Introduction: Navigating the Global Market for how long does it take to replace a starter motor

In the dynamic landscape of automotive maintenance, understanding how long it takes to replace a starter motor is crucial for B2B buyers looking to optimize their fleet management. A malfunctioning starter motor can halt operations, leading to costly downtime and inefficiencies. This guide provides an in-depth exploration of the replacement process, covering essential aspects such as the average time required, cost considerations, types of starter motors, and best practices for supplier vetting.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Germany and Brazil, face unique challenges in sourcing quality automotive parts and services. This comprehensive resource empowers decision-makers to navigate these complexities effectively. By understanding the intricacies of starter motor replacement—from the symptoms of failure to the time investment involved—buyers can make informed purchasing decisions that align with their operational needs.

Additionally, this guide delves into the various applications of starter motors across different vehicle types, enabling buyers to tailor their procurement strategies accordingly. With actionable insights and expert recommendations, stakeholders can enhance their understanding of the market, ensuring they select the right components and services that drive efficiency and reliability in their automotive operations.

Table Of Contents

- Top 4 How Long Does It Take To Replace A Starter Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how long does it take to replace a starter motor

- Understanding how long does it take to replace a starter motor Types and Variations

- Key Industrial Applications of how long does it take to replace a starter motor

- 3 Common User Pain Points for ‘how long does it take to replace a starter motor’ & Their Solutions

- Strategic Material Selection Guide for how long does it take to replace a starter motor

- In-depth Look: Manufacturing Processes and Quality Assurance for how long does it take to replace a starter motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does it take to replace a starter motor’

- Comprehensive Cost and Pricing Analysis for how long does it take to replace a starter motor Sourcing

- Alternatives Analysis: Comparing how long does it take to replace a starter motor With Other Solutions

- Essential Technical Properties and Trade Terminology for how long does it take to replace a starter motor

- Navigating Market Dynamics and Sourcing Trends in the how long does it take to replace a starter motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how long does it take to replace a starter motor

- Strategic Sourcing Conclusion and Outlook for how long does it take to replace a starter motor

- Important Disclaimer & Terms of Use

Understanding how long does it take to replace a starter motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Replacement | Typically requires 2-4 hours; accessible starters. | Fleet management, automotive repair shops | Pros: Quick turnaround, cost-effective. Cons: May require additional parts if complications arise. |

| Complex Installation | Takes longer (up to 6 hours); intricate design. | Specialty automotive services | Pros: Thorough service, addresses hidden issues. Cons: Higher labor costs, longer downtime. |

| DIY Replacement | 1-3 hours for skilled individuals; requires tools. | Independent mechanics, DIY enthusiasts | Pros: Cost savings, hands-on experience. Cons: Risk of improper installation, requires expertise. |

| Electric Starter Upgrade | Varies based on vehicle; modern systems may take longer. | High-performance vehicle modifications | Pros: Enhanced performance, reliability. Cons: Higher upfront costs, may require specialized knowledge. |

| Commercial Vehicle Service | 3-5 hours on average; heavy-duty starters. | Logistics companies, transportation firms | Pros: Tailored for heavy use, durability. Cons: Potentially higher service fees, longer wait times. |

What Are the Characteristics of Standard Replacement for Starter Motors?

Standard replacement of starter motors generally takes between 2 to 4 hours, depending on the accessibility of the starter in the vehicle. This type is suitable for most passenger vehicles where the starter is easily reachable. B2B buyers in fleet management or automotive repair shops benefit from this quick turnaround, allowing for efficient service and reduced vehicle downtime. However, complications may arise that necessitate additional parts, potentially increasing costs.

How Does Complex Installation Affect Time and Costs?

Complex installations can extend the replacement time to as much as 6 hours, especially for vehicles with intricate designs that require disassembly of multiple components. This type is often needed in specialty automotive services where precision is paramount. While it ensures thorough servicing and addresses underlying issues, the higher labor costs and extended vehicle downtime may deter some buyers, making it essential for businesses to weigh immediate needs against long-term benefits.

Who Benefits from DIY Replacement of Starter Motors?

DIY replacement can take between 1 to 3 hours, appealing to skilled individuals who possess the necessary tools and knowledge. This option is popular among independent mechanics and DIY enthusiasts, allowing them to save on labor costs while gaining hands-on experience. However, the risks of improper installation can lead to further issues, making it vital for buyers to assess their own expertise before opting for this route.

What Are the Advantages of Electric Starter Upgrades?

Electric starter upgrades vary in time based on the vehicle and its electrical system, often requiring longer installation times due to modern technological complexities. This option is primarily targeted at high-performance vehicle modifications, appealing to businesses focused on enhancing vehicle reliability and performance. While the benefits include increased efficiency, the higher upfront costs and the need for specialized knowledge may limit its appeal to certain buyers.

How Does Commercial Vehicle Service Differ in Starter Replacement?

For commercial vehicles, the replacement of heavy-duty starters typically takes 3 to 5 hours. This type of service is crucial for logistics companies and transportation firms that rely on their vehicles for operations. The tailored approach ensures durability under heavy use, making it a worthy investment. However, potential service fees and longer wait times could be a drawback, emphasizing the need for companies to evaluate their operational priorities when selecting service options.

Key Industrial Applications of how long does it take to replace a starter motor

| Industry/Sector | Specific Application of how long does it take to replace a starter motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Scheduling starter motor replacements efficiently | Reduces downtime for vehicles, improving service capacity | Availability of skilled technicians and tools |

| Fleet Management | Optimizing maintenance schedules for starter motor replacements | Enhances fleet reliability and minimizes operational disruptions | Access to quality starter motors and parts suppliers |

| Transportation Services | Ensuring timely replacement of starter motors in commercial vehicles | Prevents unexpected breakdowns, ensuring on-time deliveries | Understanding of local vehicle models and parts compatibility |

| Mining Operations | Implementing preventive maintenance for heavy machinery starters | Increases machinery uptime, reducing costly delays | Sourcing durable starter motors suited for harsh conditions |

| Agricultural Equipment | Managing starter motor replacements in farming machinery | Ensures operational efficiency during critical harvest periods | Availability of agricultural-specific starter motor models |

How Do Automotive Repair Shops Benefit from Knowing Replacement Times for Starter Motors?

Automotive repair shops can significantly enhance their service efficiency by understanding how long it takes to replace a starter motor. Knowing the average replacement time (typically 2 to 4 hours) allows shops to schedule jobs effectively, thereby reducing vehicle downtime. This efficiency not only improves customer satisfaction but also allows for a higher turnover of services. Repair shops in regions like Africa and South America may need to consider local vehicle models and parts availability to optimize their operations further.

How Does Fleet Management Enhance Reliability with Starter Motor Replacement Knowledge?

For fleet management companies, understanding the time required to replace starter motors is crucial for maintaining vehicle reliability. By proactively scheduling these replacements, fleets can avoid unexpected breakdowns that lead to operational disruptions. This is particularly vital in regions with challenging road conditions, where vehicle reliability is paramount. Effective sourcing of starter motors that fit various vehicle models in their fleet can streamline maintenance processes and reduce costs.

What Are the Advantages for Transportation Services in Timely Starter Motor Replacement?

Transportation service providers rely heavily on their vehicles for timely deliveries, making the knowledge of starter motor replacement times essential. A swift replacement process can prevent breakdowns that disrupt service schedules and impact customer trust. In areas like the Middle East, where extreme temperatures can affect vehicle performance, sourcing high-quality starter motors that can withstand such conditions is vital for operational continuity.

How Do Mining Operations Increase Uptime by Managing Starter Motor Replacements?

In mining operations, heavy machinery plays a critical role in productivity, and starter motors are essential for initiating their function. Understanding the replacement timeline helps mine operators implement preventive maintenance schedules, minimizing the risk of equipment failure. Given the harsh environments typical in mining sites, sourcing durable and reliable starter motors becomes a priority to ensure that operations run smoothly without costly delays.

Why Is It Important for Agricultural Equipment to Have Efficient Starter Motor Replacement?

Agricultural machinery often operates under tight schedules, especially during harvest seasons. Knowing how long it takes to replace starter motors allows farmers to plan maintenance activities without disrupting their operations. In regions like Brazil, where agricultural practices vary widely, sourcing the right starter motors that are compatible with specific equipment types is crucial for maintaining efficiency and productivity during peak farming periods.

3 Common User Pain Points for ‘how long does it take to replace a starter motor’ & Their Solutions

Scenario 1: Understanding the Time Investment in Starter Motor Replacement

The Problem: B2B buyers often struggle to estimate the time required for replacing a starter motor, particularly when managing fleet vehicles. This uncertainty can lead to operational downtime and impact overall productivity. For instance, a logistics company may face delays if a truck is out of service longer than anticipated due to starter motor issues. Additionally, buyers must balance the urgency of repairs with the need to maintain cost efficiency, complicating decision-making.

The Solution: To effectively manage the time investment for starter motor replacements, B2B buyers should implement a systematic approach that includes vehicle diagnostics and maintenance scheduling. Utilizing fleet management software can help track the health of each vehicle, providing alerts for potential starter motor failures before they escalate. Collaborating with trusted mechanics or service providers can also yield accurate time estimates based on specific vehicle models, ensuring that buyers are not left in the dark regarding expected repair durations. By proactively scheduling routine checks and establishing a reliable network of service providers, companies can minimize downtime and optimize operational efficiency.

Scenario 2: Dealing with Variability in Starter Motor Replacement Times

The Problem: A significant pain point for B2B buyers is the variability in replacement times based on different vehicle models and the complexity of the starter motor’s location. For instance, a company with a diverse fleet may find that some vehicles require only a couple of hours for starter motor replacement, while others could take upwards of four hours. This inconsistency can disrupt logistics and lead to budget overruns if not adequately planned for.

The Solution: To mitigate the impact of variability, B2B buyers should maintain a comprehensive database that documents the average replacement times for starter motors across their fleet. Including details about the specific make, model, and any known complexities will create a valuable resource for planning maintenance. Additionally, engaging with experienced automotive technicians to gain insights into common issues can help establish realistic timelines for repairs. By preparing for these variances in advance, businesses can allocate resources more effectively and avoid unexpected disruptions to their operations.

Scenario 3: Budgeting for Starter Motor Replacement Costs and Time

The Problem: Many B2B buyers face challenges in budgeting for starter motor replacements due to the dual factors of labor and parts costs, coupled with the time required for repairs. This financial uncertainty can lead to cash flow issues, especially for businesses that rely on a fleet of vehicles. If a starter motor fails unexpectedly, the associated costs and downtime can strain operational budgets and affect overall business performance.

The Solution: To effectively budget for starter motor replacements, B2B buyers should conduct a thorough cost analysis that includes parts, labor, and potential downtime. Establishing relationships with multiple suppliers can provide competitive pricing on starter motors, while also allowing for bulk purchasing discounts. Additionally, incorporating a contingency fund for unexpected repairs can help manage cash flow. Buyers should also consider negotiating service agreements with mechanics that outline fixed labor rates and guaranteed replacement times, providing more predictable budgeting. By taking a proactive approach to financial planning, companies can better absorb the costs associated with starter motor replacements, ensuring they remain financially agile even in the face of unexpected repairs.

Strategic Material Selection Guide for how long does it take to replace a starter motor

What Are the Common Materials Used in Starter Motor Replacement?

When considering the replacement of a starter motor, the selection of materials can significantly influence the performance, durability, and overall cost of the component. Here, we analyze four common materials used in starter motors, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Steel

Key Properties:

Steel is known for its high tensile strength and durability, making it a preferred choice for various automotive components. It can withstand high temperatures and pressures, which is essential in the automotive environment.

Pros & Cons:

Steel components are generally more durable and can handle significant wear and tear. However, they are susceptible to corrosion if not properly treated, which can lead to premature failure. The manufacturing complexity is moderate, as steel can be easily shaped and welded.

Impact on Application:

Steel’s compatibility with high-stress applications makes it suitable for starter motors. However, in humid or corrosive environments, the risk of rust can affect performance.

Considerations for International Buyers:

Compliance with international standards like ASTM or DIN is crucial, especially in regions like Europe and South America, where stringent regulations exist. Buyers should also consider the availability of corrosion-resistant coatings to enhance longevity.

2. Aluminum

Key Properties:

Aluminum is lightweight and has excellent corrosion resistance, making it suitable for automotive applications. It can withstand moderate temperatures and pressures.

Illustrative image related to how long does it take to replace a starter motor

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, which can improve fuel efficiency in vehicles. However, it has lower tensile strength compared to steel, which may limit its use in high-stress applications. Manufacturing processes for aluminum can be more complex and costly.

Impact on Application:

Aluminum is ideal for starter motors in vehicles designed for fuel efficiency. However, its lower strength may not be suitable for heavy-duty applications.

Considerations for International Buyers:

In regions like Africa and the Middle East, where temperatures can soar, aluminum’s heat resistance is a plus. Buyers should ensure that the aluminum used meets local standards for automotive components.

Illustrative image related to how long does it take to replace a starter motor

3. Copper

Key Properties:

Copper has excellent electrical conductivity and thermal properties, making it essential for electrical connections in starter motors. It is resistant to corrosion and can operate effectively in a wide range of temperatures.

Pros & Cons:

The key advantage of copper is its superior conductivity, which enhances the efficiency of the starter motor. However, copper is relatively expensive compared to other materials and can be prone to fatigue over time.

Impact on Application:

Copper is crucial for wiring and connections within the starter motor, ensuring efficient energy transfer. Its high cost may be a limiting factor for budget-conscious buyers.

Illustrative image related to how long does it take to replace a starter motor

Considerations for International Buyers:

Copper components must comply with electrical standards, which vary by region. Buyers in Europe, for instance, may need to adhere to specific EU regulations regarding electrical safety.

4. Plastic Composites

Key Properties:

Plastic composites are lightweight and can be engineered for specific properties, such as heat resistance and electrical insulation. They are generally resistant to corrosion.

Pros & Cons:

The lightweight nature of plastic composites can reduce the overall weight of the starter motor, improving vehicle efficiency. However, they may not withstand high temperatures or mechanical stress as well as metals, limiting their application in high-performance vehicles.

Impact on Application:

Plastic composites are often used in non-structural components of starter motors, such as housings. Their performance can be affected by environmental factors, such as UV exposure.

Considerations for International Buyers:

In regions with extreme weather conditions, the choice of plastic composite must be carefully considered to ensure durability. Compliance with local environmental regulations regarding plastics is also essential.

Summary Table of Material Selection for Starter Motors

| Material | Typical Use Case for how long does it take to replace a starter motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components of starter motors | High durability and strength | Prone to corrosion without treatment | Medium |

| Aluminum | Lightweight starter motor designs | Excellent corrosion resistance | Lower tensile strength | High |

| Copper | Electrical connections within the starter motor | Superior electrical conductivity | High cost and fatigue potential | High |

| Plastic Composites | Non-structural components and housings | Lightweight and corrosion-resistant | Limited temperature and stress tolerance | Medium |

This analysis provides a comprehensive overview of material considerations for starter motor replacement, aiding international B2B buyers in making informed decisions tailored to their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how long does it take to replace a starter motor

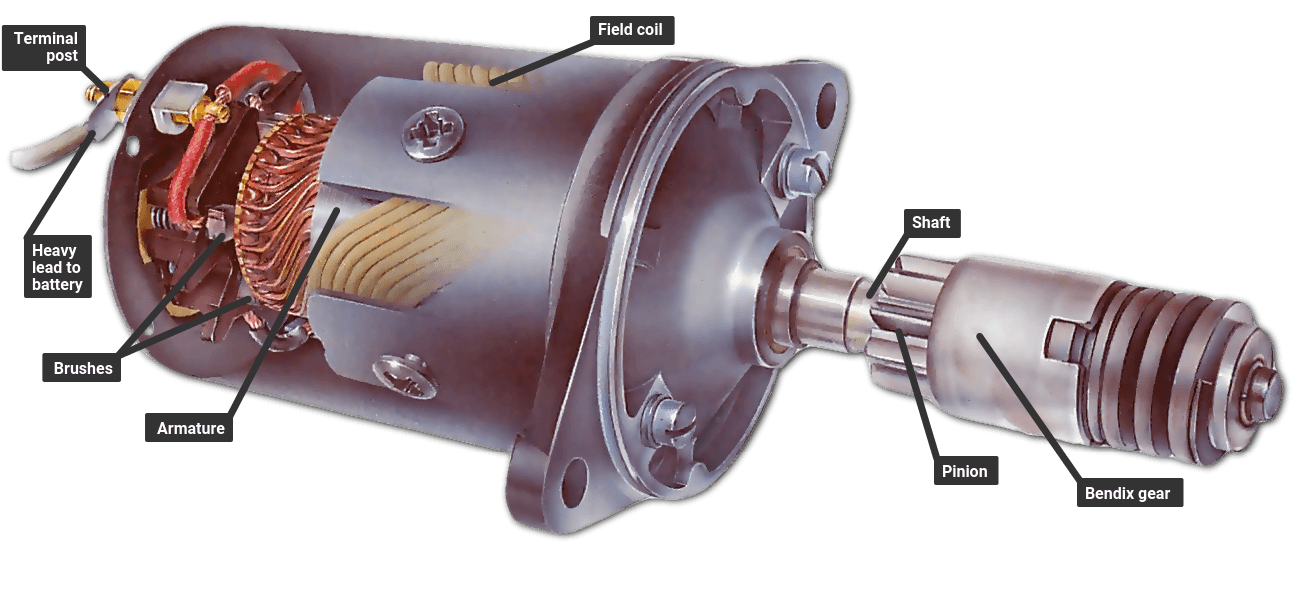

What Are the Typical Manufacturing Processes for Starter Motors?

The manufacturing of starter motors involves several critical stages, each designed to ensure the final product meets performance standards essential for vehicle functionality. For B2B buyers, understanding these processes can provide insights into the quality and reliability of the components they are sourcing.

What Are the Main Stages of Starter Motor Manufacturing?

-

Material Preparation:

The manufacturing process begins with selecting high-quality raw materials, including copper for windings, steel for the housing, and various alloys for components like the pinion gear. These materials undergo rigorous quality checks to ensure they meet specifications regarding conductivity, durability, and resistance to wear. -

Forming:

The forming stage involves shaping the raw materials into the required components. Techniques such as stamping, forging, and machining are employed to create parts like the starter housing, armature, and end bells. Precision is crucial in this stage to ensure that parts fit together correctly, which affects the motor’s overall efficiency and longevity. -

Assembly:

During assembly, components are brought together using automated processes and skilled labor. This stage includes inserting the armature into the housing, attaching the brushes, and connecting electrical components. Each assembly line is equipped with specialized tools and fixtures to enhance efficiency and minimize errors. -

Finishing:

The finishing stage includes painting, coating, or plating to protect the starter motor from corrosion and wear. Additionally, final assembly checks are performed to verify that all components are correctly installed and that the motor meets specified tolerances.

How Is Quality Assurance Incorporated in Starter Motor Production?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each starter motor meets international and industry-specific standards. For B2B buyers, understanding these QA measures can inform their purchasing decisions and risk assessments.

What International Standards Should B2B Buyers Be Aware Of?

-

ISO 9001:

Many manufacturers adhere to ISO 9001, a standard that outlines criteria for a quality management system (QMS). Compliance ensures that the manufacturing processes are consistent and that products meet customer and regulatory requirements. -

CE Marking:

For products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards. This mark is crucial for buyers in Europe, particularly in countries like Germany. -

API Standards:

In specific markets, such as the oil and gas industry, adherence to API (American Petroleum Institute) standards may be relevant. These standards ensure that products can operate safely and effectively in demanding environments.

What Are the Key Quality Control Checkpoints in Starter Motor Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure the integrity of the final product. Here are the primary checkpoints:

-

Incoming Quality Control (IQC):

This checkpoint occurs before materials enter the production line. Incoming materials are inspected for quality and compliance with specifications. This step is crucial for maintaining high standards throughout the manufacturing process. -

In-Process Quality Control (IPQC):

During the manufacturing stages, IPQC involves regular inspections to ensure that parts are being produced according to design specifications. This includes checking dimensions, tolerances, and the quality of assembly work. -

Final Quality Control (FQC):

Once the starter motor is fully assembled, it undergoes FQC, where it is tested for performance and reliability. Common tests include electrical continuity checks, torque testing, and endurance testing to simulate real-world operating conditions.

What Testing Methods Are Commonly Used in Starter Motor Quality Control?

Testing methods are vital for verifying the functionality and durability of starter motors. Here are some common testing techniques:

-

Electrical Testing: This includes measuring voltage, current draw, and resistance to ensure the motor operates within specified limits.

-

Functional Testing: Motors are tested under simulated conditions to ensure they can start an engine effectively. This often involves running the motor while monitoring its performance metrics.

-

Endurance Testing: Motors are subjected to prolonged use to evaluate their durability and reliability under extended operating conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential to mitigate risks associated with product quality.

Illustrative image related to how long does it take to replace a starter motor

-

Supplier Audits:

Conducting audits of potential suppliers can help buyers assess their manufacturing processes and quality assurance practices. This includes reviewing documentation related to compliance with international standards and inspecting manufacturing facilities. -

Quality Reports:

Requesting quality control reports can provide insights into a supplier’s performance history. These reports should include information on defect rates, testing outcomes, and corrective actions taken for any non-conformities. -

Third-Party Inspections:

Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s manufacturing processes and product quality. These agencies can conduct inspections at various stages of production, offering additional assurance to buyers.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances, including:

-

Cultural Differences: Understanding cultural attitudes towards quality can affect how rigorously a supplier adheres to standards.

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should be aware of these to ensure compliance and avoid potential legal issues.

-

Communication: Clear communication regarding quality expectations and standards is crucial, particularly when dealing with suppliers in different countries. Establishing a robust line of communication can help resolve issues more efficiently.

By understanding the manufacturing processes and quality assurance practices involved in starter motor production, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does it take to replace a starter motor’

Introduction

Replacing a starter motor is a critical maintenance task that ensures vehicles operate efficiently. For B2B buyers, especially those in sectors reliant on vehicle fleets, understanding the replacement process and time frame is vital for operational planning and cost management. This guide provides a step-by-step checklist to help you navigate the sourcing and replacement of starter motors effectively.

Step 1: Assess the Vehicle’s Requirements

Understanding the specific requirements of the vehicles in your fleet is essential. Different makes and models may have unique starter motor specifications, including size and electrical ratings. Gather technical documentation to ascertain the exact starter motor needed for each vehicle type.

Step 2: Determine the Average Replacement Time

Establish the average time required for starter motor replacement across your fleet. Generally, this can range from 2 to 4 hours depending on the vehicle’s design and accessibility. Knowing this will help you schedule maintenance effectively to minimize downtime.

Illustrative image related to how long does it take to replace a starter motor

Step 3: Identify Qualified Suppliers

Research and compile a list of potential suppliers who can provide starter motors and installation services. Look for suppliers with a strong reputation in the market and consider their geographic proximity to reduce shipping times and costs. Check for supplier reviews and case studies from similar businesses.

Step 4: Verify Product Quality and Compliance

Before making a purchase, ensure that the starter motors meet industry standards and regulations. Request certifications that demonstrate compliance with local and international quality standards. High-quality components can reduce the likelihood of premature failure and ensure reliability.

Step 5: Evaluate Installation Expertise

If you plan to outsource the installation, assess the expertise of the mechanics or service providers. Inquire about their experience with starter motor replacements and request references from previous clients. This step is crucial to ensure that the installation is performed correctly, avoiding potential issues down the line.

Step 6: Consider Maintenance and Support Options

Inquire about warranty and support services for the starter motors. A solid warranty indicates the manufacturer’s confidence in their product, while reliable support can be invaluable in addressing any issues post-installation. Ensure you understand the terms of the warranty and what is covered.

Step 7: Plan for Regular Maintenance Checks

Establish a routine for inspecting and maintaining starter motors as part of your vehicle care program. Regular checks can preempt potential failures and extend the lifespan of the starter motors. Document any signs of wear or issues to assist in timely replacements and maintain operational efficiency.

By following this checklist, B2B buyers can ensure a smooth process when sourcing and replacing starter motors, ultimately leading to improved vehicle reliability and operational efficiency.

Comprehensive Cost and Pricing Analysis for how long does it take to replace a starter motor Sourcing

What Are the Key Cost Components for Replacing a Starter Motor?

When considering the replacement of a starter motor, understanding the cost structure is crucial for B2B buyers. The main cost components involved include:

-

Materials: The primary material cost is the starter motor itself, which typically ranges from $100 to $400 depending on the make and model. Additional materials may include wiring, connectors, and any necessary mounting hardware.

-

Labor: Labor costs can vary significantly based on the complexity of the installation. On average, professional installation can take anywhere from 2 to 4 hours, translating to labor costs that can range from $100 to several hundred dollars, depending on local rates.

-

Manufacturing Overhead: This includes costs associated with production facilities, equipment depreciation, and utilities. For manufacturers, these costs are factored into the pricing of the starter motor.

-

Tooling: Specific tools may be required for the installation and replacement of starter motors, particularly for unique vehicle designs. This can include specialized wrenches, torque wrenches, and electrical testing equipment.

-

Quality Control (QC): Ensuring that the starter motors meet required specifications and performance standards can incur additional costs. Quality assurance processes are critical, especially for B2B transactions where reliability is paramount.

-

Logistics: Shipping costs can vary based on the origin of the starter motors and the destination. Buyers should consider the logistics involved, particularly for international shipping, which may include tariffs and customs duties.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Starter Motor Replacement Costs?

Several factors can influence the pricing of starter motor replacements:

-

Volume/MOQ: Purchasing in larger quantities often leads to significant discounts. B2B buyers should assess their needs carefully to negotiate better terms.

-

Specifications and Customization: Custom or specialized starter motors for unique vehicle models can increase costs. Buyers should evaluate whether standard options meet their needs before opting for custom solutions.

-

Materials: The quality of materials used in manufacturing the starter motor can impact pricing. Higher quality components may lead to longer-lasting performance, ultimately reducing Total Cost of Ownership (TCO).

-

Quality and Certifications: Motors that come with industry certifications or warranties may carry a higher price but offer greater peace of mind regarding performance and reliability.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings can influence pricing. Establishing a strong relationship with suppliers can lead to better pricing and terms.

-

Incoterms: Understanding the delivery terms and responsibilities defined by Incoterms can affect the overall cost. Buyers should clarify these terms to avoid unexpected expenses.

What Are the Best Tips for Buyers to Ensure Cost-Efficiency?

B2B buyers can implement several strategies to optimize costs when sourcing starter motors:

-

Negotiation: Engage in discussions with suppliers to secure better pricing or terms, particularly when placing bulk orders. Leverage market knowledge to negotiate effectively.

-

Cost-Efficiency: Assess the Total Cost of Ownership rather than just the upfront costs. Consider factors like durability, warranty, and maintenance when evaluating different options.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local market conditions that could affect pricing.

-

Supplier Diversification: Establish relationships with multiple suppliers to ensure competitive pricing and availability. This can also mitigate risks associated with supply chain disruptions.

-

Market Research: Regularly conduct market research to stay informed about price trends and emerging suppliers, which can provide leverage in negotiations and sourcing decisions.

Disclaimer for Indicative Prices

The prices mentioned in this analysis are indicative and can vary based on multiple factors including geographic location, market conditions, and individual supplier pricing strategies. Buyers should conduct thorough research and obtain quotes from multiple suppliers to ensure they receive the best value.

Alternatives Analysis: Comparing how long does it take to replace a starter motor With Other Solutions

Introduction: Exploring Alternatives to Starter Motor Replacement

When it comes to ensuring vehicle functionality, the starter motor plays a crucial role. However, replacing a starter motor can be time-consuming and costly, prompting many businesses to explore alternative solutions. This analysis compares the time and efficiency of starter motor replacement against other viable options, allowing B2B buyers to make informed decisions based on their operational needs.

Comparison Table

| Comparison Aspect | How Long Does It Take To Replace A Starter Motor | Battery Jump Start | Starter Relay Replacement |

|---|---|---|---|

| Performance | Restores full functionality of the vehicle | Temporarily starts the vehicle | May fix starting issues if relay is faulty |

| Cost | $100 – $400 (parts) + labor | Minimal (cost of jumper cables) | $20 – $50 (parts) + labor |

| Ease of Implementation | Requires mechanical knowledge and tools | Simple, requires no special tools | Moderate; requires some electrical knowledge |

| Maintenance | Low (if replaced correctly) | Frequent use may lead to battery wear | Low; generally maintenance-free |

| Best Use Case | Permanent solution for a failed starter motor | Quick fix for a dead battery | Cost-effective solution for electrical issues |

Detailed Breakdown of Alternatives

Battery Jump Start: A Quick Temporary Solution

A battery jump start is an immediate solution for vehicles that fail to start due to a depleted battery rather than a faulty starter motor. This method is advantageous for businesses needing a quick fix to get vehicles back on the road without incurring significant costs. However, it’s essential to note that this is not a long-term solution. Frequent reliance on jump starts can lead to battery wear, which may necessitate further replacements or repairs.

Starter Relay Replacement: Cost-Effective Electrical Fix

Replacing a starter relay can be a viable alternative when the starting issue stems from an electrical fault rather than the starter motor itself. This process typically takes less time—often around 30 minutes to an hour—and incurs lower costs, making it an appealing option for businesses operating on tight budgets. However, it requires some understanding of electrical systems, which may necessitate professional assistance if staff are not adequately trained. While this solution can resolve specific starting issues, it is not a substitute for a fully functional starter motor in the long run.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate solution for vehicle starting issues depends on a variety of factors, including urgency, cost, and the specific nature of the problem. For businesses that require immediate functionality, a battery jump start may suffice temporarily, while those facing recurring electrical issues might benefit from a starter relay replacement. However, when a starter motor has reached the end of its lifespan, investing the time and resources into a complete replacement is often the best course of action. By evaluating these alternatives, B2B buyers can align their choices with their operational demands and budgetary constraints, ensuring their fleet remains reliable and efficient.

Essential Technical Properties and Trade Terminology for how long does it take to replace a starter motor

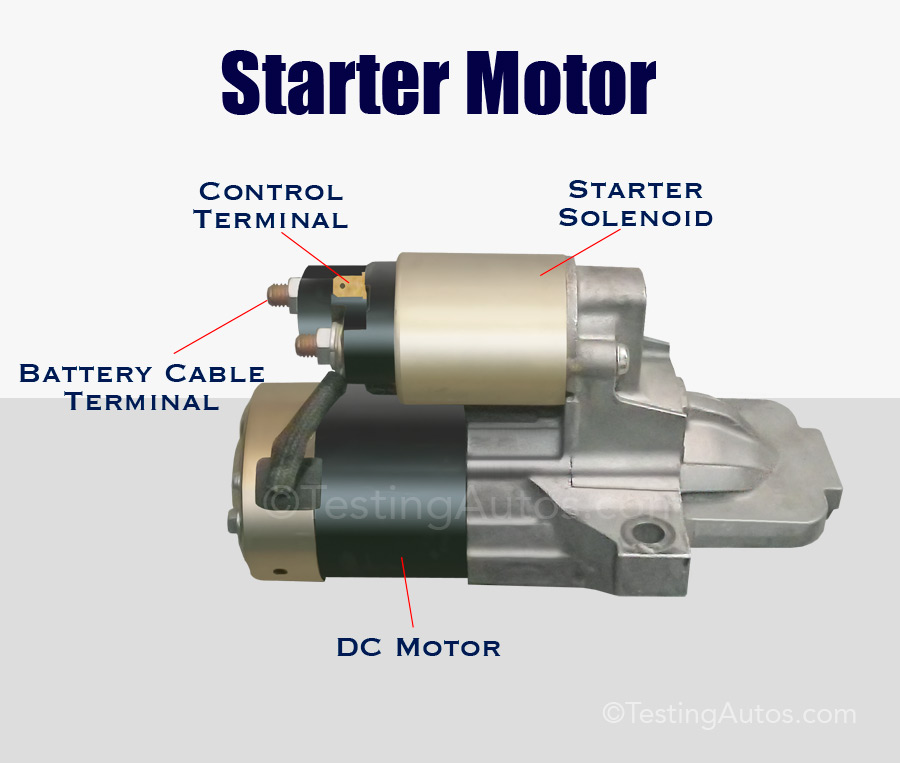

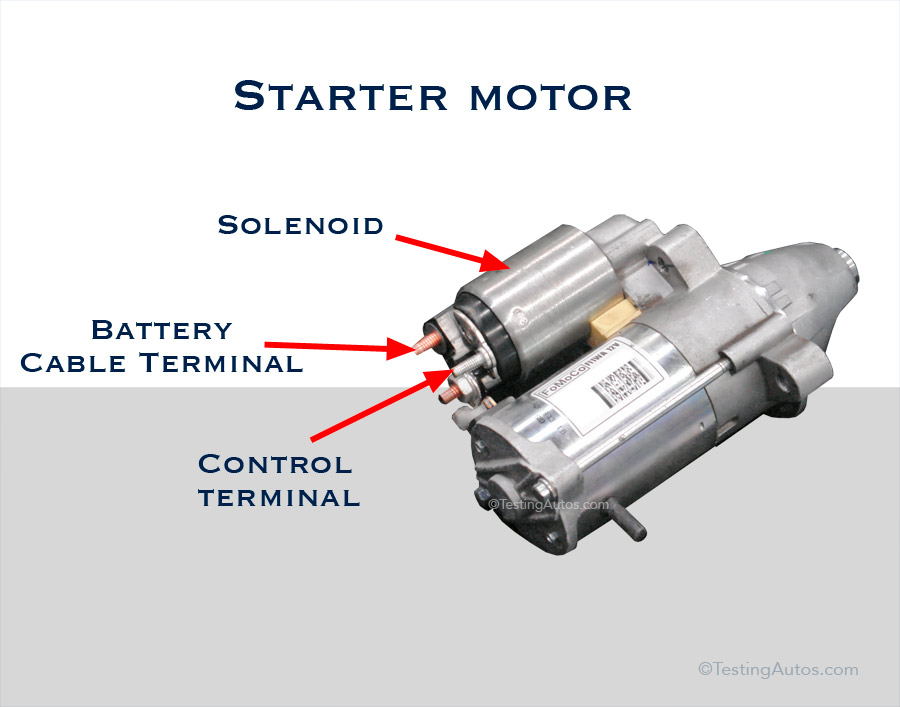

What Are the Key Technical Properties Related to Starter Motor Replacement Time?

When considering the replacement of a starter motor, several technical specifications play a crucial role in determining the efficiency and effectiveness of the process. Understanding these properties can help B2B buyers make informed decisions, especially when sourcing parts or services.

1. Material Grade

The material grade of the starter motor can influence both its durability and weight. Common materials include high-grade steel for the casing and copper for wiring. Higher material grades often mean increased resistance to wear and tear, which can reduce the frequency of replacements. For B2B buyers, investing in higher-grade materials may lead to long-term cost savings through improved reliability.

2. Torque Specifications

Torque specifications are critical when installing a starter motor. Each motor will have a specific torque requirement for its mounting bolts, which ensures proper seating and function. If the torque is insufficient, it can lead to vibrations and premature wear; too much torque can damage the motor. Understanding these specifications helps buyers ensure that their mechanics adhere to best practices during installation.

3. Electrical Ratings

Electrical ratings, such as voltage and current draw, are vital to the starter motor’s operation. Most automotive starters operate at 12 volts and require significant current to engage. B2B buyers should ensure that the starter they procure matches the electrical specifications of the vehicle to prevent performance issues and potential electrical failures.

4. Compatibility and Fitment

The compatibility of the starter motor with specific vehicle models is essential. Factors such as mounting location, connector types, and dimensions must align with the vehicle’s design. For B2B buyers, confirming compatibility can minimize installation time and costs, reducing the likelihood of returns and exchanges.

Illustrative image related to how long does it take to replace a starter motor

5. Heat Resistance

Starter motors generate heat during operation, so heat resistance is an important property. Components must withstand high temperatures without degrading. Buyers should consider this property when selecting motors, especially in regions with extreme climates, to ensure longevity and performance.

What Are Common Trade Terminology and Concepts in Starter Motor Replacement?

Understanding industry jargon is crucial for effective communication and negotiation in B2B contexts. Here are some essential terms related to starter motor replacement:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are designed to meet the specific standards and fitment of the vehicle, ensuring reliability. B2B buyers often prefer OEM parts for their guaranteed compatibility and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ helps in budgeting and inventory management, particularly when dealing with starter motors that may have varying demand across different markets.

3. RFQ (Request for Quotation)

An RFQ is a standard business process for soliciting price quotes from suppliers. B2B buyers can use RFQs to obtain competitive pricing for starter motors and related services, ensuring they receive the best possible deal.

Illustrative image related to how long does it take to replace a starter motor

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is crucial for B2B transactions, as they affect shipping costs, risk management, and delivery timelines.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is essential for effective inventory management and ensuring timely vehicle repairs.

In summary, grasping the essential technical properties and trade terminology associated with starter motor replacement can significantly enhance the decision-making process for B2B buyers. By focusing on quality specifications and industry terms, buyers can ensure they select the right products and services, ultimately leading to more efficient operations and satisfied customers.

Navigating Market Dynamics and Sourcing Trends in the how long does it take to replace a starter motor Sector

What Are the Current Trends Affecting the Replacement of Starter Motors?

The global automotive industry is witnessing significant shifts that directly impact the replacement of starter motors. A primary driver is the increasing reliance on advanced automotive technologies, such as electric vehicles (EVs) and hybrid systems. These vehicles often utilize more sophisticated starter systems, which require specialized knowledge and tools for replacement. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these technological advancements is crucial for sourcing parts and services effectively.

Emerging trends also include the growing importance of online marketplaces and digital platforms for sourcing automotive components. Buyers can now access a wider array of suppliers, compare prices, and read reviews, which enhances decision-making processes. This trend is particularly beneficial for businesses in developing regions where traditional supply chains may be less reliable. Furthermore, the rise of telematics and connected vehicles is changing how maintenance is approached. Predictive maintenance technologies can alert users to starter motor issues before they become critical, allowing for proactive replacements and minimizing downtime.

Illustrative image related to how long does it take to replace a starter motor

Additionally, the labor market dynamics are shifting, with skilled technicians becoming increasingly scarce. This scarcity can affect replacement times, as more complex installations may require specialized expertise. International buyers should consider the availability of qualified labor in their regions when planning for starter motor replacements, as this may influence both cost and timing.

How Do Sustainability and Ethical Sourcing Impact Starter Motor Replacement?

Sustainability is becoming a central focus for B2B buyers in the automotive sector, including those involved in the replacement of starter motors. The environmental impact of automotive components is significant, from resource extraction to manufacturing and disposal. Ethical sourcing practices are essential in mitigating these impacts, and businesses are increasingly looking for suppliers who prioritize sustainability in their operations.

For instance, sourcing starter motors made from recycled materials or from manufacturers that adhere to environmentally friendly practices can greatly reduce the carbon footprint associated with replacements. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming vital in supplier evaluations. Buyers should actively seek out suppliers with ‘green’ certifications, as this not only aligns with corporate social responsibility goals but also enhances brand reputation.

Moreover, the shift towards electric vehicles also prompts a reconsideration of sourcing practices. As the market adapts to new technologies, buyers must ensure that their supply chains are equipped to handle components specific to EVs, including those related to the starter systems in hybrid models. This transition requires a commitment to ongoing education about sustainable practices and the adoption of technologies that support ethical sourcing.

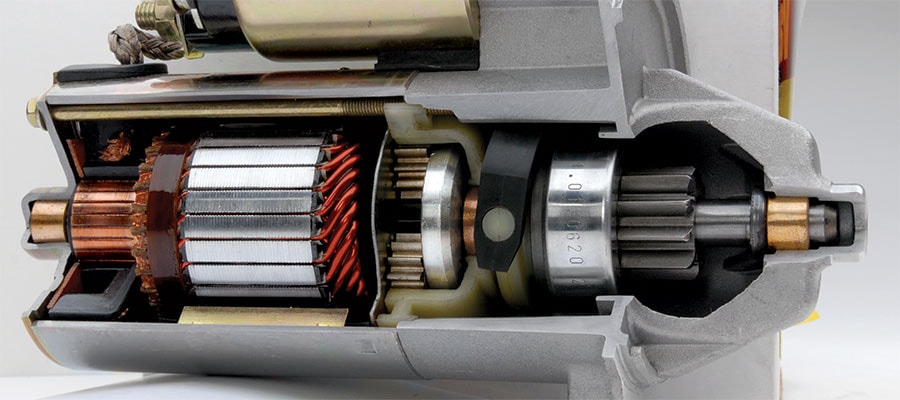

How Has the Replacement Process for Starter Motors Evolved Over Time?

The evolution of starter motor technology has significantly influenced the replacement process. Historically, starter motors were relatively simple devices that could be replaced with basic tools and knowledge. However, as automotive technology has advanced, starter motors have become more integrated with complex electrical systems, requiring specialized skills for replacement.

Illustrative image related to how long does it take to replace a starter motor

In the past, a straightforward replacement might take an hour or less, depending on the vehicle model. Today, it can take anywhere from two to four hours, particularly for modern vehicles with compact designs or additional components that obstruct access to the starter. This evolution highlights the importance of understanding vehicle specifications and the need for technicians to be well-trained in contemporary automotive technologies.

As vehicles become more sophisticated, so too does the expertise required for maintenance and repair. Consequently, businesses must invest in training and development to ensure that their workforce is equipped to handle these advanced systems, aligning with the trend toward digital and connected vehicles. This evolution underscores the necessity for B2B buyers to consider the capabilities of their service providers when planning for starter motor replacements.

Frequently Asked Questions (FAQs) for B2B Buyers of how long does it take to replace a starter motor

-

1. How long does it typically take to replace a starter motor?

The time required to replace a starter motor generally ranges from 2 to 4 hours, depending on the vehicle’s make and model. For cars with easier access to the starter, the replacement can be completed in approximately 2 hours. However, if the starter is located in a more complex position requiring additional disassembly, it may take up to 4 hours. It’s advisable for B2B buyers to consult with their mechanics for a more precise estimate based on specific vehicle requirements. -

2. What are the common signs that a starter motor needs replacement?

Common indicators that a starter motor may need replacement include the engine failing to start, persistent clicking sounds when the ignition is turned, grinding noises, or even smoke emanating from the starter area. If these symptoms are observed, it is crucial to address the issue promptly to avoid further vehicle complications. B2B buyers should ensure that their teams are trained to recognize these signs to facilitate timely replacements. -

3. What tools and materials are required for replacing a starter motor?

To successfully replace a starter motor, a standard toolkit is necessary, which typically includes a socket set, ratchet, torque wrench, screwdrivers, and pliers. Additionally, having a new starter motor on hand is essential. For vehicles that require more intricate disassembly, specialized tools may also be needed. B2B buyers should ensure their maintenance teams are equipped with the right tools to streamline the replacement process. -

4. Are there specific considerations for international shipping of starter motors?

When sourcing starter motors internationally, it’s important to consider the shipping regulations and customs requirements of both the exporting and importing countries. Documentation such as invoices, packing lists, and certificates of origin may be required. Additionally, working with reliable logistics partners can help navigate potential delays or issues during transit, ensuring timely delivery. -

5. How can I vet suppliers for starter motors?

To vet suppliers effectively, consider their industry reputation, years of experience, and customer reviews. Request certifications or compliance documentation to verify that they meet international quality standards. Establishing communication to gauge their responsiveness and willingness to provide product details can also help assess reliability. Consider trial orders to evaluate product quality and service before committing to larger purchases. -

6. What are the typical payment terms when sourcing starter motors?

Payment terms can vary widely among suppliers, but typical arrangements may include upfront payments, partial payments, or net payment terms (e.g., net 30 or net 60 days). B2B buyers should clarify these terms during negotiations and ensure they align with their cash flow capabilities. Using secure payment methods can also mitigate risks associated with international transactions. -

7. Is customization available for starter motors, and how does it impact lead time?

Many suppliers offer customization options for starter motors, such as specific sizes, power ratings, or connectors tailored to particular vehicle models. However, customization can extend lead times, often requiring additional manufacturing time and testing. B2B buyers should discuss customization needs early in the sourcing process to understand the implications for delivery schedules. -

8. What quality assurance measures should be in place for starter motor replacements?

Implementing a robust quality assurance process is crucial when replacing starter motors. This includes inspecting the new starter before installation, ensuring compatibility with the vehicle, and conducting functional tests post-installation. B2B buyers should work with suppliers who provide warranties and guarantees on their products, allowing for recourse in case of defects or failures shortly after installation.

Top 4 How Long Does It Take To Replace A Starter Motor Manufacturers & Suppliers List

1. Yamaha – FZ6 Fazer (2004 – 2009)

2. Copilot Search – Starter Motor Replacement

Domain: copilotsearch.com

Registered: 2015 (10 years)

Introduction: Starter motor replacement time: 2 to 4 hours; Importance: Vital for starting the engine; Symptoms of failure: Car won’t start, clicking or grinding noises, smoke from the engine, oil on the starter; Replacement recommendation: Professional replacement is safest; Factors affecting replacement time: Vehicle type, accessibility of the starter, mechanic’s skill level.

3. AutoAdvisor – Starter Motor Replacement

Domain: autoadvisor.co.uk

Registered: 2009 (16 years)

Introduction: Starter Motor Replacement: Get quotes for starter motor repair or replacement. Symptoms of a faulty starter motor include a dull clicking noise, smoke from the bonnet, oil on the starter, engine refusal to crank, and grinding noises. Replacement typically takes 2-4 hours. Starter motors usually last 5-7 years. Repair costs vary by car make/model and location. No upfront payment required; pay only …

4. AC Delco – Starter Replacement for C5 Corvette

Domain: corvetteforum.com

Registered: 1999 (26 years)

Introduction: Starter replacement for C5 Corvette (1997-2004) takes approximately 1 to 2 hours for an average mechanic. It requires disconnecting the exhaust from the manifold to the muffler for easier access. Recommended starter part is AC Delco 3361922A, with a suggestion to consider a truck starter (Bosch SR8581N) to reduce the risk of breaking the ear off the block. The truck starter may come with a longer …

Strategic Sourcing Conclusion and Outlook for how long does it take to replace a starter motor

The process of replacing a starter motor typically takes between 2 to 4 hours, influenced by vehicle design and accessibility. For B2B buyers, understanding the nuances of this replacement can significantly impact operational efficiency. A well-functioning starter is crucial for vehicle performance, and timely replacements can prevent costly downtimes and disruptions.

Strategic sourcing plays a vital role in ensuring that you acquire quality starter motors at competitive prices. Building relationships with reliable suppliers can not only streamline your procurement process but also provide access to valuable insights on installation and maintenance, enhancing your operational capabilities.

As you navigate the complexities of automotive parts procurement, consider leveraging local suppliers within Africa, South America, the Middle East, and Europe to reduce lead times and transportation costs. By prioritizing strategic sourcing, you position your organization to respond quickly to maintenance needs, ultimately improving your fleet’s reliability and performance.

Stay proactive in your sourcing strategies to ensure your operations run smoothly. Engage with trusted partners and explore innovative solutions to keep your vehicles in top condition. The future of your fleet’s efficiency depends on the choices you make today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how long does it take to replace a starter motor