Introduction: Navigating the Global Market for car starter motor solenoid

In the dynamic world of automotive components, sourcing reliable car starter motor solenoids is crucial for maintaining operational efficiency and minimizing vehicle downtime. International B2B buyers face significant challenges in identifying quality suppliers, understanding product specifications, and navigating varying market conditions across regions, including Africa, South America, the Middle East, and Europe. This comprehensive guide aims to address these challenges by providing in-depth insights into the types of starter motor solenoids available, their applications across different vehicle models, and essential considerations for supplier vetting.

Through this guide, you will gain valuable knowledge about the cost factors associated with car starter motor solenoids, enabling you to make informed purchasing decisions tailored to your business needs. We will explore critical aspects such as the common causes of solenoid failures, preventative maintenance tips, and best practices for ensuring the longevity of these essential components. By equipping yourself with this information, you can not only enhance your procurement strategy but also foster strong partnerships with suppliers who align with your quality standards.

Whether you are based in Nigeria, Germany, or anywhere in between, this guide empowers you to navigate the global market for car starter motor solenoids effectively. By making informed choices, you can ensure that your fleet remains reliable, safe, and ready to perform at its best.

Table Of Contents

- Top 2 Car Starter Motor Solenoid Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for car starter motor solenoid

- Understanding car starter motor solenoid Types and Variations

- Key Industrial Applications of car starter motor solenoid

- 3 Common User Pain Points for ‘car starter motor solenoid’ & Their Solutions

- Strategic Material Selection Guide for car starter motor solenoid

- In-depth Look: Manufacturing Processes and Quality Assurance for car starter motor solenoid

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘car starter motor solenoid’

- Comprehensive Cost and Pricing Analysis for car starter motor solenoid Sourcing

- Alternatives Analysis: Comparing car starter motor solenoid With Other Solutions

- Essential Technical Properties and Trade Terminology for car starter motor solenoid

- Navigating Market Dynamics and Sourcing Trends in the car starter motor solenoid Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of car starter motor solenoid

- Strategic Sourcing Conclusion and Outlook for car starter motor solenoid

- Important Disclaimer & Terms of Use

Understanding car starter motor solenoid Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electromagnetic Solenoid | Utilizes electromagnetic force to engage the starter motor. | Automotive manufacturing, aftermarket parts. | Pros: Reliable, widely used. Cons: Sensitive to electrical issues. |

| Miniature Solenoid | Compact design, ideal for space-constrained vehicles. | Compact vehicles, motorcycles, and scooters. | Pros: Space-efficient, lightweight. Cons: Limited power output. |

| Continuous Duty Solenoid | Designed for prolonged use without overheating. | Heavy machinery, commercial vehicles. | Pros: Durable, suitable for heavy loads. Cons: Typically more expensive. |

| Pull-in Solenoid | Engages quickly, suitable for high-torque applications. | Racing cars, performance vehicles. | Pros: Fast engagement, high torque. Cons: May wear faster under extreme use. |

| Latching Solenoid | Maintains position without continuous power. | Electric vehicles, remote starters. | Pros: Energy-efficient, reliable hold. Cons: More complex circuitry required. |

What Are the Characteristics and Suitability of Electromagnetic Solenoids for B2B Buyers?

Electromagnetic solenoids are the most common type used in starter motors, leveraging electromagnetic force to engage the starter motor when the ignition key is turned. They are suitable for a wide range of applications, from passenger vehicles to industrial machinery. B2B buyers should consider the solenoid’s voltage compatibility, as well as its electrical durability, to ensure reliability in various operational environments.

How Do Miniature Solenoids Serve Specific Market Needs?

Miniature solenoids are characterized by their compact size, making them ideal for applications where space is limited, such as in motorcycles and small cars. These solenoids are lightweight and often used in low-power applications. Buyers should assess the performance specifications, including the maximum current and torque, to ensure they meet the demands of their specific vehicle models.

Why Choose Continuous Duty Solenoids for Heavy-Duty Applications?

Continuous duty solenoids are engineered for extended use without the risk of overheating, making them ideal for heavy machinery and commercial vehicles that require reliable starting systems under demanding conditions. They are built to withstand high loads and frequent operation. B2B purchasers should evaluate the solenoid’s thermal management features and overall durability to ensure long-term performance and reduce maintenance costs.

What Advantages Do Pull-in Solenoids Offer for Performance Vehicles?

Pull-in solenoids are designed for rapid engagement, providing high torque for applications that require quick starts, such as racing cars. Their ability to engage swiftly makes them suitable for high-performance vehicles. Buyers should consider the solenoid’s response time and torque rating to match the performance needs of their vehicles, especially in competitive environments.

How Do Latching Solenoids Enhance Energy Efficiency in Electric Vehicles?

Latching solenoids are unique in that they maintain their position without needing continuous power, making them a valuable component in electric vehicles and remote starter systems. They are energy-efficient and can help reduce battery drain. B2B buyers should focus on the solenoid’s power consumption and reliability to ensure it meets the needs of modern electric vehicle designs, which often prioritize energy efficiency and sustainability.

Key Industrial Applications of car starter motor solenoid

| Industry/Sector | Specific Application of car starter motor solenoid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Integration in starter systems for vehicles | Ensures reliable engine start-up and performance | Quality certification, compatibility with various vehicle models, and supply chain reliability |

| Heavy Equipment | Use in construction machinery and commercial vehicles | Enhances operational uptime and reduces maintenance costs | Durability under harsh conditions, availability of replacement parts, and performance in extreme temperatures |

| Agricultural Machinery | Application in tractors and farming equipment | Improves efficiency in field operations and reduces downtime | Resistance to corrosion, ease of installation, and compliance with international agricultural standards |

| Marine Industry | Utilization in boats and marine vehicles | Ensures dependable starts in challenging environments | Waterproofing features, compatibility with marine electrical systems, and certifications for marine use |

| Aftermarket Automotive Parts | Replacement parts for various vehicle models | Meets demand for quality replacements, enhancing vehicle longevity | Availability of OEM specifications, competitive pricing, and distribution logistics for timely delivery |

How is the car starter motor solenoid utilized in the automotive manufacturing sector?

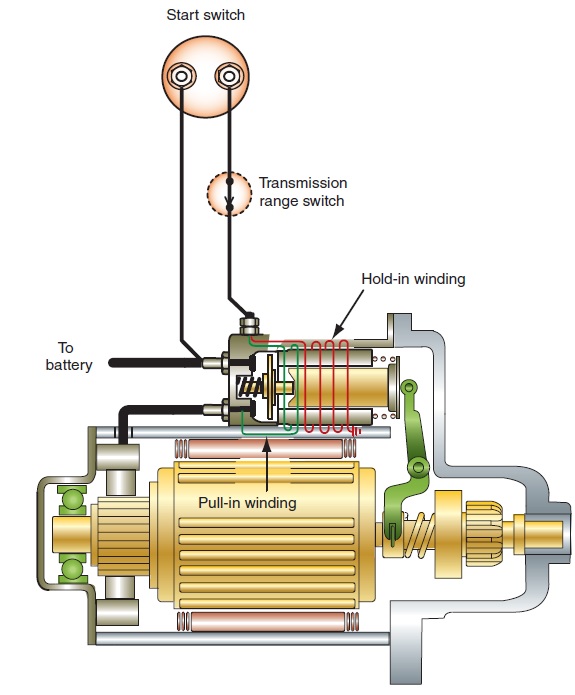

In automotive manufacturing, the starter motor solenoid is critical for the engine start-up system. It acts as a relay, engaging the starter motor when the ignition key is turned. This ensures that vehicles start reliably, which is essential for manufacturers aiming to meet quality standards and customer satisfaction. B2B buyers in this sector must prioritize sourcing solenoids that meet specific automotive certifications and compatibility with various vehicle models to avoid production delays.

What role does the car starter motor solenoid play in heavy equipment applications?

In the heavy equipment sector, car starter motor solenoids are used in construction machinery and commercial vehicles. They ensure that large engines start efficiently, minimizing downtime on job sites. For buyers in this industry, the solenoids must be durable, capable of withstanding harsh conditions, and easily replaceable to maintain operational efficiency. Sourcing considerations include the solenoid’s performance in extreme temperatures and its resistance to wear and tear.

How does the agricultural machinery sector benefit from car starter motor solenoids?

Agricultural machinery, such as tractors and harvesters, relies on starter motor solenoids for dependable engine operation in the field. These solenoids improve the efficiency of farming operations by ensuring that equipment starts quickly, even under challenging conditions. Buyers in this sector should focus on solenoids that resist corrosion and provide easy installation. Compliance with international agricultural standards is also a crucial factor in the sourcing process.

Why is the car starter motor solenoid important in the marine industry?

In the marine industry, starter motor solenoids are essential for ensuring reliable engine starts in boats and other marine vehicles. Given the unique challenges posed by wet environments, these solenoids must be designed with waterproofing features and compatibility with marine electrical systems. B2B buyers should seek solenoids that have undergone rigorous testing for marine use and possess relevant certifications to ensure safety and reliability on the water.

How does the aftermarket automotive parts sector utilize car starter motor solenoids?

The aftermarket automotive parts industry often relies on car starter motor solenoids as replacement components for various vehicle models. These solenoids are crucial for maintaining vehicle performance and longevity. Buyers in this sector should prioritize sourcing solenoids that meet OEM specifications and offer competitive pricing. Efficient distribution logistics are also vital to ensure timely delivery and meet market demands for quality replacement parts.

3 Common User Pain Points for ‘car starter motor solenoid’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Solenoids

The Problem:

B2B buyers, particularly those operating in regions like Africa and South America, often face challenges in sourcing high-quality car starter motor solenoids. The market may be flooded with low-quality parts that compromise the reliability of their vehicles. Buyers may struggle with inconsistent supply chains, leading to delays in production and potential loss of revenue. Additionally, they may lack the technical expertise to differentiate between premium and subpar products, resulting in costly mistakes.

Illustrative image related to car starter motor solenoid

The Solution:

To mitigate these challenges, B2B buyers should establish partnerships with reputable suppliers known for their quality assurance processes. Conducting thorough market research to identify manufacturers with a proven track record is essential. Buyers can request samples and technical specifications to evaluate the solenoid’s performance and durability. Furthermore, leveraging online platforms that provide customer reviews and ratings can aid in making informed purchasing decisions. Establishing long-term relationships with suppliers who prioritize quality will help ensure a steady supply of reliable starter solenoids, ultimately enhancing operational efficiency.

Scenario 2: Understanding Installation Challenges and Technical Specifications

The Problem:

Another common pain point for B2B buyers is the complexity of installing car starter motor solenoids. Without clear guidelines and understanding of technical specifications, installation errors can lead to operational inefficiencies and increased repair costs. This issue is particularly prevalent in regions where technical expertise may be limited, leaving buyers vulnerable to miscommunication and improper installations that can further damage the vehicle.

The Solution:

To address installation challenges, buyers should seek solenoids that come with comprehensive installation manuals and technical support. Investing in training programs for their staff or partnering with local mechanics can significantly enhance installation competency. Additionally, suppliers should provide detailed product specifications, including compatibility information and wiring diagrams, to facilitate a smoother installation process. By prioritizing educational resources and technical support, buyers can ensure proper installation and reduce the likelihood of future failures.

Scenario 3: Managing Maintenance and Longevity of Starter Solenoids

The Problem:

B2B buyers often grapple with the maintenance and longevity of starter motor solenoids, particularly in harsh environments. Factors such as extreme temperatures, humidity, and dust can accelerate wear and tear, leading to frequent replacements and unexpected vehicle downtimes. This situation can strain operational budgets and impact service delivery, especially for businesses relying on a fleet of vehicles.

The Solution:

To enhance the longevity of starter solenoids, buyers should implement a proactive maintenance schedule that includes regular inspections and cleaning of the solenoids and their connections. Educating staff on identifying early signs of wear, such as corrosion or unusual sounds during startup, can lead to timely interventions before failures occur. Additionally, sourcing solenoids specifically designed for harsh conditions can provide extra durability. Manufacturers offering extended warranties or guarantees can also be a reliable choice, ensuring peace of mind for buyers concerned about long-term performance. By adopting a preventive maintenance approach and choosing robust products, businesses can minimize downtime and optimize their vehicle operations.

Strategic Material Selection Guide for car starter motor solenoid

What Are the Common Materials Used for Car Starter Motor Solenoids?

When selecting materials for car starter motor solenoids, it is essential to consider their properties, advantages, and limitations. Here, we analyze four common materials used in the manufacturing of solenoids, focusing on their suitability for B2B buyers across diverse international markets.

1. Copper

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It can withstand high temperatures, making it suitable for the automotive environment.

Pros & Cons: The primary advantage of copper is its superior conductivity, which ensures efficient performance of the starter motor. However, it is relatively expensive compared to other materials, and its weight can be a drawback in applications where reducing mass is critical. Additionally, copper can be susceptible to corrosion if not properly treated.

Impact on Application: Copper is compatible with various automotive fluids and environments, ensuring reliable operation. Its high conductivity is particularly beneficial in applications requiring rapid electrical response.

Considerations for International Buyers: Buyers in regions like Germany and Nigeria should ensure compliance with industry standards such as DIN and ASTM for copper quality. The availability of high-grade copper may vary by region, impacting procurement strategies.

Illustrative image related to car starter motor solenoid

2. Steel

Key Properties: Steel offers high tensile strength and durability, making it a robust choice for solenoids. It can withstand significant mechanical stress and is often treated for corrosion resistance.

Pros & Cons: Steel’s strength makes it suitable for high-stress applications, and it is generally more cost-effective than copper. However, its weight can be a disadvantage, and if not properly coated, it can be prone to rust and corrosion, particularly in humid environments.

Impact on Application: Steel’s mechanical properties allow it to perform well under high pressure and temperature conditions, making it suitable for heavy-duty applications. However, its compatibility with corrosive environments must be considered.

Illustrative image related to car starter motor solenoid

Considerations for International Buyers: Buyers should look for steel that meets relevant standards, such as JIS for Japan or ASTM for the U.S. The choice of coating (e.g., zinc plating) can also impact performance and longevity in different climates.

3. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can handle moderate temperatures and is often used in applications where weight reduction is crucial.

Pros & Cons: The main advantage of aluminum is its low weight, which can enhance vehicle efficiency. However, it has lower tensile strength compared to steel and copper, which may limit its use in high-stress applications. Additionally, aluminum can be more expensive than steel.

Impact on Application: Aluminum’s corrosion resistance makes it suitable for applications exposed to moisture and other corrosive elements. However, its lower strength may not make it ideal for all starter motor applications.

Considerations for International Buyers: Compliance with international standards like ASTM is essential for aluminum components. Buyers should also consider the availability of aluminum alloys that meet specific performance requirements.

4. Plastic Composites

Key Properties: Plastic composites are lightweight and can be engineered for various properties, including electrical insulation and corrosion resistance. They can also be molded into complex shapes.

Pros & Cons: The primary advantage of plastic composites is their versatility and low weight, which can lead to cost savings in manufacturing. However, they may not withstand high temperatures and mechanical stress as effectively as metals.

Impact on Application: Plastic composites can be used in non-load-bearing components of the solenoid, such as housings or insulation parts. Their compatibility with electrical insulation makes them suitable for specific applications.

Considerations for International Buyers: Buyers should ensure that plastic composites meet relevant safety and performance standards. The choice of material can be influenced by local regulations and environmental considerations.

Summary Table

| Material | Typical Use Case for car starter motor solenoid | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical contacts and terminals | Excellent conductivity | High cost, weight issues | High |

| Steel | Structural components | High strength and durability | Prone to rust if uncoated | Medium |

| Aluminum | Lightweight components | Low weight, corrosion resistance | Lower strength compared to metals | Medium |

| Plastic Composites | Insulation and non-load-bearing parts | Versatile, lightweight | Limited temperature and stress tolerance | Low |

This guide provides a comprehensive overview of material selection for car starter motor solenoids, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for car starter motor solenoid

What Are the Main Stages of Manufacturing a Car Starter Motor Solenoid?

The manufacturing process of car starter motor solenoids involves several critical stages, each designed to ensure the component meets performance and reliability standards. Below are the primary stages of manufacturing:

Material Preparation: What Materials Are Used in Solenoid Production?

The first step in the manufacturing process is material preparation. Common materials used for car starter motor solenoids include high-grade steel, copper, and specialized alloys. These materials are selected for their electrical conductivity, mechanical strength, and resistance to corrosion.

- Steel Components: Often used for the solenoid housing and plunger due to its durability and ability to withstand high temperatures.

- Copper Wire: Used for the winding of the solenoid coil to ensure efficient electrical conductivity.

- Insulating Materials: High-quality insulation materials are utilized to prevent short circuits and ensure the longevity of the solenoid.

Forming: How Are Solenoid Components Shaped?

Once the materials are prepared, the next phase is forming. This involves shaping the components through processes such as:

- Stamping: Steel sheets are stamped into the desired shapes for the solenoid casing and internal components.

- Winding: Copper wire is precisely wound around a core to form the solenoid coil. The winding process must be consistent to ensure uniform electrical performance.

- Casting: Some components may be cast in molds, especially intricate parts that require specific geometries.

Assembly: What Does the Assembly Process Look Like?

The assembly stage is where individual components come together to form the complete solenoid. This involves:

- Joining Components: Parts such as the coil, plunger, and housing are assembled using techniques like welding or soldering.

- Electrical Connections: Ensuring that all electrical connections are secure and properly insulated is crucial for performance.

- Mechanical Assembly: The assembled solenoid is fitted with a spring mechanism that allows it to engage and disengage smoothly when the ignition is activated.

Finishing: What Finishing Techniques Are Employed?

Finishing processes are essential for enhancing the solenoid’s performance and durability. Common finishing techniques include:

- Coating: Application of protective coatings to resist corrosion and wear.

- Quality Inspection: Initial inspections are performed to ensure all components meet specifications before moving to quality control.

How Is Quality Assurance Implemented in Solenoid Manufacturing?

Quality assurance (QA) is vital for ensuring that car starter motor solenoids perform reliably under various operating conditions. Key QA practices include:

Illustrative image related to car starter motor solenoid

What International Standards Should Buyers Be Aware Of?

Many manufacturers adhere to international quality standards to ensure their products meet global expectations. The most relevant standards include:

- ISO 9001: This standard focuses on quality management systems and is widely recognized. It ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products marketed in Europe, CE marking indicates compliance with EU safety and environmental regulations.

- API Standards: Specific to certain applications, these standards ensure that products meet industry-specific requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical throughout the manufacturing process. Typical checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected for quality before they enter the manufacturing process. This step helps to catch issues early and ensures only high-quality materials are used.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the production process and ensure that components are being produced to specification.

- Final Quality Control (FQC): Once assembly is complete, a final inspection is performed to verify that the solenoid functions correctly and meets all performance standards.

What Common Testing Methods Are Used?

Manufacturers utilize various testing methods to ensure solenoids meet performance standards:

- Electrical Testing: Checks for proper electrical conductivity and functionality of the solenoid.

- Mechanical Testing: Evaluates the physical integrity and mechanical performance of the solenoid under various conditions.

- Environmental Testing: Assesses the solenoid’s performance under extreme temperatures and humidity levels to ensure reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are actionable steps:

Illustrative image related to car starter motor solenoid

What Should Buyers Look for in Supplier Audits?

- Supplier Audits: Conducting or requesting audits of the manufacturing facility can provide insights into the supplier’s quality control processes. Look for evidence of adherence to international standards like ISO 9001.

- Quality Reports: Request quality assurance reports that detail inspection results and any corrective actions taken in response to quality issues.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can add an extra layer of verification. These independent entities can conduct thorough inspections and tests, providing unbiased assessments of the manufacturer’s quality practices.

What Are the QC and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is crucial for B2B buyers operating across different regions. Here are key considerations:

- Regional Compliance: Different regions may have specific regulations and compliance requirements. For example, products sold in the EU must adhere to CE marking requirements, while other regions may have their own certifications.

- Cultural Understanding: Building relationships with suppliers who understand local regulations and market needs can facilitate smoother transactions and compliance with quality standards.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can ensure they source reliable and high-quality car starter motor solenoids, minimizing the risk of failures and enhancing customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car starter motor solenoid’

In the competitive landscape of automotive parts procurement, sourcing a reliable car starter motor solenoid is crucial for ensuring operational efficiency and minimizing downtime. This guide provides a structured checklist for B2B buyers to navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline the technical specifications required for the starter motor solenoid. This includes parameters such as voltage rating, size, and compatibility with specific vehicle models. A well-defined specification ensures that you receive products that meet your operational needs and helps avoid costly mismatches.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in automotive electrical components. Utilize online platforms, industry directories, and trade shows to compile a list of manufacturers and distributors. Pay attention to their market reputation and customer feedback, as this can provide insights into their reliability and service quality.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is essential to ensure compliance with industry standards and regulations. Look for certifications such as ISO 9001 for quality management systems and specific automotive standards like IATF 16949. These certifications indicate that the supplier adheres to rigorous quality control processes, which can significantly impact the reliability of the solenoids.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the starter motor solenoids from shortlisted suppliers. Testing samples allows you to assess the quality, performance, and compatibility of the components with your vehicles. This step is vital for preventing future operational issues and ensuring that the parts meet your specified requirements.

Step 5: Inquire About Warranty and Return Policies

Understanding the warranty and return policies of potential suppliers is crucial for mitigating risks associated with product defects. Inquire about the duration of the warranty, the process for claims, and any associated costs. A robust warranty policy indicates the supplier’s confidence in their product quality and provides you with protection against unforeseen failures.

Step 6: Assess Logistics and Delivery Capabilities

Evaluate the supplier’s logistics capabilities, including lead times, shipping options, and delivery reliability. Consider suppliers who can meet your delivery timelines consistently, especially if you operate in regions with logistical challenges. Efficient logistics can significantly reduce downtime and ensure that your operations run smoothly.

Step 7: Negotiate Pricing and Payment Terms

Once you have selected a preferred supplier, enter negotiations regarding pricing and payment terms. Be transparent about your budget constraints while also considering bulk purchase discounts or long-term partnership agreements. Establishing favorable payment terms can enhance your cash flow management and strengthen supplier relationships.

Following this checklist will equip B2B buyers with the necessary tools to procure high-quality car starter motor solenoids effectively. By adhering to these steps, you can ensure a reliable supply chain that supports your automotive operations.

Comprehensive Cost and Pricing Analysis for car starter motor solenoid Sourcing

What Are the Key Cost Components in Sourcing Car Starter Motor Solenoids?

When sourcing car starter motor solenoids, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The quality of materials significantly influences the cost. Common materials include copper for wiring, steel for the solenoid casing, and various plastics. Higher quality materials can enhance durability and performance but may increase the initial cost.

-

Labor: Labor costs vary by region and can impact the overall pricing of solenoids. Skilled labor is often necessary for assembly and quality assurance, which may be more expensive in developed markets compared to emerging markets.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Initial tooling costs can be substantial, particularly for custom or high-precision parts. These costs should be amortized over the production volume to understand the per-unit cost better.

-

Quality Control (QC): Implementing rigorous QC processes ensures that solenoids meet industry standards. While this may add to upfront costs, it can prevent costly defects and returns.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, play a crucial role in overall pricing. International buyers should consider the logistics implications of sourcing from different regions.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary widely based on supplier reputation, service level, and market demand.

How Do Price Influencers Affect Car Starter Motor Solenoid Costs?

Several factors can influence the pricing of car starter motor solenoids, which international buyers should consider:

-

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs. Understanding minimum order quantities (MOQs) can help buyers negotiate better pricing.

-

Specifications and Customization: Custom designs or specifications will generally incur higher costs. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications (such as ISO or TS standards) can increase costs but may offer better performance and reliability.

-

Supplier Factors: Established suppliers with a track record of reliability may charge higher prices. However, the investment can lead to reduced risks and better long-term partnerships.

-

Incoterms: The choice of Incoterms affects shipping responsibilities and costs. Understanding these terms can help buyers manage risk and avoid additional charges.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

To maximize cost-efficiency when sourcing car starter motor solenoids, consider the following tips:

-

Negotiate: Always negotiate pricing and terms with suppliers. Establishing a strong relationship can lead to better pricing and service.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, warranty, and replacement costs over the product’s life cycle. A higher-quality solenoid may reduce long-term costs.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to labor costs, material availability, and market demand. For instance, sourcing from Europe may offer high-quality products but at a premium price compared to suppliers in South America or Africa.

-

Conduct Market Research: Understanding market trends and competitor pricing can help buyers make informed decisions and negotiate effectively.

-

Request Samples: Before placing a large order, request samples to assess quality and compatibility. This can prevent costly mistakes later.

Disclaimer on Indicative Prices

Prices for car starter motor solenoids can vary widely based on the aforementioned factors. The information provided is indicative and should be used as a guideline. Always consult suppliers for the most accurate and up-to-date pricing tailored to specific requirements.

Alternatives Analysis: Comparing car starter motor solenoid With Other Solutions

Exploring Alternative Solutions to the Car Starter Motor Solenoid

When considering the reliability and efficiency of vehicle starting systems, the car starter motor solenoid is a common choice. However, there are alternative technologies and methods available that can also initiate engine start. This section explores viable alternatives, comparing their performance, cost, ease of implementation, maintenance requirements, and best use cases.

| Comparison Aspect | Car Starter Motor Solenoid | Alternative 1: Relay Start System | Alternative 2: Push-Button Start System |

|---|---|---|---|

| Performance | High reliability, directly engages starter motor | Moderate reliability, depends on relay quality | High reliability with advanced security features |

| Cost | Generally low, but replacement can be costly | Moderate, varies with relay quality | Higher initial investment but reduces wear on components |

| Ease of Implementation | Standard installation in most vehicles | Requires additional wiring and components | Simple installation with modern vehicles |

| Maintenance | Requires regular checks and cleaning | Low maintenance, but relay replacements may be needed | Minimal maintenance, mainly battery checks |

| Best Use Case | Conventional vehicles needing dependable starts | Older vehicles or custom builds needing upgrades | Luxury or modern vehicles prioritizing user convenience |

What Are the Pros and Cons of a Relay Start System?

A relay start system utilizes a relay to control the starter motor instead of a traditional solenoid. This method can reduce the wear on the ignition switch, prolonging its lifespan. One of the advantages of this system is its flexibility, allowing for custom installations in older vehicles. However, the performance of a relay system is contingent on the quality of the relay used; a poor-quality relay can lead to starting failures. Moreover, the additional wiring needed for installation may complicate the process, making it less ideal for those seeking a straightforward solution.

What Are the Advantages and Disadvantages of a Push-Button Start System?

The push-button start system is an increasingly popular choice in modern vehicles, providing convenience and a high-tech feel. This system often integrates with advanced security features, such as keyless entry, enhancing vehicle protection. The main benefit is ease of use; drivers can start their vehicles with a simple button press. However, the initial cost of installation can be higher, especially in vehicles not originally designed for this technology. Additionally, while maintenance is low, users must ensure the battery is always functional, as a dead battery can prevent the system from working altogether.

Conclusion: How Should B2B Buyers Choose the Right Solution?

For B2B buyers, the choice between a car starter motor solenoid and its alternatives ultimately hinges on specific needs and vehicle types. If reliability and low cost are paramount, the traditional solenoid remains a solid choice. However, for those seeking modern features and enhanced convenience, investing in a push-button start system might be worthwhile, especially in luxury or newer vehicles. Relay systems can be an excellent middle ground for custom builds or older models needing upgrades. Evaluating factors such as vehicle type, budget constraints, and maintenance capabilities will guide buyers in selecting the most appropriate solution for their operational needs.

Illustrative image related to car starter motor solenoid

Essential Technical Properties and Trade Terminology for car starter motor solenoid

What Are the Key Technical Properties of Car Starter Motor Solenoids?

Understanding the technical specifications of car starter motor solenoids is essential for B2B buyers, as these properties directly impact performance, reliability, and compatibility with various vehicle models. Here are some critical specifications:

1. Material Grade

The material used in the construction of a starter solenoid significantly influences its durability and performance. Common materials include high-grade steel for the housing and copper for electrical contacts. High-quality materials ensure resistance to corrosion, wear, and thermal degradation, which is crucial for solenoids that operate in harsh environments. Selecting a solenoid with appropriate material grades can lead to longer service life and reduced maintenance costs.

2. Electrical Resistance

Electrical resistance is a critical property that affects the efficiency of the solenoid. A lower resistance value typically indicates better conductivity, allowing for a more efficient transfer of electrical current from the battery to the starter motor. This is particularly important in high-demand situations, such as starting a cold engine. B2B buyers should prioritize solenoids with optimal resistance values to ensure reliable performance under various conditions.

3. Tolerance Levels

Tolerance levels refer to the allowable deviation from specified dimensions in the solenoid components. High tolerance levels in manufacturing ensure precise fit and function, reducing the likelihood of mechanical failure. For B2B buyers, understanding tolerance specifications is vital for ensuring compatibility with specific vehicle models and preventing installation issues that could lead to costly repairs.

4. Operating Voltage

The operating voltage of a starter solenoid typically ranges from 12V to 24V, depending on the vehicle type. Selecting a solenoid with the correct operating voltage is crucial for optimal functionality. B2B buyers should ensure that the solenoid’s voltage matches that of the vehicle’s electrical system to prevent malfunction and ensure safe operation.

5. Actuation Force

Actuation force is the amount of force required to engage the starter motor. This property is essential for ensuring that the solenoid can effectively transmit the necessary power to start the engine. Buyers should consider the actuation force in relation to the engine size and specifications of the vehicle to avoid performance issues.

Illustrative image related to car starter motor solenoid

6. Temperature Range

The temperature range specifies the operational limits within which the solenoid can function effectively. Solenoids designed to withstand extreme temperatures are particularly important in regions with harsh climates. Understanding this specification helps buyers select solenoids that will perform reliably regardless of environmental conditions.

What Are Common Trade Terms Related to Car Starter Motor Solenoids?

Familiarity with industry jargon can streamline the procurement process and improve communication between buyers and suppliers. Here are several essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts produced by the original manufacturer of the vehicle. Buying OEM solenoids ensures compatibility and reliability, making them a preferred choice for many businesses. It is crucial for B2B buyers to understand the benefits of OEM products versus aftermarket alternatives, as this can affect warranty and service life.

Illustrative image related to car starter motor solenoid

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it affects inventory management and cost efficiency. Buyers should negotiate MOQ terms to align with their purchasing needs while ensuring they do not overstock or face shortages.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This term is vital for B2B transactions, as it helps establish competitive pricing and terms. Crafting a detailed RFQ can lead to better negotiations and supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with these terms helps B2B buyers understand shipping costs, risk management, and delivery timelines, which are critical for international procurement.

Illustrative image related to car starter motor solenoid

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. Understanding lead times is essential for B2B buyers to manage inventory effectively and plan for production schedules. Longer lead times may require strategic planning to avoid operational disruptions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring car starter motor solenoids, ensuring they select products that meet their operational needs while optimizing costs.

Navigating Market Dynamics and Sourcing Trends in the car starter motor solenoid Sector

What Are the Current Market Dynamics and Key Trends for Car Starter Motor Solenoids?

The car starter motor solenoid sector is experiencing a transformative phase driven by several global trends. Increasing vehicle production and the rising demand for fuel-efficient automobiles are pivotal factors fueling market growth. As countries in Africa, South America, the Middle East, and Europe expand their automotive markets, there is a notable rise in the demand for reliable starting systems. For instance, Nigeria’s automotive industry is burgeoning, requiring robust supply chains to meet the needs of local manufacturers. Similarly, Germany, with its advanced automotive sector, is pushing for innovative solutions, emphasizing the importance of technological advancements in starter motor solenoids.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are becoming increasingly relevant in the sourcing process. B2B buyers are now leveraging these technologies to streamline procurement, ensuring timely delivery and better inventory management. Additionally, there is a growing trend toward customization, where manufacturers offer tailored solutions to meet specific client requirements. This trend is particularly significant in markets where vehicle specifications can vary widely, such as in South America and Africa.

Furthermore, the rise of electric vehicles (EVs) is reshaping the landscape of the starter motor solenoid market. While traditional combustion engines are still prevalent, the shift toward hybrid and fully electric vehicles is prompting suppliers to innovate. This transition presents opportunities for international buyers to engage with suppliers that are investing in advanced technologies and sustainable practices.

How Is Sustainability and Ethical Sourcing Shaping the Car Starter Motor Solenoid Sector?

Sustainability has become a central pillar in the automotive industry, significantly influencing the sourcing of car starter motor solenoids. Environmental concerns regarding the impact of manufacturing processes on climate change are prompting businesses to adopt eco-friendly practices. International buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint, whether through energy-efficient manufacturing processes or sustainable sourcing of materials.

Ethical supply chains are equally crucial. Buyers are scrutinizing suppliers for compliance with labor laws and ethical sourcing standards. This is especially pertinent in regions like Africa and South America, where labor practices may vary significantly. Companies that obtain certifications for sustainable practices, such as ISO 14001 or the Global Recycled Standard, are gaining a competitive edge. These certifications assure buyers that their suppliers are committed to minimizing environmental impact and promoting responsible sourcing.

Moreover, the materials used in manufacturing car starter motor solenoids are under review. Buyers are seeking components made from recycled or sustainably sourced materials, thereby supporting a circular economy. As the demand for green products continues to rise, suppliers who invest in sustainable practices are likely to see increased business from conscientious buyers.

What Is the Historical Context of the Car Starter Motor Solenoid Market?

The evolution of the car starter motor solenoid can be traced back to the early 20th century when automobiles began to transition from hand-cranked engines to electric starters. Initially, solenoids were simple mechanical devices, but advancements in electrical engineering led to more efficient designs, enhancing reliability and performance. By the mid-20th century, the introduction of electronic ignition systems further revolutionized the starter solenoid’s role, integrating it into the broader electrical systems of vehicles.

Illustrative image related to car starter motor solenoid

In recent decades, the focus has shifted towards improving the durability and efficiency of starter solenoids in response to the growing demands of modern vehicles. As automotive technology continues to evolve, particularly with the rise of electric and hybrid vehicles, the design and functionality of starter motor solenoids are expected to advance further, catering to new market needs and environmental standards. This historical context is crucial for B2B buyers as it underscores the importance of selecting suppliers that not only understand these trends but are also capable of innovating alongside them.

Frequently Asked Questions (FAQs) for B2B Buyers of car starter motor solenoid

-

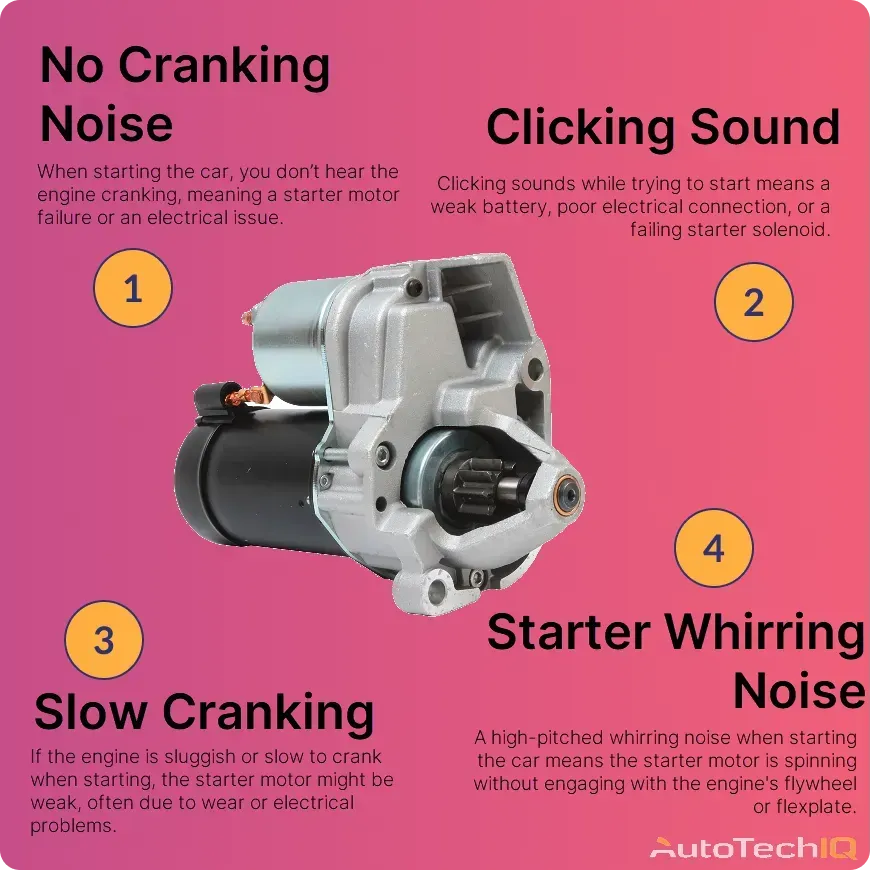

How do I identify a failing starter motor solenoid?

Identifying a failing starter motor solenoid can be critical in preventing a no-start situation. Common symptoms include a clicking sound when turning the ignition key, no response at all, intermittent starting issues, and a slow cranking engine. If you experience these signs, it’s advisable to have the solenoid tested or replaced promptly to avoid further complications. -

What is the best starter motor solenoid for high-performance vehicles?

For high-performance vehicles, opt for solenoids designed for higher amperage and durability. Look for models with robust construction, high-temperature resistance, and reliable electrical contacts. Brands that specialize in performance parts often provide solenoids with advanced features to enhance starting efficiency and reliability under demanding conditions. -

How can I ensure quality when sourcing starter motor solenoids from international suppliers?

To ensure quality, start by vetting suppliers through their certifications and industry standards compliance. Request samples to evaluate their products firsthand and consider third-party quality assurance inspections. Establish a clear communication channel to discuss specifications, performance expectations, and warranty terms, which can help ensure that the solenoids meet your quality requirements. -

What are the typical minimum order quantities (MOQs) for starter motor solenoids?

MOQs for starter motor solenoids can vary significantly depending on the supplier and the type of solenoid. Generally, you can expect MOQs to range from 100 to 1,000 units. Discuss your specific needs with potential suppliers to negotiate favorable terms, especially if you are entering a new market or seeking to test the demand for a particular product. -

What payment terms are commonly accepted when purchasing starter motor solenoids internationally?

Common payment terms include upfront payment, letter of credit, or net 30/60/90 days depending on the supplier’s policies. Some suppliers may also offer discounts for early payments or larger orders. It’s advisable to clarify payment terms in the contract to avoid misunderstandings and ensure that both parties are aligned on the financial aspects of the transaction. -

What logistics considerations should I keep in mind when importing starter motor solenoids?

When importing starter motor solenoids, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with automotive parts to ensure timely and safe delivery. Additionally, factor in lead times, storage, and handling requirements to streamline the logistics process and avoid delays in your supply chain. -

How can I customize starter motor solenoids for my specific needs?

Customization options for starter motor solenoids can include variations in voltage, current ratings, and physical dimensions. Work closely with manufacturers to specify your requirements, and inquire about the possibility of custom designs or modifications. Providing detailed specifications and discussing your application needs will facilitate the development of a tailored solution. -

What are the best practices for maintaining starter motor solenoids to extend their lifespan?

Regular maintenance is crucial for extending the lifespan of starter motor solenoids. Implement routine inspections to check for corrosion, loose connections, and damaged wiring. Keep the solenoid clean and free of dirt, and ensure that the electrical contacts are secure. Additionally, encourage regular use of the vehicle to prevent solenoid degradation from inactivity.

Top 2 Car Starter Motor Solenoid Manufacturers & Suppliers List

1. Reddit – Starter Solenoid Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The starter solenoid in a car serves to move the starter gear to mesh with the flywheel, allowing the engine to start. It operates by using a small amperage input (e.g., 10 amps) to switch a large amperage output (e.g., 200 amps) to the starter, enabling a small current to control a circuit that outputs a large current. If the starter solenoid is malfunctioning, the starter may produce a whine sou…

2. Solenoid Starter – Activation Guide

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: The solenoid in a starter typically has three terminals: 1) B terminal for power from the battery, 2) S terminal for ignition switch, and 3) R terminal for a coil pack. To jump the solenoid, connect the B and S terminals to activate the solenoid and energize the starter. For non pre-engaged starters with a Bendix, you can also connect terminal ‘B’ to terminal ‘M’ if the solenoid is faulty. The R t…

Strategic Sourcing Conclusion and Outlook for car starter motor solenoid

In the competitive landscape of automotive parts, particularly for car starter motor solenoids, strategic sourcing emerges as a critical factor for success. Understanding the essential role of the solenoid in vehicle performance can help international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, make informed purchasing decisions. Key takeaways emphasize the importance of reliability, quality, and the potential cost savings associated with preventative maintenance. By sourcing high-quality solenoids and ensuring regular inspections, businesses can minimize downtime and enhance customer satisfaction.

Moreover, establishing strong relationships with suppliers can lead to favorable terms and improved access to innovative technologies. As the automotive market continues to evolve, international buyers must stay ahead by investing in quality components that support their operational needs and customer expectations.

Looking forward, proactive sourcing strategies will be essential in navigating the complexities of the automotive supply chain. Engage with reputable suppliers, prioritize quality, and implement regular maintenance practices to ensure that your automotive solutions remain reliable and efficient. Don’t hesitate—take the necessary steps today to secure your supply chain for a more resilient tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to car starter motor solenoid