Introduction: Navigating the Global Market for partes del motor de arranque

The global market for partes del motor de arranque is increasingly complex, presenting unique challenges for international B2B buyers. As the demand for efficient and reliable vehicle ignition systems grows, sourcing high-quality starter motor components has become critical for maintaining operational efficiency and customer satisfaction. This guide serves as a comprehensive resource, addressing key considerations such as the various types of starter motor parts, their applications across different vehicle models, and the best practices for supplier vetting.

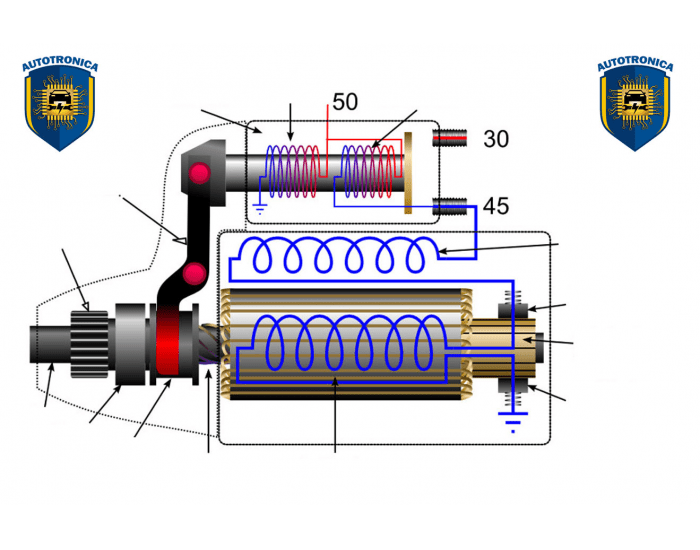

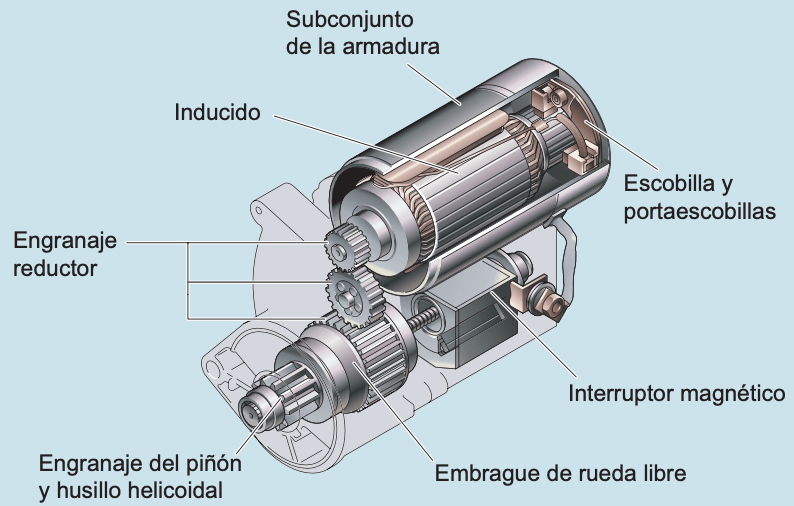

In addition to exploring cost implications and potential sourcing strategies, this guide empowers decision-makers from diverse regions—including Africa, South America, the Middle East, and Europe (notably Germany and Brazil)—to make informed purchasing decisions. By equipping buyers with in-depth knowledge about the essential components of starter motors—such as electric motors, solenoids, and bendix mechanisms—this guide aims to enhance procurement strategies and minimize risks associated with subpar products.

Ultimately, understanding the intricacies of partes del motor de arranque will not only facilitate successful transactions but also foster long-term partnerships with reliable suppliers, ensuring that businesses remain competitive in an ever-evolving automotive landscape.

Table Of Contents

- Top 4 Partes Del Motor De Arranque Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for partes del motor de arranque

- Understanding partes del motor de arranque Types and Variations

- Key Industrial Applications of partes del motor de arranque

- 3 Common User Pain Points for ‘partes del motor de arranque’ & Their Solutions

- Strategic Material Selection Guide for partes del motor de arranque

- In-depth Look: Manufacturing Processes and Quality Assurance for partes del motor de arranque

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘partes del motor de arranque’

- Comprehensive Cost and Pricing Analysis for partes del motor de arranque Sourcing

- Alternatives Analysis: Comparing partes del motor de arranque With Other Solutions

- Essential Technical Properties and Trade Terminology for partes del motor de arranque

- Navigating Market Dynamics and Sourcing Trends in the partes del motor de arranque Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of partes del motor de arranque

- Strategic Sourcing Conclusion and Outlook for partes del motor de arranque

- Important Disclaimer & Terms of Use

Understanding partes del motor de arranque Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Starter Motor | Uses a DC motor to convert electrical energy to mechanical energy; common in most vehicles. | Automotive manufacturing and repair shops. | Pros: Widely available, cost-effective; Cons: Limited efficiency in extreme conditions. |

| High Torque Starter Motor | Enhanced design for higher torque output; ideal for larger engines or heavy-duty applications. | Heavy machinery, commercial vehicles. | Pros: Reliable under heavy loads; Cons: Higher cost and weight. |

| Mini Starter Motor | Compact design, lighter weight; suitable for performance vehicles. | Racing and performance automotive markets. | Pros: Space-saving, improved performance; Cons: May require specific installation considerations. |

| Gear Reduction Starter Motor | Utilizes gears to increase torque while reducing motor size; efficient power usage. | High-performance vehicles, off-road applications. | Pros: Improved efficiency and reliability; Cons: More complex installation and higher cost. |

| Permanent Magnet Starter Motor | Incorporates permanent magnets for enhanced efficiency and reduced size. | Electric vehicles, hybrid systems. | Pros: Energy-efficient, lightweight; Cons: More expensive and sensitive to temperature variations. |

What Are the Characteristics of Standard Starter Motors?

Standard starter motors are the most prevalent type found in vehicles today. They operate using a direct current (DC) motor that converts electrical energy from the battery into mechanical energy, allowing the engine to crank. These motors are typically used in passenger vehicles and are characterized by their cost-effectiveness and availability. B2B buyers should consider the compatibility with their vehicle types and the availability of replacement parts when purchasing.

How Do High Torque Starter Motors Stand Out?

High torque starter motors are specifically designed for applications requiring additional power, such as larger engines found in commercial vehicles and heavy machinery. Their enhanced design allows them to deliver higher torque, making them suitable for starting engines under challenging conditions. B2B buyers in industries like construction or transportation should weigh the benefits of reliability against the higher costs associated with these motors.

What Advantages Do Mini Starter Motors Offer?

Mini starter motors are compact and lightweight, making them ideal for performance vehicles where space is at a premium. They provide efficient performance and can improve overall vehicle dynamics. However, they may have specific installation requirements and may not be suitable for all vehicle types. B2B buyers in the racing and high-performance automotive sectors should evaluate the trade-offs between size and power output.

Why Choose Gear Reduction Starter Motors?

Gear reduction starter motors use a gear mechanism to amplify torque while minimizing motor size, which enhances efficiency. They are particularly useful in high-performance vehicles and off-road applications where reliability is crucial. B2B buyers should consider the complexity of installation and the potential for increased costs when opting for this type of starter motor.

What Makes Permanent Magnet Starter Motors Unique?

Permanent magnet starter motors utilize permanent magnets to improve efficiency and reduce size, making them increasingly popular in electric and hybrid vehicles. These motors are lightweight and energy-efficient but may come with a higher price tag and sensitivity to temperature fluctuations. B2B buyers focused on cutting-edge automotive technologies should assess their specific applications to determine if the benefits outweigh the costs.

Key Industrial Applications of partes del motor de arranque

| Industry/Sector | Specific Application of partes del motor de arranque | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Integration of starter motor parts in vehicle assembly | Ensures reliable vehicle performance and safety | Quality certifications, compatibility with various vehicle models, and supply chain reliability. |

| Heavy Machinery | Use in construction and agricultural equipment | Enhances operational efficiency and reduces downtime | Durability under extreme conditions, availability of spare parts, and adherence to industry standards. |

| Transportation Services | Maintenance of fleet vehicles | Minimizes operational disruptions and maintenance costs | Bulk purchasing options, supplier reputation, and after-sales support. |

| Marine Industry | Installation in marine engines | Improves start-up reliability in harsh environments | Corrosion resistance, compliance with maritime regulations, and lead times for delivery. |

| Renewable Energy | Application in wind turbine generators | Supports efficient energy conversion processes | Technical specifications, integration with existing systems, and sourcing of sustainable materials. |

How Are partes del motor de arranque Used in Automotive Manufacturing?

In the automotive manufacturing sector, partes del motor de arranque are critical for the assembly of vehicles. These components, especially the solenoid and motor electric, ensure that vehicles start reliably, contributing to overall safety and performance. Buyers in this sector need to prioritize components that meet stringent quality standards and are compatible with diverse vehicle models. Additionally, understanding the supply chain dynamics is essential to mitigate delays and ensure consistent production timelines.

What Role Do Motor Starter Parts Play in Heavy Machinery?

Heavy machinery, including construction and agricultural equipment, relies heavily on starter motor parts for effective operation. The rugged environments in which these machines operate necessitate components that are durable and capable of withstanding extreme conditions. Buyers should focus on sourcing high-quality parts that offer reliability and performance to minimize downtime. Furthermore, ensuring the availability of spare parts is crucial for ongoing maintenance and operational efficiency.

How Are partes del motor de arranque Essential for Transportation Services?

In the transportation services industry, maintaining fleet vehicles with reliable starter motor components is paramount. The efficiency of these components directly impacts operational costs and service reliability. B2B buyers should consider bulk purchasing agreements to optimize costs and ensure a steady supply of quality parts. Additionally, suppliers with strong reputations and robust after-sales support can provide the necessary assurance for long-term partnerships.

Why Are Starter Motor Parts Important in the Marine Industry?

The marine industry presents unique challenges for starter motor parts due to harsh environmental conditions, including exposure to saltwater and extreme weather. Components such as the rotor and stator must be resistant to corrosion and designed to operate reliably in these environments. Buyers in this sector should prioritize sourcing parts that comply with maritime regulations and offer quick delivery times to minimize potential operational disruptions.

How Do partes del motor de arranque Contribute to Renewable Energy Solutions?

In the renewable energy sector, particularly in wind turbine generators, starter motor parts play a vital role in the energy conversion process. These components must be engineered to support efficient operations while also aligning with sustainability goals. Buyers should focus on the technical specifications that ensure compatibility with existing systems and consider sourcing materials that reflect environmental responsibility. This focus not only enhances operational efficiency but also aligns with global sustainability initiatives.

3 Common User Pain Points for ‘partes del motor de arranque’ & Their Solutions

Scenario 1: Inconsistent Performance of Starter Motor Components

The Problem: B2B buyers often encounter issues with the reliability of starter motor components, leading to inconsistent performance in vehicles. This can stem from subpar quality parts that fail prematurely, causing delays in operations and additional costs for replacements. For companies relying on fleet vehicles, such failures can disrupt logistics and damage client relationships, as unexpected downtime translates to lost revenue and customer dissatisfaction.

The Solution: To mitigate this risk, buyers should prioritize sourcing parts from reputable manufacturers known for stringent quality control processes. Conducting thorough research on supplier certifications, such as ISO standards, can ensure that the components meet high-quality benchmarks. Additionally, implementing a preventive maintenance schedule that includes regular inspections of starter motor parts—like solenoids, brushes, and the Bendix mechanism—can help identify wear and tear before they lead to failures. Engaging in long-term contracts with trusted suppliers can also help secure better pricing and availability, ensuring that high-quality parts are always on hand.

Scenario 2: Difficulty in Identifying the Right Starter Motor Parts

The Problem: Many B2B buyers face challenges in identifying the correct starter motor parts for specific vehicle models, leading to improper installations or mismatched components. This issue is particularly prevalent in markets with diverse vehicle makes and models, where a lack of standardized parts can complicate sourcing. Incorrect parts can lead to operational inefficiencies and increased maintenance costs, as well as potential safety risks if vehicles do not operate as intended.

The Solution: To address this challenge, buyers should invest in comprehensive parts catalogs or databases that clearly list compatible starter motor components by vehicle make and model. Collaborating with knowledgeable suppliers who provide technical support can further enhance the sourcing process. Utilizing advanced tools like VIN (Vehicle Identification Number) lookups can help ensure that the correct parts are specified. Additionally, maintaining open communication with suppliers about future vehicle needs and changes in fleet composition can enable proactive sourcing strategies.

Scenario 3: High Costs of Maintenance and Replacement Parts

The Problem: Rising costs associated with the maintenance and replacement of starter motor parts can strain budgets for B2B buyers, especially in regions where import tariffs and logistical challenges add to expenses. The financial burden is compounded when parts fail unexpectedly, leading to emergency purchases at inflated prices. Companies often find themselves caught in a cycle of high costs that affect overall operational efficiency and profitability.

The Solution: To combat these costs, B2B buyers should explore bulk purchasing agreements with manufacturers or wholesalers to secure lower prices on starter motor components. Establishing long-term relationships with suppliers can also lead to discounts and exclusive deals. Furthermore, investing in training for maintenance staff on proper installation and care of starter motor parts can extend the lifespan of these components, reducing the frequency of replacements. Implementing a robust inventory management system can help track usage patterns and forecast future needs, ensuring that parts are purchased at the optimal time to take advantage of pricing fluctuations.

Strategic Material Selection Guide for partes del motor de arranque

What Are the Common Materials Used in partes del motor de arranque?

When selecting materials for components of the starter motor, several factors must be considered, including performance, durability, and cost. The following analysis covers four common materials: steel, copper, aluminum, and plastic composites. Each material is evaluated based on its properties, advantages, disadvantages, and suitability for international markets.

Steel: A Reliable Choice for Durability

Key Properties: Steel is known for its high tensile strength and excellent wear resistance. It can withstand high temperatures and pressures, making it suitable for components like the rotor and stator in starter motors.

Pros & Cons: The durability of steel is a significant advantage, ensuring a long lifespan for components. However, it is heavier than other materials, which may affect the overall weight of the starter motor. Additionally, steel is prone to corrosion if not properly treated, which can be a concern in humid or saline environments.

Impact on Application: Steel components are highly compatible with various automotive applications, providing robust performance under demanding conditions. However, buyers should ensure that steel parts are treated or coated to resist corrosion, especially in regions with harsh climates.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local environmental conditions when selecting steel components. Compliance with international standards such as ASTM and DIN for corrosion resistance is crucial.

Copper: The Electrical Conductor

Key Properties: Copper has excellent electrical conductivity, making it ideal for components like brushes and solenoids in starter motors. It also has good thermal conductivity, which helps dissipate heat.

Pros & Cons: The primary advantage of copper is its superior conductivity, which enhances the efficiency of the starter motor. However, copper is more expensive than steel and can be susceptible to corrosion if not properly insulated.

Impact on Application: Copper components ensure reliable electrical connections, critical for the effective operation of starter motors. However, buyers must consider the potential for oxidation, which can impede performance over time.

Considerations for International Buyers: In Europe, particularly Germany, there are strict regulations regarding the use of copper in automotive applications. Buyers should ensure that their suppliers adhere to these standards to prevent compliance issues.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight and has good corrosion resistance, making it an attractive option for starter motor housings and other components. It can withstand moderate temperatures and pressures.

Pros & Cons: The lightweight nature of aluminum helps reduce the overall weight of the vehicle, improving fuel efficiency. However, aluminum is less durable than steel and may not withstand high-stress applications as effectively.

Impact on Application: Aluminum components are suitable for applications where weight reduction is a priority. However, careful consideration must be given to the mechanical stress they will endure.

Considerations for International Buyers: Buyers in the Middle East and Africa should evaluate the availability and cost of aluminum. Compliance with international standards for aluminum alloys is also essential to ensure product reliability.

Plastic Composites: The Modern Solution

Key Properties: Plastic composites are lightweight, resistant to corrosion, and can be molded into complex shapes. They are often used for non-structural components like housings and covers.

Pros & Cons: The main advantage of plastic composites is their versatility and low weight. However, they may not offer the same level of durability as metals and can be affected by high temperatures.

Impact on Application: Plastic components are ideal for reducing weight and improving fuel efficiency but may not be suitable for high-stress applications. Buyers should assess the specific requirements of their applications.

Considerations for International Buyers: In Europe, regulations surrounding the use of plastics in automotive applications are stringent. Buyers must ensure compliance with these regulations to avoid potential penalties.

Summary Table of Material Selection

| Material | Typical Use Case for partes del motor de arranque | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Rotor, stator components | High durability | Prone to corrosion | Medium |

| Copper | Brushes, solenoids | Excellent electrical conductivity | Higher cost, oxidation risk | High |

| Aluminum | Housings, non-structural components | Lightweight, corrosion-resistant | Less durable under stress | Medium |

| Plastic Composites | Housings, covers | Versatile, lightweight | Limited durability | Low |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to procure components for starter motors. Understanding the properties and implications of each material helps ensure that the right choices are made for performance and compliance in various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for partes del motor de arranque

What Are the Key Stages in the Manufacturing Process of Starter Motor Parts?

The manufacturing of starter motor parts involves several critical stages, each designed to ensure that the components meet stringent performance and safety standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step in manufacturing starter motor parts involves the selection and preparation of raw materials. Common materials include high-grade steel for the motor casing, copper for electrical components, and various alloys for gears and other mechanical parts. Suppliers must ensure that materials meet international standards, such as ASTM or ISO specifications, to guarantee durability and performance. Material testing for tensile strength, conductivity, and corrosion resistance is often conducted at this stage. -

Forming Techniques for Precision Components

Forming techniques vary depending on the specific part being manufactured. For instance, the rotor and stator components typically undergo processes like stamping or machining. Stamping involves using a die to cut and shape materials, while machining employs CNC (Computer Numerical Control) tools for precision shaping and drilling. Additionally, die-casting may be used for producing complex shapes with high accuracy, particularly for the solenoid housing and Bendix mechanism. Each method is chosen based on the required tolerances and production volumes. -

Assembly of Components

Once the individual parts are formed, the assembly process begins. This stage is critical as it involves combining various components such as the motor, solenoid, brushes, and other electrical elements. Typically, assembly lines are used to streamline the process, ensuring that each component is installed in the correct sequence. Quality checks during assembly include visual inspections and functional tests to confirm that the parts fit together correctly and function as intended. -

Finishing Processes for Enhanced Performance

After assembly, finishing processes are applied to improve the durability and functionality of the starter motor parts. These may include surface treatments like anodizing or powder coating to enhance corrosion resistance, as well as lubrication for moving parts to reduce wear and tear. Balancing is also performed on rotating components to minimize vibrations during operation. Each finishing technique is selected based on the specific requirements of the component and its intended application.

What Quality Assurance Standards Are Relevant for Starter Motor Parts Manufacturing?

Quality assurance (QA) is essential in the manufacturing of starter motor parts to ensure reliability and safety. Various international and industry-specific standards are relevant, including:

-

ISO 9001

This widely recognized standard focuses on quality management systems (QMS) and is applicable across various industries, including automotive manufacturing. Compliance with ISO 9001 signifies that a manufacturer has implemented effective processes for consistent quality control and continuous improvement. -

CE Marking

For products sold in the European market, CE marking indicates compliance with European safety, health, and environmental protection standards. Manufacturers must ensure that their starter motor parts meet the necessary directives, such as the Machinery Directive and Low Voltage Directive. -

API Standards

The American Petroleum Institute (API) sets standards for components used in engines and machinery. While more commonly associated with oil and gas, certain API standards may apply to starter motors used in heavy-duty applications, ensuring compatibility and performance under demanding conditions.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

To maintain high-quality standards throughout the manufacturing process, several quality control (QC) checkpoints are typically implemented:

-

Incoming Quality Control (IQC)

This checkpoint occurs at the initial stage of production, where raw materials and components are inspected before being used in the manufacturing process. Testing may include dimensional checks, material property evaluations, and verification of supplier certifications. -

In-Process Quality Control (IPQC)

During the manufacturing and assembly stages, IPQC ensures that each process step adheres to quality standards. This may involve monitoring machine settings, conducting mid-process inspections, and testing the functionality of assembled components. -

Final Quality Control (FQC)

Before shipping, FQC involves comprehensive testing of the finished starter motor parts. This includes functional tests to ensure that each component operates as intended, as well as checks for compliance with specifications and safety standards. Often, random sampling is used to validate quality across production batches.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier QC processes is crucial to ensure the reliability of the products. Here are several strategies:

-

Conducting Audits

Regular audits of potential suppliers can provide insight into their manufacturing practices and quality control measures. Buyers should request audit reports that detail the supplier’s compliance with relevant standards, as well as their internal QC procedures. -

Requesting Quality Reports

Suppliers should be able to provide documentation, such as certificates of conformity, test reports, and inspection records. These documents serve as evidence of compliance with international standards and the effectiveness of their quality management systems. -

Third-Party Inspections

Engaging third-party inspection agencies can provide an objective evaluation of a supplier’s manufacturing processes and QC practices. These agencies often have established protocols for assessing compliance with industry standards and can help mitigate risks associated with purchasing.

What Are the Specific QC and Certification Nuances for International Buyers?

When dealing with international suppliers, buyers must be aware of specific nuances regarding QC and certification:

Illustrative image related to partes del motor de arranque

-

Understanding Regional Standards

Different regions may have varying requirements for certifications and quality standards. For instance, while ISO 9001 is globally recognized, additional local certifications may be necessary for specific markets. Buyers should familiarize themselves with these regional standards to ensure compliance. -

Navigating Trade Regulations

Import/export regulations can affect the certification requirements for starter motor parts. Buyers must ensure that their suppliers understand and comply with these regulations to avoid potential delays or penalties during shipping. -

Cultural and Communication Considerations

Effective communication is vital in ensuring that quality expectations are clearly understood and met. Buyers should be prepared to engage in discussions about quality standards, production processes, and testing methods with suppliers from different cultural backgrounds.

By understanding the manufacturing processes and quality assurance practices for starter motor parts, B2B buyers can make informed decisions and establish partnerships that prioritize reliability and safety in their automotive supply chains.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘partes del motor de arranque’

This practical sourcing guide is designed to assist international B2B buyers in procuring components for the motor de arranque (starter motor). As these parts are critical for the efficient operation of vehicles, understanding the procurement process is essential to ensure quality and reliability.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the specifications for each component of the motor de arranque. This includes details such as voltage requirements, size, and material compatibility. Having precise specifications helps to eliminate unsuitable options and ensures that the parts you source will meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in automotive parts, particularly motor de arranque components. Look for manufacturers with a strong track record in quality and reliability. Utilize industry directories, trade shows, and online platforms to compile a list of candidates.

- Consider Regional Suppliers: Focus on suppliers from regions known for automotive manufacturing, such as Europe and South America, to leverage local expertise and faster shipping times.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess the necessary certifications relevant to automotive parts, such as ISO 9001 or other quality management standards. Certifications indicate adherence to industry standards, which is crucial for ensuring product reliability and safety.

- Request Documentation: Ask for copies of certifications and any quality control processes they have in place to ensure compliance with international standards.

Step 4: Assess Quality Control Measures

Inquire about the quality control measures implemented by the suppliers. Understanding their testing and inspection processes will give you confidence in the quality of the components you are sourcing.

- Look for Testing Protocols: Ensure that the supplier conducts rigorous testing for each part, including performance tests and failure analysis, to guarantee reliability.

Step 5: Request Samples

Before making a bulk purchase, request samples of the motor de arranque components. This will allow you to evaluate the quality and compatibility of the parts with your specific requirements.

- Conduct Practical Tests: Test the samples in real-world conditions to ensure they perform as expected in your applications.

Step 6: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, discuss pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing structures, especially for bulk orders.

- Consider Long-Term Relationships: Establishing a long-term partnership can lead to favorable terms and priority service in the future.

Step 7: Establish a Logistics Plan

Plan the logistics of sourcing, including shipping methods and timelines. Understanding the logistics will help you manage inventory effectively and minimize downtime in your operations.

- Evaluate Customs and Import Regulations: Be aware of any import duties or regulations that may apply to the motor de arranque parts you are sourcing to avoid unexpected costs and delays.

Following this step-by-step checklist will facilitate a systematic approach to sourcing motor de arranque components, ensuring that you obtain high-quality parts that meet your operational needs while fostering productive supplier relationships.

Comprehensive Cost and Pricing Analysis for partes del motor de arranque Sourcing

Understanding the cost structure and pricing dynamics of partes del motor de arranque (starter motor parts) is crucial for international B2B buyers aiming to source these components effectively. A comprehensive analysis reveals several key cost components, price influencers, and practical tips for negotiation and procurement.

What Are the Key Cost Components for partes del motor de arranque?

-

Materials: The primary materials used in starter motor parts include copper, steel, and various alloys. The cost of these raw materials fluctuates based on global market conditions. For instance, copper prices can significantly impact the overall cost, given its essential role in electrical components.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing; however, this can sometimes be offset by longer lead times or varying quality levels.

-

Manufacturing Overhead: This encompasses costs related to factory operations, such as utilities, rent, and salaries of non-production staff. Efficient manufacturing processes can help keep these costs down, which is particularly important for bulk orders.

-

Tooling: Custom tooling for specific parts can be a significant upfront investment. For buyers seeking tailored components, understanding tooling costs is essential, as these can be amortized over larger order volumes.

-

Quality Control (QC): Ensuring that each part meets specified standards requires investment in quality control processes. This may involve testing and inspection, which can add to the total cost but is vital for maintaining product reliability.

-

Logistics: Transportation costs depend on the distance between the supplier and the buyer, as well as the chosen shipping method. Incoterms play a critical role in defining who is responsible for these costs and risks, affecting the final price.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can vary based on market demand, competition, and the supplier’s pricing strategy.

How Do Volume and Specifications Influence Pricing?

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should inquire about minimum order quantities (MOQs) as they can significantly influence pricing structures.

Specifications and Customization: Custom parts designed to meet specific performance criteria or certifications may incur additional costs. It’s important for buyers to clearly define their requirements to avoid unexpected expenses.

Quality and Certifications: Parts that meet higher quality standards or specific industry certifications (like ISO or TS) may come at a premium. Buyers should weigh the benefits of these certifications against the potential cost savings of sourcing lower-quality components.

What Buyer Tips Can Enhance Negotiation and Cost-Efficiency?

-

Negotiate Terms: Open discussions about pricing, payment terms, and delivery schedules can yield better deals. Suppliers may be willing to negotiate if they see a long-term partnership potential.

-

Consider Total Cost of Ownership (TCO): When evaluating suppliers, look beyond the initial purchase price. Consider factors like shipping, handling, and potential maintenance costs associated with the parts over their lifespan.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying supply chain dynamics and currency fluctuations that impact pricing. For instance, buyers from Africa or South America may face higher shipping costs or tariffs that need to be factored into the total cost.

-

Leverage Incoterms: Familiarize yourself with Incoterms to clarify responsibilities regarding shipping, insurance, and duties. This knowledge can help you negotiate better terms and avoid unexpected costs.

Conclusion

Navigating the complexities of sourcing partes del motor de arranque requires a thorough understanding of cost structures and pricing influencers. By focusing on the outlined components and employing strategic negotiation tactics, international B2B buyers can optimize their procurement processes and achieve cost-efficiency. Always remember that prices can vary based on numerous factors, and maintaining open communication with suppliers is key to ensuring a successful sourcing experience.

Alternatives Analysis: Comparing partes del motor de arranque With Other Solutions

Exploring Alternatives to ‘Partes del Motor de Arranque’

When considering the components of a vehicle’s starting system, particularly the ‘partes del motor de arranque,’ it’s crucial to evaluate alternative technologies that can achieve similar objectives. This analysis provides insights into how these alternatives compare in terms of performance, cost, ease of implementation, maintenance, and ideal use cases.

Comparison Table

| Comparison Aspect | ‘Partes Del Motor De Arranque’ | Alternative 1: Capacitor Start System | Alternative 2: Pneumatic Starter |

|---|---|---|---|

| Performance | High torque, reliable starting | Moderate torque, quick starts | High torque, fast response |

| Cost | Moderate initial investment | Lower upfront costs | Higher initial investment |

| Ease of Implementation | Requires specific installation | Simple installation | Complex installation |

| Maintenance | Regular checks needed | Minimal maintenance | High maintenance required |

| Best Use Case | Standard vehicles, combustion engines | Racing vehicles, lightweight applications | Heavy machinery, industrial uses |

In-Depth Analysis of Alternatives

Alternative 1: Capacitor Start System

The capacitor start system utilizes electrical capacitors to provide a burst of energy for starting the engine. This method is known for its quick response time and lower initial costs compared to traditional starters. However, while the performance is adequate for smaller applications or racing vehicles, it may not provide the same reliability as a traditional motor starter in standard vehicles. Maintenance is relatively minimal, but the system may require careful handling to avoid damage to the capacitors.

Alternative 2: Pneumatic Starter

Pneumatic starters operate using compressed air to initiate the engine’s operation. This technology is particularly advantageous in heavy machinery and industrial applications where electric systems might struggle under extreme conditions. While pneumatic starters deliver high torque and rapid engagement, they come with a higher initial investment and complex installation requirements. Moreover, they demand frequent maintenance to ensure the air supply is clean and the system is functioning correctly.

Conclusion: Choosing the Right Solution for Your Needs

In selecting the appropriate starting system for your vehicles or machinery, B2B buyers should consider their specific operational requirements, budget constraints, and the environment in which the equipment will be used. While ‘partes del motor de arranque’ remain the standard for many vehicles due to their reliability and performance, alternatives like capacitor start systems and pneumatic starters offer unique benefits that may align better with particular applications. Conducting a thorough assessment of these factors will guide buyers in making informed decisions that enhance efficiency and reduce operational costs.

Essential Technical Properties and Trade Terminology for partes del motor de arranque

What Are the Key Technical Properties of ‘partes del motor de arranque’?

When sourcing components for the starter motor, understanding the critical technical properties is vital for ensuring performance and reliability. Here are some essential specifications to consider:

-

Material Grade

The material used in manufacturing starter motor components significantly affects durability and performance. Common materials include high-grade steel for gears and copper for electrical contacts. Choosing components made from the appropriate material grade helps ensure resistance to wear and corrosion, which is crucial in diverse environments, especially in regions with extreme weather conditions. -

Tolerance Levels

Tolerance refers to the acceptable deviation in dimensions during manufacturing. For instance, the fit between the Bendix drive and the flywheel must meet specific tolerances to avoid engagement issues. Proper tolerance levels ensure components fit together smoothly, reducing the risk of mechanical failures and extending the lifespan of the starter motor. -

Electrical Resistance

This property is particularly important for components like brushes and the rotor. Low electrical resistance is essential for efficient energy transfer from the battery to the starter motor. High-quality components with optimal resistance characteristics minimize energy losses, which is crucial for efficient vehicle operation, especially in large fleets or commercial applications. -

Operating Temperature Range

Starter motors operate in various temperatures, from freezing conditions to extreme heat. Components must be rated to withstand these conditions without compromising functionality. Understanding the operating temperature range helps in selecting the right parts for specific regional climates, ensuring reliable performance across different applications. -

Power Rating

The power rating of the starter motor, typically measured in horsepower or watts, indicates its ability to crank the engine. This specification is crucial for OEMs and aftermarket suppliers when matching starter motors with specific engine types. Selecting the correct power rating helps ensure that the starter motor can reliably start the engine under various conditions.

What Are Common Trade Terms Used in the ‘partes del motor de arranque’ Industry?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms that decision-makers should know:

Illustrative image related to partes del motor de arranque

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are used in the assembly of vehicles. For B2B buyers, sourcing OEM parts ensures compatibility and quality, as these components are made to the manufacturer’s specifications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to avoid excess inventory and manage cash flow effectively, especially in regions with fluctuating demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to obtain pricing and terms for a specific quantity of goods. For B2B buyers, issuing an RFQ is a strategic way to compare offers and negotiate better deals while ensuring they receive the necessary specifications. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping costs, insurance, and liability. Familiarity with Incoterms helps buyers in negotiating contracts and understanding their obligations in cross-border transactions. -

Lead Time

Lead time refers to the period from placing an order to receiving the goods. For B2B operations, understanding lead times is essential for inventory management and planning, particularly in just-in-time manufacturing environments. -

Aftermarket

This term refers to parts and accessories that are not sourced from the original manufacturer. For B2B buyers, the aftermarket can offer cost-effective alternatives to OEM parts, but it is essential to ensure that quality and compatibility are maintained.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing components for starter motors, ensuring quality and reliability in their operations.

Navigating Market Dynamics and Sourcing Trends in the partes del motor de arranque Sector

What Are the Key Trends Shaping the Global Market for partes del motor de arranque?

The partes del motor de arranque market is experiencing significant growth, driven by several global factors. The increasing demand for automobiles, particularly in emerging markets such as Africa and South America, is a primary driver. As vehicle ownership rises in these regions, so does the need for efficient starting systems. Additionally, advancements in electric vehicle (EV) technology are reshaping sourcing trends, as manufacturers seek components that are compatible with both traditional internal combustion engines and electric drivetrains.

One of the most notable trends is the integration of smart technologies into automotive components. The rise of Internet of Things (IoT) applications is prompting manufacturers to develop smart motor starters that provide real-time diagnostics and enhance vehicle performance. This trend is particularly relevant for international B2B buyers looking to invest in cutting-edge technology that can offer a competitive edge.

Moreover, supply chain dynamics are evolving, with an increasing emphasis on global sourcing strategies. Buyers from Europe, especially Germany, are keen on securing high-quality components that meet stringent automotive standards, while those in regions like the Middle East are focusing on strategic partnerships to enhance local manufacturing capabilities. The demand for just-in-time sourcing practices is also on the rise, helping businesses manage inventory costs and improve responsiveness to market changes.

How Important Is Sustainability and Ethical Sourcing in the partes del motor de arranque Sector?

Sustainability has become a critical consideration for B2B buyers in the partes del motor de arranque sector. The environmental impact of automotive manufacturing is under scrutiny, prompting companies to adopt greener practices. Ethical sourcing of materials is now essential, as buyers increasingly prefer suppliers that demonstrate a commitment to reducing their carbon footprint and minimizing waste.

Certification in green materials, such as those that comply with ISO 14001 standards, is becoming a key requirement for suppliers. Buyers should prioritize partnerships with manufacturers who utilize recycled or sustainably sourced materials in their components. This not only reduces environmental impact but also aligns with the growing consumer demand for environmentally responsible products.

Moreover, transparency in supply chains is vital for ethical sourcing. B2B buyers must ensure that their suppliers adhere to ethical labor practices, avoiding partnerships with companies that exploit workers or engage in environmentally harmful practices. As the market evolves, organizations that prioritize sustainability and ethical sourcing will likely gain a competitive advantage and foster stronger relationships with conscientious consumers and businesses alike.

How Has the partes del motor de arranque Sector Evolved Over Time?

The evolution of the partes del motor de arranque sector is marked by significant technological advancements and shifts in consumer demand. Initially, vehicles relied on manual cranking systems to start engines, a labor-intensive process that was phased out with the introduction of electric starters in the early 20th century. General Motors played a pivotal role in this transition by patenting an automated ignition system that revolutionized vehicle operation.

As automotive technology progressed, so did the design and functionality of motor starters. Modern motor starters are now compact, efficient, and integrated with advanced electronics that enhance performance and reliability. The industry’s focus has shifted toward developing components that not only meet increasing performance demands but also comply with stringent environmental regulations.

Today, the partes del motor de arranque market is poised for further transformation, driven by the advent of electric and hybrid vehicles. As these technologies continue to gain traction, the sector will likely witness a surge in innovation aimed at creating more efficient and sustainable starting systems. B2B buyers must stay informed about these developments to make strategic sourcing decisions that align with future market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of partes del motor de arranque

-

How do I identify quality suppliers for partes del motor de arranque?

To identify quality suppliers for starter motor parts, start by researching manufacturers with a strong reputation in the automotive industry. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Request product samples to assess material quality and durability. Additionally, check reviews and testimonials from other B2B buyers to gauge supplier reliability. Engaging in industry trade shows can also help you connect with reputable suppliers and see their products firsthand. -

What is the best material for manufacturing partes del motor de arranque?

The best materials for manufacturing starter motor parts include high-grade steel and copper for components like the rotor and stator, due to their excellent conductivity and strength. Additionally, using high-quality plastic or composite materials for insulators can enhance durability and reduce weight. Ensuring the materials meet industry standards will not only improve performance but also increase the lifespan of the parts, leading to better customer satisfaction and lower replacement costs. -

What customization options are available for partes del motor de arranque?

Customization options for starter motor parts can include variations in size, voltage specifications, and materials to meet specific vehicle requirements. Many manufacturers offer tailored solutions to fit unique applications, such as heavy-duty vehicles or specific engine types. When sourcing, communicate your exact specifications and consider discussing potential enhancements, such as improved thermal resistance or weight reduction, to optimize performance for your target market. -

What are the typical minimum order quantities (MOQ) for partes del motor de arranque?

Minimum order quantities (MOQ) for starter motor parts can vary significantly based on the supplier and the specific components. Generally, MOQs can range from 100 to 1,000 units. Larger manufacturers may have higher MOQs, while smaller suppliers might be more flexible. Always clarify MOQs during negotiations to ensure they align with your purchasing capacity and market demand. This is especially important for new buyers looking to test the market before committing to larger orders. -

What payment terms should I expect when sourcing partes del motor de arranque?

Payment terms for sourcing starter motor parts typically include options like upfront payment, partial payment upon order confirmation, and the balance upon delivery. Some suppliers may offer credit terms for established buyers. It’s crucial to negotiate terms that suit your cash flow and risk tolerance. Additionally, consider using secure payment methods, such as letters of credit or escrow services, to protect your investment and ensure compliance with international trade regulations. -

How can I ensure quality assurance (QA) for partes del motor de arranque?

To ensure quality assurance for starter motor parts, request detailed product specifications and quality control processes from suppliers. Many reputable manufacturers conduct rigorous testing, including performance, durability, and safety assessments. You can also consider third-party inspections or audits to verify compliance with international standards. Establishing a clear return policy for defective items can further protect your interests and maintain customer satisfaction. -

What logistics considerations should I keep in mind when sourcing partes del motor de arranque internationally?

When sourcing starter motor parts internationally, consider logistics factors such as shipping methods, delivery times, and customs regulations. Evaluate the total landed cost, which includes shipping, duties, and taxes, to ensure your pricing remains competitive. Partnering with experienced freight forwarders can streamline the shipping process and help navigate international trade complexities. Additionally, ensure that your supplier can provide the necessary documentation for customs clearance to avoid delays. -

What are common issues I might face when sourcing partes del motor de arranque?

Common issues when sourcing starter motor parts include quality inconsistencies, communication barriers, and unexpected delays in production or shipping. To mitigate these challenges, establish clear communication channels with suppliers and set realistic timelines. Regularly monitor production progress and maintain an open dialogue about any potential issues. It’s also beneficial to have contingency plans in place, such as alternative suppliers or inventory strategies, to minimize disruptions in your supply chain.

Top 4 Partes Del Motor De Arranque Manufacturers & Suppliers List

1. Autonocion – Motor de Arranque del Coche

Domain: autonocion.com

Registered: 2011 (14 years)

Introduction: Motor de arranque del coche: Es un motor eléctrico que da vida al coche, venciendo la resistencia inicial de los componentes cinemáticos al arrancar. Se compone de tres partes principales: el interruptor de encendido, la batería y el motor de arranque. El motor de arranque incluye varios componentes: carcasa, bobinas inductoras, inducido (o rotor), escobillas, bendix (o impulsor), solenoide, horqu…

2. Facebook – Campo de Bobina y Bobinado

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Campo de Bobina y Bobinado, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Scribd – Motor de Arranque

Domain: es.scribd.com

Registered: 2006 (19 years)

Introduction: El motor de arranque es un motor eléctrico auxiliar alimentado por la batería que produce energía mecánica para poner en marcha el motor de combustión interna. Las principales partes del motor de arranque incluyen: 1. Motor eléctrico 2. Solenoide 3. Horquilla 4. Tapa lateral. También se analizan posibles averías del sistema de arranque y se proporciona información sobre cómo retirar y reemplazar e…

4. RentingFinders – Motor de Arranque

Domain: rentingfinders.com

Registered: 2017 (8 years)

Introduction: El motor de arranque es un dispositivo que permite iniciar el proceso de combustión en un motor de vehículo. Funciona convirtiendo la energía eléctrica de la batería en energía cinética para hacer girar el cigüeñal. Se compone de siete piezas principales: carcasa, horquilla, solenoide, impulsor, escobillas, rotor y bobina inductora. El solenoide activa el motor de arranque al cerrar el circuito, m…

Strategic Sourcing Conclusion and Outlook for partes del motor de arranque

How Can Strategic Sourcing Enhance Your Procurement of Motor Starter Parts?

In the dynamic landscape of automotive components, particularly for motor starter parts, strategic sourcing emerges as a critical factor for success. By understanding the intricate functions of each component—such as the electric motor, solenoid, and bendix—you can make informed decisions that enhance operational efficiency and reduce downtime. Prioritizing quality and reliability in sourcing not only ensures seamless vehicle performance but also builds long-term partnerships with suppliers who understand your specific market needs.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe, you have the opportunity to leverage global supply chains and tap into emerging markets for sourcing these essential components. Engaging with suppliers who adhere to stringent quality standards can lead to significant cost savings and improved product longevity.

Looking ahead, the automotive industry is poised for advancements that will further revolutionize motor starter technologies. Now is the time to align your sourcing strategies with these trends, ensuring you remain competitive. Take proactive steps to evaluate and strengthen your supply chain partnerships, and position your business to capitalize on future innovations in motor starter components.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.