Introduction: Navigating the Global Market for change a headlight

The demand for reliable automotive lighting solutions has never been more pressing, especially for B2B buyers looking to source quality products for their fleets. Understanding how to change a headlight efficiently is crucial not just for vehicle maintenance but also for ensuring safety on the roads. This guide provides a comprehensive overview of the various types of headlight bulbs available, their applications, and critical factors to consider when sourcing these essential components.

In a global market where quality and reliability can vary significantly, this resource will empower international buyers from Africa, South America, the Middle East, and Europe—including key markets like Brazil and Vietnam—to make informed purchasing decisions. By delving into aspects such as supplier vetting, cost considerations, and industry standards, readers will gain actionable insights that can streamline their procurement processes and enhance operational efficiency.

Additionally, the guide addresses common challenges faced by B2B buyers, including navigating different regulations and standards across regions. With this essential knowledge, organizations can not only improve their vehicle maintenance protocols but also enhance overall safety and visibility in various driving conditions. By the end of this guide, you will be equipped with the tools to confidently select and change headlight components that meet your specific needs.

Table Of Contents

- Top 3 Change A Headlight Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for change a headlight

- Understanding change a headlight Types and Variations

- Key Industrial Applications of change a headlight

- 3 Common User Pain Points for ‘change a headlight’ & Their Solutions

- Strategic Material Selection Guide for change a headlight

- In-depth Look: Manufacturing Processes and Quality Assurance for change a headlight

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘change a headlight’

- Comprehensive Cost and Pricing Analysis for change a headlight Sourcing

- Alternatives Analysis: Comparing change a headlight With Other Solutions

- Essential Technical Properties and Trade Terminology for change a headlight

- Navigating Market Dynamics and Sourcing Trends in the change a headlight Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of change a headlight

- Strategic Sourcing Conclusion and Outlook for change a headlight

- Important Disclaimer & Terms of Use

Understanding change a headlight Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Halogen Bulbs | Traditional lighting technology; affordable; moderate lifespan | Automotive repair shops, fleet management | Pros: Cost-effective, easy to replace. Cons: Shorter lifespan compared to newer technologies. |

| HID (High-Intensity Discharge) | Bright, white light; longer lifespan; requires ballast | Premium vehicle manufacturers, luxury car servicing | Pros: Excellent visibility, energy-efficient. Cons: Higher initial cost, complex installation. |

| LED (Light Emitting Diode) | Long lifespan; energy-efficient; low heat generation | Electric vehicle manufacturers, aftermarket upgrades | Pros: Durability, lower energy consumption. Cons: Higher upfront cost, may require assembly change. |

| Xenon Bulbs | Bright light output; cooler color temperature; often used in luxury vehicles | High-end automotive services, specialty shops | Pros: Superior visibility, stylish appearance. Cons: Expensive, sensitive to environmental conditions. |

| Sealed Beam Units | Integrated bulb and lens; used in older vehicles; easy replacement | Classic car restoration, specialty vehicle repair | Pros: Simple installation, consistent performance. Cons: Limited compatibility with modern vehicles. |

What Are the Characteristics of Halogen Bulbs?

Halogen bulbs are the most common type of headlight used in vehicles due to their affordability and ease of replacement. They produce a warm light and are available in various wattages. B2B buyers, particularly those in automotive repair shops or fleet management, find halogen bulbs appealing due to their low cost and widespread compatibility with numerous vehicle models. However, their lifespan is generally shorter than newer technologies, which could lead to more frequent replacements.

How Do HID Bulbs Stand Out?

HID bulbs provide a much brighter and whiter light compared to traditional halogen options, significantly improving visibility for nighttime driving. They require a ballast to operate and are often found in high-end vehicles. B2B applications include premium vehicle manufacturers and luxury car servicing centers. While they offer excellent performance and energy efficiency, the initial investment is higher, and installation can be more complex, making them a consideration for businesses focused on quality and performance.

Why Choose LED Headlights?

LED headlights are known for their long lifespan and energy efficiency, generating less heat than halogen or HID bulbs. They are becoming increasingly popular in electric vehicle manufacturing and aftermarket upgrades. For B2B buyers, LEDs offer durability and lower energy consumption, making them a cost-effective choice in the long run. However, the higher upfront cost and potential need for assembly changes can be barriers for some buyers.

What Are the Benefits of Xenon Bulbs?

Xenon bulbs are designed to produce a bright light output with a cooler color temperature, often used in luxury vehicles. They enhance visibility and are favored by high-end automotive services and specialty shops. Despite their appealing aesthetics and performance, xenon bulbs come with a higher price tag and can be sensitive to environmental conditions, which may impact their longevity.

How Do Sealed Beam Units Function?

Sealed beam units combine the bulb and lens into a single unit, making them easy to replace. They are commonly found in older vehicles and are ideal for classic car restoration and specialty vehicle repair. While they offer consistent performance and straightforward installation, their compatibility with modern vehicles is limited, which could be a consideration for B2B buyers focused on servicing a diverse range of vehicles.

Illustrative image related to change a headlight

Key Industrial Applications of change a headlight

| Industry/Sector | Specific Application of change a headlight | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Replacement of headlights in service centers | Enhances vehicle safety and compliance | Quality certification, compatibility with various models |

| Fleet Management | Regular headlight maintenance for commercial fleets | Reduces downtime and improves driver safety | Bulk purchasing options, durability under various conditions |

| Public Transportation | Headlight upgrades for buses and coaches | Improves visibility and passenger safety | Compliance with local regulations, energy efficiency |

| Construction and Mining | Headlight replacements for heavy machinery | Ensures operational safety in low visibility | Robustness of bulbs, resistance to vibrations and weather |

| Logistics and Shipping | Headlight maintenance for delivery vehicles | Enhances delivery efficiency and safety | Availability of quick delivery parts, compatibility checks |

How is ‘change a headlight’ utilized in the Automotive Repair Industry?

In the automotive repair industry, changing headlights is a routine service offered by mechanics and auto shops. Headlight failure is common due to age, temperature fluctuations, and road conditions. By providing timely headlight replacements, service centers enhance vehicle safety and ensure compliance with legal requirements for road visibility. For international B2B buyers, sourcing high-quality bulbs that fit a wide range of vehicle models is crucial. Factors like certification standards and warranty periods should be considered to ensure reliability and customer satisfaction.

What role does headlight maintenance play in Fleet Management?

Fleet management companies rely on regular headlight maintenance to ensure the safety of their drivers and vehicles. Since commercial fleets often operate in various environmental conditions, maintaining optimal headlight performance is essential to minimize accidents and improve visibility during night operations. Bulk purchasing options for durable, high-lumen bulbs can provide cost savings and ensure consistency across the fleet. International buyers should consider the logistics of sourcing, including shipping times and availability of parts, to avoid operational disruptions.

Why is headlight replacement critical for Public Transportation?

Public transportation systems, such as buses and coaches, prioritize passenger safety and compliance with traffic regulations. Regular headlight upgrades are necessary to maintain optimal visibility, especially in adverse weather conditions or low-light environments. By investing in high-quality, energy-efficient lighting solutions, transportation authorities can improve overall safety and reduce maintenance costs over time. International buyers must ensure that the products meet local standards and regulations, which may vary significantly across regions.

How does headlight replacement affect Construction and Mining operations?

In construction and mining, heavy machinery often operates in low-visibility conditions, making reliable headlights crucial for safety. Regular replacement of headlights on this equipment ensures operators can navigate safely, reducing the risk of accidents. Buyers in this sector should focus on sourcing robust bulbs that can withstand vibrations, dust, and extreme temperatures. Additionally, considering the lifecycle of the products and the availability of replacement parts in remote areas can significantly enhance operational efficiency.

What benefits does headlight maintenance provide for Logistics and Shipping?

For logistics and shipping companies, maintaining the functionality of delivery vehicle headlights is vital for ensuring timely and safe deliveries. Properly functioning headlights enhance visibility for drivers, particularly during night shifts or inclement weather. International buyers should prioritize sourcing reliable and efficient lighting solutions that can withstand the rigors of long-distance travel. Quick delivery options for replacement parts and compatibility with various vehicle models are also essential considerations to minimize downtime and maintain operational efficiency.

3 Common User Pain Points for ‘change a headlight’ & Their Solutions

Scenario 1: Difficulty in Identifying the Correct Headlight Bulb

The Problem:

B2B buyers, such as fleet managers or automotive parts retailers, often encounter challenges when it comes to identifying the correct headlight bulb for various vehicle models. With a multitude of bulb types, sizes, and specifications available in the market, it can be overwhelming to ensure they are sourcing the right product. Misidentifying a bulb can lead to increased costs, wasted time, and potential safety hazards if the wrong bulbs are installed in vehicles.

Illustrative image related to change a headlight

The Solution:

To effectively address this issue, B2B buyers should invest in reliable bulb identification resources. Utilizing comprehensive databases or cataloging systems that list vehicle makes, models, and compatible bulb specifications can streamline the selection process. Additionally, leveraging the expertise of suppliers who offer personalized assistance or online tools for bulb identification can enhance accuracy. When ordering, buyers should double-check the bulb size by referring to the vehicle’s owner manual or using the part number printed on the old bulb. This proactive approach minimizes errors and ensures the correct products are sourced, ultimately saving time and reducing operational costs.

Scenario 2: Managing the Installation Process for Multiple Vehicles

The Problem:

B2B buyers who manage fleets or automotive service centers often face the challenge of efficiently changing headlights across numerous vehicles. This task can be time-consuming, especially when different vehicle models require varied installation processes. Without a streamlined approach, this can lead to extended downtimes, affecting service schedules and customer satisfaction.

The Solution:

To optimize the installation process, B2B buyers should develop a standardized procedure that can be applied across different vehicle types. Investing in a training program for technicians can equip them with the necessary skills to handle various installation scenarios confidently. Providing a toolkit that includes essential tools—like screwdrivers, ratchets, and safety gear—will facilitate quicker changes. Additionally, creating a detailed guide or checklist for each vehicle model can help technicians follow a consistent procedure. This structured approach not only speeds up the installation process but also enhances service quality, leading to improved customer satisfaction and reduced operational disruptions.

Illustrative image related to change a headlight

Scenario 3: Addressing Safety Concerns with Headlight Functionality

The Problem:

B2B buyers, particularly those responsible for fleet safety, often grapple with the issue of ensuring that all vehicles have functioning headlights. Dim or malfunctioning headlights can pose serious safety risks, especially in regions with poor lighting conditions. This can result in accidents, liability issues, and decreased vehicle performance, which are significant concerns for businesses operating fleets.

The Solution:

To mitigate these safety concerns, B2B buyers should implement a proactive headlight maintenance program. This could include regular vehicle inspections focused on headlight functionality, where technicians assess both the brightness and alignment of headlights. Establishing a schedule for routine checks can ensure that headlights are replaced before they fail, maintaining optimal visibility for drivers. Additionally, educating drivers on the importance of reporting any headlight issues immediately can foster a culture of safety within the organization. Partnering with reputable suppliers for quality bulbs ensures that replacements meet safety standards and are durable, reducing the frequency of replacements and enhancing overall fleet safety.

Strategic Material Selection Guide for change a headlight

What Materials Are Commonly Used for Headlight Components?

When selecting materials for headlight components, manufacturers typically consider several options, each with distinct properties and performance characteristics. The choice of material can significantly impact the durability, efficiency, and compliance of headlight assemblies, especially in diverse international markets.

1. Polycarbonate

Key Properties: Polycarbonate is a high-performance thermoplastic known for its excellent impact resistance and optical clarity. It can withstand temperatures ranging from -40°C to 120°C, making it suitable for various environmental conditions.

Pros & Cons: The primary advantage of polycarbonate is its lightweight nature and high strength, which contributes to fuel efficiency in vehicles. However, it can be prone to scratching and may require additional coatings for UV protection, increasing manufacturing complexity and costs.

Illustrative image related to change a headlight

Impact on Application: Polycarbonate’s compatibility with various lighting technologies, including halogen and HID systems, makes it versatile. However, its susceptibility to UV degradation can affect performance over time, necessitating regular maintenance or replacement.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that polycarbonate components meet local UV resistance standards, as prolonged sun exposure can lead to degradation. Compliance with ASTM or ISO standards is also essential for ensuring quality and safety.

2. Glass

Key Properties: Glass offers excellent optical clarity and is highly resistant to scratches and UV radiation. It can endure high temperatures, typically up to 300°C, which is beneficial for high-intensity lighting applications.

Illustrative image related to change a headlight

Pros & Cons: The durability of glass makes it a preferred choice for high-performance headlights. However, its weight can negatively impact vehicle efficiency, and it is more prone to shattering upon impact compared to polycarbonate.

Impact on Application: Glass is particularly effective in applications requiring high light transmission and resistance to environmental factors. However, its fragility can pose challenges in rugged terrains commonly found in developing regions.

Considerations for International Buyers: Buyers should be aware of local regulations regarding glass usage in automotive applications. Compliance with safety standards, such as those set by the European Union or local automotive safety authorities, is crucial.

3. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a high thermal conductivity, which helps dissipate heat generated by headlight bulbs. It can withstand temperatures up to 150°C, making it suitable for various automotive applications.

Pros & Cons: The primary advantage of aluminum is its strength-to-weight ratio, which enhances vehicle performance. However, it can be more expensive than other materials and may require specialized manufacturing processes.

Impact on Application: Aluminum’s thermal properties are beneficial in preventing overheating, especially in high-performance lighting systems. Its corrosion resistance is particularly advantageous in humid or coastal environments.

Considerations for International Buyers: In regions like the Middle East, where humidity can be high, aluminum components must meet specific corrosion resistance standards. Compliance with JIS or DIN standards can assure buyers of the material’s quality and performance.

4. Thermoplastic Elastomers (TPE)

Key Properties: TPEs are flexible, durable, and resistant to temperature extremes, making them suitable for sealing applications in headlight assemblies. They typically operate effectively between -30°C and 100°C.

Pros & Cons: TPEs offer excellent flexibility and resistance to environmental stress, which can enhance the longevity of headlight seals. However, they may not provide the same level of rigidity as other materials, which can be a limitation in structural applications.

Impact on Application: TPEs are ideal for applications requiring flexibility and durability, such as gaskets and seals in headlight assemblies. Their performance can be affected by exposure to certain chemicals, which should be considered in various markets.

Considerations for International Buyers: Buyers should ensure that TPEs used in headlight assemblies comply with local environmental regulations, especially in regions with strict chemical exposure limits. Understanding the local standards, such as ASTM or ISO, is essential for ensuring compliance.

Summary Table of Material Selection for Headlight Components

| Material | Typical Use Case for change a headlight | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Headlight lenses | Lightweight and impact-resistant | Prone to scratching | Medium |

| Glass | Headlight lenses | Excellent optical clarity | Fragile and heavy | High |

| Aluminum | Headlight housing | Corrosion-resistant and lightweight | Higher manufacturing costs | High |

| Thermoplastic Elastomers | Seals and gaskets | Flexible and durable | Limited rigidity | Medium |

This strategic material selection guide provides insights into the various materials used in headlight manufacturing, emphasizing their properties, advantages, and considerations for international B2B buyers. Understanding these factors can aid in making informed purchasing decisions that align with local regulations and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for change a headlight

What Are the Main Stages of Headlight Manufacturing?

The manufacturing process for headlights, particularly bulbs, involves several crucial stages, each designed to ensure high-quality output. Understanding these stages can help B2B buyers assess potential suppliers more effectively.

How Is Material Prepared for Headlight Production?

The process begins with material preparation, where raw materials such as glass, metal filaments, and electrical components are sourced and inspected for quality. For halogen bulbs, quartz glass is commonly used due to its ability to withstand high temperatures. The glass is cut into specific shapes and sizes, while metal components are prepped through processes like stamping or machining. Suppliers often adhere to international material standards to ensure consistency and reliability, making it essential for buyers to verify these standards during procurement.

What Techniques Are Used in the Forming Stage of Headlights?

Once materials are prepared, the forming stage begins. This involves shaping the glass into bulbs, which can be done through processes like blowing, pressing, or molding. For halogen bulbs, the filament is carefully positioned within the bulb, and the bulb is sealed to maintain vacuum or gas pressure. Advanced techniques, such as automated assembly lines, are frequently employed to enhance precision and reduce production time. B2B buyers should inquire about the machinery and technology used by suppliers, as modern techniques often lead to better quality and efficiency.

How Are Headlights Assembled and Finished?

What Is the Assembly Process for Headlights?

After the forming stage, the assembly of headlights occurs. This includes integrating the bulb into the headlight housing along with other components like reflectors and lenses. The assembly process varies significantly between manufacturers, with some opting for fully automated systems while others may utilize manual labor for intricate tasks. It’s important for buyers to understand the assembly techniques employed, as this can affect the durability and performance of the final product.

What Finishing Techniques Are Commonly Applied?

Finishing touches such as coating and polishing are applied to enhance the aesthetic appeal and functionality of the headlights. This may include anti-fogging treatments and UV protection coatings to prevent degradation over time. The finishing process also involves rigorous cleaning to ensure that no contaminants are present, which could affect performance. Buyers should verify the finishing techniques used by suppliers, as these can significantly impact the longevity and effectiveness of the headlights.

What Quality Assurance Processes Are Essential for Headlight Production?

Quality assurance (QA) is critical in the manufacturing of headlights to meet both safety and performance standards. Suppliers must implement comprehensive QA processes to ensure that each product is reliable and meets international regulations.

Illustrative image related to change a headlight

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 are essential benchmarks for quality management systems. Compliance with ISO standards indicates that a manufacturer follows established protocols for quality assurance throughout the production process. Additionally, industry-specific certifications such as CE marking in Europe and API standards in the oil and gas sector can provide further assurance of product quality. B2B buyers should prioritize suppliers that are certified to these standards to mitigate risks associated with product failures.

What Are the Key Quality Control Checkpoints in Headlight Manufacturing?

Quality control (QC) checkpoints are integral to maintaining high standards. These typically include:

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Monitoring production processes to identify defects early, allowing for timely corrective actions.

- Final Quality Control (FQC): Conducting thorough inspections of the finished products to ensure they conform to all specifications before shipment.

These checkpoints help ensure that any potential issues are identified and addressed at various stages of production, thereby enhancing overall product reliability.

How Are Common Testing Methods Applied in Headlight Manufacturing?

Testing methods are pivotal in ensuring that headlights perform effectively under various conditions. Common testing methods include:

Illustrative image related to change a headlight

- Photometric Testing: This evaluates the light output and distribution of the headlights to ensure compliance with legal standards.

- Thermal Testing: Assessing how headlights perform under extreme temperature variations to confirm durability.

- Vibration Testing: Simulating road conditions to ensure that the components can withstand vibrations without failure.

B2B buyers should inquire about the specific testing methods employed by suppliers, as this can provide insights into the quality and reliability of the headlights.

How Can B2B Buyers Verify Supplier Quality Control?

What Steps Can Buyers Take to Ensure Supplier Compliance?

To ensure that suppliers adhere to quality control standards, B2B buyers should consider the following steps:

- Conduct Audits: Regular audits of suppliers can help verify their compliance with quality standards and identify areas for improvement.

- Request Quality Reports: Suppliers should be able to provide documented evidence of their quality assurance processes and results from testing.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices.

These measures help B2B buyers mitigate risks and ensure that they are partnering with reliable suppliers.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in QC and certification. Different regions may have varying regulations regarding automotive products, which can impact compliance.

- Regional Certifications: Understanding local certifications and regulations is crucial for ensuring that products are legally compliant in the target market. For instance, while CE marking is essential in Europe, other regions may have different requirements.

- Cultural Considerations: The approach to quality assurance may differ based on regional practices. Buyers should be prepared to adapt their expectations and requirements accordingly.

By understanding these nuances, B2B buyers can navigate the complexities of international procurement more effectively, ensuring that they source high-quality headlights that meet their specific needs.

Illustrative image related to change a headlight

Practical Sourcing Guide: A Step-by-Step Checklist for ‘change a headlight’

This practical sourcing guide provides a step-by-step checklist for B2B buyers looking to procure components or services related to changing headlights. Understanding the intricacies of headlight replacement is essential for enhancing vehicle safety and compliance. This guide will help you make informed decisions when sourcing headlight bulbs, tools, and services.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical before engaging suppliers. Determine the type of headlight bulbs compatible with your vehicles, including sizes and types (e.g., halogen, HID, LED). This ensures that you procure the right products that meet your operational requirements and safety standards.

Step 2: Research and Identify Potential Suppliers

Conduct thorough market research to identify potential suppliers who specialize in automotive lighting. Look for suppliers with a robust portfolio of headlight products and services. Utilize online platforms, industry directories, and trade shows to gather a list of reputable suppliers.

- Tip: Consider suppliers that have experience in your target markets, such as Africa, South America, the Middle East, and Europe, as they will be more attuned to regional regulations and customer preferences.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that potential suppliers have the necessary certifications. Check for ISO certifications, compliance with local automotive standards, and any quality assurance certifications relevant to headlight products.

- Why It Matters: Certifications assure you of the supplier’s commitment to quality and safety, reducing the risk of defective products that could compromise vehicle safety.

Step 4: Request Product Samples

Obtaining samples of headlight bulbs is a crucial step in the sourcing process. Evaluate the quality, brightness, and longevity of the samples provided by suppliers. This hands-on assessment will help you gauge whether the products meet your expectations and requirements.

Step 5: Assess Pricing and Payment Terms

Request detailed pricing information from your shortlisted suppliers. Analyze the pricing structure, including bulk order discounts and payment terms. Understanding the total cost of ownership, including shipping and potential import duties, will help you budget effectively.

- Consideration: Compare pricing against the quality and specifications to ensure you are getting the best value for your investment.

Step 6: Review Warranty and After-Sales Support

A comprehensive warranty and robust after-sales support are essential for ensuring peace of mind. Review the warranty terms provided by the supplier and inquire about their support services for product installation and troubleshooting.

- Importance: Strong after-sales support can save you time and money, especially if you encounter issues with the headlight bulbs after installation.

Step 7: Finalize Your Supplier Selection

After conducting thorough evaluations, finalize your supplier selection. Prepare a detailed contract that outlines all agreed-upon terms, including delivery timelines, payment schedules, and service level agreements.

- Final Check: Ensure that the contract includes clauses for returns and exchanges in case the products do not meet the specified requirements.

By following this checklist, B2B buyers can confidently source headlight products and services that meet their operational needs while ensuring compliance with industry standards.

Comprehensive Cost and Pricing Analysis for change a headlight Sourcing

What Are the Key Cost Components for Sourcing Headlight Replacement?

When sourcing headlight replacements for automotive applications, it’s essential to understand the various cost components that contribute to the overall pricing structure. The primary cost elements include:

-

Materials: The choice of materials significantly affects the pricing. Headlight bulbs can be made from incandescent, halogen, HID, or LED technologies, each with different cost implications. LED bulbs, for instance, tend to be more expensive upfront but offer longer lifespans and lower energy consumption.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing and assembly. In regions with higher labor costs, such as Europe, the impact on pricing can be substantial. Conversely, sourcing from countries with lower labor costs, such as parts of Africa or South America, can provide cost savings.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize overhead costs, thus affecting the final pricing.

-

Tooling: Initial tooling costs for molds and equipment required to manufacture specific types of headlight bulbs can be significant. Custom designs will incur higher tooling costs, impacting overall pricing.

-

Quality Control (QC): Ensuring the reliability and safety of headlight bulbs is crucial. Robust QC processes add to the manufacturing costs but are essential for maintaining quality standards and compliance with international regulations.

-

Logistics: Shipping and handling costs can vary based on the geographical location of suppliers and buyers. Incoterms play a vital role in determining who bears these costs. Understanding logistics can help in negotiating better terms.

-

Margin: Suppliers typically add a profit margin to cover risks and ensure sustainability. This margin can vary based on competition, demand, and market dynamics.

What Influences Pricing for Headlight Sourcing?

Several factors can influence the pricing of headlight bulbs, which international B2B buyers should consider:

-

Volume/MOQ: Purchasing in larger volumes often leads to discounts. Buyers should negotiate minimum order quantities (MOQ) to achieve better pricing.

-

Specifications and Customization: Custom specifications, such as special color temperatures or unique designs, can increase costs. Buyers should balance customization needs with budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) generally command higher prices. Buyers should evaluate whether the benefits justify the costs.

-

Supplier Factors: The reputation, reliability, and financial stability of the supplier can impact pricing. Engaging with established suppliers may yield better service and quality assurance.

-

Incoterms: Understanding delivery terms is crucial for cost management. Incoterms define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risks, which can affect the total landed cost.

What Are the Best Buyer Tips for Cost-Efficiency in Headlight Sourcing?

B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing headlight replacements:

-

Negotiation Skills: Effective negotiation can lead to significant savings. Buyers should prepare by understanding market prices and being clear about their requirements.

-

Total Cost of Ownership (TCO): Rather than focusing solely on upfront costs, consider the total cost of ownership, which includes maintenance, energy savings, and lifespan. This approach may justify higher initial investments in quality products.

-

Pricing Nuances for International Buyers: When sourcing from diverse regions like Africa, South America, or Europe, be aware of currency fluctuations, import duties, and trade tariffs that can affect overall costs. Conduct thorough market research to navigate these complexities effectively.

-

Long-Term Partnerships: Building long-term relationships with suppliers can facilitate better pricing and service. Consider loyalty agreements or contracts that can lock in favorable pricing terms.

-

Market Trends and Innovations: Stay informed about industry trends and new technologies that may offer better efficiency or lower costs. Innovations in LED technology, for instance, may provide long-term savings despite higher initial costs.

Understanding these cost structures and pricing influencers can empower B2B buyers to make informed decisions, optimize their sourcing strategies, and achieve better overall value in headlight procurement.

Alternatives Analysis: Comparing change a headlight With Other Solutions

Understanding Alternatives to Changing a Headlight

When it comes to vehicle maintenance, particularly in the context of headlights, B2B buyers are often presented with several options. While changing a headlight bulb remains a common solution, alternative technologies and methods can offer different benefits. This analysis will explore the traditional method of changing a headlight bulb alongside two viable alternatives: upgrading to LED headlight systems and utilizing headlight restoration kits. Each option has distinct performance metrics, costs, and maintenance requirements that can influence a buyer’s decision.

Comparison Table

| Comparison Aspect | Change A Headlight | LED Headlight System | Headlight Restoration Kit |

|---|---|---|---|

| Performance | Moderate brightness; typically 1000-2000 lumens | High brightness; up to 4000 lumens | Restores faded headlights to near original clarity |

| Cost | Low ($20-$100 per bulb) | High ($100-$300 per set) | Moderate ($15-$50 per kit) |

| Ease of Implementation | Simple DIY; requires minimal tools | Moderate; may require professional installation | Easy DIY; requires minimal tools |

| Maintenance | Requires replacement every 1-2 years | Long-lasting; 10,000+ hours lifespan | Needs reapplication every 6-12 months |

| Best Use Case | Standard vehicles needing basic lighting | Vehicles requiring superior visibility, especially in low-light conditions | Older vehicles with yellowed or cloudy lenses |

Detailed Breakdown of Alternatives

What are the Benefits and Drawbacks of Upgrading to an LED Headlight System?

LED headlight systems provide significantly higher brightness and visibility compared to traditional halogen bulbs, making them ideal for vehicles frequently driven in poor lighting conditions. They offer a longer lifespan, often exceeding 10,000 hours, which reduces the frequency of replacements. However, the initial investment is higher, and installation can be complex, sometimes requiring professional assistance. This option is best suited for B2B buyers looking to enhance safety features in fleet vehicles or high-performance cars.

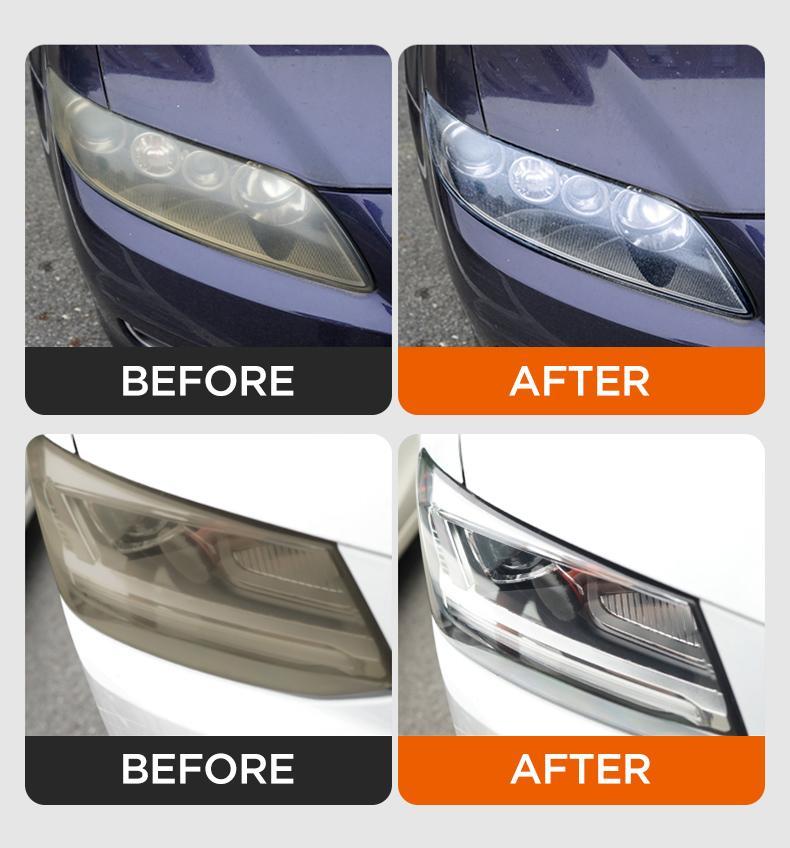

How Effective are Headlight Restoration Kits for Older Vehicles?

Headlight restoration kits are designed to improve the clarity of cloudy or yellowed headlight lenses, enhancing overall visibility without the need to replace the entire bulb system. These kits are relatively inexpensive and easy to use, making them a cost-effective solution for older vehicles. However, the restoration effects are not permanent, often requiring reapplication every 6 to 12 months. This method is ideal for businesses managing older fleets that do not want to incur the costs of full headlight replacements.

Illustrative image related to change a headlight

Conclusion: How Should B2B Buyers Choose the Right Headlight Solution?

When selecting the appropriate headlight solution, B2B buyers must evaluate their specific needs and operational context. If long-term visibility and brightness are paramount, investing in LED systems could provide the best return on investment despite the higher upfront cost. For businesses managing older vehicle fleets, headlight restoration kits offer an economical way to maintain safety without significant expenditures. Ultimately, understanding the balance between performance, cost, and ease of maintenance will help buyers make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for change a headlight

What Are the Key Technical Properties for Changing a Headlight?

When considering the replacement of headlight bulbs, several technical properties are critical for ensuring optimal performance and compatibility. Understanding these specifications can significantly impact purchasing decisions and overall vehicle safety.

1. Bulb Type

Headlight bulbs come in various types, including halogen, HID (High-Intensity Discharge), and LED (Light Emitting Diode). Each type has distinct characteristics related to brightness, energy efficiency, and lifespan. For instance, LED bulbs tend to last longer and consume less power than halogen bulbs, making them a popular choice for modern vehicles. B2B buyers should consider the bulb type that aligns with their vehicle specifications and customer preferences.

2. Lumen Output

Lumen output measures the brightness of the headlight. Higher lumen ratings indicate brighter lights, which can enhance visibility during night driving or adverse weather conditions. B2B buyers must evaluate the lumen output to ensure they meet local regulations and provide adequate illumination for safe driving.

3. Color Temperature

Color temperature is measured in Kelvin (K) and affects the light’s appearance. For example, bulbs with a color temperature of 3000K emit a warm yellow light, while those at 6000K provide a cool white light. A higher color temperature typically results in better visibility and contrast on reflective surfaces. Understanding color temperature helps businesses cater to market demands for aesthetics and functionality.

4. Bulb Lifespan

The lifespan of a headlight bulb is crucial for long-term cost-effectiveness. Different bulb types have varying lifespans; for instance, LED bulbs can last up to 25,000 hours, while halogen bulbs may only last around 1,000 hours. B2B buyers should prioritize bulbs with longer lifespans to reduce replacement frequency and associated labor costs.

5. Fitment and Compatibility

Each vehicle model requires specific bulb sizes and fittings. Identifying the correct fitment ensures that the bulbs will install correctly and function as intended. Businesses should maintain an updated inventory or catalog that matches bulb specifications to vehicle models, preventing compatibility issues and enhancing customer satisfaction.

Illustrative image related to change a headlight

What Are Common Trade Terms Related to Changing Headlights?

A solid understanding of industry terminology is essential for B2B transactions in the automotive lighting sector. Here are several key terms that buyers and sellers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle’s original manufacturer. In the context of headlight bulbs, OEM products are designed to meet the specific standards and performance criteria set by the vehicle manufacturer. B2B buyers may prefer OEM parts for their guaranteed compatibility and reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is vital for B2B buyers to manage inventory levels and cash flow effectively. Suppliers may set MOQs to optimize production costs and minimize waste.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. In the context of headlight bulbs, businesses can use RFQs to compare prices and terms from different suppliers, ensuring they receive the best value for their purchases.

Illustrative image related to change a headlight

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers. They clarify aspects such as shipping costs, insurance, and risk transfer. Understanding Incoterms is essential for B2B buyers engaged in cross-border transactions to ensure clarity and avoid disputes.

5. Aftermarket

The aftermarket refers to parts and accessories that are not sourced from the original vehicle manufacturer. Aftermarket headlight bulbs may offer alternative options that can be more cost-effective or provide enhanced performance. B2B buyers should evaluate the quality and compatibility of aftermarket products to ensure they meet customer expectations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing headlight bulbs, ultimately enhancing their offerings and ensuring customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the change a headlight Sector

What Are the Current Market Dynamics Influencing the Change a Headlight Sector?

The global automotive lighting market, particularly the headlight segment, is experiencing significant transformation driven by technological advancements and changing consumer preferences. Key trends include the transition from traditional halogen bulbs to more efficient LED and HID (High-Intensity Discharge) systems. This shift not only enhances visibility and safety but also aligns with the growing demand for energy-efficient solutions among environmentally-conscious consumers. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, these trends present opportunities to source innovative products that meet both regulatory standards and customer expectations.

Emerging technologies, such as smart lighting systems that adapt to driving conditions, are also gaining traction. These systems not only improve safety but can reduce the frequency of headlight replacements, a factor that may influence purchasing decisions. Additionally, the rise of e-commerce platforms is reshaping the sourcing landscape, allowing buyers to access a wider variety of products and suppliers, thereby fostering competitive pricing and improved logistics.

As the automotive industry increasingly prioritizes sustainability, B2B buyers must also consider the implications of sourcing practices and product lifecycle management. This evolving landscape requires a keen understanding of market dynamics and the ability to adapt sourcing strategies to meet changing demands.

How Are Sustainability and Ethical Sourcing Reshaping the Change a Headlight Market?

Sustainability has emerged as a critical factor in the automotive sector, particularly concerning lighting products. The environmental impact of headlight manufacturing and disposal is substantial, prompting buyers to seek suppliers who adhere to sustainable practices. This includes the use of recyclable materials and energy-efficient manufacturing processes.

Ethical sourcing is becoming increasingly important as consumers and businesses alike demand transparency in supply chains. Buyers are encouraged to partner with manufacturers that hold certifications such as ISO 14001 for environmental management or those that utilize eco-friendly materials in their products. By prioritizing suppliers with a commitment to sustainability, businesses can mitigate risks associated with environmental regulations and enhance their corporate social responsibility profiles.

Furthermore, the demand for “green” headlights, such as those using LED technology, is on the rise. LEDs not only consume less power but also have a longer lifespan compared to traditional bulbs, reducing waste and the frequency of replacements. For B2B buyers, investing in these innovative solutions not only meets regulatory compliance but also aligns with broader sustainability goals, appealing to a growing base of environmentally-conscious consumers.

How Has the Change a Headlight Sector Evolved Over Time?

The change a headlight sector has witnessed considerable evolution since the introduction of automotive lighting. Initially dominated by incandescent bulbs, the market has transitioned towards more advanced technologies, such as halogen, HID, and LED systems. This shift began in earnest in the late 20th century when safety regulations and consumer preferences started to favor brighter and more energy-efficient options.

Today, the focus is on integrating smart technology into headlight systems, with features that enhance visibility while reducing energy consumption. This evolution not only reflects advancements in automotive technology but also underscores the importance of adapting to consumer demands for safety, efficiency, and sustainability. As the market continues to evolve, B2B buyers must stay informed about these trends to capitalize on opportunities that align with their strategic objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of change a headlight

-

How do I solve the problem of dim or non-functioning headlights?

To address dim or non-functioning headlights, first inspect the bulbs. If only one is out, replace it, but it’s advisable to change both for uniformity. Check the fuse to ensure it isn’t blown, as a dual failure often indicates an electrical issue rather than bulb failure. If the problem persists, investigate further into wiring or switch issues. For B2B buyers, sourcing quality bulbs from reputable suppliers can minimize these problems, ensuring a reliable product that meets performance standards. -

What is the best type of headlight bulb for enhanced visibility?

For enhanced visibility, LED headlight bulbs are often the best choice due to their superior brightness and energy efficiency compared to traditional halogen bulbs. They provide a cooler color temperature, improving contrast and clarity on the road. However, halogen bulbs are still popular for their cost-effectiveness and ease of replacement. When sourcing, consider the specific needs of your market, such as local regulations and customer preferences, to determine the optimal product for your clientele. -

What should I consider when sourcing headlight bulbs for international markets?

When sourcing headlight bulbs for international markets, consider local regulations regarding bulb specifications and safety standards. Ensure compliance with varying voltage and wattage requirements across regions, particularly in Africa, South America, the Middle East, and Europe. Additionally, assess the reliability of suppliers by checking certifications, product reviews, and their experience in exporting to your target region. Establishing a local partnership can also enhance logistics and customer support. -

What are the minimum order quantities (MOQ) for headlight bulbs from suppliers?

Minimum order quantities (MOQ) for headlight bulbs can vary widely based on the supplier and the specific bulb type. Generally, MOQs can range from 100 to 1,000 units, depending on the manufacturer’s production capabilities and market demand. For B2B buyers, negotiating the MOQ can be beneficial, especially if you’re looking to test a new product line. Always inquire about flexibility in MOQs to accommodate varying inventory needs. -

How do I vet suppliers for headlight bulbs?

To vet suppliers for headlight bulbs, start by researching their reputation in the market. Look for reviews, testimonials, and case studies that highlight their reliability and product quality. Request samples to assess the product firsthand. Verify certifications that comply with international safety and quality standards. Additionally, consider their customer service responsiveness and ability to meet delivery schedules, as these factors are crucial for maintaining a smooth supply chain. -

What payment terms should I negotiate with headlight bulb suppliers?

When negotiating payment terms with suppliers, consider options like net 30 or net 60 days to allow for cash flow management. Establishing a letter of credit can provide security for both parties in international transactions. It’s also beneficial to discuss partial payments upon order confirmation and the remainder upon delivery. Ensure clarity on payment methods accepted, such as bank transfers, credit cards, or digital payment platforms, to streamline the transaction process. -

How can I ensure quality assurance for headlight bulbs sourced internationally?

To ensure quality assurance for internationally sourced headlight bulbs, implement a robust quality control process. This can include pre-shipment inspections to verify compliance with specifications and safety standards. Establish clear quality benchmarks and conduct regular audits of the supplier’s manufacturing processes. Collaborating with third-party inspection services can provide additional assurance. Building strong relationships with suppliers can also facilitate open communication regarding quality expectations and improvements. -

What logistics considerations should I keep in mind when importing headlight bulbs?

When importing headlight bulbs, consider the logistics of shipping, customs clearance, and potential tariffs. Choose a reliable freight forwarder experienced in handling automotive products to ensure safe and timely delivery. Understand the import regulations of your destination country, including any certifications required for automotive parts. Additionally, plan for potential delays due to customs inspections, and ensure your supply chain is flexible enough to accommodate unforeseen circumstances.

Top 3 Change A Headlight Manufacturers & Suppliers List

1. Car Maintenance – Headlight Bulb Replacement

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Car Maintenance – Headlight Bulb Replacement, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Facebook – Headlight Replacement Guide

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Headlight Replacement Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. J.D. Power – Headlight Replacement Guide

Domain: jdpower.com

Registered: 1995 (30 years)

Introduction: Headlight replacement involves understanding the causes of headlight failure, which include age, extreme temperature changes, damage to the light housing, and oxidation. To determine if the issue is a blown bulb or a fuse, check if one or both headlights are out. If only one is out, it is likely a bulb issue. The replacement process includes purchasing the correct bulb based on the vehicle’s make,…

Strategic Sourcing Conclusion and Outlook for change a headlight

In conclusion, the process of changing a headlight is not just about enhancing visibility; it reflects a critical aspect of vehicle maintenance that can significantly impact safety and operational efficiency. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of headlight sourcing is essential. Prioritizing quality bulbs that offer optimal throw distance, color temperature, and longevity can lead to better performance and reduced costs over time.

Strategic sourcing plays a pivotal role in ensuring that your business partners provide reliable products that meet local regulations and customer expectations. By collaborating with suppliers that offer a range of options—such as halogen, HID, and LED bulbs—you can cater to diverse market needs while enhancing customer satisfaction.

As we look toward the future, now is the time to evaluate your sourcing strategies. Consider investing in innovative lighting solutions that improve vehicle safety and comply with evolving standards. Engage with trusted suppliers and stay informed about the latest advancements in automotive lighting technology to secure your competitive edge in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.