Introduction: Navigating the Global Market for alternator chinese

In the ever-evolving landscape of international trade, sourcing reliable and high-quality Chinese alternators can be a daunting challenge for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. These buyers often grapple with ensuring product quality, navigating regulatory standards, and managing supply chain complexities. This comprehensive guide is designed to address these challenges head-on, providing a holistic approach to understanding the global market for Chinese alternators.

Within this guide, you will find detailed insights into various types of alternators, including single-phase and three-phase models, their applications in industries ranging from automotive to renewable energy, and the critical factors to consider when vetting suppliers. Additionally, we will explore cost considerations, shipping logistics, and best practices for negotiating contracts to secure the best deals.

By empowering B2B buyers with actionable knowledge and expert advice, this guide aims to simplify the purchasing process, enabling informed decision-making. Whether you are a buyer in Nigeria looking for robust diesel generator alternators or a Brazilian entrepreneur seeking cost-effective solutions for your manufacturing needs, this resource will equip you with the tools necessary to navigate the complexities of sourcing Chinese alternators effectively.

Table Of Contents

- Top 4 Alternator Chinese Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator chinese

- Understanding alternator chinese Types and Variations

- Key Industrial Applications of alternator chinese

- 3 Common User Pain Points for ‘alternator chinese’ & Their Solutions

- Strategic Material Selection Guide for alternator chinese

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator chinese

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator chinese’

- Comprehensive Cost and Pricing Analysis for alternator chinese Sourcing

- Alternatives Analysis: Comparing alternator chinese With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator chinese

- Navigating Market Dynamics and Sourcing Trends in the alternator chinese Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator chinese

- Strategic Sourcing Conclusion and Outlook for alternator chinese

- Important Disclaimer & Terms of Use

Understanding alternator chinese Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Alternator | Produces alternating current; compact design | Automotive, industrial machinery | Pros: Reliable power output; versatile applications. Cons: May require specific maintenance. |

| Brushless Alternator | Reduced wear and tear; no brushes needed | Renewable energy systems, generators | Pros: Lower maintenance costs; longer lifespan. Cons: Higher initial investment. |

| Synchronous Alternator | Operates at constant speed; high efficiency | Power plants, large-scale generators | Pros: Stable frequency output; ideal for grid connection. Cons: Complex installation. |

| Single-Phase Alternator | Simple design; typically lower power output | Small appliances, residential use | Pros: Cost-effective; easy to install. Cons: Limited power capacity. |

| Three-Phase Alternator | High power output; balanced load distribution | Industrial applications, heavy machinery | Pros: Efficient power transmission; better load handling. Cons: More complex circuitry. |

What Are the Characteristics of AC Alternators and Their Suitability for B2B Buyers?

AC alternators are widely used due to their ability to generate alternating current, making them essential for automotive and industrial applications. Their compact design allows for easy integration into various systems. When considering an AC alternator, B2B buyers should evaluate the reliability of the power output and the need for regular maintenance, which can influence operational efficiency and costs.

How Do Brushless Alternators Differ from Traditional Models?

Brushless alternators are characterized by their lack of brushes, which significantly reduces wear and tear. This feature makes them particularly suitable for renewable energy systems and generators, where longevity and minimal maintenance are critical. For B2B buyers, the initial investment may be higher, but the long-term savings in maintenance and replacement parts can justify the cost.

What Are the Advantages of Synchronous Alternators for Large-Scale Applications?

Synchronous alternators operate at a constant speed and are known for their high efficiency, making them ideal for power plants and large-scale generators. Their ability to maintain a stable frequency output is crucial for grid connection. B2B purchasers should consider the complexity of installation and the need for skilled technicians, which can add to the initial setup costs.

Why Choose Single-Phase Alternators for Smaller Applications?

Single-phase alternators are typically used in small appliances and residential settings due to their straightforward design and lower power output. They are cost-effective and easy to install, making them attractive for B2B buyers looking for budget-friendly options. However, their limited capacity may restrict their use in larger applications.

What Makes Three-Phase Alternators Ideal for Industrial Use?

Three-phase alternators offer high power output and balanced load distribution, making them suitable for industrial applications and heavy machinery. Their efficiency in power transmission and superior load handling capabilities are significant advantages for B2B buyers. However, the complexity of their circuitry may require additional expertise for installation and maintenance, influencing the overall cost of ownership.

Key Industrial Applications of alternator chinese

| Industry/Sector | Specific Application of alternator chinese | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Power generation in vehicles (cars, trucks) | Reliable electrical supply for vehicle systems, enhancing performance and durability. | Quality standards, compatibility with vehicle models, voltage requirements. |

| Renewable Energy | Integration in wind and solar power systems | Efficient conversion of renewable energy into usable AC electricity, promoting sustainability. | Certifications for renewable applications, efficiency ratings, and durability in diverse climates. |

| Construction | Backup power generation for construction sites | Ensures continuous operation of equipment and tools, minimizing downtime. | Fuel type compatibility, power output specifications, and portability for site conditions. |

| Marine | Power supply for boats and ships | Reliable energy source for navigation and onboard systems, enhancing safety. | Marine-grade specifications, corrosion resistance, and compliance with maritime regulations. |

| Industrial Manufacturing | Powering machinery and equipment in factories | Supports productivity by providing stable power for heavy machinery, reducing operational interruptions. | Sourcing from reputable manufacturers, assessing load requirements, and ensuring after-sales support. |

How is ‘alternator chinese’ Used in the Automotive Sector?

In the automotive industry, ‘alternator chinese’ is critical for generating electrical power within vehicles. It converts mechanical energy from the engine into alternating current (AC), which powers essential systems such as lighting, ignition, and infotainment. Reliable performance is crucial as vehicle owners expect consistent functionality. International buyers should consider compatibility with specific vehicle models, quality certifications, and the voltage output to ensure optimal performance and longevity.

What Role Does ‘alternator chinese’ Play in Renewable Energy Applications?

In renewable energy applications, particularly in wind and solar installations, ‘alternator chinese’ is utilized to convert generated energy into usable AC electricity. This conversion is vital for integrating renewable sources into the grid or for local consumption. Buyers should prioritize efficiency ratings and certifications that validate the alternator’s performance in renewable contexts. Additionally, durability against environmental factors such as humidity and temperature fluctuations is essential for long-term operation.

How is ‘alternator chinese’ Essential for Construction Sites?

Construction sites often require temporary power solutions, making ‘alternator chinese’ indispensable for providing backup power to tools and equipment. This ensures that operations can continue smoothly, minimizing downtime and associated costs. When sourcing alternators for construction, buyers must consider fuel type compatibility, the required power output based on equipment needs, and portability to adapt to changing site conditions.

Why is ‘alternator chinese’ Important in Marine Applications?

In the marine sector, ‘alternator chinese’ serves as a reliable power source for boats and ships, supplying electricity for navigation, communication, and onboard systems. The reliability of the alternator is vital for safety and operational efficiency at sea. Buyers should focus on marine-grade specifications that include corrosion resistance and compliance with maritime safety regulations to ensure longevity and performance in harsh marine environments.

How Does ‘alternator chinese’ Support Industrial Manufacturing?

In industrial manufacturing, ‘alternator chinese’ is crucial for powering heavy machinery and equipment. A stable power supply enhances productivity by reducing operational interruptions, thus improving overall efficiency. Businesses must assess their load requirements and ensure they are sourcing from reputable manufacturers that provide adequate after-sales support and warranties, ensuring that production processes remain uninterrupted.

3 Common User Pain Points for ‘alternator chinese’ & Their Solutions

Scenario 1: Quality Assurance in Sourcing Chinese Alternators

The Problem: One of the most pressing challenges faced by B2B buyers sourcing alternators from China is the inconsistency in product quality. Many buyers have experienced issues where the alternators do not meet the specified performance standards or durability requirements, leading to operational inefficiencies and increased costs. This is particularly concerning for businesses in sectors like automotive or industrial machinery, where reliability is paramount.

The Solution: To mitigate quality risks, buyers should conduct thorough due diligence on potential suppliers. This includes checking for certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, buyers should request product samples to evaluate performance before placing larger orders. Establishing clear specifications for the alternators—such as voltage, power output, and dimensions—will help ensure that the products meet operational needs. Collaborating with a local quality control agency can also provide peace of mind, as they can conduct inspections during production and before shipment to verify compliance with the specified standards.

Scenario 2: Navigating Language Barriers and Communication Issues

The Problem: Communication can often become a significant barrier when dealing with manufacturers in China, particularly for international buyers from regions like Africa or South America. Misunderstandings regarding specifications, order quantities, or delivery timelines can lead to costly delays and frustration. These communication challenges can result in receiving incorrect products or misaligned expectations about delivery schedules.

The Solution: To enhance communication, buyers should consider hiring a professional translator or working with a sourcing agent who is fluent in both English and Mandarin. This can help bridge the gap and ensure that technical specifications are clearly understood. Additionally, utilizing visual aids such as diagrams or charts when discussing product specifications can help clarify expectations. Regular follow-ups via email or messaging platforms can keep all parties aligned on the project’s status, thereby reducing the chances of miscommunication.

Scenario 3: Understanding Import Regulations and Compliance

The Problem: International buyers often struggle with navigating the complex web of import regulations and compliance requirements when sourcing alternators from China. This can lead to unexpected delays at customs or even penalties if products do not meet local standards. For instance, buyers in Europe may face stringent EU regulations regarding electrical safety and emissions, making compliance critical.

The Solution: It is essential for buyers to familiarize themselves with the import regulations specific to their regions before placing orders. This includes understanding certifications required for electrical products, such as CE marking in Europe or NOM certification in Mexico. Collaborating with a freight forwarder who specializes in international shipping can also streamline the process, as they can provide guidance on documentation and compliance. Furthermore, maintaining open lines of communication with suppliers about compliance can prevent issues, as they may be able to assist in meeting regulatory requirements or provide necessary documentation for customs clearance.

Strategic Material Selection Guide for alternator chinese

What Materials Are Commonly Used in Chinese Alternators?

When selecting materials for alternators, especially those manufactured in China, it is essential to consider the properties and performance characteristics of each material. This analysis focuses on four common materials: aluminum, copper, steel, and plastic composites. Each material offers unique advantages and disadvantages that can significantly affect the performance and suitability of the alternator for various applications.

How Does Aluminum Perform in Alternator Manufacturing?

Aluminum is a widely used material in alternator construction due to its lightweight and excellent thermal conductivity. It typically has a temperature rating of up to 150°C and is resistant to corrosion, making it suitable for various environmental conditions. The primary advantage of aluminum is its low weight, which contributes to overall vehicle efficiency. However, its lower strength compared to steel can be a limitation in high-stress applications. International buyers should ensure that aluminum components comply with standards such as ASTM B221 or JIS H4000, which govern the quality and performance of aluminum alloys.

What Role Does Copper Play in Alternator Efficiency?

Copper is essential in alternators for its superior electrical conductivity, which enhances efficiency and performance. It can withstand high temperatures and has excellent resistance to corrosion, making it ideal for electrical connections within the alternator. The primary disadvantage of copper is its higher cost and weight compared to aluminum. Buyers in regions like Africa and South America should consider the availability of copper and its price fluctuations, which can impact overall production costs. Compliance with international standards such as ASTM B170 for copper quality is crucial for ensuring reliability.

Why Is Steel Used in Alternator Construction?

Steel is often employed in alternator frames and housing due to its high strength and durability. It can withstand significant mechanical stress and has a temperature rating that can exceed 200°C, making it suitable for heavy-duty applications. The downside of steel is its susceptibility to corrosion, which can be mitigated through coatings or galvanization. For international buyers, understanding the specific steel grades, such as those outlined in ASTM A36 or JIS G3101, is essential to ensure compatibility with their operational environments, especially in humid or corrosive conditions.

How Do Plastic Composites Enhance Alternator Design?

Plastic composites are increasingly used in alternator components due to their lightweight and corrosion-resistant properties. They can operate effectively at temperatures up to 120°C and provide good insulation for electrical parts. The main advantages of plastic composites are their lower manufacturing costs and ease of molding into complex shapes. However, they may not offer the same mechanical strength as metals, making them less suitable for high-stress applications. Buyers should ensure that the chosen plastic materials comply with relevant standards, such as ASTM D638 for tensile properties, to guarantee performance.

Summary Table of Material Selection for Chinese Alternators

| Material | Typical Use Case for alternator chinese | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and casing | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Copper | Windings and electrical connections | Excellent electrical conductivity | Higher cost and weight | High |

| Steel | Frame and structural components | High strength and durability | Susceptible to corrosion | Medium |

| Plastic Composites | Insulation and non-structural parts | Lightweight and cost-effective | Lower mechanical strength | Low |

This guide provides a comprehensive overview of the materials used in Chinese alternators, highlighting their properties and considerations for international B2B buyers. Understanding these factors will enable buyers to make informed decisions that align with their operational requirements and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator chinese

What Are the Main Stages of Manufacturing Chinese Alternators?

The manufacturing of alternators in China involves a series of well-defined stages aimed at ensuring product quality and performance. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality raw materials such as copper, aluminum, and steel. These materials are critical for the electrical and mechanical components of the alternator. Suppliers often conduct rigorous testing to ensure that materials meet industry standards before they are used in production.

-

Forming: This stage involves shaping the raw materials into the required components. Techniques such as stamping, machining, and die-casting are commonly employed. For instance, rotor and stator components are typically machined to precise specifications to ensure optimal performance.

-

Assembly: Once the components are formed, they are assembled into a complete alternator. This process may involve manual and automated methods, ensuring that each part fits correctly and functions as intended. Key components such as bearings, windings, and housing are carefully integrated during this stage.

-

Finishing: The final stage involves applying surface treatments and protective coatings to enhance durability and performance. This may include painting, anodizing, or applying insulation materials. The finishing process also includes quality checks to ensure that the alternators meet aesthetic and functional standards.

What Quality Control Measures Are Implemented in Chinese Alternator Manufacturing?

Quality assurance is a critical aspect of the manufacturing process for alternators. Manufacturers in China adhere to international and industry-specific standards to ensure product reliability and safety.

-

Adherence to International Standards: Many Chinese manufacturers comply with ISO 9001, which outlines requirements for a quality management system. This certification demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be pursued depending on the application of the alternators.

-

Quality Control Checkpoints: The quality control process typically includes several checkpoints:

– Incoming Quality Control (IQC): This initial inspection focuses on the raw materials and components received from suppliers. Materials are tested against specifications to prevent defects from entering the production line.

– In-Process Quality Control (IPQC): During the manufacturing stages, operators conduct ongoing inspections to ensure that each component meets predefined quality criteria. This helps identify issues early in the process.

– Final Quality Control (FQC): After assembly, the completed alternators undergo final inspections and testing. This includes performance tests to verify electrical output and mechanical integrity. -

Testing Methods for Quality Assurance: Common testing methods include:

– Electrical Testing: Assessing voltage output, current efficiency, and insulation resistance to ensure that the alternator performs as expected.

– Mechanical Testing: Evaluating the physical integrity of components under stress to verify durability.

– Vibration and Noise Testing: Ensuring that the alternator operates smoothly without excessive noise or vibration, which can indicate underlying issues.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of Chinese alternator manufacturers is crucial.

-

Conducting Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Buyers can assess compliance with international standards and industry-specific certifications during these audits.

-

Requesting Quality Reports: Suppliers should provide documentation regarding their quality control procedures, including inspection reports, test results, and certifications. Buyers should not hesitate to request these documents to ensure transparency.

-

Engaging Third-Party Inspection Services: Utilizing third-party inspection services can provide an objective assessment of the manufacturer’s quality control processes. These services can conduct inspections at various stages of production and deliver detailed reports on compliance with specified quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control in Chinese manufacturing is essential for B2B buyers. Here are several key points to consider:

-

Cultural Differences in Quality Expectations: Buyers from different regions may have varying expectations regarding quality and performance. It is vital to communicate specific requirements clearly and ensure that manufacturers understand these expectations.

-

Language Barriers: Language differences can lead to misunderstandings regarding quality specifications. Buyers should consider employing bilingual staff or translators to facilitate effective communication with manufacturers.

-

Regulatory Compliance: Different regions have distinct regulatory requirements. Buyers should ensure that the alternators comply with local regulations in their target markets, which may involve additional certifications or testing.

-

After-Sales Support and Warranty: A robust after-sales support system and warranty policy are indicators of a manufacturer’s confidence in their product quality. Buyers should inquire about these aspects to safeguard their investment.

Conclusion

The manufacturing processes and quality assurance measures for Chinese alternators are designed to meet international standards and ensure product reliability. By understanding the stages of manufacturing, quality control measures, and ways to verify supplier practices, B2B buyers can make informed decisions when sourcing alternators from China. This knowledge is particularly valuable for buyers from diverse markets, enabling them to navigate potential challenges and foster successful partnerships with manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator chinese’

In today’s global marketplace, sourcing high-quality alternators from China can be a strategic move for businesses looking to optimize their operations. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to have a clear understanding of your technical requirements for the alternators. This includes specifications such as power output, voltage, phase type (single or three-phase), and any additional features like brushless technology or built-in voltage regulation. By outlining these details, you ensure that potential suppliers can meet your specific needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable manufacturers and suppliers in China. Utilize platforms like Alibaba, Global Sources, or industry-specific directories to compile a list of potential vendors. Look for suppliers with positive reviews, a solid track record, and experience in exporting to your region, as this can significantly impact communication and logistics.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 for quality management systems and CE or UL certifications for safety compliance. These certifications indicate that the supplier adheres to international standards, which is crucial for ensuring product reliability and safety. Request documentation and verify its authenticity through the issuing bodies.

Step 4: Request Samples and Technical Data

Before placing a bulk order, request samples of the alternators to assess their quality firsthand. Along with the samples, ask for detailed technical data sheets that outline performance metrics and material specifications. This step allows you to evaluate whether the products align with your technical requirements and quality expectations.

Step 5: Negotiate Terms and Pricing

Once you have identified suitable suppliers, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget and seek competitive pricing without compromising quality. Discuss payment options that protect your interests, such as letters of credit or escrow services, especially for first-time transactions.

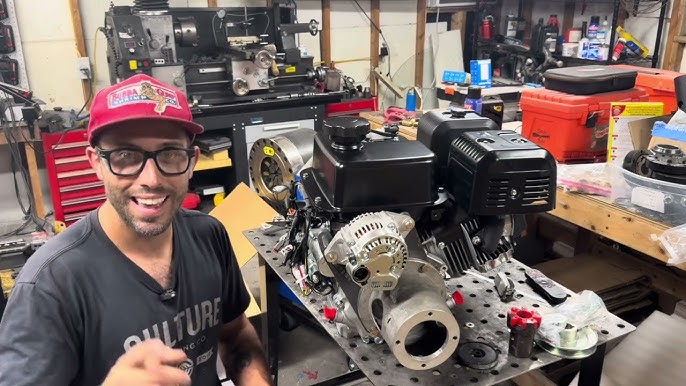

Illustrative image related to alternator chinese

Step 6: Plan Logistics and Shipping

After finalizing the order, coordinate logistics to ensure smooth shipping. Determine the most efficient shipping methods, considering factors like cost, speed, and reliability. Discuss with your supplier the best practices for packaging and labeling, as this can minimize the risk of damage during transit.

Step 7: Establish a Communication Plan

Maintain open lines of communication throughout the procurement process. Set up regular check-ins to monitor production timelines and address any potential issues promptly. Effective communication can foster a strong relationship with your supplier and help ensure that your order is fulfilled to your satisfaction.

By following this checklist, international B2B buyers can streamline their sourcing process for Chinese alternators, leading to successful procurement and long-term partnerships.

Comprehensive Cost and Pricing Analysis for alternator chinese Sourcing

What Are the Key Cost Components in Sourcing Chinese Alternators?

When sourcing alternators from China, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality copper, steel, and other components used in manufacturing alternators can vary in price based on market conditions and supplier sourcing.

-

Labor: Labor costs in China are generally lower than in many Western countries. However, the cost can fluctuate based on the region and the complexity of the manufacturing process. Skilled labor for specialized tasks may incur higher costs.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, rent, and administrative expenses. Efficient manufacturing practices can help minimize these overheads.

-

Tooling: Initial tooling costs for custom alternators can be substantial. This expense is often amortized over the production run, making it crucial to consider the order volume when evaluating total costs.

-

Quality Control (QC): Implementing stringent quality control measures can add to costs but is essential to ensure product reliability, especially for critical applications. Investing in QC can reduce long-term costs associated with defects and returns.

-

Logistics: Shipping costs can vary significantly based on the shipping method, distance, and weight of the goods. Understanding Incoterms is vital for determining who bears these costs.

-

Margin: Suppliers will typically apply a markup to cover their costs and generate profit. This margin can vary based on competition and perceived product value.

How Do Price Influencers Affect the Cost of Alternators from China?

Several factors influence the pricing of alternators sourced from China:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often qualify for discounts, making it crucial to assess your needs and negotiate accordingly.

-

Specifications and Customization: Custom specifications can lead to higher costs due to the need for specialized materials or tooling. Clearly defining your requirements upfront can help mitigate unexpected expenses.

-

Materials and Quality Certifications: The choice of materials not only affects the cost but also the quality of the alternator. Certifications such as ISO and CE can enhance product credibility but may also increase costs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge higher prices due to their track record, while newer suppliers might offer lower prices to attract business.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is crucial as they dictate who is responsible for shipping costs and insurance. This can significantly impact the total landed cost of the alternators.

What Tips Can Help International B2B Buyers Optimize Their Sourcing Strategy?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance sourcing efficiency:

-

Negotiation: Always negotiate prices and terms with suppliers. Building a good relationship can lead to better deals and flexibility in terms.

-

Cost-Efficiency: Consider not just the purchase price but the total cost of ownership, including maintenance and potential downtime costs. Investing in higher-quality alternators may yield savings in the long run.

-

Understand Pricing Nuances: Pricing can vary based on the time of year, demand cycles, and international trade conditions. Stay informed about market trends to make timely purchasing decisions.

-

Sample Orders: Before committing to a large order, consider placing a sample order to evaluate product quality and supplier reliability. This can prevent costly mistakes down the line.

-

Documentation and Compliance: Ensure that all necessary documentation is in order to avoid customs delays and additional costs. Familiarize yourself with local regulations regarding imported electrical components.

Disclaimer on Pricing

The prices mentioned in various sources are indicative and can fluctuate based on market conditions, order volume, and specific supplier negotiations. Always conduct thorough due diligence and request updated quotes before finalizing any purchasing decisions.

Alternatives Analysis: Comparing alternator chinese With Other Solutions

Exploring Alternatives to ‘Alternator Chinese’ for B2B Buyers

In the competitive landscape of electrical machinery, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the alternatives to ‘alternator Chinese’ is crucial for B2B buyers. This section presents a comparative analysis of ‘alternator Chinese’ against two viable alternatives: European alternators and Japanese alternators. Each solution offers unique benefits and drawbacks that can influence purchasing decisions.

| Comparison Aspect | ‘Alternator Chinese’ | European Alternators | Japanese Alternators |

|---|---|---|---|

| Performance | Good efficiency, suitable for various applications | High efficiency, reliable performance | Superior performance, advanced technology |

| Cost | Generally lower cost (approx. $30-$100) | Higher cost (approx. $150-$500) | Moderate cost (approx. $100-$300) |

| Ease of Implementation | Simple installation, widely available | Moderate complexity, requires skilled labor | Easy installation, user-friendly designs |

| Maintenance | Minimal maintenance, readily available parts | Regular maintenance required, parts may be costly | Low maintenance, high-quality components |

| Best Use Case | Ideal for budget-conscious projects | Best for high-demand industrial applications | Perfect for performance-critical environments |

What Are the Advantages and Disadvantages of European Alternators?

European alternators are known for their reliability and high efficiency. They typically utilize advanced engineering practices, ensuring long-lasting performance. However, the upfront costs can be significantly higher than Chinese alternatives, which may deter budget-sensitive buyers. Furthermore, maintenance may require specialized knowledge, potentially increasing overall expenses. These alternators are best suited for industries where performance is critical, such as manufacturing and heavy machinery.

How Do Japanese Alternators Compare?

Japanese alternators combine innovative technology with a reputation for quality. They often feature advanced designs that enhance performance and energy efficiency. While they fall into a moderate price range, they provide a good balance between cost and performance. Maintenance is generally low, thanks to high-quality components. Japanese alternators are especially effective in automotive applications and high-performance settings, making them a suitable choice for businesses focused on reliability and efficiency.

How Should B2B Buyers Choose the Right Solution?

When selecting between ‘alternator Chinese’ and its alternatives, B2B buyers should consider several factors: their specific operational needs, budget constraints, and the intended application of the alternators. If cost is a primary concern and the application is not heavily demanding, ‘alternator Chinese’ might be the best option. Conversely, for high-performance requirements or reliability in critical applications, investing in European or Japanese alternators may yield better long-term benefits. Ultimately, thorough research and a clear understanding of project requirements will guide buyers toward the most suitable choice for their business.

Essential Technical Properties and Trade Terminology for alternator chinese

What Are the Key Technical Properties of Alternators for B2B Buyers?

When evaluating alternators, particularly those sourced from Chinese manufacturers, understanding specific technical properties is crucial. Here are several key specifications that are vital for decision-making in B2B transactions:

-

Output Voltage (V)

The output voltage of an alternator determines its suitability for various applications. Common output voltages include 12V, 24V, and 400V for industrial uses. Buyers must ensure that the alternator’s voltage matches their operational requirements to prevent equipment failure or inefficiency. -

Power Rating (kW or kVA)

The power rating indicates the maximum output of the alternator, typically measured in kilowatts (kW) or kilovolt-amperes (kVA). This specification helps buyers assess whether the alternator can meet the energy demands of their machinery or systems. Choosing an alternator with an adequate power rating is essential to avoid underperformance or potential damage. -

Frequency (Hz)

The operating frequency of an alternator, usually 50Hz or 60Hz, is critical for compatibility with electrical systems. Buyers must confirm that the frequency aligns with their local grid standards or specific equipment requirements to ensure optimal operation and compliance with electrical codes. -

Efficiency (%)

Efficiency refers to the ratio of useful power output to total power input. A higher efficiency percentage means lower energy losses and cost savings over time. For B2B buyers, selecting a highly efficient alternator can significantly reduce operational costs, especially in large-scale applications. -

Material Grade

The materials used in manufacturing alternators, such as copper for windings and steel for housings, affect durability and performance. Understanding the material grade helps buyers assess the longevity and reliability of the alternator, which is particularly important in demanding environments. -

Cooling Method

Alternators may employ various cooling methods, including air or water cooling. The choice of cooling method impacts the alternator’s performance and lifespan, especially in high-temperature applications. B2B buyers should consider the operating environment when evaluating cooling options.

What Are Common Trade Terms Related to Alternators?

Familiarity with industry jargon is essential for smooth transactions and negotiations. Here are several common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components used in another company’s end products. In the context of alternators, OEM parts are typically designed to meet specific performance standards and compatibility with branded machinery, ensuring reliability and quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for buyers to plan their inventory and budget effectively. Suppliers may have different MOQs based on production costs, so negotiation might be necessary for bulk purchases. -

RFQ (Request for Quotation)

An RFQ is a formal request for a price quote from suppliers. It typically includes product specifications, quantities, and delivery terms. Issuing an RFQ is a strategic step in sourcing alternators, allowing buyers to compare prices and terms from multiple vendors. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Common Incoterms related to shipping alternators include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding these terms helps buyers clarify shipping costs and risk responsibilities. -

Warranty Period

The warranty period defines the duration during which the manufacturer guarantees the product against defects. A longer warranty can indicate higher confidence in the product’s reliability. Buyers should always review warranty terms as part of their evaluation process. -

AVR (Automatic Voltage Regulator)

An AVR is a device that maintains a constant voltage level in alternators. Understanding the role of AVR helps buyers choose alternators that offer stable performance, especially in fluctuating load conditions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring alternators from Chinese manufacturers, ensuring they select the right products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the alternator chinese Sector

What Are the Key Drivers and Trends in the Global Alternator Market?

The global alternator market is witnessing significant growth, driven by rising demand for reliable power generation and increasing applications in various industries, including automotive, marine, and renewable energy. Key trends include the shift towards more energy-efficient technologies and the integration of smart technologies in alternator design. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

Emerging technologies such as brushless alternators and those incorporating advanced control systems are gaining traction, enhancing efficiency and reducing maintenance costs. Furthermore, the growing trend of electrification in vehicles is leading to increased demand for high-performance alternators. Buyers must also consider the local regulatory environments and the impact of global supply chain disruptions, which have been exacerbated by recent geopolitical tensions and the ongoing effects of the COVID-19 pandemic.

In markets like Nigeria and Brazil, where infrastructure development is accelerating, there is a rising demand for alternators in construction and agriculture sectors. Similarly, in the Middle East, the push towards renewable energy projects is creating new opportunities for alternator suppliers. International buyers should leverage these trends to identify strategic partnerships and innovative solutions that align with their operational needs.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in Alternator Procurement?

Sustainability is increasingly becoming a focal point for B2B buyers in the alternator sector. The environmental impact of manufacturing processes, including emissions and resource consumption, necessitates a shift towards more sustainable practices. Ethical sourcing is not just a regulatory requirement but also a competitive advantage. Buyers should prioritize suppliers who demonstrate a commitment to sustainability through certifications like ISO 14001, which relates to effective environmental management systems.

Furthermore, the use of eco-friendly materials and production techniques is gaining importance. B2B buyers can enhance their supply chains by sourcing alternators made from recycled materials or those that utilize green manufacturing processes. This not only minimizes the environmental footprint but also aligns with the growing consumer demand for sustainable products.

Illustrative image related to alternator chinese

Engaging with suppliers who actively participate in sustainability initiatives can also improve brand reputation and customer loyalty. As global consumers become more environmentally conscious, aligning procurement strategies with sustainable practices will be essential for long-term success in the alternator market.

What Is the Historical Context of the Alternator Market?

The alternator’s evolution traces back to the late 19th century, when it was first developed as a means to convert mechanical energy into electrical energy, primarily for use in power generation. The introduction of the automobile in the early 20th century catalyzed the alternator’s adoption, as vehicles required reliable electrical systems for lighting and ignition.

Over the decades, advancements in technology have led to the development of more efficient and compact designs, particularly with the introduction of brushless and synchronous alternators. These innovations have significantly improved the reliability and performance of alternators in various applications, from automotive to industrial settings. Understanding this historical context can help B2B buyers appreciate the technological advancements and market shifts that have shaped the current landscape, allowing for more informed sourcing decisions.

In summary, the alternator market is influenced by several dynamic factors, including technological advancements, sustainability concerns, and historical developments that continue to shape the procurement landscape for international B2B buyers. By staying informed and adaptable, buyers can effectively navigate these changes to meet their operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator chinese

-

How do I ensure the quality of Chinese alternators before purchasing?

To ensure the quality of Chinese alternators, conduct thorough supplier vetting by checking their certifications, such as ISO 9001, and requesting product samples. Visit their manufacturing facilities if possible, or utilize third-party inspection services to assess product quality before shipment. Additionally, review customer feedback and ratings on platforms like Alibaba or Global Sources to gauge the supplier’s reliability and product performance. -

What are the common specifications I should look for in a Chinese alternator?

When sourcing a Chinese alternator, focus on specifications such as voltage output (e.g., 220V or 400V), phase type (single-phase or three-phase), and power rating (kW). Assess the alternator’s efficiency, weight, and dimensions to ensure it meets your operational needs. Verify compatibility with your existing equipment and inquire about features like brushless technology or built-in voltage regulators for enhanced performance. -

What is the minimum order quantity (MOQ) for Chinese alternators?

MOQs for Chinese alternators vary significantly between suppliers, typically ranging from 5 to 100 units. It’s essential to confirm the MOQ with your chosen supplier, as lower MOQs may be available for established customers or specific product lines. If you require a smaller quantity, consider negotiating with the supplier or exploring group buying options with other businesses to meet MOQ requirements. -

What payment terms should I expect when sourcing alternators from China?

Payment terms for purchasing alternators from Chinese suppliers generally include options like T/T (Telegraphic Transfer), L/C (Letter of Credit), or PayPal. Common arrangements involve a 30% deposit upfront with the balance paid before shipment. Be sure to clarify the terms and negotiate conditions that protect your interests, such as payment upon successful inspection of goods or escrow services for larger transactions. -

How can I customize my order of Chinese alternators?

To customize your order of Chinese alternators, communicate your specific requirements to the supplier, such as branding, color, or technical specifications. Many manufacturers offer customization options, but it’s important to discuss any additional costs and lead times associated with these changes. Providing detailed drawings or specifications can help ensure the supplier understands your needs and can deliver the desired product. -

What should I know about shipping and logistics when importing alternators from China?

When importing alternators from China, familiarize yourself with shipping options, including air freight for faster delivery and sea freight for cost-effectiveness. Consider the total landed cost, which includes shipping, customs duties, and taxes. Collaborate with a reliable freight forwarder who can assist with documentation and customs clearance to avoid delays and ensure compliance with local regulations in your destination country. -

How do I handle warranty and after-sales service for Chinese alternators?

Discuss warranty terms with your supplier before finalizing the purchase. Most Chinese alternators come with a warranty period, typically ranging from 6 months to 2 years. Ensure you understand the process for claiming warranty service, including any required documentation and shipping costs for returns. Establishing a good relationship with the supplier can facilitate smoother after-sales support and repairs if needed. -

What are the common challenges faced when sourcing alternators from China?

Common challenges when sourcing alternators from China include language barriers, quality inconsistencies, and shipping delays. To mitigate these issues, work with suppliers who have a strong reputation and good communication skills. Utilize platforms that offer buyer protection, and consider hiring a local agent or third-party inspection service to assist with quality control and logistics, ensuring a smoother sourcing process.

Top 4 Alternator Chinese Manufacturers & Suppliers List

1. Yellow Bridge – Alternator Solutions

Domain: yellowbridge.com

Registered: 2003 (22 years)

Introduction: alternator: An old term for an electric generator that produces alternating current (especially in automobiles). In Mandarin, it is referred to as 交流发电机 (jiāoliú fādiànjī).

2. DB Electronics – Budget Alternator

Domain: community.cartalk.com

Registered: 1995 (30 years)

Introduction: Budget alternator (new) from China, brand: DB Electronics, purchase price: $101 (including tax), sourced from Amazon, voltage output: mid 14 volts, warranty: 1 year, concerns about quality due to thinner copper wire core, potential for failure, local rebuild options available.

3. Reverso – Alternator

Domain: context.reverso.net

Registered: 2000 (25 years)

Introduction: 交流发电机 (alternator) 是一种用于发电的设备,常见于车辆和工业应用中。它的主要功能是将机械能转换为电能,提供电力给汽车的电气系统。该设备通常配备有调节装置,以确保稳定的电流输出。交流发电机的安装和维护需要遵循特定的程序,包括检查电池与发电机之间的连接线束。

4. Does Not Apply – Chinese Generator 5.5 KW Alternator/ AVR

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Chinese Generator 5.5 KW Alternator/ AVR”, “condition”: “New”, “quantity_available”: 1, “item_number”: “352771382034”, “brand”: “Does Not Apply”, “manufacturer_part_number”: “Does Not Apply”, “price”: “$50.00”, “payment_options”: “4 interest-free payments of $12.50 available with Klarna”, “shipping_info”: “Item does not ship to you from Prince George, British Columbia, Canada”, “…

Strategic Sourcing Conclusion and Outlook for alternator chinese

As the global demand for reliable power solutions continues to rise, strategic sourcing of Chinese alternators offers significant advantages for international B2B buyers. Key takeaways from this guide emphasize the importance of understanding product specifications, quality assurance, and the competitive pricing landscape that Chinese manufacturers provide. By leveraging the diverse offerings available, businesses can ensure that they meet their operational needs while also maintaining cost efficiency.

Sourcing from established Chinese manufacturers not only enhances supply chain reliability but also opens up opportunities for long-term partnerships that can lead to innovative solutions tailored to specific markets. This is particularly relevant for buyers in Africa, South America, the Middle East, and Europe, where robust and efficient power generation is crucial for economic growth and development.

Looking ahead, international B2B buyers are encouraged to engage actively with Chinese suppliers to explore customized solutions that align with their specific requirements. By prioritizing strategic sourcing of quality alternators, businesses can secure a competitive edge in their respective markets. Embrace this opportunity to invest in dependable power solutions that will support your growth and sustainability objectives.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.