Introduction: Navigating the Global Market for higher amp alternator benefits

In an increasingly electrified world, sourcing higher amp alternators presents a pivotal challenge for international B2B buyers. As industries expand their reliance on advanced electrical systems, the demand for high-output alternators—capable of supporting multiple electronic devices without compromising performance—has surged. This guide addresses the complexities of selecting the right alternator, detailing the various types available, their specific applications across diverse sectors, and the essential factors to consider when vetting suppliers.

From understanding the intricacies of installation and maintenance costs to evaluating the efficiency and durability of high-output models, this comprehensive resource equips buyers from Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—with actionable insights. By navigating the nuances of higher amp alternator benefits, businesses can make informed purchasing decisions that enhance operational efficiency and reduce long-term costs.

Whether you are upgrading existing equipment or outfitting new vehicles, this guide serves as your roadmap to understanding the crucial elements that drive successful sourcing and procurement. Empower your organization with the knowledge to invest wisely in high-output alternators, ensuring your electrical systems can meet the demands of today and the challenges of tomorrow.

Table Of Contents

- Top 7 Higher Amp Alternator Benefits Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for higher amp alternator benefits

- Understanding higher amp alternator benefits Types and Variations

- Key Industrial Applications of higher amp alternator benefits

- 3 Common User Pain Points for ‘higher amp alternator benefits’ & Their Solutions

- Strategic Material Selection Guide for higher amp alternator benefits

- In-depth Look: Manufacturing Processes and Quality Assurance for higher amp alternator benefits

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘higher amp alternator benefits’

- Comprehensive Cost and Pricing Analysis for higher amp alternator benefits Sourcing

- Alternatives Analysis: Comparing higher amp alternator benefits With Other Solutions

- Essential Technical Properties and Trade Terminology for higher amp alternator benefits

- Navigating Market Dynamics and Sourcing Trends in the higher amp alternator benefits Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of higher amp alternator benefits

- Strategic Sourcing Conclusion and Outlook for higher amp alternator benefits

- Important Disclaimer & Terms of Use

Understanding higher amp alternator benefits Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Output Alternators | Increased amperage output, efficient cooling | Automotive aftermarket, heavy-duty vehicles | Pros: Powers multiple electronics efficiently; Cons: Higher initial investment. |

| Marine Alternators | Corrosion-resistant materials, designed for high humidity | Boat manufacturing, marine repairs | Pros: Durable in harsh environments; Cons: May require specialized installation. |

| Performance Alternators | Lightweight design, optimized for racing | Motorsports, performance vehicles | Pros: Enhanced performance under load; Cons: Higher maintenance due to extreme use. |

| Industrial Alternators | Robust construction, high power capacity | Manufacturing plants, construction equipment | Pros: Reliable power for heavy machinery; Cons: Bulkier and may require custom fittings. |

| Dual-Voltage Alternators | Capability to output different voltages | Specialty vehicles, emergency services | Pros: Versatile for various applications; Cons: More complex electrical systems may be needed. |

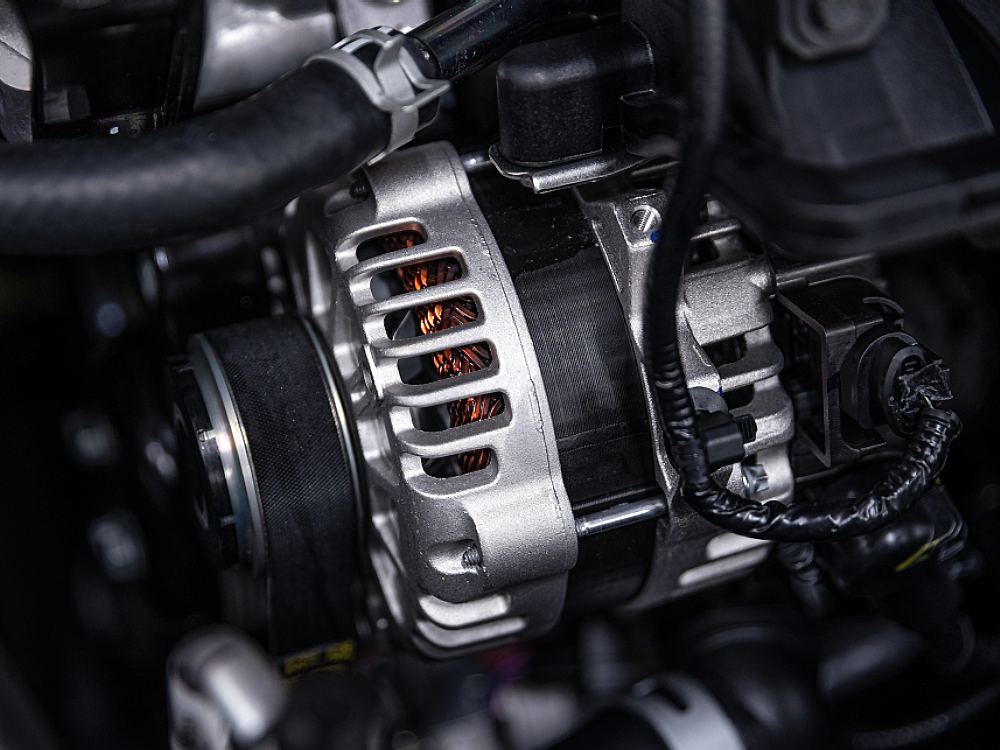

What are High-Output Alternators and Their B2B Suitability?

High-output alternators are designed to provide significantly higher amperage than standard models, making them ideal for vehicles that require additional electrical power, such as those with upgraded audio systems or multiple electronic devices. They are particularly suitable for the automotive aftermarket, where demand for enhanced vehicle performance is high. When considering a purchase, businesses should assess the specific power requirements of their vehicles and the potential return on investment through improved efficiency and reduced battery replacements.

How Do Marine Alternators Address Industry Needs?

Marine alternators are specifically designed to withstand the harsh conditions of marine environments, featuring corrosion-resistant materials and high humidity tolerance. These alternators are commonly used in boat manufacturing and marine repairs. Buyers should consider the environmental conditions in which the alternator will operate, as durability and reliability are critical in preventing costly downtimes in marine applications.

What Makes Performance Alternators Ideal for Motorsports?

Performance alternators are engineered for high-efficiency output and are often lighter than traditional models, making them suitable for motorsports and high-performance vehicles. These alternators provide enhanced performance under load, crucial for competitive racing scenarios. However, buyers should be aware of the potential for increased maintenance due to the extreme conditions they endure and weigh the benefits against the costs associated with higher performance.

Why Choose Industrial Alternators for Heavy Machinery?

Industrial alternators are built for robustness and high power capacity, making them essential for manufacturing plants and construction equipment. Their construction is designed to handle the demands of heavy machinery, ensuring reliable power supply for continuous operations. Businesses should evaluate the size and fitting requirements of these alternators, as they are generally bulkier and may necessitate custom installation solutions.

What Are the Benefits of Dual-Voltage Alternators for Specialty Applications?

Dual-voltage alternators offer the flexibility of supplying different voltage outputs, making them suitable for specialty vehicles and emergency services where varied electrical demands exist. Their versatility is a significant advantage, but buyers must also consider the complexity of the electrical systems that may be required to accommodate this feature. Understanding the specific applications and potential future needs can help businesses make informed purchasing decisions.

Key Industrial Applications of higher amp alternator benefits

| Industry/Sector | Specific Application of higher amp alternator benefits | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Supporting advanced electronic systems in vehicles | Enhances vehicle performance and reliability, reducing warranty claims | Ensure compatibility with existing vehicle models and systems |

| Renewable Energy | Powering solar and wind energy systems | Increases energy efficiency and reliability of energy output | Look for alternators with high durability and environmental ratings |

| Construction | Operating heavy machinery and tools | Ensures consistent power supply, minimizing downtime and delays | Consider load capacity and installation flexibility |

| Marine & Shipping | Supporting onboard electrical systems in vessels | Improves operational efficiency and safety of maritime operations | Evaluate marine-grade specifications and corrosion resistance |

| Telecommunications | Powering communication towers and equipment | Ensures uninterrupted service and reduces maintenance costs | Focus on sourcing from reputable manufacturers with warranty support |

How Are Higher Amp Alternators Beneficial in Automotive Manufacturing?

In the automotive manufacturing sector, higher amp alternators are essential for vehicles equipped with advanced electronic systems, including infotainment, navigation, and safety features. These alternators provide sufficient power to support multiple systems simultaneously, enhancing overall vehicle performance and reliability. For international buyers, particularly in regions like Africa and South America, ensuring compatibility with specific vehicle models and systems is crucial. This consideration helps avoid costly modifications and warranty claims due to electrical failures.

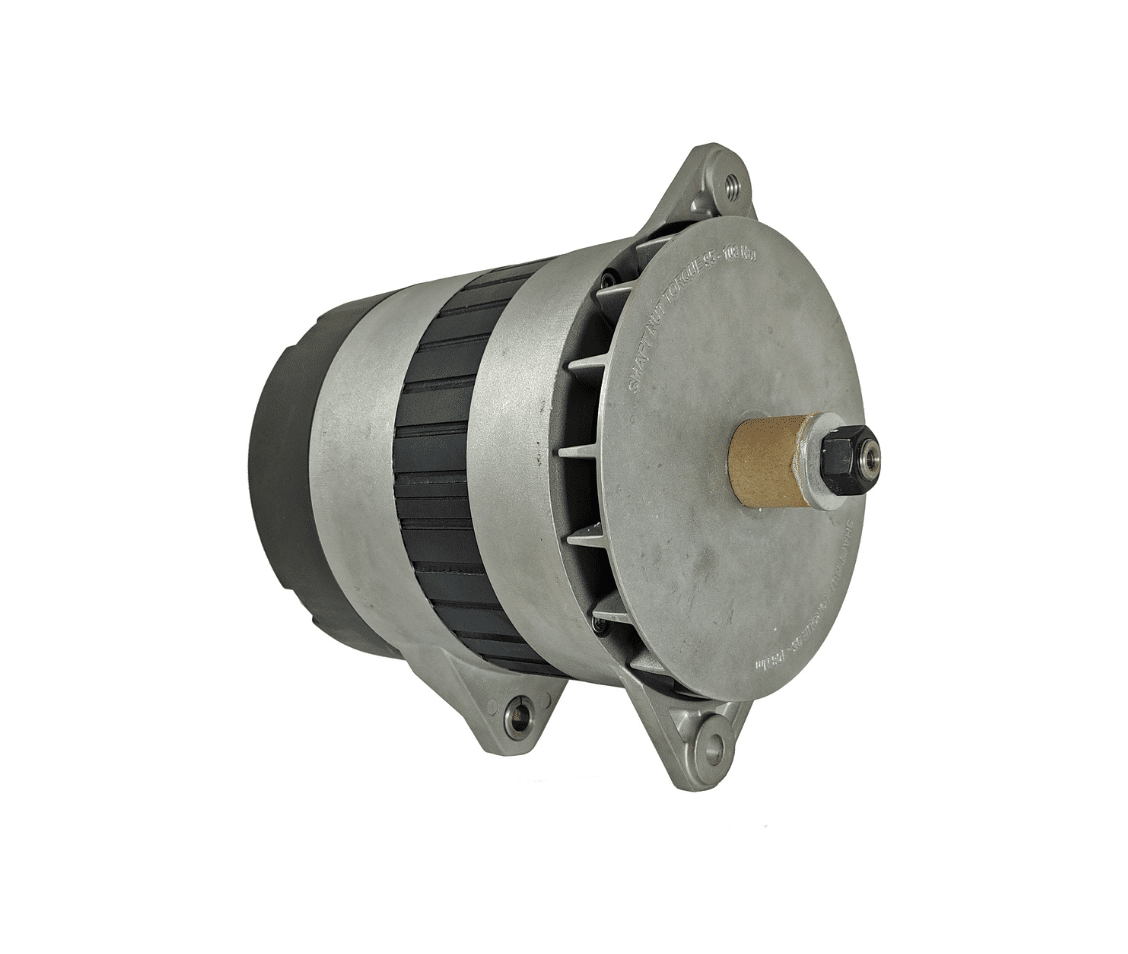

Illustrative image related to higher amp alternator benefits

How Do Higher Amp Alternators Improve Renewable Energy Systems?

In the renewable energy industry, higher amp alternators are vital in powering solar and wind energy systems. They enhance energy efficiency by converting mechanical energy into electrical energy more effectively, ensuring a reliable energy output. This is especially important for businesses in the Middle East, where solar energy is increasingly utilized. When sourcing alternators for these applications, businesses should prioritize durability and environmental ratings, as these factors significantly impact long-term performance and maintenance costs.

What Role Do Higher Amp Alternators Play in Construction?

In the construction industry, higher amp alternators are used to power heavy machinery and tools, ensuring a consistent power supply that minimizes downtime. This reliability is critical for maintaining project timelines and controlling costs. For B2B buyers in Europe, who may face strict regulations regarding equipment efficiency, considering load capacity and installation flexibility is essential. These factors help ensure that the chosen alternators can meet the demanding operational requirements of various construction sites.

How Are Higher Amp Alternators Used in Marine & Shipping Applications?

In the marine and shipping sector, higher amp alternators support onboard electrical systems that are crucial for navigation, communication, and safety. By improving operational efficiency, these alternators help ensure that vessels can operate safely and effectively in diverse maritime environments. For international buyers, especially those in regions with harsh marine conditions, evaluating marine-grade specifications and corrosion resistance is vital to ensure longevity and reliability in challenging environments.

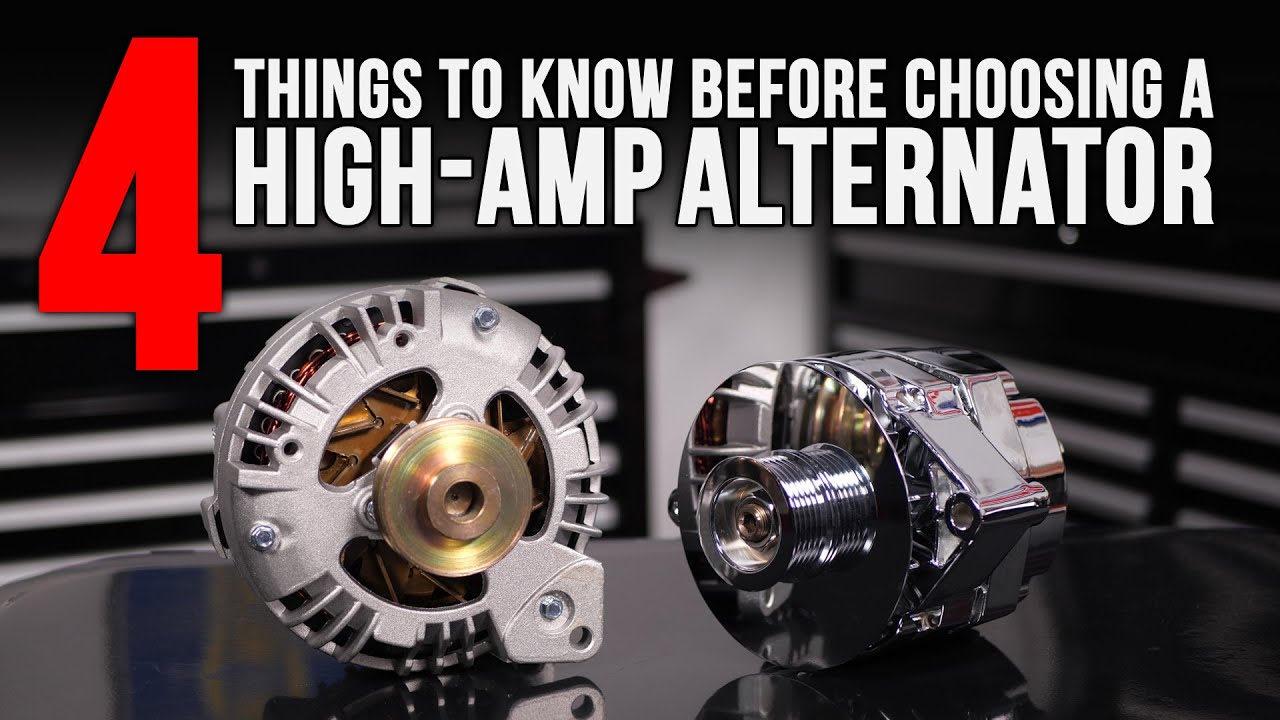

Illustrative image related to higher amp alternator benefits

How Do Higher Amp Alternators Benefit Telecommunications?

In telecommunications, higher amp alternators power communication towers and equipment, providing the necessary energy to maintain uninterrupted service. This reliability is crucial for reducing maintenance costs and ensuring consistent connectivity for users. For B2B buyers in regions like Saudi Arabia, where infrastructure development is rapidly advancing, focusing on sourcing from reputable manufacturers with warranty support can help mitigate risks associated with equipment failure, thereby enhancing overall service reliability.

3 Common User Pain Points for ‘higher amp alternator benefits’ & Their Solutions

Scenario 1: Insufficient Power Supply for Modern Equipment

The Problem: In many industries, businesses are increasingly reliant on modern vehicles equipped with high-tech devices, from GPS systems to advanced audio equipment. A common challenge arises when standard alternators fail to provide the necessary power for these electrical loads, leading to performance issues and potential equipment failure. For a B2B buyer managing a fleet, this can translate to operational inefficiencies, increased downtime, and the risk of costly repairs or replacements.

The Solution: To address insufficient power supply, B2B buyers should consider upgrading to higher amp alternators that can accommodate the increased electrical demands of modern equipment. When sourcing these alternators, it’s crucial to assess the total amperage required by all devices in use. Buyers should collaborate with manufacturers or distributors to identify models that offer higher output without compromising on efficiency. Additionally, consulting with a qualified automotive technician during installation can ensure that the alternator is compatible with the vehicle’s electrical system. This proactive approach will help mitigate risks associated with power shortages, leading to enhanced vehicle reliability and performance.

Illustrative image related to higher amp alternator benefits

Scenario 2: Overheating Issues with High-Output Alternators

The Problem: While higher amp alternators are designed to handle increased electrical loads, they can sometimes cause overheating due to the added strain on the vehicle’s electrical system. This is a significant concern for B2B buyers who operate vehicles in extreme climates or under heavy loads. Overheating can lead to severe damage, resulting in expensive repairs and extended vehicle downtime, which directly impacts the bottom line.

The Solution: To prevent overheating, buyers should look for high-output alternators that come with built-in thermal management features, such as heat sinks or advanced cooling systems. It’s also essential to regularly monitor the electrical system for signs of overheating. Implementing a maintenance schedule that includes checking the alternator’s connections, wiring, and cooling mechanisms can help identify potential issues before they escalate. Buyers should also consider investing in external cooling fans or heat shields for vehicles operating in particularly hot environments. By prioritizing these preventive measures, businesses can extend the lifespan of their alternators and ensure consistent performance.

Scenario 3: High Initial Investment Costs and ROI Concerns

The Problem: Upgrading to a higher amp alternator often comes with a higher upfront cost, which can be a significant barrier for B2B buyers, especially small and medium-sized enterprises (SMEs). Concerns about whether the investment will yield a tangible return, in terms of improved efficiency and reduced maintenance costs, can create hesitation in making the upgrade.

The Solution: To justify the investment in higher amp alternators, buyers should conduct a cost-benefit analysis that includes potential savings from reduced maintenance and downtime. Gathering data on the total cost of ownership, including the lifespan of standard versus high-output alternators, can help in making an informed decision. Additionally, buyers should seek out vendors that offer warranties and post-installation support, ensuring that the investment is protected. Engaging in discussions with other businesses that have made similar upgrades can provide valuable insights and real-world examples of ROI. By taking a data-driven approach, B2B buyers can confidently invest in higher amp alternators that ultimately enhance their operational efficiency and profitability.

Illustrative image related to higher amp alternator benefits

Strategic Material Selection Guide for higher amp alternator benefits

What Materials Are Commonly Used in Higher Amp Alternators?

When selecting materials for higher amp alternators, it’s crucial to consider their properties, advantages, and limitations. The right material can significantly enhance performance, durability, and efficiency, which are vital for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe.

How Do Copper and Aluminum Compare for Higher Amp Alternators?

Copper is a widely used material in electrical components due to its excellent conductivity and thermal properties. It can handle high temperatures and has a high melting point, making it suitable for high-load applications. However, copper is heavier and more expensive than alternatives like aluminum.

Pros: Copper offers superior electrical conductivity, which is essential for efficient energy transfer in higher amp alternators. It also has good corrosion resistance, ensuring longevity.

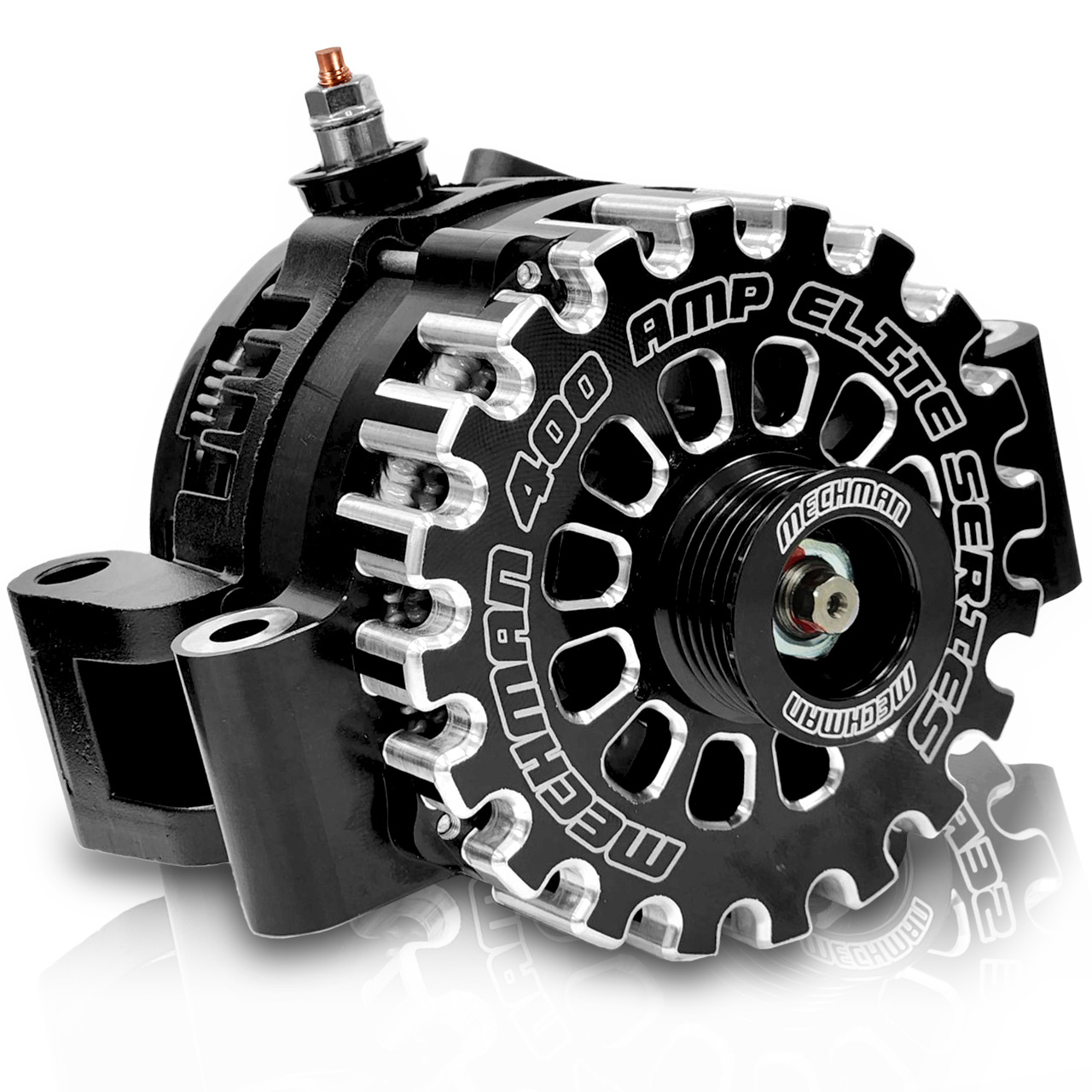

Illustrative image related to higher amp alternator benefits

Cons: The higher cost and weight can be significant drawbacks, particularly for applications where weight reduction is critical. Additionally, the manufacturing process can be more complex, leading to increased production costs.

Impact on Application: Copper is ideal for applications requiring high conductivity and reliability, such as automotive and industrial settings. However, B2B buyers must consider the additional weight and cost implications.

What Role Does Aluminum Play in Higher Amp Alternators?

Aluminum is another popular choice, known for its lightweight nature and reasonable conductivity. While it doesn’t match copper’s conductivity, it offers a good balance of performance and cost.

Pros: Aluminum is significantly lighter than copper, making it easier to handle and install. It is also less expensive, which can be a crucial factor for budget-conscious buyers.

Cons: The conductivity of aluminum is lower than that of copper, which may necessitate larger wire sizes to achieve the same performance level. Additionally, aluminum can be more susceptible to corrosion unless properly treated.

Impact on Application: Aluminum is suitable for applications where weight savings are essential, such as in racing or high-performance vehicles. Buyers in regions with high humidity or saline environments should consider corrosion resistance treatments.

How Does Steel Fit into the Picture for Higher Amp Alternators?

Steel, particularly stainless steel, is often used for structural components of alternators. It provides excellent strength and durability, making it suitable for high-stress applications.

Pros: Steel is robust and resistant to mechanical wear, providing long service life. Stainless steel offers good corrosion resistance, which is beneficial in various environmental conditions.

Cons: Steel is heavier than both copper and aluminum, which could impact overall vehicle weight. It also has lower electrical conductivity, making it less suitable for wiring applications.

Impact on Application: Steel is often used for mounting brackets and housings in alternators, where strength is more critical than conductivity. B2B buyers should consider the trade-off between weight and durability.

Illustrative image related to higher amp alternator benefits

What About Composite Materials for Higher Amp Alternators?

Composite materials, such as carbon fiber or fiberglass, are increasingly being explored for their lightweight and high-strength properties. These materials are not typically used for electrical conduction but can be beneficial in non-conductive components.

Pros: Composites are exceptionally lightweight and can be engineered for specific mechanical properties. They also provide excellent resistance to corrosion and environmental factors.

Cons: The cost of composite materials can be significantly higher than metals, and their manufacturing processes can be complex, potentially leading to longer lead times.

Impact on Application: Composites can be used in housings or non-conductive parts of alternators, especially in high-performance applications. Buyers need to consider the cost-benefit ratio carefully.

Summary Table of Material Selection for Higher Amp Alternators

| Material | Typical Use Case for higher amp alternator benefits | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and conductive components | Superior electrical conductivity | Higher cost and weight | High |

| Aluminum | Wiring and structural components | Lightweight and cost-effective | Lower conductivity and corrosion risk | Medium |

| Steel | Mounting brackets and housings | Excellent strength and durability | Heavier and lower conductivity | Medium |

| Composite | Non-conductive components and housings | Lightweight and corrosion-resistant | High cost and complex manufacturing | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in higher amp alternators, helping them make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for higher amp alternator benefits

What Are the Key Stages in the Manufacturing Process of Higher Amp Alternators?

The manufacturing process of higher amp alternators involves several critical stages, each designed to ensure the final product meets the rigorous demands of modern electrical systems. Understanding these stages can help B2B buyers assess the quality and reliability of the alternators they are considering for their applications.

1. Material Preparation: What Materials Are Used and Why?

The first stage in the manufacturing of higher amp alternators is material preparation. High-quality materials are essential for ensuring durability and performance. Commonly used materials include:

- Copper: Utilized for windings due to its excellent electrical conductivity.

- Aluminum: Often used for the housing and other structural components because it is lightweight yet strong.

- Magnetic Steel: Employed in the rotor and stator, providing the necessary magnetic fields for operation.

The selection of these materials is crucial, as they directly influence the alternator’s efficiency, heat dissipation, and overall performance.

2. Forming: How Are Components Shaped and Sized?

The forming stage involves shaping the prepared materials into specific components necessary for the alternator’s assembly. Techniques used in this stage include:

- Stamping: Used to create flat components from sheets of metal, such as the stator and rotor laminations.

- Die Casting: Employed for producing complex shapes, particularly in aluminum housings, ensuring precise dimensions and minimal waste.

- Winding: Copper wire is wound into coils for the stator, a critical step that affects the alternator’s electrical output.

This stage is vital for achieving the precise tolerances required for high-performance applications.

3. Assembly: How Are Components Brought Together?

Once the individual components are formed, they move to the assembly stage. This process includes:

- Component Integration: All parts, including the rotor, stator, bearings, and housing, are assembled in a clean environment to prevent contamination.

- Electrical Connections: Ensuring that all electrical connections are secure and properly insulated to prevent shorts and ensure reliable operation.

- Calibration: The assembled alternator is calibrated to ensure it meets specified output requirements.

An efficient assembly process is critical for maintaining quality and performance standards.

4. Finishing: What Final Touches Are Added?

The finishing stage includes several processes designed to enhance the alternator’s durability and aesthetics:

- Coating: Application of protective coatings to prevent corrosion and wear, especially in environments with harsh conditions.

- Labeling and Branding: Ensuring that all products are correctly labeled with specifications and manufacturer information for traceability.

- Packaging: Proper packaging is essential to protect the alternators during transport, reducing the risk of damage.

A thorough finishing process ensures that the product not only performs well but also withstands the rigors of shipping and handling.

What Quality Assurance Practices Are Essential for Higher Amp Alternators?

Quality assurance (QA) is a critical component of the manufacturing process for higher amp alternators. B2B buyers should be aware of the QA practices that ensure product reliability and performance.

1. What International Standards Should B2B Buyers Look For?

Adherence to international quality standards is crucial for ensuring the reliability of higher amp alternators. Key standards include:

- ISO 9001: This standard outlines requirements for a quality management system (QMS) and is essential for manufacturers aiming to deliver consistent quality.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards, crucial for buyers in Europe.

- API Standards: Relevant for alternators used in specific industrial applications, ensuring they meet performance and safety requirements.

These standards provide assurance that manufacturers maintain a high level of quality throughout their processes.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to the manufacturing process, helping to identify and address potential issues early. Common checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing monitoring during manufacturing to identify defects or deviations in real-time.

- Final Quality Control (FQC): Comprehensive testing of the finished alternators to ensure they meet performance specifications before shipping.

Implementing these checkpoints helps maintain quality throughout the production cycle.

3. What Common Testing Methods Are Used?

Testing methods are vital for verifying the performance and safety of higher amp alternators. Common tests include:

- Electrical Testing: Measuring output voltage and current to ensure compliance with specifications.

- Thermal Testing: Assessing heat generation and dissipation under load to prevent overheating.

- Mechanical Testing: Evaluating the structural integrity of components to ensure durability.

These tests provide critical data that B2B buyers can use to assess the reliability of the alternators.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in international markets, verifying the quality control processes of suppliers is essential. Here are actionable steps to ensure quality:

1. What Role Do Audits Play in Supplier Verification?

Conducting supplier audits can provide deep insights into their quality control practices. Buyers should consider:

- On-Site Audits: Visiting the manufacturing facility to observe processes and practices firsthand.

- Documentation Review: Examining quality management documentation, including ISO certifications and QC reports.

Audits help buyers confirm that suppliers adhere to industry standards and maintain rigorous quality control practices.

2. How Can Buyers Use Reports and Third-Party Inspections?

Requesting reports from suppliers, including testing results and quality control metrics, can help buyers evaluate product quality. Additionally, engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and products.

3. What Are the Nuances of QC/Certifications for International Buyers?

International buyers must be aware of specific nuances related to quality control and certifications. These may include:

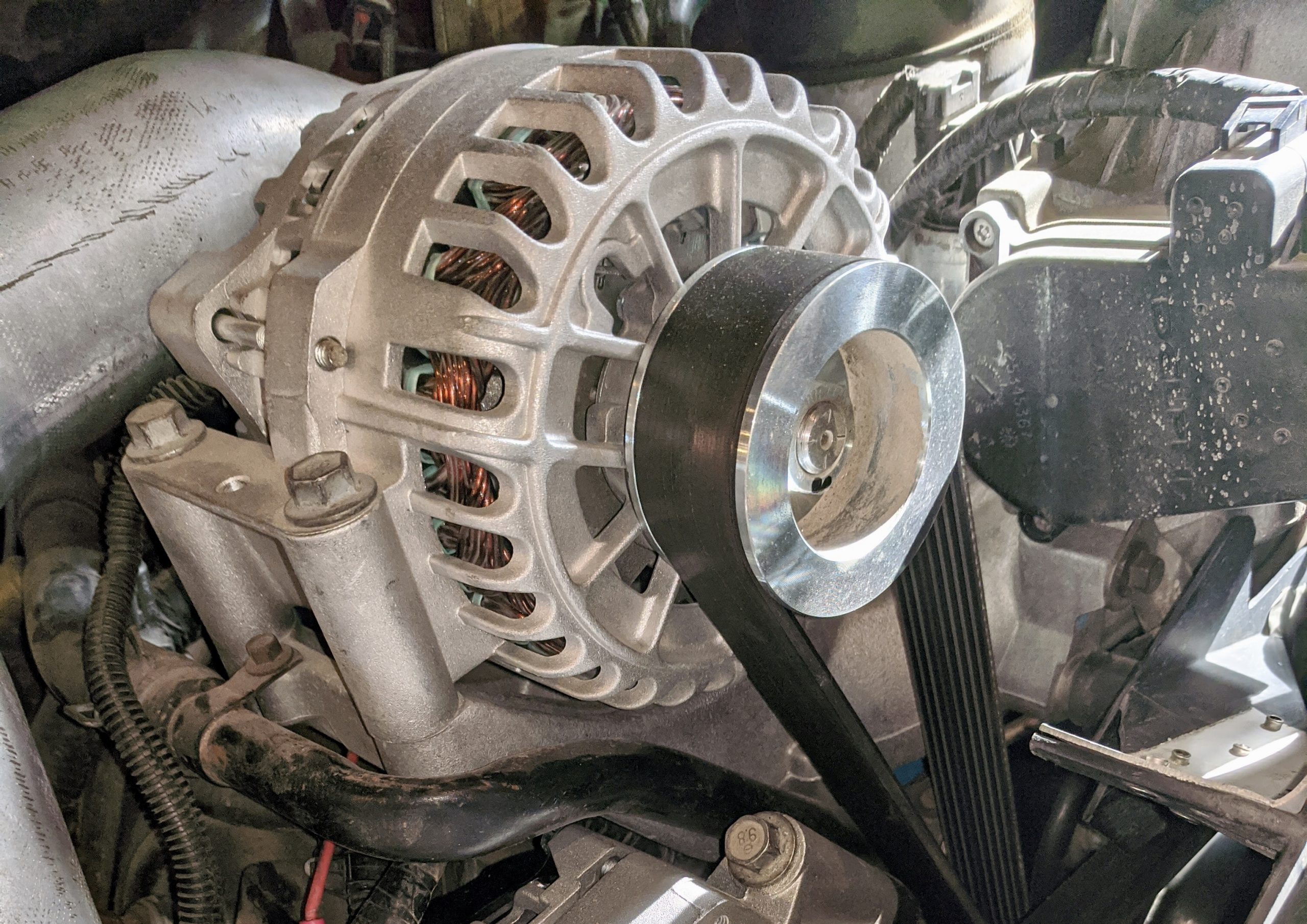

Illustrative image related to higher amp alternator benefits

- Regulatory Requirements: Understanding local regulations and standards in target markets, such as those in Africa, South America, the Middle East, and Europe.

- Cultural Considerations: Different regions may have varying expectations regarding quality and compliance, which can impact supplier selection.

By understanding these nuances, buyers can make informed decisions that align with their quality assurance needs.

Conclusion

The manufacturing processes and quality assurance practices for higher amp alternators are crucial elements that B2B buyers must consider. By understanding the stages of manufacturing, the importance of quality control, and the methods for verifying supplier reliability, buyers can make informed purchasing decisions that lead to successful outcomes in their operations. Investing time in evaluating these factors ensures that the selected alternators will meet the demands of modern electrical systems, ultimately contributing to enhanced performance and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘higher amp alternator benefits’

This guide serves as a practical checklist for B2B buyers looking to procure high-output alternators, specifically focusing on their benefits. Understanding the value of these components is essential for enhancing vehicle performance and ensuring reliability, particularly in markets with growing demands for efficient power management.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing high-output alternators. This includes determining the required amperage based on the electrical load of the vehicle and any additional accessories. Knowing these specifications helps narrow down options and ensures compatibility with existing systems.

- Consider your electrical needs: Identify all devices and systems that will draw power.

- Assess vehicle requirements: Different vehicles may have varying power demands; ensure you understand yours.

Step 2: Research Available Brands and Models

Conduct thorough research on reputable brands and models of high-output alternators. Not all alternators are created equal, and selecting a trusted brand can significantly impact performance and longevity. Pay attention to manufacturer reviews, ratings, and feedback from other users in your industry.

- Look for industry-recognized brands: Brands with certifications or endorsements from automotive associations often indicate reliability.

- Compare specifications: Ensure that the models you are considering meet or exceed your defined technical specifications.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their certifications and industry standards compliance. This step is vital to ensure that the products meet international quality benchmarks, which can affect performance and safety.

- Check for ISO certifications: Suppliers with ISO certifications demonstrate adherence to quality management standards.

- Review warranty and support options: A good warranty can provide peace of mind and indicates the supplier’s confidence in their product.

Step 4: Request Product Samples

Whenever possible, request samples of the high-output alternators you are considering. Physical inspection allows you to assess build quality and compatibility with your systems. Testing a sample can also help identify any potential issues before making a bulk purchase.

Illustrative image related to higher amp alternator benefits

- Conduct performance tests: Ensure that the alternator can handle the expected load without overheating or other issues.

- Check installation ease: Evaluate how straightforward the installation process is, as complex installations can lead to additional costs.

Step 5: Assess Total Cost of Ownership

Consider the total cost of ownership, which includes the initial purchase price, installation costs, and potential maintenance expenses. Sometimes, cheaper alternatives may lead to higher long-term costs due to inefficiencies or frequent repairs.

- Calculate long-term savings: Consider how improved fuel efficiency and reduced battery replacements may offset higher initial costs.

- Evaluate installation requirements: Factor in any additional components or modifications that may be needed for installation.

Step 6: Negotiate Terms and Conditions

Once you have selected potential suppliers, engage in negotiations to secure favorable terms. This can include pricing, payment terms, delivery timelines, and after-sales support. Strong negotiation can lead to cost savings and better service.

- Clarify payment terms: Ensure you understand when payments are due and any potential penalties.

- Discuss after-sales support: Confirm the level of technical support available after purchase, which can be crucial for troubleshooting.

Step 7: Finalize Your Purchase Decision

After thorough evaluation and negotiation, make your final purchase decision. Ensure that all agreements are documented, and confirm delivery schedules and installation support. This step solidifies your investment in high-output alternators and sets the stage for improved vehicle performance.

- Review all agreements: Ensure that all terms discussed are reflected in the contract.

- Plan for installation: Coordinate with your team or a technician to ensure a smooth installation process once the alternators arrive.

By following these steps, B2B buyers can effectively navigate the procurement process for high-output alternators, ensuring they select the best options to meet their needs while maximizing efficiency and performance.

Comprehensive Cost and Pricing Analysis for higher amp alternator benefits Sourcing

Analyzing the cost structure and pricing for higher amp alternators is crucial for B2B buyers looking to optimize their procurement strategies. Understanding the various cost components and price influencers allows companies to make informed decisions that align with their operational needs and financial goals.

What Are the Key Cost Components in Higher Amp Alternator Production?

The cost structure of higher amp alternators typically includes several critical components:

-

Materials: The quality of materials used significantly impacts the cost. High-output alternators often require premium materials for durability and efficiency, such as copper windings and robust housing. The choice of materials can influence both performance and pricing.

-

Labor: Skilled labor is essential in the assembly of high-output alternators. The complexity of the design necessitates trained technicians, which can elevate labor costs. Labor costs can vary based on geographic location, with higher wages in developed regions compared to emerging markets.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, but initial investments in automation may be required.

-

Tooling: The initial setup for specialized tooling can be significant. Custom tools designed for high-output alternators may lead to higher upfront costs, but they can also enhance production efficiency in the long run.

-

Quality Control (QC): Ensuring that alternators meet stringent quality standards is crucial. Investments in QC processes can add to the overall cost but are necessary to minimize returns and enhance customer satisfaction.

-

Logistics: Shipping and handling costs are vital, particularly for international buyers. Factors such as distance, shipping methods, and freight rates can significantly affect logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. The margin can vary widely based on market demand, competition, and the specific supplier’s business model.

How Do Price Influencers Affect Higher Amp Alternator Costs?

Several factors can influence the pricing of higher amp alternators:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Tailored solutions or specific amperage requirements can lead to higher costs. Buyers should evaluate whether customization is necessary or if standard models suffice.

-

Material Quality and Certifications: High-quality materials and compliance with international standards can increase costs but may also enhance product reliability and performance, making them worthwhile investments.

-

Supplier Factors: Reputation, reliability, and historical performance of suppliers can impact pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The chosen Incoterms (International Commercial Terms) will dictate responsibility for shipping, insurance, and tariffs, affecting the overall cost structure.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Higher Amp Alternators?

-

Negotiation: Engage in open discussions with suppliers to negotiate terms and pricing. Highlighting potential long-term partnerships can encourage suppliers to offer better rates.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost of ownership, including installation, maintenance, and energy efficiency. High-output alternators that may cost more upfront can save money over time through improved efficiency.

-

Pricing Nuances for International Buyers: When sourcing from regions like Africa, South America, the Middle East, and Europe, understand local market conditions and currency fluctuations. This knowledge can aid in price negotiations and budgeting.

-

Research and Compare: Conduct thorough research to compare different suppliers and models. Utilizing online platforms and industry networks can provide insights into pricing trends and supplier reliability.

Disclaimer on Indicative Prices

Pricing for higher amp alternators can vary widely based on the factors mentioned above. It is essential for buyers to conduct market research and obtain multiple quotes to get a realistic understanding of the costs involved. Prices are subject to change based on market conditions, supplier capabilities, and changes in raw material costs.

Alternatives Analysis: Comparing higher amp alternator benefits With Other Solutions

Exploring Alternatives to Higher Amp Alternator Benefits

In the quest for enhanced vehicle performance and efficiency, businesses often evaluate various solutions to meet their electrical power needs. While higher amp alternators provide distinct advantages, it is essential to consider alternative methods that may also fulfill these requirements. This comparison will examine higher amp alternators against battery upgrades and DC-DC converters, two viable alternatives that can address similar electrical demands.

| Comparison Aspect | Higher Amp Alternator Benefits | Battery Upgrade | DC-DC Converter |

|---|---|---|---|

| Performance | High current capacity for multiple electrical loads | Increased capacity for longer usage | Efficient power management with adjustable output |

| Cost | Higher initial installation cost; potential long-term savings | Moderate cost; may require frequent replacements | Lower upfront cost, but can add complexity |

| Ease of Implementation | Generally straightforward installation | Installation can vary; may require professional help | Requires proper sizing and compatibility checks |

| Maintenance | Lower maintenance due to fewer heat issues | Regular monitoring and replacement needed | Minimal maintenance but depends on load |

| Best Use Case | Vehicles with high electrical demands (e.g., audio systems) | Ideal for vehicles needing extended battery life | Suitable for off-grid applications or hybrid systems |

Understanding Battery Upgrades as an Alternative

Battery upgrades involve replacing standard batteries with higher capacity or specialized batteries, such as lithium-ion or AGM (Absorbent Glass Mat) types. These batteries can provide extended energy storage, allowing vehicles to run additional electrical systems without frequent recharges.

Pros: Battery upgrades can significantly enhance the energy reserve, enabling longer usage times for electrical components. They are often easier to install than alternator upgrades, as they typically fit standard battery compartments.

Cons: However, higher capacity batteries can be costly and may require regular replacements. Additionally, they may not resolve the issue of charging efficiency, especially if the vehicle’s alternator is underpowered.

Evaluating DC-DC Converters as a Solution

DC-DC converters are devices that can efficiently convert one voltage level to another, allowing for better power management in vehicles with multiple electrical systems. They can optimize power distribution and maintain stable voltage levels for sensitive electronics.

Pros: DC-DC converters are generally more cost-effective than higher amp alternators and can be easier to install. They are excellent for applications where voltage regulation is crucial, such as in off-grid systems or electric vehicles.

Cons: The complexity of sizing and ensuring compatibility with existing systems can be a drawback. If not correctly configured, they may lead to inefficiencies or even damage sensitive electronic components.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the best solution for your vehicle’s electrical demands, it’s crucial for B2B buyers to consider the specific requirements of their applications. Higher amp alternators are excellent for vehicles with significant electrical loads, while battery upgrades may be more suitable for those needing extended usage without frequent charging. DC-DC converters offer a versatile option for efficient power management, particularly in specialized applications. Evaluating the performance, cost, ease of implementation, and maintenance requirements of each alternative will empower buyers to make informed decisions that align with their operational needs.

Essential Technical Properties and Trade Terminology for higher amp alternator benefits

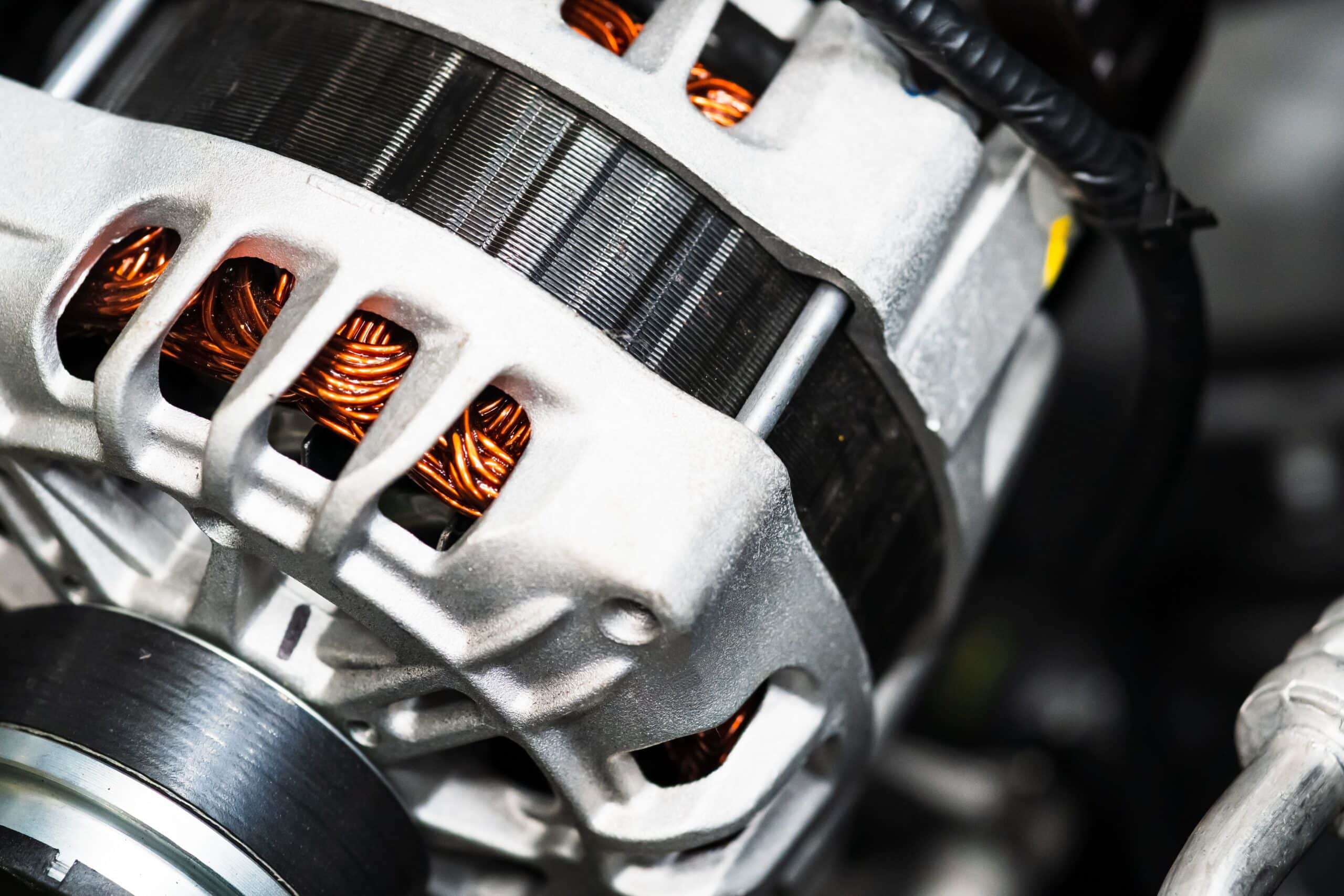

What Are the Key Technical Properties of Higher Amp Alternators?

When evaluating higher amp alternators, several technical specifications are critical for B2B buyers to understand. These properties not only influence performance but also determine compatibility with existing systems.

1. Ampere Rating (A)

The ampere rating indicates the maximum electrical output the alternator can deliver. Higher amp ratings are essential for vehicles with numerous electronic devices, ensuring that all systems function without draining the battery. For B2B buyers, understanding the required amperage helps in selecting an alternator that meets their operational needs while avoiding potential overloading issues.

Illustrative image related to higher amp alternator benefits

2. Voltage Output (V)

Most automotive alternators are designed to operate at 12 volts, but higher amp models may offer options for higher voltages. This specification is crucial for compatibility with various electrical systems. B2B purchasers should ensure that the alternator’s voltage output matches their vehicle’s requirements to prevent electrical failures.

3. Efficiency Rating

Efficiency ratings indicate how effectively an alternator converts mechanical energy into electrical energy. Higher efficiency ratings lead to reduced heat generation and improved fuel economy. For businesses, investing in efficient alternators can translate into long-term savings on fuel costs and maintenance.

4. Cooling Mechanism

Alternators generate heat during operation, especially when under heavy load. Some higher amp models come equipped with advanced cooling mechanisms, such as integrated fans or heat sinks. Understanding the cooling capabilities of an alternator is vital for B2B buyers to prevent overheating and ensure reliable operation, especially in high-demand scenarios.

5. Material Grade

The material used in the construction of the alternator, such as aluminum or copper, affects durability and performance. Higher-grade materials can withstand harsher conditions and improve the lifespan of the alternator. B2B buyers should consider the material properties to ensure they select a product that meets their operational demands and environmental conditions.

Illustrative image related to higher amp alternator benefits

6. Mounting Style

Different vehicles require specific mounting styles for alternators. Understanding these styles—whether side-mounted, top-mounted, or custom configurations—ensures compatibility with existing systems. For B2B buyers, selecting an alternator with the correct mounting style prevents additional costs and complications during installation.

What Trade Terminology Should B2B Buyers Know About Higher Amp Alternators?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms relevant to higher amp alternators.

1. OEM (Original Equipment Manufacturer)

OEM refers to the company that manufactures parts that are used in the production of vehicles. When purchasing alternators, knowing whether a part is OEM can assure quality and compatibility with existing systems. B2B buyers often prefer OEM parts for their reliability and performance.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to plan their purchases effectively and manage inventory levels. This term often impacts bulk buying decisions and pricing negotiations.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers for specific products. For B2B buyers looking for higher amp alternators, issuing an RFQ can help in obtaining competitive pricing and understanding supplier capabilities.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is vital for B2B transactions, as they dictate who is responsible for shipping costs, insurance, and customs clearance, which can significantly impact overall costs.

Illustrative image related to higher amp alternator benefits

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For businesses relying on higher amp alternators for operations, understanding lead times helps in planning and minimizing downtime.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing higher amp alternators, ensuring compatibility, efficiency, and cost-effectiveness in their operations.

Navigating Market Dynamics and Sourcing Trends in the higher amp alternator benefits Sector

What Are the Key Market Drivers for Higher Amp Alternator Benefits?

The global demand for higher amp alternators is on the rise, driven by several key factors. Firstly, the increasing reliance on electronic systems in vehicles—such as advanced audio systems, infotainment, and safety features—has necessitated the need for more powerful alternators. Emerging markets in Africa and South America, particularly countries like Brazil, are witnessing a surge in automotive sales, further amplifying this demand. Additionally, the growth of electric and hybrid vehicles in regions like Europe and the Middle East is reshaping market dynamics, as these vehicles require higher output for efficient battery charging.

Illustrative image related to higher amp alternator benefits

Technological advancements are also transforming the industry. Manufacturers are increasingly adopting smart technologies to enhance alternator performance, focusing on efficiency and reliability. This trend aligns with the growing interest in reducing vehicle emissions and improving fuel economy. Furthermore, international B2B buyers are showing a preference for suppliers who offer innovative solutions tailored to their specific needs, including customizable alternator options that meet varying electrical load requirements.

How Are Sustainability and Ethical Sourcing Influencing the Higher Amp Alternator Market?

Sustainability has emerged as a cornerstone of modern B2B practices, significantly impacting the higher amp alternator sector. As global awareness regarding environmental issues increases, buyers are prioritizing products that minimize ecological footprints. Higher amp alternators, when designed with energy-efficient technologies, contribute to reduced fuel consumption and lower emissions, making them attractive options for environmentally-conscious businesses.

Moreover, ethical sourcing is becoming a critical consideration. Buyers are increasingly demanding transparency in the supply chain, seeking manufacturers who adhere to sustainable practices. This includes using ‘green’ materials and obtaining certifications that validate their commitment to environmental stewardship. For instance, certifications such as ISO 14001 indicate that a manufacturer has established an effective environmental management system. Suppliers who can demonstrate compliance with these standards are likely to gain a competitive edge in the market.

How Has the Higher Amp Alternator Market Evolved Over Time?

The evolution of higher amp alternators can be traced back to the growing complexity of automotive electrical systems. Initially designed for basic functionality, traditional alternators struggled to meet the demands of modern vehicles equipped with multiple electronic devices. The introduction of high-output alternators addressed this challenge, allowing vehicles to operate efficiently under increased electrical loads.

As consumer preferences shifted towards enhanced performance and reliability, manufacturers began innovating, integrating advanced technologies to improve efficiency and reduce heat generation. This historical shift has laid the groundwork for today’s market, where high-output alternators not only serve as power sources but also contribute to overall vehicle performance and sustainability.

Conclusion

In summary, the higher amp alternator market is driven by a convergence of technological advancements, increasing demand for electronic systems, and a strong emphasis on sustainability and ethical sourcing. International B2B buyers, particularly from emerging markets in Africa, South America, and the Middle East, should consider these dynamics when making sourcing decisions. By aligning with suppliers who prioritize innovation and sustainability, businesses can enhance their operational efficiency and contribute to a greener future.

Frequently Asked Questions (FAQs) for B2B Buyers of higher amp alternator benefits

1. How can I determine if a higher amp alternator is suitable for my business needs?

To assess if a higher amp alternator is suitable for your business, consider the electrical load requirements of your vehicles or equipment. Evaluate the number and type of electrical components you plan to power, such as audio systems, lighting, or climate control. Additionally, consider your current alternator’s performance; if you’re frequently experiencing battery drain or electrical failures, an upgrade may be warranted. Finally, consult with your supplier to ensure compatibility with your existing systems and to discuss the potential benefits in terms of efficiency and long-term savings.

2. What are the key benefits of using a high-output alternator in commercial vehicles?

High-output alternators provide several benefits for commercial vehicles, including increased power capacity to support multiple electrical devices without straining the battery. This leads to improved reliability and less frequent battery replacements, reducing maintenance costs. Additionally, these alternators are generally more efficient, resulting in better fuel economy. The ability to run high-demand equipment like refrigeration units or advanced navigation systems can significantly enhance operational efficiency and service delivery in various industries.

3. What factors should I consider when sourcing high-output alternators from international suppliers?

When sourcing high-output alternators internationally, consider the supplier’s reputation, certifications, and compliance with local regulations. Evaluate their production capacity, lead times, and ability to provide customization if required. It’s also essential to assess their quality assurance processes to ensure product reliability. Additionally, inquire about warranties, after-sales support, and the supplier’s experience with shipping and logistics to your region, as these can impact overall procurement efficiency.

4. Are there minimum order quantities (MOQs) for high-output alternators when sourcing from suppliers?

Minimum order quantities (MOQs) for high-output alternators can vary significantly between suppliers. Some may offer flexible MOQs, while others might require bulk orders to justify production runs or reduce costs. It’s essential to communicate your needs clearly with potential suppliers and negotiate MOQs that align with your business requirements. Additionally, consider the benefits of bulk purchasing, such as reduced unit costs and improved logistics efficiency.

5. What payment terms are typically offered by suppliers of higher amp alternators?

Payment terms for high-output alternators can vary widely among suppliers. Common terms include upfront payments, partial payments upon order confirmation, and balance upon delivery. Some suppliers may also offer credit terms for established businesses, allowing for payment within a specified period post-delivery. It’s crucial to negotiate terms that align with your cash flow and financial strategy while ensuring that you have adequate protection in place for your orders.

6. How can I ensure the quality of high-output alternators before purchase?

To ensure the quality of high-output alternators, request detailed product specifications and certifications from your supplier, such as ISO or SAE standards. Conduct a thorough supplier vetting process, including checking reviews and testimonials from other businesses. If possible, arrange for sample testing or audits of the manufacturing facility. Furthermore, inquire about the supplier’s quality assurance protocols and warranty policies to ensure you are protected against defects or performance issues.

7. What logistics considerations should I keep in mind when importing high-output alternators?

When importing high-output alternators, consider shipping methods, customs regulations, and potential tariffs that may apply to your region. Evaluate the logistics provider’s reliability and experience in handling automotive components. Additionally, factor in lead times for production and shipping, as well as warehousing needs upon arrival. It’s also wise to have a contingency plan for unexpected delays or issues during transit to avoid disruptions in your operations.

8. Can high-output alternators be customized to meet specific business requirements?

Yes, many suppliers offer customization options for high-output alternators to meet specific business needs. Customization can include adjustments in amperage ratings, physical dimensions, and connectors to ensure compatibility with your vehicles or equipment. When discussing customization, provide detailed specifications and requirements to your supplier. Keep in mind that custom orders may have longer lead times and potentially higher costs, so plan accordingly to align with your operational timelines.

Top 7 Higher Amp Alternator Benefits Manufacturers & Suppliers List

1. High Output Alternator – 180-230 Amp Replacement

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: High output alternator (180-230 amp) to replace an 80 amp alternator; used for a 1000w kicker sub setup; concern about potential harm to the car.

2. Rick’s Auto Center – High-Output Alternator

Domain: ricksautocenterllc.com

Registered: 2010 (15 years)

Introduction: High-output alternator offers increased power output, enhanced charging capability, consistent voltage output, improved performance in demanding conditions, compatibility with upgraded electrical systems, and future-proofing for vehicles. It delivers greater power with higher amperage, faster battery charging, and stable voltage supply to protect sensitive electronic devices.

3. Facebook – Battery Health Tips

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Battery Health Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. LS1 Tech – High Output Alternators

Domain: ls1tech.com

Registered: 2001 (24 years)

Introduction: High output alternators require more horsepower from the engine to create extra electrical power. They draw extra horsepower only when producing more electric power. Once the battery is charged, they draw the same power as any other alternator with the same electrical load. A higher amp alternator is generally bigger and heavier, absorbing more power even when not connected. Heavy-duty alternators…

5. Delcoremy – Oversized Alternator Benefits

Domain: delcoremy.com

Registered: 1998 (27 years)

Introduction: Benefits of Oversizing an Alternator: 1. Fuel Savings: An oversized alternator (approximately double the rated output) operates efficiently at 35-50% of its rated output, reducing fuel consumption. 2. Longer Alternator Life: Running at lower output reduces strain, leading to cooler operation and increased lifespan of components like bearing grease, rectifier diodes, and stator insulation. 3. Bette…

6. Eco-Tech – High Amp Alternators

Domain: ecotechalternators.com

Registered: 2012 (13 years)

Introduction: Eco-Tech High Amp Alternators utilize patented technology with permanent magnets to generate high output at low RPMs. Key specifications include: 14V/325A and 28V/200A options, with the Eco-Tech 305-I alternator producing 260 Amperes at 1,800 RPM, compared to competitors’ 2000 RPM. Competitors’ 320 Amp rated alternators deliver only 85-90 Amperes at idle. Benefits include improved alternator life …

7. Steve Meade Designs – 240 Amp Alternator Upgrade

Domain: stevemeadedesigns.com

Registered: 2006 (19 years)

Introduction: Upgrading alternator to 220 amp or higher, considering XS D3400 battery, current setup includes 120 amp alternator, yellow top battery, 0 gauge wiring, and Big 3 upgrade. Discussion on benefits of higher output alternator for improved sound and performance, with suggestions for 240 amp alternator and secondary battery.

Strategic Sourcing Conclusion and Outlook for higher amp alternator benefits

In today’s competitive landscape, the strategic sourcing of higher amp alternators is paramount for businesses seeking to enhance their operational efficiency and reliability. The advantages of high-output alternators—including improved energy efficiency, reduced maintenance costs, and the ability to support multiple electronic devices—make them an attractive investment for companies across various sectors. By understanding the unique needs of your operations and leveraging the benefits of these advanced systems, businesses can achieve significant cost savings and operational improvements.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe continue to navigate the complexities of sourcing, a focused approach to evaluating high-output alternators can yield substantial returns. It is crucial to consider not only the initial investment but also the long-term benefits of enhanced performance and reduced downtime.

Looking ahead, the demand for higher amp alternators is likely to grow as industries become increasingly reliant on sophisticated electrical systems. Now is the time to engage with trusted suppliers and explore options that align with your operational goals. Make informed decisions today to future-proof your business and optimize your power solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.