Introduction: Navigating the Global Market for alternator and starter parts wholesale

Navigating the global market for alternator and starter parts wholesale presents a significant challenge for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe. The complexity of sourcing high-quality components at competitive prices can lead to uncertainty and inefficiencies in procurement processes. This guide is designed to provide a comprehensive overview of the alternator and starter parts wholesale landscape, covering a wide range of topics including types of parts available, their applications across various industries, and effective supplier vetting strategies.

By delving into the nuances of the market, this guide empowers buyers to make informed purchasing decisions that enhance their operational efficiency. From understanding the differences between aftermarket and OEM parts to exploring the latest advancements in starter and alternator technology, we aim to equip you with actionable insights. Additionally, we will discuss cost factors, shipping considerations, and warranty options that are crucial for minimizing risks and maximizing value.

Whether you are based in Saudi Arabia, Nigeria, or elsewhere, this guide serves as a vital resource to help you navigate the complexities of sourcing alternator and starter parts, ensuring you find reliable suppliers that meet your specific needs and expectations.

Table Of Contents

- Top 5 Alternator And Starter Parts Wholesale Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator and starter parts wholesale

- Understanding alternator and starter parts wholesale Types and Variations

- Key Industrial Applications of alternator and starter parts wholesale

- 3 Common User Pain Points for ‘alternator and starter parts wholesale’ & Their Solutions

- Strategic Material Selection Guide for alternator and starter parts wholesale

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator and starter parts wholesale

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator and starter parts wholesale’

- Comprehensive Cost and Pricing Analysis for alternator and starter parts wholesale Sourcing

- Alternatives Analysis: Comparing alternator and starter parts wholesale With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator and starter parts wholesale

- Navigating Market Dynamics and Sourcing Trends in the alternator and starter parts wholesale Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator and starter parts wholesale

- Strategic Sourcing Conclusion and Outlook for alternator and starter parts wholesale

- Important Disclaimer & Terms of Use

Understanding alternator and starter parts wholesale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Starter Parts | Includes solenoids, brushes, and assemblies. | Automotive, Marine, Agricultural | Pros: Essential for starting engines; readily available. Cons: Quality varies; requires proper matching to vehicle specs. |

| Alternator Parts | Comprises voltage regulators, bearings, and rectifiers. | Automotive, Heavy Trucks, Industrial | Pros: Critical for vehicle electrical systems; extensive aftermarket options. Cons: Complexity in compatibility; possible need for technical expertise. |

| Rebuild Kits | Complete sets containing all necessary components for repair. | Automotive, Industrial, Marine | Pros: Cost-effective; ensures all parts are compatible. Cons: May require skilled labor for installation; not all kits are comprehensive. |

| High Output Components | Upgraded parts for increased performance, like heavy-duty regulators. | Performance Vehicles, Commercial Trucks | Pros: Enhances vehicle efficiency; ideal for demanding applications. Cons: Higher cost; may require additional upgrades to the system. |

| OEM vs. Aftermarket Parts | Original Equipment Manufacturer parts versus aftermarket alternatives. | All sectors needing replacements | Pros: OEM ensures compatibility; aftermarket often more affordable. Cons: OEM can be pricier; aftermarket quality can be inconsistent. |

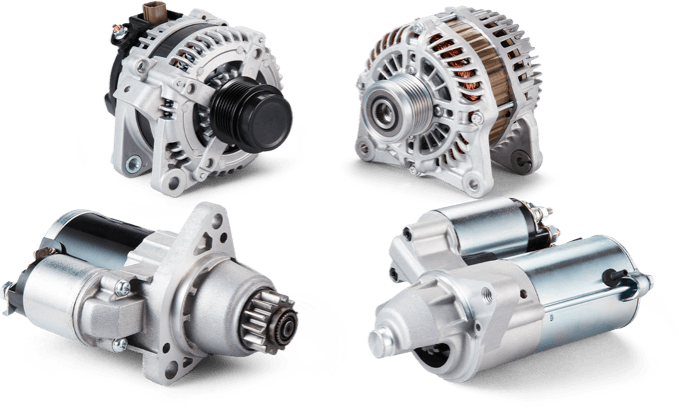

What Are the Key Characteristics of Starter Parts for B2B Buyers?

Starter parts encompass a variety of components, including solenoids, brushes, and complete starter assemblies. These parts are essential for initiating engine operation across various applications, such as automotive, marine, and agricultural machinery. B2B buyers should consider the specific requirements of their vehicles or machinery, ensuring compatibility and quality. The availability of these parts in bulk can also lead to cost savings, but buyers must remain vigilant about the quality and origin of the parts to avoid performance issues.

How Do Alternator Parts Differ in Functionality and Application?

Alternator parts, such as voltage regulators, bearings, and rectifiers, play a vital role in maintaining the electrical system of vehicles. These components are integral to both automotive and industrial applications, ensuring that power is generated and regulated effectively. B2B buyers must focus on sourcing high-quality parts that meet OEM specifications to ensure reliability. Compatibility is a critical factor, as alternator parts must match the vehicle’s electrical system precisely to avoid failures and subsequent costs.

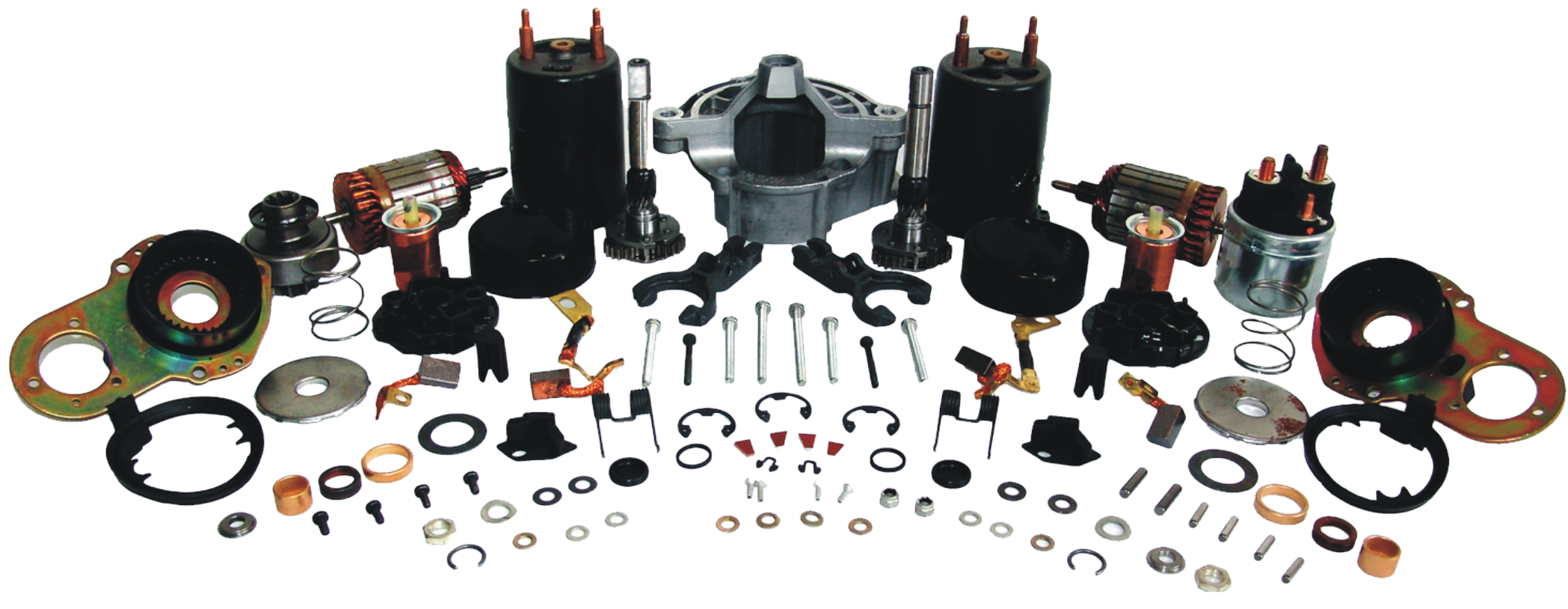

What Are the Benefits of Using Rebuild Kits for Alternators and Starters?

Rebuild kits provide a comprehensive solution for repairing starters and alternators, often including all necessary components for a complete overhaul. This approach is particularly beneficial for B2B buyers seeking cost-effective solutions without compromising quality. While these kits can save money and time, they typically require skilled labor for installation. Buyers should assess the completeness of the kit and ensure it includes all essential components to avoid additional purchases.

What Advantages Do High Output Components Offer to B2B Buyers?

High output components, such as heavy-duty voltage regulators and upgraded stators, are designed for performance vehicles and commercial trucks that require enhanced electrical capacity. These parts are ideal for applications where increased power demand is common, such as in heavy-duty machinery or performance racing. However, B2B buyers should be prepared for higher initial costs and ensure that their existing systems can accommodate these upgrades to prevent compatibility issues.

Should B2B Buyers Choose OEM or Aftermarket Parts?

The choice between OEM and aftermarket parts can significantly impact the quality and cost of repairs. OEM parts are manufactured to the exact specifications of the original equipment, ensuring a perfect fit and reliability. However, they often come at a premium price. Conversely, aftermarket parts can provide substantial savings but may vary in quality. B2B buyers should weigh their priorities—whether they prioritize cost savings or guaranteed compatibility and reliability—when making purchasing decisions.

Key Industrial Applications of alternator and starter parts wholesale

| Industry/Sector | Specific Application of alternator and starter parts wholesale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Supply of starter and alternator parts for vehicle repairs | Reduces downtime, enhances customer satisfaction, and increases repeat business | Quality assurance, compatibility with various vehicle models, and prompt delivery |

| Agriculture | Alternators for agricultural machinery like tractors | Ensures reliable operation of machinery, leading to higher productivity | Durability in harsh conditions, availability of OEM and aftermarket parts |

| Marine | Starter parts for boats and marine engines | Enhances reliability and performance of marine vessels | Resistance to corrosion, compliance with marine standards, and quick shipping options |

| Heavy Equipment | Alternator and starter components for construction machinery | Minimizes operational disruptions and extends equipment lifespan | Bulk purchasing options, technical support, and warranty services |

| Power Sports | Starter and alternator parts for ATVs and motorcycles | Improves performance and reliability of recreational vehicles | Availability of specialized parts, competitive pricing, and fast shipping |

How Do Automotive Repair Shops Benefit from Wholesale Alternator and Starter Parts?

Automotive repair shops rely heavily on a steady supply of quality starter and alternator parts to service a wide range of vehicles. By sourcing these components wholesale, businesses can significantly reduce repair times, which translates to higher customer satisfaction and increased repeat business. Key considerations for international buyers include ensuring parts are compatible with various vehicle models and maintaining quality assurance to meet local regulations.

What Role Do Alternators Play in Agricultural Machinery?

In the agriculture sector, alternators are vital for ensuring that machinery like tractors operates reliably. A consistent supply of high-quality alternators and starter parts can enhance productivity by minimizing machinery downtime during critical farming seasons. Buyers must consider the durability of parts in harsh operating conditions and the availability of both OEM and aftermarket options to meet specific machinery requirements.

How Are Marine Applications Enhanced by Starter Parts?

In the marine industry, the reliability of starter parts is crucial for the performance of boats and marine engines. Wholesale sourcing of these parts ensures that marine operators can maintain their vessels effectively, reducing the risk of operational failures at sea. Buyers should prioritize components that resist corrosion and comply with marine standards, ensuring longevity and reliability in saltwater environments.

Why Are Alternators Important for Heavy Equipment?

Heavy equipment, such as construction machinery, requires robust alternators and starter components to function efficiently. The availability of these parts wholesale allows businesses to minimize operational disruptions, thereby extending the lifespan of their equipment. When sourcing for this sector, buyers should look for bulk purchasing options, technical support, and comprehensive warranty services to protect their investments.

How Do Power Sports Companies Benefit from Specialized Starter Parts?

In the power sports industry, the performance of recreational vehicles like ATVs and motorcycles is heavily dependent on the quality of starter and alternator parts. Wholesale suppliers can offer specialized components that improve vehicle performance and reliability. Key sourcing considerations include the availability of unique parts tailored to specific models, competitive pricing, and fast shipping to meet the demands of this fast-paced market.

3 Common User Pain Points for ‘alternator and starter parts wholesale’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Alternator and Starter Parts

The Problem:

B2B buyers often face challenges in ensuring the quality of alternator and starter parts, especially when sourcing from international suppliers. Given the competitive landscape, buyers may receive products that do not meet the required specifications or quality standards. This can lead to increased return rates, customer dissatisfaction, and potential damage to their own brand reputation. For buyers from regions like Africa or South America, where local suppliers may be limited, the risk is even greater when importing parts that could affect vehicle performance.

The Solution:

To mitigate quality issues, buyers should prioritize suppliers who provide comprehensive product specifications and testing certifications. Before committing to a purchase, request performance sheets and warranty information, as these documents can serve as proof of quality. Additionally, consider establishing relationships with suppliers who offer samples before placing bulk orders. This allows buyers to inspect and test the products firsthand, ensuring they meet their standards. Leveraging platforms that feature user reviews and ratings can also help buyers gauge the reliability of their suppliers. Building a checklist of quality assurance criteria tailored to specific vehicle models can streamline the sourcing process, making it easier to identify suitable parts.

Scenario 2: Managing Inventory and Supply Chain Disruptions

The Problem:

B2B buyers frequently struggle with managing inventory levels and supply chain disruptions, which can cause delays in fulfilling customer orders. This issue is particularly acute in regions with limited logistics infrastructure or during peak demand seasons. Buyers may find themselves either overstocked with slow-moving parts or understocked with high-demand items, leading to lost sales opportunities and increased holding costs.

The Solution:

Implementing a just-in-time (JIT) inventory system can significantly enhance inventory management. This approach minimizes excess stock while ensuring that essential parts are readily available. Buyers should work closely with their suppliers to forecast demand based on historical data and market trends, adjusting orders accordingly. Establishing a reliable communication channel with suppliers can help buyers stay informed about potential delays and lead times. Utilizing inventory management software can also aid in tracking stock levels and automating reorder points, ensuring that buyers maintain optimal inventory without overcommitting resources.

Scenario 3: Addressing Compatibility and Specification Issues

The Problem:

A common pain point for B2B buyers is the compatibility of alternator and starter parts with specific vehicle models. Inaccurate part specifications can lead to incorrect orders, resulting in returns and wasted time. This issue can be particularly frustrating for buyers working with a diverse range of vehicles, such as agricultural equipment or commercial trucks, where part specifications may vary widely.

The Solution:

To combat compatibility issues, buyers should invest in robust parts identification tools and resources. Utilizing databases that allow for cross-referencing part numbers can help confirm that the parts ordered will fit the intended vehicles. Additionally, buyers should consider partnering with suppliers who provide detailed catalogs and online resources that include application guides and compatibility charts. Training staff on how to accurately identify and specify parts can also reduce errors in ordering. Regularly updating the parts database with the latest vehicle models and specifications ensures that buyers remain informed and can make accurate purchasing decisions.

Strategic Material Selection Guide for alternator and starter parts wholesale

What Are the Key Materials Used in Alternator and Starter Parts?

When selecting materials for alternator and starter parts, several common options stand out due to their unique properties and performance characteristics. Understanding these materials can help international B2B buyers make informed decisions that align with their operational needs and regional standards.

Illustrative image related to alternator and starter parts wholesale

How Does Copper Influence Performance in Alternator and Starter Parts?

Copper is a highly conductive metal, making it an excellent choice for electrical components in alternators and starters. Its key properties include high electrical conductivity, good thermal conductivity, and resistance to corrosion. Copper can withstand high temperatures, which is critical for parts that operate in demanding environments.

Pros: Copper’s high conductivity ensures efficient energy transfer, which is vital for the performance of alternators and starters. It is also relatively easy to machine and shape, allowing for complex designs.

Cons: However, copper is more expensive than some alternatives and can be prone to oxidation, which may affect performance if not properly treated. Additionally, its weight can be a concern in applications where weight savings are critical.

Impact on Application: Copper is particularly suitable for wiring and electrical connections, where efficiency and reliability are paramount.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM B170 for copper wire. Understanding local market preferences for copper versus aluminum can also guide purchasing decisions.

Why Is Aluminum a Popular Choice for Alternator and Starter Components?

Aluminum is another common material used in alternator and starter components due to its lightweight nature and good corrosion resistance. It has a lower density than copper, making it advantageous for applications where weight reduction is essential.

Pros: Aluminum is cost-effective and offers good thermal conductivity, which helps in heat dissipation. Its resistance to corrosion makes it suitable for various environmental conditions.

Cons: On the downside, aluminum has lower electrical conductivity compared to copper, which may affect performance in some applications. It is also less durable under high-stress conditions.

Illustrative image related to alternator and starter parts wholesale

Impact on Application: Aluminum is often used in housings and casings for alternators and starters, where weight savings are crucial without significantly compromising performance.

International Considerations: Buyers should consider compliance with standards like ASTM B221 for aluminum extrusions. In regions like the Middle East, where high temperatures are common, ensuring the aluminum alloy can withstand such conditions is vital.

What Role Does Steel Play in the Durability of Alternator and Starter Parts?

Steel, particularly stainless steel, is frequently used in components that require high strength and durability. Its key properties include excellent tensile strength, resistance to wear, and good corrosion resistance when alloyed correctly.

Pros: Steel’s strength makes it ideal for components that experience high mechanical stress, such as starter gears and brackets. It is also widely available and cost-effective.

Cons: However, steel can be heavier than aluminum and copper, which may not be suitable for all applications. It can also be susceptible to rust if not properly treated.

Impact on Application: Steel is typically used in structural components where strength is more critical than weight, such as mounting brackets and gear assemblies.

International Considerations: Buyers should ensure compliance with standards like ASTM A240 for stainless steel. In regions with high humidity, such as parts of Africa, selecting stainless steel over carbon steel can mitigate corrosion issues.

How Does Plastic Contribute to the Functionality of Alternator and Starter Parts?

Plastics, particularly engineered thermoplastics, are increasingly used in alternator and starter parts due to their versatility and lightweight nature. Key properties include good electrical insulation, resistance to chemicals, and low weight.

Pros: Plastics can be molded into complex shapes, allowing for innovative designs. They are also resistant to corrosion and can be cost-effective compared to metals.

Cons: The main limitation is that plastics may not withstand high temperatures as well as metals, which can lead to deformation or failure in high-stress applications.

Impact on Application: Plastics are often used for insulation components and covers, where electrical isolation is necessary.

International Considerations: Buyers should ensure compliance with standards such as ASTM D638 for plastic materials. In regions like Europe, where environmental regulations are stringent, choosing recyclable plastics can be a selling point.

Summary Table of Material Properties

| Material | Typical Use Case for alternator and starter parts wholesale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical wiring and connections | High electrical conductivity | Expensive and prone to oxidation | High |

| Aluminum | Housings and casings | Lightweight and cost-effective | Lower electrical conductivity | Medium |

| Steel | Structural components (e.g., brackets) | High strength and durability | Heavier and susceptible to rust | Medium |

| Plastic | Insulation components and covers | Versatile and lightweight | Limited heat resistance | Low |

This material selection guide provides a comprehensive overview for B2B buyers in the alternator and starter parts wholesale market, enabling informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator and starter parts wholesale

What Are the Key Stages in the Manufacturing Process of Alternator and Starter Parts?

The manufacturing process for alternator and starter parts involves several critical stages that ensure the production of high-quality components. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in the manufacturing process involves sourcing high-grade raw materials such as copper, aluminum, and steel. These materials are often subjected to rigorous testing to ensure they meet the necessary specifications for electrical conductivity and durability. Suppliers typically provide mill certificates to verify the quality of the raw materials.

-

Forming: In this stage, the prepared materials are shaped into the required components using various techniques such as stamping, casting, or machining. For example, rotor and stator components are often produced through stamping processes that create precise shapes needed for optimal performance.

-

Assembly: Once the individual parts are formed, they are assembled into complete units. This assembly process may involve manual labor as well as automated machinery to ensure consistent quality. Key components like bearings, voltage regulators, and brushes are integrated during this phase, which is crucial for the overall performance of the alternator or starter.

-

Finishing: The final stage involves applying protective coatings, such as anti-corrosive finishes or insulation, which enhance the durability and lifespan of the parts. Quality checks are also conducted to ensure that the finished products meet specified tolerances and standards.

Which Key Techniques Are Used in the Manufacturing of Alternator and Starter Parts?

Manufacturers employ various techniques throughout the production process to ensure high quality and performance. These techniques include:

-

Precision Machining: This is essential for creating components that require tight tolerances, such as gears and shafts. CNC (Computer Numerical Control) machines are commonly used for this purpose.

-

Die Casting: Often used for producing complex shapes, die casting allows for the efficient production of aluminum and zinc components that are lightweight yet strong.

-

Welding and Soldering: These techniques are vital for joining parts together, particularly in assembly. Proper welding ensures that the structural integrity of components is maintained.

-

Quality-Controlled Testing: Throughout the manufacturing process, various tests are conducted, such as torque tests, electrical tests, and thermal imaging to ensure that each component performs effectively under operational conditions.

What Are the International Standards for Quality Assurance in Alternator and Starter Parts Manufacturing?

Quality assurance is crucial in the manufacturing of alternator and starter parts, particularly for B2B buyers looking for reliable suppliers. Several international standards guide this process:

-

ISO 9001: This is a widely recognized quality management standard that outlines requirements for consistent quality in products and services. Manufacturers seeking ISO 9001 certification demonstrate their commitment to quality management principles, including customer focus and continuous improvement.

-

CE Marking: For products sold in the European market, CE marking indicates compliance with EU safety, health, and environmental protection standards. Manufacturers must ensure their products meet these regulations to gain access to this lucrative market.

-

API Standards: In some cases, especially for heavy-duty applications, adherence to API (American Petroleum Institute) standards can be critical. These standards ensure that parts meet specific performance and safety criteria.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is an integral part of the manufacturing process, and it typically includes several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Suppliers must provide documentation and samples for testing to ensure compliance with specified standards.

-

In-Process Quality Control (IPQC): As parts move through the manufacturing process, in-process checks are performed to monitor quality at various stages. This includes inspections during machining, assembly, and finishing.

-

Final Quality Control (FQC): Once the manufacturing process is complete, a final inspection is carried out. This involves testing the completed units to ensure they meet all performance specifications before shipping.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are some methods to ensure supplier reliability:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facility’s processes, equipment, and quality management systems directly. This firsthand evaluation can reveal the supplier’s commitment to quality.

-

Requesting Documentation: Buyers should request quality assurance documentation, including certifications, test reports, and quality manuals. This information can provide insights into the supplier’s adherence to international standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of verification. These agencies can perform independent checks on the products, ensuring they meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control in international trade can present unique challenges. Here are some nuances to consider:

Illustrative image related to alternator and starter parts wholesale

-

Cultural Differences: Understanding local business practices and cultural differences is vital. What is considered standard practice in one region may not be the same in another, which can affect communication and expectations.

-

Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. B2B buyers must ensure that their suppliers comply with the specific regulations of the target market.

-

Language Barriers: Language differences can complicate the communication of quality standards and requirements. Clear and concise communication is essential to avoid misunderstandings that could impact product quality.

By focusing on these manufacturing processes and quality assurance standards, B2B buyers can make informed decisions when sourcing alternator and starter parts, ensuring they partner with reliable suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator and starter parts wholesale’

Introduction

In the competitive landscape of wholesale procurement for alternator and starter parts, having a clear sourcing strategy is essential for success. This guide provides a step-by-step checklist to help B2B buyers streamline their purchasing process, ensuring they secure high-quality products that meet their operational needs. Whether you’re sourcing for automotive, marine, or industrial applications, following these steps will enhance your procurement efficiency and supplier reliability.

Step 1: Define Your Technical Specifications

Understanding the exact requirements for the alternator and starter parts you need is crucial. This includes specifications such as voltage, amperage, and compatibility with specific vehicle models or machinery types. Clearly defined technical specifications help in avoiding mismatches and ensure that the parts will perform optimally in their intended applications.

- Identify the necessary part numbers: Compile a list of the specific parts required, including rebuild kits, brushes, and solenoids.

- Consider application needs: Different industries may require specific features such as durability for heavy-duty use or efficiency for marine applications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in alternator and starter parts. Look for suppliers with a proven track record in your target regions, such as Africa, South America, or the Middle East.

Illustrative image related to alternator and starter parts wholesale

- Check supplier reviews and ratings: Utilize platforms like Google, industry forums, and social media to gather insights about supplier reliability.

- Evaluate their product range: Ensure the supplier offers a comprehensive selection of parts that meet your specifications.

Step 3: Verify Supplier Certifications

Before entering into a contract, verify that potential suppliers hold necessary certifications and comply with industry standards. This ensures that the products you purchase are safe, reliable, and of high quality.

- Request documentation: Ask for certifications such as ISO, CE, or specific automotive standards relevant to your region.

- Understand warranty and return policies: A solid warranty indicates confidence in their products and reduces your risk in the event of defects.

Step 4: Evaluate Pricing and Payment Terms

Compare pricing structures from multiple suppliers to ensure you receive competitive rates. Understanding payment terms is equally important, as they can impact your cash flow and operational efficiency.

- Inquire about bulk discounts: Many suppliers offer discounts for large orders, which can significantly reduce costs.

- Clarify payment methods: Determine if suppliers accept various payment options, such as credit terms or electronic payments, which can enhance convenience.

Step 5: Assess Shipping and Delivery Capabilities

Efficient logistics are critical for timely delivery of parts, especially in industries where downtime can be costly. Evaluate the shipping options and lead times offered by your potential suppliers.

- Check for same-day shipping options: Suppliers that can ship promptly will help you minimize wait times.

- Understand international shipping regulations: Ensure your supplier is knowledgeable about customs and import regulations relevant to your region.

Step 6: Request Samples or Trial Orders

Before making a large purchase, request samples or place a small trial order to assess product quality and supplier reliability. This step can save you from potential future issues with product performance.

Illustrative image related to alternator and starter parts wholesale

- Evaluate the quality of samples: Inspect the samples for adherence to your specifications and overall quality.

- Test compatibility: If possible, test the parts in real-world applications to confirm their performance.

Step 7: Establish a Long-Term Relationship

Building a long-term relationship with a reliable supplier can lead to better pricing, priority service, and access to new products. Maintain open communication and provide feedback to foster a mutually beneficial partnership.

- Regularly review performance: Schedule periodic evaluations to discuss performance and address any issues.

- Explore joint marketing opportunities: Collaborate with your suppliers for promotional activities that benefit both parties.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing alternator and starter parts wholesale, ensuring they make informed decisions that support their business objectives.

Comprehensive Cost and Pricing Analysis for alternator and starter parts wholesale Sourcing

What Are the Key Cost Components in Alternator and Starter Parts Wholesale Sourcing?

When sourcing alternator and starter parts wholesale, several cost components contribute to the overall pricing structure. Understanding these elements is essential for B2B buyers looking to optimize their purchasing strategies.

Illustrative image related to alternator and starter parts wholesale

-

Materials: The quality and type of raw materials used in manufacturing alternators and starters significantly influence costs. High-grade materials, such as copper for windings or durable plastics for housings, may incur higher upfront costs but can lead to better performance and longevity.

-

Labor: Labor costs encompass wages for skilled workers involved in manufacturing, assembly, and quality control. Regions with lower labor costs may present opportunities for savings, but it’s crucial to balance this with potential quality implications.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and factory operations. Efficient manufacturing processes can reduce overhead, enabling competitive pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom parts. These expenses are often amortized over the production volume, so larger orders can mitigate the per-unit cost.

-

Quality Control (QC): Implementing rigorous QC measures is vital for ensuring product reliability. While this adds to costs, it can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping and handling costs can vary widely based on distance, shipping method, and order size. For international buyers, understanding shipping terms and potential customs fees is critical.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. This margin can fluctuate based on market demand and competition.

What Influences Pricing in the Wholesale Alternator and Starter Parts Market?

Several factors can affect the pricing of alternator and starter parts, particularly for international B2B buyers.

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer tiered pricing based on order size. Larger orders can lead to significant discounts, making it advantageous for buyers with high demand.

-

Specifications and Customization: Custom parts or specific specifications may attract higher prices due to the additional complexity involved in manufacturing. Buyers should assess whether customization is necessary for their applications.

-

Material Quality and Certifications: Parts that meet specific industry standards or certifications (e.g., ISO, CE) generally command higher prices. Buyers should weigh the benefits of certified parts against their budget constraints.

-

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers with a history of quality may charge more but provide peace of mind regarding product performance.

-

Incoterms: Understanding the Incoterms used in the transaction can help buyers calculate total costs, including shipping and duty. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost.

How Can Buyers Negotiate Effectively for Alternator and Starter Parts?

Effective negotiation strategies can help B2B buyers secure favorable terms and pricing:

-

Research and Benchmarking: Buyers should conduct market research to understand prevailing prices and identify competitive suppliers. Benchmarking against similar products can provide leverage in negotiations.

-

Total Cost of Ownership (TCO): Buyers should consider the TCO, which includes not just the purchase price but also maintenance, warranty, and potential downtime costs. Emphasizing TCO can strengthen the case for negotiating better terms.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and service. Long-term partnerships may yield additional benefits, such as priority service or exclusive deals.

-

Flexibility: Being open to adjusting order quantities or timelines can provide negotiation leverage. Suppliers may be more willing to offer discounts for larger, committed orders.

What Should International Buyers Consider for Cost-Efficiency?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, several nuances can impact cost-efficiency:

-

Currency Fluctuations: Be aware of currency exchange rates, as these can significantly affect purchasing power and total costs.

-

Import Regulations: Understanding local import regulations and potential tariffs can prevent unexpected costs. Engage with local customs brokers for guidance.

-

Shipping Logistics: Evaluate different shipping methods for cost and time efficiency. Consider consolidating shipments to reduce overall freight costs.

-

Local Market Knowledge: Partner with local distributors who understand the market dynamics and can offer insights into pricing trends and customer preferences.

Disclaimer on Indicative Prices

Prices for alternator and starter parts can vary widely based on the factors mentioned above. Buyers should consult with multiple suppliers for current pricing and consider all cost components to make informed purchasing decisions.

Alternatives Analysis: Comparing alternator and starter parts wholesale With Other Solutions

Understanding Alternatives in Alternator and Starter Parts Wholesale

In the competitive landscape of automotive parts supply, businesses often face the challenge of selecting the most suitable sourcing method for alternator and starter parts. While wholesale purchasing remains a popular choice, it’s essential to explore alternative solutions that could potentially offer better performance, cost savings, or convenience. This analysis will compare the wholesale procurement of alternator and starter parts against two viable alternatives: direct manufacturer partnerships and aftermarket part sourcing.

Comparison Table

| Comparison Aspect | Alternator And Starter Parts Wholesale | Direct Manufacturer Partnerships | Aftermarket Part Sourcing |

|---|---|---|---|

| Performance | High-quality parts with extensive inventory | OEM parts with guaranteed performance | Varies significantly; can be lower quality |

| Cost | Competitive pricing for bulk orders | Potentially higher due to OEM branding | Often lower, but quality may vary |

| Ease of Implementation | Simple ordering process, quick shipping | Complex negotiations and contracts | Easy access through various suppliers |

| Maintenance | Generally low; focus on quality parts | OEM support and warranty included | May require more frequent replacements |

| Best Use Case | Bulk purchasing for repair shops and wholesalers | Long-term partnerships for consistent quality | Budget-conscious buyers looking for savings |

In-Depth Analysis of Alternatives

Direct Manufacturer Partnerships

Partnering directly with manufacturers can ensure that businesses receive original equipment manufacturer (OEM) parts, which are often synonymous with reliability and performance. This approach allows for tailored agreements that can include volume discounts and dedicated customer service. However, the downside is that establishing these partnerships can be time-consuming and may involve complex negotiations. Additionally, the costs associated with OEM parts can be significantly higher than those of wholesale alternatives, limiting accessibility for smaller businesses.

Aftermarket Part Sourcing

Sourcing aftermarket parts can provide significant cost savings and a broader selection of components. This method is particularly appealing to budget-conscious buyers who seek competitive pricing. However, the quality of aftermarket parts can vary widely, leading to potential performance issues and increased maintenance needs. Businesses must conduct thorough research to ensure they select reputable aftermarket suppliers to mitigate these risks.

Conclusion: How to Choose the Right Solution for Your Business

When choosing the right solution for sourcing alternator and starter parts, B2B buyers should carefully assess their specific needs. For those focused on volume and seeking high-quality components, wholesale purchasing remains a strong option. However, if reliability and performance are paramount, establishing direct partnerships with manufacturers could be more beneficial despite the higher costs. Conversely, businesses looking to maximize savings might consider aftermarket sourcing, provided they are willing to invest time in vetting suppliers. By weighing these factors, buyers can make informed decisions that align with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for alternator and starter parts wholesale

What Are the Essential Technical Properties of Alternator and Starter Parts?

When sourcing alternator and starter parts, understanding key technical properties is crucial for ensuring quality and compatibility. Below are some of the most important specifications to consider:

-

Material Grade

The material grade of components like brushes, rotors, and stators is pivotal in determining durability and performance. Common materials include copper for conductors due to its excellent electrical conductivity, and high-grade steel for structural parts to withstand wear. In a B2B context, selecting parts with appropriate material grades can lead to longer-lasting products, reducing the frequency of replacements and associated costs. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension or measured value. In alternators and starters, precise tolerances are critical for the fit and function of components. For example, the tolerance on rotor shaft diameters must align closely with bearing sizes to prevent premature wear. For wholesale buyers, understanding tolerances helps in selecting parts that meet exact specifications, thereby minimizing installation issues and enhancing overall system reliability. -

Amperage Rating

This rating indicates the maximum electrical current a component can handle. For alternators, higher amperage ratings typically correlate with greater power output, essential for vehicles with numerous electrical accessories. In a wholesale purchasing scenario, selecting parts with appropriate amperage ratings ensures compatibility with the intended applications, preventing failures and enhancing customer satisfaction. -

Voltage Rating

Voltage ratings indicate the maximum voltage a component can safely handle. Alternators generally operate at 12V or 24V, depending on the vehicle type. Understanding voltage ratings is crucial for B2B buyers to ensure that the parts sourced match the electrical requirements of the vehicles they service, reducing the risk of electrical failures. -

Bearing Type and Quality

Bearings in alternators and starters are critical for smooth operation. High-quality bearings reduce friction and heat, prolonging the life of the component. Different types of bearings, such as ball or roller bearings, can affect performance. Buyers should prioritize suppliers that offer parts with quality bearings to ensure longevity and reliability.

What Are Common Trade Terms in the Alternator and Starter Parts Wholesale Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the wholesale market. Here are some key terms to know:

Illustrative image related to alternator and starter parts wholesale

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle or component. These parts are typically considered higher quality and more reliable compared to aftermarket alternatives. In a B2B context, buyers often prefer OEM parts for ensuring compatibility and maintaining warranty standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to align their purchasing strategies with supplier requirements, ensuring they meet minimum thresholds for cost-effectiveness and supply chain efficiency. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. In the alternator and starter parts industry, RFQs are essential for comparing prices and terms from multiple suppliers, aiding in informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They outline aspects such as shipping, insurance, and duties. For B2B buyers, understanding Incoterms is crucial for managing logistics and ensuring clarity in supply chain operations. -

Aftermarket Parts

Aftermarket parts are components made by companies other than the OEM. They are often more cost-effective but may vary in quality. Wholesale buyers should assess the reputation of aftermarket manufacturers to ensure they are procuring reliable components.

By grasping these technical properties and trade terms, international B2B buyers can enhance their procurement strategies, ensuring they source high-quality alternator and starter parts that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the alternator and starter parts wholesale Sector

What Are the Current Market Dynamics in the Alternator and Starter Parts Wholesale Sector?

The global market for alternator and starter parts is driven by several key factors, including the growth of the automotive industry, increasing demand for electric vehicles (EVs), and the rising need for replacement parts due to vehicle aging. In regions like Africa, South America, the Middle East, and Europe, the expansion of urban centers and the associated rise in vehicle ownership are significant contributors to this market growth. Additionally, the trend towards sustainability is pushing manufacturers to innovate, leading to the development of more efficient and environmentally friendly parts.

Emerging technologies such as e-commerce platforms and digital supply chain management systems are transforming how international B2B buyers source alternator and starter parts. These advancements facilitate real-time inventory management and enhance communication between suppliers and buyers, leading to improved efficiency and reduced lead times. Furthermore, the rise of online marketplaces allows buyers to access a broader range of products from various suppliers, promoting competitive pricing and greater choice.

International buyers are also increasingly seeking suppliers that offer comprehensive product catalogs, including hard-to-find parts and rebuild kits. This trend is particularly relevant in emerging markets, where local workshops and small repair businesses require a reliable source of diverse parts to meet customer demands. In summary, understanding these market dynamics is crucial for B2B buyers aiming to navigate the evolving landscape of the alternator and starter parts wholesale sector.

How Is Sustainability and Ethical Sourcing Reshaping the B2B Landscape?

Sustainability and ethical sourcing are becoming increasingly important in the alternator and starter parts wholesale sector. As environmental concerns grow, buyers are more aware of the ecological impact of their sourcing decisions. This has led to a heightened demand for suppliers who prioritize sustainable practices, such as using recycled materials and minimizing waste in their manufacturing processes.

In response to this shift, many suppliers are obtaining green certifications that demonstrate their commitment to environmentally friendly practices. These certifications can significantly influence purchasing decisions, as buyers often prefer to partner with companies that align with their values regarding sustainability. Moreover, integrating ethical sourcing into the supply chain not only enhances a company’s reputation but also opens up access to new markets that prioritize responsible business practices.

For B2B buyers, focusing on sustainability means looking for suppliers who are transparent about their sourcing methods and who can provide documentation on the environmental impact of their products. By prioritizing suppliers that utilize green materials and adopt eco-friendly practices, buyers can contribute to a more sustainable future while also satisfying the growing consumer demand for environmentally responsible products.

What Is the Historical Context Behind the Alternator and Starter Parts Wholesale Sector?

The alternator and starter parts wholesale sector has evolved significantly since the introduction of the automobile. Initially dominated by a few manufacturers, the market has expanded to include a diverse range of suppliers offering both OEM and aftermarket parts. As vehicle technology advanced, so did the complexity of alternators and starters, leading to the development of specialized repair kits and components.

The rise of the aftermarket parts industry can be traced back to the 1970s, when vehicle maintenance became more accessible to the average consumer, fueling a demand for cost-effective replacement parts. This evolution has been supported by the growth of e-commerce, enabling suppliers to reach global markets and providing buyers with greater access to a wide variety of parts. Today, the sector continues to adapt to technological advancements and changing consumer preferences, ensuring that it remains a vital component of the automotive supply chain.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator and starter parts wholesale

-

How do I solve quality issues with alternator and starter parts?

To address quality issues, start by ensuring that you are sourcing from reputable suppliers with a proven track record. Request product samples to assess quality before placing larger orders. Additionally, inquire about the supplier’s quality assurance processes, including testing and certification of parts. Establish clear specifications for the parts you need, and consider implementing a return policy for defective items. Regular communication with your supplier can also help identify and rectify potential issues early in the process. -

What is the best alternator and starter parts supplier for international buyers?

The best supplier will depend on your specific needs, including part types, pricing, and shipping capabilities. Look for suppliers with a wide range of inventory, including hard-to-find parts, and those that offer customization options. Evaluate their shipping terms and reliability, particularly for international deliveries. Consider suppliers with established reputations in your target markets, such as Africa, South America, the Middle East, and Europe, as they may have tailored solutions for local regulations and market demands. -

What are the minimum order quantities (MOQs) for alternator and starter parts?

Minimum order quantities (MOQs) can vary widely among suppliers. Some may have low MOQs for standard parts, while others might require larger quantities for specialized or custom items. It’s essential to clarify MOQs during your initial discussions with potential suppliers. If you are a smaller buyer, inquire about flexibility or options to combine orders with other buyers to meet MOQ requirements. Additionally, some suppliers may offer tiered pricing based on order volume, which can influence your purchasing strategy. -

How can I vet suppliers for alternator and starter parts?

Vetting suppliers is critical to ensure reliability and quality. Start by researching the supplier’s reputation through online reviews and testimonials. Request references from other international buyers, particularly those in your region. Evaluate their product catalog for quality and range. Additionally, inquire about their certifications and compliance with industry standards. A visit to their facility, if feasible, can provide deeper insights into their operations. Finally, ensure they have robust customer service and support mechanisms in place. -

What payment terms should I expect when buying wholesale?

Payment terms can vary significantly among suppliers. Common options include payment upon order, net 30, or net 60 days. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Be sure to discuss any potential discounts for upfront payments or bulk orders. Understanding the payment terms early in the negotiation process can help you manage cash flow effectively and avoid surprises down the line. -

How do I handle customs and logistics for international shipments?

Handling customs and logistics requires careful planning. First, ensure that you understand the import regulations in your country, including any tariffs or taxes applicable to alternator and starter parts. Work with suppliers who have experience with international shipping, as they can help navigate documentation and compliance requirements. Consider partnering with a freight forwarder to manage logistics efficiently. Establish clear communication with your supplier regarding shipping timelines and tracking information to minimize delays. -

What quality assurance processes should I look for in a supplier?

A reliable supplier should have established quality assurance (QA) processes in place. Inquire about their testing protocols for alternator and starter parts, including performance testing and compliance with industry standards. Look for suppliers who provide detailed documentation, such as performance sheets or certifications, for their products. Additionally, ask about their return policy for defective items and their commitment to continuous improvement in quality control. A strong QA process helps ensure you receive consistent, high-quality parts. -

Can I customize alternator and starter parts for my specific needs?

Many suppliers offer customization options to accommodate specific requirements, such as unique part numbers or configurations. When considering a supplier, inquire about their ability to provide custom solutions and the associated costs. Be prepared to provide detailed specifications to facilitate the customization process. Additionally, discuss lead times for custom orders, as they may differ from standard products. Customization can enhance your competitive edge by allowing you to meet the unique demands of your market.

Top 5 Alternator And Starter Parts Wholesale Manufacturers & Suppliers List

1. Maniac Electric Motors – Alternator Rebuild Kits

Domain: maniacelectricmotors.com

Registered: 2007 (18 years)

Introduction: Alternator Parts and Starter Parts for Rebuilding. Key products include: Alternator Rebuild Kits, Bearings, Alternator Brushes/Brush Holders/Assemblies, Alternator Repair Connectors, Alternator Pulleys, Starter Solenoids, Alternator Voltage Regulators, Starter Brushes, Sets, and Brush Holder Assemblies. Specific kits mentioned: Alternator Rebuild Kit for Volvo with Bosch 0125812009, 0125812012; Al…

2. Just Parts, Inc. – Electrical Parts

Domain: justpartsinc.com

Registered: 2002 (23 years)

Introduction: Just Parts, Inc. is a wholesale supplier of electrical parts, specifically focusing on alternators, starters, and generators. They offer over 10,000 parts numbers for various applications including automotive, diesel, industrial, marine, and recreational vehicles. The company provides aftermarket parts with some OEM lines available, such as Briggs & Stratton, Tecumseh, and United Technologies. The…

3. Discount Starter & Alternator – Aftermarket Starters & Alternators

Domain: discountstarterandalternator.com

Registered: 2004 (21 years)

Introduction: Discount Starter & Alternator offers high quality aftermarket starters and alternators at the lowest prices. They provide free same-day shipping on orders placed by 3 PM EST, a 12-month warranty on all products, and easy returns within 30 days for a full refund. The company serves various vehicle types including Powersports, Agricultural, Marine, Car & Truck, Lawn & Garden, and Industrial. They al…

4. Alternator Starter Rebuild Kits – High Amp Alternators

Domain: alternatorstarterrebuildkits.com

Registered: 2010 (15 years)

Introduction: Alternator Starter Rebuild Kits; High Amp Alternators; Alternator Parts including Bearings, Voltage Regulators, Diodes, and Pulleys; Specialized kits for Chrysler, Dodge, Plymouth Mini Vans (2001-2007, 3.3L, 3.8L); Educational resources on alternator and starter systems; Rebuilder in a Box concept; Focus on common failure parts; Support for DIY rebuilders; Articles on installation, diagnostics, an…

5. Quick Start Automotive Electric – Heavy Duty Chrysler External By-Pass Voltage Regulator Kit

Domain: store.alternatorparts.com

Registered: 1999 (26 years)

Introduction: High Output Alternators, Starters, Parts and More from Quick Start Automotive Electric. Products include:

1. ERCKFRM – Heavy Duty Chrysler, Dodge, Jeep External By-Pass Voltage Regulator Kit with Field Replacement Module – Price: $99.95

2. ERCK – External Voltage Regulator Kit for Chrysler Dodge Jeep Alternators – Price: $89.95

3. W3013 – HD Relay with Plug Kit, 12 gauge power wire, 5 Terminals -…

Strategic Sourcing Conclusion and Outlook for alternator and starter parts wholesale

In the dynamic landscape of alternator and starter parts wholesale, strategic sourcing remains paramount for B2B buyers. By focusing on quality, availability, and supplier reliability, businesses can ensure they meet customer demands effectively while optimizing costs. Engaging with reputable suppliers that offer a diverse range of products—from premium rebuild kits to hard-to-find components—can significantly enhance operational efficiency and customer satisfaction.

Moreover, understanding regional market trends is crucial, particularly for international buyers from Africa, South America, the Middle East, and Europe. Countries like Saudi Arabia and Nigeria present unique opportunities for growth, driven by increasing vehicle ownership and the demand for high-quality automotive parts.

Illustrative image related to alternator and starter parts wholesale

As you navigate this competitive market, consider leveraging technology and data analytics to inform your sourcing decisions. Building strong relationships with suppliers who prioritize fast shipping and responsive customer service can give you a competitive edge.

Looking ahead, the future of the alternator and starter parts industry is bright, with advancements in product quality and customer service driving innovation. Embrace these opportunities to enhance your sourcing strategies, and position your business for success in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.