Introduction: Navigating the Global Market for how much is a headlight replacement

In the dynamic landscape of the automotive industry, understanding how much a headlight replacement costs is a crucial aspect for international B2B buyers. Whether you’re sourcing components for fleet maintenance or managing a workshop, the challenge lies in navigating the diverse range of headlight types, installation complexities, and fluctuating prices across different regions. This comprehensive guide delves into various headlight options, from budget-friendly halogen bulbs to advanced LED assemblies, and the implications of each choice on overall vehicle safety and maintenance costs.

Our guide goes beyond mere pricing to equip you with actionable insights on supplier vetting, regional cost variations, and the latest trends in automotive lighting technology. For businesses operating in Africa, South America, the Middle East, and Europe—such as in Saudi Arabia or Germany—making informed purchasing decisions is essential to maintaining competitive advantage and ensuring compliance with local regulations.

By providing an in-depth analysis of headlight replacement options, associated labor costs, and best practices for sourcing, this guide empowers B2B buyers to optimize their procurement strategies. Ultimately, our aim is to enhance your understanding of the global market for automotive lighting solutions, enabling you to make choices that support safety, cost-effectiveness, and operational efficiency.

Table Of Contents

- Top 5 How Much Is A Headlight Replacement Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much is a headlight replacement

- Understanding how much is a headlight replacement Types and Variations

- Key Industrial Applications of how much is a headlight replacement

- 3 Common User Pain Points for ‘how much is a headlight replacement’ & Their Solutions

- Strategic Material Selection Guide for how much is a headlight replacement

- In-depth Look: Manufacturing Processes and Quality Assurance for how much is a headlight replacement

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much is a headlight replacement’

- Comprehensive Cost and Pricing Analysis for how much is a headlight replacement Sourcing

- Alternatives Analysis: Comparing how much is a headlight replacement With Other Solutions

- Essential Technical Properties and Trade Terminology for how much is a headlight replacement

- Navigating Market Dynamics and Sourcing Trends in the how much is a headlight replacement Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much is a headlight replacement

- Strategic Sourcing Conclusion and Outlook for how much is a headlight replacement

- Important Disclaimer & Terms of Use

Understanding how much is a headlight replacement Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Halogen Bulbs | Cost-effective, short lifespan (500-1,000 hours) | General automotive repair shops | Pros: Low initial cost; easy to replace. Cons: Frequent replacements needed; less energy-efficient. |

| HID (High-Intensity Discharge) | Brighter output, longer lifespan (2,000-10,000 hours) | Luxury vehicle service centers | Pros: Superior illumination; energy-efficient. Cons: Higher cost; may require specialized installation. |

| LED (Light Emitting Diode) | Very long lifespan (up to 40,000 hours), high efficiency | Advanced automotive manufacturers | Pros: Durable; low power consumption. Cons: High upfront cost; potential compatibility issues. |

| Complete Headlight Assembly | All components included, often sealed units | Automotive repair and parts distributors | Pros: Simplifies installation; ensures compatibility. Cons: Expensive; may require professional installation. |

| Adaptive Headlights | Advanced features like auto-leveling and directional lighting | High-end automotive service shops | Pros: Enhanced safety and visibility; modern technology. Cons: Very high replacement costs; complex repairs. |

What Are Halogen Bulbs and Their B2B Implications?

Halogen bulbs are the most common type of headlight used in vehicles due to their affordability and ease of replacement. They typically last between 500 to 1,000 hours and are ideal for general automotive repair shops that prioritize cost-effective solutions. B2B buyers should consider the frequency of replacements and the associated labor costs, as halogen bulbs may need to be replaced more often than other types.

How Do HID Bulbs Differ in Performance for Businesses?

HID bulbs provide brighter illumination and have a longer lifespan compared to halogen options, lasting between 2,000 to 10,000 hours. They are commonly used in luxury vehicles and are suitable for B2B applications that require enhanced visibility. While they offer significant advantages in terms of brightness and energy efficiency, buyers must weigh the higher initial costs and potential need for specialized installation against their benefits.

Why Are LED Bulbs Gaining Popularity Among B2B Buyers?

LED bulbs are becoming increasingly popular due to their longevity, lasting up to 40,000 hours, and energy efficiency. They are favored by advanced automotive manufacturers and businesses focused on sustainability. B2B buyers should consider the high upfront costs and ensure compatibility with existing systems, as well as the potential for significant long-term savings on replacements and energy consumption.

What Should Businesses Know About Complete Headlight Assemblies?

Complete headlight assemblies include all necessary components and are often sealed units. They simplify the installation process, making them suitable for automotive repair and parts distributors. However, the cost can be significantly higher, and buyers should factor in the necessity of professional installation for complex models. This option is ideal for businesses looking to ensure compatibility and reduce the risk of installation errors.

How Do Adaptive Headlights Enhance Vehicle Safety for Businesses?

Adaptive headlights feature advanced technologies such as auto-leveling and directional lighting, providing superior visibility and safety. They are often found in high-end vehicles and are best suited for automotive service shops that cater to luxury brands. However, the high replacement costs and complexity of repairs can be a deterrent for some businesses. B2B buyers must evaluate the benefits of enhanced safety against the potential financial implications.

Key Industrial Applications of how much is a headlight replacement

| Industry/Sector | Specific Application of how much is a headlight replacement | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Bulk purchasing of headlight bulbs and assemblies | Cost savings through bulk discounts and increased inventory turnover | Supplier reliability, product quality, and warranty terms |

| Vehicle Fleet Management | Regular maintenance and replacement of headlights | Enhanced safety and compliance with regulations for fleet vehicles | Availability of OEM versus aftermarket parts and pricing |

| Transportation & Logistics | Ensuring headlight functionality in delivery vehicles | Reduced accident risk and improved delivery reliability | Lead times for parts delivery and international shipping costs |

| Automotive Manufacturing | Integration of advanced headlight technology in new models | Competitive advantage through innovative lighting solutions | Compliance with international standards and certifications |

| Retail Automotive Parts | Offering a diverse range of headlight options for customers | Increased sales and customer satisfaction | Knowledge of regional market preferences and sourcing costs |

How Do Automotive Repair Shops Benefit from Headlight Replacement Costs?

Automotive repair shops can significantly benefit from understanding the costs associated with headlight replacements. By bulk purchasing headlight bulbs and assemblies, these shops can take advantage of cost savings, ensuring they maintain a healthy inventory that meets customer demand. Additionally, repair shops need to consider supplier reliability and product quality to ensure customer satisfaction. This is especially important in regions like Africa and South America, where access to reliable parts can be limited.

Illustrative image related to how much is a headlight replacement

What Are the Specific Needs of Vehicle Fleet Management in Headlight Replacement?

Vehicle fleet management companies must prioritize the regular maintenance and timely replacement of headlights to ensure safety and compliance with road regulations. This proactive approach minimizes the risk of accidents and enhances the reliability of their delivery services. For international buyers, it is crucial to evaluate the availability of OEM versus aftermarket parts, as this affects both pricing and quality. Additionally, understanding local regulations regarding vehicle lighting can impact sourcing decisions.

How Does Transportation & Logistics Benefit from Effective Headlight Management?

In the transportation and logistics sector, ensuring that delivery vehicles have functioning headlights is vital for reducing accident risks, especially during night-time operations. Regular headlight maintenance can lead to improved delivery reliability and safety. Companies must consider lead times for parts delivery, particularly when sourcing internationally, as delays can affect operational efficiency. Understanding shipping costs and timelines is essential for effective planning.

Why Is Headlight Technology Important for Automotive Manufacturing?

Automotive manufacturers must stay ahead of the curve by integrating advanced headlight technology into their new models. This not only enhances vehicle safety but also provides a competitive edge in the market. Manufacturers need to ensure that their products comply with international standards and certifications, which can vary between regions such as Europe and the Middle East. This compliance is crucial for market entry and acceptance.

Illustrative image related to how much is a headlight replacement

How Can Retail Automotive Parts Stores Increase Sales through Headlight Replacement Knowledge?

Retail automotive parts stores can boost sales by offering a diverse range of headlight options tailored to customer needs. By understanding the costs associated with different types of headlight replacements, these stores can provide valuable information to customers, enhancing satisfaction and loyalty. Additionally, knowledge of regional market preferences and sourcing costs can help optimize inventory and pricing strategies, ensuring competitiveness in both local and international markets.

3 Common User Pain Points for ‘how much is a headlight replacement’ & Their Solutions

Scenario 1: Navigating Cost Variability in Headlight Replacement

The Problem: B2B buyers in the automotive industry often face the challenge of unpredictable costs associated with headlight replacements. This is especially true when dealing with a diverse range of vehicle models and types. For instance, a company managing a fleet of vehicles may encounter varying replacement costs—from simple halogen bulbs costing $10 to complex LED systems that can exceed $1,000. This unpredictability can complicate budgeting and financial forecasting, leading to potential overspending or inadequate funds for necessary repairs.

The Solution: To effectively manage these costs, B2B buyers should implement a standardized approach to headlight replacement. Begin by creating a comprehensive inventory of all vehicles in the fleet, noting their specific headlight requirements, including bulb type and assembly complexity. Utilize this data to negotiate bulk purchasing agreements with suppliers, which can significantly reduce costs. Additionally, incorporating a scheduled maintenance program can help identify potential headlight issues before they become critical, allowing for timely replacements at lower costs. By establishing a clear understanding of each vehicle’s needs and maintaining open communication with suppliers, businesses can better control headlight replacement expenses and enhance their budgeting processes.

Scenario 2: Understanding Installation Costs and Challenges

The Problem: Many B2B buyers are unprepared for the labor costs associated with headlight replacement. When outsourcing to professional mechanics, businesses often discover that installation fees can range from $100 to $400, depending on the complexity of the job. This can lead to unexpected expenses, particularly if the installation requires additional labor for removing vehicle components or if multiple vehicles need service at the same time.

Illustrative image related to how much is a headlight replacement

The Solution: To mitigate these unexpected labor costs, buyers should consider investing in training for in-house maintenance staff. By equipping a small team with the skills necessary to perform headlight replacements, companies can significantly reduce reliance on external mechanics. This not only lowers costs but also speeds up the replacement process, minimizing vehicle downtime. Additionally, businesses should develop a partnership with a local mechanic for complex replacements, ensuring they have a reliable source for assistance without incurring excessive fees. This hybrid approach allows for cost-effective and efficient headlight maintenance.

Scenario 3: Sourcing Quality Parts Amidst Market Confusion

The Problem: B2B buyers frequently struggle to navigate the overwhelming variety of headlight products available in the market. With numerous options, including halogen, HID, and LED bulbs, along with various brands and specifications, it can be challenging to determine which products are both cost-effective and reliable. Inadequate knowledge can lead to purchasing subpar components, resulting in frequent replacements and safety issues.

The Solution: To ensure the procurement of quality headlight parts, B2B buyers should establish a clear set of criteria for sourcing. This includes seeking products that meet regulatory standards (like DOT certification), evaluating supplier reputations, and prioritizing warranties and return policies. It’s also beneficial to create a standardized parts list for each vehicle type in the fleet, which streamlines purchasing decisions and reduces the risk of errors. Additionally, engaging with industry experts or attending trade shows can provide insights into emerging technologies and best practices in headlight technology. By making informed purchasing decisions based on comprehensive research and established criteria, businesses can enhance their fleet’s safety and reduce long-term maintenance costs.

Illustrative image related to how much is a headlight replacement

Strategic Material Selection Guide for how much is a headlight replacement

What Materials Are Commonly Used in Headlight Replacements?

When considering headlight replacements, various materials are employed in the construction of bulbs, assemblies, and housings. Each material has unique properties that affect performance, durability, and cost, making it essential for B2B buyers to understand their implications.

What Are the Key Properties of Polycarbonate in Headlight Assemblies?

Polycarbonate is a popular material for headlight lenses due to its excellent impact resistance and lightweight nature. It can withstand high temperatures and is less prone to shattering compared to glass. Polycarbonate also offers good UV resistance, which is crucial for maintaining clarity over time. However, it is more susceptible to scratching and may require additional coatings to enhance durability.

Pros: Lightweight, high impact resistance, good UV stability.

Cons: Scratches easily, may require protective coatings, can yellow over time.

Impact on Application: Ideal for vehicles requiring lightweight components that can endure environmental stress.

International Considerations: Compliance with standards such as ASTM and ISO is crucial, especially in regions like Europe and the Middle East, where regulations on material safety and environmental impact are stringent.

Illustrative image related to how much is a headlight replacement

How Does Glass Compare as a Material for Headlight Lenses?

Glass has been a traditional choice for headlight lenses due to its clarity and resistance to scratching. It also provides excellent UV protection and does not yellow over time. However, glass is heavier and more fragile than polycarbonate, which can lead to higher shipping costs and increased risk of damage during installation.

Pros: Excellent optical clarity, scratch resistance, long-lasting.

Cons: Heavier, more fragile, higher shipping costs.

Impact on Application: Suitable for luxury vehicles where aesthetics and clarity are prioritized.

International Considerations: In regions like Germany, where high-quality standards are enforced, glass lenses may be preferred for their durability and performance.

What Role Do Halogen Bulbs Play in Headlight Replacement Costs?

Halogen bulbs are commonly used in headlight replacements due to their affordability and ease of installation. They provide good illumination but have a shorter lifespan compared to more advanced options like HID or LED bulbs. Halogen bulbs operate at high temperatures, which can affect their longevity and efficiency.

Illustrative image related to how much is a headlight replacement

Pros: Low cost, easy to replace, decent illumination.

Cons: Short lifespan, high heat generation, less energy-efficient.

Impact on Application: Ideal for budget-conscious consumers or older vehicle models.

International Considerations: Halogen bulbs must meet local regulations, such as those set by the NHTSA in the U.S. or equivalent standards in Europe and South America.

Why Are HID and LED Bulbs Gaining Popularity in Headlight Replacements?

HID (High-Intensity Discharge) and LED (Light Emitting Diode) bulbs are increasingly popular due to their superior brightness and energy efficiency. While they have a higher initial cost, their longer lifespan and lower energy consumption can result in cost savings over time. However, they may require more complex installation processes and specialized fixtures.

Pros: High brightness, energy-efficient, long lifespan.

Cons: Higher upfront costs, complex installation, potential compatibility issues.

Impact on Application: Best for modern vehicles with advanced lighting systems and for buyers looking for long-term savings.

International Considerations: Compliance with local regulations regarding light output and energy consumption is essential, especially in regions with stringent automotive standards.

Summary Table of Material Considerations for Headlight Replacement

| Material | Typical Use Case for how much is a headlight replacement | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Headlight assemblies in mid-range vehicles | Lightweight and impact-resistant | Susceptible to scratches and yellowing | Medium |

| Glass | Luxury vehicle headlight lenses | Excellent clarity and scratch resistance | Heavier and more fragile | High |

| Halogen Bulbs | Budget-friendly headlight replacements | Low cost and easy to replace | Short lifespan and high heat | Low |

| HID/LED Bulbs | Modern vehicles with advanced lighting systems | High brightness and energy efficiency | Higher upfront cost and installation complexity | High |

Understanding these materials and their implications can help B2B buyers make informed decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for how much is a headlight replacement

What Are the Main Stages of Manufacturing Headlight Components?

The manufacturing process for headlight replacements involves several critical stages that ensure the final product meets quality, safety, and performance standards. Understanding these stages is vital for B2B buyers seeking reliable suppliers.

Illustrative image related to how much is a headlight replacement

1. Material Preparation

The first step in the manufacturing process is the preparation of raw materials. Common materials used in headlight production include glass, polycarbonate, and various metals for the housing. Suppliers must ensure that these materials meet international quality standards, such as ISO 9001, to guarantee durability and performance.

During this stage, materials are sourced from certified vendors, and their quality is assessed through Incoming Quality Control (IQC). This involves inspections to check for defects, chemical composition, and compliance with safety regulations.

2. Forming Components

Once materials are prepared, the next step is forming the various components of the headlight. This includes creating lenses, reflectors, and housings. Techniques such as injection molding for plastic components and glass blowing for lenses are commonly used.

Illustrative image related to how much is a headlight replacement

Advanced technologies, like computer numerical control (CNC) machining, ensure precision in forming complex shapes, which is critical for optimal light distribution. B2B buyers should inquire about the machinery and technologies used by suppliers to guarantee they are using state-of-the-art methods.

3. Assembly of Headlight Units

After the components are formed, they undergo assembly. This process can be labor-intensive and requires skilled technicians to ensure proper alignment and sealing of parts. Automation is increasingly being adopted in assembly lines to enhance efficiency and reduce human error.

Quality checks during assembly, known as In-Process Quality Control (IPQC), are vital to ensure that each headlight unit meets design specifications. This may include visual inspections and functional testing to confirm that all components work together effectively.

Illustrative image related to how much is a headlight replacement

4. Finishing Processes

Finishing processes include surface treatments, such as coating and polishing, to enhance durability and aesthetics. For example, anti-fogging coatings may be applied to lenses, while corrosion-resistant finishes are used on metal parts.

At this stage, Final Quality Control (FQC) is performed, which includes rigorous testing for light output, durability, and weather resistance. B2B buyers should request information on the specific finishing processes used by suppliers to understand the longevity and performance of the products.

What Are the Quality Control Standards for Headlight Manufacturing?

Quality control (QC) is an essential aspect of headlight manufacturing, ensuring that products are safe and meet market expectations. International and industry-specific standards guide these processes.

International Standards: ISO 9001

ISO 9001 is a widely recognized international standard for quality management systems. Compliance indicates that a manufacturer has established processes to consistently provide products that meet customer and regulatory requirements. For B2B buyers, ensuring that suppliers are ISO 9001 certified is a critical step in verifying quality assurance practices.

Illustrative image related to how much is a headlight replacement

Industry-Specific Standards: CE and API

In addition to ISO standards, specific certifications such as CE marking (Conformité Européenne) and API (American Petroleum Institute) may apply, especially for products sold in Europe. CE marking ensures that products meet EU safety, health, and environmental protection standards, which is crucial for compliance in European markets.

What Are the Key Quality Control Checkpoints in Headlight Production?

Quality control in headlight manufacturing is multi-faceted, encompassing various checkpoints throughout the production process. Understanding these checkpoints helps B2B buyers assess supplier reliability.

Incoming Quality Control (IQC)

IQC focuses on the inspection of raw materials upon arrival at the manufacturing facility. This step is crucial for detecting defects before production begins. Materials that fail to meet quality standards are rejected or returned.

In-Process Quality Control (IPQC)

IPQC is conducted throughout the manufacturing stages. It involves monitoring processes and conducting tests to ensure that components meet specifications during production. This can include dimensional checks and functional tests to catch potential issues early.

Illustrative image related to how much is a headlight replacement

Final Quality Control (FQC)

FQC is the last line of defense before products are shipped. This phase includes comprehensive testing of the final headlight units to ensure they meet all functional, aesthetic, and safety standards. Common tests include light output measurements, durability assessments, and environmental simulations.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers must take proactive steps to ensure that their suppliers adhere to quality control practices that meet international standards. Here are some effective strategies:

Conduct Supplier Audits

Regular audits of suppliers provide insights into their manufacturing processes and quality control measures. These audits can help identify potential issues and ensure compliance with industry standards. Buyers should develop a checklist based on relevant certifications and manufacturing practices to guide these audits.

Request Quality Assurance Reports

Suppliers should provide documentation detailing their quality assurance processes, including results from IQC, IPQC, and FQC. These reports can offer valuable information about the reliability of the supplier’s products and their commitment to quality.

Utilize Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These organizations can conduct detailed evaluations and testing of products to ensure compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control when sourcing headlight replacements.

Regional Standards and Compliance

Different regions may have varying quality standards and regulations. For instance, products sold in Europe must comply with CE marking requirements, while Middle Eastern countries may have their own set of regulations. Buyers should ensure that suppliers understand and comply with the specific standards relevant to their target markets.

Illustrative image related to how much is a headlight replacement

Cultural Considerations in Quality Assurance

Cultural differences can influence quality assurance practices. B2B buyers should engage in open communication with suppliers to understand their quality control philosophies and practices. Building a strong relationship with suppliers can facilitate better compliance and quality outcomes.

Conclusion

In-depth knowledge of manufacturing processes and quality assurance measures is crucial for B2B buyers in the headlight replacement market. By understanding the stages of production, relevant international standards, quality control checkpoints, and verification methods, buyers can make informed decisions and establish fruitful partnerships with reliable suppliers. This proactive approach not only enhances product safety and performance but also contributes to the overall success of their business operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much is a headlight replacement’

To assist B2B buyers in navigating the complexities of headlight replacement costs, this practical sourcing guide outlines essential steps for making informed procurement decisions. Understanding the nuances of headlight types, labor costs, and supplier reliability can lead to significant savings and improved safety for vehicle fleets.

Step 1: Identify Your Vehicle’s Headlight Requirements

Before sourcing replacement headlights, ascertain the specific requirements for your vehicle models. Each make and model may require different types of bulbs or assemblies, such as halogen, HID, or LED. Checking the vehicle’s owner manual or consulting with your maintenance team will ensure that you procure the correct parts.

Step 2: Research Bulb Types and Costs

Understanding the various types of headlights and their associated costs is critical for budget planning. Halogen bulbs tend to be the most affordable but have a shorter lifespan, while HID and LED options offer longer life and better visibility at a higher price. Evaluating the long-term costs, including installation, can help you select the best option for your fleet.

Step 3: Evaluate Installation Options

Consider whether you will perform the installation in-house or outsource it to a professional mechanic. If you opt for professional installation, be prepared for labor costs, which can significantly impact the overall expense. Assess the technical capabilities of your maintenance team to determine if DIY installation is feasible, which can save money.

Step 4: Verify Supplier Certifications

When selecting suppliers for headlight components, ensure they hold relevant certifications and comply with local regulations. Look for suppliers that provide products meeting industry standards, such as DOT certification for bulbs. This guarantees that the products are safe and reliable, reducing the risk of future issues.

Step 5: Request Samples and Conduct Quality Checks

Before placing a bulk order, request samples of the headlight bulbs or assemblies. Conduct thorough quality checks to ensure they meet your specifications and performance standards. This step is vital to avoid issues that could arise from defective products, which can lead to additional costs and safety hazards.

Step 6: Review Warranty and Return Policies

Examine the warranty and return policies offered by potential suppliers. Reliable suppliers should provide warranties that cover defects and premature failures, safeguarding your investment. A clear return policy is also essential for managing any unforeseen issues with the products.

Step 7: Negotiate Terms and Pricing

Once you have identified suitable suppliers, engage in negotiations to secure favorable terms and pricing. Consider bulk purchasing agreements or long-term contracts that may provide discounts. Building a strong relationship with your suppliers can lead to better service and more competitive pricing over time.

By following this checklist, B2B buyers can confidently navigate the procurement process for headlight replacements, ensuring they make cost-effective and informed decisions that enhance safety and efficiency in their operations.

Comprehensive Cost and Pricing Analysis for how much is a headlight replacement Sourcing

What Are the Key Cost Components for Headlight Replacement in B2B Sourcing?

When analyzing the costs associated with headlight replacement, several key components contribute to the overall pricing structure. These include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

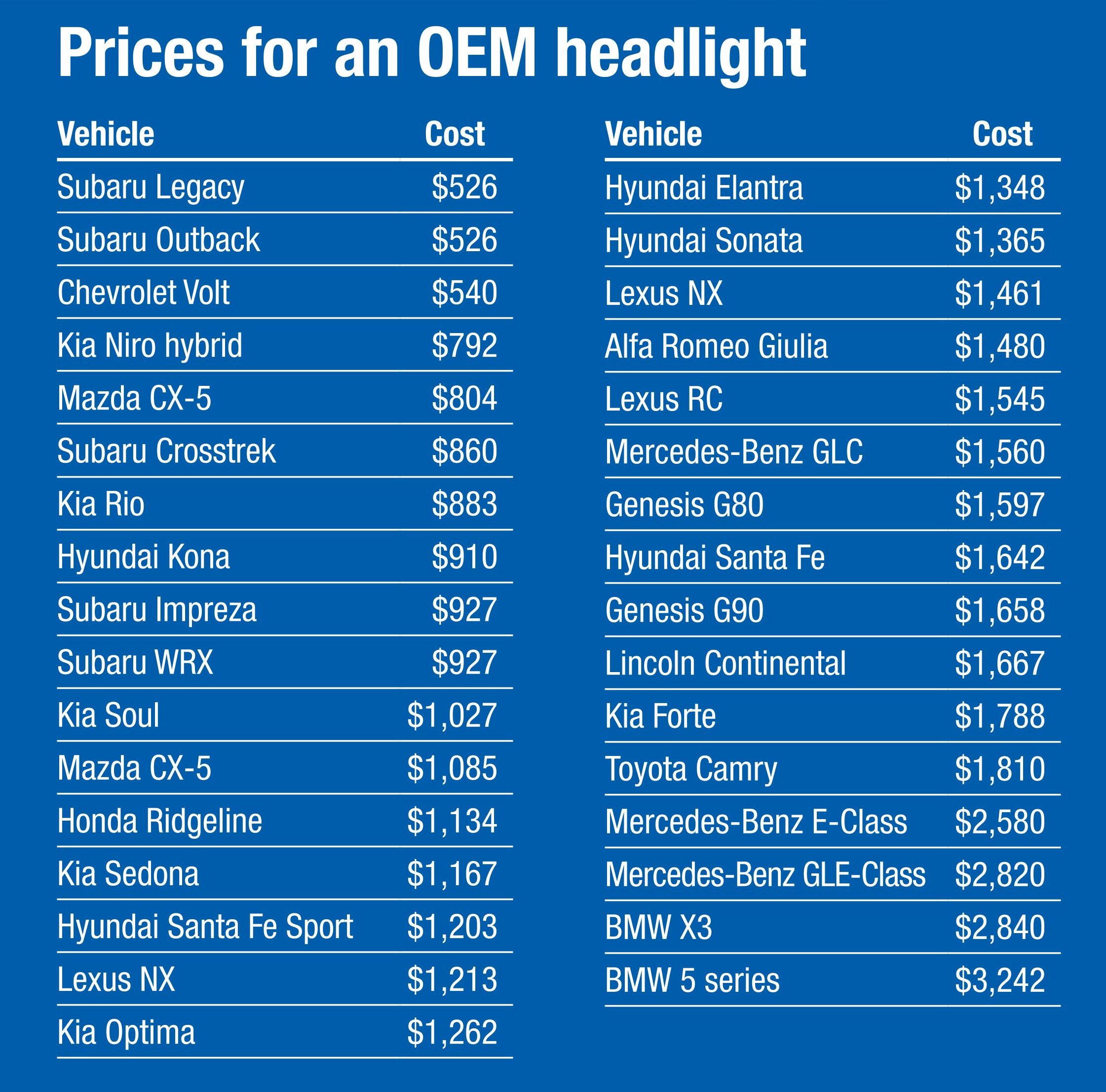

Materials: The type of headlight bulb significantly influences material costs. Halogen bulbs can range from $10 to $40, while more advanced systems like HID or LED bulbs can exceed $100. If the entire headlight assembly needs replacement, costs can soar from $30 to over $4,000, depending on the vehicle’s specifications and technology.

Labor: Labor costs are another critical factor. Professional installation can add $30 to $300 to the total expense, depending on the complexity of the installation. For B2B buyers, understanding the labor market in their region can help negotiate better rates for installation services.

Illustrative image related to how much is a headlight replacement

Manufacturing Overhead and Tooling: These costs can vary significantly based on the production scale. Larger volume orders may benefit from economies of scale, reducing per-unit costs. Tooling costs also play a role, especially for custom or specialized headlight designs.

Quality Control (QC): Ensuring that headlight products meet safety and performance standards incurs additional QC costs. Buyers should prioritize suppliers who invest in robust QC processes to minimize the risk of defective products.

Logistics: Shipping and handling costs can vary based on the origin of the product, shipping methods, and Incoterms. Understanding these factors is crucial for international buyers, as shipping costs can dramatically affect the total landed cost.

Margin: Finally, suppliers will add a profit margin to cover their costs and ensure profitability. This margin can vary based on the competitive landscape and the perceived value of the product.

What Price Influencers Should B2B Buyers Consider?

Several factors can influence the pricing of headlight replacements beyond the basic cost structure.

Illustrative image related to how much is a headlight replacement

Volume/MOQ: Purchasing in larger quantities can often lead to lower per-unit costs. B2B buyers should assess their inventory needs and negotiate minimum order quantities (MOQs) to take advantage of bulk pricing.

Specifications and Customization: Customized headlight solutions may incur additional costs. Buyers should clearly define their specifications and determine if customization is necessary, as this can significantly affect both lead times and pricing.

Materials and Quality Certifications: The type of materials used in headlight production and any relevant quality certifications can influence costs. Buyers should ensure that the products meet industry standards, particularly in regions with stringent automotive regulations.

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers with a track record of quality and service may command higher prices but offer better long-term value.

Illustrative image related to how much is a headlight replacement

Incoterms: Understanding the shipping terms agreed upon with suppliers is essential. Different Incoterms can affect who bears the costs and risks of transportation, which can ultimately influence the overall cost structure.

What Are the Best Practices for B2B Buyers in Headlight Replacement?

To optimize costs and ensure a smooth purchasing process, B2B buyers should consider the following tips:

Negotiation: Engage suppliers in discussions about pricing, especially if placing large orders. Negotiating terms can lead to significant savings.

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as durability, energy efficiency, and warranty offerings.

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, tariffs, and import duties that could affect pricing. It’s important to factor in these elements when calculating total costs.

Disclaimer for Indicative Prices: Keep in mind that prices can fluctuate based on market conditions, supplier pricing strategies, and changes in material costs. It’s advisable to conduct regular market assessments to stay informed about pricing trends.

Illustrative image related to how much is a headlight replacement

By understanding these cost components, price influencers, and best practices, B2B buyers can make informed decisions and optimize their headlight replacement sourcing strategies.

Alternatives Analysis: Comparing how much is a headlight replacement With Other Solutions

Understanding Alternatives for Headlight Replacement Solutions

When considering headlight replacement, B2B buyers should explore various alternatives that can serve similar purposes, such as improving vehicle visibility and safety. The solutions include traditional headlight replacement, headlight restoration kits, and advanced lighting technologies such as LED retrofits. Each alternative presents unique advantages and potential drawbacks that can influence the decision-making process.

| Comparison Aspect | How Much Is A Headlight Replacement | Headlight Restoration Kit | LED Retrofit |

|---|---|---|---|

| Performance | Restores original lighting function | Improves clarity but limited to existing bulbs | Higher brightness and energy efficiency |

| Cost | $30 – $4,000 (depending on type) | $20 – $50 | $50 – $200 per bulb |

| Ease of Implementation | Moderate; may require professional help | Easy; DIY-friendly | Moderate; may require professional installation |

| Maintenance | Periodic replacement needed | Requires reapplication over time | Long-lasting with minimal maintenance |

| Best Use Case | When bulb or assembly fails | For cloudy or yellowed lenses | Upgrading for better performance |

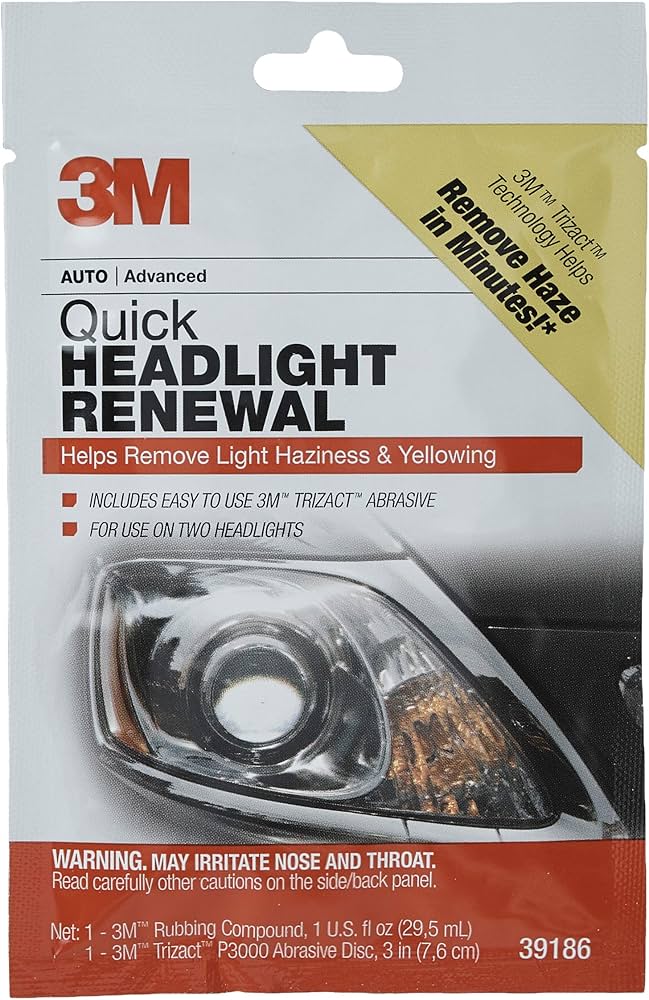

What Are the Pros and Cons of Headlight Restoration Kits?

Headlight restoration kits offer a cost-effective solution for improving the clarity of existing headlights. These kits typically include sanding pads, polish, and sealants that can rejuvenate cloudy or yellowed lenses. The primary advantage is their ease of use, allowing vehicle owners to perform the restoration themselves, often for a fraction of the cost of a full replacement. However, these kits may not address underlying issues if the bulbs themselves are burned out or damaged, and the results can diminish over time, necessitating reapplication.

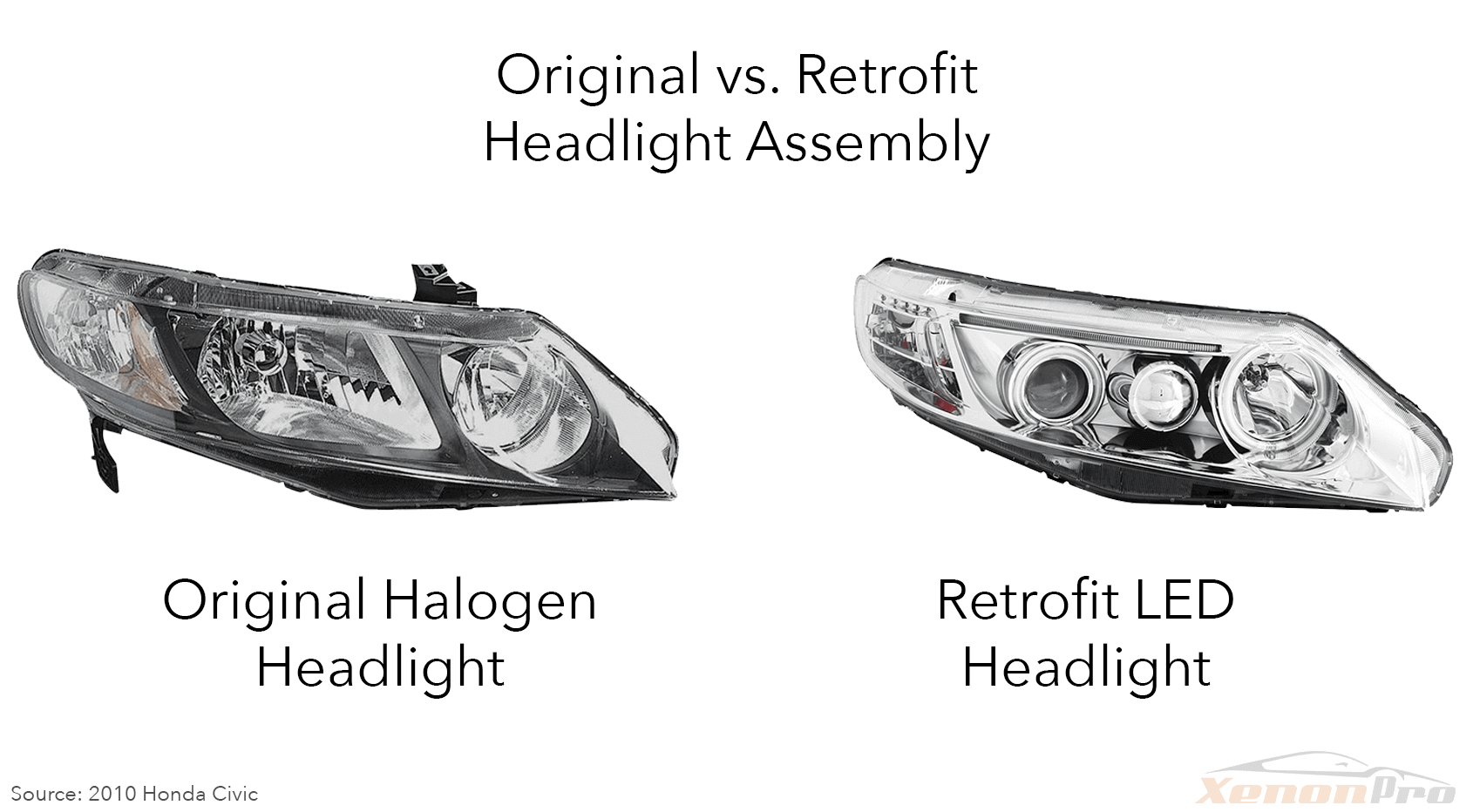

How Does LED Retrofit Compare to Traditional Headlight Replacement?

LED retrofits provide a modern alternative to traditional headlight replacements. They offer superior brightness, enhanced visibility, and lower energy consumption compared to halogen or HID bulbs. The installation of LED bulbs can be straightforward for some vehicles, but others may require professional help to ensure compatibility with existing systems. While the upfront costs can be higher—ranging from $50 to $200 per bulb—the long lifespan (up to 40,000 hours) and reduced maintenance needs make them a compelling choice for many B2B buyers focused on long-term value.

Illustrative image related to how much is a headlight replacement

Conclusion: How Can B2B Buyers Choose the Right Headlight Solution?

For B2B buyers, selecting the appropriate headlight solution involves evaluating the specific needs of their fleet or vehicles. Factors such as budget constraints, vehicle type, and maintenance capabilities should guide the decision. If cost-effectiveness is paramount and existing headlights are still functional, restoration kits may suffice. However, for those looking to enhance visibility and safety in the long run, investing in LED technology or planning for traditional replacements could yield better performance and reliability. Ultimately, the choice should align with the overall operational strategy and safety standards of the organization.

Essential Technical Properties and Trade Terminology for how much is a headlight replacement

What Are the Essential Technical Properties for Headlight Replacement?

When considering headlight replacements, understanding the technical properties involved is crucial for B2B buyers. Here are some key specifications:

1. Bulb Type

Different types of headlight bulbs, such as Halogen, HID (High-Intensity Discharge), and LED (Light Emitting Diode), have varying lifespans, brightness levels, and costs. Halogen bulbs are the most affordable but have a shorter lifespan (500 to 1,000 hours). HID bulbs offer greater brightness and longevity (2,000 to 10,000 hours), while LEDs are the most durable, often lasting up to 40,000 hours. Selecting the right bulb type can impact both the initial investment and long-term maintenance costs.

2. Material Grade

The materials used in the construction of headlight assemblies and bulbs significantly affect performance and durability. For instance, high-quality polycarbonate or tempered glass is often used for lenses to resist scratches and impacts. Understanding the material grade helps buyers evaluate the longevity and reliability of the headlight components they are purchasing.

3. Lumen Output

Lumen output measures the brightness of a bulb. Higher lumens indicate a brighter light, which is essential for visibility and safety. For B2B buyers, knowing the lumen output helps in selecting headlights that meet specific visibility requirements, especially in regions with poor lighting conditions.

Illustrative image related to how much is a headlight replacement

4. Power Consumption

Power consumption is a critical specification, especially for businesses looking to manage energy costs. LED bulbs typically consume less power than halogen or HID bulbs, providing a more energy-efficient solution. Evaluating power consumption can lead to significant cost savings, particularly for fleets or organizations managing multiple vehicles.

5. Compatibility and Fitment

Headlight assemblies must be compatible with specific vehicle models. Buyers should ensure that the replacement parts fit their vehicle’s make, model, and year. This compatibility is essential to avoid costly returns and ensure proper installation, which can save time and money in the long run.

6. IP Rating (Ingress Protection)

The IP rating indicates the degree of protection against dust and moisture. A higher IP rating signifies better resistance to environmental elements, which is vital for vehicles operating in harsh conditions. For B2B buyers, investing in headlights with a suitable IP rating can enhance reliability and reduce maintenance frequency.

Illustrative image related to how much is a headlight replacement

What Trade Terms Should B2B Buyers Know When Purchasing Headlight Replacements?

Familiarity with industry terminology can streamline procurement processes and enhance communication with suppliers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle’s original manufacturer. Choosing OEM parts ensures compatibility and quality, which is essential for maintaining vehicle performance and safety.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers plan inventory and manage costs effectively, particularly when sourcing bulk headlight replacements.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Issuing an RFQ can help buyers compare offers and negotiate better deals on headlight replacements.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery obligations associated with headlight procurement.

5. Warranty Period

The warranty period indicates how long a product is covered against defects. Understanding warranty terms can provide peace of mind and is crucial when assessing the long-term value of headlight replacements.

6. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Knowing the lead time is critical for managing inventory and ensuring timely replacements, especially in sectors with strict operational deadlines.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding headlight replacements, ensuring safety, compliance, and cost-effectiveness for their fleets or service offerings.

Navigating Market Dynamics and Sourcing Trends in the how much is a headlight replacement Sector

What Are the Current Market Dynamics and Key Trends in the Headlight Replacement Sector?

The global headlight replacement market is witnessing a notable shift driven by advancements in automotive technology and changing consumer preferences. Factors such as increasing road safety awareness and stringent regulations regarding vehicle lighting are propelling demand for high-quality headlights. In regions like Europe and the Middle East, where regulatory standards are particularly stringent, the preference for advanced lighting technologies such as LED and HID is on the rise. These technologies offer not only better visibility but also longer service life, which is appealing to both consumers and B2B buyers looking to enhance their service offerings.

Emerging trends in the B2B sourcing landscape include a growing focus on e-commerce platforms that facilitate direct sourcing of parts, allowing buyers to access a broader range of products and prices. Additionally, the rise of smart automotive technologies is leading to a demand for more complex headlight assemblies that integrate adaptive lighting systems. In Africa and South America, while the market is still evolving, the introduction of affordable and efficient aftermarket solutions is gaining traction, as local buyers seek cost-effective options without compromising on quality.

The market is also influenced by the increasing prevalence of electric vehicles (EVs), which often utilize advanced lighting systems. B2B buyers must stay informed about these technological advancements to remain competitive. Overall, understanding these dynamics will be crucial for international buyers looking to navigate the complexities of the headlight replacement market effectively.

How Is Sustainability and Ethical Sourcing Impacting the Headlight Replacement Sector?

As sustainability becomes a priority across industries, the headlight replacement sector is no exception. Environmental concerns surrounding automotive parts manufacturing and disposal are prompting B2B buyers to seek suppliers who adhere to sustainable practices. The use of eco-friendly materials in headlight production, such as recyclable plastics and energy-efficient manufacturing processes, is increasingly important for brands aiming to align with consumer expectations.

Ethical sourcing is another critical aspect, as buyers are keen to establish partnerships with suppliers who uphold fair labor practices and transparency in their supply chains. Certifications such as ISO 14001 for environmental management and other green certifications are becoming prerequisites for suppliers seeking to capture the attention of conscientious B2B buyers. Additionally, the trend towards remanufactured or refurbished headlight assemblies is gaining momentum, offering a sustainable alternative that reduces waste while providing cost savings.

In the context of the African and South American markets, where resource constraints may pose challenges, the adoption of sustainable practices can differentiate suppliers and enhance brand loyalty. B2B buyers must prioritize partnerships that reflect their commitment to sustainability, as this can influence purchasing decisions and contribute to a positive corporate image.

What Is the Evolution of Headlight Technology and Its Relevance to B2B Buyers?

Historically, headlight technology was limited to incandescent bulbs, which were relatively inexpensive but had a short lifespan. Over the years, advancements have led to the introduction of halogen, HID, and LED technologies, each offering distinct advantages in terms of brightness, energy efficiency, and longevity. The transition from simple bulb replacements to complex headlight assemblies reflects the automotive industry’s evolution towards more sophisticated lighting systems.

For B2B buyers, understanding this evolution is essential for making informed sourcing decisions. The complexity of modern headlight systems often necessitates specialized knowledge for installation and maintenance, which can impact service costs and customer satisfaction. As a result, suppliers who offer comprehensive support, including installation training and technical resources, are likely to hold a competitive advantage.

In summary, the headlight replacement sector is undergoing significant transformations influenced by technology, sustainability, and market dynamics. B2B buyers must stay abreast of these changes to leverage opportunities and maintain a competitive edge in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of how much is a headlight replacement

-

How do I determine the cost of a headlight replacement for my vehicle?

To assess the cost of headlight replacement, first identify the type of headlight your vehicle requires—options typically include halogen, HID, or LED bulbs. Prices can range from $10 to over $100 per bulb, while complete headlight assemblies can exceed $4,000 for high-end models. Consider additional costs such as labor if you are hiring a mechanic, which can range from $30 to $400 depending on installation complexity. Additionally, factor in any potential shipping or import duties if sourcing internationally. -

What is the best type of headlight for my vehicle?

Choosing the best headlight depends on your vehicle’s specifications and intended usage. Halogen bulbs are cost-effective but have a shorter lifespan, typically lasting 500-1,000 hours. HID bulbs offer brighter illumination and a longer lifespan (2,000-10,000 hours), while LEDs can last up to 40,000 hours but are generally more expensive. Assess your vehicle’s requirements and consult your owner’s manual or a trusted supplier to determine compatibility and optimal performance. -

How can I vet suppliers for headlight replacements?

When vetting suppliers, check their certifications and compliance with international standards, such as ISO or DOT regulations for automotive parts. Evaluate their reputation through customer reviews and industry referrals. Request samples to assess product quality and performance. Additionally, inquire about their supply chain reliability, lead times, and ability to meet your specific needs, such as customization or bulk orders. -

What are the minimum order quantities (MOQ) for headlight replacements?

Minimum order quantities can vary significantly among suppliers and depend on the type of headlights being sourced. Some manufacturers may have a MOQ of as low as 50 units for standard bulbs, while others may require orders of 500 or more for specialized assemblies. Discuss your requirements directly with suppliers to negotiate terms that fit your business needs and ensure they can accommodate your expected sales volume. -

What payment terms should I expect when sourcing headlights internationally?

Payment terms vary by supplier and may include options like advance payment, letters of credit, or payment upon delivery. Commonly, suppliers may request a deposit (e.g., 30-50%) with the balance due prior to shipment. It’s important to clarify these terms upfront and ensure they align with your cash flow management. Additionally, consider discussing potential discounts for early payments or bulk orders to optimize your procurement strategy. -

How does logistics impact the cost of headlight replacements?

Logistics can significantly affect the overall cost of headlight replacements, especially when sourcing internationally. Shipping fees, customs duties, and handling charges should all be factored into your budget. Opt for suppliers who have established logistics partnerships to minimize costs and ensure timely delivery. Additionally, consider the mode of transport (air vs. sea) based on urgency and cost-effectiveness, and maintain clear communication regarding shipment tracking. -

What quality assurance measures should I look for in headlight suppliers?

When sourcing headlights, it’s crucial to ensure that suppliers have robust quality assurance protocols in place. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Request information on their testing procedures for durability, brightness, and compliance with safety regulations. Additionally, inquire about return policies and warranty terms to safeguard your investment and mitigate risks associated with defective products. -

How can I handle customs and import regulations when sourcing headlights?

Navigating customs and import regulations is essential when sourcing headlights internationally. Familiarize yourself with the import duties, tariffs, and regulations specific to your country and the country of the supplier. Engage with customs brokers or logistics experts who can assist in ensuring compliance and facilitate smooth clearance processes. Always provide accurate documentation to avoid delays and additional costs, and maintain a proactive communication line with your supplier regarding shipping timelines and requirements.

Top 5 How Much Is A Headlight Replacement Manufacturers & Suppliers List

1. Ford – Fusion Headlight Replacement

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2014 Ford Fusion, front left headlight bulb replacement, estimated labor cost $300, requires extensive labor including lifting the vehicle and removing several body panels.

2. XenonPro – Headlight Replacement Cost Guide

Domain: xenonpro.com

Registered: 2013 (12 years)

Introduction: Headlight Replacement Cost Guide: 1. Factory Halogen Bulb Cost: $30 – $50 per pair, Lifespan: 1,000+ hours. 2. Factory Xenon HID Bulb Cost: $50 – $150 per pair, Lifespan: 10,000+ hours. 3. Factory LED Bulb Cost: N/A (entire assembly must be replaced), Lifespan: 30,000+ hours. 4. LED Conversion Kit Cost: $60 – $200, Lifespan: 5,000+ hours. 5. HID Conversion Kit Cost: $50 – $200, Lifespan: 5,000+ ho…

3. CarParts – Headlights Assembly

Domain: carparts.com

Registered: 1999 (26 years)

Introduction: Car Headlights – Halogen, HID, Xenon, LED Assembly from $70. Available for driver and passenger sides. High-quality replacements from respected manufacturers. Various lighting technologies for different makes and models. Fast shipping and hassle-free returns.

4. Honda Clarity – Headlight Replacement Costs

Domain: insideevsforum.com

Registered: 2017 (8 years)

Introduction: Headlight replacement for Honda Clarity costs $1500 per headlight, totaling $3000 for both. The headlights use a sealed assembly with no replaceable bulbs, likely consisting of a string of LEDs. Some users suggest potential alternatives like polishing hazy lenses or checking for cheaper options online, with some listings on eBay around $1300 for a pair. The vehicle was purchased in 2018.

5. Toyota – Camry SE Low Beam Bulb Replacement

Domain: community.cartalk.com

Registered: 1995 (30 years)

Introduction: 2016 Toyota Camry SE (2.5L 4-cylinder), Low Beam Bulb Replacement, Dealer Quote: $445 for both bulbs, Bulb Cost: $35 each, Labor Charge: $375, Bulb Type: Halogen Low Beam.

Strategic Sourcing Conclusion and Outlook for how much is a headlight replacement

What Are the Key Takeaways for B2B Buyers on Headlight Replacement Costs?

Understanding the cost of headlight replacement is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The price range for headlight bulbs varies significantly, from as low as $10 for basic halogen bulbs to over $4,000 for advanced LED assemblies. This variability underscores the importance of strategic sourcing. Buyers should consider the total cost of ownership, which includes parts, labor, and the frequency of replacements, to make informed procurement decisions.

Investing in high-quality bulbs not only enhances vehicle safety but also reduces the frequency of replacements and potential downtime. Furthermore, choosing suppliers who offer comprehensive product information and support can streamline the procurement process, ensuring that businesses receive reliable parts that meet safety standards.

How Can You Optimize Your Sourcing Strategy?

As you navigate the complexities of headlight replacement, prioritize partnerships with reputable suppliers who can provide a range of products tailored to various vehicle models and types. By doing so, you can enhance your operational efficiency and contribute to road safety in your market. Embrace a proactive approach to sourcing, ensuring that you stay ahead of the curve in this vital component of vehicle maintenance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.