Introduction: Navigating the Global Market for automotive starter parts

In an increasingly interconnected world, sourcing automotive starter parts presents a unique challenge for international B2B buyers. Whether you are a distributor in Brazil or a fleet manager in Saudi Arabia, navigating the complexities of global supply chains while ensuring quality and cost-effectiveness is paramount. This guide addresses these challenges head-on, providing a comprehensive overview of automotive starter parts, including types, applications, and essential considerations for supplier vetting.

With an inventory that spans over 10,000 part numbers, our resource delves into various starter options suitable for light and heavy-duty vehicles, agricultural machinery, and marine applications. We will explore the nuances of new versus remanufactured parts, the importance of quality assurance, and the implications of environmental sustainability in your purchasing decisions.

Designed specifically for B2B buyers from Africa, South America, the Middle East, and Europe, this guide empowers you to make informed choices that align with your operational needs and budget constraints. By understanding the critical factors that influence the global market for automotive starter parts, you can enhance your procurement strategy, optimize supply chain efficiency, and ultimately drive your business’s success in a competitive landscape.

Table Of Contents

- Top 2 Automotive Starter Parts Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automotive starter parts

- Understanding automotive starter parts Types and Variations

- Key Industrial Applications of automotive starter parts

- 3 Common User Pain Points for ‘automotive starter parts’ & Their Solutions

- Strategic Material Selection Guide for automotive starter parts

- In-depth Look: Manufacturing Processes and Quality Assurance for automotive starter parts

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive starter parts’

- Comprehensive Cost and Pricing Analysis for automotive starter parts Sourcing

- Alternatives Analysis: Comparing automotive starter parts With Other Solutions

- Essential Technical Properties and Trade Terminology for automotive starter parts

- Navigating Market Dynamics and Sourcing Trends in the automotive starter parts Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automotive starter parts

- Strategic Sourcing Conclusion and Outlook for automotive starter parts

- Important Disclaimer & Terms of Use

Understanding automotive starter parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gear Reduction Starters | Compact design, higher torque output, lightweight | Passenger vehicles, light trucks | Pros: Improved efficiency; Cons: Higher initial cost. |

| Permanent Magnet Starters | Utilizes permanent magnets for lightweight and compact design | Small engines, motorcycles, agricultural vehicles | Pros: Smaller size; Cons: Limited power for larger applications. |

| Remanufactured Starters | Rebuilt to OEM specifications, cost-effective | Aftermarket parts suppliers, repair shops | Pros: Cost savings; Cons: May have shorter lifespan than new. |

| High-Performance Starters | Enhanced components for racing and heavy-duty applications | Racing vehicles, heavy-duty trucks | Pros: Superior performance; Cons: Higher price point. |

| Solenoid Integrated Starters | Built-in solenoid for compact installation | Various automotive applications | Pros: Space-saving design; Cons: Limited serviceability. |

What are Gear Reduction Starters and Their Applications?

Gear reduction starters are designed to provide higher torque in a compact form. They employ a gear mechanism that amplifies the motor’s torque, making them ideal for starting larger engines found in passenger vehicles and light trucks. B2B buyers should consider the balance between initial costs and efficiency gains, as these starters can lead to better performance in demanding conditions.

Why Choose Permanent Magnet Starters?

Permanent magnet starters are known for their lightweight and compact design, making them suitable for applications in small engines, motorcycles, and agricultural vehicles. Their efficiency and reduced size make them an attractive option for manufacturers looking to optimize space and weight. However, buyers should note that while they excel in small applications, they may not deliver sufficient power for larger vehicles.

What Are the Benefits of Remanufactured Starters?

Remanufactured starters are a cost-effective alternative to new units, as they are rebuilt to meet OEM specifications. They are widely used in aftermarket parts supply and repair shops, allowing businesses to provide quality products without the high costs associated with new starters. However, it’s essential for buyers to consider the potential for a shorter lifespan compared to brand new components.

When Should You Consider High-Performance Starters?

High-performance starters are specifically designed for racing and heavy-duty applications, featuring enhanced components that withstand higher demands. They are ideal for use in racing vehicles and heavy-duty trucks where performance is paramount. Buyers should be prepared for a higher price point but can expect superior reliability and torque output in return.

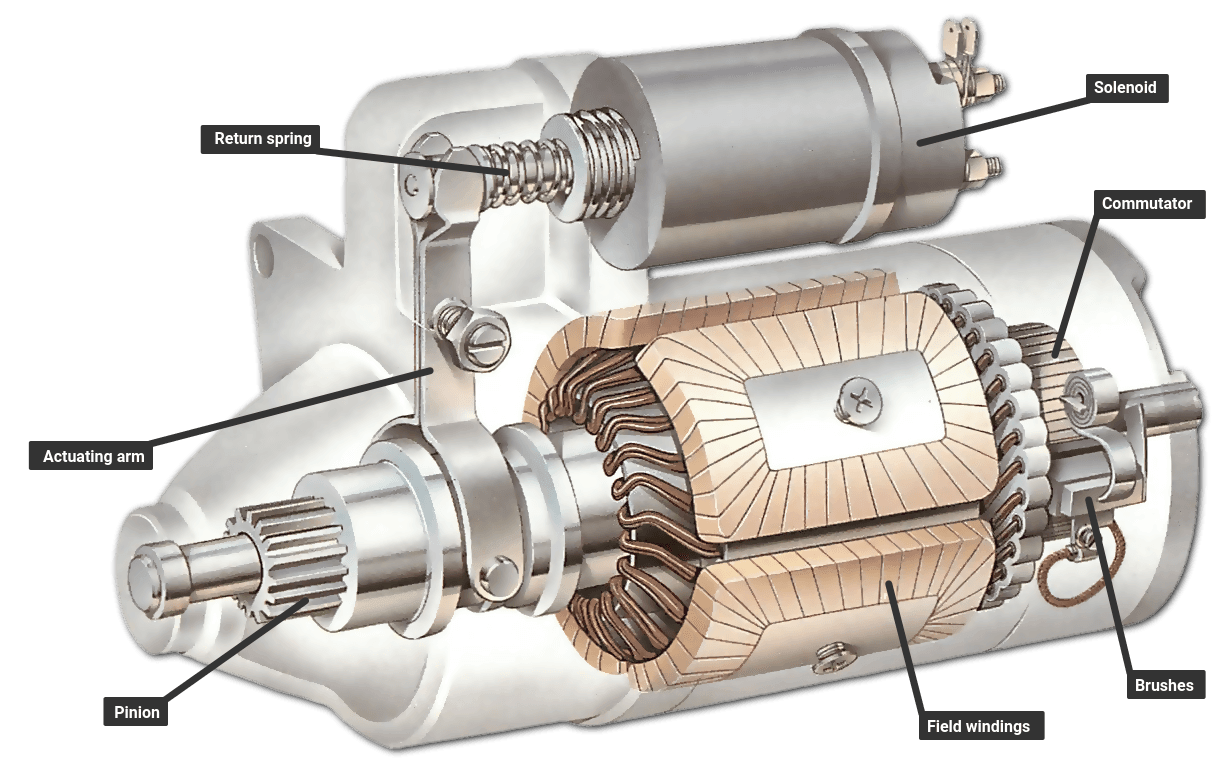

What Are the Advantages of Solenoid Integrated Starters?

Solenoid integrated starters come with a built-in solenoid, allowing for a more compact installation. This design is applicable across various automotive sectors. While they save space and simplify installation, buyers should consider the trade-off in serviceability, as these units can be more challenging to repair if issues arise.

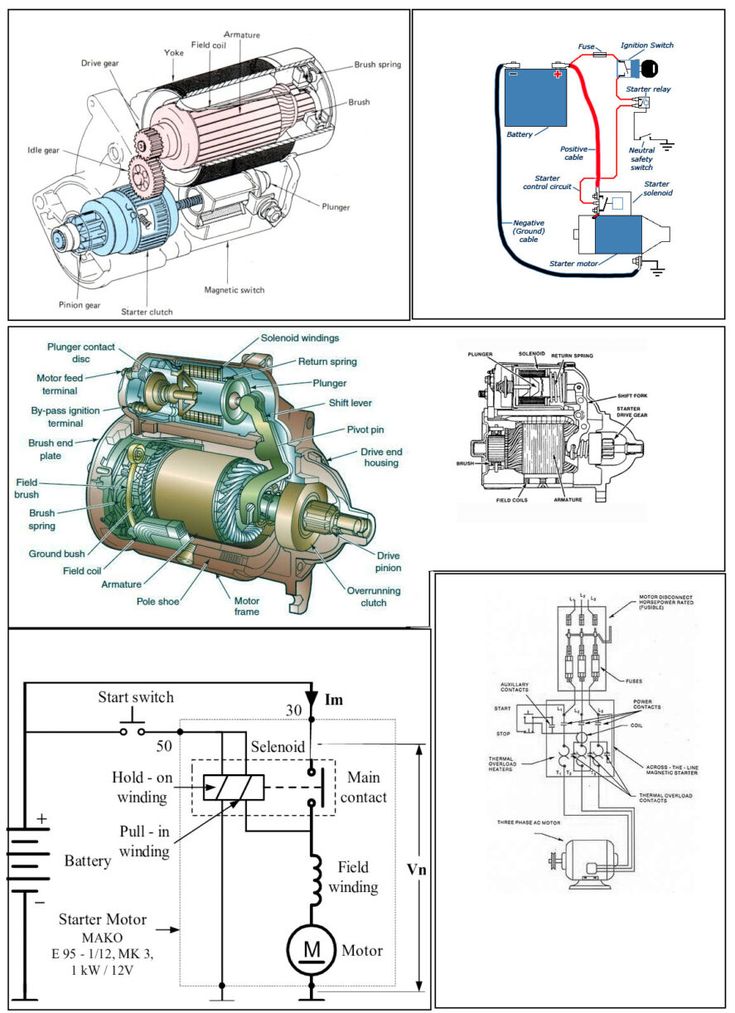

Illustrative image related to automotive starter parts

Key Industrial Applications of automotive starter parts

| Industry/Sector | Specific Application of automotive starter parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of new vehicles | Ensures reliable vehicle performance and customer satisfaction | Quality assurance and compliance with OEM specifications |

| Heavy-Duty Equipment | Construction machinery and trucks | Enhances operational efficiency and reduces downtime | Durability and compatibility with varying power requirements |

| Agricultural Machinery | Tractors and harvesters | Supports consistent performance in rugged environments | Availability of parts for diverse agricultural equipment |

| Marine Industry | Boat engines | Provides reliable starting in harsh marine conditions | Resistance to corrosion and environmental factors |

| Aftermarket Services | Remanufacturing and repair of starter systems | Cost-effective solutions for extending product life | Access to high-quality remanufactured parts and kits |

How Are Automotive Starter Parts Used in Automotive Manufacturing?

In the automotive manufacturing sector, starter parts are integral to the assembly of new vehicles. They ensure that engines start reliably under various conditions, directly impacting customer satisfaction and brand reputation. B2B buyers in this sector must prioritize sourcing starter parts that meet OEM specifications, ensuring quality and compliance. Manufacturers often face challenges such as fluctuating demand and the need for just-in-time delivery, making reliable suppliers crucial.

What Role Do Automotive Starter Parts Play in Heavy-Duty Equipment?

Heavy-duty equipment, such as construction machinery and trucks, relies on robust starter parts to initiate engine operation. These components are designed to withstand extreme conditions, enhancing operational efficiency and minimizing downtime. B2B buyers in this sector should focus on sourcing durable starter parts that can handle high torque demands and varying power requirements. Additionally, compatibility with diverse equipment models is essential for seamless integration.

How Are Starter Parts Essential for Agricultural Machinery?

In the agricultural sector, starter parts are vital for the operation of tractors and harvesters. These machines often work in rugged environments, necessitating reliable starting systems to ensure consistent performance. Buyers must consider the availability of parts for a wide range of agricultural equipment, as well as their ability to perform in extreme weather conditions. Sourcing high-quality components can significantly reduce maintenance costs and downtime, contributing to overall productivity.

Why Are Starter Parts Critical in the Marine Industry?

The marine industry utilizes starter parts in boat engines, where reliability is paramount due to the harsh marine environment. These components must withstand exposure to saltwater and other corrosive elements, ensuring dependable performance. B2B buyers in this sector should prioritize sourcing starter parts that are specifically designed for marine applications, focusing on corrosion resistance and the ability to function in challenging conditions. This ensures that vessels remain operational and safe.

How Do Aftermarket Services Benefit from Automotive Starter Parts?

Aftermarket services play a significant role in the remanufacturing and repair of starter systems. Sourcing high-quality remanufactured parts allows businesses to offer cost-effective solutions to customers, extending the life of existing equipment. Buyers in this sector should ensure access to a wide range of premium parts and rebuild kits, which can enhance customer satisfaction and loyalty. Additionally, understanding the specific needs of various vehicle models is crucial for successful aftermarket service.

3 Common User Pain Points for ‘automotive starter parts’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Starter Parts Procurement

The Problem: In the competitive landscape of automotive parts, B2B buyers often grapple with ensuring the quality and reliability of starter parts. Sourcing from unfamiliar suppliers can lead to receiving substandard products that fail to meet performance standards. This challenge is compounded in regions with varying quality control measures, leading to concerns about the longevity and reliability of the components being purchased. A faulty starter can not only disrupt operations but also tarnish a buyer’s reputation if customers receive unreliable vehicles or machinery.

The Solution: To mitigate quality concerns, B2B buyers should prioritize suppliers that provide transparent quality assurance processes. Look for vendors who offer detailed specifications and testing protocols for their starter parts, including performance sheets and certifications. Establishing relationships with manufacturers known for their rigorous testing, such as DENSO or Bosch, can also enhance confidence in product quality. Additionally, consider requesting samples or conducting small-scale trials before committing to larger orders. Implementing a robust supplier evaluation process that includes checking references and past performance can further ensure that only premium quality starter parts are procured.

Scenario 2: Overcoming Compatibility Issues with Diverse Vehicle Models

The Problem: Many B2B buyers face compatibility challenges when sourcing automotive starter parts due to the vast array of vehicle makes and models. This is particularly evident in regions like Africa and South America, where imported vehicles may require specific starter parts that are not readily available locally. The risk of ordering incorrect parts not only leads to increased costs but also impacts the ability to fulfill customer orders promptly, causing potential loss of business.

The Solution: To address compatibility issues, B2B buyers should invest in comprehensive databases or inventory management systems that detail the specifications of starter parts for various vehicle models. Utilizing tools that allow for cross-referencing OEM part numbers with aftermarket options can streamline the procurement process. Partnering with suppliers who have a wide-ranging inventory and can provide guidance on compatibility can also be beneficial. Furthermore, educating the purchasing team on the nuances of starter specifications—such as voltage ratings and pinion gear sizes—can empower them to make informed decisions, reducing the likelihood of errors.

Scenario 3: Managing Cost Constraints in Starter Parts Replacement

The Problem: Cost management is a persistent challenge for B2B buyers in the automotive industry, particularly when it comes to sourcing starter parts. The need for reliable components often clashes with budget constraints, leading buyers to compromise on quality or availability. This dilemma is especially acute in markets where price sensitivity is high, and buyers must balance quality with cost-effectiveness to maintain competitiveness.

The Solution: To effectively manage costs without sacrificing quality, B2B buyers should explore bulk purchasing agreements or long-term contracts with reliable suppliers. Many manufacturers offer discounts for large orders or loyalty programs that can yield significant savings over time. Additionally, considering remanufactured starter parts can be a cost-effective solution; these components are often refurbished to meet original performance standards at a lower price point. Buyers should also engage in thorough market research to identify emerging suppliers who can offer competitive pricing without compromising quality. Establishing a proactive inventory management strategy that anticipates demand can help reduce rush orders, which are typically more expensive.

Strategic Material Selection Guide for automotive starter parts

What Are the Key Materials Used in Automotive Starter Parts?

When selecting materials for automotive starter parts, several factors must be considered, including performance, durability, cost, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of starter components, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform in Automotive Starter Parts?

Steel is a widely used material in automotive starter parts due to its excellent strength and durability. It typically exhibits high tensile strength, making it suitable for components that endure significant mechanical stress, such as the starter housing and pinion gears. Steel also has good temperature resistance, withstanding high operating temperatures without significant deformation.

Illustrative image related to automotive starter parts

Pros: Steel’s durability and strength make it ideal for heavy-duty applications. It is also relatively inexpensive compared to other materials, making it a cost-effective choice for manufacturers.

Cons: Steel is susceptible to corrosion, which can be a significant drawback in environments with high humidity or exposure to road salt. Additionally, its weight can be a disadvantage in applications where reducing overall mass is critical.

Impact on Application: Steel components are well-suited for high-torque applications but require protective coatings or treatments to enhance corrosion resistance.

What Role Does Aluminum Play in Automotive Starter Parts?

Aluminum is another popular choice for automotive starter parts, particularly in components such as housings and brackets. Its lightweight nature contributes to overall vehicle efficiency, and it offers good corrosion resistance, especially when anodized.

Pros: The primary advantage of aluminum is its low weight, which helps improve fuel efficiency. It also has good thermal conductivity, which aids in heat dissipation.

Cons: While aluminum is strong, it is not as durable as steel and can be more susceptible to deformation under high stress. The cost of aluminum can also be higher, depending on market conditions.

Impact on Application: Aluminum is ideal for applications where weight savings are critical, but care must be taken to ensure that the design accommodates its lower strength compared to steel.

Why Is Copper Essential in Automotive Starter Parts?

Copper is often used in electrical components of automotive starters, such as terminals and wiring. Its excellent electrical conductivity ensures efficient power transfer, which is critical for starter performance.

Pros: Copper’s high conductivity and resistance to corrosion make it an excellent choice for electrical connections. It also has good thermal properties, allowing it to handle heat generated during operation effectively.

Cons: The primary disadvantage of copper is its cost, which can be significantly higher than that of steel or aluminum. Additionally, copper is relatively soft, making it less suitable for structural components.

Impact on Application: Copper is essential for components that require reliable electrical performance, but its higher cost may necessitate careful consideration in budget-sensitive projects.

How Does Plastic Contribute to Automotive Starter Parts?

Plastics, particularly engineering-grade polymers, are increasingly used in automotive starter parts for components like covers and insulators. These materials offer excellent resistance to corrosion and can be molded into complex shapes.

Pros: Plastics are lightweight and resistant to corrosion, making them suitable for various environmental conditions. They can also be produced at a lower cost, especially in high-volume applications.

Illustrative image related to automotive starter parts

Cons: Plastics generally have lower mechanical strength compared to metals and may not withstand high temperatures or mechanical stresses as effectively.

Impact on Application: Plastic components are ideal for non-structural applications where weight savings and corrosion resistance are essential, but they may not be suitable for high-stress areas.

Summary of Material Selection for Automotive Starter Parts

| Material | Typical Use Case for automotive starter parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Starter housings, pinion gears | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Housings, brackets | Lightweight, good corrosion resistance | Less durable than steel | Medium-High |

| Copper | Electrical terminals, wiring | Excellent electrical conductivity | Higher cost, relatively soft | High |

| Plastic | Covers, insulators | Lightweight, corrosion-resistant | Lower mechanical strength | Low-Medium |

This guide highlights the critical materials used in automotive starter parts, offering insights that can help international B2B buyers make informed decisions based on performance requirements, cost considerations, and compliance with industry standards.

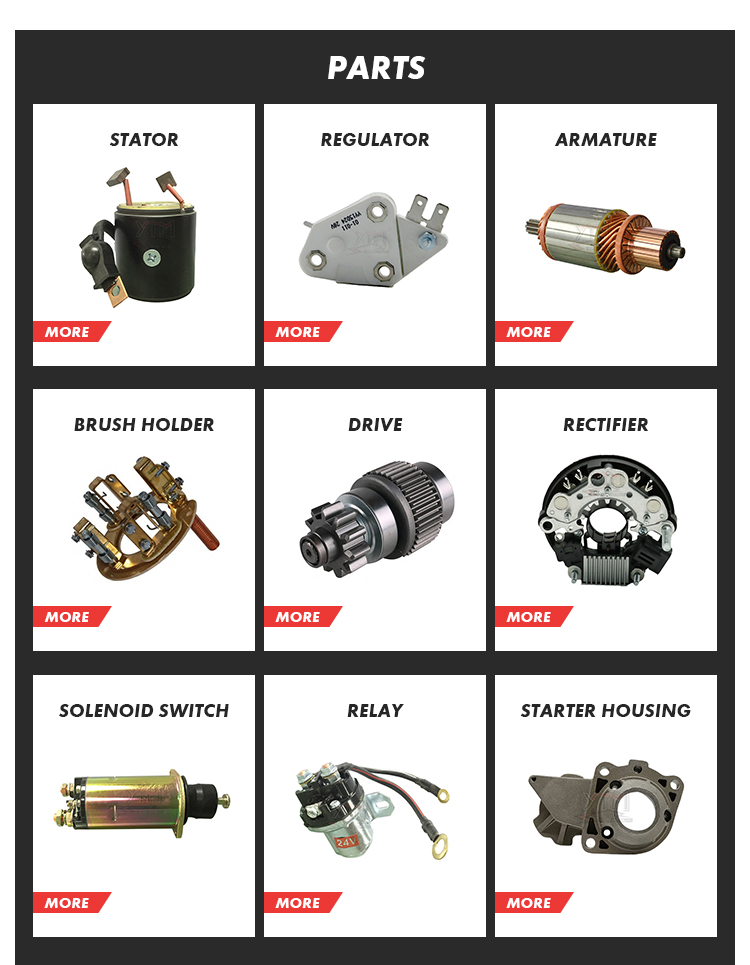

In-depth Look: Manufacturing Processes and Quality Assurance for automotive starter parts

What Are the Main Stages in the Manufacturing Process of Automotive Starter Parts?

The manufacturing process of automotive starter parts typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that the final product meets performance and quality standards.

-

Material Preparation: This stage begins with sourcing high-quality raw materials, such as steel and copper. These materials are often selected based on their electrical conductivity, durability, and resistance to corrosion. Advanced techniques like thermal treatment may be used to enhance the properties of these materials before they are processed further.

-

Forming: In this stage, the prepared materials undergo various forming processes, including stamping, machining, and casting. For instance, components like the armature and field coils are typically stamped from sheets of metal, while housings may be cast to provide the necessary strength and weight balance. Precision in this stage is crucial, as any deviations can affect the starter’s performance.

-

Assembly: Once the individual components are formed, they are assembled into the final starter unit. This involves intricate processes such as soldering and bolting, ensuring that all parts fit together seamlessly. Automated assembly lines are often employed to enhance efficiency and reduce human error during this stage.

-

Finishing: The finishing stage includes various surface treatments such as painting, coating, or plating to protect against corrosion and wear. This step is essential for ensuring the longevity and reliability of the starter parts, especially in harsh operating environments.

What Quality Control Measures Are Commonly Employed?

Quality assurance is integral to the manufacturing of automotive starter parts, with various international standards and industry-specific regulations guiding the process. Understanding these measures is essential for B2B buyers, especially those operating across different regions.

-

International Standards: Compliance with ISO 9001 is a fundamental requirement for many manufacturers. This standard focuses on quality management systems and ensures that companies consistently provide products that meet customer and regulatory requirements. Additionally, certifications like CE (Conformité Européenne) or API (American Petroleum Institute) are crucial for specific markets and applications.

-

Quality Control Checkpoints: Quality control typically involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This step involves inspecting raw materials before production begins. It ensures that the materials meet specified standards and are free from defects.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to monitor the quality of components. This includes measuring tolerances and conducting tests on assembled units to ensure they meet performance specifications.

– Final Quality Control (FQC): Once the starters are assembled, they undergo final inspections and testing. This includes performance testing under various conditions to ensure reliability and functionality.

What Testing Methods Are Commonly Used for Automotive Starter Parts?

Testing methods are crucial for verifying the performance and reliability of automotive starter parts. Manufacturers often employ several testing techniques to ensure that their products meet stringent quality standards.

-

Electrical Testing: This involves checking the electrical conductivity of components, ensuring that connections are secure and that the starter can handle the required voltage and current. High-voltage tests are often performed on armatures and field coils to verify their performance under load.

-

Mechanical Testing: Components are subjected to mechanical stress tests to evaluate their durability and strength. This may include fatigue testing to simulate long-term use and environmental testing to assess performance under extreme temperatures and conditions.

-

Functional Testing: Each starter unit is typically bench-tested to confirm that it operates correctly. This involves checking the cranking torque and ensuring that the starter engages and disengages properly.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is critical to ensure product reliability.

-

Supplier Audits: Conducting audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. Buyers should request access to audit reports and quality certifications to assess compliance with international standards.

-

Quality Reports: Suppliers should provide detailed quality reports that outline their quality assurance processes, including results from various testing stages. These reports can help buyers understand the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s operations. These agencies can conduct random inspections and tests on products before shipment, ensuring that they meet the agreed-upon specifications.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances when sourcing automotive starter parts. Factors such as regional standards, certification requirements, and logistical considerations can impact the purchasing process.

-

Regional Compliance: Different regions may have specific compliance requirements. For example, products sold in the European market often require CE marking, while those in the U.S. may need to meet additional EPA regulations. Buyers should familiarize themselves with these requirements to avoid regulatory issues.

-

Cultural Considerations: Understanding cultural differences in business practices can aid in fostering successful supplier relationships. Effective communication regarding quality expectations and standards is vital to ensure that both parties are aligned.

-

Logistics and Transportation: Quality control does not end with manufacturing. The transportation of starter parts can introduce additional risks, such as damage during shipping. Buyers should ensure that their suppliers have robust logistics processes in place, including proper packaging and handling procedures to protect the products during transit.

By comprehensively understanding the manufacturing processes and quality assurance practices for automotive starter parts, B2B buyers can make informed decisions, ensuring they source reliable, high-quality components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive starter parts’

Introduction

Sourcing automotive starter parts requires a strategic approach to ensure quality, reliability, and compliance with regional standards. This guide provides a step-by-step checklist designed to assist B2B buyers in navigating the procurement process effectively. By following these steps, you can make informed decisions that align with your operational needs and market demands.

1. Define Your Technical Specifications

Start by clearly outlining the specifications for the starter parts you need. Consider factors such as vehicle compatibility, voltage ratings (e.g., 12V, 24V), and torque requirements. This step is crucial as it sets the foundation for your procurement process and ensures that the parts will meet the operational demands of your vehicles.

Illustrative image related to automotive starter parts

2. Research and Identify Reliable Suppliers

Conduct thorough research to identify potential suppliers who specialize in automotive starter parts. Look for suppliers with a proven track record in your region, particularly those who understand the specific needs of the African, South American, Middle Eastern, and European markets. Reliable suppliers should have a robust inventory and provide detailed product information.

3. Evaluate Supplier Certifications

Verify that potential suppliers possess relevant certifications and quality standards, such as ISO 9001 or equivalent. These certifications indicate that the supplier adheres to quality management practices, ensuring that the parts meet international quality standards. Additionally, inquire about compliance with regional regulations and environmental standards, which can be critical in specific markets.

4. Request Samples and Test Quality

Before placing a large order, request samples of the starter parts to assess their quality firsthand. Testing samples can help you evaluate factors like durability, performance under various conditions, and compatibility with your vehicles. This step minimizes the risk of receiving defective parts and ensures that the products meet your expectations.

Illustrative image related to automotive starter parts

5. Review Terms and Conditions

Carefully examine the terms and conditions of the purchase agreement. Pay attention to warranties, return policies, and delivery timelines. Understanding these terms is vital to protect your investment and ensure that you have recourse in case of issues with the parts received.

6. Negotiate Pricing and Payment Terms

Engage in negotiations to secure favorable pricing and payment terms. Consider bulk purchase discounts, payment schedules, and shipping costs. Effective negotiation can lead to significant cost savings, especially for larger orders, and help establish a long-term relationship with your supplier.

7. Establish a Communication Plan

Set up a clear communication plan with your chosen supplier. Regular updates regarding order status, shipping timelines, and any potential issues are essential for smooth operations. A well-defined communication strategy fosters transparency and builds trust, ensuring a more efficient procurement process.

By following this checklist, B2B buyers can streamline their sourcing process for automotive starter parts, ensuring they select high-quality products that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for automotive starter parts Sourcing

What Are the Key Cost Components of Automotive Starter Parts?

When sourcing automotive starter parts, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts cost. High-grade metals and durable plastics are preferred for their longevity and performance but come at a premium. For instance, copper terminals and high-voltage tested components enhance reliability but increase material costs.

-

Labor: Labor costs vary based on geographic location and the complexity of manufacturing processes. Skilled labor is often required for assembly and quality assurance, influencing overall pricing.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and administrative expenses. Efficient production methods can reduce these overheads, allowing for competitive pricing.

-

Tooling: Initial investment in specialized tooling for production can be substantial. However, once amortized over large production runs, these costs can be minimized in per-unit pricing.

-

Quality Control (QC): Rigorous testing and quality assurance processes are critical in the automotive industry. These practices ensure that parts meet safety and performance standards but can add to the overall production cost.

-

Logistics: Transportation and shipping costs can vary significantly based on the supplier’s location and the destination market. International shipping may involve customs duties and tariffs, impacting the final cost to buyers.

-

Margin: Suppliers typically add a margin to cover business risks and ensure profitability. This margin can vary widely depending on market competition and supplier reputation.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence the pricing of automotive starter parts, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to discounts. Establishing a long-term relationship with suppliers can also secure better pricing terms based on consistent order volumes.

-

Specifications and Customization: Customized parts that meet specific vehicle requirements may command higher prices. Buyers should weigh the benefits of tailored solutions against potential cost increases.

-

Materials and Quality Certifications: The quality of materials and certifications (e.g., ISO, TS16949) can significantly affect pricing. Premium products typically include enhanced warranties and performance guarantees.

-

Supplier Factors: The reputation and reliability of the supplier can impact price. Established suppliers may charge more but offer superior quality and service, leading to lower Total Cost of Ownership (TCO).

-

Incoterms: Understanding shipping terms is crucial. Different Incoterms (e.g., FOB, CIF) can affect the total landed cost of products, influencing overall purchasing decisions.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

To optimize sourcing strategies and achieve cost savings, international B2B buyers should consider the following tips:

-

Negotiate Terms: Leverage volume purchases and long-term agreements to negotiate better pricing and payment terms. A clear understanding of the supplier’s cost structure can provide leverage during negotiations.

-

Evaluate Total Cost of Ownership: Consider not only the purchase price but also factors like reliability, warranty, and maintenance costs. Investing in higher-quality parts may reduce long-term expenses.

-

Understand Pricing Nuances for International Markets: Different regions may have varying pricing strategies based on local market conditions. For instance, buyers from Africa and South America may encounter additional challenges like currency fluctuations and import tariffs, which can affect final costs.

-

Conduct Market Research: Regularly analyze market trends and competitor pricing. This knowledge can empower buyers to make informed decisions and identify opportunities for savings.

In conclusion, by understanding the cost components and pricing influencers, along with implementing strategic sourcing tips, international B2B buyers can enhance their purchasing decisions for automotive starter parts. It is essential to remain informed and adaptable to ensure a competitive edge in the global market.

Alternatives Analysis: Comparing automotive starter parts With Other Solutions

Exploring Alternative Solutions to Automotive Starter Parts

In the automotive industry, the choice of components can significantly affect performance, reliability, and overall operational costs. While automotive starter parts are essential for vehicle ignition, there are viable alternatives that serve similar functions. This analysis will compare automotive starter parts with two alternative solutions: Hybrid Starter Systems and Battery-Integrated Start/Stop Systems. Understanding these alternatives will help B2B buyers make informed decisions based on their specific needs.

| Comparison Aspect | Automotive Starter Parts | Hybrid Starter Systems | Battery-Integrated Start/Stop Systems |

|---|---|---|---|

| Performance | Reliable ignition under various conditions | Offers quick starts, energy-efficient | Immediate restart capabilities, improves fuel efficiency |

| Cost | Generally lower initial costs | Higher upfront investment | Moderate costs, savings on fuel over time |

| Ease of Implementation | Straightforward installation for most vehicles | Requires specialized installation | Integrates with existing electrical systems |

| Maintenance | Routine checks needed, parts replacements common | Minimal maintenance, but complex tech | Low maintenance due to fewer mechanical parts |

| Best Use Case | Standard internal combustion engines | Hybrid and electric vehicles | Urban driving where frequent stops occur |

What Are the Advantages and Disadvantages of Hybrid Starter Systems?

Hybrid starter systems combine traditional starters with electric motors to enhance performance. They provide faster ignition and can recover energy during braking, making them particularly effective for hybrid and electric vehicles. However, the complexity of these systems can lead to higher installation costs and may require specialized technicians for maintenance. While they offer significant performance benefits, the initial investment may be a barrier for some businesses.

How Do Battery-Integrated Start/Stop Systems Work and What Are Their Benefits?

Battery-integrated start/stop systems are designed to shut off the engine when the vehicle is stationary and restart it when the driver releases the brake. This technology significantly improves fuel efficiency, especially in urban environments where frequent stops are common. While the system requires a specialized battery and can be more costly than traditional starters, the long-term savings on fuel can offset these initial expenses. Additionally, these systems require less maintenance, as they have fewer moving parts compared to traditional starters.

Illustrative image related to automotive starter parts

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between automotive starter parts and alternative solutions, B2B buyers should evaluate their specific operational requirements. Factors such as the type of vehicles in use, the driving conditions, and budget constraints play crucial roles in this decision-making process. For businesses focused on traditional internal combustion engines and looking for cost-effective solutions, automotive starter parts may be the best choice. Conversely, companies investing in hybrid or electric vehicles should consider hybrid starter systems or battery-integrated solutions for enhanced performance and efficiency. Ultimately, understanding the trade-offs between upfront costs and long-term savings will guide buyers to the most suitable option for their fleet.

Essential Technical Properties and Trade Terminology for automotive starter parts

What Are the Key Technical Properties of Automotive Starter Parts?

When sourcing automotive starter parts, understanding the technical specifications is essential for ensuring product quality and compatibility. Here are some critical specifications to consider:

1. Material Grade

The material grade of starter components, such as the housing and gears, significantly impacts durability and performance. Common materials include high-grade steel and aluminum alloys, which provide strength and resistance to wear and corrosion. For B2B buyers, selecting the right material can enhance the lifespan of the starter, reducing the need for frequent replacements and thereby lowering overall maintenance costs.

2. Torque Rating

Torque rating refers to the amount of rotational force the starter can generate. It is typically measured in Newton-meters (Nm) or foot-pounds (ft-lbs). A higher torque rating indicates better performance in starting engines, especially in extreme conditions such as cold weather. B2B buyers should ensure that the torque rating aligns with the specifications of the vehicles they service, as inadequate torque can lead to starting failures.

3. Voltage Rating

Most automotive starters operate on 12V or 24V systems, with the voltage rating being a crucial specification. The voltage rating must match the vehicle’s electrical system to prevent damage and ensure proper functionality. Buyers should confirm the voltage requirements for their applications to ensure compatibility and optimal performance.

4. K/W Rating

The kilowatt (kW) rating indicates the power output of the starter motor. This specification is vital when matching starters to specific vehicles, as different engines require varying power levels for effective starting. Selecting a starter with the appropriate kW rating can prevent excessive wear and ensure reliable performance under different operating conditions.

5. Pinion Gear Teeth Count

The number of teeth on the pinion gear is another essential property. This specification affects the engagement with the flywheel and can influence starting efficiency. A mismatch in teeth count can lead to poor engagement, resulting in starter failures. B2B buyers should verify this detail to ensure compatibility with the vehicle’s flywheel.

6. Testing Standards

Manufacturers often adhere to industry testing standards to ensure reliability and performance. These tests may include high-voltage testing of armatures and field coils, which are crucial for confirming that the starter will perform as expected under various conditions. For buyers, sourcing products from manufacturers that follow rigorous testing protocols can provide peace of mind regarding product quality.

What Common Trade Terms Should B2B Buyers Know in the Automotive Starter Parts Industry?

Understanding industry jargon can enhance communication and facilitate smoother transactions. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle’s original manufacturer. These parts are designed to meet specific vehicle standards, ensuring compatibility and reliability. B2B buyers often prefer OEM parts for their quality assurance and warranty coverage.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest order quantity a supplier is willing to accept. This term is crucial for B2B buyers as it affects inventory management and purchasing strategies. Knowing the MOQ helps businesses optimize stock levels and manage cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing RFQs can streamline the procurement process and ensure competitive pricing from multiple suppliers, aiding in better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers engaged in international trade, as they help clarify delivery responsibilities and costs.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. This term is essential for B2B buyers as it affects inventory planning and customer satisfaction. Knowing the lead time can help businesses manage expectations and ensure timely deliveries.

Illustrative image related to automotive starter parts

6. Warranty Period

The warranty period is the duration a manufacturer guarantees the product against defects. For B2B buyers, understanding warranty terms is critical for assessing risk and ensuring product reliability over time. A longer warranty period often indicates higher confidence in product quality from the manufacturer.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right automotive starter parts for their business needs.

Navigating Market Dynamics and Sourcing Trends in the automotive starter parts Sector

What Are the Current Market Dynamics and Key Trends in the Automotive Starter Parts Sector?

The automotive starter parts market is witnessing significant growth driven by several global factors. Increased vehicle production, particularly in emerging markets in Africa, South America, and the Middle East, is a primary driver. As these regions enhance their automotive manufacturing capabilities, there is a rising demand for reliable starter components. Additionally, the shift towards electric vehicles (EVs) and hybrid models is reshaping sourcing strategies, with a growing emphasis on components that can support new technologies.

International B2B buyers are increasingly leveraging digital platforms for sourcing automotive starter parts. E-commerce solutions and B2B marketplaces provide access to a wider inventory and enable buyers to compare prices and quality easily. Moreover, advanced technologies such as AI and machine learning are being integrated into supply chain management, allowing for more efficient inventory control and predictive analytics, which can anticipate demand fluctuations.

Emerging trends also include the focus on remanufactured parts, which offer cost-effective and environmentally friendly alternatives to new components. As global supply chains become more interconnected, international buyers must navigate complexities related to tariffs and trade regulations, particularly in regions like Europe and the Middle East. Understanding local market dynamics and regulatory frameworks is crucial for successful sourcing strategies.

Illustrative image related to automotive starter parts

How Is Sustainability and Ethical Sourcing Shaping the Automotive Starter Parts Industry?

Sustainability is becoming a cornerstone of the automotive starter parts sector. As global awareness of environmental issues rises, manufacturers and suppliers are increasingly held accountable for their environmental impact. This shift emphasizes the importance of ethical supply chains, where sourcing practices prioritize environmentally friendly materials and processes.

For B2B buyers, selecting suppliers who adhere to sustainability standards is essential. Certifications such as ISO 14001 (Environmental Management) and adherence to the EU’s REACH regulations can serve as indicators of a supplier’s commitment to sustainable practices. Additionally, the use of recycled materials in the production of starter parts not only reduces environmental impact but can also enhance a company’s reputation among environmentally conscious consumers.

Moreover, the growing demand for ‘green’ components is prompting manufacturers to innovate. This includes developing starter parts designed for energy efficiency and lower emissions, aligning with the automotive industry’s broader shift towards sustainability. As a result, buyers should prioritize partnerships with suppliers who are not only compliant with current regulations but are also proactive in adopting sustainable practices.

Illustrative image related to automotive starter parts

How Has the Automotive Starter Parts Industry Evolved Over Time?

The automotive starter parts industry has undergone significant evolution since its inception. Initially, starters were simple mechanical devices; however, advancements in technology have transformed them into complex electrical components that enhance vehicle performance. The introduction of gear-reduction starters revolutionized the market by providing greater torque in a smaller package, addressing the growing demand for efficiency in modern vehicles.

Over the decades, the focus has shifted from merely functionality to reliability and sustainability. Remanufacturing processes have gained traction, allowing for the recycling of valuable materials and reducing waste. Today’s market is characterized by a blend of traditional and innovative practices, with an increasing emphasis on meeting the demands of both internal combustion and electric vehicles. This evolution continues to shape sourcing strategies for international B2B buyers, who must stay informed about technological advancements and regulatory changes to remain competitive in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of automotive starter parts

-

How do I determine the right automotive starter part for my vehicle?

To identify the correct automotive starter part, you should start by checking your vehicle’s make, model, and year. Utilize the part number from your existing starter or refer to your vehicle’s service manual. Many suppliers provide online tools to help match parts based on these specifications. Additionally, consider the starter’s voltage and kW rating to ensure compatibility. If needed, consult with your supplier’s technical support for assistance. -

What is the best brand of automotive starter parts for reliability?

Brands like Bosch, Denso, and Valeo are renowned for their quality and reliability in automotive starter parts. They utilize advanced manufacturing processes and high-quality materials, ensuring longevity and performance. For B2B buyers, partnering with reputable brands can reduce return rates and warranty claims, ultimately leading to increased customer satisfaction. It’s also advisable to check for remanufactured options, which can provide excellent value without compromising quality. -

What should I consider when vetting suppliers for automotive starter parts?

When vetting suppliers, consider their reputation, product quality, and industry experience. Look for suppliers who have certifications like ISO to ensure they meet international standards. Request references from other B2B clients and check online reviews. Additionally, evaluate their inventory range, lead times, and after-sales support. A reliable supplier should also be transparent about their sourcing and manufacturing processes. -

What is the typical minimum order quantity (MOQ) for automotive starter parts?

MOQs can vary significantly based on the supplier and the specific part. Typically, MOQs for automotive starter parts can range from 10 to 100 units, depending on the part’s cost and demand. Some suppliers may offer flexibility for first-time orders or for established relationships. Always inquire about potential discounts for bulk purchases, as this can significantly affect your overall costs. -

What payment terms should I expect when sourcing automotive starter parts?

Payment terms can differ by supplier but generally include options like upfront payment, net 30, or net 60 days. Some suppliers may also accept letters of credit or escrow services for larger orders. It’s essential to clarify these terms before finalizing any contracts, as they can impact your cash flow. Always ensure that payment methods are secure and reliable to protect your investment. -

How can I ensure quality assurance for automotive starter parts?

To ensure quality assurance, request detailed quality control processes from your supplier. Look for suppliers who conduct rigorous testing, including bench tests and material inspections, for their starter parts. Certifications like ISO 9001 can indicate adherence to quality management standards. Additionally, consider requesting samples or trial orders to evaluate the parts before committing to larger purchases. -

What are the logistics considerations for importing automotive starter parts?

When importing automotive starter parts, consider shipping methods, lead times, and customs regulations in your country. Choose a logistics partner experienced in handling automotive parts to avoid delays. Understand the associated costs, including duties and taxes, which can impact your total landed cost. It’s also crucial to have a clear plan for inventory management upon arrival to ensure timely distribution. -

Can I customize automotive starter parts for specific applications?

Yes, many suppliers offer customization options for automotive starter parts to meet specific application requirements. This can include modifications in voltage, size, or design features. When seeking customization, provide detailed specifications and discuss your needs with the supplier early in the process. Custom parts may come with longer lead times and potentially higher costs, so factor this into your planning.

Top 2 Automotive Starter Parts Manufacturers & Suppliers List

1. GM Parts – Automotive Alternators & Starters

Domain: gmparts.com

Registered: 1996 (29 years)

Introduction: Automotive alternators and starter parts from GM Parts include new and remanufactured options. GM Genuine Parts alternators are equipped with high-efficiency generators designed for modern vehicles, meeting GM’s noise and vibration standards. Original Equipment (OE) parts are 100% new and exact replacements for GM vehicles. Remanufactured parts, such as ACDelco Gold, are manufactured to GM specifi…

2. Quality-Built – Vehicle Starters

Domain: motorcarparts.com

Registered: 2000 (25 years)

Introduction: Vehicle Starters, Alternators, Master Cylinders, Hub Assemblies and Bearings, Brake Power Boosters, Rotors, Brake Pads and Shoes, Calipers. Brands include Quality-Built, Quality-Built Black Series, Pure Energy, D&V Electronics, Dixie Electric.

Strategic Sourcing Conclusion and Outlook for automotive starter parts

How Can Strategic Sourcing Enhance Your Procurement of Automotive Starter Parts?

In today’s competitive automotive market, effective strategic sourcing is crucial for securing high-quality starter parts that meet diverse operational needs. By partnering with reputable suppliers who offer extensive inventories and specialized products, international B2B buyers can gain access to premium starter components, including both new and remanufactured options. This not only ensures reliability but also provides cost-effective solutions that enhance overall vehicle performance.

Moreover, the emphasis on environmentally responsible practices, such as utilizing remanufactured parts, aligns with global sustainability goals, making your procurement strategy not just economically sound but also socially responsible. Buyers should prioritize suppliers who demonstrate rigorous testing and quality assurance processes, as this will significantly reduce return rates and enhance customer satisfaction.

Looking ahead, as automotive technologies evolve and demand shifts, proactive sourcing strategies will become increasingly vital. Engage with trusted manufacturers and distributors to stay ahead of market trends and supply chain challenges. By investing in strategic sourcing now, you position your business to thrive in the dynamic automotive landscape, ensuring you have the right parts when you need them most.

Illustrative image related to automotive starter parts

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.