Introduction: Navigating the Global Market for how can you tell if battery or alternator is bad

Understanding how to determine whether a battery or alternator is malfunctioning is crucial for B2B buyers in the automotive sector, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. The reliability of vehicles hinges on these two components, and any failure can lead to costly downtime and reduced productivity. This guide addresses the key challenge of diagnosing battery and alternator issues efficiently, enabling businesses to make informed sourcing decisions.

Throughout this comprehensive resource, we will explore various types of batteries and alternators, their specific applications, and the symptoms indicative of failure. We will also provide insights into supplier vetting processes, enabling buyers to identify reliable manufacturers and service providers. Additionally, the guide will cover cost considerations, helping businesses balance budget constraints with quality requirements.

By equipping international B2B buyers with actionable knowledge on diagnosing and sourcing solutions for battery and alternator problems, this guide empowers them to enhance operational efficiency. Understanding the nuances of these critical components allows businesses to minimize disruptions and maintain a competitive edge in their respective markets. Whether you are in Vietnam, Brazil, or any other region, this guide serves as a vital tool for navigating the complexities of automotive electrical systems.

Table Of Contents

- Top 2 How Can You Tell If Battery Or Alternator Is Bad Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how can you tell if battery or alternator is bad

- Understanding how can you tell if battery or alternator is bad Types and Variations

- Key Industrial Applications of how can you tell if battery or alternator is bad

- 3 Common User Pain Points for ‘how can you tell if battery or alternator is bad’ & Their Solutions

- Strategic Material Selection Guide for how can you tell if battery or alternator is bad

- In-depth Look: Manufacturing Processes and Quality Assurance for how can you tell if battery or alternator is bad

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how can you tell if battery or alternator is bad’

- Comprehensive Cost and Pricing Analysis for how can you tell if battery or alternator is bad Sourcing

- Alternatives Analysis: Comparing how can you tell if battery or alternator is bad With Other Solutions

- Essential Technical Properties and Trade Terminology for how can you tell if battery or alternator is bad

- Navigating Market Dynamics and Sourcing Trends in the how can you tell if battery or alternator is bad Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how can you tell if battery or alternator is bad

- Strategic Sourcing Conclusion and Outlook for how can you tell if battery or alternator is bad

- Important Disclaimer & Terms of Use

Understanding how can you tell if battery or alternator is bad Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Voltage Testing | Measures voltage output with a multimeter. | Automotive service centers, fleet management | Pros: Quick and easy; Cons: Requires equipment and some knowledge. |

| Load Testing | Assesses battery capacity under load conditions. | Battery suppliers, automotive repair shops | Pros: Accurate assessment; Cons: Time-consuming and requires specialized tools. |

| Visual Inspection | Checks for physical signs of wear, corrosion, or damage. | Maintenance teams, vehicle inspection services | Pros: No tools needed; Cons: Subjective and may miss hidden issues. |

| Electrical System Diagnostics | Comprehensive testing of the entire electrical system. | Automotive diagnostic specialists | Pros: Detailed insights; Cons: May require advanced training and tools. |

| Jump Start Test | Evaluates battery condition by jump-starting the vehicle. | Automotive repair, roadside assistance | Pros: Immediate indication of battery health; Cons: May not reveal underlying alternator issues. |

What is Voltage Testing and When Should It Be Used?

Voltage testing is a straightforward method that involves measuring the voltage output of a battery or alternator using a multimeter. This method is suitable for automotive service centers and fleet management operations, where quick diagnostics are essential. Buyers should consider the simplicity and speed of this test, but also recognize that it requires basic electrical knowledge and equipment, which may not be available in all settings.

How Does Load Testing Help Assess Battery Health?

Load testing evaluates a battery’s ability to perform under operational conditions by applying a load and measuring voltage drop. This method is vital for battery suppliers and automotive repair shops, as it provides an accurate assessment of battery capacity. While it offers reliable results, it is time-consuming and necessitates specialized tools, which might not be feasible for every business.

Why is Visual Inspection Important in Diagnosing Battery and Alternator Issues?

Visual inspection entails examining the battery and alternator for signs of wear, corrosion, or physical damage. This method is particularly useful for maintenance teams and vehicle inspection services, as it requires no specialized tools. However, while it is easy to implement, it is subjective and might overlook hidden problems that could compromise vehicle performance.

What Are the Benefits of Electrical System Diagnostics?

Electrical system diagnostics involve a comprehensive assessment of the vehicle’s entire electrical system, including the battery and alternator. This approach is beneficial for automotive diagnostic specialists who require detailed insights into potential issues. Although it provides thorough analysis, it often demands advanced training and tools, which may be a barrier for some businesses.

How Can a Jump Start Test Indicate Battery Health?

The jump start test is a practical method to evaluate battery health by attempting to start the vehicle with a jump. This test is commonly used by automotive repair shops and roadside assistance services. While it offers an immediate indication of battery condition, it may not effectively reveal underlying alternator problems, making it less comprehensive than other testing methods.

Key Industrial Applications of how can you tell if battery or alternator is bad

| Industry/Sector | Specific Application of how can you tell if battery or alternator is bad | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnostics for vehicle electrical issues | Improved service efficiency and customer satisfaction | Quality diagnostic tools, availability of parts |

| Transportation & Logistics | Fleet management and maintenance checks | Reduced downtime and operational costs | Reliability of components, bulk purchasing options |

| Renewable Energy | Maintenance of electric vehicle (EV) charging stations | Enhanced reliability and user trust | Compatibility with various battery types and voltages |

| Agriculture | Power management for agricultural machinery | Increased productivity and reduced equipment failure | Access to specialized equipment and training |

| Construction | Battery and alternator checks for heavy machinery | Safety assurance and operational efficiency | Availability of diagnostic services and parts |

How is ‘how can you tell if battery or alternator is bad’ Used in Automotive Repair?

In the automotive repair sector, accurately diagnosing battery or alternator issues is crucial for efficient service delivery. Mechanics utilize diagnostic tools to determine whether a vehicle’s failure to start is due to a depleted battery or a malfunctioning alternator. By identifying the root cause promptly, repair shops can reduce labor time and enhance customer satisfaction. International buyers in this sector should consider sourcing high-quality diagnostic equipment that can handle various vehicle types, as well as access to reliable replacement parts.

What Role Does This Knowledge Play in Transportation & Logistics?

For companies in transportation and logistics, maintaining a fleet of vehicles is paramount. Regular diagnostics of batteries and alternators ensure that vehicles remain operational, minimizing downtime that can lead to costly delays. Fleet managers can implement scheduled checks to prevent unexpected failures, optimizing their operational efficiency. Buyers in this industry should prioritize sourcing durable components and consider the logistics of parts delivery to avoid disruptions in service.

How Does This Apply to Renewable Energy?

In the renewable energy sector, particularly with electric vehicle (EV) charging stations, ensuring the functionality of batteries and alternators is vital for user satisfaction. A well-functioning charging station enhances reliability, encouraging more users to adopt EVs. Buyers must look for components that are compatible with various battery technologies and offer robust performance under different environmental conditions, especially in regions with fluctuating weather patterns.

Why is This Important for Agriculture?

Agricultural machinery often relies on batteries and alternators for power management, especially in remote areas where consistent electricity supply is lacking. Regular diagnostics can prevent equipment failures that may halt operations, leading to significant productivity losses. Buyers in agriculture should focus on sourcing equipment that is rugged and can withstand harsh operating environments, ensuring that their machinery remains functional throughout the farming season.

What is the Significance in Construction?

In the construction industry, heavy machinery is frequently subjected to demanding conditions that can affect battery and alternator performance. Ensuring that these components are functioning correctly is essential for safety and operational efficiency on job sites. Construction companies should source reliable diagnostic tools and parts, as well as consider training for their staff to conduct regular checks, thereby reducing the risk of equipment failure and enhancing safety protocols.

3 Common User Pain Points for ‘how can you tell if battery or alternator is bad’ & Their Solutions

Scenario 1: Difficulty Diagnosing Electrical Issues in Fleet Vehicles

The Problem: For B2B buyers managing a fleet of vehicles, diagnosing electrical issues can be a daunting task. When a vehicle fails to start or exhibits erratic electrical behavior, it can lead to downtime, lost revenue, and increased operational costs. Fleet managers often lack the specialized tools and knowledge to accurately distinguish between battery and alternator failures, which complicates the repair process and prolongs vehicle inoperability.

The Solution: To effectively diagnose whether a battery or alternator is the source of the problem, fleet managers should invest in a reliable multimeter and train their maintenance staff on its use. By measuring the battery voltage, they can determine if it’s holding a charge. A healthy battery should read around 12.6 volts when the vehicle is off. If the vehicle starts but quickly dies, this indicates a potential alternator failure. Additionally, checking the voltage while the engine is running can confirm alternator functionality; it should ideally read between 13 to 14.5 volts. Establishing a routine maintenance check for batteries and alternators can prevent sudden failures and reduce repair costs in the long run.

Scenario 2: Inconsistent Performance of Heavy Equipment

The Problem: Businesses relying on heavy equipment in construction or mining often face performance inconsistencies due to electrical issues. When machinery starts showing signs of electrical failure, such as slow starts or intermittent power loss, operators may not know whether to replace the battery or the alternator. This uncertainty can lead to unnecessary parts replacements, wasting both time and resources.

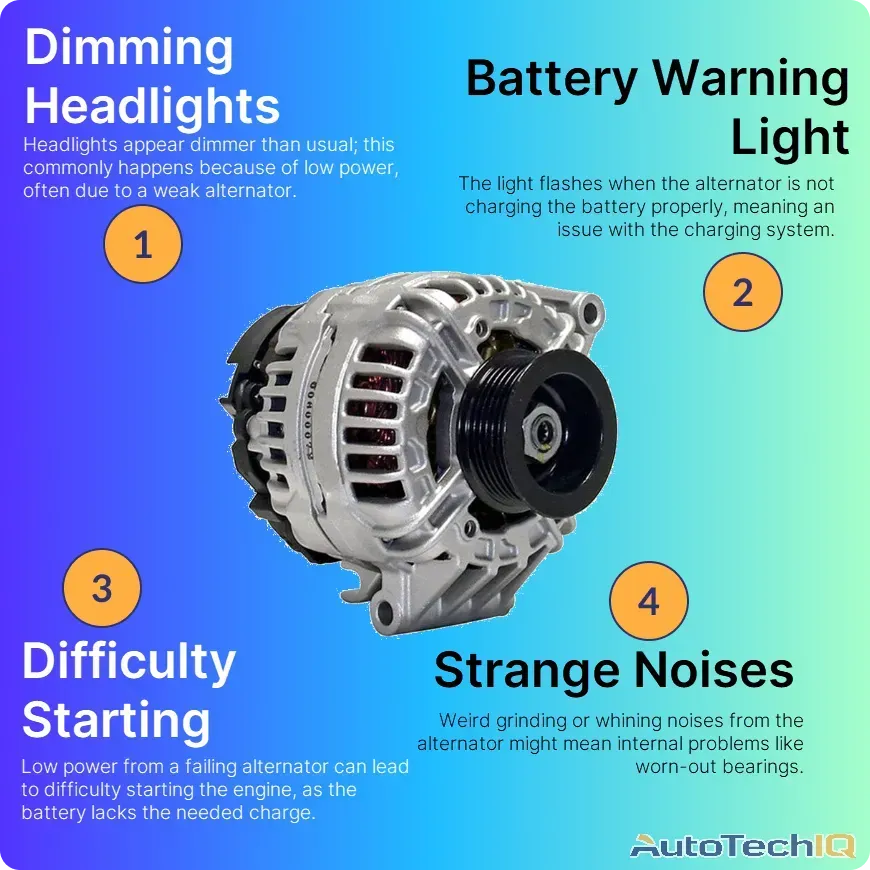

The Solution: To minimize costly guesswork, companies should implement a systematic approach to diagnosing electrical problems. First, operators should be trained to recognize key symptoms of battery versus alternator issues, such as dimming lights or unusual sounds during startup. Next, utilizing diagnostic tools specifically designed for heavy equipment can help streamline the process. For example, advanced diagnostic scanners can provide real-time data and pinpoint electrical faults. Finally, establishing a preventive maintenance schedule that includes regular testing of both the battery and alternator can significantly reduce downtime and enhance the reliability of heavy machinery.

Illustrative image related to how can you tell if battery or alternator is bad

Scenario 3: Lack of Access to Quality Replacement Parts

The Problem: B2B buyers, especially in regions with limited access to automotive parts, often struggle to find reliable replacements for batteries and alternators. This scarcity can lead to prolonged vehicle downtime and increased repair costs, particularly when local suppliers do not stock quality parts. Furthermore, the difficulty in sourcing the right specifications may lead to compatibility issues and subpar performance.

The Solution: To address this challenge, businesses should build relationships with reputable suppliers who specialize in automotive parts, ensuring access to high-quality batteries and alternators. Conducting thorough research online to identify suppliers with good reviews and a track record of reliability can be beneficial. Additionally, leveraging technology to track inventory and automate orders for commonly used parts can streamline the procurement process. Establishing partnerships with manufacturers for bulk purchasing can also reduce costs and improve supply chain efficiency, ultimately ensuring that vehicles remain operational without unnecessary delays. Regularly engaging with suppliers for updates on new products can help businesses stay ahead in sourcing the best solutions for their electrical needs.

Strategic Material Selection Guide for how can you tell if battery or alternator is bad

What Materials Are Commonly Used in Battery and Alternator Diagnostics?

When diagnosing battery and alternator issues, several materials are utilized in the tools and equipment designed for testing. Understanding these materials can help international B2B buyers make informed decisions about sourcing and using diagnostic equipment effectively.

1. Copper

Key Properties:

Copper is highly conductive, with excellent electrical properties that allow for efficient current flow. It also has a good temperature tolerance, typically operating well in environments ranging from -40°C to 200°C.

Pros & Cons:

Copper’s high conductivity makes it ideal for electrical connections, ensuring minimal energy loss. However, it is prone to corrosion, especially in humid or saline environments, which can lead to increased maintenance costs. Additionally, copper is relatively expensive compared to alternatives like aluminum.

Impact on Application:

Copper’s superior conductivity is crucial for accurate voltage readings in diagnostic tools. However, buyers in regions with high humidity, such as parts of Africa and South America, should consider protective coatings to mitigate corrosion.

Specific Considerations for International B2B Buyers:

Copper must comply with international standards such as ASTM B170 for electrical conductors. Buyers should ensure that their suppliers provide certified materials to avoid quality issues.

2. Aluminum

Key Properties:

Aluminum is lightweight and offers good conductivity, although not as high as copper. It has a decent temperature rating and exhibits good resistance to corrosion due to its natural oxide layer.

Illustrative image related to how can you tell if battery or alternator is bad

Pros & Cons:

The primary advantage of aluminum is its cost-effectiveness and lightweight nature, making it easier to handle and install. However, its lower conductivity means that larger cross-sections are needed to match copper’s performance, which can increase manufacturing complexity.

Impact on Application:

Aluminum is often used in wiring for diagnostic equipment where weight is a concern. However, the reduced conductivity can lead to inaccuracies in measurements if not properly accounted for.

Specific Considerations for International B2B Buyers:

Aluminum must meet standards like ASTM B221. Buyers should also consider the local availability of aluminum components to ensure timely procurement.

3. Plastic (Polymer Composites)

Key Properties:

Plastic materials, particularly polymer composites, are lightweight, corrosion-resistant, and can withstand a range of temperatures depending on the specific type used.

Pros & Cons:

The primary advantage of plastics is their resistance to environmental factors, which makes them ideal for housing and insulation in diagnostic tools. However, they may not withstand extreme temperatures as well as metals, and their mechanical strength can be lower.

Impact on Application:

Plastics are commonly used for casings and insulators in multimeters and other diagnostic equipment. Their lightweight nature aids in portability, but care must be taken to ensure they are not exposed to extreme conditions.

Specific Considerations for International B2B Buyers:

Buyers should verify compliance with international standards such as ISO 9001 for quality management. Additionally, understanding local regulations regarding plastic use can help avoid compliance issues.

4. Silicone

Key Properties:

Silicone is known for its flexibility, high-temperature resistance (typically from -60°C to 230°C), and excellent electrical insulation properties.

Pros & Cons:

Silicone’s flexibility makes it ideal for applications requiring movement or vibration resistance. However, it can be more expensive than traditional rubber materials and may not be as durable under mechanical stress.

Impact on Application:

Silicone is often used in connectors and seals in diagnostic equipment to prevent moisture ingress. Its high-temperature tolerance is beneficial in automotive environments.

Specific Considerations for International B2B Buyers:

Silicone components should comply with standards like ASTM D412 for tensile strength. Buyers should ensure that suppliers can provide documentation of compliance to avoid quality issues.

Summary Table

| Material | Typical Use Case for how can you tell if battery or alternator is bad | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections in multimeters and testers | Excellent conductivity | Prone to corrosion | High |

| Aluminum | Wiring for diagnostic equipment | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Plastic | Casings and insulation for diagnostic tools | Corrosion-resistant and lightweight | Lower mechanical strength | Low |

| Silicone | Connectors and seals in diagnostic equipment | High-temperature resistance | More expensive than traditional materials | Medium |

This analysis provides a comprehensive overview of materials commonly used in battery and alternator diagnostics, helping B2B buyers make informed decisions tailored to their specific regional needs and operational contexts.

In-depth Look: Manufacturing Processes and Quality Assurance for how can you tell if battery or alternator is bad

What Are the Main Stages in the Manufacturing Process for Batteries and Alternators?

The manufacturing processes for batteries and alternators are intricate, involving several stages to ensure high performance and reliability. Understanding these stages can help B2B buyers make informed decisions about their suppliers.

Illustrative image related to how can you tell if battery or alternator is bad

Material Preparation: What Raw Materials Are Used?

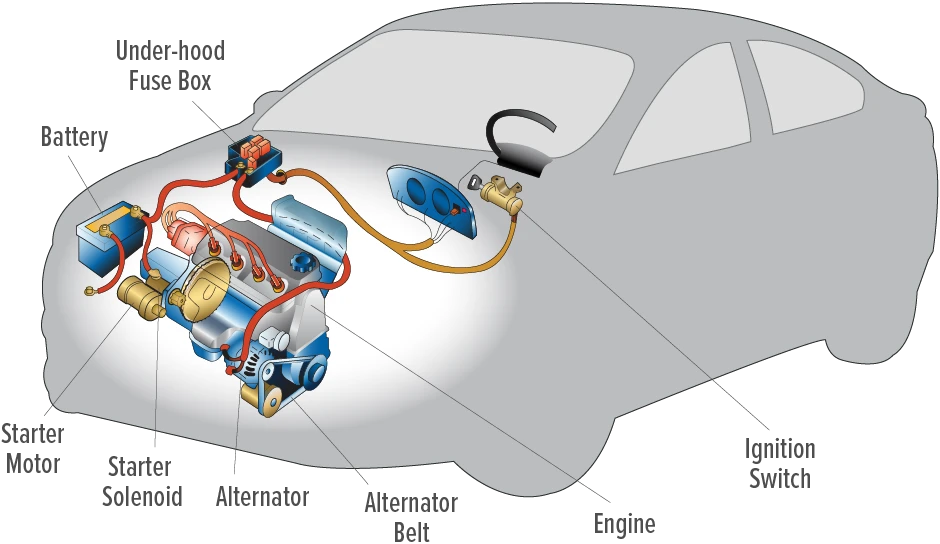

The first stage in the manufacturing of batteries and alternators involves the preparation of raw materials. For batteries, this includes lead, sulfuric acid, and plastic for the casing. Lead-acid batteries, the most common type, require precise formulations to optimize performance and longevity. In the case of alternators, copper, aluminum, and steel are essential components. Copper is primarily used for windings, while aluminum is often used for the housing due to its lightweight and corrosion-resistant properties.

Forming: How Are Components Shaped and Assembled?

In the forming stage, raw materials undergo various processes to create the necessary components. For batteries, the lead is processed into plates that are then coated with a paste made from lead dioxide. These plates are stacked and separated by insulating materials to create cells.

For alternators, the forming process involves stamping metal parts, winding copper wire into coils, and assembling the rotor and stator. This stage is critical as it determines the efficiency and output of the alternator. Precision in this phase is vital to ensure the components fit together seamlessly, thereby minimizing energy losses.

Assembly: What Techniques Ensure Quality?

The assembly stage combines all manufactured components into a final product. For batteries, this involves integrating the cells into a single unit, filling them with electrolyte, and sealing them. Automated assembly lines are often used to enhance efficiency and reduce human error.

Illustrative image related to how can you tell if battery or alternator is bad

In alternator production, the assembly process includes attaching the rotor to the stator, connecting the voltage regulator, and integrating the rectifier. Techniques such as robotic arms and automated testing stations help maintain high standards of precision and efficiency.

Finishing: How Is the Product Prepared for Market?

Finishing processes include cleaning, coating, and packaging. For batteries, protective coatings are applied to prevent corrosion, and labels are affixed for compliance with international standards. In alternators, finishing may involve anodizing aluminum parts for durability and aesthetic appeal.

The final inspection is performed before packaging, ensuring that each unit meets the required specifications.

What Quality Control Measures Are Applied in Battery and Alternator Manufacturing?

Quality control (QC) is paramount in the manufacturing processes for batteries and alternators. Various international and industry-specific standards guide these QC practices.

What International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is one of the most recognized international quality management standards that manufacturers adhere to. This standard focuses on continuous improvement and customer satisfaction, which is crucial for B2B buyers looking for reliable suppliers. Other relevant certifications may include CE marking in Europe, which indicates compliance with health, safety, and environmental protection standards.

Illustrative image related to how can you tell if battery or alternator is bad

What Are Key QC Checkpoints in Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process.

-

Incoming Quality Control (IQC): This stage assesses the quality of incoming raw materials. Suppliers must provide certification for materials, and tests are conducted to verify compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, components are regularly checked for dimensional accuracy and performance. This may include voltage testing for batteries and output testing for alternators.

-

Final Quality Control (FQC): Once the products are assembled, they undergo comprehensive testing to ensure they meet performance standards. This may involve checking the battery’s voltage and capacity or the alternator’s output under load.

What Testing Methods Are Commonly Used in Battery and Alternator QC?

B2B buyers should be aware of common testing methods employed in the quality assurance of batteries and alternators:

-

Voltage and Capacity Testing: For batteries, this involves measuring voltage levels and the ability to hold a charge. A good battery typically shows around 12.6 volts at rest.

-

Load Testing: Alternators are tested under simulated loads to ensure they produce adequate voltage and current. This can reveal issues that may not be apparent under idle conditions.

-

Thermal Imaging: This method identifies hotspots in alternators, indicating potential failure points.

-

Durability Testing: Both batteries and alternators undergo stress tests to simulate extreme operating conditions, ensuring they can withstand real-world applications.

How Can B2B Buyers Verify Supplier QC Practices?

B2B buyers must conduct due diligence to verify the QC practices of potential suppliers. Here are actionable steps:

-

Supplier Audits: Regular audits can help assess whether suppliers adhere to international standards and internal QC processes. This includes checking documentation, procedures, and compliance with regulatory requirements.

-

Requesting Quality Reports: Suppliers should be willing to provide detailed QC reports, including results from testing and inspections. These documents can help buyers assess the reliability of the products.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased view of a supplier’s QC practices. These inspections often include checks on manufacturing processes, material quality, and finished product testing.

What Are the Unique QC Considerations for International B2B Buyers?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, there are unique QC nuances to consider:

Illustrative image related to how can you tell if battery or alternator is bad

-

Regulatory Compliance: Different regions have varying regulations concerning battery and alternator safety and environmental impact. Buyers must ensure that suppliers comply with local laws, which may include waste disposal and recycling requirements.

-

Cultural and Logistical Differences: Understanding the manufacturing culture and logistical challenges in different countries can affect product quality. Buyers should consider the supplier’s ability to deliver consistently, especially in remote areas.

-

Geopolitical Factors: Buyers should be aware of geopolitical issues that could disrupt supply chains. This includes evaluating suppliers based on their ability to navigate these challenges effectively.

By understanding the manufacturing processes and quality assurance measures in battery and alternator production, B2B buyers can make more informed purchasing decisions, ensuring they source reliable and high-quality products for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how can you tell if battery or alternator is bad’

In the automotive industry, accurately diagnosing whether a battery or alternator is faulty is crucial for maintaining vehicle performance and reliability. This guide provides a systematic approach for B2B buyers to assess the condition of batteries and alternators effectively, ensuring informed procurement decisions.

Step 1: Understand the Functions of Battery and Alternator

Before diving into diagnostics, it is essential to comprehend the roles of both components. The battery primarily starts the vehicle and supplies power to accessories when the engine isn’t running, while the alternator generates electricity to recharge the battery and power the vehicle’s electrical systems. Knowing these functions helps in identifying symptoms of failure.

Step 2: Identify Common Symptoms of a Bad Battery

Recognizing the signs of a failing battery is the first step in your assessment. Look for:

– Failure to start the vehicle: If the engine doesn’t turn over or makes a clicking sound, the battery may be dead.

– Slow cranking: This is especially prevalent in colder climates, indicating the battery is struggling to provide sufficient power.

Step 3: Look for Signs of Alternator Failure

The alternator’s performance can be assessed through specific indicators. Pay attention to:

– Dimming or flickering lights: If headlights or interior lights fluctuate in brightness, it suggests inconsistent voltage supply from the alternator.

– Electrical accessory malfunctions: Unexplained shutdowns or erratic behavior of electrical components can signal alternator issues.

Step 4: Conduct a Voltage Test with a Multimeter

Using a multimeter provides a clear indication of both battery and alternator health. Follow these steps:

– Test the battery voltage: A healthy battery should read around 12.6 volts. If it’s below this, consider recharging or replacing it.

– Check alternator output: With the engine running, measure the voltage at the battery terminals. A reading between 13 and 14.5 volts indicates proper alternator function.

Step 5: Evaluate the Battery’s Charge Retention

To determine if a battery holds a charge, fully charge it and leave it idle for 24-48 hours before retesting. A significant drop in voltage during this period indicates a compromised battery. This step is essential for avoiding premature battery replacements and ensuring long-term operational efficiency.

Step 6: Assess Supplier Capabilities for Diagnostic Tools

When sourcing replacement batteries or alternators, evaluate suppliers based on their diagnostic equipment offerings. Look for:

– Availability of multimeters and testing devices: Reliable suppliers should provide tools that help in the diagnosis of battery and alternator issues.

– Technical support: Ensure that the supplier offers guidance or training on using diagnostic equipment effectively.

Step 7: Establish a Maintenance Schedule for Battery and Alternator

Preventive maintenance is key to extending the life of both components. Develop a regular inspection plan that includes:

– Cleaning battery terminals: Regularly check for corrosion and clean terminals to ensure optimal electrical contact.

– Periodic voltage checks: Schedule voltage tests every few months to catch potential issues early.

Illustrative image related to how can you tell if battery or alternator is bad

By following these steps, B2B buyers can effectively determine the health of batteries and alternators, ensuring they make informed decisions when procuring replacements or tools for diagnosis.

Comprehensive Cost and Pricing Analysis for how can you tell if battery or alternator is bad Sourcing

What Are the Key Cost Components for Diagnosing Battery or Alternator Issues?

Understanding the cost structure associated with diagnosing battery or alternator problems is crucial for B2B buyers, particularly those operating in international markets like Africa, South America, the Middle East, and Europe. The primary cost components include:

-

Materials: The cost of diagnostic tools such as multimeters, battery testers, and alternator testers can vary significantly. High-quality tools often come with certifications and warranties, which can influence pricing.

-

Labor: Skilled labor is essential for accurate diagnosis and repair. Labor costs can fluctuate based on local wage standards and the complexity of the diagnosis. In regions with a high demand for automotive services, labor costs may be elevated.

-

Manufacturing Overhead: Overhead costs, including utilities, rent, and administrative expenses, can impact the pricing of diagnostic tools and services. Companies operating in high-cost areas will naturally pass these expenses onto the buyer.

-

Tooling: Specialized equipment for testing and repairing batteries and alternators requires initial investment and maintenance costs, which are reflected in the pricing structure of these services.

-

Quality Control (QC): Ensuring that diagnostic tools are reliable and accurate involves rigorous quality control processes, adding another layer to the cost structure.

-

Logistics: Transportation costs for tools and parts, especially in international trade, can be significant. Factors such as shipping distance, customs duties, and handling fees can all influence overall costs.

-

Margin: Suppliers generally add a profit margin to their pricing, which can vary depending on market conditions and competitive dynamics.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence pricing when sourcing diagnostic solutions for battery and alternator issues:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts, while smaller orders may incur higher per-unit costs. International buyers should consider their projected needs to optimize costs.

-

Specifications and Customization: Custom or specialized diagnostic tools can command higher prices due to the additional engineering and manufacturing processes involved. Buyers should evaluate whether standard solutions may suffice for their needs.

-

Material Quality and Certifications: Tools that meet specific industry standards or certifications may cost more but provide better reliability and durability. International buyers must assess these factors against their operational requirements.

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer competitive pricing to gain market share.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Buyers must understand these terms to avoid unexpected expenses in logistics and customs.

What Buyer Tips Can Enhance Cost-Efficiency?

For international B2B buyers, particularly those in developing markets, several strategies can enhance cost-efficiency when sourcing diagnostic solutions:

-

Negotiate Pricing: Engage in discussions with suppliers to explore volume discounts or extended payment terms, which can alleviate immediate financial burdens.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but the long-term costs associated with maintenance, reliability, and potential downtime caused by faulty tools. A higher upfront investment in quality tools may lead to lower TCO.

-

Understand Pricing Nuances for International Markets: Currency fluctuations, tariffs, and local market conditions can all affect pricing. Buyers should stay informed about these factors to make better purchasing decisions.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to preferential pricing, improved service, and access to new products.

-

Leverage Local Knowledge: Collaborating with local distributors who understand the market dynamics can help in finding the best deals and navigating the complexities of international sourcing.

Disclaimer on Indicative Prices

Prices for diagnostic tools and services can vary widely based on geographic location, market conditions, and specific product specifications. Buyers should conduct thorough market research and supplier evaluations to obtain the most accurate and relevant pricing information for their unique needs.

Alternatives Analysis: Comparing how can you tell if battery or alternator is bad With Other Solutions

Understanding Alternative Solutions for Diagnosing Battery and Alternator Issues

When it comes to diagnosing whether a vehicle’s battery or alternator is malfunctioning, various methods and technologies can be employed. Each approach offers unique advantages and limitations, making it essential for B2B buyers to evaluate their specific needs and operational contexts. Below, we compare the traditional method of diagnosing battery and alternator issues against two alternative solutions: professional diagnostic tools and mobile app-based diagnostics.

Comparison Table

| Comparison Aspect | How Can You Tell If Battery Or Alternator Is Bad | Professional Diagnostic Tools | Mobile App-Based Diagnostics |

|---|---|---|---|

| Performance | Reliable if basic tests are conducted correctly | High accuracy with detailed analysis | Variable accuracy; dependent on device compatibility |

| Cost | Low; typically requires minimal tools (e.g., multimeter) | Moderate; costs can range from $100 to $500 | Low; often free or low-cost apps with limited features |

| Ease of Implementation | Requires some technical knowledge for effective testing | Requires specialized training or hiring a technician | User-friendly; requires a compatible vehicle interface |

| Maintenance | Minimal; regular checks needed for accuracy | Moderate; tools may need calibration | Low; apps require software updates |

| Best Use Case | Suitable for basic troubleshooting in non-commercial settings | Best for in-depth diagnostics in workshops | Ideal for quick assessments by drivers or fleet managers |

Detailed Breakdown of Alternatives

Professional Diagnostic Tools

Professional diagnostic tools are sophisticated devices used by automotive technicians to analyze vehicle performance and pinpoint issues with the electrical system, including batteries and alternators. These tools can provide comprehensive data, including fault codes and real-time metrics, which can greatly enhance diagnostic accuracy.

Pros:

– High accuracy and detail, allowing for precise diagnostics.

– Can identify multiple issues simultaneously, saving time.

Cons:

– Higher initial investment and potential ongoing costs for maintenance.

– Requires trained personnel to operate effectively, which could lead to added labor costs.

Illustrative image related to how can you tell if battery or alternator is bad

Mobile App-Based Diagnostics

Mobile applications designed for vehicle diagnostics can offer a convenient solution for monitoring battery and alternator health. By connecting to the vehicle’s onboard diagnostics (OBD-II) system, these apps can provide users with real-time data and alerts about potential issues.

Pros:

– Cost-effective and easily accessible; many apps are free or low-cost.

– User-friendly interface allows even non-technical users to perform basic diagnostics.

Cons:

– Variable accuracy; results can depend on the quality of the app and the vehicle’s compatibility.

– Limited functionality compared to professional tools, often providing only surface-level insights.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, selecting the right diagnostic solution for battery and alternator issues hinges on several factors, including the scale of operation, budget constraints, and the level of technical expertise available. For smaller businesses or individuals, using basic diagnostic methods may suffice, especially if they have some technical knowledge. In contrast, larger operations or workshops might benefit from the investment in professional diagnostic tools to ensure high accuracy and efficiency. Alternatively, mobile app-based diagnostics can serve as a useful adjunct for quick assessments, particularly in fleet management scenarios. Ultimately, the best choice will align with operational needs and financial considerations, ensuring the most effective maintenance of vehicle performance.

Essential Technical Properties and Trade Terminology for how can you tell if battery or alternator is bad

What Key Technical Properties Should You Consider When Diagnosing Battery or Alternator Issues?

Understanding the technical properties related to batteries and alternators is crucial for B2B buyers, especially when making informed purchasing decisions. Here are some critical specifications to consider:

-

Voltage Output (V)

The standard voltage output for a healthy automotive battery is approximately 12.6 volts when fully charged. For alternators, the output typically ranges from 13 to 14.5 volts. This measurement is vital, as it indicates whether the battery is being adequately charged while the engine runs. A voltage reading below these levels may signal a malfunction, prompting further testing or replacement. -

Amperage Rating (A)

The amperage rating of an alternator can vary significantly based on the vehicle type and its electrical demands. Most passenger vehicle alternators range from 130 to 200 amps, while high-performance or commercial vehicles may require up to 400 amps. Understanding amperage is essential when assessing whether an alternator can support additional electrical loads, such as upgraded audio systems or other accessories. -

Cold Cranking Amps (CCA)

CCA measures a battery’s ability to start an engine in cold temperatures. The higher the CCA, the better the battery can perform under these conditions. This specification is particularly relevant in regions with extreme weather, as it affects the reliability of battery performance. B2B buyers should consider this rating when sourcing batteries for diverse climates. -

Cycle Life

Cycle life refers to the number of charge and discharge cycles a battery can undergo before its capacity significantly diminishes. Batteries with higher cycle lives are more suited for applications that require frequent starts and stops. This property is crucial for businesses operating vehicles in urban settings or for those using electric vehicles, as it impacts long-term operational costs. -

Internal Resistance (IR)

The internal resistance of a battery affects its efficiency and overall performance. A battery with high internal resistance will generate heat and lose voltage under load, reducing its effectiveness. Monitoring this property can help buyers identify aging batteries that may need replacement, ensuring optimal vehicle performance.

What Trade Terminology Is Essential for Understanding Battery and Alternator Performance?

Familiarity with industry terminology can greatly enhance communication and negotiations in the B2B sector. Here are key terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are marketed under another company’s brand name. In the context of batteries and alternators, OEM components are often preferred for their reliability and compatibility with existing systems. B2B buyers should ensure that they are sourcing OEM parts to maintain vehicle integrity. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses looking to manage inventory effectively and negotiate better pricing. Buyers should discuss MOQ with suppliers to align their purchasing strategies with their operational needs. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This is essential for comparing costs and services when sourcing batteries and alternators. An effective RFQ can help businesses secure competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers operating in global markets, as they affect the overall cost and logistics of acquiring batteries and alternators. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For businesses that rely on timely vehicle maintenance, understanding lead times is essential for operational planning. Buyers should inquire about lead times when negotiating with suppliers to avoid unexpected delays.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when diagnosing and sourcing solutions for battery and alternator issues.

Navigating Market Dynamics and Sourcing Trends in the how can you tell if battery or alternator is bad Sector

Market Overview & Key Trends in Battery and Alternator Diagnostics

The global automotive aftermarket is witnessing a dynamic shift, propelled by technological advancements and evolving consumer preferences. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of battery and alternator diagnostics is crucial. Emerging technologies, including advanced diagnostic tools and artificial intelligence, are streamlining the identification of battery and alternator issues. These innovations enable businesses to offer more efficient services, reducing downtime and enhancing customer satisfaction.

Moreover, the growing trend of electric vehicles (EVs) is reshaping the market landscape. As more consumers transition to EVs, the demand for battery performance diagnostics is surging. This shift necessitates that suppliers adapt their offerings to include specialized tools and training for EV components. Additionally, the rise of e-commerce platforms is influencing sourcing strategies, allowing buyers to access a wider range of diagnostic tools and components more conveniently.

Understanding local market dynamics is also essential. For example, in regions with extreme weather conditions, such as the Middle East and Northern Europe, the performance of batteries and alternators can be significantly impacted. This necessitates the sourcing of high-quality components that can withstand harsh conditions. B2B buyers must stay informed about regional trends and select suppliers that align with their operational needs to maintain competitive advantage.

How Can Sustainability & Ethical Sourcing Impact Battery and Alternator Diagnostics?

Sustainability and ethical sourcing are increasingly important in the automotive aftermarket, particularly concerning battery and alternator diagnostics. The environmental impact of battery production, particularly with lead-acid batteries, raises concerns about pollution and waste. B2B buyers are now prioritizing suppliers that demonstrate commitment to sustainability through responsible sourcing of materials and adherence to environmental regulations.

The adoption of ‘green’ certifications is becoming a critical factor in supplier selection. Certifications such as ISO 14001 for environmental management systems signal a supplier’s commitment to sustainable practices. Buyers are encouraged to seek partners who utilize eco-friendly materials in their products, including recyclable components for batteries and alternators. This not only aligns with corporate social responsibility goals but also attracts a growing segment of environmentally-conscious customers.

Furthermore, as regulations surrounding battery disposal tighten globally, buyers must ensure that their supply chains comply with these standards. Ethical sourcing practices can mitigate risks associated with non-compliance and enhance brand reputation. By prioritizing sustainability, businesses can also leverage marketing advantages, appealing to consumers who value eco-friendly practices.

Brief Evolution of Battery and Alternator Diagnostics

The evolution of battery and alternator diagnostics has been influenced by advancements in automotive technology and increased consumer expectations for reliability. Initially, diagnostics were largely mechanical, relying on visual inspections and basic electrical tests. However, as vehicles became more complex, the need for sophisticated diagnostic tools emerged.

The introduction of multimeters and specialized diagnostic equipment revolutionized the industry, allowing for more accurate assessments of battery and alternator performance. In recent years, the integration of software solutions and mobile applications has further streamlined diagnostics, enabling technicians to quickly identify issues and recommend solutions. This evolution reflects a broader trend in the automotive sector towards enhanced efficiency and customer-centric service delivery, making it imperative for B2B buyers to stay abreast of these developments to remain competitive.

Frequently Asked Questions (FAQs) for B2B Buyers of how can you tell if battery or alternator is bad

-

How do I determine if my vehicle’s battery or alternator is faulty?

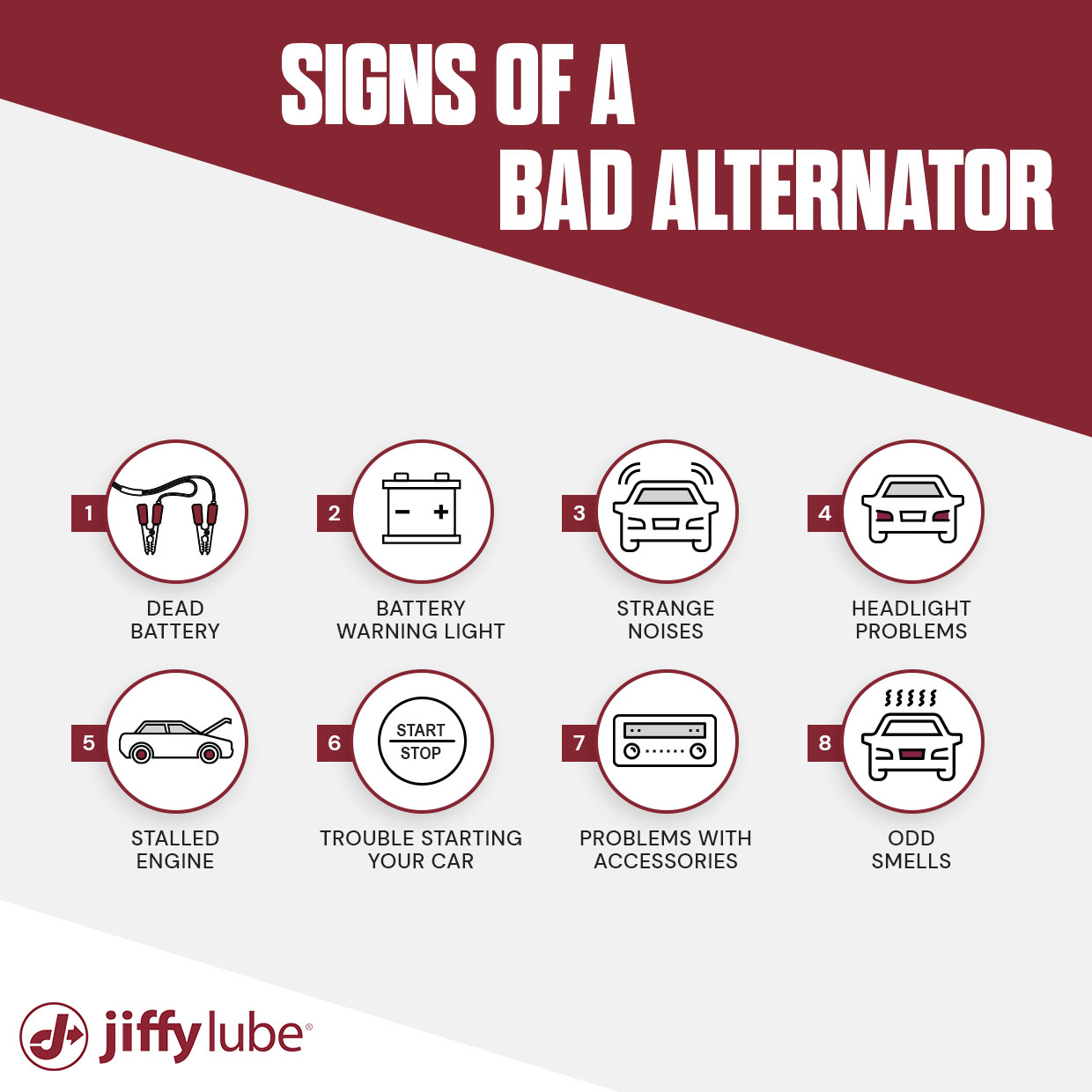

To diagnose whether the issue lies with the battery or alternator, start by checking the battery voltage using a multimeter. A healthy battery should read around 12.6 volts when the engine is off. If you start the engine and the voltage rises between 13 to 14.5 volts, the alternator is functioning correctly. If the battery voltage drops significantly after testing, it indicates a battery issue. Additionally, signs like dimming lights or difficulty starting the vehicle may suggest an alternator problem. -

What are the common symptoms of a bad battery?

Common symptoms of a failing battery include difficulty starting the vehicle, slow cranking of the engine, and the presence of a clicking sound when attempting to start. In colder climates, battery performance can decline further, leading to more pronounced issues. If the battery cannot hold a charge or frequently requires jump-starts, it may be time to replace it. Regular maintenance and testing can help prolong battery life and prevent unexpected failures. -

What are the telltale signs of a failing alternator?

Signs of a failing alternator include dimming or flickering headlights, erratic electrical accessory performance, and warning lights on the dashboard. If the vehicle starts but then dies shortly after, this may indicate an alternator problem, as it is responsible for maintaining electrical power while the engine runs. Monitoring these symptoms can help in early diagnosis and prevent further complications. -

How can I ensure quality when sourcing batteries and alternators internationally?

When sourcing batteries and alternators from international suppliers, consider conducting thorough supplier vetting, including reviewing certifications, customer testimonials, and industry experience. Request samples for quality inspection and ensure compliance with local regulations and standards. Establish clear communication with suppliers to discuss specifications, customization options, and any potential quality assurance processes they have in place. -

What customization options are available for batteries and alternators?

Customization options for batteries and alternators can vary based on supplier capabilities. Common customizations include size, voltage, capacity, and terminal types. Some suppliers may also offer branding options, such as logo printing on batteries. Be sure to communicate your specific requirements and inquire about minimum order quantities (MOQs) for customized products to align with your business needs. -

What should I know about minimum order quantities (MOQs) for batteries and alternators?

Minimum order quantities (MOQs) can vary significantly between suppliers and depend on factors like product type, customization, and production capabilities. When negotiating with suppliers, clarify their MOQ policies and see if they can accommodate smaller orders, especially if you’re a new business. Understanding MOQs is essential for managing inventory costs and ensuring you can meet market demand without overstocking. -

How do payment terms typically work for international B2B transactions?

Payment terms for international B2B transactions often include options such as advance payment, letters of credit, or payment upon delivery. It’s crucial to establish clear payment terms before finalizing any agreements. Discuss potential discounts for early payments or flexible terms based on order volume. Always ensure that payment methods are secure and compliant with international trade regulations to mitigate risks. -

What logistics considerations should I keep in mind when importing batteries and alternators?

When importing batteries and alternators, consider logistics factors such as shipping methods, customs clearance, and import regulations specific to your country. Research the best shipping options to minimize costs and transit times. Additionally, ensure that your suppliers provide necessary documentation, such as certificates of origin and compliance, to facilitate smooth customs processing. Partnering with a reliable logistics provider can help streamline the import process and ensure timely delivery of your products.

Top 2 How Can You Tell If Battery Or Alternator Is Bad Manufacturers & Suppliers List

1. Nationwide – Alternator Insights

Domain: blog.nationwide.com

Registered: 1994 (31 years)

Introduction: Alternator: Powers the car when the engine is running, charges the battery, typically lasts the lifetime of the car but can require repair or replacement due to wear and tear. Signs of a bad alternator include dim interior lights, fluctuating headlights, growling noises, and burning smells. Battery: Stores power, starts the engine, delivers electricity to the ignition system, works with the altern…

2. Alternator Testing – Risks and Recommendations

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: The text discusses a technique to test an alternator by removing a 12V battery lead while the vehicle is running. It highlights that this method is not recommended due to potential damage to the vehicle’s electronics and the alternator itself. It emphasizes that the battery plays a crucial role in filtering spikes and transients, and disconnecting it can lead to damage. A safer alternative mention…

Strategic Sourcing Conclusion and Outlook for how can you tell if battery or alternator is bad

In summary, understanding the differences between battery and alternator issues is critical for maintaining vehicle performance and minimizing downtime. Key indicators of battery failure include slow cranking, clicking sounds, or a complete inability to start the vehicle, while alternator problems often manifest as fluctuating light brightness or electrical accessory malfunctions. For B2B buyers, sourcing high-quality batteries and alternators is essential to ensure reliability and longevity in their fleet operations.

Strategic sourcing not only enables businesses to secure cost-effective solutions but also fosters relationships with suppliers who can provide ongoing support and technical expertise. As you navigate the complexities of vehicle maintenance, consider leveraging local suppliers and manufacturers in Africa, South America, the Middle East, and Europe to enhance your supply chain resilience.

Looking ahead, staying informed about advancements in battery and alternator technologies can provide a competitive edge. We encourage you to engage with trusted suppliers and invest in quality components to ensure your operations run smoothly. By prioritizing reliability and performance, your business can thrive in today’s dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.