeters or specialized alternator testers can provide precise readings of voltage output and current draw. Additionally, establishing clear diagnostic protocols that emphasize the importance of checking the alternator before replacing the battery can significantly reduce misdiagnoses. By equipping technicians with the right tools and knowledge, repair shops can ensure they provide accurate diagnoses, ultimately saving costs and enhancing customer satisfaction.

Scenario 2: Limited Availability of Quality Replacement Parts

The Problem: B2B buyers often encounter the issue of sourcing reliable replacement alternators and components. In regions like Africa and South America, the market can be flooded with subpar parts that may fail prematurely, leading to repeated repairs and unhappy customers. This inconsistency not only affects the operational efficiency of repair shops but can also result in potential liability issues if a faulty part causes further damage.

Illustrative image related to que pasa cuando falla el alternador

The Solution: To address the challenge of sourcing quality parts, B2B buyers should establish strong relationships with reputable suppliers who provide OEM or high-quality aftermarket components. It’s beneficial to conduct thorough market research to identify suppliers with a proven track record of reliability. Additionally, buyers should consider implementing a quality assurance process that includes evaluating parts upon arrival and maintaining a close relationship with suppliers to ensure they meet specific standards. Utilizing digital platforms or marketplaces that specialize in automotive parts can also streamline the procurement process, allowing buyers to compare products and reviews efficiently. By prioritizing quality in their sourcing strategy, buyers can minimize the risk of future failures and maintain a high standard of service.

Scenario 3: Lack of Understanding of Electrical Systems and Their Interconnectivity

The Problem: A common pain point for B2B buyers is the lack of comprehensive knowledge about how alternators interact with other electrical components in a vehicle. Many technicians may understand how to replace an alternator but lack insight into the broader electrical system, which can lead to incomplete repairs and recurring issues. This knowledge gap can also result in inefficient troubleshooting processes, prolonging vehicle downtime and frustrating customers.

The Solution: To combat this knowledge gap, B2B buyers should invest in ongoing education and training for their technicians, focusing on the interconnectivity of vehicle electrical systems. Workshops, online courses, and hands-on training sessions can enhance understanding of how alternators, batteries, and other components work together. Additionally, promoting a culture of collaboration within the workshop—where technicians can share insights and solutions—can foster a deeper understanding of complex electrical issues. Implementing diagnostic software that provides a comprehensive overview of the vehicle’s electrical system can also aid technicians in identifying problems more effectively. By enhancing their team’s expertise in electrical systems, repair shops can ensure more efficient troubleshooting and repair processes, leading to improved customer satisfaction and retention.

Strategic Material Selection Guide for que pasa cuando falla el alternador

What Materials Are Commonly Used in Alternator Components?

When dealing with alternator failures, the selection of materials for components is critical to ensure optimal performance and longevity. Here, we analyze four common materials used in alternators, focusing on their properties, advantages, and considerations for international B2B buyers.

1. Copper

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It can withstand high temperatures, making it suitable for various electrical applications.

Pros & Cons: The primary advantage of copper is its superior conductivity, which enhances the efficiency of alternators. However, copper is relatively expensive compared to other conductive materials, and its weight can be a drawback in applications where weight reduction is critical.

Impact on Application: Copper’s high conductivity ensures that alternators can effectively charge batteries and power electrical systems. However, its susceptibility to oxidation can impact performance if not properly coated or maintained.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B170 for copper wire. In regions like Africa and the Middle East, where environmental conditions can be harsh, selecting corrosion-resistant copper alloys may be beneficial.

2. Aluminum

Key Properties: Aluminum is lightweight, has good electrical conductivity, and exhibits excellent corrosion resistance. It can operate effectively at moderate temperatures and is often used in structural components of alternators.

Pros & Cons: The lightweight nature of aluminum makes it an attractive option for automotive applications, reducing overall vehicle weight and improving fuel efficiency. However, its conductivity is lower than that of copper, which may necessitate larger cross-sectional areas for wiring.

Impact on Application: Aluminum is often used in the casing and brackets of alternators, providing structural integrity while minimizing weight. Its corrosion resistance is particularly advantageous in humid or coastal environments.

Illustrative image related to que pasa cuando falla el alternador

Considerations for International Buyers: Buyers should be aware of local regulations regarding aluminum recycling and sustainability practices. Compliance with standards such as ASTM B221 for aluminum extrusions is also essential.

3. Steel

Key Properties: Steel is known for its strength and durability. It can withstand high pressures and temperatures, making it suitable for structural components of alternators.

Pros & Cons: The strength of steel provides robustness, ensuring that alternator components can endure mechanical stress. However, steel is heavier than aluminum and can be prone to rust if not properly coated.

Impact on Application: Steel is commonly used in the housing and mounting brackets of alternators, providing stability and protection to internal components. Its durability can enhance the lifespan of the alternator, especially in rugged environments.

Considerations for International Buyers: Buyers should consider the impact of local climate on steel components, particularly in humid regions where rust can be a concern. Compliance with standards such as ASTM A36 for structural steel is important to ensure quality.

4. Plastic Composites

Key Properties: Plastic composites are lightweight, resistant to corrosion, and can be molded into complex shapes. They can also withstand a range of temperatures, depending on the specific type of plastic used.

Illustrative image related to que pasa cuando falla el alternador

Pros & Cons: The primary advantage of plastic composites is their versatility and low weight, which can lead to improved fuel efficiency in vehicles. However, they may not offer the same level of strength as metals, potentially limiting their use in high-stress applications.

Impact on Application: Plastic composites are often used for insulating components and housing in alternators, protecting sensitive electrical parts from environmental factors. Their lightweight nature can help reduce overall vehicle weight.

Considerations for International Buyers: Buyers should ensure that the selected plastic composites meet relevant standards for automotive applications, such as ISO 9001 for quality management. Additionally, awareness of local recycling policies for plastics is crucial.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for que pasa cuando falla el alternador | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical wiring and connections | Excellent electrical conductivity | High cost and weight | High |

| Aluminum | Casing and structural components | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Steel | Housing and mounting brackets | High strength and durability | Heavier and prone to rust | Medium |

| Plastic Composites | Insulating components and housings | Lightweight and versatile | Lower strength compared to metals | Low |

This guide provides B2B buyers with essential insights into material selection for alternators, enabling informed decisions that enhance product performance and reliability in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for que pasa cuando falla el alternador

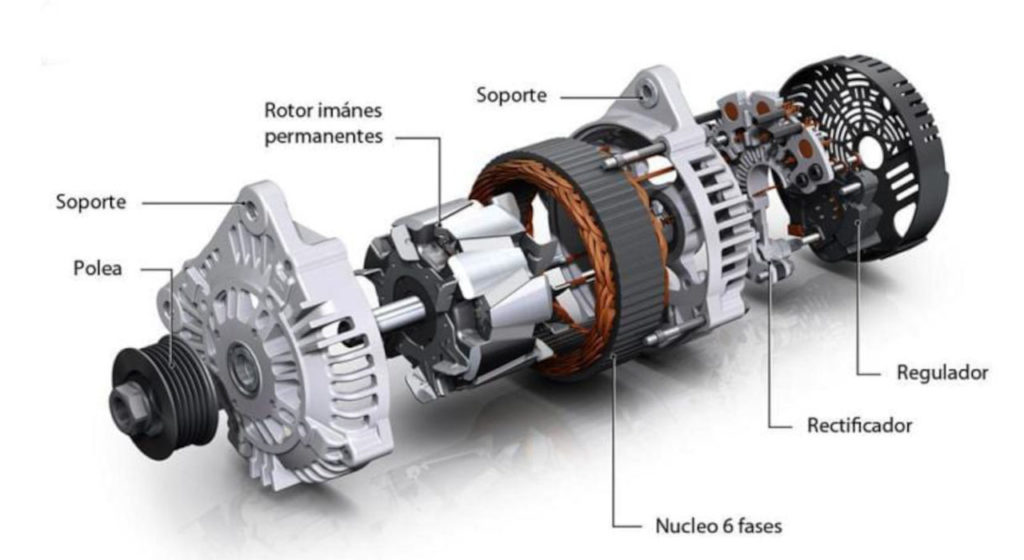

What Are the Main Stages of Manufacturing Alternators?

Manufacturing alternators involves several critical stages that ensure the final product meets performance and reliability standards. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials such as copper for windings, silicon steel for the stator and rotor, and durable plastics for housing. Each material must meet specific industry standards to ensure optimal performance and durability. Suppliers often conduct incoming quality control (IQC) to verify that materials conform to specifications, which is crucial for the subsequent manufacturing steps.

-

Forming: During the forming stage, the raw materials undergo various processes to create the core components of the alternator. Techniques such as stamping, forging, and machining are employed to shape the metal parts accurately. For instance, the stator and rotor are typically stamped from silicon steel sheets and then laminated to reduce energy losses. Precision in this stage is vital, as any defects can lead to inefficiencies in the alternator’s performance.

-

Assembly: Once the components are formed, they are assembled into the final alternator unit. This stage may involve automated processes, such as robotic assembly for windings, as well as manual assembly for more intricate components. Quality control measures, including in-process quality control (IPQC), are implemented to ensure that each component is correctly installed and functions as intended. This includes checking the alignment of parts and the integrity of electrical connections.

-

Finishing: The finishing stage involves applying protective coatings and conducting final inspections. Components may be painted or treated to resist corrosion and wear, enhancing the longevity of the alternator. Final quality checks (FQC) are performed to ensure that the alternator meets all specifications, including electrical performance tests and mechanical durability assessments.

How Do Quality Assurance Processes Ensure Reliability in Alternators?

Quality assurance (QA) is a fundamental aspect of alternator manufacturing, ensuring that each unit produced is reliable and performs consistently. Several international and industry-specific standards guide these QA processes.

-

International Standards: Compliance with ISO 9001 is essential, as this standard outlines the requirements for a quality management system (QMS). Organizations that adhere to ISO 9001 demonstrate a commitment to quality and customer satisfaction, which is critical for B2B buyers seeking dependable suppliers.

-

Industry-Specific Standards: In addition to ISO certifications, alternator manufacturers may also comply with specific industry standards such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for automotive applications. These certifications ensure that products meet safety and performance requirements, providing additional reassurance to buyers.

-

Quality Control Checkpoints: Manufacturers implement various checkpoints throughout the production process:

– Incoming Quality Control (IQC): Verifies raw materials upon receipt.

– In-Process Quality Control (IPQC): Monitors critical manufacturing stages to catch defects early.

– Final Quality Control (FQC): Conducts thorough testing on completed alternators, including load tests and performance assessments.

What Common Testing Methods Are Used in Quality Control for Alternators?

Testing methods are crucial for verifying the performance and reliability of alternators. Common testing techniques include:

-

Electrical Testing: This includes measuring voltage output, current flow, and efficiency under load conditions. Electrical testing ensures that the alternator generates sufficient power and that all connections are secure.

-

Mechanical Testing: Mechanical tests assess the physical integrity of the alternator. This may involve vibration analysis, thermal imaging, and torque testing to evaluate the performance under various operating conditions.

-

Environmental Testing: To ensure that alternators can withstand harsh conditions, manufacturers often perform environmental tests such as humidity, temperature cycling, and corrosion resistance tests. These tests simulate real-world conditions and help identify potential weaknesses.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring product reliability. Here are some strategies to consider:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall production environment. This firsthand evaluation can provide insights into the supplier’s commitment to quality.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including test results and compliance certificates. Reviewing these documents helps buyers understand the supplier’s adherence to industry standards.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased evaluation of the supplier’s quality practices. These inspections often include random sampling of products for testing, ensuring that the products meet the required specifications before shipment.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing alternators internationally, it is crucial for B2B buyers to understand the nuances of quality control and certification:

-

Regional Standards: Different regions may have specific certification requirements. For example, products sold in the European Union must often have CE marking, while products in the U.S. may need to comply with SAE (Society of Automotive Engineers) standards. Understanding these regional differences can prevent compliance issues.

-

Cultural Considerations: Quality expectations may vary across cultures. B2B buyers should communicate clearly with suppliers about their quality standards and expectations, ensuring that both parties are aligned.

-

Long-Term Partnerships: Establishing long-term relationships with reliable suppliers can enhance quality assurance. Ongoing communication and collaboration can help address quality issues proactively and foster a culture of continuous improvement.

In conclusion, understanding the manufacturing processes and quality assurance practices for alternators is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions that ultimately enhance their product offerings and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘que pasa cuando falla el alternador’

In the competitive landscape of automotive parts procurement, understanding the implications of alternator failures is vital for maintaining vehicle performance and customer satisfaction. This guide serves as a practical checklist for B2B buyers aiming to source reliable solutions and parts related to alternator issues.

1. Identify Common Symptoms of Alternator Failure

Understanding the typical signs of alternator failure will help you make informed procurement decisions. Symptoms such as dimming headlights, dashboard warning lights, or difficulties starting the vehicle can indicate a malfunctioning alternator. Recognizing these signs early allows you to source appropriate replacement parts before they lead to more significant vehicle issues.

Illustrative image related to que pasa cuando falla el alternador

2. Define Your Technical Specifications

Before sourcing, it’s essential to outline the technical specifications required for the alternator. This includes the type of vehicle, engine specifications, and electrical requirements. Clearly defined specifications help ensure compatibility and performance, reducing the risk of returns or operational failures.

3. Research Reputable Suppliers

Conduct thorough research to identify suppliers with a proven track record in the automotive parts industry. Look for reviews, testimonials, and case studies that highlight their reliability and quality. A reputable supplier will not only provide quality parts but also support your business with excellent customer service.

4. Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications and adhere to international quality standards. Certifications such as ISO 9001 indicate a commitment to quality management practices. Verify these credentials to ensure you’re sourcing from a supplier that prioritizes quality and compliance.

5. Request Product Samples

Before making large orders, request product samples to assess quality firsthand. Evaluating the physical attributes and functionality of the alternator can help confirm that the parts meet your technical specifications. This step is crucial to avoid costly mistakes that could arise from ordering bulk quantities of subpar products.

6. Evaluate Warranty and After-Sales Support

Investigate the warranty terms offered by suppliers and the level of after-sales support available. A robust warranty can protect your investment and provides peace of mind should any issues arise post-purchase. Additionally, reliable after-sales support can assist in troubleshooting and resolving any complications quickly.

7. Negotiate Pricing and Terms

Finally, engage in negotiations to secure favorable pricing and payment terms. Understanding market prices for alternators and related components allows you to negotiate effectively. Consider bulk purchase discounts or long-term partnership agreements that could provide cost benefits over time.

By following this practical checklist, B2B buyers can navigate the complexities of sourcing alternator parts more effectively, ensuring they meet their operational needs while maintaining high-quality standards for their customers.

Illustrative image related to que pasa cuando falla el alternador

Comprehensive Cost and Pricing Analysis for que pasa cuando falla el alternador Sourcing

What are the Key Cost Components in Sourcing Alternators?

When sourcing alternators, understanding the cost structure is crucial for B2B buyers. The primary components that contribute to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials can vary significantly based on quality and sourcing location. For alternators, essential components include copper wire, steel, and various electronic parts. Prices can fluctuate due to market demand and geopolitical factors, especially when sourcing from different regions.

-

Labor: Labor costs will differ depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this can impact quality. It’s essential to balance labor costs with skill levels to ensure a high-quality product.

-

Manufacturing Overhead: This includes costs associated with production facilities, machinery maintenance, and operational expenses. Efficient manufacturing processes can help minimize overhead, ultimately affecting the pricing structure.

-

Tooling: Initial tooling costs can be significant, especially for custom alternators. These costs must be amortized over the production volume, influencing the unit price.

-

Quality Control (QC): Ensuring that alternators meet international standards is vital. QC processes add to the cost but are necessary to reduce warranty claims and enhance customer satisfaction.

-

Logistics: Transportation costs can vary widely based on distance and shipping methods. For international buyers, understanding Incoterms is essential to clarify responsibility for shipping costs and risks.

-

Margin: Supplier margins can vary based on the level of customization and demand for specific alternators. Buyers should be aware that a higher margin often correlates with enhanced service and quality assurances.

What Factors Influence Pricing for Alternators?

Pricing for alternators is influenced by several factors that buyers should consider:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly impact pricing. Larger orders usually come with bulk pricing discounts, making it advantageous for buyers to consolidate their purchases.

-

Specifications and Customization: Customized alternators can lead to higher costs due to additional tooling and specialized materials. Buyers should assess whether the added features are necessary for their application.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO standards) can increase costs but often lead to better performance and longer lifespan. Evaluating the Total Cost of Ownership (TCO) can provide insights into whether the upfront investment is justified.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their quality assurance processes and proven track record.

-

Incoterms: Understanding the terms of shipping and delivery can help buyers manage costs effectively. Different Incoterms can significantly alter the total expenses involved in sourcing.

What Tips Can Help Buyers Negotiate Better Prices for Alternators?

To optimize costs when sourcing alternators, buyers should consider the following strategies:

-

Negotiate Effectively: Building strong relationships with suppliers can lead to better pricing and terms. Establishing trust can often yield better negotiation outcomes.

-

Focus on Cost-Efficiency: Analyze all cost components, not just the unit price. This includes shipping, tariffs, and potential tariffs when importing goods.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term implications of maintenance, durability, and warranty. Investing in higher quality components may result in lower overall costs.

-

Understand Pricing Nuances for International Sourcing: Different regions may have varying standards, regulations, and costs. Being informed about these factors can lead to better decision-making.

-

Stay Informed on Market Trends: Keeping an eye on market trends and forecasts can provide leverage in negotiations and help anticipate price fluctuations.

Disclaimer on Pricing

Prices for alternators can fluctuate based on various market conditions and supplier negotiations. The information provided is indicative and should be further researched for specific sourcing decisions. Always consult with multiple suppliers to ensure competitive pricing and quality assurance.

Alternatives Analysis: Comparing que pasa cuando falla el alternador With Other Solutions

Exploring Alternatives for Addressing Alternator Failures

When dealing with alternator failures, businesses must consider various solutions to mitigate the impact on vehicle performance and reliability. Understanding the alternatives can help B2B buyers make informed decisions that align with their operational needs and budget constraints.

| Comparison Aspect | Que Pasa Cuando Falla El Alternador | Alternative 1: Battery Replacement | Alternative 2: Solar-Powered Charging Systems |

|---|---|---|---|

| Performance | Essential for vehicle electrical systems; failure leads to battery drain and operational issues. | Provides temporary power but does not address alternator issues. | Offers renewable energy, reduces dependency on alternators, but requires initial setup. |

| Cost | Repair or replacement costs vary, typically higher than battery replacement. | Lower upfront costs, but may incur repeated expenses if issues persist. | Higher initial investment; potential long-term savings on fuel and energy. |

| Ease of Implementation | Requires professional diagnosis and repair; may involve downtime. | Quick and straightforward, usually requires minimal tools. | Installation can be complex; requires expertise in solar technology. |

| Maintenance | Regular checks needed to avoid future failures; moderate maintenance costs. | Minimal maintenance; battery checks are straightforward. | Regular cleaning and occasional battery checks needed; higher maintenance in harsh climates. |

| Best Use Case | Best for maintaining vehicle electrical integrity and performance. | Suitable for short-term solutions or when immediate alternator repair is not feasible. | Ideal for businesses seeking sustainable energy solutions and long-term cost savings. |

Detailed Breakdown of Alternatives

Alternative 1: Battery Replacement

Replacing a faulty battery may seem like a straightforward solution when faced with electrical issues. This approach is often less expensive and can be executed quickly, making it appealing for businesses needing immediate results. However, this method only addresses the symptoms rather than the root cause. If the alternator remains faulty, the new battery will likely drain just as quickly, leading to recurring costs and potential downtime.

Alternative 2: Solar-Powered Charging Systems

Solar-powered charging systems represent an innovative approach to vehicle energy management. They harness renewable energy to maintain battery charge, reducing reliance on traditional alternators. While this solution requires a significant initial investment and specialized installation, it can lead to long-term savings and environmental benefits. However, businesses must consider the complexity of installation and ongoing maintenance, particularly in regions with less consistent sunlight.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, the decision on how to address alternator failures should be guided by a comprehensive analysis of operational requirements, budget constraints, and long-term strategic goals. If immediate performance is critical, addressing the alternator directly may be the best route. However, for those looking to innovate or reduce long-term costs, exploring battery replacements or solar-powered solutions could provide viable alternatives. Ultimately, the right choice will depend on each business’s unique circumstances and future objectives.

Essential Technical Properties and Trade Terminology for que pasa cuando falla el alternador

What Are the Key Technical Properties of Alternators and Their Importance in B2B Transactions?

Understanding the essential technical properties of alternators is crucial for businesses involved in automotive parts supply. Here are some key specifications that B2B buyers should consider:

1. Output Voltage

The standard output voltage for most automotive alternators is typically between 12V and 14.5V. This specification is critical, as it determines the alternator’s ability to charge the vehicle’s battery effectively. In B2B contexts, ensuring the correct voltage rating can prevent compatibility issues and enhance customer satisfaction.

2. Amperage Rating

The amperage rating indicates the maximum electrical current the alternator can supply to the vehicle’s electrical system. Most alternators range from 40 to 150 amps. For B2B buyers, understanding this specification is essential for selecting the right alternator that can support the electrical demands of different vehicle models, thereby reducing the risk of premature failure.

3. Efficiency Rating

The efficiency of an alternator is a measure of how well it converts mechanical energy into electrical energy, often expressed as a percentage. A higher efficiency rating means less energy loss in the form of heat, which translates to better fuel economy for the vehicle. For B2B buyers, focusing on efficiency can lead to more sustainable product offerings and competitive advantages in the market.

4. Cooling Mechanism

Alternators may feature various cooling mechanisms, such as air-cooled or liquid-cooled designs. The choice of cooling method affects the alternator’s performance and longevity. B2B buyers should consider these specifications when sourcing products to ensure they meet the operational demands of the vehicles they serve.

5. Mounting Type

The mounting type of an alternator can vary significantly between vehicle models, including styles such as side mount or front mount. This specification is crucial for compatibility in replacement parts. B2B suppliers must ensure they provide alternators with the correct mounting type to avoid installation issues, which can lead to customer dissatisfaction.

What Are the Common Trade Terms Related to Alternators?

Familiarity with industry jargon can significantly enhance communication and efficiency in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. In the alternator market, OEM components are often preferred for their reliability and compatibility. B2B buyers should prioritize OEM parts to ensure quality and reduce the risk of future failures.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to optimize inventory levels and manage cash flow effectively. It ensures that businesses maintain sufficient stock without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and availability for specific products. In the context of alternators, an RFQ can help buyers compare options from different suppliers and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. For B2B buyers in the automotive sector, understanding Incoterms is essential to navigate global trade effectively.

5. Aftermarket Parts

Aftermarket parts are components made by companies other than the original manufacturer. These parts can offer cost-effective alternatives to OEM components. B2B buyers should evaluate the quality and warranty of aftermarket alternators to ensure they meet customer expectations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and ultimately improve customer satisfaction in the automotive market.

Navigating Market Dynamics and Sourcing Trends in the que pasa cuando falla el alternador Sector

What Are the Current Market Dynamics Impacting the Alternator Sector?

The global automotive industry is witnessing significant shifts driven by technological advancements, changing consumer preferences, and regulatory frameworks. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. A notable trend is the increased integration of smart technologies in vehicle systems, including alternators. Advanced diagnostics and predictive maintenance tools are becoming standard, allowing for proactive identification of alternator failures. This trend is particularly relevant for workshops and distributors who prioritize efficiency and customer satisfaction.

Illustrative image related to que pasa cuando falla el alternador

Emerging markets are also seeing a surge in electric and hybrid vehicles, which require more sophisticated alternator systems to support their unique energy needs. Consequently, suppliers are adapting their product offerings, focusing on high-performance, energy-efficient alternators that meet the demands of modern vehicles. Additionally, B2B buyers are increasingly seeking reliable suppliers who can provide not only quality components but also technical support and training to help their teams diagnose and repair alternator issues effectively.

Moreover, global supply chain challenges and geopolitical tensions have prompted buyers to diversify their sourcing strategies. Establishing relationships with manufacturers from different regions can mitigate risks associated with supply disruptions. Companies are also prioritizing local suppliers to enhance responsiveness and reduce lead times, ensuring that they can promptly address the needs of their customers.

How Can Sustainability and Ethical Sourcing Enhance Your Supply Chain in the Alternator Sector?

As sustainability becomes a pivotal consideration across industries, the alternator sector is no exception. B2B buyers are increasingly aware of the environmental impact associated with automotive components. This has led to a demand for ethical sourcing practices that minimize ecological footprints and promote responsible manufacturing processes. For instance, suppliers are now expected to demonstrate transparency in their sourcing of materials, ensuring that components are made from recycled or sustainably sourced materials wherever possible.

The use of ‘green’ certifications is also gaining traction. Certifications such as ISO 14001, which focuses on effective environmental management systems, can enhance a supplier’s credibility. Buyers are encouraged to partner with manufacturers who prioritize eco-friendly practices, as this not only aligns with corporate social responsibility goals but also appeals to an environmentally conscious consumer base.

Illustrative image related to que pasa cuando falla el alternador

Additionally, the adoption of circular economy principles is becoming more relevant. This includes designing alternators that are easier to recycle and refurbish, thereby extending their lifecycle and reducing waste. B2B buyers who engage in sustainable practices can differentiate themselves in the market, appealing to clients who prioritize environmental stewardship.

What Is the Historical Context of the Alternator’s Evolution in the Automotive Industry?

The alternator has undergone significant transformations since its inception in the early 20th century. Initially designed to convert mechanical energy into electrical energy to power vehicle lighting, advancements in technology have transformed the alternator into a critical component of modern automotive electrical systems.

Over the decades, the shift from direct current (DC) generators to alternating current (AC) alternators marked a pivotal change, enhancing efficiency and reliability. With the introduction of electronic components and smart technology, modern alternators are now equipped with advanced features such as voltage regulation and diagnostic capabilities. This evolution reflects the broader trends in the automotive industry towards increased efficiency, performance, and connectivity, making it essential for B2B buyers to stay informed about the latest advancements in alternator technology and sourcing options.

In conclusion, navigating the complexities of the alternator sector requires a keen understanding of market dynamics, a commitment to sustainability, and an appreciation of the historical context that shapes current practices. B2B buyers who adapt to these trends will not only enhance their operational efficiency but also position themselves as leaders in a rapidly evolving marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of que pasa cuando falla el alternador

-

How do I identify symptoms of a failing alternator?

Identifying the symptoms of a failing alternator is crucial for timely intervention. Common indicators include a dashboard battery light, dimming headlights, and electrical component malfunctions such as slow power windows or a struggling air conditioning system. If the vehicle experiences difficulty starting or if the battery discharges frequently, these are strong signs of alternator issues. Conducting a thorough electrical test can help confirm whether the alternator is generating adequate power or if it needs replacement. -

What are the best practices for maintaining alternators?

Regular maintenance is essential for prolonging the life of an alternator. Ensure that the alternator belt is properly tensioned and free from wear, as a loose or damaged belt can lead to insufficient power generation. Additionally, inspect electrical connections for corrosion and ensure the alternator is securely mounted. Periodic testing of the alternator’s output can help catch potential issues early, preventing unexpected failures that could disrupt operations. -

What is the best type of alternator for commercial vehicles?

The best type of alternator for commercial vehicles depends on the specific power requirements and usage conditions. Heavy-duty alternators with higher amperage ratings are ideal for vehicles that power multiple electrical components. Consider brands that offer robust warranties and have a reputation for reliability in the commercial sector. Additionally, selecting alternators with features like temperature regulation can enhance performance in extreme conditions, ensuring longevity and reliability. -

What customization options are available for alternators?

Many suppliers offer customization options for alternators to meet specific needs. Customizations can include varying amperage outputs, modifications for unique mounting configurations, or enhancements for extreme environmental conditions. When sourcing alternators, inquire about the supplier’s capabilities for custom designs and the minimum order quantities required for such modifications to ensure they align with your operational needs. -

How can I vet suppliers for alternators?

Vetting suppliers for alternators involves evaluating their reputation, product quality, and customer service. Begin by checking their certifications and industry standards compliance. Look for reviews and testimonials from other B2B buyers to gauge reliability. Request samples to assess product quality firsthand, and inquire about their warranty policies and after-sales support to ensure they align with your expectations. -

What are the minimum order quantities (MOQ) for alternators?

Minimum order quantities for alternators can vary widely between suppliers based on production capabilities and product types. Generally, MOQs can range from a few units for standard alternators to larger quantities for custom designs. It’s essential to discuss MOQs upfront with potential suppliers to ensure they align with your purchasing strategy and inventory management practices. -

What are typical payment terms for B2B purchases of alternators?

Payment terms for B2B purchases of alternators typically vary by supplier and can include options such as net 30, net 60, or even upfront payments for large orders. Some suppliers may offer discounts for early payments or bulk purchases. It’s advisable to negotiate terms that suit your cash flow situation while ensuring the supplier’s requirements are met to establish a mutually beneficial relationship. -

How do logistics and shipping impact the procurement of alternators?

Logistics and shipping play a crucial role in the timely procurement of alternators. Factors such as shipping methods, lead times, and customs regulations can significantly affect delivery schedules. When sourcing alternators from international suppliers, consider their shipping capabilities and reliability. It’s beneficial to work with suppliers who have established logistics networks to minimize delays and ensure that products arrive in good condition and on time.

Top 3 Que Pasa Cuando Falla El Alternador Manufacturers & Suppliers List

1. Valeo – Alternadores

Domain: valeoservice.com.br

Registered: 2000 (25 years)

Introduction: El alternador es un componente eléctrico esencial en los vehículos, responsable de mantener la batería cargada y garantizar el suministro de energía necesario para el funcionamiento de diversos sistemas eléctricos. Un alternador defectuoso puede generar problemas como: 1. Luz de batería encendida en el tablero. 2. Fallos en el sistema eléctrico (faros, vidrios eléctricos, aire acondicionado). 3. D…

2. Endurance Warranty – Planes de Protección Vehicular

Domain: endurancewarranty.com

Registered: 2009 (16 years)

Introduction: Endurance Warranty ofrece planes de protección vehicular que ayudan a los propietarios a ahorrar en reparaciones de vehículos. Se destaca la importancia de una garantía extendida para protegerse contra fallas inesperadas de componentes, como el alternador. El alternador es un generador eléctrico que convierte energía cinética en energía eléctrica, alimentando los sistemas eléctricos del coche y ma…

3. Autocosmos – Alternador

Domain: noticias.autocosmos.com.mx

Registered: 1999 (26 years)

Introduction: El alternador es un componente crítico del vehículo que convierte la energía mecánica del cigüeñal en electricidad. Suministra energía a los accesorios del auto y mantiene la batería cargada. Las cinco señales de problemas en el alternador incluyen: 1. Luz de advertencia en el panel de instrumentos, que puede indicar problemas con el voltaje. 2. Disminución en la intensidad de las luces y mal func…

Strategic Sourcing Conclusion and Outlook for que pasa cuando falla el alternador

What Are the Key Takeaways for International B2B Buyers Regarding Alternator Failures?

Understanding the implications of alternator failures is crucial for businesses operating in the automotive sector. Recognizing the symptoms of a defective alternator—such as dimming lights, difficulty starting vehicles, and electrical system malfunctions—enables workshops to provide timely and accurate diagnostics. This not only enhances customer satisfaction but also reduces the likelihood of costly repairs stemming from misdiagnosis.

Strategic sourcing of high-quality alternators and components can significantly impact operational efficiency. By partnering with reputable suppliers, businesses can ensure they have access to reliable parts that meet industry standards. This proactive approach not only minimizes downtime for clients but also strengthens the service reputation of automotive workshops across diverse markets, including Africa, South America, the Middle East, and Europe.

As the automotive landscape continues to evolve, embracing innovative sourcing strategies will be vital. International B2B buyers are encouraged to prioritize partnerships that enhance their product offerings and service capabilities. By doing so, they can stay ahead of market demands and contribute to a more sustainable automotive future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to que pasa cuando falla el alternador

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.