Introduction: Navigating the Global Market for failed starter symptoms

In the ever-evolving landscape of automotive maintenance, understanding the symptoms of a failed starter is crucial for international B2B buyers. Whether you are sourcing parts for fleet vehicles in Africa, South America, the Middle East, or Europe, the ability to accurately identify and respond to failed starter symptoms can significantly impact operational efficiency and cost management. The starter is a vital component in the vehicle’s ignition system, and its failure can lead to operational downtime, increased repair costs, and customer dissatisfaction.

This comprehensive guide delves into the various types of starter failures, their symptoms, and actionable troubleshooting steps. We will explore the critical applications of starter systems across different vehicle types, from passenger cars to commercial fleets, ensuring that you have a holistic understanding of the market. Additionally, we will provide insights into supplier vetting processes, cost considerations, and best practices for maintenance, empowering you to make informed purchasing decisions.

By equipping yourself with the knowledge presented in this guide, you will be better positioned to navigate the complexities of sourcing reliable starter components. With a focus on practical solutions and expert advice, this resource aims to enhance your procurement strategy, ultimately driving efficiency and profitability in your operations.

Table Of Contents

- Top 3 Failed Starter Symptoms Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for failed starter symptoms

- Understanding failed starter symptoms Types and Variations

- Key Industrial Applications of failed starter symptoms

- 3 Common User Pain Points for ‘failed starter symptoms’ & Their Solutions

- Strategic Material Selection Guide for failed starter symptoms

- In-depth Look: Manufacturing Processes and Quality Assurance for failed starter symptoms

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘failed starter symptoms’

- Comprehensive Cost and Pricing Analysis for failed starter symptoms Sourcing

- Alternatives Analysis: Comparing failed starter symptoms With Other Solutions

- Essential Technical Properties and Trade Terminology for failed starter symptoms

- Navigating Market Dynamics and Sourcing Trends in the failed starter symptoms Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of failed starter symptoms

- Strategic Sourcing Conclusion and Outlook for failed starter symptoms

- Important Disclaimer & Terms of Use

Understanding failed starter symptoms Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clicking Sound | A distinct clicking noise when the ignition is turned. | Automotive repair shops, fleet services | Pros: Easy to diagnose; quick fix possible. Cons: May indicate underlying issues. |

| Whirring or Grinding Noise | Unusual sounds during ignition attempts. | Heavy machinery maintenance, vehicle fleets | Pros: Clear symptom of starter issues. Cons: May require replacement rather than repair. |

| Dashboard Lights On, No Start | Instrument cluster lights up but engine fails to crank. | Commercial vehicle service providers | Pros: Indicates electrical issue; may be battery-related. Cons: Requires further diagnostic testing. |

| Smoke or Burning Smell | Visible smoke or odor during starting attempts. | Emergency vehicle services, logistics | Pros: Immediate indication of serious failure. Cons: Indicates severe damage; costly repairs likely. |

| Oil Leakage | Oil-soaked starter indicating potential leaks. | Automotive parts suppliers, mechanics | Pros: Identifies broader engine issues. Cons: Requires comprehensive inspection and potential repairs. |

What Are the Key Characteristics of a Clicking Sound in Starters?

The clicking sound is often the first sign of starter failure. This symptom indicates that the starter motor is receiving power but is unable to engage the engine. For B2B buyers, especially those in automotive repair and fleet services, this symptom is critical. It can often be resolved with a simple battery check or connection tightening, making it a cost-effective issue to address. However, it may also suggest deeper electrical problems that could lead to more significant repairs, thus necessitating thorough diagnostics.

How Can Whirring or Grinding Noises Impact Your Operations?

Whirring or grinding noises during ignition attempts are clear indicators of starter issues. These sounds typically suggest that the starter gear is not properly engaging with the flywheel, which can lead to complete starter failure. For businesses operating heavy machinery or vehicle fleets, recognizing this symptom is vital for minimizing downtime. While these noises can sometimes be remedied with repairs, they often indicate that replacement is necessary, which can incur higher costs and logistical challenges.

Why Is It Important to Recognize Dashboard Lights On with No Start?

When the dashboard lights illuminate but the engine does not crank, it signals a potential starter or electrical system failure. This symptom is particularly relevant for commercial vehicle service providers who need to ensure fleet readiness. Identifying this issue early can prevent more extensive diagnostics and repairs. However, it often requires further testing to determine whether the starter, battery, or alternator is at fault, which can extend repair times and impact service schedules.

What Are the Implications of Smoke or a Burning Smell from the Starter?

The presence of smoke or a burning smell during starting attempts is a serious indicator of starter failure. This symptom suggests overheating or electrical shorts, which can lead to catastrophic failures if not addressed promptly. For emergency vehicle services and logistics companies, this is a critical concern as it can result in significant downtime and costly repairs. Immediate professional intervention is required to prevent further damage and restore operational efficiency.

How Does Oil Leakage Affect Starter Functionality?

Oil leakage onto the starter can severely impair its functionality, leading to premature failure. This symptom often indicates broader engine issues that need to be addressed. For automotive parts suppliers and mechanics, recognizing oil-soaked starters is essential for providing comprehensive service. Addressing oil leaks not only ensures the starter’s longevity but also prevents potential damage to other engine components, making it a key consideration for B2B buyers focused on vehicle maintenance and repair.

Key Industrial Applications of failed starter symptoms

| Industry/Sector | Specific Application of failed starter symptoms | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnostics in workshop settings for vehicle starters | Reduces downtime and enhances customer satisfaction through efficient repairs | Availability of diagnostic tools and skilled technicians |

| Transportation & Logistics | Fleet maintenance for commercial vehicles | Ensures operational reliability and minimizes unexpected breakdowns | Access to quality replacement parts and maintenance contracts |

| Construction Equipment | Maintenance of heavy machinery and equipment | Prevents costly delays in projects due to equipment failure | Supplier reliability and availability of specialized starter components |

| Agriculture | Repair and maintenance of farm machinery | Enhances productivity and reduces the risk of crop loss | Sourcing durable and weather-resistant components for harsh environments |

| Mining | Maintenance of vehicles and machinery in remote locations | Ensures continuous operation and safety in challenging environments | Logistics for parts delivery and expertise in rugged machinery repair |

How Are Failed Starter Symptoms Applied in the Automotive Repair Industry?

In the automotive repair sector, diagnosing failed starter symptoms is crucial for workshop efficiency. Mechanics utilize signs like clicking sounds or a non-responsive engine to quickly identify starter issues, facilitating prompt repairs. This not only reduces vehicle downtime but also enhances customer satisfaction as vehicles are returned to service more swiftly. For international B2B buyers, sourcing reliable diagnostic tools and ensuring skilled technicians are available is vital for maintaining high service standards.

What Role Do Failed Starter Symptoms Play in Transportation & Logistics?

Within the transportation and logistics industry, fleet maintenance hinges on recognizing failed starter symptoms. Identifying issues early, such as dim lights or unusual noises, allows fleet managers to schedule timely repairs, thus preventing unexpected breakdowns that can disrupt operations. This proactive approach enhances reliability and efficiency, critical in maintaining service contracts. Buyers should focus on establishing relationships with suppliers who provide quality replacement parts and offer comprehensive maintenance contracts to support ongoing vehicle performance.

How Are Failed Starter Symptoms Relevant in Construction Equipment Maintenance?

In the construction industry, equipment reliability is paramount, making the identification of failed starter symptoms essential. Symptoms like grinding noises or smoking from the starter can indicate potential failures that could halt operations. By addressing these issues promptly, construction firms can avoid costly project delays. Buyers should consider sourcing durable and weather-resistant starter components, as well as ensuring that suppliers can provide timely support for repairs in often harsh working environments.

Why Are Failed Starter Symptoms Important for Agricultural Machinery?

For agricultural operations, recognizing failed starter symptoms in farm machinery is vital to prevent productivity losses. Symptoms such as slow engine cranking or clicking sounds can signal starter issues that, if left unaddressed, may lead to machinery failure during critical planting or harvesting periods. B2B buyers in this sector should prioritize sourcing parts that are not only reliable but also designed to withstand the rigors of outdoor use, ensuring that their equipment operates smoothly throughout the growing season.

How Do Failed Starter Symptoms Impact Mining Operations?

In mining, where vehicles and machinery often operate in remote locations, understanding failed starter symptoms is crucial for maintaining continuous operations. Symptoms like a single click when attempting to start can indicate starter failure, potentially jeopardizing safety and productivity. To mitigate these risks, mining companies must ensure a steady supply of quality parts and have technicians available who are experienced in repairing rugged machinery. Logistics for parts delivery and expertise in maintenance are critical considerations for international buyers in this sector.

3 Common User Pain Points for ‘failed starter symptoms’ & Their Solutions

Scenario 1: Delayed Shipments Due to Starter Failures

The Problem: A logistics company based in South Africa has a fleet of delivery trucks. Recently, they have been experiencing frequent starter failures, leading to delays in their shipment schedules. The issue escalates during peak delivery seasons when the demand is high, causing lost revenue and customer dissatisfaction. The challenge lies in diagnosing whether the problem is with the starter, battery, or alternator, as symptoms often overlap, complicating timely repairs.

The Solution: To mitigate this issue, B2B buyers should invest in comprehensive diagnostic tools specifically designed for their fleet vehicles. These tools can help accurately determine whether the starter, battery, or alternator is at fault, enabling quicker repairs. Additionally, implementing a regular maintenance schedule that includes checking the starter’s condition can prevent unexpected failures. Establishing partnerships with reliable automotive service providers for regular inspections and repairs can also streamline operations. Moreover, educating drivers on recognizing early warning signs of starter failure, such as unusual noises or delayed engine cranking, can significantly reduce downtime.

Illustrative image related to failed starter symptoms

Scenario 2: Increased Repair Costs from Misdiagnosis

The Problem: An automotive parts distributor in Brazil faces rising repair costs due to frequent misdiagnosis of starter symptoms. Mechanics often replace batteries or alternators when the actual issue lies with the starter. This not only leads to unnecessary parts replacements but also strains relationships with clients who expect accurate assessments and cost-effective solutions.

The Solution: To address this pain point, it is essential for B2B buyers to provide their clients with detailed training on starter systems and symptom identification. Hosting workshops or webinars that educate mechanics on the specific signs of starter failure, such as clicking sounds or dashboard alerts, can empower them to make more informed decisions. Additionally, offering a comprehensive starter troubleshooting guide can help mechanics better assess the situation before replacing parts. By promoting the use of diagnostic equipment that tests the starter’s performance, buyers can help ensure that repairs are accurately diagnosed, thus reducing unnecessary costs and improving client satisfaction.

Scenario 3: Inventory Management Challenges for Starter Parts

The Problem: A vehicle repair shop in the Middle East is struggling with inventory management for starter parts due to the unpredictable nature of starter failures. They often find themselves either overstocked on certain models or understocked on others, leading to wasted resources or delays in servicing vehicles. This inconsistency affects their operational efficiency and profitability.

The Solution: To streamline inventory management, B2B buyers should implement an inventory tracking system that monitors starter part usage and failure trends. By analyzing historical data on starter replacements and correlating it with seasonal demand, repair shops can better predict which parts to stock up on. Additionally, establishing relationships with multiple suppliers can ensure quick access to necessary parts without overcommitting to inventory. Adopting a just-in-time inventory strategy can also help maintain optimal stock levels while minimizing waste. Regularly reviewing inventory turnover rates and adjusting orders based on demand forecasts will ensure that the repair shop is prepared for any surge in starter-related repairs, thereby enhancing service delivery and profitability.

Strategic Material Selection Guide for failed starter symptoms

What Materials Are Commonly Used in Starter Systems and Their Performance?

When evaluating materials for components related to failed starter symptoms, it is essential to consider the properties and performance characteristics that directly affect durability, functionality, and compatibility with various environments. Below, we analyze several materials commonly used in starter systems, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Copper Benefit Starter Systems?

Key Properties: Copper is known for its excellent electrical conductivity and thermal properties, making it ideal for electrical connections in starter systems. It can withstand moderate temperatures and has good corrosion resistance when properly treated.

Pros & Cons: The primary advantage of copper is its superior conductivity, which ensures efficient power transfer from the battery to the starter. However, copper can be more expensive than alternatives like aluminum and is prone to corrosion if not adequately protected, particularly in humid or saline environments.

Impact on Application: Copper’s high conductivity is crucial for ensuring reliable starter performance. However, in regions with high humidity or salt exposure, the risk of corrosion necessitates protective coatings or treatments.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with standards such as ASTM B187 for copper products. Additionally, they should consider local environmental conditions that may affect copper’s longevity.

Illustrative image related to failed starter symptoms

Why Choose Aluminum for Starter Components?

Key Properties: Aluminum is lightweight and has good corrosion resistance, particularly when anodized. It can handle moderate temperatures but has lower conductivity compared to copper.

Pros & Cons: The lightweight nature of aluminum makes it suitable for applications where weight is a concern, such as in automotive design. However, its lower conductivity can lead to inefficiencies in power transfer, and its mechanical properties may not be as robust as those of copper.

Impact on Application: Aluminum is often used in starter housings and components where weight reduction is essential. However, its use in electrical connections should be carefully evaluated to avoid performance issues.

Considerations for International Buyers: Buyers in Europe and South America should be aware of standards such as EN 573 for aluminum alloys. They should also consider the local availability of aluminum and its treatment processes to ensure optimal performance.

What Role Does Steel Play in Starter Systems?

Key Properties: Steel offers high strength and durability, with good resistance to wear and tear. It can handle high temperatures but is susceptible to corrosion if not treated.

Pros & Cons: The strength of steel makes it suitable for structural components in starter systems, such as mounting brackets. However, untreated steel can rust, especially in coastal or humid climates, leading to potential failures.

Impact on Application: Steel is often used in components that require high mechanical strength. Buyers must ensure that any steel components are adequately treated or coated to prevent corrosion.

Considerations for International Buyers: Compliance with standards such as ASTM A36 for structural steel is crucial. Buyers should also consider local environmental conditions and the need for corrosion-resistant coatings.

How Do Plastics Enhance Starter Components?

Key Properties: Plastics, particularly high-performance polymers, offer lightweight, corrosion resistance, and electrical insulation properties. They can operate effectively within a range of temperatures.

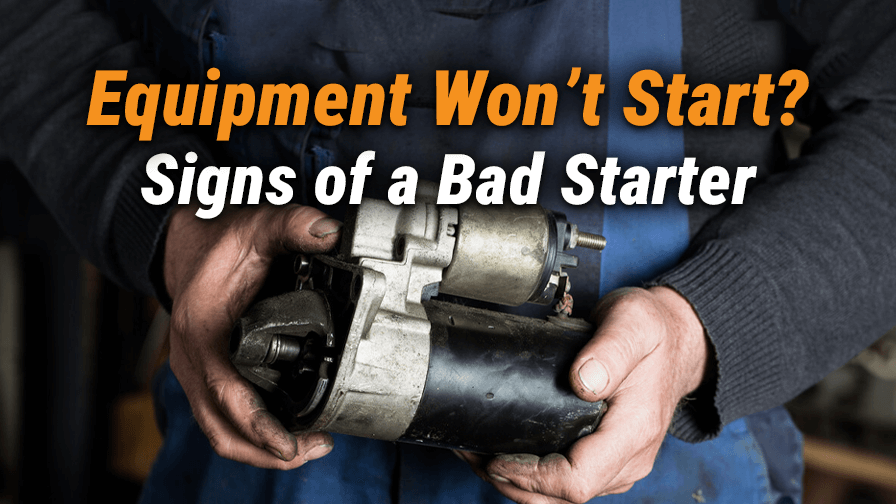

Illustrative image related to failed starter symptoms

Pros & Cons: Plastics are often used for non-structural components, providing insulation and reducing weight. However, they may not withstand high temperatures as effectively as metals, and their mechanical strength can be lower.

Impact on Application: Plastics can be ideal for housings and insulation components within the starter system. However, their use in high-stress applications should be approached with caution.

Considerations for International Buyers: Buyers should ensure that the plastics used meet relevant standards such as ISO 9001 for quality management. Additionally, they should consider the specific thermal and mechanical requirements of their applications.

Summary Table of Material Selection for Starter Systems

| Material | Typical Use Case for failed starter symptoms | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections in starters | Excellent electrical conductivity | Prone to corrosion without treatment | High |

| Aluminum | Starter housings and lightweight components | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Steel | Structural components like brackets | High strength and durability | Susceptible to corrosion | Medium |

| Plastics | Insulation and non-structural components | Lightweight and corrosion-resistant | Lower mechanical strength | Low |

This analysis provides B2B buyers with actionable insights into material selection for starter systems, emphasizing the importance of understanding both the performance characteristics and the environmental conditions specific to their regions.

In-depth Look: Manufacturing Processes and Quality Assurance for failed starter symptoms

What are the Key Stages in the Manufacturing Process of Starters?

The manufacturing process of automotive starters involves several crucial stages, each designed to ensure the final product meets rigorous performance and quality standards. Understanding these stages helps B2B buyers make informed decisions when sourcing from suppliers.

1. Material Preparation: What Materials Are Used in Starter Manufacturing?

The first step in starter manufacturing is the careful selection and preparation of materials. Starters typically consist of metals like aluminum and steel, as well as various electrical components such as copper windings and magnets. Suppliers must ensure that these materials comply with international standards to guarantee durability and performance.

Key techniques in this stage include:

- Material Inspection: Ensuring raw materials meet specifications through chemical and physical testing.

- Machining: Cutting and shaping materials to precise dimensions, which is critical for components like the starter motor and gear assembly.

2. Forming: How Are Starter Components Shaped?

Once materials are prepared, the next stage involves forming components into their final shapes. This can include processes like die-casting for aluminum parts, stamping for metal casings, and winding for copper coils.

Techniques employed during this stage may include:

- CNC Machining: Automated cutting processes that ensure high precision and repeatability.

- Injection Molding: Used for creating plastic components, which are often part of the housing or insulation.

3. Assembly: How Are Starters Assembled?

Assembly is a critical phase where all components come together to form the final starter unit. This process can be labor-intensive and often requires skilled technicians to ensure that each part is correctly positioned and secured.

Key assembly techniques include:

- Manual Assembly: Skilled workers assemble components, ensuring proper alignment and connection.

- Automated Assembly Lines: Utilizing robotics to speed up production while maintaining high accuracy.

Quality checks during assembly are crucial. Manufacturers often employ techniques like torque testing and visual inspections to ensure that each starter is assembled correctly.

4. Finishing: What Final Touches Are Applied to Starters?

The finishing stage involves applying protective coatings, such as paints or rust inhibitors, to increase the longevity of the starter. This step also includes final inspections to check for cosmetic and functional defects.

Techniques used in the finishing process may include:

- Electroplating: Enhancing corrosion resistance for metal parts.

- Painting or Coating: Providing an aesthetic finish and additional protection.

What Quality Assurance Processes Are Essential for Starters?

Quality assurance (QA) is vital in the manufacturing of starters to ensure reliability and safety. B2B buyers must understand the various quality assurance processes and international standards that govern this industry.

Relevant International Standards: What Certifications Should Buyers Look For?

Several international standards are applicable to starter manufacturing, including:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality throughout the production process.

- CE Marking: Indicates compliance with European safety standards, particularly important for buyers in Europe.

- API Specifications: Relevant for automotive parts, ensuring they meet industry performance standards.

Key Quality Control Checkpoints: How Are Starters Tested?

Quality control (QC) checkpoints are integral to maintaining product quality at various stages of manufacturing:

- Incoming Quality Control (IQC): Assessing the quality of incoming materials before they enter the production line.

- In-Process Quality Control (IPQC): Conducting tests during the manufacturing process to detect defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all specifications before shipment.

Common testing methods for starters include:

- Electrical Testing: Verifying that the starter operates within specified voltage and current parameters.

- Durability Testing: Assessing the starter’s performance under various environmental conditions, including extreme temperatures and humidity.

- Noise and Vibration Testing: Ensuring that the starter operates quietly and smoothly.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential for ensuring product reliability.

What Audit Processes Should Be Implemented?

- Supplier Audits: Regular audits of suppliers can help verify compliance with international quality standards. Buyers should request documentation of these audits, including any corrective actions taken.

- Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes and results from any testing performed.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes. These inspections typically include:

- Pre-shipment Inspections: Ensuring that products meet specifications before they are shipped.

- Random Sampling: Testing a selection of products from a batch to verify overall quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate specific nuances related to quality control, especially when sourcing from regions with different regulatory standards.

- Cultural Differences: Understanding local manufacturing practices and quality expectations can aid in establishing better supplier relationships.

- Regulatory Compliance: Buyers must ensure that suppliers comply with both local and international regulations relevant to automotive parts, which can differ significantly by region.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring that the starters they source are reliable and meet the required performance standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘failed starter symptoms’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure solutions for diagnosing and addressing failed starter symptoms in vehicles. Understanding the complexities of starter systems is crucial for effective troubleshooting and ensuring that your procurement decisions lead to reliable vehicle performance. This checklist will help you systematically evaluate your needs and find the right suppliers.

Step 1: Identify Specific Symptoms

Understanding the specific symptoms of a failed starter is the first step in your procurement process. Look for indicators such as unusual sounds (clicking or grinding), non-responsive engines, or dashboard lights that illuminate without the engine starting. Documenting these symptoms will help you communicate effectively with suppliers and technicians, ensuring they can provide the most relevant solutions.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications needed for the starter system components. This includes voltage ratings, size compatibility, and the specific vehicle models you are servicing. By defining these parameters, you can avoid miscommunications with suppliers and ensure that the products you source will fit your operational requirements.

Step 3: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in starter systems and related components. Look for companies with a solid reputation and experience in your target regions, such as Africa, South America, the Middle East, and Europe. Utilize online reviews, industry reports, and trade associations to gather insights about their reliability and service quality.

Step 4: Verify Supplier Certifications

Before proceeding with any supplier, verify their certifications and industry standards compliance. This includes checking for ISO certifications, quality management systems, and any relevant local regulations. Ensuring that your supplier adheres to these standards can mitigate risks associated with product failures and enhance your operational efficiency.

Illustrative image related to failed starter symptoms

Step 5: Request Samples or Demonstrations

Once you have shortlisted potential suppliers, request samples or demonstrations of their starter systems. This step allows you to assess the quality and performance of their products firsthand. Pay attention to the ease of installation, compatibility with existing systems, and overall functionality during testing.

Step 6: Evaluate Warranty and Support Options

Evaluate the warranty and support options offered by suppliers. A comprehensive warranty can protect your investment and provide peace of mind in case of defects or failures. Additionally, ensure that the supplier offers robust customer support, including technical assistance and troubleshooting resources, which can be invaluable in maintaining system performance.

Step 7: Compare Pricing and Terms

Finally, compare pricing and procurement terms from various suppliers. Look beyond the initial cost; consider factors such as bulk pricing, shipping costs, and lead times. A thorough cost analysis can help you make an informed decision that balances quality and budget constraints, ensuring long-term satisfaction with your procurement choices.

Illustrative image related to failed starter symptoms

By following this checklist, you can effectively navigate the complexities of sourcing solutions for failed starter symptoms and ensure a successful procurement process.

Comprehensive Cost and Pricing Analysis for failed starter symptoms Sourcing

What Are the Key Cost Components in Sourcing Solutions for Failed Starter Symptoms?

When sourcing components related to failed starter symptoms, several cost components must be taken into account. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metals and electronic components often lead to better-performing starters but can increase upfront costs. Conversely, cheaper materials may reduce initial expenses but could result in higher failure rates and subsequent costs.

-

Labor: Labor costs vary by region and can be influenced by skill levels and local wage standards. For instance, manufacturing in regions with lower labor costs might seem attractive, but quality may suffer, leading to higher long-term expenses for repairs and replacements.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help keep these costs low.

-

Tooling: The requirement for specialized tools can add to initial costs. Custom tooling for specific starter designs may be necessary, and this should be factored into the pricing structure.

-

Quality Control (QC): Implementing robust QC measures ensures that the final product meets reliability standards. While this adds to the cost, it is a crucial investment to reduce the risk of failures that could lead to warranty claims and customer dissatisfaction.

-

Logistics: Shipping and handling can significantly affect total costs, especially for international transactions. Buyers should consider not only the freight charges but also customs duties and potential delays.

-

Margin: Suppliers typically add a profit margin to their cost structure. Understanding the market dynamics can help buyers negotiate better pricing.

How Do Price Influencers Affect Sourcing for Failed Starter Symptoms?

Several factors can influence pricing, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities can lead to significant discounts, allowing for a more favorable cost structure. Establishing a good relationship with suppliers can also provide leverage for better pricing.

-

Specifications and Customization: Customized solutions often come at a premium. Buyers should clearly define their requirements to avoid unnecessary costs associated with last-minute changes.

-

Materials: The choice of materials can dictate price variances. Premium materials may enhance performance and longevity but will incur higher costs. Balance the need for quality against budget constraints.

-

Quality and Certifications: Products that meet international quality standards may be priced higher due to the rigorous testing and certification processes. However, these certifications can offer peace of mind regarding reliability.

-

Supplier Factors: Supplier reputation, reliability, and market presence can impact pricing. Established suppliers with proven track records may charge higher prices, reflecting their quality assurance and service levels.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is essential. They define responsibilities for costs and risks, which can influence the total landed cost of the products.

What Are the Best Practices for Buyers Sourcing Failed Starter Solutions?

To optimize sourcing strategies, buyers should adopt the following best practices:

-

Negotiation: Engage in open discussions with suppliers to negotiate better terms and pricing. Leverage bulk purchasing to secure discounts.

-

Cost Efficiency: Look beyond the initial purchase price. Consider the Total Cost of Ownership (TCO), which includes maintenance, warranty, and replacement costs. This will provide a clearer picture of long-term value.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and local market conditions that can affect pricing. Establishing contracts in stable currencies can mitigate risks.

-

Quality Assurance: Prioritize suppliers who offer warranties and have a solid reputation for quality. This can reduce the likelihood of costly failures down the line.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service in the long run. Regular communication and feedback can foster collaboration.

Disclaimer on Indicative Prices

Prices for components related to failed starter symptoms can vary widely based on the factors discussed above. Buyers are advised to conduct thorough research and obtain multiple quotes to ensure they are getting competitive pricing aligned with their specific needs.

Alternatives Analysis: Comparing failed starter symptoms With Other Solutions

Exploring Alternatives to Failed Starter Symptoms for Automotive Solutions

When it comes to diagnosing automotive issues, particularly with vehicle starting problems, understanding the symptoms of a failed starter is critical. However, B2B buyers should also consider alternative diagnostic methods or technologies that can provide similar insights into vehicle performance and reliability. This analysis compares ‘failed starter symptoms’ with two alternative approaches: advanced diagnostic tools and mobile mechanic services.

Illustrative image related to failed starter symptoms

| Comparison Aspect | Failed Starter Symptoms | Advanced Diagnostic Tools | Mobile Mechanic Services |

|---|---|---|---|

| Performance | Identifies starter issues through symptoms like clicking sounds or dashboard alerts. | Provides comprehensive diagnostics and can identify multiple vehicle issues quickly. | Offers hands-on diagnosis and repair at the location of the vehicle, ensuring convenience. |

| Cost | Low cost for basic troubleshooting but may lead to higher repair costs if the issue is misdiagnosed. | Initial investment can be high, but can save costs in the long run by reducing misdiagnoses. | Costs vary based on service but typically include labor and travel fees. |

| Ease of Implementation | Requires basic knowledge of vehicle systems; can be challenging for non-experts. | Requires trained personnel to operate the tools effectively; some tools are user-friendly for laypersons. | Highly convenient as services are brought to the customer’s location, but availability may vary. |

| Maintenance | Minimal; involves periodic checks on symptoms and vehicle performance. | Requires regular updates and maintenance of diagnostic software and tools. | Ongoing relationships with mechanics may lead to better long-term vehicle care. |

| Best Use Case | Suitable for quick assessments by those familiar with automotive systems. | Ideal for businesses with fleets needing regular and thorough diagnostics. | Best for individual vehicle owners or small businesses needing on-site services without the hassle of towing. |

What Are the Pros and Cons of Advanced Diagnostic Tools?

Advanced diagnostic tools utilize cutting-edge technology to provide detailed insights into vehicle performance. These tools can quickly identify issues beyond just the starter, such as problems with the alternator or battery. The pros include a comprehensive analysis that can prevent misdiagnosis and save on repair costs. However, the initial investment can be significant, and the need for trained personnel to operate these tools effectively can be a barrier for smaller businesses.

How Do Mobile Mechanic Services Compare?

Mobile mechanic services offer the convenience of on-site diagnostics and repairs, which is particularly beneficial for businesses with fleets or individual customers who may not have the time to visit a repair shop. These services can diagnose issues, including those related to the starter, and provide immediate repairs. While the convenience is a major advantage, costs can vary based on the mechanic’s travel distance and service fees, and availability may be limited in certain regions.

Conclusion: Choosing the Right Solution for Your Needs

B2B buyers must weigh the pros and cons of each alternative when considering how to address failed starter symptoms. For those with a strong understanding of vehicle systems, relying on symptom identification can be sufficient for quick assessments. Alternatively, investing in advanced diagnostic tools may be more beneficial for businesses that require thorough and accurate diagnostics across multiple vehicles. Finally, mobile mechanic services provide a convenient option for immediate assistance but may come with variability in cost and availability. Ultimately, selecting the right solution will depend on the specific needs, budget, and operational structure of the buyer’s business.

Essential Technical Properties and Trade Terminology for failed starter symptoms

What Are the Key Technical Properties of Starter Systems and Their Failures?

In the context of automotive starter systems, understanding the essential technical properties is crucial for B2B buyers to ensure they procure reliable components. Here are some critical specifications to consider:

Illustrative image related to failed starter symptoms

-

Material Grade

– The materials used in starter construction, such as aluminum, copper, and steel, directly affect durability and performance. High-grade materials can withstand harsh conditions, reducing the likelihood of failure. For buyers, selecting components made from premium materials can lead to longer service life and lower replacement costs. -

Electrical Resistance

– The electrical resistance of starter components, such as the windings and connections, impacts efficiency. Lower resistance translates to better conductivity, which is vital for reliable engine cranking. Buyers should evaluate the resistance specifications to ensure optimal performance, particularly in regions with extreme temperatures. -

Torque Rating

– Torque rating indicates the amount of rotational force a starter can exert to turn the engine over. This is particularly important for larger engines that require more power to start. Understanding torque ratings helps buyers match starters to specific engine requirements, avoiding performance issues or failures. -

Temperature Tolerance

– Starters must operate effectively within a certain temperature range. Components that can withstand extreme heat or cold are essential in regions with fluctuating climates. Buyers should prioritize starters with high-temperature tolerance to prevent premature failure, which can lead to costly downtimes. -

Duty Cycle

– The duty cycle defines how long a starter can operate before needing a cooldown period. This specification is crucial for high-demand applications, such as fleet vehicles or heavy machinery. Buyers should consider the duty cycle to ensure that the starter can handle their operational needs without risk of overheating or failure.

What Are Common Trade Terms in the Starter Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation processes for B2B buyers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– OEM refers to products made by the original manufacturer of a vehicle. These parts often ensure compatibility and quality but can be more expensive. Buyers should weigh the benefits of OEM parts against aftermarket options based on their specific needs and budgets. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers manage inventory effectively and negotiate better pricing terms. It’s particularly important for businesses looking to maintain a steady supply without overcommitting financially. -

RFQ (Request for Quotation)

– An RFQ is a formal process where buyers request pricing and terms from suppliers. This document typically includes detailed specifications and quantities. Buyers should prepare comprehensive RFQs to ensure they receive accurate and competitive quotes, facilitating better procurement decisions. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for managing shipping costs, risks, and delivery responsibilities. Buyers should familiarize themselves with relevant Incoterms to avoid misunderstandings and ensure smooth transactions. -

Warranty Period

– The warranty period refers to the timeframe during which a manufacturer guarantees the performance of a starter. This is a crucial consideration for buyers, as a longer warranty often indicates confidence in product quality. Evaluating warranty terms can help buyers mitigate risks associated with component failures. -

Aftermarket Parts

– Aftermarket parts are components made by third-party manufacturers, not by the original vehicle manufacturer. These parts can offer cost savings and variety, but their quality may vary. Buyers should assess aftermarket options based on performance reviews and compatibility with their specific vehicles.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when procuring starter systems, ensuring they select the most suitable components for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the failed starter symptoms Sector

What Are the Key Trends Affecting the Failed Starter Symptoms Market?

The market for components related to failed starter symptoms is influenced by several global drivers, particularly as automotive technology evolves. One major trend is the increasing integration of electric vehicles (EVs) into the global automotive landscape. As more manufacturers pivot towards EVs, traditional starter systems will undergo significant changes, prompting B2B buyers to seek out innovative solutions and components that meet new standards.

Another emerging trend is the rise of digital diagnostic tools that help identify starter-related issues more effectively. These tools leverage advanced algorithms and machine learning, enabling technicians to pinpoint problems quickly and accurately. Consequently, international buyers, particularly from regions like Africa and South America, should consider suppliers who are adopting these technological advancements to improve service efficiency.

Additionally, the demand for high-quality, durable components remains strong as businesses strive to minimize downtime and repair costs. This is particularly relevant in regions such as the Middle East and Europe, where extreme weather conditions can accelerate wear and tear on starter systems. Understanding these dynamics can help B2B buyers make informed sourcing decisions, prioritizing suppliers that offer reliable products and innovative diagnostic solutions.

How Important Is Sustainability and Ethical Sourcing in the Failed Starter Symptoms Sector?

Sustainability and ethical sourcing are becoming increasingly critical in the failed starter symptoms sector. Environmental concerns are driving manufacturers to adopt practices that minimize waste and reduce the carbon footprint of their products. This includes using recycled materials and ensuring that production processes comply with stringent environmental regulations.

For B2B buyers, the importance of ethical supply chains cannot be overstated. Suppliers who prioritize sustainability not only enhance their brand image but also contribute to a positive corporate social responsibility (CSR) profile. B2B buyers from regions such as Europe, where consumers are increasingly aware of ethical sourcing, may find that partnering with sustainable suppliers opens up new market opportunities.

Moreover, certifications such as ISO 14001, which focuses on effective environmental management systems, can serve as valuable indicators of a supplier’s commitment to sustainability. Buyers should actively seek out suppliers who possess such certifications or use ‘green’ materials in their manufacturing processes, as this can significantly enhance product appeal in eco-conscious markets.

What Is the Historical Context of the Failed Starter Symptoms Market?

The evolution of the failed starter symptoms market can be traced back to the early days of automotive engineering. Initially, vehicles relied on simple mechanical systems for starting engines, which were prone to frequent failures. With advancements in technology, the introduction of electric starters revolutionized the automotive industry, significantly improving reliability and performance.

Over the decades, as vehicles became more complex with the integration of electronic systems, the interdependence of the battery, alternator, and starter emerged as a critical factor in vehicle functionality. This evolution necessitated a corresponding growth in the aftermarket sector, where B2B suppliers began to offer specialized components and diagnostic tools to address increasingly sophisticated starter issues.

Today, the market continues to evolve, driven by technological advancements and changing consumer expectations. As electric vehicles gain traction and sustainability becomes a priority, the failed starter symptoms sector will likely see further innovations that cater to both performance and environmental needs. Understanding this historical context can help B2B buyers appreciate the complexity of sourcing and the importance of partnering with forward-thinking suppliers.

Frequently Asked Questions (FAQs) for B2B Buyers of failed starter symptoms

-

How do I identify symptoms of a failed starter in vehicles?

Identifying a failed starter involves observing specific symptoms. Common signs include unusual sounds such as clicking or grinding when turning the key, a dashboard that lights up without the engine cranking, and repeated failure to start even after jump-starting attempts. If you notice smoke or burning smells, it’s essential to seek professional help immediately. Regular maintenance checks can also help identify starter issues before they lead to a complete failure. -

What is the best way to troubleshoot a starter problem?

To troubleshoot a starter problem, first, check the battery and its connections, as many issues stem from these components. A weak battery or corroded cables can mimic starter failure. If the battery checks out, try tapping the starter gently, which may realign its internal components temporarily. If your vehicle won’t start in “park,” try “neutral.” If these steps fail, consult a professional technician for a thorough inspection. -

How can I ensure the quality of starters sourced from international suppliers?

To ensure quality, vet suppliers by reviewing their certifications, production standards, and customer feedback. Request samples for testing and evaluate their compliance with international quality assurance standards. Establish clear communication regarding quality expectations and inspection processes. Consider suppliers who offer warranty periods, as this indicates confidence in their product quality. -

What are common payment terms in international trade for automotive parts?

Payment terms can vary significantly among suppliers, but common options include letters of credit, advance payments, and open account terms. It’s essential to negotiate terms that protect your financial interests while fostering a good relationship with the supplier. Understanding the currency exchange implications and ensuring secure transaction methods are also crucial for international deals. -

What is the minimum order quantity (MOQ) for starters when sourcing internationally?

MOQs for starters can vary based on the manufacturer and market demand. Typically, they range from 50 to several hundred units. Discussing your specific needs with potential suppliers can help negotiate lower MOQs, especially if you are a new buyer or placing a first order. Be prepared to provide forecasts of future orders to encourage flexibility in MOQs. -

How do logistics impact the sourcing of starters from different regions?

Logistics play a critical role in sourcing starters, influencing lead times and costs. Consider the shipping methods, transit times, and customs regulations of the supplier’s country. Assessing the reliability of freight forwarders and understanding potential delays due to geopolitical issues or local regulations is vital. Establishing a logistics plan that includes contingency measures can mitigate risks and ensure timely delivery. -

What should I look for in a warranty when purchasing starters?

When evaluating warranties for starters, consider the duration, coverage scope, and any conditions that might void the warranty. A warranty should ideally cover defects in materials and workmanship. Understand the claim process and whether you need to return faulty products. A robust warranty indicates the supplier’s confidence in their product and provides peace of mind for your investment. -

How can I customize starter specifications to meet my business needs?

Customizing starter specifications typically involves collaborating with the supplier during the design phase. Clearly communicate your requirements regarding voltage, size, and compatibility with specific vehicle models. Providing detailed technical specifications and performance benchmarks will help suppliers tailor their products to your needs. Additionally, consider the implications of customization on lead times and costs, and ensure that any changes align with your overall procurement strategy.

Top 3 Failed Starter Symptoms Manufacturers & Suppliers List

1. Reddit – Bad Starter Diagnosis

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Bad Starter Diagnosis, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Subaru – Starter Motor Issues

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: 2004 Subaru WRX; original equipment starter motor; symptoms include grinding screech on cold starts, low amplitude grinding squeal on warm days; concerns about starter motor failure; battery not new but not original; alternator voltage appears good; potential issues with starter gears, solenoid, or clutch; recommendation to check starter motor and consider replacement if symptoms persist.

3. Facebook – Troubleshooting Solenoid Issues

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Troubleshooting Solenoid Issues, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for failed starter symptoms

How Can Understanding Failed Starter Symptoms Enhance Your Strategic Sourcing?

In summary, recognizing the symptoms of a failing starter is crucial for B2B buyers, especially in regions where vehicle reliability is paramount for business operations. By understanding the interplay between the battery, alternator, and starter, businesses can make informed decisions when sourcing replacement parts or services. Key indicators such as unusual noises, dashboard alerts, and the vehicle’s responsiveness should prompt immediate assessment and action.

Strategic sourcing not only ensures the procurement of high-quality components but also fosters relationships with reliable suppliers who can provide ongoing support and maintenance. This proactive approach minimizes downtime, ultimately enhancing operational efficiency and reducing costs.

As international buyers from Africa, South America, the Middle East, and Europe navigate the complexities of vehicle maintenance, investing in quality parts and expert services is essential. By prioritizing strategic sourcing, you position your business for success in an increasingly competitive landscape. Embrace the opportunity to elevate your procurement strategies and ensure that your fleet remains reliable and ready to meet the demands of your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.