Introduction: Navigating the Global Market for truck starter motor

In the competitive landscape of the trucking industry, sourcing high-quality truck starter motors can pose a significant challenge for businesses operating across diverse markets. Whether you are navigating the bustling streets of Lagos, the industrial hubs of Germany, or the vast landscapes of South America, ensuring that your fleet is equipped with reliable starter motors is crucial for maintaining operational efficiency and reducing downtime. This guide addresses the complexities involved in sourcing truck starter motors, providing insights into various types, applications, and the essential factors to consider when selecting suppliers.

As international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, you need a comprehensive understanding of the market dynamics, including the latest technological advancements and cost implications associated with truck starter motors. This guide empowers you with actionable insights that streamline the purchasing process, from vetting suppliers to understanding the intricacies of pricing and product specifications. We will explore the key manufacturers, compare product offerings, and discuss the importance of sourcing durable components that can withstand harsh operating conditions.

By the end of this guide, you will be equipped with the knowledge necessary to make informed purchasing decisions, ensuring that your fleet remains reliable and efficient in the face of global challenges. Let’s embark on this journey to simplify the sourcing of truck starter motors and enhance your operational success.

Table Of Contents

- Top 1 Truck Starter Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for truck starter motor

- Understanding truck starter motor Types and Variations

- Key Industrial Applications of truck starter motor

- 3 Common User Pain Points for ‘truck starter motor’ & Their Solutions

- Strategic Material Selection Guide for truck starter motor

- In-depth Look: Manufacturing Processes and Quality Assurance for truck starter motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘truck starter motor’

- Comprehensive Cost and Pricing Analysis for truck starter motor Sourcing

- Alternatives Analysis: Comparing truck starter motor With Other Solutions

- Essential Technical Properties and Trade Terminology for truck starter motor

- Navigating Market Dynamics and Sourcing Trends in the truck starter motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of truck starter motor

- Strategic Sourcing Conclusion and Outlook for truck starter motor

- Important Disclaimer & Terms of Use

Understanding truck starter motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gear Reduction Starter | Compact design with reduced weight; higher torque output. | Heavy-duty trucks, construction vehicles | Pros: Lightweight, efficient torque; Cons: Higher cost. |

| Permanent Magnet Starter | Utilizes permanent magnets for faster start-up times. | Delivery trucks, buses | Pros: Quick start, less maintenance; Cons: Limited durability in extreme conditions. |

| Solenoid Starter | Features an electromagnetic solenoid for engagement. | Commercial fleets, agricultural vehicles | Pros: Reliable engagement; Cons: Can be heavier and bulkier. |

| High-Performance Starter | Designed for high-output applications; withstands extreme conditions. | Racing trucks, emergency vehicles | Pros: Superior performance, reliability; Cons: Higher price point. |

| Remanufactured Starter | Rebuilt from used parts; cost-effective alternative. | Budget-conscious fleets | Pros: Cost savings, eco-friendly; Cons: Potentially shorter lifespan than new units. |

What Are the Characteristics of Gear Reduction Starters?

Gear reduction starters are engineered for optimal torque output while maintaining a compact design. This feature makes them particularly beneficial for heavy-duty trucks and construction vehicles that require reliable starting power, especially in challenging conditions. B2B buyers should consider the weight and efficiency of these starters, as they can enhance overall vehicle performance. However, the initial investment may be higher compared to standard starters, making it crucial to evaluate long-term operational costs.

How Do Permanent Magnet Starters Benefit Businesses?

Permanent magnet starters leverage the power of permanent magnets, allowing for quicker start-up times and reduced energy consumption. They are commonly used in delivery trucks and buses, where reliability and efficiency are paramount. For B2B buyers, the maintenance advantages and quick start capabilities are significant selling points. However, businesses operating in extreme environments may need to consider the durability of these units, as they may not perform as well under severe conditions.

Why Choose Solenoid Starters for Commercial Applications?

Solenoid starters utilize an electromagnetic solenoid to engage the starter motor, providing a reliable starting mechanism. They are widely used across commercial fleets and agricultural vehicles due to their dependable performance. When purchasing solenoid starters, B2B buyers should assess the balance between weight and bulk, as these units can be heavier than other types. While they offer reliability, the added weight may impact vehicle efficiency in some applications.

What Makes High-Performance Starters Ideal for Specialized Uses?

High-performance starters are specifically designed to handle extreme conditions and high-output applications, making them ideal for racing trucks and emergency vehicles. These starters provide superior performance and reliability, which are critical in high-stakes environments. B2B buyers should weigh the benefits of enhanced performance against the higher price point, ensuring that their investment aligns with their operational needs and budget constraints.

How Can Remanufactured Starters Serve Budget-Conscious Fleets?

Remanufactured starters present a cost-effective solution for budget-conscious fleets looking to minimize expenses without sacrificing quality. These starters are rebuilt from used components, offering a sustainable alternative to new units. For B2B buyers, the environmental benefits and potential savings are compelling. However, it is essential to consider the potential trade-off in lifespan when compared to brand-new starters, as remanufactured units may not last as long under heavy use.

Key Industrial Applications of truck starter motor

| Industry/Sector | Specific Application of truck starter motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Heavy-duty truck fleets for logistics | Ensures reliable vehicle start-up, minimizing downtime during operations | Durability in extreme conditions, compatibility with various truck models |

| Construction | Construction vehicles and equipment | Facilitates quick mobilization of heavy machinery, enhancing project efficiency | High torque output, availability of replacement parts |

| Agriculture | Agricultural trucks and machinery | Provides dependable starting in remote locations, supporting timely harvesting | Resistance to dust and moisture, ease of maintenance |

| Mining | Heavy-duty vehicles in mining operations | Reduces operational delays, ensuring continuous productivity in harsh environments | Performance under extreme conditions, compliance with safety standards |

| Emergency Services | Fire trucks and ambulances | Guarantees immediate response capabilities, crucial for public safety | Reliability, rapid availability of parts for emergency repairs |

How is the Truck Starter Motor Used in the Transportation Sector?

In the transportation sector, truck starter motors are vital for heavy-duty truck fleets that facilitate logistics and goods movement. These motors ensure reliable start-up in various conditions, preventing delays that could lead to financial losses. For international buyers, especially in regions like Africa and South America, sourcing durable starter motors that can withstand high temperatures and rough terrains is essential. Compatibility with diverse truck models is also a critical consideration to avoid operational disruptions.

What Role Does the Truck Starter Motor Play in Construction?

Construction vehicles and equipment rely heavily on truck starter motors to ensure quick mobilization at job sites. A dependable starter motor minimizes downtime, allowing for efficient project execution. Buyers in this sector should prioritize motors that offer high torque output and can endure the demanding conditions of construction sites. Additionally, the availability of replacement parts is crucial to maintain operational continuity without extended delays.

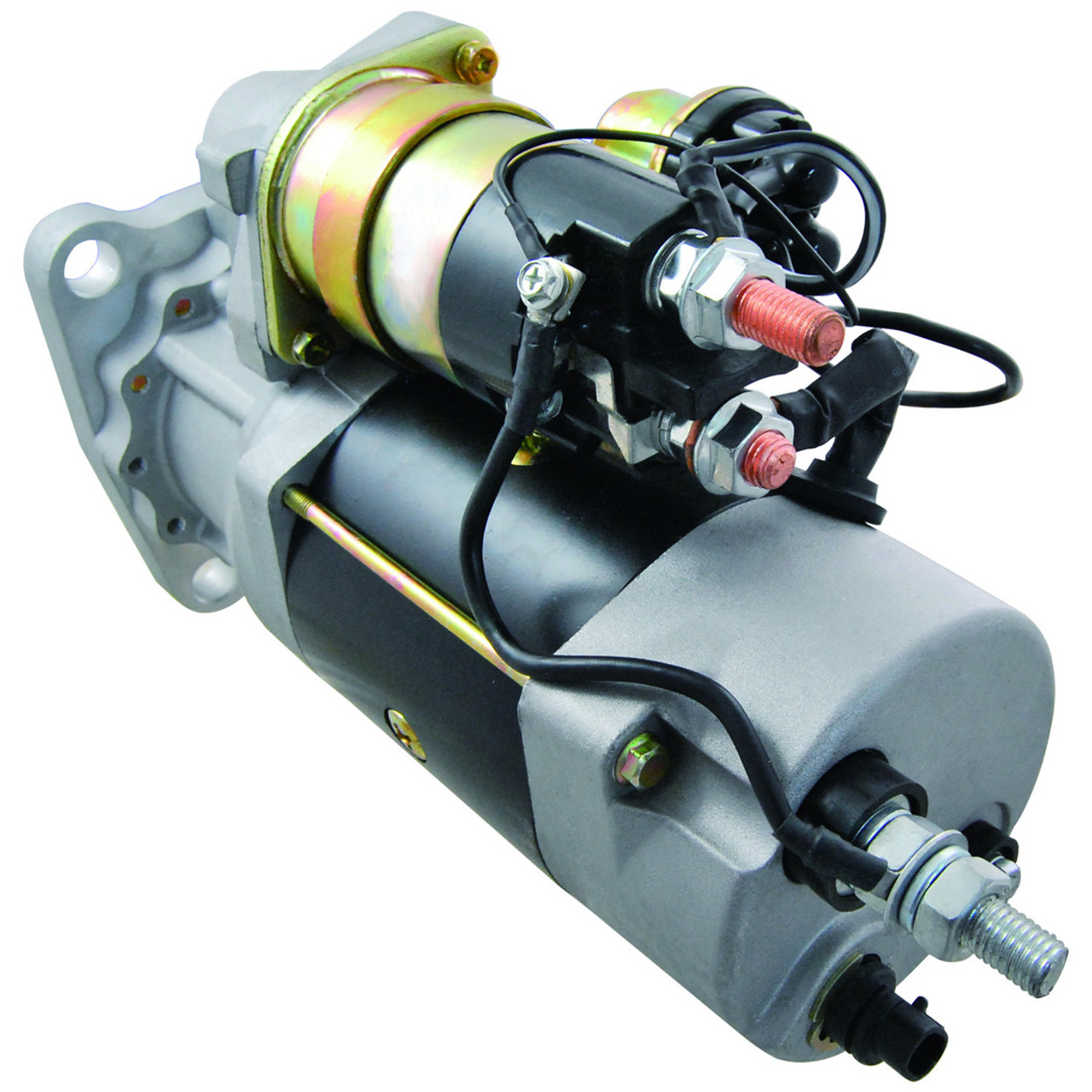

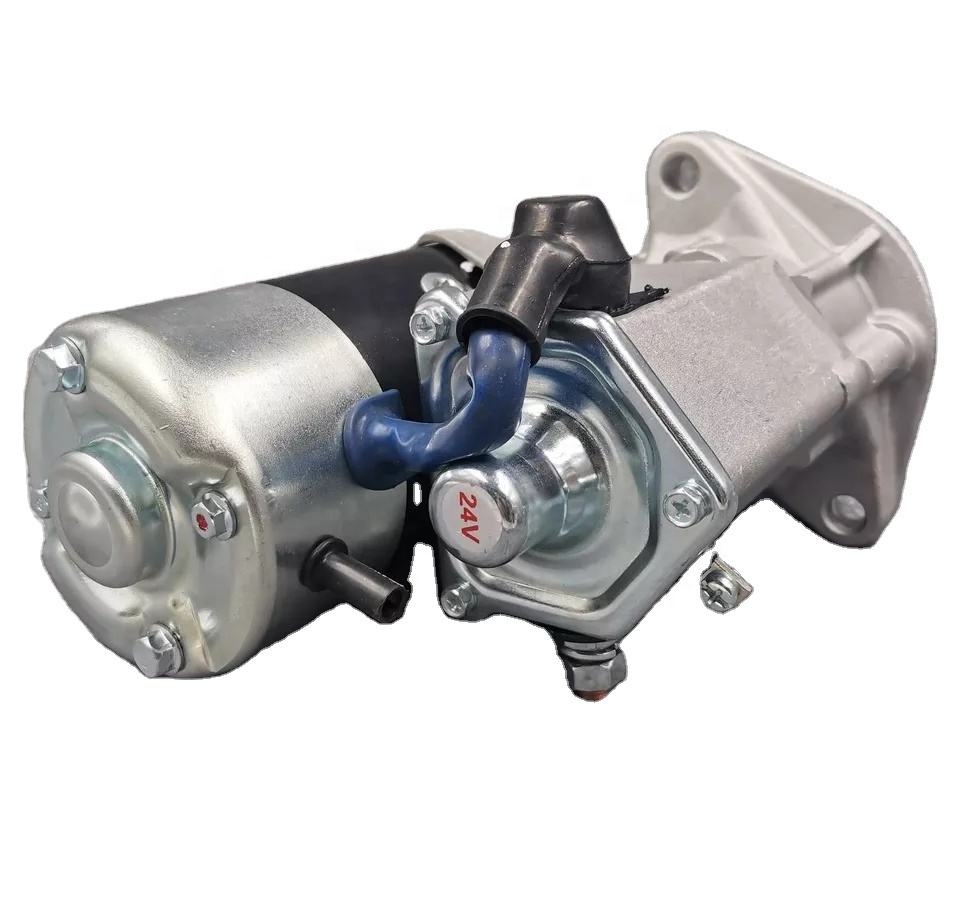

Illustrative image related to truck starter motor

How Does the Truck Starter Motor Support Agricultural Operations?

In agriculture, starter motors are crucial for tractors and other machinery, enabling reliable starting in remote areas where downtime can affect harvest timelines. These motors must be robust enough to resist dust and moisture, ensuring functionality in varied weather conditions. For B2B buyers in regions like the Middle East and Europe, it is important to consider the ease of maintenance and the availability of parts to minimize disruptions during critical farming periods.

Why is the Truck Starter Motor Essential in Mining Operations?

Mining operations depend on heavy-duty vehicles equipped with starter motors to minimize operational delays. The harsh conditions typical of mining sites demand starter motors that perform reliably under extreme temperatures and rugged environments. Sourcing considerations should include compliance with safety standards and the ability to deliver consistent performance. This is especially relevant for international buyers who may face logistical challenges in remote mining locations.

How is the Truck Starter Motor Critical for Emergency Services?

In emergency services, such as fire trucks and ambulances, the reliability of truck starter motors is paramount for ensuring immediate response capabilities. A malfunctioning starter can lead to critical delays in life-saving situations. Buyers in this sector must focus on sourcing motors that guarantee quick activation and have a robust support system for rapid parts replacement. Reliability and performance are crucial factors that can significantly impact public safety and operational effectiveness.

Illustrative image related to truck starter motor

3 Common User Pain Points for ‘truck starter motor’ & Their Solutions

Scenario 1: Frequent Starter Motor Failures in Harsh Environments

The Problem: B2B buyers in regions with extreme weather conditions, such as high heat or severe cold, often face frequent starter motor failures. These failures can lead to unexpected downtime, jeopardizing delivery schedules and incurring additional costs. The challenge is exacerbated in areas where roads may be unpaved, putting additional strain on the vehicle’s electrical components. This not only affects the reliability of the trucks but also disrupts the entire supply chain, leading to potential losses in revenue and customer trust.

The Solution: To mitigate these issues, it is essential to invest in heavy-duty starter motors specifically designed for extreme conditions. Buyers should look for products from reputable manufacturers that emphasize durability and performance under harsh environmental factors. Furthermore, utilizing starter motors with advanced features, such as enhanced insulation and corrosion-resistant materials, can significantly improve reliability. Implementing a preventive maintenance schedule that includes regular inspections and testing can also help identify potential issues before they lead to complete failures. This proactive approach ensures that the trucks are always ready to perform, regardless of the conditions.

Scenario 2: Difficulty in Sourcing Compatible Starter Motors

The Problem: Many B2B buyers encounter challenges when sourcing starter motors that are compatible with their specific truck models. Inconsistent part numbers and a lack of standardized specifications across different manufacturers can lead to confusion and errors in ordering. This issue is particularly pronounced for buyers managing fleets with diverse vehicle types, leading to delays in repairs and increased operational costs.

The Solution: Buyers can alleviate this problem by utilizing a comprehensive cross-reference chart provided by manufacturers or suppliers. These charts allow for easy comparison of starter motor specifications across different brands, ensuring compatibility with existing fleet vehicles. Additionally, establishing a relationship with a reliable supplier who understands the unique needs of the business can streamline the procurement process. Engaging in bulk purchasing agreements can also offer better pricing and guaranteed availability of parts, minimizing downtime and ensuring that the fleet remains operational.

Illustrative image related to truck starter motor

Scenario 3: High Costs Associated with Starter Motor Replacements

The Problem: The financial burden of frequent starter motor replacements can be significant for B2B buyers, particularly for those operating large fleets. High-quality starter motors can be expensive, and the costs associated with labor for replacements can add up quickly. This challenge is compounded by the need for continuous operations, leaving little room for downtime or delays in repairs.

The Solution: To manage costs effectively, buyers should consider investing in remanufactured starter motors. These parts often meet or exceed OEM specifications while being significantly less expensive than new units. Furthermore, implementing a robust maintenance program focused on the electrical system can prolong the lifespan of starter motors. Regularly cleaning connections, checking for corrosion, and ensuring proper battery health can prevent premature failures. Additionally, training staff to perform basic troubleshooting can reduce reliance on external mechanics, further cutting down costs. By adopting these strategies, buyers can maintain a balance between quality and cost-efficiency in their operations.

Strategic Material Selection Guide for truck starter motor

What Are the Key Materials Used in Truck Starter Motors?

When selecting materials for truck starter motors, it’s essential to consider the properties that impact performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the manufacturing of truck starter motors, providing insights relevant to international B2B buyers.

How Does Steel Influence the Performance of Truck Starter Motors?

Steel is a widely used material for truck starter motors, particularly for the housing and internal components. Its key properties include high tensile strength and excellent wear resistance, making it suitable for demanding applications. Steel can withstand high temperatures and pressures, which is crucial for the performance of starter motors in heavy-duty trucks.

Pros: Steel’s durability ensures a long service life, while its availability keeps manufacturing costs relatively low. Additionally, steel can be easily machined to precise specifications, allowing for complex designs.

Cons: However, steel is susceptible to corrosion, especially in humid or saline environments, which can be a concern in regions like Africa and the Middle East. Protective coatings or treatments are often necessary, adding to manufacturing complexity and cost.

Impact on Application: Steel is compatible with various media, including engine oil and fuel, making it a versatile choice. However, buyers should consider the environmental conditions in their regions to ensure longevity.

What Role Does Aluminum Play in Truck Starter Motor Design?

Aluminum is increasingly favored for truck starter motors due to its lightweight nature and excellent corrosion resistance. This material typically boasts a lower density than steel, which can enhance fuel efficiency in heavy-duty trucks.

Pros: The primary advantage of aluminum is its resistance to corrosion, making it ideal for harsh environments. Additionally, its lightweight properties can lead to reduced overall vehicle weight, improving fuel economy.

Cons: The downside is that aluminum is generally less durable than steel, particularly under high-stress conditions. It may also be more expensive to machine, which can increase production costs.

Impact on Application: Aluminum is particularly suitable for applications where weight reduction is critical. However, buyers must ensure that the aluminum used meets the necessary strength specifications for their specific starter motor applications.

How Does Copper Improve Electrical Conductivity in Starter Motors?

Copper is a vital material for electrical components within starter motors, such as windings and connectors. Its high electrical conductivity ensures efficient energy transfer, which is essential for reliable motor operation.

Pros: The primary advantage of copper is its superior conductivity, which enhances performance and reduces energy losses. Copper’s ductility also allows for easy shaping and integration into complex electrical designs.

Illustrative image related to truck starter motor

Cons: On the downside, copper is prone to corrosion, especially in environments with high humidity or exposure to chemicals. This susceptibility can lead to increased maintenance needs and potential failures.

Impact on Application: Copper’s compatibility with electrical systems makes it indispensable in starter motors. International buyers should be aware of the need for protective coatings or treatments to mitigate corrosion risks, particularly in tropical climates.

What Advantages Does Plastic Offer in Truck Starter Motor Components?

Plastic, particularly high-performance polymers, is often used in non-structural components of truck starter motors, such as housings and insulators. Its key properties include lightweight and excellent insulation capabilities.

Pros: The main advantage of plastic is its lightweight nature, which contributes to overall vehicle efficiency. Additionally, plastics can provide excellent electrical insulation, reducing the risk of short circuits.

Cons: However, plastics may not withstand high temperatures as effectively as metals, which can limit their applications in high-stress environments. They can also be more susceptible to wear over time.

Impact on Application: Plastics are suitable for components that do not experience extreme mechanical stress. Buyers should consider the temperature ratings of the plastics used to ensure they meet operational demands.

Summary Table of Material Selection for Truck Starter Motors

| Material | Typical Use Case for truck starter motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Housing and internal components | High durability and strength | Susceptible to corrosion | Medium |

| Aluminum | Lightweight components | Excellent corrosion resistance | Less durable under stress | High |

| Copper | Electrical windings and connectors | Superior electrical conductivity | Prone to corrosion | Medium |

| Plastic | Non-structural components | Lightweight and insulating | Limited high-temperature resistance | Low |

This guide provides a comprehensive overview of the materials commonly used in truck starter motors, helping international B2B buyers make informed decisions based on performance, cost, and environmental considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for truck starter motor

What Are the Key Stages in the Manufacturing Process of Truck Starter Motors?

The manufacturing process of truck starter motors involves several critical stages, each designed to ensure high performance and reliability in demanding environments. Understanding these stages is essential for B2B buyers looking to source high-quality products.

Material Preparation: What Materials Are Used in Truck Starter Motors?

The first step in the manufacturing process is the preparation of raw materials. Common materials include high-grade steel for the housing, copper for the windings, and various alloys for the rotor and stator components. The selection of materials is crucial as they must withstand high temperatures and heavy usage. Suppliers often conduct material tests to ensure that the components meet industry standards, which is a critical point for buyers to verify.

How Are Truck Starter Motors Formed and Assembled?

The forming stage involves machining processes such as stamping, forging, and casting, which create the motor’s various parts. Advanced CNC (Computer Numerical Control) machines are typically employed to ensure precision in the manufacturing of components like the armature and field coils. After forming, the assembly stage begins, where components are meticulously put together. This includes the installation of brushes, bearings, and other internal mechanisms that contribute to the starter motor’s functionality.

During assembly, automated assembly lines may be utilized to enhance efficiency and reduce human error. However, manual assembly is also common for intricate components that require a higher level of precision.

What Finishing Processes Are Applied to Truck Starter Motors?

Finishing processes are critical for enhancing the durability and performance of starter motors. These may include surface treatments such as anodizing or powder coating, which protect against corrosion and wear. Additionally, balancing and testing of the assembled units are conducted to ensure they operate smoothly and reliably under load. The finishing stage culminates in the application of labels and compliance marks, which are essential for international trade.

What Quality Assurance Practices Should B2B Buyers Look for in Truck Starter Motor Suppliers?

Quality assurance (QA) is an integral part of the manufacturing process, particularly for components like truck starter motors that are subjected to extreme conditions. Buyers should be aware of the various international standards and checkpoints that manufacturers follow.

Which International Standards Should Be Considered in Quality Assurance?

Most reputable manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with these standards ensures that suppliers have established processes for continuous improvement and customer satisfaction. Additionally, other certifications like CE for Europe and API for specific applications may be relevant, depending on the market and the intended use of the starter motors.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch any defects early. Common checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival at the manufacturing facility.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to ensure that components are being produced to specification.

- Final Quality Control (FQC): Comprehensive testing of the completed starter motors before they are packaged and shipped.

These checkpoints help in maintaining high-quality standards and reducing the risk of defective products reaching the market.

How Can B2B Buyers Verify the Quality Control Processes of Suppliers?

To ensure that a supplier adheres to stringent quality control measures, B2B buyers can take several actionable steps:

-

Conduct Supplier Audits: Regular audits of the manufacturing facilities can provide insights into the supplier’s adherence to quality standards and their manufacturing processes.

-

Request Quality Assurance Reports: Suppliers should be able to provide documentation demonstrating compliance with international standards, including certificates of conformity and test results.

-

Engage Third-Party Inspectors: Utilizing independent inspectors can help verify that the manufacturing process and products meet specified quality requirements. This is particularly important for international transactions where trust may be a concern.

What Testing Methods Are Commonly Used for Truck Starter Motors?

Testing methods for truck starter motors vary but generally include:

- Electrical Testing: Ensuring that the motor operates within specified voltage and current parameters.

- Durability Testing: Assessing the motor’s performance under simulated extreme conditions to ensure reliability.

- Performance Testing: Measuring the motor’s starting torque and speed to confirm that it meets the manufacturer’s specifications.

These tests are crucial for validating the performance and longevity of starter motors, ensuring they can handle the rigors of heavy-duty applications.

What Are the Specific Quality Control Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of regional regulations that may affect quality assurance. For example, compliance with local safety standards and environmental regulations is crucial, especially for buyers in Europe where standards are particularly stringent.

Additionally, understanding the logistics of international shipping, including customs inspections and potential delays, can help mitigate risks associated with sourcing products globally. Buyers should also be aware of warranty terms and after-sales support, as these can vary significantly between suppliers.

Conclusion

In summary, the manufacturing processes and quality assurance for truck starter motors are complex and require careful consideration by B2B buyers. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier practices, buyers can make informed decisions that enhance their supply chain reliability. This knowledge not only aids in sourcing high-quality starter motors but also fosters long-term partnerships with manufacturers committed to excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘truck starter motor’

Introduction

Sourcing high-quality truck starter motors is essential for ensuring the reliability and efficiency of your fleet. This guide provides a clear, actionable checklist for B2B buyers to follow when procuring starter motors, helping you make informed decisions and avoid common pitfalls.

Step 1: Define Your Technical Specifications

Understanding your specific technical requirements is the first step in sourcing a truck starter motor. Consider factors such as voltage, engine compatibility, and torque specifications. This clarity will help you communicate effectively with suppliers and ensure that the products you source meet your operational needs.

Step 2: Research Reputable Suppliers

Identifying reliable suppliers is crucial for securing high-quality products. Look for suppliers with established reputations in the industry, particularly those who specialize in heavy-duty truck parts. Utilize platforms like trade directories and industry forums to gather a list of potential suppliers, and check customer reviews to gauge their reliability.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier choice, verify that they hold relevant industry certifications. Certifications such as ISO 9001 or equivalent demonstrate that a supplier adheres to quality management standards. Additionally, confirm that their products meet international safety and environmental standards, which is particularly important in regions with strict regulations.

Step 4: Request Product Samples

Whenever possible, request samples of the truck starter motors you are considering. This allows you to assess the quality, compatibility, and performance of the product firsthand. Ensure that the samples meet your defined technical specifications and operational requirements before making a bulk order.

Step 5: Compare Pricing and Terms

Pricing can vary significantly among suppliers, so it’s vital to conduct a thorough comparison. Obtain quotes from multiple suppliers, considering not just the price but also the terms of sale, warranty, and after-sales support. Look for suppliers that offer competitive pricing without compromising on quality, and consider the total cost of ownership, including installation and maintenance.

Step 6: Assess Delivery and Logistics Capabilities

A supplier’s ability to deliver on time is as important as the quality of their products. Evaluate their logistics capabilities, including shipping options and lead times. Ensure that they can meet your delivery requirements, especially if you are operating in regions with challenging supply chain dynamics.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful procurement process. Establish clear channels of communication with your supplier, including points of contact for order updates, technical support, and issue resolution. Ensure that you have a mutual understanding of expectations regarding timelines, product specifications, and after-sales service.

Illustrative image related to truck starter motor

By following this checklist, B2B buyers can navigate the complexities of sourcing truck starter motors more effectively, ensuring they make informed and strategic procurement decisions.

Comprehensive Cost and Pricing Analysis for truck starter motor Sourcing

What Are the Key Cost Components for Truck Starter Motors?

When sourcing truck starter motors, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality and type of materials used in manufacturing starter motors significantly affect the price. High-performance materials can lead to higher costs but often translate to improved durability and reliability.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this can come at the expense of quality.

-

Manufacturing Overhead: This includes expenses related to the production facilities, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce overhead costs, thus affecting the final price.

-

Tooling: The cost of tools and molds necessary for production can be substantial, especially for custom designs. This is particularly relevant if you require specific configurations or features in your starter motors.

-

Quality Control (QC): Rigorous QC processes ensure that each starter motor meets performance standards. While this adds to the cost, it is critical for maintaining product reliability and customer satisfaction.

-

Logistics: Shipping and handling fees can vary based on the distance, shipping method, and packaging requirements. For international buyers, understanding Incoterms is crucial for calculating total logistics costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This can vary widely based on brand reputation, market demand, and competitive positioning.

How Do Price Influencers Impact Sourcing Decisions?

Several factors influence the pricing of truck starter motors, which buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to better pricing due to economies of scale. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Customized starter motors with specific features or certifications will generally incur higher costs. It is essential to balance the need for customization with budget constraints.

-

Materials and Quality Certifications: Motors made from premium materials and those that meet international quality standards may command higher prices. Buyers in Europe, for example, may prioritize certified products due to stringent regulations.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established brands may charge more due to their perceived quality and service reliability.

-

Incoterms: Understanding the agreed-upon Incoterms can help buyers evaluate the total cost of ownership. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the final price.

What Are the Best Tips for Negotiating Truck Starter Motor Prices?

International B2B buyers should adopt strategic approaches to negotiate better prices and terms:

-

Conduct Market Research: Familiarize yourself with average pricing in your region and the specific features of the starter motors you require. This knowledge can empower your negotiation position.

-

Leverage Volume Discounts: If possible, consolidate your orders to meet or exceed the MOQ for better pricing. Suppliers are often more willing to negotiate on larger orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, warranties, and potential failures. A slightly higher upfront investment may result in lower TCO if the product offers superior reliability.

-

Be Clear on Specifications: Clearly communicate your needs regarding specifications and certifications. This clarity can prevent misunderstandings that might lead to increased costs later in the process.

-

Explore Remanufactured Options: For cost-sensitive buyers, consider sourcing remanufactured starter motors. These can provide significant savings while still offering reliable performance.

Conclusion: Understanding Pricing Nuances in International Sourcing

For buyers in regions like Africa, South America, the Middle East, and Europe, it is vital to navigate the complexities of truck starter motor pricing carefully. By understanding the cost components, price influencers, and effective negotiation strategies, you can make informed decisions that align with your operational needs and budget constraints. Always remember that prices can fluctuate based on market conditions, so it is prudent to seek multiple quotes and build strong relationships with suppliers to secure the best possible deals.

Alternatives Analysis: Comparing truck starter motor With Other Solutions

Exploring Alternatives to Truck Starter Motors

In the realm of heavy-duty trucking, ensuring reliable vehicle operation is paramount. While truck starter motors are a common solution for initiating engine function, there are alternative technologies and methods worth considering. This analysis aims to provide a clear comparison between truck starter motors and other viable alternatives, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Truck Starter Motor | Lithium-ion Battery Systems | Compressed Air Start Systems |

|---|---|---|---|

| Performance | Reliable under various conditions | High efficiency, quick starts | Effective in extreme cold conditions |

| Cost | Moderate initial investment | Higher initial costs, lower lifecycle cost | Moderate to high investment |

| Ease of Implementation | Standard installation procedures | Requires specialized installation | Complex setup with air compression systems |

| Maintenance | Regular checks needed | Minimal maintenance | Requires regular checks and air supply |

| Best Use Case | Long-haul trucking in various climates | Urban transport with frequent starts | Off-road and extreme environments |

Detailed Breakdown of Alternatives

Lithium-ion Battery Systems

Lithium-ion battery systems are emerging as a robust alternative to traditional truck starter motors. These systems provide high efficiency and rapid starting capabilities, making them ideal for urban transport where frequent stops and starts are common. However, the initial investment is significantly higher compared to conventional starter motors. While they require minimal maintenance, the specialized installation can pose challenges for some operators. Their lifecycle cost may ultimately be lower, making them an attractive option for businesses focused on long-term savings.

Compressed Air Start Systems

Compressed air start systems offer a unique approach to engine ignition, particularly beneficial in extreme weather conditions. These systems utilize compressed air to initiate engine function, which can be particularly effective in cold climates where battery performance may be compromised. However, the complexity of installation and the need for a reliable air supply can make this solution less appealing for some buyers. Regular maintenance is necessary to ensure the air system remains operational, adding to the overall upkeep requirements.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating alternatives to truck starter motors, B2B buyers should consider their specific operational needs and environmental conditions. Truck starter motors offer a proven, reliable solution suitable for a wide range of scenarios, particularly long-haul trucking. However, for businesses operating in urban settings or extreme conditions, lithium-ion battery systems or compressed air start systems may provide enhanced performance and efficiency. Ultimately, the choice will depend on factors such as budget, maintenance capabilities, and the specific demands of the trucking operation. By carefully assessing these elements, buyers can make informed decisions that best suit their operational requirements.

Essential Technical Properties and Trade Terminology for truck starter motor

What Are the Key Technical Properties of Truck Starter Motors?

Understanding the technical specifications of truck starter motors is crucial for B2B buyers to ensure they select the right components for their fleet needs. Here are some essential properties:

-

Voltage Rating

– The voltage rating, typically 12V or 24V, indicates the electrical input required for the starter motor to function. This specification is vital as it must match the truck’s electrical system to ensure proper operation. Incorrect voltage can lead to starter failure or damage to the vehicle’s electrical components. -

Torque Output

– Torque output measures the rotational force the starter motor can exert to turn the engine over. High torque is essential for heavy-duty applications, especially in cold weather or when starting large engines. This specification helps buyers assess if a starter motor can reliably start their specific truck models under varying conditions. -

Material Grade

– The material used in the construction of the starter motor, such as high-grade steel or aluminum, affects its durability and performance. Higher-grade materials are more resistant to wear and tear, especially in harsh environments, making them preferable for long-haul operations. Buyers should consider material quality to ensure longevity and reduce maintenance costs. -

Gear Reduction Ratio

– This specification refers to the ratio of the starter motor’s output speed to the input speed. A higher gear reduction ratio allows for more torque at lower speeds, making it easier to start heavy-duty engines. Understanding this ratio is essential for buyers to ensure compatibility with their engine specifications. -

Operating Temperature Range

– Starter motors are designed to function within specific temperature ranges. Knowing the operating temperature range is crucial for applications in extreme climates, such as high heat in the Middle East or cold in Europe. Selecting a starter motor with an appropriate temperature rating can prevent premature failures. -

Duty Cycle

– The duty cycle indicates how long a starter motor can operate before it requires a cooling period. Heavy-duty applications often require motors with a higher duty cycle to accommodate frequent starts without overheating. Buyers should consider this property to ensure their starter motors can handle their operational demands.

What Are Common Trade Terms in the Truck Starter Motor Industry?

Familiarity with industry terminology can facilitate smoother transactions and better decision-making. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

– OEM refers to parts made by the original manufacturer of the vehicle. In the context of starter motors, OEM parts are preferred for their guaranteed compatibility and reliability. Buyers often seek OEM components to ensure optimal performance and maintain warranty coverage. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory costs effectively. Suppliers may set MOQs to ensure that production and shipping costs are covered. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. In the context of starter motors, submitting an RFQ allows buyers to compare offers and select the best deal based on price, quality, and delivery time. -

Incoterms (International Commercial Terms)

– Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is crucial for B2B transactions, especially for international buyers, to avoid misunderstandings related to delivery and liability. -

Aftermarket Parts

– Aftermarket parts are components produced by companies other than the OEM. They are often more affordable and can provide equivalent or improved performance. Buyers should evaluate the quality of aftermarket starter motors to ensure they meet their operational standards. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is critical for inventory management and planning, especially when sourcing starter motors for large fleets or urgent repairs.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ensuring they invest in the right starter motors that meet their operational needs while navigating the complexities of the international market.

Navigating Market Dynamics and Sourcing Trends in the truck starter motor Sector

What Are the Current Market Dynamics and Key Trends Affecting the Truck Starter Motor Sector?

The truck starter motor sector is witnessing significant growth driven by several global factors. Increased demand for heavy-duty trucks, particularly in emerging markets like Nigeria and Brazil, is prompting manufacturers to innovate and improve the efficiency of their products. The rise of e-commerce and logistics has further accelerated the need for reliable starter motors to ensure that fleets operate without interruption. Additionally, technological advancements such as smart starters and integration with telematics systems are reshaping the market landscape, allowing for better performance monitoring and predictive maintenance.

International B2B buyers are increasingly prioritizing partnerships with suppliers that offer high-quality components tailored for specific vehicle models. This trend towards specialization is crucial, as the diversity of truck models and the harsh operating conditions in regions like the Middle East necessitate durable and reliable products. Furthermore, the growing trend of remanufactured starter motors is gaining traction due to cost-effectiveness and environmental sustainability, appealing to budget-conscious companies in regions facing economic challenges.

Illustrative image related to truck starter motor

How Is Sustainability Influencing Sourcing in the Truck Starter Motor Industry?

Sustainability is becoming a critical consideration for B2B buyers in the truck starter motor sector. The environmental impact of manufacturing processes is under scrutiny, prompting businesses to seek suppliers who adhere to sustainable practices. Ethical sourcing is not only about reducing carbon footprints but also involves ensuring fair labor practices throughout the supply chain.

Buyers are increasingly looking for suppliers that can provide ‘green’ certifications, indicating that products are manufactured using eco-friendly materials and processes. For instance, starter motors made with recyclable components or utilizing low-emission manufacturing techniques are becoming more desirable. Emphasizing sustainability can enhance a company’s brand reputation and align with the growing consumer demand for environmentally responsible products, particularly in European markets where such values are integral to purchasing decisions.

What Is the Historical Context of Truck Starter Motors and Its Relevance Today?

The evolution of truck starter motors has been marked by significant technological advancements since their inception in the early 20th century. Initially, starter motors were simple hand-cranked devices, but as engine technology advanced, the need for reliable and efficient electrical starters became paramount.

Today, modern starter motors are designed to withstand extreme conditions, reflecting the rigorous demands of heavy-duty applications. The transition from traditional DC motors to advanced technologies, such as gear reduction starters, has improved efficiency and reduced weight, allowing trucks to operate more effectively in diverse environments. Understanding this evolution is crucial for B2B buyers, as it highlights the importance of investing in high-quality, innovative products that meet the demands of contemporary logistics and transportation.

In summary, the truck starter motor sector is shaped by emerging market dynamics, sustainability pressures, and a rich history of technological advancement. International B2B buyers must navigate these trends carefully to make informed sourcing decisions that align with both operational needs and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of truck starter motor

-

1. How do I choose the right starter motor for my truck?

Selecting the appropriate starter motor for your truck involves understanding both the specifications of your vehicle and the demands of your operations. Begin by identifying the engine size and type of your truck, as well as the voltage requirements (typically 12V or 24V). Additionally, consider the environmental conditions in which your truck operates—extreme temperatures may necessitate a more robust starter. It is also beneficial to consult with reliable suppliers who can provide cross-reference charts to match your needs with compatible products from various manufacturers. -

2. What are the benefits of purchasing remanufactured truck starter motors?

Remanufactured truck starter motors offer several advantages, including cost savings and environmental benefits. These units are typically less expensive than brand-new starters, making them a budget-friendly option for fleet operators. Moreover, purchasing remanufactured parts can contribute to sustainability by reducing waste and minimizing the demand for new materials. When choosing remanufactured options, ensure you source from reputable suppliers who guarantee quality and provide warranties. -

3. What factors should I consider when vetting suppliers for truck starter motors?

When vetting suppliers for truck starter motors, consider their industry experience, product quality, and customer service reputation. Look for suppliers with a robust portfolio of reputable brands, as well as positive reviews from other B2B buyers. Verify that they adhere to international quality standards and offer warranties on their products. Additionally, assess their logistics capabilities, including shipping times and costs, especially if you’re sourcing from different continents like Africa or South America. -

4. How do I negotiate favorable payment terms with suppliers?

Negotiating payment terms can significantly impact your cash flow and overall purchasing strategy. Begin by understanding your budget and expected delivery timelines. Discuss options such as net 30 or net 60 terms, which allow you time to generate revenue before payment is due. Some suppliers may offer discounts for early payments or bulk orders, so it’s important to inquire about these possibilities. Always ensure that the agreed terms are documented in your contract to avoid any misunderstandings. -

5. What is the typical minimum order quantity (MOQ) for truck starter motors?

The minimum order quantity (MOQ) for truck starter motors can vary widely based on the supplier and the type of motor. Generally, MOQs can range from a few units to several dozen, particularly for specialized or high-demand models. If you are a small business or just starting out, discuss your needs with suppliers; some may be willing to accommodate smaller orders or allow for flexibility in MOQs. Establishing a good relationship with your supplier can also lead to more favorable terms over time. -

6. How can I ensure quality assurance (QA) for the starter motors I purchase?

To ensure quality assurance for your starter motors, collaborate with suppliers who implement strict QA processes. Request information about their testing methods and certifications that validate their products meet industry standards. Additionally, consider asking for samples or trial units before placing a bulk order to assess performance. Regular communication and feedback with your supplier regarding product quality can help maintain high standards and address any issues promptly. -

7. What logistics considerations should I keep in mind when sourcing truck starter motors internationally?

When sourcing truck starter motors internationally, logistics play a crucial role in your supply chain efficiency. Consider factors such as shipping methods, estimated delivery times, and customs regulations in your country. It is also important to evaluate the total landed cost, which includes shipping, duties, and taxes, to ensure you remain within budget. Partnering with suppliers who have established logistics networks can facilitate smoother transactions and reduce delays. -

8. What are the common issues faced when installing truck starter motors, and how can they be resolved?

Common issues during the installation of truck starter motors include misalignment, electrical connection failures, and inadequate power supply. To resolve these problems, ensure that the starter is correctly aligned with the engine and that all electrical connections are secure and free of corrosion. Additionally, verify that the vehicle’s battery is fully charged and compatible with the starter motor specifications. Consulting with a qualified technician or referring to installation guides can also help ensure a successful installation.

Top 1 Truck Starter Motor Manufacturers & Suppliers List

1. Delco Remy – Heavy Duty On-Highway Truck Starters

Domain: delcoremy.com

Registered: 1998 (27 years)

Introduction: Heavy Duty On-Highway Truck Starters include the following models: 28MT Gear Reduction Starter, 31MT Gear Reduction Starter, 37MT Straight Drive Starter, 38MT Gear Reduction Starter, 38MT+ Gear Reduction Starter, 39MT Gear Reduction Starter, 41MT Straight Drive Starter, 42MT Straight Drive Starter, 50MT Straight Drive Starter, and 150MT Gear Reduction Starter. Key features include Electrical Soft-…

Strategic Sourcing Conclusion and Outlook for truck starter motor

What Are the Key Takeaways for B2B Buyers in Sourcing Truck Starter Motors?

In the competitive landscape of truck starter motors, strategic sourcing is essential for international buyers aiming to optimize their supply chains. Key takeaways include understanding the importance of selecting high-quality, reliable starter motors that can withstand harsh operational conditions. Investing in reputable brands such as Delco Remy and Mitsubishi ensures durability and reduces the risk of costly downtimes. Furthermore, considering remanufactured options can be both cost-effective and environmentally friendly, providing additional savings without compromising quality.

How Can International Buyers Benefit from Strategic Sourcing?

The value of strategic sourcing extends beyond mere cost savings; it encompasses building long-term relationships with trusted suppliers, ensuring timely delivery, and gaining access to a wider range of products. For buyers in regions like Africa, South America, the Middle East, and Europe, leveraging local partnerships can enhance logistical efficiency and responsiveness to market demands.

What Is the Future Outlook for Truck Starter Motor Procurement?

As the demand for heavy-duty trucks continues to rise globally, the outlook for truck starter motor procurement remains positive. By prioritizing strategic sourcing practices, businesses can position themselves to capitalize on emerging market opportunities. Now is the time for international buyers to take proactive steps—evaluate your current sourcing strategies and connect with reliable suppliers to ensure your fleet’s performance and reliability well into the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to truck starter motor

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.