Introduction: Navigating the Global Market for how do you know if its the starter or alternator

Understanding whether the issue with your vehicle lies in the starter or alternator can be a daunting challenge for international B2B buyers in the automotive sector. With the intricate relationship between these components, misdiagnosis can lead to costly errors and inefficient repairs. This guide, “How Do You Know If It’s the Starter or Alternator?” addresses these challenges head-on by providing a comprehensive overview of the signs, symptoms, and troubleshooting techniques for both components.

We delve into the specific types of starters and alternators, their applications in various vehicle models, and the common pitfalls in sourcing these critical parts. Additionally, this guide emphasizes the importance of supplier vetting, ensuring that buyers can identify reputable manufacturers and distributors that meet their specific needs. Cost considerations are also addressed, equipping buyers with the knowledge to make informed purchasing decisions.

For B2B buyers from regions like Africa, South America, the Middle East, and Europe—including countries such as Nigeria and Vietnam—this guide serves as a vital resource. It empowers decision-makers by enhancing their understanding of automotive electrical systems, thereby minimizing downtime and maximizing operational efficiency. By the end of this guide, you will be equipped with actionable insights to confidently navigate the complexities of sourcing starter and alternator components.

Table Of Contents

- Top 2 How Do You Know If Its The Starter Or Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do you know if its the starter or alternator

- Understanding how do you know if its the starter or alternator Types and Variations

- Key Industrial Applications of how do you know if its the starter or alternator

- 3 Common User Pain Points for ‘how do you know if its the starter or alternator’ & Their Solutions

- Strategic Material Selection Guide for how do you know if its the starter or alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for how do you know if its the starter or alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you know if its the starter or alternator’

- Comprehensive Cost and Pricing Analysis for how do you know if its the starter or alternator Sourcing

- Alternatives Analysis: Comparing how do you know if its the starter or alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for how do you know if its the starter or alternator

- Navigating Market Dynamics and Sourcing Trends in the how do you know if its the starter or alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do you know if its the starter or alternator

- Strategic Sourcing Conclusion and Outlook for how do you know if its the starter or alternator

- Important Disclaimer & Terms of Use

Understanding how do you know if its the starter or alternator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Starter Motor Symptoms | Whirring or grinding noises, single click without crank | Automotive repair shops, fleet services | Pros: Easy to identify; quick diagnostics. Cons: May require complete replacement. |

| Alternator Performance | Dimming lights, fluctuating voltage, battery warning light | Automotive manufacturing, vehicle maintenance | Pros: Detects power generation issues early. Cons: Complex diagnostics may require specialized tools. |

| Battery Failure Indicators | Slow cranking, bloated battery case, sulfur smell | Battery suppliers, automotive service centers | Pros: Clear signs; often easy to replace. Cons: Symptoms can mimic other issues. |

| Electrical System Diagnostics | Voltage tests, load testing, multimeter readings | Auto electrical specialists, fleet operators | Pros: Comprehensive assessment; identifies multiple issues. Cons: Time-consuming; requires technical expertise. |

| Jump-Start Testing Method | Battery boost followed by performance observation | General automotive repair, roadside assistance | Pros: Quick initial diagnosis; low cost. Cons: Only offers temporary solution; may not reveal underlying issues. |

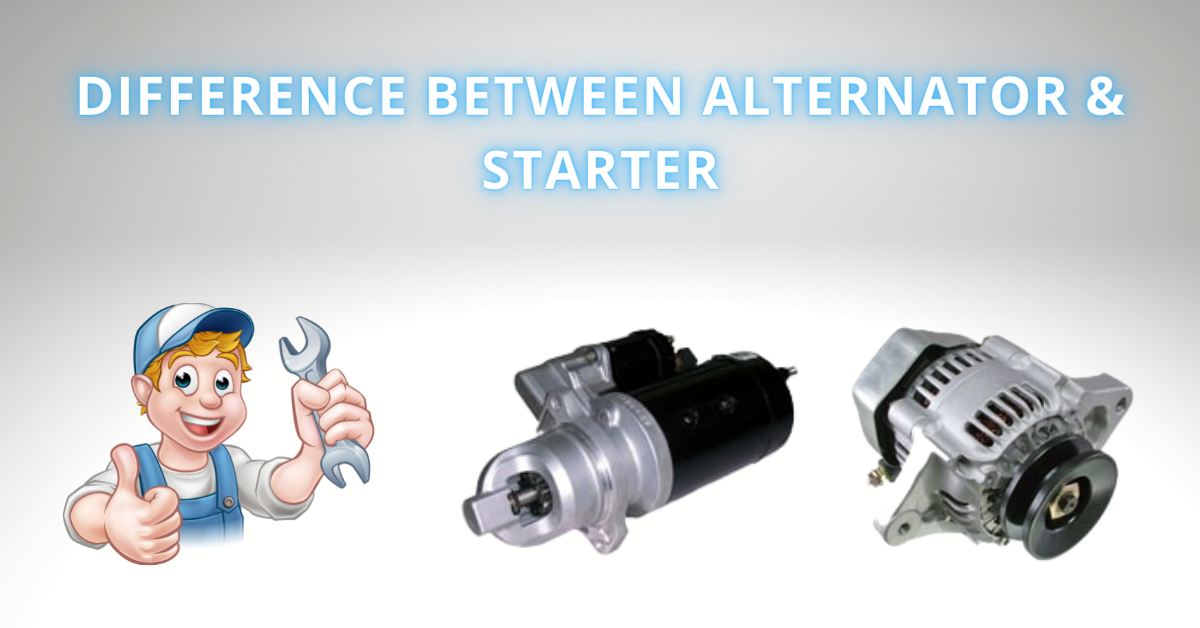

What Are the Key Symptoms of Starter Motor Failure?

Starter motors are critical for initiating engine operation. Key symptoms include whirring or grinding noises when attempting to start the vehicle, or a single click with no engine crank. These indicators are particularly relevant for automotive repair shops and fleet services that need to quickly diagnose issues. Buyers should consider that while identifying starter problems can be straightforward, solutions often involve complete replacements, which can be costly.

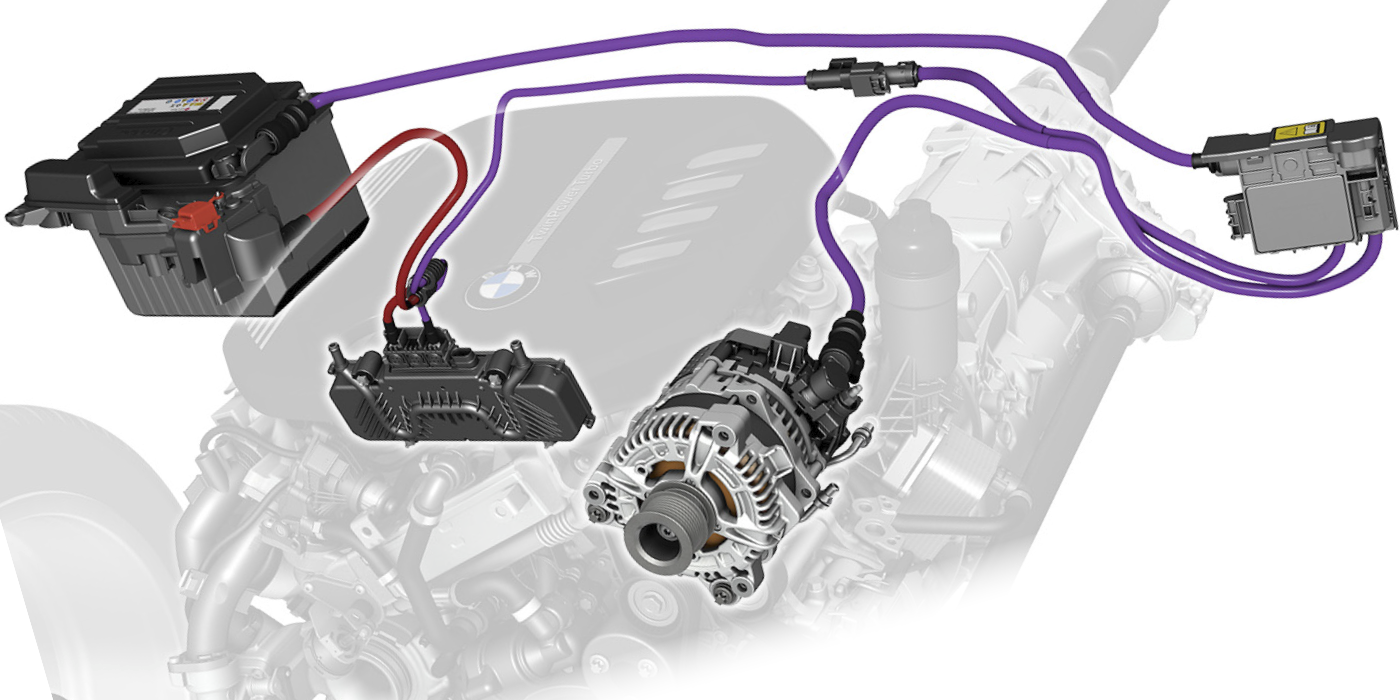

How to Recognize Alternator Performance Issues?

Alternators are responsible for supplying power while the vehicle is running. Symptoms of failure include dimming headlights, fluctuating voltage readings, and illuminated battery warning lights. This information is vital for automotive manufacturers and vehicle maintenance providers. Early detection can prevent further electrical issues, but diagnosing alternator problems can be complex and may require specialized tools, which adds to the overall cost.

What Are the Signs of Battery Failure?

Battery failure is often characterized by slow engine cranking, a bloated battery case, or a sulfur smell. These signs are particularly useful for battery suppliers and automotive service centers to identify when a battery needs replacement. While the symptoms are usually clear and the replacement process straightforward, they can sometimes be confused with issues arising from the starter or alternator.

How Do Electrical System Diagnostics Help in Identifying Issues?

Electrical system diagnostics involve voltage tests, load testing, and multimeter readings to assess the health of the starter, alternator, and battery. This method is essential for auto electrical specialists and fleet operators who require a comprehensive understanding of their vehicles’ electrical systems. While it provides a thorough assessment, this approach can be time-consuming and requires technical expertise, which may not always be readily available.

What Is the Role of Jump-Start Testing in Diagnostics?

Jump-start testing is a quick method to determine whether the battery, starter, or alternator is the source of a vehicle’s issues. By boosting the battery and observing the vehicle’s performance, automotive repair services and roadside assistance providers can make quick assessments. Although this method is cost-effective and straightforward, it may only offer a temporary solution and might not reveal deeper underlying problems that need to be addressed.

Key Industrial Applications of how do you know if its the starter or alternator

| Industry/Sector | Specific Application of how do you know if its the starter or alternator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnosing electrical issues in vehicles for repair shops | Reduces downtime and increases customer satisfaction | Quality testing equipment and trained technicians needed |

| Fleet Management | Regular maintenance checks on fleet vehicles to ensure operational efficiency | Minimizes unexpected breakdowns and repair costs | Reliable sourcing of parts and tools for diagnostics |

| Agricultural Machinery | Troubleshooting starter and alternator issues in tractors and harvesters | Ensures continuous operation during critical farming seasons | Availability of durable components suitable for harsh conditions |

| Mining Operations | Maintenance of heavy machinery to prevent operational failures | Increases productivity and reduces costly machine downtime | Access to specialized equipment and trained personnel |

| Construction Equipment | Ensuring proper function of starters and alternators in construction vehicles | Enhances project timelines and reduces operational costs | Sourcing high-quality parts that meet industry standards |

How is ‘how do you know if it’s the starter or alternator’ used in Automotive Repair?

In automotive repair shops, accurately diagnosing whether a vehicle’s problem lies with the starter or alternator is crucial for efficient service delivery. Technicians utilize specific tests, such as voltage checks and jump-start diagnostics, to determine the faulty component. This process not only speeds up repairs but also enhances customer satisfaction by providing reliable service. International B2B buyers need to ensure they have access to quality diagnostic tools and adequately trained technicians to maintain competitive service levels.

What are the implications for Fleet Management?

In fleet management, understanding the interplay between the starter and alternator is essential for maintaining a fleet’s operational efficiency. Regular checks can prevent unexpected vehicle failures, which can lead to costly delays and decreased productivity. Fleet managers must source reliable parts and diagnostic tools to ensure their vehicles remain in optimal condition. Additionally, they should consider the availability of support services to facilitate quick repairs, especially in regions with limited access to automotive resources.

How does this apply to Agricultural Machinery?

For agricultural machinery, diagnosing starter and alternator issues is vital to ensure uninterrupted operations during planting and harvesting seasons. Farmers rely heavily on tractors and other equipment, and any downtime can result in significant financial losses. B2B buyers in this sector should prioritize sourcing durable components that can withstand harsh environmental conditions. Furthermore, having access to knowledgeable technicians who can quickly troubleshoot and resolve issues is critical for maintaining productivity in the agricultural sector.

What role does it play in Mining Operations?

In mining operations, the reliability of heavy machinery is paramount. Diagnosing starter and alternator failures quickly can prevent costly downtime and enhance overall productivity. Mining companies must invest in high-quality diagnostic equipment and components that can withstand the rigors of a mining environment. Additionally, sourcing skilled technicians who can perform timely maintenance checks is essential to minimize operational disruptions and maintain safety standards in the field.

How is it relevant in Construction Equipment?

In the construction industry, ensuring that starters and alternators function properly is crucial for keeping projects on schedule. Construction vehicles are often subject to rigorous use, and any failure can lead to delays and increased costs. B2B buyers must focus on sourcing high-quality parts that meet industry standards and provide robust performance. Furthermore, having access to reliable diagnostic tools and qualified personnel can significantly enhance the efficiency of maintenance operations, ensuring that equipment is always ready for use.

3 Common User Pain Points for ‘how do you know if its the starter or alternator’ & Their Solutions

Scenario 1: Diagnosing the Problem Under Time Constraints

The Problem: In the fast-paced world of automotive repair, time is money. B2B buyers, such as fleet managers or auto repair shop owners, often face the challenge of diagnosing whether a vehicle’s failure to start is due to the starter or the alternator. This uncertainty can lead to prolonged downtime, which negatively impacts productivity and customer satisfaction. Moreover, misdiagnosing the issue can lead to unnecessary parts replacements, further increasing costs.

The Solution: To effectively diagnose the issue, implement a systematic troubleshooting approach. Start with a comprehensive checklist that includes the symptoms displayed by the vehicle. For instance, if the vehicle makes a clicking sound when attempting to start, this often indicates a starter issue. Conversely, if the vehicle starts but then dies when the battery is disconnected, the alternator may be at fault. Equip your technicians with a jump-start kit and a multimeter to test voltage levels. This not only helps in identifying the faulty component but also speeds up the repair process. Additionally, invest in diagnostic tools that can provide real-time data on the vehicle’s electrical system, allowing for quicker and more accurate assessments.

Scenario 2: Sourcing Reliable Replacement Parts

The Problem: Once a faulty component has been identified, the next hurdle is sourcing reliable replacement parts. B2B buyers, particularly those operating in regions with limited access to quality automotive parts, may struggle to find trustworthy suppliers. Poor-quality parts can lead to recurring issues, damaging relationships with customers and undermining the reputation of the repair shop or fleet management.

The Solution: Build strong relationships with reputable suppliers who specialize in automotive parts. Consider establishing partnerships with manufacturers known for their quality and reliability. Utilize online platforms and marketplaces that cater specifically to B2B buyers, ensuring they provide thorough product specifications and certifications. When sourcing parts, prioritize those with warranties or guarantees, as this reduces the risk associated with potential failures. Additionally, stay informed about local and international trends in automotive parts, which can help you negotiate better pricing and access to new technologies.

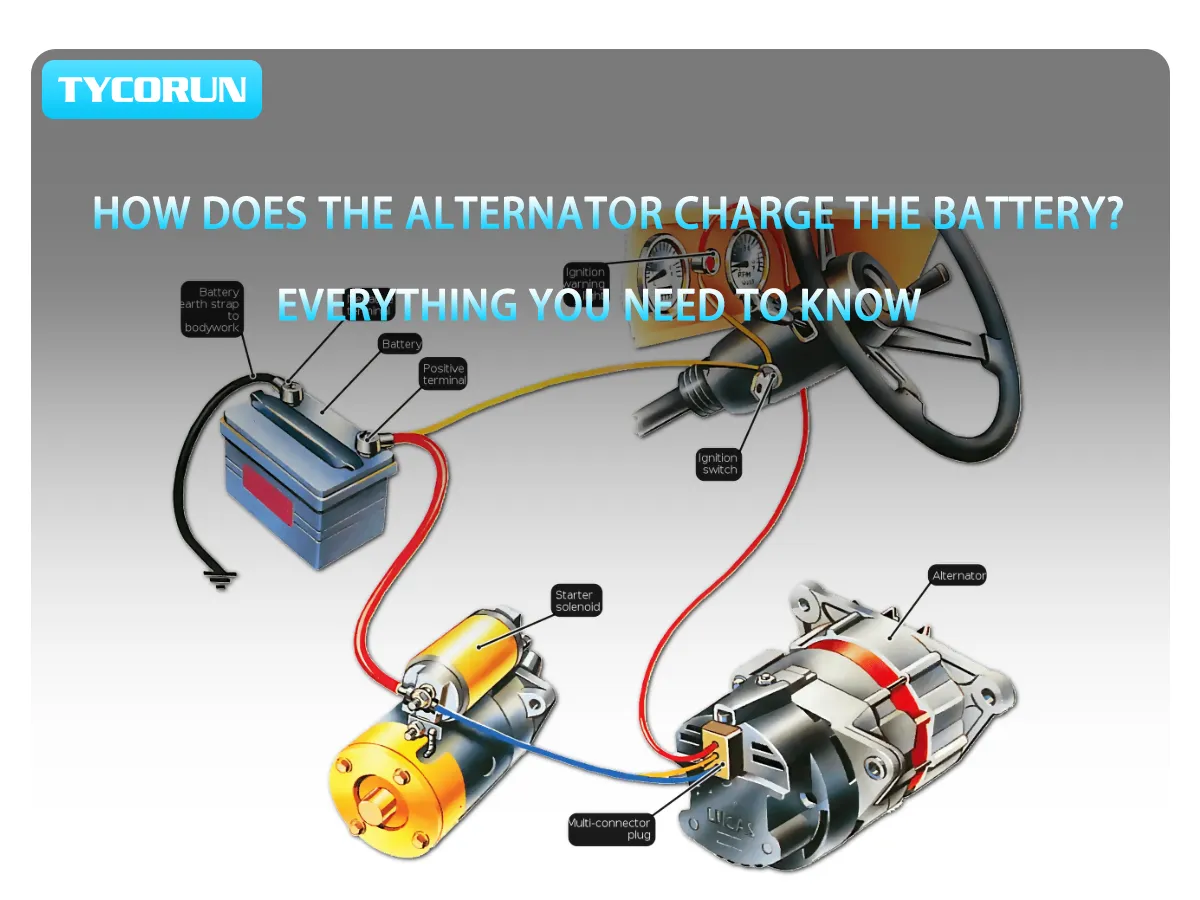

Illustrative image related to how do you know if its the starter or alternator

Scenario 3: Training Technicians on Troubleshooting

The Problem: Another significant challenge faced by B2B buyers is the varying levels of expertise among technicians in diagnosing and repairing starter and alternator issues. Inadequate training can lead to misdiagnosis and inefficient repairs, costing businesses time and money. This is especially pertinent in regions where access to advanced technical training is limited.

The Solution: Invest in continuous training programs that focus on the latest diagnostic techniques and repair methods for starters and alternators. Organize workshops with industry experts who can provide hands-on training, simulations, and case studies. Encourage technicians to pursue certifications from recognized automotive organizations, which not only enhances their skills but also boosts the credibility of your business. Utilize online resources, such as webinars and instructional videos, to supplement in-person training. By fostering a culture of learning and improvement, you can ensure that your team is well-equipped to handle complex diagnostics and repairs, ultimately leading to increased efficiency and customer satisfaction.

Strategic Material Selection Guide for how do you know if its the starter or alternator

What Are the Key Materials Used in Starters and Alternators?

When diagnosing issues with starters and alternators, understanding the materials involved can significantly impact performance and longevity. The following analysis covers common materials used in these components, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Copper in Starters and Alternators?

Copper is widely used in electrical components due to its excellent conductivity and resistance to corrosion. The key properties of copper include a high electrical conductivity rating (around 59% IACS), good thermal conductivity, and a melting point of approximately 1,984°F (1,085°C).

Pros: Copper is durable, easy to work with, and has a low electrical resistance, making it ideal for wiring and connections in starters and alternators. Its excellent thermal properties help dissipate heat, which is crucial for maintaining performance.

Cons: The primary disadvantage is its susceptibility to corrosion, especially in humid or saline environments. Additionally, copper can be more expensive than alternative materials like aluminum.

Impact on Application: Copper’s high conductivity ensures efficient energy transfer, which is essential for the reliable operation of starters and alternators. However, in regions with high humidity, additional protective coatings may be necessary to prevent corrosion.

Considerations for International Buyers: Buyers in Africa, South America, the Middle East, and Europe should ensure compliance with local standards for electrical components, such as ASTM or DIN. Copper’s cost may vary based on regional availability and market fluctuations.

Illustrative image related to how do you know if its the starter or alternator

How Does Aluminum Compare for Use in Starters and Alternators?

Aluminum is another common material in automotive electrical components, particularly for housing and structural elements. It has a lower density than copper, making it lighter, and a melting point of about 1,221°F (660°C).

Pros: Aluminum is lightweight, corrosion-resistant, and cost-effective compared to copper. Its lower weight can contribute to better fuel efficiency in vehicles.

Cons: While aluminum has decent electrical conductivity (about 61% that of copper), it is not as effective in high-performance applications. Additionally, it can be more challenging to solder and may require specialized techniques for assembly.

Impact on Application: Aluminum’s lightweight nature can enhance vehicle performance, but its lower conductivity may necessitate thicker wires or larger connectors, which could complicate design.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades that meet their performance requirements and comply with local manufacturing standards. In regions where weight is a critical factor, aluminum’s advantages may outweigh its limitations.

What Role Does Steel Play in Starters and Alternators?

Steel is often used for structural components in starters and alternators, such as casings and support brackets. The material is known for its strength and durability, with a melting point of around 2,500°F (1,370°C).

Pros: Steel provides excellent structural integrity and can withstand high temperatures and mechanical stress, making it ideal for components that require robustness.

Cons: Steel is heavier than both copper and aluminum, which can negatively impact overall vehicle weight. It is also prone to rust if not properly coated or treated.

Impact on Application: Steel’s strength is beneficial for protecting sensitive internal components, but its weight can be a disadvantage in performance-focused applications.

Considerations for International Buyers: Buyers should consider the environmental conditions in their regions, as steel may require additional coatings to prevent rust. Compliance with local standards for mechanical properties is also essential.

What About Plastic and Composites in Starters and Alternators?

Plastics and composites are increasingly used for non-structural components in starters and alternators, such as housings and insulators. These materials are lightweight, with varying thermal and chemical resistance properties.

Pros: Plastics are lightweight, corrosion-resistant, and can be molded into complex shapes, allowing for design flexibility. They are also generally less expensive than metals.

Cons: Plastics may not withstand high temperatures as well as metals and can degrade over time when exposed to certain chemicals or UV light.

Illustrative image related to how do you know if its the starter or alternator

Impact on Application: The use of plastics can reduce overall weight and manufacturing costs, but their limitations in high-temperature environments must be considered.

Considerations for International Buyers: Buyers should ensure that the plastics used meet local standards for automotive applications, particularly in terms of thermal and chemical resistance.

Summary Table of Material Considerations

| Material | Typical Use Case for how do you know if its the starter or alternator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical wiring and connections in starters and alternators | Excellent conductivity | Susceptible to corrosion | High |

| Aluminum | Structural components and housings | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Steel | Casings and structural supports | High strength and durability | Heavier and prone to rust | Medium |

| Plastic | Non-structural components like housings and insulators | Lightweight and design flexibility | Limited thermal resistance | Low |

This analysis provides a comprehensive overview of materials relevant to starters and alternators, offering actionable insights for B2B buyers in various international markets. Understanding these materials can help in making informed purchasing decisions that align with performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how do you know if its the starter or alternator

What Are the Key Stages in Manufacturing Starters and Alternators?

Manufacturing starters and alternators involves several critical stages, each requiring precision and quality control to ensure optimal performance. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Starters and Alternators?

Material preparation is fundamental in ensuring that components meet the necessary specifications. Typically, manufacturers source high-grade materials like copper for windings, steel for housings, and durable plastics for insulation. Before production begins, these materials undergo rigorous quality checks to confirm they meet industry standards.

What Forming Techniques Are Used in Starter and Alternator Production?

The forming stage involves shaping the prepared materials into usable components. Techniques such as stamping, machining, and injection molding are common. For starters, components like the armature and stator are often stamped from metal sheets and then machined to achieve precise dimensions. In alternators, the rotor is typically cast and then machined to ensure a perfect fit within the assembly.

How Are Starters and Alternators Assembled?

Assembly is a critical stage where individual components come together to create a functioning unit. This process often involves both manual and automated operations. Key components such as the rotor, stator, bearings, and housing are assembled using specific torque settings to prevent future failures. Manufacturers often implement fixtures that hold components in place during assembly, reducing the risk of misalignment.

What Finishing Processes Ensure Quality in Starters and Alternators?

Finishing processes are vital for enhancing the durability and functionality of starters and alternators. These processes may include surface treatment, painting, and applying protective coatings to prevent corrosion. Additionally, manufacturers may conduct performance tests to ensure that the final product meets the desired specifications.

Illustrative image related to how do you know if its the starter or alternator

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is crucial in the manufacturing of starters and alternators. International standards such as ISO 9001 are widely recognized and indicate that a manufacturer adheres to a quality management system. Compliance with these standards ensures that products are consistent, reliable, and of high quality.

What Industry-Specific Certifications Are Important for Starters and Alternators?

In addition to general quality standards, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can further assure B2B buyers of a manufacturer’s commitment to quality. CE marking indicates compliance with European health and safety regulations, while API certification is particularly relevant for manufacturers producing components for the automotive and petroleum industries.

How Are Quality Control Checkpoints Implemented in Manufacturing?

Quality control checkpoints are essential for maintaining product integrity throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components before they enter the production line. Any non-compliant materials are rejected or reworked.

-

In-Process Quality Control (IPQC): During the assembly process, regular checks are performed to ensure that all components are assembled correctly and that any deviations from specifications are addressed immediately.

-

Final Quality Control (FQC): Once the product is assembled, it undergoes a final inspection and testing phase to confirm it meets all performance standards. This may include electrical testing, thermal cycling, and vibration tests.

What Common Testing Methods Are Used for Starters and Alternators?

Testing methods vary, but they typically include electrical testing to verify output and performance under load, thermal testing to assess heat resistance, and mechanical testing to check structural integrity. Additionally, manufacturers may use automated testing equipment to ensure consistent results and reduce human error.

Illustrative image related to how do you know if its the starter or alternator

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must conduct thorough due diligence when selecting suppliers. Here are some strategies to verify a supplier’s quality control processes:

-

Supplier Audits: Regular audits can provide insight into a supplier’s manufacturing processes and quality control measures. Buyers can assess compliance with international standards and industry-specific certifications during these audits.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide transparency about their manufacturing processes, testing results, and any non-conformance issues encountered.

-

Third-Party Inspections: Engaging third-party inspection services can further validate the supplier’s quality control measures. These independent entities can conduct inspections at various stages of the manufacturing process to ensure compliance with agreed-upon standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of certain nuances:

-

Regulatory Compliance: Different regions have varying regulations regarding automotive parts. Buyers should ensure that suppliers comply with local regulations, as well as international standards.

-

Cultural and Language Barriers: Communication can sometimes be a challenge. Establishing clear guidelines and expectations can help mitigate misunderstandings.

-

Supply Chain Considerations: International shipping can introduce additional complexities. Buyers should be aware of the potential for delays and ensure that their suppliers have robust logistics and quality assurance processes in place.

Conclusion

Understanding the manufacturing processes and quality assurance measures for starters and alternators is crucial for B2B buyers. By familiarizing themselves with these stages, standards, and verification methods, businesses can make informed decisions when selecting suppliers, ensuring they receive high-quality components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you know if its the starter or alternator’

In the complex world of automotive components, accurately diagnosing whether an issue stems from the starter or alternator is crucial for effective procurement and maintenance. This guide provides a practical checklist to help B2B buyers navigate the process of identifying the right parts and suppliers.

Step 1: Understand the Symptoms of Failure

Before sourcing components, familiarize yourself with the common symptoms of starter and alternator failures. This knowledge allows you to make informed decisions about what parts you might need to procure.

- Starter Symptoms: Look for signs such as clicking sounds without engine cranking or a whirring noise when attempting to start.

- Alternator Symptoms: Indicators include dimming lights, a fluctuating voltage gauge, or a battery that repeatedly dies.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications of the parts you need. This ensures that the components you procure are compatible with the vehicles you service.

- Starter Specifications: Include details like the voltage, gear type, and mounting configuration.

- Alternator Specifications: Specify output amperage, pulley design, and electrical connectors.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your needs. This step is critical to avoid delays and ensure quality.

- Supplier Background: Request company profiles, product catalogs, and customer references.

- Industry Experience: Look for suppliers that have a proven track record in providing starters and alternators for your specific vehicle types.

Step 4: Request Product Samples

Before making a bulk purchase, ask for product samples. This allows you to verify the quality and compatibility of the parts.

- Quality Inspection: Examine the components for manufacturing defects or signs of wear.

- Compatibility Testing: Ensure the samples function correctly in the vehicles you service.

Step 5: Check for Certifications and Compliance

Ensure that the parts meet relevant industry standards and regulations. This is vital for maintaining safety and performance.

- Quality Certifications: Look for ISO, SAE, or equivalent certifications that indicate adherence to quality standards.

- Compliance with Local Regulations: Verify that the parts meet the regulatory requirements in your target markets, such as those in Africa, South America, and Europe.

Step 6: Analyze Pricing and Payment Terms

Understand the pricing structure and payment options available from suppliers. This is essential for budgeting and cash flow management.

- Cost Breakdown: Request detailed quotes that include unit prices, shipping costs, and any additional fees.

- Payment Flexibility: Inquire about payment terms, such as credit options or discounts for bulk orders.

Step 7: Establish a Communication Plan

Set up a clear communication strategy with your chosen suppliers. Effective communication can prevent misunderstandings and ensure timely updates.

- Point of Contact: Designate a specific contact person for all inquiries and updates.

- Regular Updates: Schedule periodic check-ins to discuss order status and any potential issues.

By following this checklist, B2B buyers can effectively determine whether the issue is related to the starter or alternator, ensuring they procure the right parts and maintain operational efficiency.

Comprehensive Cost and Pricing Analysis for how do you know if its the starter or alternator Sourcing

What Are the Key Cost Components in Sourcing Starter and Alternator Components?

Understanding the cost structure when sourcing components like starters and alternators is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The quality of raw materials directly influences the performance and longevity of starters and alternators. Components such as copper windings, magnets, and metal casings are critical. Pricing can vary significantly based on material quality, with higher-grade materials often leading to better performance and longer life spans.

-

Labor: Labor costs can vary widely depending on the region and the complexity of assembly processes. Countries with lower labor costs may offer more competitive pricing, but it’s essential to consider the trade-off with skill levels and quality of workmanship.

-

Manufacturing Overhead: This includes costs associated with running manufacturing facilities, such as utilities, equipment maintenance, and administrative expenses. Efficient production processes can help minimize overhead costs, impacting the overall pricing.

-

Tooling: The initial investment in tooling can be substantial, especially for custom or specialized parts. B2B buyers should inquire about these costs, as they may be amortized over larger production runs, affecting per-unit pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the parts meet industry standards and regulations. While this may add to initial costs, it ultimately reduces the risk of defects and warranty claims, leading to lower Total Cost of Ownership (TCO).

-

Logistics: Shipping and handling costs are pivotal, especially for international buyers. Factors such as distance, shipping method, and customs duties can significantly impact the final cost. Understanding the logistics framework is essential for accurate budgeting.

-

Margin: Suppliers will typically include a margin in their pricing to cover their risks and profit. Buyers should compare margins across different suppliers to ensure they are getting a competitive deal.

How Do Price Influencers Affect the Cost of Starters and Alternators?

Several price influencers can affect the sourcing costs for starters and alternators.

-

Volume/MOQ: Bulk purchasing can often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to maximize savings.

-

Specs/Customization: Custom specifications can lead to higher costs due to additional tooling and labor requirements. Buyers must balance the need for customization with budget constraints.

-

Materials: As mentioned, the choice of materials plays a significant role in pricing. Opting for standard materials can reduce costs, but may compromise performance.

-

Quality/Certifications: Components that meet international quality standards or certifications may carry a premium price. Buyers should assess whether these certifications are necessary for their markets.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market entry.

-

Incoterms: Understanding the implications of Incoterms on shipping costs is critical for international buyers. The choice of terms affects who bears the shipping and insurance costs, impacting overall pricing.

What Are Essential Buyer Tips for Cost-Efficiency in Sourcing Starters and Alternators?

-

Negotiation: Always negotiate prices and terms. Building relationships with suppliers can lead to better pricing and more favorable terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership, not just the purchase price. Consider long-term costs such as maintenance, warranty, and potential downtime.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and taxes that can impact final costs. Understanding local market conditions in regions like Africa, South America, the Middle East, and Europe will help in making informed sourcing decisions.

-

Disclaimer for Indicative Prices: Always request detailed quotes, as prices can vary widely based on the factors discussed. The market is dynamic, and prices may fluctuate based on supply chain conditions and demand.

By considering these components and tips, international B2B buyers can make informed decisions when sourcing starters and alternators, ensuring they balance cost with quality and performance.

Alternatives Analysis: Comparing how do you know if its the starter or alternator With Other Solutions

Understanding Alternative Solutions for Diagnosing Starter or Alternator Issues

In the automotive industry, identifying whether a problem lies with the starter or alternator is crucial for efficient vehicle maintenance. However, various alternative diagnostic methods can help streamline this process. Understanding these alternatives can empower B2B buyers to make informed decisions regarding service options and technology investments.

| Comparison Aspect | How Do You Know If It’s The Starter Or Alternator | Battery Load Tester | On-Board Diagnostics (OBD-II) Scanner |

|---|---|---|---|

| Performance | Relies on manual testing and observation | Provides quantitative data on battery health | Offers comprehensive diagnostics of multiple systems |

| Cost | Low (basic tools needed) | Moderate (around $50-$100) | Higher (typically $100-$300) |

| Ease of Implementation | Requires some technical knowledge | Fairly easy to use with basic training | User-friendly with intuitive interfaces |

| Maintenance | Minimal; mostly observational | Low; requires battery maintenance | Regular software updates needed |

| Best Use Case | Ideal for initial troubleshooting | Best for battery health assessment | Ideal for comprehensive diagnostics across multiple vehicle systems |

What Are the Advantages and Disadvantages of Using a Battery Load Tester?

A battery load tester is a device that applies a load to the battery while measuring its voltage output. This method is effective for diagnosing battery issues, which can sometimes mimic starter or alternator problems. The primary advantage of this tool is its cost-effectiveness and ease of use, making it accessible for many workshops. However, it only assesses the battery’s condition and does not provide insights into the starter or alternator, potentially leading to misdiagnosis if used in isolation.

How Does an On-Board Diagnostics (OBD-II) Scanner Compare?

An OBD-II scanner is a sophisticated tool that connects to a vehicle’s onboard computer to retrieve diagnostic trouble codes (DTCs) and real-time data. This method excels in providing a holistic view of the vehicle’s electrical system, including the battery, starter, and alternator. The major advantage is its ability to diagnose multiple issues beyond just the starting system. However, the initial investment is higher, and it may require some training to interpret the data effectively. This makes it less accessible for smaller workshops compared to simpler methods.

Conclusion: How Can B2B Buyers Choose the Right Diagnostic Solution?

When selecting a diagnostic solution for determining whether issues stem from the starter or alternator, B2B buyers should consider their specific operational needs and budget constraints. For those looking for a straightforward, low-cost option, manual testing can be effective. However, businesses that require more comprehensive diagnostics and can invest in advanced tools may find that an OBD-II scanner offers significant long-term benefits. Ultimately, the right choice will depend on the unique demands of the operation, the types of vehicles serviced, and the technical expertise available in-house.

Essential Technical Properties and Trade Terminology for how do you know if its the starter or alternator

What Are the Key Technical Properties to Consider When Diagnosing Starter or Alternator Issues?

Understanding the technical properties of starters and alternators is crucial for B2B buyers in the automotive parts industry. Here are some essential specifications to consider:

-

Material Composition

The materials used in the construction of starters and alternators significantly impact their durability and performance. Common materials include high-grade steel for the casing and copper for windings. High-quality materials resist corrosion and wear, which is vital in harsh environments typical in regions like Africa and South America. Choosing components made from superior materials ensures longer lifespan and reliability, reducing the frequency of replacements. -

Torque Specifications

Torque refers to the rotational force generated by the starter motor. It is measured in Newton-meters (Nm) and is critical for ensuring the engine cranks effectively. For instance, a starter with a torque rating too low may struggle to turn over larger engines, leading to potential failures in starting. B2B buyers should prioritize starters that meet or exceed OEM torque specifications for optimal performance. -

Electrical Resistance

Electrical resistance is a measure of how much a component opposes the flow of electric current. For starters and alternators, lower resistance indicates better conductivity and efficiency. This is particularly important in regions with fluctuating electrical supply, as components with high resistance can lead to overheating and premature failure. Understanding resistance specifications helps buyers select components that maintain optimal functionality. -

Voltage Ratings

Most automotive starters and alternators operate on a 12-volt system, but variations exist. Voltage ratings must align with the specific vehicle requirements to prevent damage. B2B buyers should ensure that the components meet the voltage demands of the vehicles they serve, especially when dealing with diverse fleets across different regions. -

Tolerance Levels

Tolerance levels refer to the permissible limits of variation in the dimensions of components. For starters and alternators, tight tolerances are essential for proper fit and function. Loose tolerances can lead to misalignment, resulting in mechanical failure. Buyers should look for parts that adhere to strict tolerance standards to ensure compatibility with their vehicle models.

Which Trade Terms Are Essential for Understanding Starter and Alternator Procurement?

Familiarity with industry jargon can streamline the procurement process for B2B buyers. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle manufacturer or their authorized suppliers. These parts are designed to meet specific performance standards. For buyers, sourcing OEM parts ensures compatibility and reliability, making them a preferred choice for fleet maintenance and repairs. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier requires a buyer to purchase. Understanding MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs to align with their purchasing needs, particularly when dealing with smaller volumes typical in certain markets. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Buyers utilize RFQs to compare offers from multiple suppliers, ensuring they obtain competitive pricing and favorable terms. This process is vital for cost-effective procurement strategies. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations in international transactions, ensuring compliance and reducing the risk of unexpected costs. -

Lead Time

Lead time refers to the period from placing an order to receiving the product. Understanding lead times is essential for inventory planning and ensuring timely repairs. Buyers should consider lead times when sourcing starters and alternators, especially in markets with longer supply chains.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when navigating the complexities of starter and alternator procurement, ensuring operational efficiency and reliability in their automotive operations.

Navigating Market Dynamics and Sourcing Trends in the how do you know if its the starter or alternator Sector

How Are Global Drivers Influencing the Starter and Alternator Market?

The automotive sector is undergoing significant transformations driven by technological advancements and changing consumer preferences. One major trend is the increasing demand for electric vehicles (EVs), which rely heavily on efficient battery, starter, and alternator systems. In regions like Africa and South America, where the automotive market is rapidly expanding, there is a notable shift towards sourcing components that support hybrid and electric technologies. This transition is also evident in the Middle East and Europe, where governments are incentivizing EV adoption through subsidies and infrastructure investments.

Moreover, international B2B buyers are increasingly focused on the quality and reliability of automotive components. With the complexity of diagnosing issues between starters, alternators, and batteries, there is a growing need for suppliers to provide detailed specifications and performance guarantees. Additionally, the rise of digital platforms for sourcing components has streamlined procurement processes, enabling buyers to compare products and suppliers more effectively.

As the market evolves, the integration of smart technologies into automotive components is also gaining traction. Features such as smart battery management systems and advanced diagnostics are becoming essential. Buyers are seeking suppliers who can offer these innovations, as they enhance vehicle performance and reduce maintenance costs.

Illustrative image related to how do you know if its the starter or alternator

What Role Does Sustainability Play in Sourcing Starter and Alternator Components?

Sustainability is becoming a critical consideration for international B2B buyers, particularly in sectors like automotive where environmental impact is under scrutiny. The sourcing of starters and alternators is no exception, as manufacturers are increasingly expected to adopt ethical practices and reduce their carbon footprint. Suppliers that prioritize sustainable materials and processes are more likely to attract discerning buyers who value corporate responsibility.

Environmental certifications, such as ISO 14001, are gaining importance in the sourcing process. Buyers are looking for suppliers that can demonstrate compliance with these standards, ensuring that their products are manufactured with minimal environmental impact. Additionally, the use of recyclable materials in starters and alternators not only supports sustainability but also appeals to businesses looking to enhance their brand image.

In regions like Africa and South America, where environmental regulations may be less stringent, the push for sustainability is often driven by global market expectations. Buyers from these regions are increasingly aligning their sourcing strategies with international standards to improve their competitiveness. By prioritizing ethical sourcing and sustainability, companies can position themselves as leaders in a market that is increasingly valuing green practices.

Illustrative image related to how do you know if its the starter or alternator

How Has the Starter and Alternator Market Evolved Over Time?

Historically, the starter and alternator market has been characterized by mechanical simplicity, primarily focused on traditional internal combustion engine vehicles. However, the advent of electronic systems and the growing complexity of modern vehicles have transformed this landscape. In the early 2000s, advancements in materials and manufacturing processes began to enhance the efficiency and reliability of starters and alternators, paving the way for improved performance.

As electric and hybrid vehicles gained popularity, the market saw a significant shift toward components designed for these technologies. This evolution has been fueled by the increasing demand for energy efficiency and the need for lighter, more compact systems. International B2B buyers are now faced with a wide array of options, from traditional components to advanced systems capable of supporting the latest automotive technologies.

The continuous innovation in battery technology, coupled with the rise of smart vehicles, indicates that the market will continue to evolve. Understanding these historical trends and their implications for the future is essential for B2B buyers aiming to navigate the complexities of sourcing starters and alternators in a dynamic automotive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of how do you know if its the starter or alternator

-

How can I determine if the issue is with the starter or the alternator?

To identify whether the problem lies with the starter or alternator, start by observing the vehicle’s symptoms. If the engine fails to crank but you hear a clicking sound when turning the key, the starter may be faulty. Conversely, if the engine cranks but does not start, or if it starts and then dies shortly after, the alternator could be the issue. Conducting a jump-start test can also help; if the vehicle starts with a jump but dies once disconnected, the alternator is likely not functioning properly. -

What are the common signs of a failing starter?

A failing starter typically exhibits several signs. Look for unusual noises, such as grinding or clicking sounds when attempting to start the vehicle. If the engine does not crank at all but other electrical components like lights and radio function normally, the starter may be the culprit. Additionally, excessive heat or smoke from the starter area can indicate severe failure, necessitating immediate inspection or replacement. -

What are the symptoms of a bad alternator?

Common symptoms of a bad alternator include dim or flickering headlights, dashboard warning lights illuminating, and electrical accessories functioning poorly. If the vehicle frequently stalls or the battery dies even after being charged, the alternator may not be generating sufficient power. Observing fluctuating voltage readings on a gauge can also indicate alternator issues. -

What factors should I consider when sourcing starters and alternators from international suppliers?

When sourcing starters and alternators internationally, consider factors such as supplier reliability, quality certifications, and compliance with international standards. Assess the supplier’s experience in the automotive sector and their ability to provide customized solutions. Additionally, investigate their logistics capabilities and lead times, as these can impact your supply chain efficiency. -

How can I vet potential suppliers for automotive parts?

Vetting potential suppliers involves several steps: review their reputation through customer testimonials and industry references, verify certifications, and assess their production capabilities. Conducting an on-site audit can also provide insights into their quality control processes. Furthermore, ensure they have a robust after-sales support system to address any issues post-purchase. -

What minimum order quantities (MOQ) should I expect for starters and alternators?

Minimum order quantities can vary widely based on the supplier and product type. Generally, expect MOQs to range from 50 to 500 units, depending on the supplier’s production capacity and your negotiation skills. It’s advisable to discuss MOQs upfront and explore potential flexibility, especially if you’re testing a new market or product line. -

What payment terms are typically offered by international suppliers?

Payment terms from international suppliers can differ significantly. Common arrangements include advance payment, letter of credit, or partial payment upfront with the balance due upon delivery. Negotiate terms that balance your cash flow needs with supplier requirements, and consider using escrow services to protect both parties in transactions. -

What quality assurance measures should I request from suppliers?

Requesting quality assurance measures is crucial in ensuring product reliability. Inquire about the supplier’s quality control processes, including testing protocols for starters and alternators. Certifications such as ISO 9001 can indicate a commitment to quality. Additionally, ask for samples or third-party inspection reports before finalizing bulk orders to ensure product consistency and performance.

Top 2 How Do You Know If Its The Starter Or Alternator Manufacturers & Suppliers List

1. Reddit – Battery and Alternator Basics

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The battery provides power to all electronics, including the starter. The alternator charges the battery when the engine is running. The starter uses battery power to turn over the engine. Symptoms of a dead battery include no power at all, while a failing alternator may cause the battery light to be on when the engine is running.

2. Honda Civic – Starting Issue

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: 2006 Honda Civic EX 1.8L 4 Cylinder; issues with starting; new battery installed; symptoms include weak cranking, single click when attempting to start; potential problems identified: bad starter, bad alternator, or faulty battery cables; updates indicate starter was the issue.

Strategic Sourcing Conclusion and Outlook for how do you know if its the starter or alternator

In conclusion, understanding the interplay between the starter, alternator, and battery is crucial for effective vehicle maintenance and management. For B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe, strategic sourcing of quality automotive components can significantly enhance operational efficiency. Recognizing the signs of failure in these components—such as dimming lights indicating an alternator issue or clicking sounds suggesting a starter malfunction—can save both time and resources.

Investing in reliable parts and services not only minimizes downtime but also extends the lifespan of your vehicles. As you navigate the complexities of sourcing, prioritize suppliers that offer comprehensive diagnostics and high-quality replacements tailored to your regional needs.

Looking ahead, the automotive landscape will continue to evolve, emphasizing the importance of technology and innovation in sourcing strategies. Stay proactive in your approach by building partnerships with trusted suppliers who understand the unique challenges of your market. By doing so, you can ensure that your fleet remains operational and efficient, ready to meet future demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.